A

Th e

Component Manufacturing dverti$ dverti $ er

Don’t Forget! You Saw it in the

Adverti$$er

January 2024 #16294 Page #42

Inspiration to Feed The Beast! in 2024 s we all plan for a productive and profitable 2024, I would like to celebrate three 2023 Feed The Beast success stories: a multi-million-dollar plant expansion, a complete saw shop makeover, and a plant renovation. All three of these projects implemented some or all of Enventek’s “out-of-thebox” Process Organization Technology to produce more trusses with a significant Edmond Lim, P.Eng. reduction in operating costs. Processes were simplified and standardized as part LimTek Solutions Inc. of the in-line or just-in-time workflow implemented. Just-in-time workflow is a gutsy move, and yes it requires total trust and confidence from the top down, but more importantly the systems and machinery must be proven and robust enough to be quickly brought back online if and when there is a glitch.

A

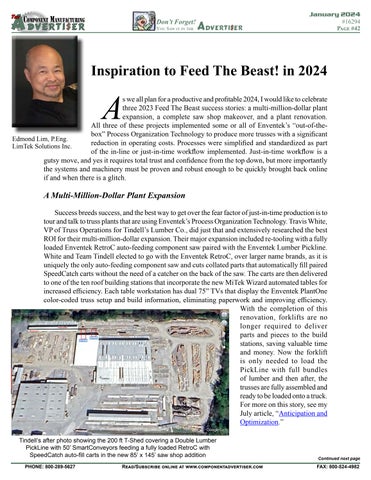

A Multi-Million-Dollar Plant Expansion Success breeds success, and the best way to get over the fear factor of just-in-time production is to tour and talk to truss plants that are using Enventek’s Process Organization Technology. Travis White, VP of Truss Operations for Tindell’s Lumber Co., did just that and extensively researched the best ROI for their multi-million-dollar expansion. Their major expansion included re-tooling with a fully loaded Enventek RetroC auto-feeding component saw paired with the Enventek Lumber Pickline. White and Team Tindell elected to go with the Enventek RetroC, over larger name brands, as it is uniquely the only auto-feeding component saw and cuts collated parts that automatically fill paired SpeedCatch carts without the need of a catcher on the back of the saw. The carts are then delivered to one of the ten roof building stations that incorporate the new MiTek Wizard automated tables for increased efficiency. Each table workstation has dual 75” TVs that display the Enventek PlantOne color-coded truss setup and build information, eliminating paperwork and improving efficiency. With the completion of this renovation, forklifts are no longer required to deliver parts and pieces to the build stations, saving valuable time and money. Now the forklift is only needed to load the PickLine with full bundles of lumber and then after, the trusses are fully assembled and ready to be loaded onto a truck. For more on this story, see my July article, “Anticipation and Optimization.” Tindell’s after photo showing the 200 ft T-Shed covering a Double Lumber PickLine with 50’ SmartConveyors feeding a fully loaded RetroC with SpeedCatch auto-fill carts in the new 85’ x 145’ saw shop addition PHONE: 800-289-5627

Read/Subscribe online at www.componentadvertiser.com

Continued next page

FAX: 800-524-4982