A dverti $ er Component manufaCturing

Serving the Structural Building componentS induStry

S

“Striking Gold with Posi-Strut in Carson City” Cover story on page 62

A dverti $ er Component manufaCturing

Anna Stamm – Advertiser Forum: Employment: Livelihood or Commodity?

Joe Kannapell: Home Building Technology, Part VII: Carol Sanford’s Quantum Leap

Wendy Boyd – Spida Machinery: Beyond the Booth: Real Conversations, Real Solutions at BCMC 2025

Todd Drummond Consulting, LLC: The Time for Improvement is Always Now

Glenn Traylor: How Will the Changes to ANSI/TPI 1 Impact Your Truss Builders and InHouse Inspectors?

Ed Lim – LimTek Solutions: Seven Decades of Construction Innovation

Steve Shrader – Hundegger: Automation is Here, and It Doesn’t Need a Supervisor to Nudge It Along

Casey Harless – Stiles Machinery: To Precut or Not to Precut? That is the Question

Landon Boucher – MiTek: Striking Gold with Posi-Strut in Carson City

Bryan Shinn – Precision Equipment: Precision Equipment Manufacturing Announces New Truss/Wall Panel Step Deck Trailers

Carl Villella – Acceptance Leasing: Fueling Growth: How Equipment Financing Aligns with U.S. Business Optimism

Thomas McAnally – TheJobLine: A Smart Way to Hire in a Tight Industry

Geordie Secord – Design Connections: Beating the Big Job Board Blues

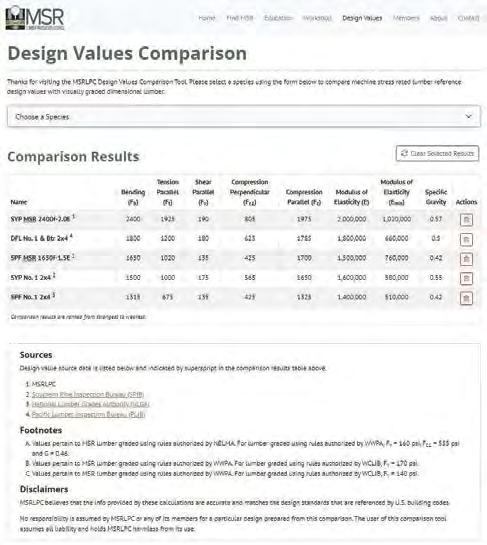

MSR Lumber Producers Council: MSR Workshop: Relax, Connect, Learn

Ryan Colker –International Code Council: Protecting Tomorrow: Why Advocating for Safety and Building Codes Matters Today

MiTek Staff: Changes in Flat Roof Snow Calculation in ASCE 7-22

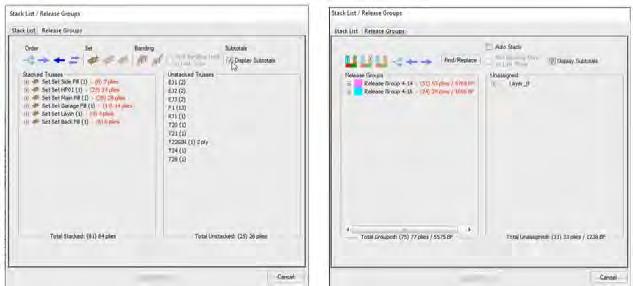

Simpson Strong-Tie Staff: Utilizing Stack List and Release Groups

Joe Kannapell – The Last Word: Discovering Excellence in Germany

A dverti $ er

the Structural Building componentS induStry

New & Used Equipment

Saws

Truss Equipment

Panel Equipment

Trucks & Trailers

Misc. Equipment

Door | Stair | Window Equipment

Safety First

Calendar of Events

TheJobLine - Jobs & Candidates

Industry News

Directory

Hiring-Zone - Jobs & Subcontractors

4Ward Solutions Group

Acceptance Leasing & Financing

Acer, Inc

Advanced Component Solutions

All Points Technical

Alpine

BuyMetrics

Clark Industries, Inc.

Eagle Metal Products

Eide Machinery Sales, Inc.

Element Equipment

Fitzgerald Group

Hiring-Z one

HOLTEC USA

Hundegger USA

LimTek Solutions

MiTek

Panels Plus

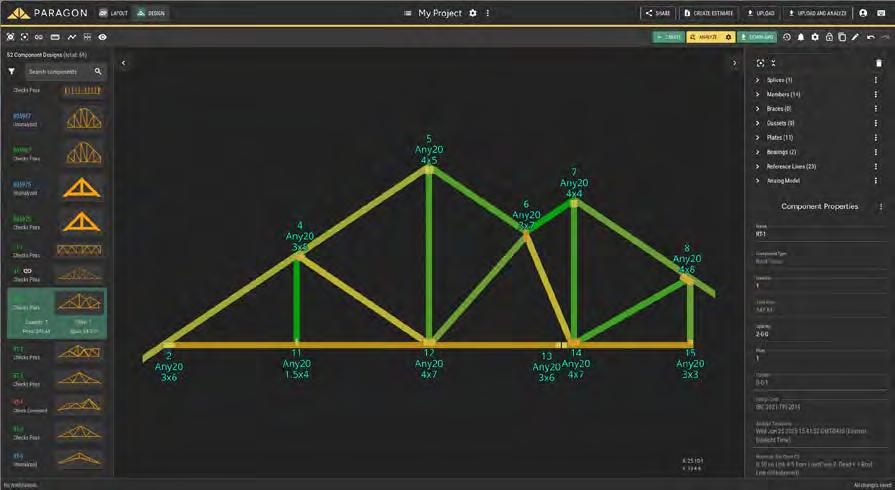

Paragon

Precision Equipment

ROGworx Automation

Simpson Strong-Tie

Spida USA

Stiles Machinery

The Hain Company

TheJobLine

Timber Products Inspection

Todd Drummond Consulting, LLC

Triad | RUVO | Merrick Machine

Truss Builder Parts

Vekta Automation

Wasserman & Associates

West Fraser Wolf X Machina

Wood Tech Systems

27,29,39,45,51,53,59,60,61,65,67,71,77, 79,80,81,93,95,99,101,105,112,117,120,125,127,129,139,141,142

Publisher Thomas McAnally twm@componentadvertiser.org

Editor Anna L. Stamm

800-289-5627 x 3 anna@componentadvertiser.org

Distributed FREE Via e-mail subscription Download PDF or Read on line at www.componentadvertiser.com

News of Interest and Advertising inquiries can be submitted to: anna@componentadvertiser.org An Open Forum for many sources.

Deadline 20th of each month. Articles, Trade Names, and Logos are the property of their respective owner or creator unless otherwise noted

Disclaimer: We reserve the right to refuse any advertisement or material that we deem not in the interest of the industry or the Advertiser. Permission to use content is the responsibility of the contributor including permissions to use any likeness of persons.

The Advertiser is provided “As Is” including typographical errors, omissions, and mistakes both intentional and unintentional.

Believe it at your own risk!

Copyright 2008-2025

Component Manufacturing Advertiser

The Advertiser 7586 Becks Grove Road Freetown, Indiana 47235 no reproduction in whole or in part without permission from the component manufacturing advertiser Archive Copies Available On Line www.componentadvertiser.com

Anna L. Stamm Director of Communications and Marketing Component Manufacturing Advertiser.

Advertiser Forum

Employment: Livelihood or Commodity?

Last month’s article by Thom, “The Cost of Convenience: How Offshore and Remote Design are Undermining the Future of the Truss Industry,” generated a fair amount of feedback, and that feedback was generally fair. But, let’s unpack some additional dynamics.

The central concern of Thom’s article is that “…companies have embraced remote designers and offshore design firms…[which is] slowly eroding the pipeline of in-house talent on which the industry depends.” Certainly, this is a valid concern, and companies should be cognizant of their long-term capacity and knowledge base. But, this will not affect everyone equally, and much will be influenced by what you think employment is: livelihood or commodity.

From the Employer’s Perspective

The component industry has been blessed with countless family-owned businesses that have created “work families” of their own, some for many decades. This heart and caring is a legacy of which we can all be proud. For such tightly knit groups, developing in-house talent is essential. Moreover, in a general sense, these employers care about their employees and do not see them as merely cogs in the machine.

In comparison are companies in which employees are commodities, not existing in an idealized state of community. Can these companies be successful with remote designers and offshore design firms? Absolutely! Contract design services are a valuable resource – and companies can do very well taking advantage of them.

From the Employee’s Perspective

Many of us probably thought at some point that we would land a job that carried us through our lives, only to realize later this was an increasingly rare occurrence. Even so, some have achieved this goal and work for companies where their jobs are recognized as their livelihood.

But, just as all companies are not the same, neither are all employees. Many highly skilled individuals are “merely” contract workers, and they (we) are no less talented, motivated, or proficient.

Modern Resources and Opportunities

If you have hired contract workers whose performance is not to your liking, then you may need to try the services provided by one of our advertisers, such as 4Ward Solutions Group or All Points Technical! Many plate suppliers offer design service options too.

Like life, this is never going to be a black-and-white issue, and there is plenty of benefit in the gray areas, for both employers and employees.

Monet DeSauw FWA 500 Floor Web Cutter

• Push Button Powered Blade Angulations

• Single Push Button Setting for 2 Blades per Side

• Electronic Digital Readouts

• Backup Mechanical Indicators

• Cuts 4 Angle Webs, Cantilever Webs (2 piece webs) & Square Blocks

• Magazine Lumber Feed for 3x2, 4x2 and 6x2 Lumber 12 1/2” to 48 1/2” Length Capacity (7” Minimum on Square Blocks)

• 60 Pieces per Minute

• (4) Internal 16” Blades & (1) External 16” Cut-Off Blade

• Pneumatic Blade Brake on External Blade

• Dust Hoods

• Belt Waste Conveyor (under saw)

• Add $4,300 for 12’ Incline Waste Conveyor (adjacent to saw)

• Add $2,100 for Extra Set of Blades

• 480 Volt / 3 Phase FOBMO Call For Pricing

• Automated (Truss Design Software Download) or SemiAutomated (Touch Screen Entry) Operation

• All Movements are Computer & PLC Controlled

• Comprehensive Setup Screens Display Each Piece with Setup Data

• 22” x 40 Tooth Blade on PAE Cut 1 or 2 Boards up to 20’ (2 Second Plunge Cut)

• Cut Chords, Webs, Rafters, Wedges & Stair Stringers

• Cut Long Scarfs by MultiPlunging

• Servo Positioning on Infeed, Angle & Outfeed Pusher

• Over Travel Protection

• Ink Jet Printer

• Lumber Optimization Program

• Belt Waste Conveyor

• 480 Volt / 3 Phase / 60 Amp

• Includes 5 Day Onsite Installation & Training

• Optional Monet DeSauw Live Deck, Bunk Feeder & Incline Belt Waste Conveyor FOB MO Call For Pricing

• Touch Screen User Interface with Backup Mechanical Controls

• 3 Operating Modes: Auto, SemiAuto & Manual

• All 20 Axes of Movements are Computer & PLC Controlled

• Comprehensive Setup Screens Display Each Piece with Setup Data

• Anti-Collision & Optimizing Programming

• Auto Calibration Productivity & Time Tracking

• Maintenance Diagnostics

• Variable Speed Conveyor (0-50 Flights per Minute)with Powered Hold Downs

• (1) 30” x 80 Tooth Blade (27 3/4” Scarf on PAE)

• (4) 16” x 40 Tooth Blades (13 1/2” Scarf on Centerline)

• Pneumatic Blade Brakes on all 5 Blades

• 16 1/2” to 20’ Length Capacity (11” Minimum on Square End Blocks)

• Vibrating Waste Conveyor Under Saw

• 480 Volt / 3 Phase

• Includes 4 Day Onsite Installation & Training

• Add $2,900 for Extra Set of Blades

• Optional Live Deck, Label Printer, Ink Jet Printer, Catcher Display & Incline Belt Waste Conveyor.

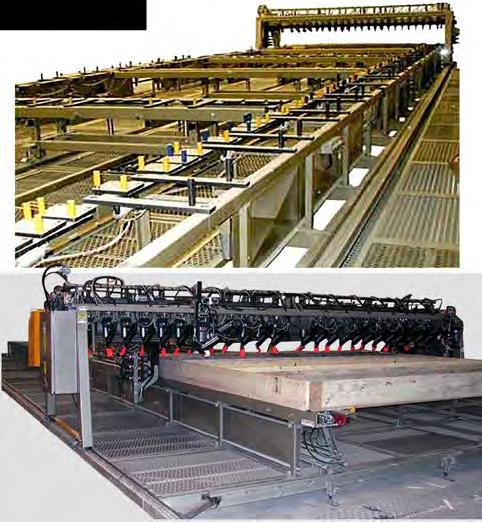

EZ-SET AUTO JIGGING EXCLUSIVE & PATENTED DESIGN

Automatic Truss Jigging System to drastically reduce setup times. Allows for 100% embedment on the table, with top & bottom chord pucks in the same slot. TopSider or standard configurations available for conventional kick-leg, walk-thru, or our new trackless 8' and 10' continuous table systems. Systems for other roller & hydraulic gantries are coming soon. Available in new machine installations or for retro-fitting your existing table. The TopSider is exclusively applicable for “kick or flip leg” style truss presses such as the Tri-Axis & Lumbermater®

FEATURES / APPLICATIONS

• Capable of 100% On-Table Nail Plate Embedment

• Two Pucks Per Slot

• 24", 26", and/or 30" Spacing

• Compatible with all current major design software

• Multiple Simultaneous Layouts

That'sallthetimeittakes todrillstudsforrunningRomexorotherelectricalwireinthewallpanels

Motor: HeavyDuty5HP-3phase-220vor440v(Pleasespecifywhenordering)

MotorcarriagebearingandspindleassemblymountedonBlanchardgroundsteelplate LinealmotionishardenedandgroundVbearingsandrails

BlockSizes: 2x4through2x12infiniteheightsettingtocenter

AirSupply: 100psi10CFM

Drills: 2wing3/4'”CarbideTippedcanaccommodatesmallerorlarger

Spindles: AlloySteelpolishedandgroundprecisionshafting

Frame: 2"SteelWithPowderCoatFinish

Covers: 10Gauge(1/8"Thick)Aluminumremovable

Dimensions: Height-60inches,Width-33inches,Depth-33inches

Shippingweight: 750lbs.-(Includingcrate)

MADEINAMERICABYAMERICANS

By Joe Kannapell

Home Building Technology, Part VII: Carol Sanford’s Quantum Leap

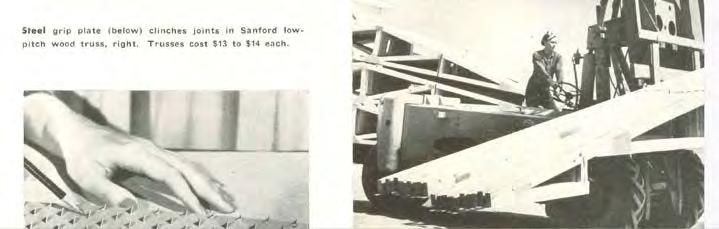

Carol Sanford came of age during the 1920s, inspired by his inventive father, during one of the most inventive periods in American history. He grew up in Canton, OH, then a center of steel and stamping industries.

After graduating from the University of Cincinnati and an architectural school in France, he went into business prefabricating homes on Lake Erie, just outside of Cleveland. As he was unable to overcome building officials’ objections to his apparently modular type of construction, he loaded up a railcar with 5 of his units and shipped them to South Florida to ply his trade, perhaps unaware that concrete block construction was the rule there. When he realized that, he went to work in Dade County selling new homes for one of the largest builders, Julius Gaines, who was attacking the dire shortage of housing on a massive scale. To expedite construction, Gaines’ crews became adept at fabricating glued, plywood-gusseted trusses on site. However, when Sanford attempted to sell houses in the City of Miami, he was required to have trusses tested, which put him in contact with Cal Jureit’s testing lab.

It is unlikely that the trusses Gaines used in largely unregulated Dade County would pass the much heavier loading that Jureit had helped Miami code officials proscribe. On Miami’s typical 2.5/12 pitched roofs carrying concrete tiles, forces at critical joints could reach 5000 lbs. It is also unlikely that Sanford’s glued gusset connections would have successfully carried that kind of load without the aid of Jureit’s engineering guidance. Yet even though Sanford’s trusses passed muster and had the benefit of Jureit’s sway with city authorities, Miami’s building department would not allow glued connections. Apparently, representatives of the Timber Engineering Company (TECO), whose split-ring connector had cornered the Miami market, cast doubt on the longevity of glued connections in the hot and humid Miami climate.

The enterprising Sanford then sought the advice of another wood connector supplier, the H-Brace Company, who had also tested connectors in Jureit’s lab. At H-Brace, he saw drawings depicting light-gauge steel plates with both nail holes and triangular-shaped teeth. Seeing the potential of this approach, Sanford had samples made, built trusses using them, and successfully passed Miami’s test requirements. When he demonstrated the utility of his new Grip-Plate to Mr. Gaines, he received a commitment to supply Grip-Plates for 400 houses per month. With that order in hand, Sanford filed for a patent, and created Sanford Truss, Inc. in 1954.

Purchasing an entry-level stamping press and opening a small shop on 7th street in Miami, Sanford quickly gained all of the Gaines’ business in what is now the Miami Gardens section of Dade County along with new housing he was building in the City of Miami. He then proceeded to convert the users of split-ring trusses in Miami. With that volume of local business, his small shop was overwhelmed with orders, enabling Sanford to sell his plates for an exorbitant price and also charge a royalty on each truss that was built with them, making money, in his words “hand-over-fist.” Gaines alone provided Sanford with $500,000 of plate business in 1954. The buzz in the building community over Sanford’s invention reached Cal Jureit, who had left the testing lab and joined a local wood truss manufacturer.

When Sanford’s invention was first recognized in the new products section of House & Home magazine in 1954, he received a flood of inquiries from across the nation. This prompted him to break ground on a large stamping plant and office north of Miami in Pompano Beach, and to move quickly to establish representation in the hottest housing markets in the country. He hired a salesman and dispatched him to Southern California to set up an office to answer the inquires he had received. He also established a presence in the Midwest, where he had previously tried to sell modular homes, since he was aware of the high concentration of prefab suppliers there who were large users of trusses.

By the time he exhibited at the 1957 NAHB Show in Chicago, Sanford was well on his way to becoming an international player, having established distributors in Australia and Europe. However, also exhibiting at the NAHB Show was Cal Jureit, selling his connector that required no nails. And back in South Florida, Ronel Corporation had begun selling its Barb-Grip plate, which also worked without nails. Both began their businesses with a superior product, and both brought strong engineering leadership to their plate businesses: GangNail with Jureit himself and Ronel with Jerry Akdoruk, who would write the first formal training course for truss designers.

Through these early years, Sanford certainly had a head start on his two new competitors, but they would quickly gain footholds in his backyard. As Sanford ramped up his plate production and distribution, he also had to expand his engineering support, especially on the West Coast. And, as Sanford began moving into the colder and more unionized markets, he heard their call for specialized machinery to improve productivity. So, only four years into the life of a brand new industry, all three players would need to step up their expertise in stamping, engineering, and machinery development to succeed. And very soon, many more new entrants would test their mettle.

Next Month: The Engineering Advantage

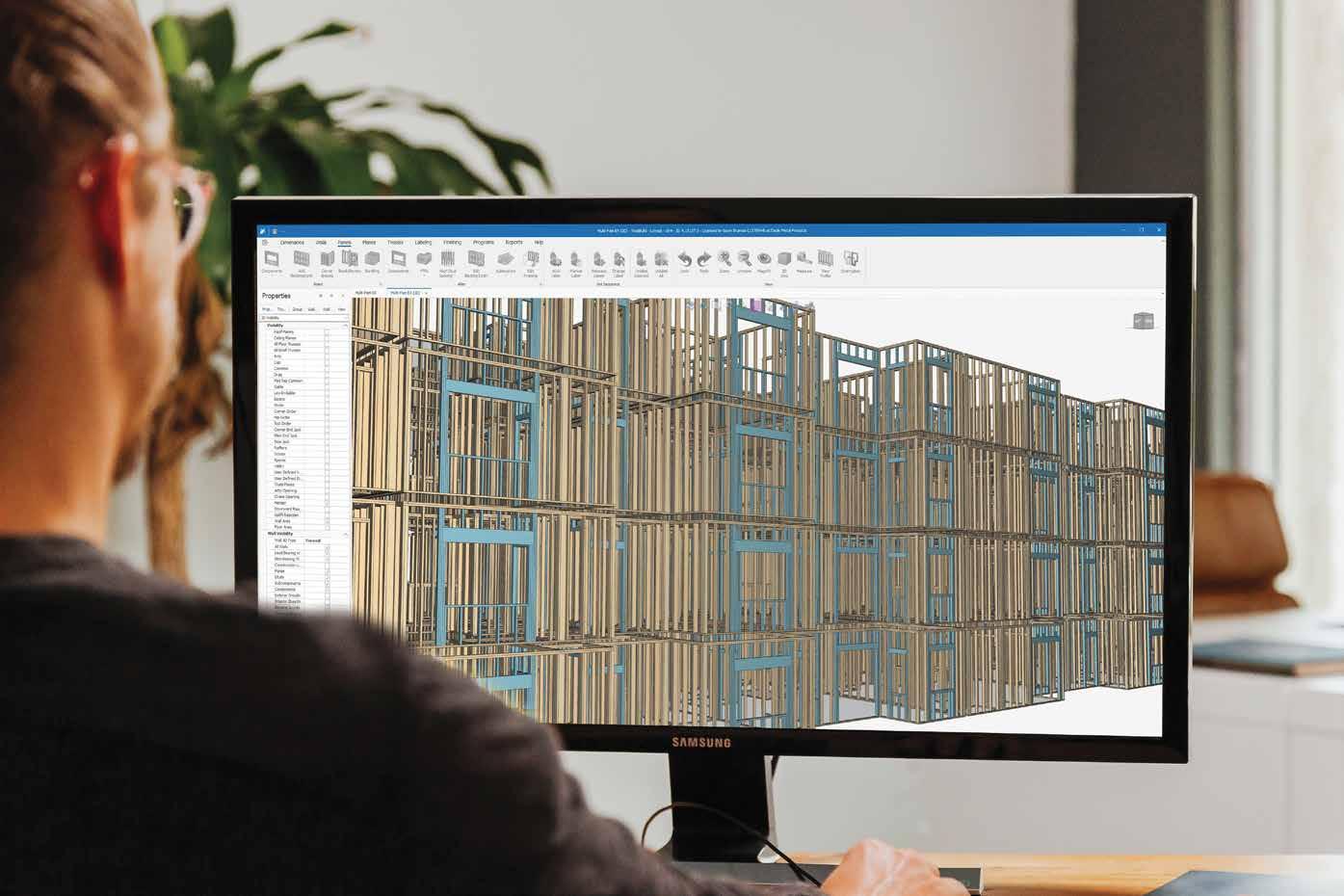

SCALE YOUR BUSINESS

Get the industry-leading software and automation technology you need to scale your business. Overcome market challenges, boost productivity, and confidently meet demand when you choose MiTek as your solution partner.

Are you ready to scale your success?

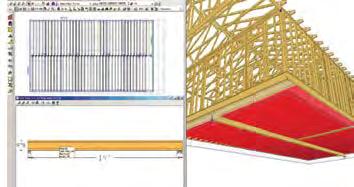

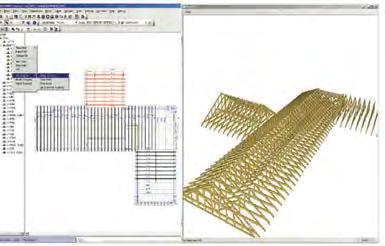

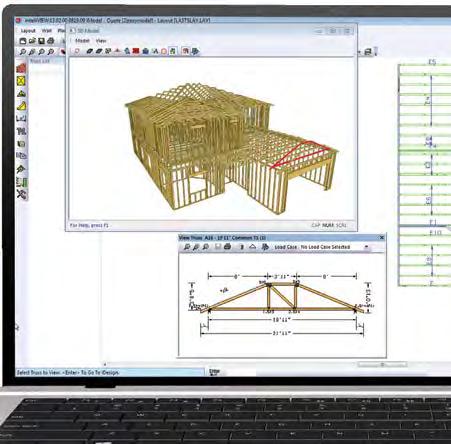

Truss solutions from idea to installation.

Transform your truss operation with an integrated solution from Simpson Strong-Tie. The industry leader in truss plates now brings you a full suite of software, equipment, hardware and services to drive truss component manufacturing from idea to installation. Start with CS Director™, CS Truss Studio™, CS EWP Studio™ and CS Producer™ for design, layout, production and project management. Use our powerful Monet DeSauw industrial saws to cut webs, chords, stair stringers, rafters and wedges with speed and precision. Specify the optimal connectors, anchors and Strong-Drive ® structural fasteners for every project. You can also complement your team with our professional truss design services at any time. Altogether, you have a smart solution made to increase productivity, ensure high quality and take your business to the next level.

To learn more, contact your representative at (800) 999-5099 or visit us online.

See ya, router. See ya, router.

SpeedWorx makes pre-cut sheathing more economical. Ditch the router and save material while increasing production.

Reliable automated machinery, built to last for generations!

“The equipment is extremely durable to stand up to the beating it takes in a truss plant”.

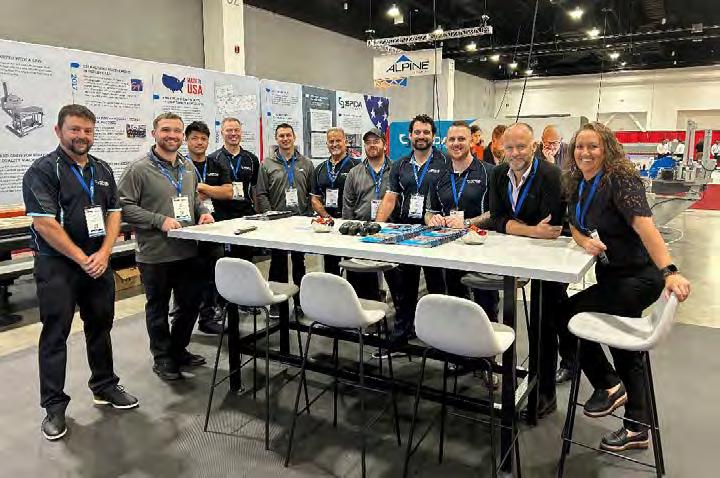

Wendy Boyd Chief Customer Officer Machinery Group Spida Machinery

Beyond the Booth: Real Conversations, Real Solutions at BCMC 2025

In the world of frame and truss manufacturing, there aren’t many events that gather the industry in quite the same way as the annual Building Component Manufacturers Conference (BCMC). It’s a touchpoint – not just for showcasing machinery and equipment, but for sharing ideas, reconnecting with old friends and connecting with new ones, and taking stock of where we’re headed.

For Spida Machinery, this kind of gathering means a lot. It’s an opportunity to pause and reflect on the work we do day in and day out – designing, building, and supporting machinery that makes real-world production better, smarter, and more reliable.

Preparing for a show like BCMC isn’t just about hauling machines to a convention center. Behind the scenes, there’s months of planning: freight logistics, technical setups, scheduling live demos, and coordinating a team that spans leadership, sales, engineering, service, and support. It’s a big task and one we take seriously, because every time we connect with a visitor, we want to show up fully prepared and ready to listen, support, and help in any way we can.

Why We Attend – To Listen and Help

When it comes to BCMC, for us, it’s much more than just the booth. We show up ready to listen to the problems and challenges customers are facing on the shop floor, ready to engage and share our experience and expertise, and ready to provide solutions to problems faced by manufacturers across our industry.

We’ve been part of this event for years because it’s where real conversations happen. We’re driven by these opportunities to talk with and help manufacturers achieve benefits such as increased efficiencies, more throughput, and reduced labor costs.

Showcasing Smarter Innovation

This year, we will have one of our most popular automated saws and the Raked Wall Line at our booth! The Spida Automated Apollo Saw is a great all-rounder when it comes to cutting. It’s a radial arm saw designed to accurately cut any angle from 9° to 171° on lumber components. Incredibly versatile, this saw is suitable for large and small factories and for frame and truss components.

The Raked Wall Line provides a simple, powerful, fast, accurate, and automated workflow to create both common walls and raked walls. This solution includes the dynamic trio of the Stud Extruder, Curved Conveyor, and Raked Wall Extruder. These three machines work together to streamline processes, increase productivity, and reduce labor.

The Stud Extruder, using configurations sent from the detailer to the touch screen, allows the operator to seamlessly process the assembly of C, L, and U studs along with the nailing of fireblocks to studs. The operator then loads assemblies easily onto the Curved Conveyor. The Curved Conveyor is used to transfer studs and minor sub-assemblies from the assembly point, direct to the Raked Wall Extruder operator. The operator can then access them, ready for insertion into a wall frame.

In addition to the machines physically at our booth, we’ll have other avenues for you to learn more about the rest of our innovative equipment too!

Machinery in Action with Live Demos!

We especially enjoy being able to provide live demos at BCMC — 3 sessions per day, so you can see the machinery in action. We will be showcasing the raked wall line where visitors will get a close-up look at how the machinery performs in real time. It’s one thing to see a machine on a brochure, it’s another thing to see the detail, speed, accuracy, and integration, right in front of you. Also, it lets visitors experience a new way to approach their own production challenges. Our team members are all mic’d up, so you’ll hear us loud and clear as we explain what’s happening, delving into the details and the benefits as well as answering questions.

These live demos always prove popular, so make sure you come along and get a spot on our viewing platform!

Powered by People

While machinery is a core focus at BCMC, it’s our people who are integral to what we do. This year at BCMC, our team will represent a wide spectrum of what Spida does: from leadership to sales and product expertise, to service, freight, and customer support. That diversity matters, because when you walk up to our booth with a question – whether it’s about machinery features, increasing throughput, scaling up, solving a bottleneck, or how to transport and install a wall line – we have people available to answer it. No matter what your business needs are, you’ll be able to talk to one of our team who can help.

And it’s not just about our own people. Whether you’re an existing customer, a long-time industry friend, or new to the Spida community, we look forward to connecting. We love being part of BCMC – we get to have valuable conversations, strengthen partnerships, and find solutions together. It’s where ideas are exchanged, challenges are solved, and innovation takes its next leap forward!

Make a Plan to Come Visit Us

BCMC is a few short months from now, and we’re already getting excited as we finalize all of our behind-the-scenes plans. There’s so much we enjoy – our friends and customers who we welcome each year, the first-time visitors who bring fresh questions, and our industry peers who challenge us to think differently.

If you’re heading to the show, please come by and have a chat with us. Whether you’re looking to expand your capabilities, improve efficiency, or just see what’s new in the world of frame and truss, our team is ready to help.

BCMC 2025 is being held September 29 to October 3 in Omaha, NE – we hope to see you there!

— Chase Barineau Vice-President Seminole Trusses, Inc.

The Auto-Feeding RetroC

The Amazing RetroC by Enventek

A complete wood processing system proven to profitably feed cut lumber to truss plants of all sizes.

Easy to use, simple robust automation that is scalable with less labor. A RetroC holds calibration.

Out Produces Any Saw in Batch Cut or Cut by Truss Mode

Auto-Feeding, no upper hold-downs (just 15 automation axes) with electronic braking. Efficient material handling that will significantly increase cut piece production with reduced operating costs and improve truss build times with consistently accurate cut pieces.

Catching labor is eliminated with our optional SpeedCatch cart system. Sophisticated SpeedCatch software enhances the efficiency of truss production by effectively collating and organizing the lumber at the truss tables. SpeedCatch upgrades the RetroC to a comprehensive one-person (sawyer) wood processing system.

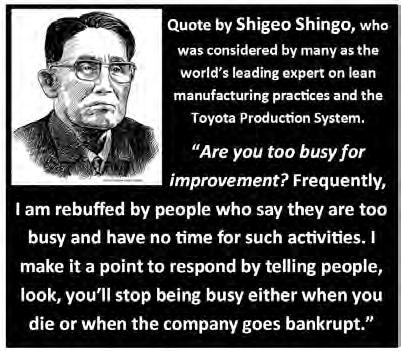

Todd Drummond

The Time for Improvement is Always Now

The summer build season is upon us, so the familiar daily time constraint challenges are back. Yet this summer build season is not like the past few years. In many regions, sales are not as strong, so margins are dropping to keep the sales volume needed to remain profitable. During the winter slowdown, many of you stated you intended to take the time and make the necessary improvements and changes to meet the ever-changing markets and competition. Now that the summer build season is back, how successful were your teams implementing those promised improvements? How much pushback or non-compliance has your group given to follow through on the promised changes?

Here are two questions for improvement that you may not even have considered:

• How dynamic is your manufacturing order scheduling, and is it possible that the scheduling process negatively impacts the margins?

• How accurate is your quoting based on the current methods? Most companies cannot explain and prove the costing methodology of the design software. They have no idea that the component design system is more of a shotgun than a rifle approach, even when each component is fully designed.

Most companies have not considered these two critical aspects of their company for many years. Instead, they think they know their processes are working well and they doubt that refinement would make any difference. But is this just wishful thinking? For each of my clients, I will explain how their scheduling and bidding methods may hinder them in different situations and how they can improve both these critical aspects. These improvements then have a very positive effect on their profitability.

Food for thought — What is the number one reason people resist any change?

Modern cognitive theory states that people tend to perceive reality in light of pre-existing expectations and will ignore large amounts of contrary data before finally changing their minds.

Psychology Studies — Author & Source Unknown

Why is this so common? It is because we are all trying to protect our Ego or Pride. We cannot see that change is needed, or if we do indeed recognize the changes needed, our pride prevents us from admitting it. If by admitting, we perceive it as, “We were wrong, and they were right.” This thinking prevents us from listening to others—an absurd way of viewing life. What worked in the past was a good thing, but we need to evolve to meet the challenges of today.

Now, consider how this mindset affects decision making during the busy build season time of the year. Why and how would anyone consider making any changes now? But, keep in mind, successful people and businesses are always busy, and they do not make excuses for being too busy for improvement. If your group did not make all the promised changes during the slower times, are you willing to act now? What can be gained by making changes now?

If you are resisting making changes now, consider this. How many companies were very busy as they went bankrupt, and when exactly did they attempt to make the needed improvements to prevent the loss of profits? The answer is simple: they did not take the time, and obviously did not know exactly what changes were needed. No matter how successful any organization has been in the past, there is no guarantee of success in the future.

How can changes be made during the busy time of the year? It may surprise some, but spending money for greater returns sometimes makes perfect sense even when your company is in cost-cutting mode. When you ask the same people the same questions, you will get the same answers because that is what they know. Maybe, just maybe, it is time to bring someone into your organization from outside your company who is not vendor-related, with “free” advice, or the common groups you interact with. As one client stated, “we can waste thousands of dollars spinning our wheels over many months, or get it done in a few weeks with you, Todd.”

“Pride goes before destruction, a haughty spirit before a fall.” — Proverbs 16:18

There is no better value than TDC for getting the best ROI for professional consulting services. TDC is your best source for learning about proven and practical lean manufacturing best practices combined with industrial engineering principles to keep your company at the leading edge of competitiveness. Cost savings and net profit gains that usually take months or years can be accomplished in weeks or months with TDC. No one is better at providing your team with proven results for good employee practices, pricing, truss labor estimation, and so many other best-in-class practices. All areas are addressed, not just manufacturing. Please do not take my word about TDC’s services, though. Read the public testimonials many current and past clients with decades of expertise and experience have been willing to give.

Website: www.todd-drummond.com • Phone (USA): 603-748-1051

E-mail: todd@todd-drummond.com • Copyrights © 2025

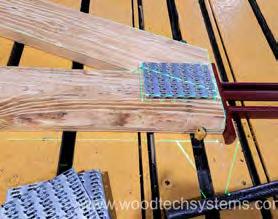

Five-blade SERVO controlled saw that has been well maintained, and is configured with [1] 30 inch blade, and [4] 20 inch blades. Cuts dimensional lumber from 2×4 through 2×12. Includes Windows 7 Pro operating system, PC controls, all available spare blades and shaker side-pans. 460 volt, 3 phase, 60 Amp electrical required. As-is, Where-is

$29,997 NOW $26,997 FOB MB Wood Tech Systems 765-751-9990 www.woodtechsystems.com

Line Expansion featuring complete Material Handling Upgrades; with High Slope Lifters, Side-Off Rolls, & Truss Conveyor Systems

Keep Materials Moving With Custom Upgrades To

Fit Your Line

Upgrade your outdated material handling systems with everything you need, configured and installed to match your equipment perfectly. We manufacture the right equipment to keep your line running efficiently. We offer Side and End Eject Units, Side Off Truss Transfer Rolls, Roll Systems, Truss Exiting Conveyors, Flat or Incline Scrap Conveyors, Unitized Truss Conveyors Systems, Lumber Infeed Decks, Floor Trucks, Teeter Carts and more! Built to last and designed to perform.

We offer a comprehensive range of field services from equipment removal & setup to technical support. Delivering expert material handling integrations into your truss production line for peak performance.

Customize your upgrades to fit your existing line. The perfect choice for Line Upgrades & Expansions or a simple replacement of your key systems. Designed to meet your exact needs & keep your production running.

We Keep Your Materials & Your Business Moving Forward.

Inspired by ten years of intensive field experience and the ample and detailed feedback of numerous customers, we’re pleased to introduce the most advanced, most enhanced and high-performance Terminailer yet - Terminailer V.8. Drawing on invaluable time in the trenches closely evaluating Terminailer’s performance under varying conditions, our engineers have incorporated critical learning and insight to enhance simplicity, performance and operator control. Just part of what V.8 offers includes:

•Vastly enhanced operator control for even greater productivity

•A redesigned nail-feed supplying EverWin PN90-PAL industrial nail guns

•Simplified pneumatics featuring direct air-supply to all six nail guns

•Even more sub-component profiles for wall design flexibility

•Rugged durability with pharmaceutical grade assembly

Developed by people who know well the mechanics, safety considerations and business aspects of wall panel production, Terminailer V.8 combines more enhancements & operator-friendly features than ever to take your productivity to the next level and beyond. Contact us to learn even more and to put the V.8 performance in motion at your facility.

The truss industry relies on 3rd party quality assurance services to provide random visits to review the plants Quality Assurance program along with their operations. If your plant needs to comply with the IRC, IBC and to those who depend on solid, experienced QA expertise, we ask you to consider selecting Timber Products Inspection, Inc. (TP) as your choice for 3rd party inspections.

Proudly serving the forest products industry for over 50 years, TP brings the expertise you need to ensure your business is successful. As a responsible partner, TP delivers to clients, employees, and the industries we serve the confidence to drive value through the effective use of our diverse professional team.

TP would like to welcome the following authorized agents to our inspection team, each of whom have many years of experience in the truss industry! • Al Coffman

Jean Hart

Curt Holler

Chuck Ray

Glenn Traylor

Elliot Wilson

If you have questions about how you can make this selection, please contact your authorized agent above or Glenn Traylor at 919-280-5905 or trusguy@gmail.com. https://www.tpinspection.com/ https://www.tpinspection.com/auditing-services/truss

By Glenn Traylor

How Will the Changes to ANSI/TPI 1 Impact Your Truss Builders

and In-House Inspectors?

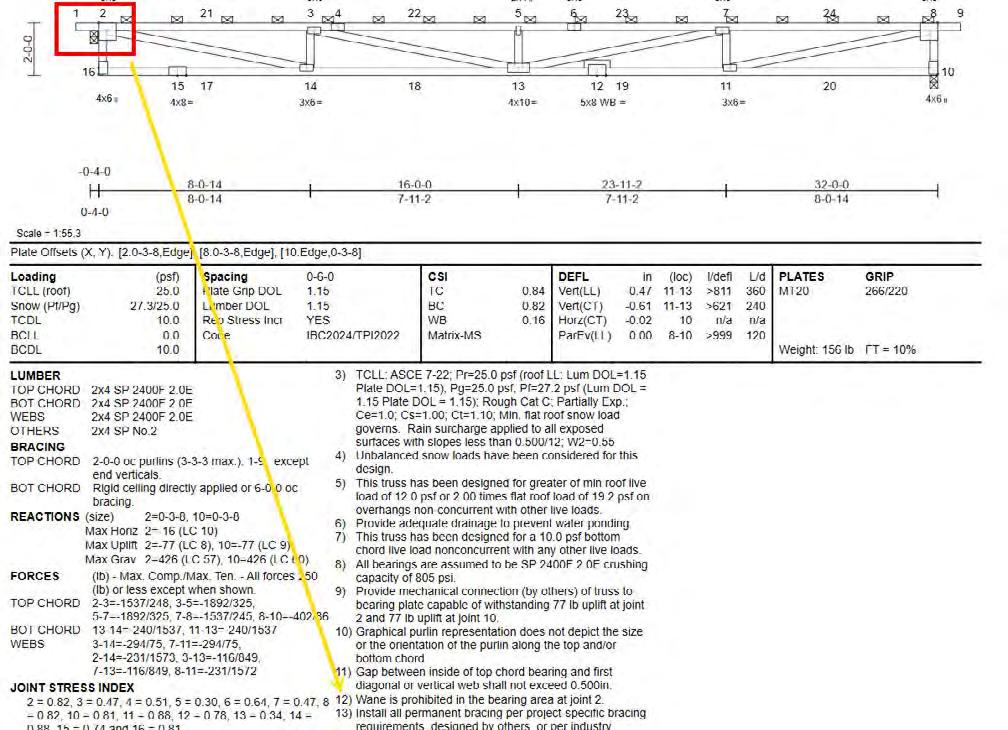

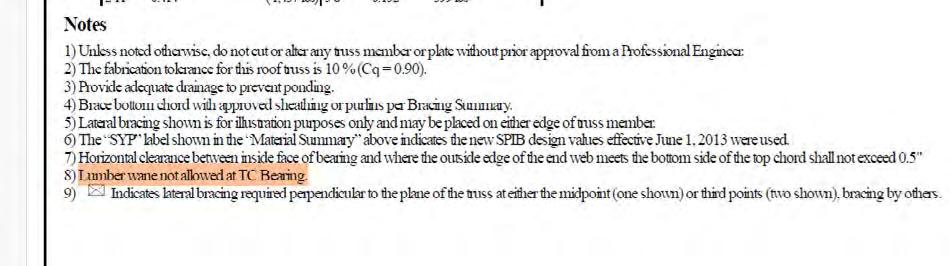

As we migrate from ANSI/TPI 1-2014 to ANSI/TPI 1-2022, it is important to discuss and be aware of Chapter 3 updates. These changes impact QC inspections and should be understood by your in-house QC inspector and your truss builders.

The changes are in two categories in Chapter 3 — a general aspects category and a group that addresses top chord bearing components, as follows.

General Aspects

Changes to 3.8 Repressing: This section was reworded to make it clear that if a plate has not been fully pressed, it can be repressed to reach full connector plate grip strength. Keep in mind that plates that have been removed are still governed by 3.9.2, which states that plate removal resulting in damaged wood is considered ineffective, and requirement 3.9.3, which allows for a 50% reduction when the lumber is not damaged.

Changes to 3.7.2.1 Plate Placement: This section was reformatted for clarification.

Top Chord Bearing Components

New 3.4.8 Lumber Wane: This new section was added to alert inspectors that lumber wane could be prohibited in the bearing area of some extended chord bearing applications.

Changes to 3.7.2.2 Alternative Positioning Procedure: Due to concerns with how this method determines suitability, extended chord bearing joints have been excluded from use with the alternative positioning procedure.

Changes to 3.7.3 Plate Rotation: Extended chord bearing joints have also been excluded from the 10-degree plate rotation tolerance. The new exception states that there is no plate rotation permitted.

What Focusing on Top Chord Bearing Components Means

Why is understanding this change important? These changes will have an impact on how your QC inspector analyzes conformance. The change also impacts truss builders because certain tolerances that were available to them previously are not necessarily allowed now.

Different software providers have addressed this in different ways, but in general, notes will be provided on the engineering drawing to indicate the controlled conditions that are not normal. For example, rotation is typically ±10 degrees, and the software designer can control this with a setting in the software. The new requirements stipulate that both zero angulation and zero wane conditions need to be maintained.

Thank you to these plate suppliers for providing the following information.

MiTek

Here is an example of how the MiTek software handles this situation by stating that “Wane is prohibited in the bearing area.”

Alpine

Alpine has taken a different approach. From their engineering department:

“[We do not have a note] to TPI 1-2022 section 3.4.8 because we design extending chord bearings considering the reduced compression-perpendicular-to-grain design value (meaning we use the 1/3rd reduction specified for cperp in top-chord-bearing joints per section 7.3.13.1 rather than specifying no wane at such bearings and using the full cperp design value).”

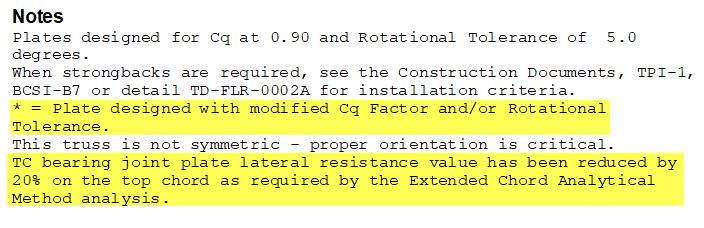

Simpson Strong-Tie

Simpson’s approach has been to address the situation in this manner.

“On the truss design drawing, we print the following note any time the analytical method has been used in analysis on a top chord bearing truss: TC bearing joint plate lateral resistance value has been reduced by 20% on the top chord as required by the Extended Chord Analytical Method analysis.”

“In addition, the Cq factor/angle on an extended top chord plate using the analytical method is forced to be 1.0 and 0 degrees respectively (as required by ANSI/TPI 1-22), so an additional note will also appear stating the following:

“ * = Plate designed with modified Cq Factor and/or Rotational Tolerance.” (The values of which are then clearly stated in the QC reports.)”

Eagle Metal

Eagle has addressed it by adding a note to their drawings stating that lumber wane is not allowed at the top chord bearing.

The Bottom Line

It is imperative for all component manufacturers to ensure that your team understands how ANSI/ TPI 1 changes affect plant procedures, and this will be directly related to the way the changes are handled by your software provider.

Regardless of how wane is addressed, rotation of the connector must be deliberately positioned correctly, and any rotation needs to be evaluated. Also, wane impacts bearing and should always be limited in situations at the bearing.

When you have questions about your specific situation, please contact your plate supplier. They are your number one resource in successfully transitioning to the new version of ANSI/TPI 1.

An ANSI/TPI 1 3rd Party Quality Assurance Authorized Agent covering the Southeastern United States, Glenn Traylor is an independent consultant with almost four decades of experience in the structural building components industry. Glenn serves as a trainer-evaluator-auditor covering sales, design, PM, QA, customer service, and production elements of the truss industry. He also provides project management specifically pertaining to structural building components, including on-site inspections and ANSI/TPI 1 compliance assessments. Glenn provides new plant and retrofit designs, equipment evaluations, ROI, capacity analysis, and CPM analysis.

Glenn Traylor Structural Building Components Industry Consultant http://www.linkedin.com/in/glenntraylor

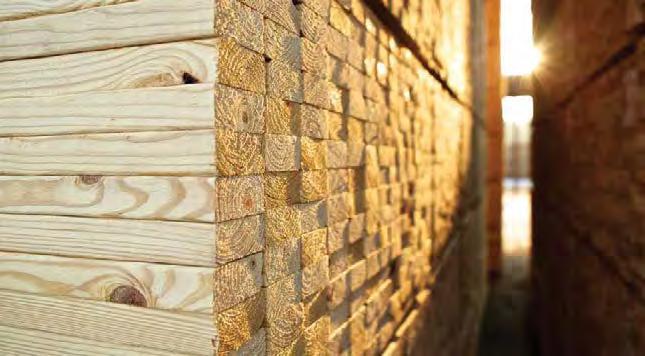

THE MOST TRUSSED NAME IN LUMBER

Why do so many manufacturers rely on West Fraser for mechanically graded lumber? With over 30 North American mills, 14 of which produce MSR, we run a highly dependable supply chain in both SYP and SPF.

Our ability to identify higher grade lumber imparts predictable strength and consistency to high-performing trusses and other products. Why not let our high production standards support yours?

Truss us – we won’t let you down.

The Ultimate

TRUSS JIGGING TABLES

Precision and Value You Can Rely On!

Upgrade your truss-building workflow with our precision engineered jigging tables – the industry standard for quality and efficiency. Built to accommodate all truss jig parts and accessories, our tables ensure a flawless fit, every time.

We combine unmatched craftsmanship with competitive prices to deliver the best value for your business. Choose us – trusted by truss builders nationwide!

We offer Machinery Services Before

Recondition | Rebuilds Replace Components

Framework | Fabricate Guards Repaint Equipment Etc.

Precision. Efficiency. Affordability..

After Restoration

info@trussbuilderparts.com 2810 Parkway St. Unit 4 | Lakeland, FL 33811 863 602 2019 www.trussbuilderparts.com

Hain Systems Framer

T+/- .010 Inches

Stop Rail: 2 x 4 x 1/4 Aluminum Extrusion

he Hain Systems Framer (HSF) will help you build square and accurate wall panels for residential or commercial construction applications. It will help you cut building costs by saving time and improving your quality. It’s a reliable, efficient and proven system that features a ruggedly simple design. The HSF is based on a proven design with over 20 years of actual production use and maintenance experience. It comes fully assembled and is designed for portable job site framing or in-plant permanent installation. The table has many optional attachments and will support Mylar Tape wall layout or any other type of layout. The optional gun rails can also be retro-fit to any table.

Stops: Jig Bored Steel

Stop Blocks: Machine Billet Aluminum

Details:

Internal Components: Hardened, Ground and Polished Steel and Billet Aluminum

Table Construction: Thick-wall Structural Steel Tubing, Jig Welded for Accuracy

Dimensions: Length: 5 feet (60”) to 60 feet (720”)

Height: 12 inches

Air Supply: 90 psi (10 CFM Air Flow Recommended)

Depth: 12 inches

Electrical Supply: 120 VAC

Powder Coat: Industrial Gray

Dimensions: Height: 43”

Length: 16’ or 20’

Width: Adjustable 8’ to 10’ or 8’ to 12’

Shipping Weight: 3000 lbs

If you are looking for the fastest, most consistent way to measure and cut your product, then the Hain Measuring System (MEA) is your answer. The MEA changes from one length t any length instantly, up to 60’, without changing the operator’s position on the line. It is also highly accurate (+/- .010) and quickly moves from one length to the next in seconds. The MEA is designed for quick and easy setup and is simple to use. Even a first time user will be productive with little or no training required. It can adapt to any saw and can be mounted to any surface so that you can integrate the MEA with your existing setup. The MEA is versatile allowing “left” or “right” handed operation and measurement in “feet and inches” or “inches” depending on your preference. The MEA is also available in a “Skid Mounted” version.

Building on Better .

Off-site construction solutions built around your business.

Build higher-quality components and modules more efficiently.

Stiles has been a trusted name in the U.S. woodworking industry for over six decades. Today, we continue to lead the way with a consultative approach to off-site construction, partnering with you to increase speed, precision, and productivity, while providing ongoing parts and service support when you need it.

Invest in equipment built to perform—and last.

Stiles is the exclusive North American provider of WEINMANN, the world’s leading machinery and equipment manufacturer for off-site construction. Whether it’s an individual machine or fully automated system, Germanengineered WEINMANN machines provide innovative solutions that revolutionize your production.

Make your good decisions work even better. Learn More

2021 Powermatic Model 511 Panel Saw 2021 Powermatic model 511 panel saw. Vertical panel saw features a powerful 3HP worm-drive motor which rotates in the carriage, adding the versatility to perform rip cuts. The solid aluminum rollers assure smooth feeding of stock and perfect 90° cuts every time. This saw will handle panels up to 5-ft tall in unlimited length. Includes horizontal and vertical scales and casters for mobility, the counterweight system keeps the saw carriage in the desired position when loading or unloading panels. Features dual 4″ dust collection ports with nylon brush surrounding the blade for superior dust collection from the front and the rear side of the panel. 115v, 1-phase electrical required.

$6,799 NOW $1,999 FOB AZ

Wood Tech Systems

765-751-9990

www.woodtechsystems.com

2023 Northfield Model 410 Upcut Saw NEW 2023 Northfield model 410 upcut saw available for immediate shipment. 90/90 degree cuts to 4″ x 10″ capacity (fence forward position) to 2″ x 14″ (fence rearward position). Saw is configured for material from left to right, with 3″ x 6″ air operated cylinder, filter, regulator, lubricator, 10 HP motor, enclosed steel base with cast iron table, magnetic starter and adjustable operating speed from 20 to 60 CPM. Includes optional two-palm controls, additional 4″ dust outlet, NEMA 12 electrics with fused disconnect and two 18″ diameter 60 tooth blades with 1″ diameter bore. 460 volt, 3 phase electrical required.

$18,630 FOB MN

Wood Tech Systems 765-751-9990

www.woodtechsystems.com

Whirlwind Model 1000 Cut-Off Saw

• 5 HP Motor with 14" Blade

• 2 3/16" x 8 1/4" Capacity

• Pneumatic Blade Guard/Lumber Clamp

• Foot Pedal Control

• Dust Collection Outlet

• 460 Volt / 3 Phase

• 1 Left Hand & 1 Right Hand Model

Available

$3,500 NOW $2,250 Each FOB NC Wasserman & Associates 800-382-0329

www.wasserman-associates.com

1982 SpeedCut MetraCut

Centerline Saw

GOOSENECK ROLL OFF TRUSS TRAILERS

26’, 32’ & 36’ sizes available, Split Rollers available too! 2 YEAR WARRANTY

ALL TRAILERS NOW AVAILABLE WITH OPTIONAL GALVANIZED ROLLERS

sales@precisionequipmfg.com

1982 Speed Cut Metra Cut, model SSA-11, centerline saw, 16″ blade, maximum cutting depth of 6″, maximum cut length of 31″, 164 deg. cutting range and 5 HP motor. Includes push-button on/off controls and analog angle measure on turntable with air stop, 20′ long infeed conveyor with OEM SpeedMeasure, 20′ long outfeed conveyor and one (1) spare blade. 208 volt, 3 phase electrical required (can be converted to 240v/440v).

$6,990 FOB WY Wood Tech Systems 765-751-9990 www.woodtechsystems.com

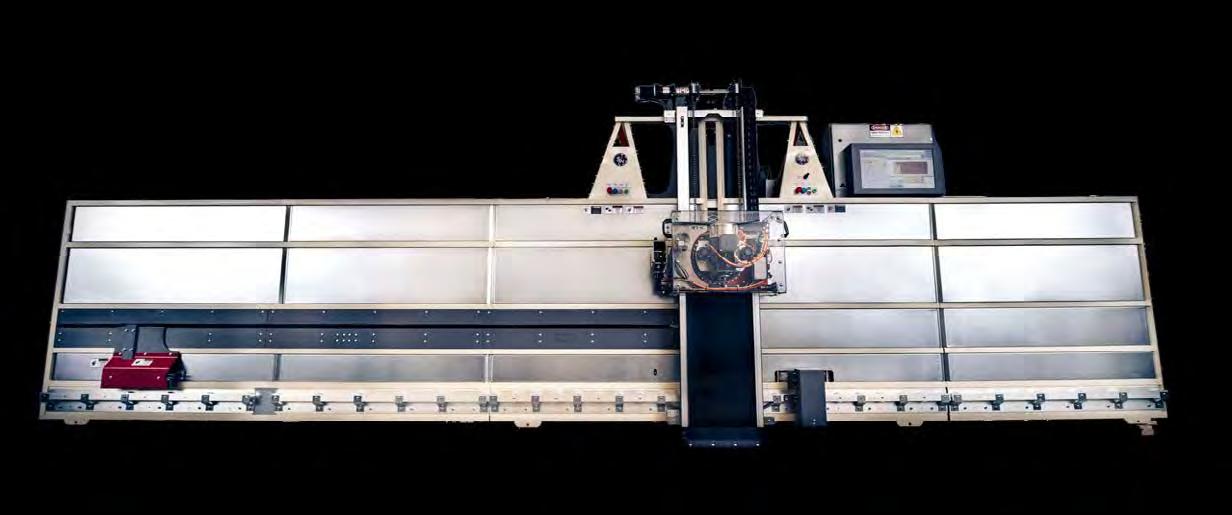

New Monet DeRobo Linear Saw

New, DeRobo linear saw by Monet organizes "fill" boards to increase optimization of each board, can produce unlimited scarf cuts, cuts 1 or 2 boards at a time and cuts webs, chords, wedges, rafters and open-stair stringers. Works with all major connector plate manufacturer's software. Features include 22 inch blade, left-to-right feed direction standard, lumber push and pull grippers for more accuracy, ink marking on the 1 1/2" face of the incoming boards and small piece capture and delivery to the front of the saw for easy access. Infeed deck and bunk feed are shown as options only. 480 volt, 3phase.

$245,000 FOB MO.

Edmond Lim, P.Eng. LimTek Solutions Inc.

Seven Decades of Construction Innovation

There has been a lot of attention paid to solving the global housing and affordability crisis. The component manufacturing and modular housing industries have been innovating for over seven decades. Much of the innovation has been successfully commercialized as evident in the annual volume of housing starts worldwide. But innovation in construction extends well beyond housing.

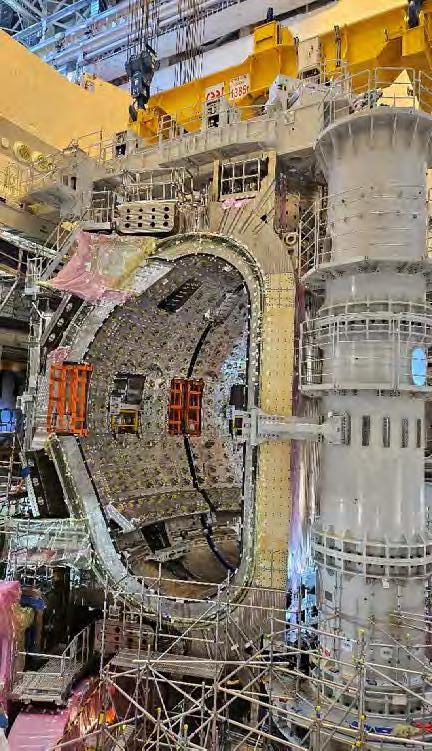

As we look forward to 2026, I had the opportunity to tour ITER, one of the largest construction sites in Europe, on the path to delivering the largest fusion energy device ever built. ITER is an acronym for International Thermonuclear Experience Reactor but also means “the way” in Latin.

ITER is one of the most ambitious energy projects in the world. As they note on their website, 33 nations are collaborating to build the world’s largest Tokamak, a magnetic fusion device that has been designed to prove the feasibility of fusion energy as a large-scale and carbonfree source of energy for mankind based on the same process that powers the Sun and stars.

That’s me standing in front of the giant 5-storey Tokamak Building which contains the ITER Tokamak fusion energy device and the Assembly Building attached to it.

Located in southern France, ITER’s fusion energy device will be used for fusion experiments and will not be a commercial fusion power plant. ITER is the unique culmination of over seven decades of international collaboration to harness the unlimited power of hydrogen fusion (“a Sun”) on earth. For more information on ITER, please visit www.iter.org

In the hills of Haute-Provence, in the south of France, ITER is a massive integrated facility that includes 50 scientific and industrial buildings on 42 hectares! The scale of the ITER plant tour is mindboggling, several magnitudes greater than any “Feed the Beast Plant Tour.” (For reference, see my previous articles, including “Inspiration for Automation in 2025,” “Incremental CapEx ROI and Plant Tours,” “Inspiration to Feed The Beast! in 2024,” and “Time to Make Time for a Feed The Beast Plant Tour!”)

Shown on the previous page is a cut-away model of the ITER Tokamak Fusion Device. For the actual device, inside the Assembly Building, high-capacity overhead gantry cranes and supplemental cranes are used to assemble and stage components to be installed in the Tokamak final location (“the pit”).

Shown here is one “D”-shaped toroidal field magnet weighing 330 tons and measuring 9 m x 17 m being prepped for installation using a massive jig.

Inside the Tokamak Pit, the Toroidal Field System will consist of eighteen of the “D”-shaped toroidal field magnets. When completed, the donut-shaped magnetic field will create 41 gigajoules of magnetic energy with a maximum magnetic field of 11.8 Tesla. This is more than 10 times greater than the strength of electromagnets used to lift cars in junkyards.

Surrounding the completed Toroidal “donut” will be a six-ring-shaped Poloidal Field System. The largest coil has a diameter of 24 meters and is 400 tons.

These magnetic coils are so big that they are manufactured on site in their own massive building. Continued

Shown next are two of the Poloidal Field Coils, including the largest 24 m coil, wrapped in protective coating, along with one of the “smaller” ring coils.

The entire fusion device is contained in a giant Cryostat vacuum vessel – the largest vacuum chamber in the world. There are four main cryostat stainless steel sections. When these massive 30 m diameter sections are assembled, they will provide a high vacuum containment system and ultra cold environment for the superconducting magnets.

Even though the site is dominated by steel and concrete, I still found some wood in the mix – including the use of wood for supports and shims!

The Cryostat base and lower cylinder have already been installed in the Tokamak pit. The upper cylinder and the top lid are stored under protective wrapping outside. Shown here is the top lid.

The entire fusion device is being constructed inside a heavily shielded (walls ~ 1 m thick) concrete chamber – the bio shield, which will be capped with a concrete lid.

In our industry, we have our own reference of what is considered a small or large project. Visiting a construction site like ITER though can remind of us what kind of scales are involved in construction projects around the world. This tour has been an eye-opener to the scope of projects that are possible in modern construction, thanks to 70 years of innovation.

Reach out to me when you’re ready to “Feed the Beast!” at your plant: https://limteksolutions.com/#solutions.

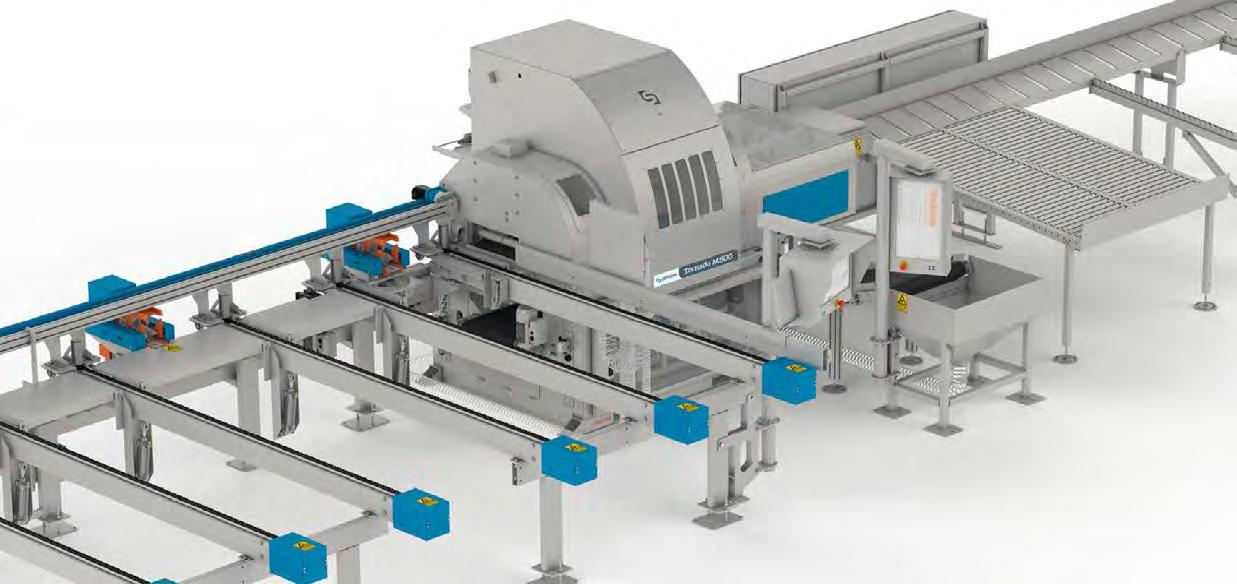

HUNDEGGER

lnnovationen fur den Holzbau

HUNDEGGER

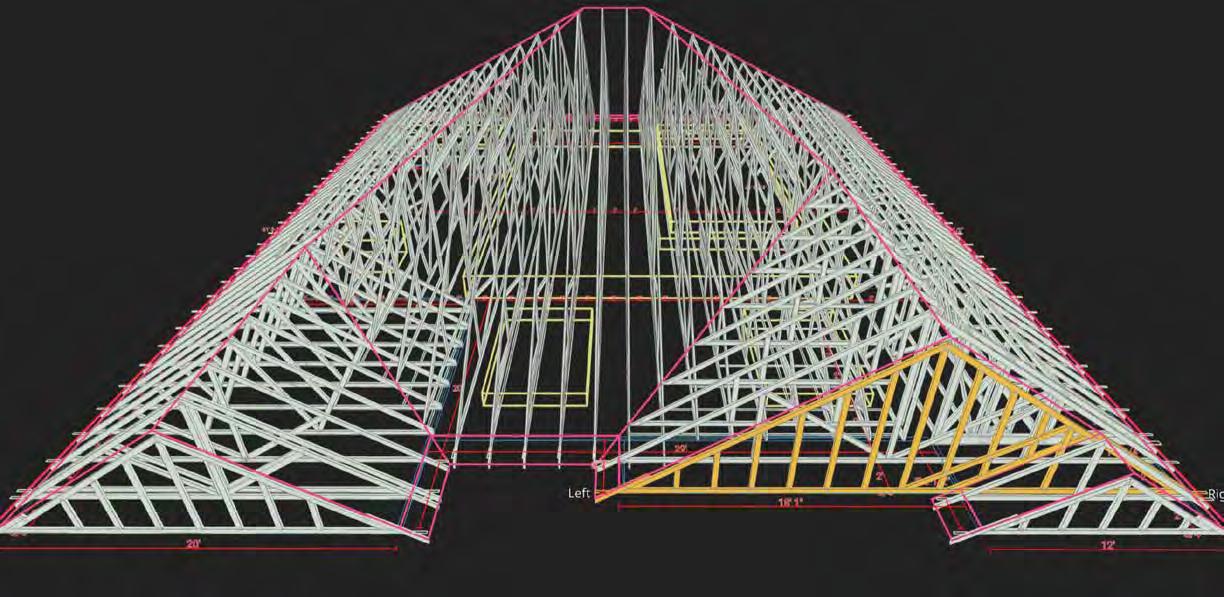

Hundegger leads the way in automation innovation for the truss component industry. Our advanced CAMBIUM software offers cutting-edge automation and digitalization solutions, revolutionizing operations, boosting productivity, and driving sustainable growth for manufacturers like you.

We go beyond standard mechanization; we champion true Automation. The Hundegger TD-II isn't just a saw-it's a transformative, comprehensive solution designed to streamline your production process. From retrieving lumber to optimizing, nesting, stacking, destacking, sorting, buffering, and precise delivery, our system ensures peak efficiency and productivity, tailored specifically to truss component manufacturing.

REVOLUTIONIZE YOUR TRUSS MANUFACTURING WITH THE HUNDEGGER TD-II

Harness the power of data with Hundegger's advanced CAMBIUM TACTICAL software. It meticulously tracks and optimizes your production, ensuring more automated operations and significant productivity gains.

We provide state-of-the-art automation and control solutions that set the industry standard. Our focus on industrial automation and robotics positions Hundegger as the leader in enhancing performance and efficiency in truss component manufacturing and beyond.

Hundegger products are essential for future-proofing your business. Elevate your productivity and secure your competitive edge with our advanced technologies and automation solutions, meticulously designed to meet the unique demands of component manufacturers today and tomorrow.

Don't get left behind. Invest in the future with true automation from Hundegger and see your business thrive.

2018 Spida Plate Marker with DeWalt Saw

• 20' of Steel Framed Table with Plastic Top

• Spida Automated 20' Length Stop/ Plate Positioner

• Auto Plate Positioning with Manual Marking

• Control Cabinet Enclosure with Touch Screen Computer

• DeWalt Model DWS780 Miter Saw

• Support Table for DeWalt Saw

• 10' Infeed Roller Conveyor

• Excludes Dust Collector & Spida Annual Support Fee

$19,900 FOB ND

Wasserman & Associates

800-382-0329

www.wasserman-associates.com

1994 Timbermill Model MH5G-20

Component Saw

Five blades cut lumber from 2″ x 4″ through 2″ x 12″, 4″ x 2″ lengths from 12 inches to 20 feet, including four-angle floor webs from 18 inches. All powered movements. Saw includes (1) 30″, (2) 20″ and (2) 14″ blades, analog scales, chain-drag scrap conveyor with chain-drag scrap incline, and an extra set of blades. Additionally this saw includes an extensive spare parts inventory including: Contacts/Starters, fuses, push buttons, limit switches, crank handles, scales/rulers/dials, angulation, conveyor, and saw motors, universal joints, and arms for outfeeds. 480 volt, 3 phase electrical required.

$17-924 FOB NC

Wood Tech Systems

765-751-9990

www.woodtechsystems.com

• Servo Controlled Single Blade Linear Saw

• 7.5 HP Motor (230 Volt/3 Phase) with 20" Blade

• Touch Screen Computer

• Ink Jet Printer

• Powered Infeed Roller Tables & Outfeed Queue System

• (2) Manual Bunk Feeders (saw can be used with or without bunk feeders)

• Waste Conveyor (includes new belt which needs to be installed)

• 240 Volt / 3 Phase

• Motion Control Upgrade in 2018

• New Computer with Touch Screen in 2019

$72,500 FOB WA

• T1 Axis Rod and Pillow Bearings replaced in 2023

• (4) T1 Linear Bearings replaced in 2023

• (4) Z1 Linear Bearing replaced in 2023

• (8) Be lt Drive Linear Bearings replaced in 2023

• Several Belt Drive Wheels replaced in 2023

• New Z1 Actuator in 2023

• Spare Parts: 2 White Drive Belts, Spare Power Cable, Rebuilt Z1 Actuator

• Video available upon request

• Automated Truss Length and Angle Cutting as directed by Truss Design Software Output

• Di rect Drive 7.5 HP Motor with Automated 160 Degree Angulation & 18" Blade

• Minumum Angle of 10 Degrees with 36" Stroke for Long Scarf Cuts

• Braked Saw Motor , Safe Grip, Variable Stroke Limiter & Plexiglass Shield for Operator Safety

• 20' of Steel Framed/MDF Table with Automated 20' Length Stop & 10'

Gravity Conveyor

• Workstation, Control Cabinet Enclosure & 21" Touch Screen Integration

• Kufo Dust Collector

• Spare Parts

• Truss Cutting Operating Software

• 480 Volt / 3 Phase

• Lighty Used

• Excludes: Installation/Training & Annual Technical Support Fee

Cuts wall and truss parts from lumber depths 2×4 through 2×12, 60”+ scarf cuts, internally optimizes material (up to 11 7/8″ x 1.5″ EWP) Includes 20 foot OEM auto-infeed conveyor and 15 foot OEM outfeed conveyor, and under-saw scrap conveyor with belt-type incline. All servo controlled functions, Microsoft Windows XP OS, 7.5 hp motor with 20” carbide tipped blade. Includes spare infeed/outfeed belt and any available spare parts. No printer is included. The door latch needs to be repaired. 220v / 3 ph power, 125 PSI air required.

BCE-MASTER

A dverti $ er

SAWS

2003 Alpine AutoMill RS Component Saw, Model 344

Computer controlled saw sets up in 2 to 19 seconds and downloads from a network or by using a touch screen for ease of operation. Five-head automated component saw works in both automated (downloading files) and semi-automated control via touchscreen input. It has [23] axes of automated movement, enhanced diagnostics, auto management reporting. The RS cuts from 13″ to 20′ long material in size ranging from 2×3″ through 2×12″, includes [3] 18″, [1] 22″ and [1] 32″ blades with air brakes, shaker pan waste conveyor to incline scrap conveyor, one set of spare blades and any available spare parts. (Infeed conveyor needs electrical service). 480v/60Hz/3Ph power.

$17,997 NOW $12,497 FOB AZ

Wood Tech Systems

765-751-9990

www.woodtechsystems.com

Striebig Optisaw, model Optisaw Automatic (Type # 5164) vertical panel saw station, with angled frame supporting material being cut: Max. cutting height (vertical) 5′-4″, max. cutting length (horizontal) 15′-1″, max. cutting thickness 2.36″. Both vertical and horizontal analog measuring scales on frame. Cutting head manually rotates from vertically to horizontally for rip vs. cross-cutting, adjustable spacers for repetitive cuts, 5.25 HP saw motor, 9.84″ diameter blade, guide bearings for travel , push button controls, e-stop button and dust extraction hose (no vacuum included). Overall footprint of station 19′-1″ wide x 4′7″ deep x 7′-10″ height. Sold for $36,000 new. 208 volt, 3 phase electrical required.

$14,490 FOB AZ Wood Tech Systems

765-751-9990

www.woodtechsystems.com

2000 Alpine AutoMill Component Saw 2000 Alpine AutoMill model 343H, (5) blade component saw, cuts lumber from 2×3 through 2×12, from 18″ to 20′, 4-angle floor webs from 18″. Includes powered length and angulation, digital readouts, (1) 32″, (3) 18″ & (1) 20″ blade, shaker under-saw scrap conveyor, incline, PC with Windows 98 o/s, and outfeed conveyor. Decommissioned in 2018. Stored indoors. 480 volt ,3 phase electrical required.

$10,497 FOB ON Wood Tech Systems

765-751-9990

www.woodtechsystems.com

Idaco Webmatic Saw

• Roof & Floor Web Saw

• Four 5 HP Saw Motors

• Cuts 2x4, 4x2 and 2x6 up to 16'

• Manual Angulation

• Waste Conveyor (under saw)

• Incline Waste Conveyor (adjacent to saw)

$8,500 FOB CO

Wasserman & Associates

800-382-0329

www.wasserman-associates.com

NEW Hain 20' Powered Measuring System

Adapts to Any Saw. Left or Right Hand Operation. Feet & Inches System (Stops at 12” Centers) or Inches System (Stops at 10” Centers). Motor: 1/4 HP Linear Actuator (110 Volt). Stop Rail: 2 x 4 x 1/4” Aluminum Extrusion. Stops: Jig Bored Steel. Stop Blocks: Machine Billet Aluminum. Optional Lengths from 5’ to 60’. Optional Gang Stop. Add $890 per 10’ Section of Heavy Duty Roller Conveyor with Stands

$8,990

Wasserman & Associates

800-382-0329

www.wasserman-associates.com

By Steve Shrader, Business Development / Operations, Hundegger USA

Automation is Here, and It Doesn’t Need a Supervisor to Nudge It Along

In an industry long defined by hard work and incremental improvement, a new chapter is being written. But not everyone seems to realize it.

Some are still telling companies to squeeze more productivity out of crews by reorganizing work paths, tracking stopwatch data, and optimizing jobsite ergonomics. Others celebrate modest efficiency gains after retraining workers to use old tools better.

But let’s be clear: That’s not automation. That’s mechanization.

Mechanization helps people move materials faster. Automation eliminates the manual thinking entirely. Mechanization still needs someone to direct the flow. Automation builds logic into the process so the flow happens without waiting for permission.

Who’s Doing the Thinking in Your Plant?

If your team still depends on pickers and whiteboards to keep production moving, you’re not running an automated facility—you’re just managing organized chaos.

We’ve seen some consultants warn that automation doesn’t fix labor problems. But in 2025, that warning misses the point. Automation literally eliminates personnel problems. That’s the point. It automates the mundane, sequences the complex, and schedules production based on demand—not availability. A smart system doesn’t need your “best guy on the floor.” It frees him to manage exceptions, not operations.

If your definition of improvement still includes clipboards and crew choreography, it’s time to upgrade your thinking.

Are We Still Celebrating 30 Percent Gains?

Lately, we’ve seen applause for production lines that gained 30 percent output after cleaning up workstations or better coordinating labor. That’s fine. But let’s not pretend this is what modern manufacturing is about.

Modern operations don’t try to stretch the crew. They try to reduce the need for the crew. And they definitely don’t rely on the same staff to guess what part goes where, and when.

Some argue that component saws are “underperforming” if they aren’t running at 60 percent or more of theoretical capacity. But we don’t measure productivity by raw blade speed. We measure it by the right part in the right place at the right time. Flooding the floor with overproduction just creates backlog, waste, and confusion. That’s not lean. That’s lazy.

Design-Led Production: The Future Is Here

Some industry voices still frame automation as a back-end problem—a machine running without enough people to feed it. But true automation starts at the design level. With the right software, the design is the process instruction.

Hundegger’s systems optimize from the office, not just the shop. Our software doesn’t just push cuts to a saw—it reverse-engineers the job from the delivery schedule, nests by output, and automatically buffers the flow. It doesn’t need someone to babysit it or make judgment calls at 7 a.m.

And when changes hit, the system adapts instantly. That’s not luck. That’s logic. Built in.

Automation Doesn’t Just Work, It Thinks

Consultants often claim that labor problems are solved by improving hiring or cross-training. That worked in 2010. But if your strategy in 2025 still revolves around staffing up and hoping your A-crew sticks around, you’re gambling with your margins.

Today’s intelligent automation pulls jobs through the plant based on data, not guesswork. No pick lists. No morning huddles. No “best guy” trying to keep the line moving.

And yes, automation literally eliminates personnel problems. That’s the point. It schedules itself, sequences jobs with downstream logic, and doesn’t need your floor supervisor to nudge it along.

Final Thought

If you’re comparing systems this year, ask tougher questions. Are you buying faster blades and more conveyors, or are you buying intelligence?

Are you empowering your crew to keep up, or empowering your system to do the thinking?

If the answer still relies on people to pick, route, decide, or adjust—then it’s not automation. It’s mechanization, with a glossy brochure.

At Hundegger, we believe automation should do more than work. It should think. And in this market, that’s not optional anymore. It’s essential.

New Monet DeSawyer ESC (Servo Controlled) Component Saw

Monet DeSauw model Desawyer ESC enhanced servo-controlled ( ESC) component saw with touch screen user interface with backup mechanical controls. Includes three operating modes: Auto (download setups from LAN or USB), Semi-auto (touch screen setup entry), and Manual (backup push-button switches for powering all movements). Includes over-travel protection, comprehensive setup screens, auto sequencing, auto-calibration and pneumatic brakes on all five () blades. One (1) 30” blade and four (4) 16” blades. Manual cut limits are 18” min., 11” min. square edge blocks, 20’ max cut. Belt under-saw waste conveyor. Voltage: 480 volt/3 phase/60 Amp. Air: 50 PSI at 5 CFM. One-year warranty included. Can be paired with a model PD-6 lumber feed system at an additional cost. Heavy duty 80 RIV chain feed system. 16’ wide x 20’ long x 36” deck height. Transfers 3’ to 20’ lumber. Includes auto-feed control, foot pedal override, forward & reverse, variable speed control with HD double-bearing construction. Other additional-cost options include, inkjet marking, label printing, backside screen display, spare blades and incline scrap conveyor.

$379,900 FOB MO

Vista "Angle Boss" Saw with 20' TigerStop

• 2012 Vista Model M-20 AutoSet Cut-Off Saw

• 0 to 75 Degree Left & Right Blade Rotation

• 10 HP/460 Volt Motor with 20" Blade

• 10' Infeed Roller Conveyor & 20' Outfeed Roller Conveyor

• 2012 TigerStop (250" Cut Length)

• TigerStop Software Version 5.30

• Excludes Dust Collector

• Video available upon request

• Price in US Dollars

$18,880 FOB MB Wasserman & Associates 800-382-0329 www.wasserman-associates.com

Safety Speed Manufacturing Model 7400 XL Panel Saw

Safety Speed Manufacturing, model 7400 XL*, vertical panel saw, 3 HP induction motor, 64 inch crosscut, 2 1/8" maximum thickness, accuracy within 0.005 inches, 13 foot long welded steel frame with integrated stand and linear V-guides, enclosed counterweight system, adjustable vertical and horizontal rules. Quick changes from vertical to horizontal cutting. Includes machined aluminum material rollers, hold down bar, wheels, quick stop gauges and material hold downs. Dust collection ready. Options available include digital readouts for vertical cuts, automated length measuring, laser guide, stop bar, vacuum and midway fence. 208-230/460 volt, 3 phase electrical (208-230 single phase, 2 HP power optional +$100.00).

$14,499 Base, FOB MN. Wood Tech Systems 765-751-9990 www.woodtechsystems.com

Safety Speed Cut Model 7000 Panel Saw

Safety Speed Manufacturing model 7000, vertical panel saw, 3 HP induction motor, 64 inch crosscut, 2 inch maximum thickness, accuracy within 1/64th of an inch, 10 foot welded steel frame with integrated stand and linear V-guides, enclosed counterweight system, adjustable vertical and horizontal rules. Quick changes from vertical to horizontal cutting. Includes machined aluminum material rollers, hold down bar, wheels, quick stop gauges and material hold downs. Dust collection ready. Options available include lower frame extensions, digital readouts, laser guide, stop bar, vacuum and midway fence. 208-230/460 volt, 3 phase electrical (208-230 single phase, 2 HP power optional +$100.00). $10,199 Base, FOB MN.

• Automated Square, Angle, Rip & Bevel Cutting

• 2x3 through 2x12 up to 16' in Length

• 5 HP Motor (recently updated) with 17" Blade

• Touchscreen Computer

• Crooked Lumber Sensor

• Ink Jet Printer

• Auto Deck (4 Chain)

• Auto Infeed Rail

• Powered Skewed Outfeed Conveyor with Roller Conveyor Receivers

• Incline Waste Conveyor

• 230 Volt / 3 Phase

• Available in late June 2025

• Video available upon request

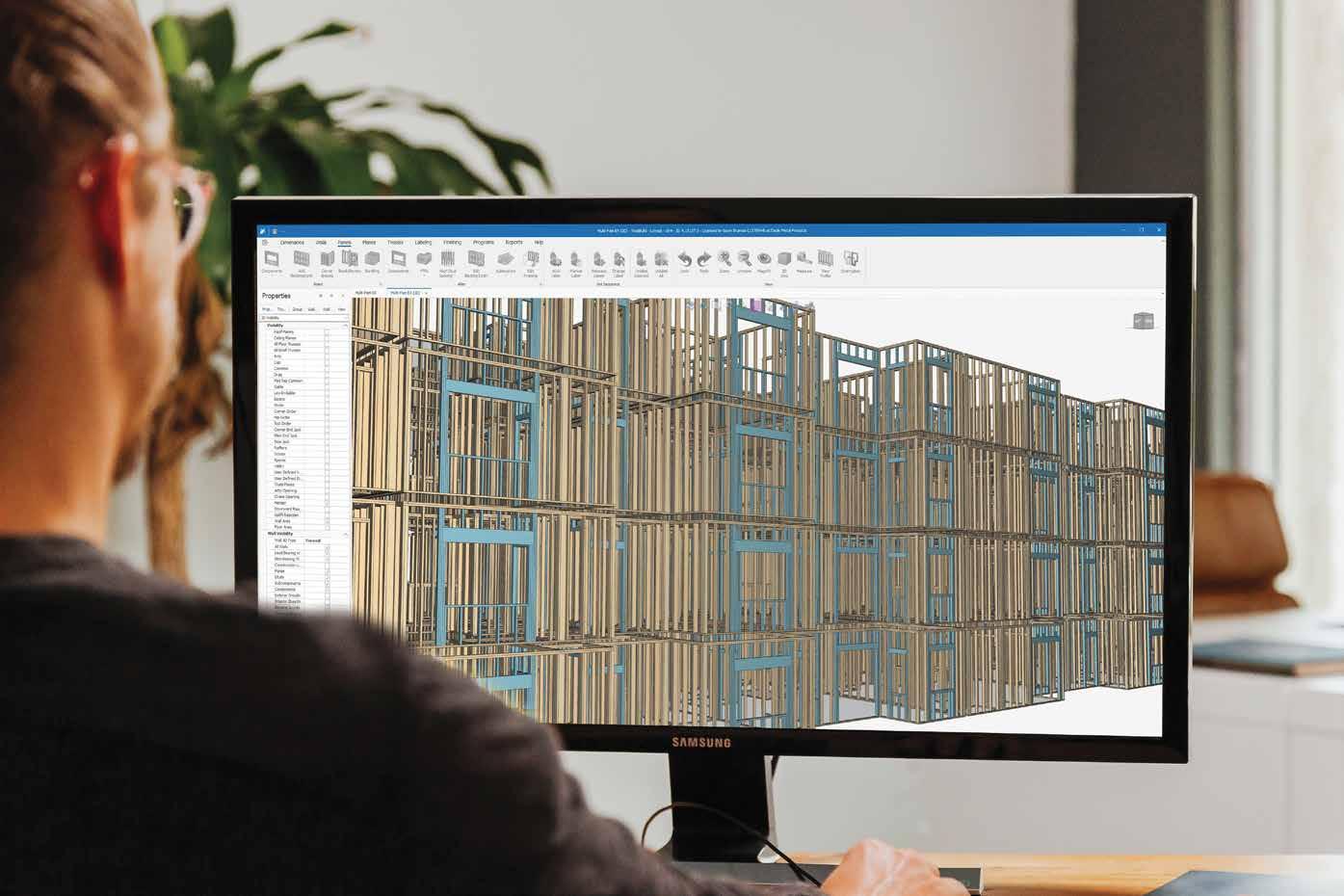

Casey Harless, Director of Construction Element Solutions Stiles Machinery

To Precut or Not to Precut?

That is the Question

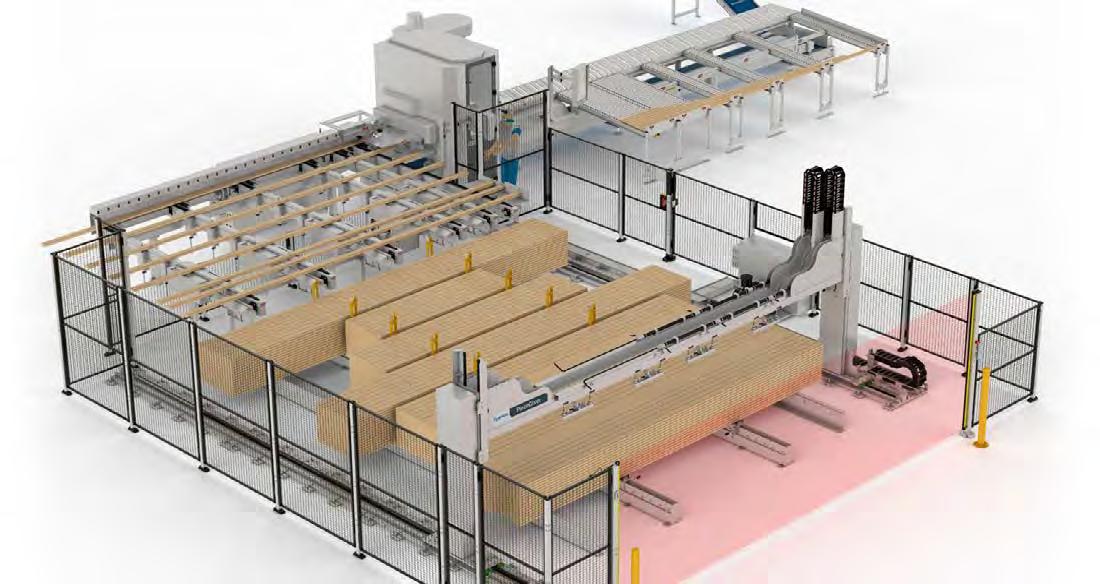

Close your eyes and imagine yourself walking through a component manufacturer’s facility. As you do this, some will see a facility with a relatively well-automated wall panel line, in which full sheets of OSB, gypsum, ZIP, etc. are being applied to the wall in line and the router on the multi-function bridge (as seen in the image) is processing window/door cutouts, MEP openings, etc. For the other group of people, we imagine a facility in which all sheathing is pre-cut (likely on some version of a vertical panel saw) and arranged on carts prior to making its way to the wall line. In this facility, you’re probably imagining many carts filled with pre-cut material, staged up for the day’s production, along with many offcuts (remnants) from the pre-cut material, which the business owner hopes to utilize.

So why do we have these two camps of business owners/operators? Suffice it to say, it seems as though there is a simple divide in manufacturing philosophies. Some companies believe there is a great yield increase (i.e., cost savings) and performance increase of the line by pre-cutting material, whereas some companies do pre-cutting out of “believed” necessity, not being aware of an automated in-line routing solution (e.g., the WEINMANN WALLTEQ). With that being said, some companies believe it’s best to utilize the in-line routing on a multi-function bridge to save space (no separate panel saw location), decrease additional material handling (less labor), reduce carting/kitting, etc. However, with the many factories we’ve visited, the common theme tends to be that whichever camp a customer falls into is based on a feeling (gut check).

The goal of this article is not to sway you towards pre-cut or full sheet material usage, but rather to focus on those companies which are pre-cutting material and offer up some ideas on how to potentially optimize, drive more efficiency, and ultimately push more product through the door day-to-day.

This is going to sound like an advertisement (and kind of is… wink wink) but the HOMAG SAWTEQ (horizontal panel saw) and CENTATEQ (flat table router) are both masters in processing pre-cut sheet material before it heads to the wall and/or floor/ceiling line(s).

The SAWTEQ is focused on cutting rectangles and squares with speed and accuracy, in both single sheets as well as stack cutting for same-patterned material.

The CENTATEQ series offers single-sheet processing but beyond rectangles and squares, meaning the ability to round corners for window/ door and/or MEP openings (something a saw blade can’t do).

Now, you’re probably thinking, “yeah, well, so can my vertical panel saw and hand router,” and you’d be right; however, here are a few bulleted areas in which we can help you improve:

• Speed: The ability to stack cut on the SAWTEQ drives higher performance.

• Data Management and Optimization: All data is transferred from your DfMA software to our proprietary Cut Rite optimization software. This allows for a seamless transition from DfMA, which passes the sheathing layer to Cut Rite for optimization. At that point, Cut Rite optimizes your board layout for the highest possible yield.

• Offcut Management: Rather than stacking up your offcuts (remnants) to hopefully use them down the road, Cut Rite stores this data, including the type of board (i.e., OSB, ZIP, gypsum, etc.), size of offcut, etc. Then, Cut Rite will automatically prioritize usage of offcuts in its board library before telling the operator to get another full-size sheet. Historically, we’ve seen some customers increase board yield by more than 20% with better usage of offcuts.

• Labeling: At the outfeed of the SAWTEQ or CENTATEQ, a printer can generate a label to apply to each piece. Either it will print a label which shows the wall layout and where to place the respective part (see image) or will print a label specifying it is an offcut. This greatly reduces the time spent at the wall line placing individual, pre-cut parts on the wall.

• Sorting/Kitting: Depending on how material is batched, the SAWTEQ/CENTATEQ, along with the Cut Rite software, can also help batch parts across different jobs for better yield. It then also provides visual queues at the operator stand (by virtual color) of which cart to place each part in (i.e., blue part to Cart 1, green part to Cart 2, etc.).

All that said, we’re not implying that pre-cutting is the right solution over in-line routing (i.e., full sheet usage), but we’ve seen many factories and believe there is a better way to do pre-cutting. If you’re pre-cutting today and would like to dive deeper into what has been said here, or if you’re in the other camp and would like to learn if this might be a fit for you in your current factory, please reach out to us! Contact Stiles Machinery at (616) 698-7500 or visit StilesMachinery.com/OSC to learn more.

Cutting, Framing and Truss Solutions - We Do It All!

We provide high quality precision machinery suitable for cutting and assembly of walls, roof trusses and floor trusses. All your needs are covered.

$349,000 Location: MO

New, Monet DeSawyer 2000, computerized, five-bladed component saw, sets up in 15 to 17 seconds, can run in manual mode, downloads projects from a network or manually using display screen controls. Features all powered movements, cuts from 15" 90/90 cuts to 20 foot length, 2 x 3" to 2 x 12" lumber depths and internal brakes are standard. Options include enhanced servo controls featuring autocalibration, catcher's display and either shaker or belt scrap conveyor and incline. 440 volt, 3 phase electrical.

NEW!

Terminailer

Price: $237,900

FOB: ND

The Terminailer all but shatters the stereotypical myth that sub-component equipment is essentially peripheral – unimportant. And it does so by quickly and accurately driving far more framing nails in your wall panel jobs than ever before. Whether in your shop or in the field, one operator sets the pace for production and quality, which reduces labor costs and other aspects of overhead.

The new Terminailer V.8 improves on the previous generation Terminailer in several key ways:

All new HMI/Software

• Siemens Pivoting HMI Touchscreen display to operate from either side

• On-screen tutorial for all menu items

• Operator now controls functions such as process speed, nail spacing, nail patterns, etc.

• Simplified input commands

Nail Feed Complete Redesign

• All new frame to allow for redesigned nail coil placement with direct feed path

• EverWin PN90-PAL industrial tools now standard equipment

• New nail guides with spring-loaded tensioners

• Nail coils move with vertical travel of the nail guns

Reengineered air system

• SMC “Soft–Start” Pneumatics

• Simplified air for control to all components: lift–cylinders, triggers, stop–gate, etc.

• Direct air supply to each nail gun for improved nailing performance

• All pneumatic elements are clearly labeled for EZ service and adjustment

Overall Features

• Pharmaceutical grade assembly, industrial grade durability

• “Block–wheel” redesign for 3X increased applied force

• Approximately 1,200# of applied clamping force resulting in straighter finished

• Subcomponents from even the poorest lumber

• Larger doors for easier access to interior elements including coil–nail spools

Terminailer is an event-driven, sub-component assembler that will quickly and accurately drive 30% to 70% of the framing nails in any wall panel job. In your shop or in the field, one operator sets the pace for production and quality. The Terminailer functions independent of design software, requires zero set-up time when switching between any configuration, and requires no special operator training.

The Terminailer is easy to move around the shop so its location can evolve as your shop evolves. With all of the nailing occurring in the closed main chamber, nail injuries and nail location misfires are eliminated, making your plant that much safer.

With nearly ten years of development from people that know machinery, it is assembled to exacting standards, well supported, and it is easily maintained with shelf-item parts. Terminailer: vetted, tested, and ready to drive maximum productivity for you. Be sure to check out our videos below for a quick review of this revolutionary machine!

240 volt, 1-phase, 30 (full load) Amps, 60 Hz electrical required. 50 SCFM @ 120 PSI air required. Net weight 7,000 lbs.

2003 Koskovich Auto Omni Component Saw

• 5 Blade Automated Component Saw

• Cuts 2x3 through 2x12 from 11" to 20'-0"

• Computer, Enclosure & Stand

• Waste Conveyor (under saw)

• E xcludes Incline Waste Conveyor (adjacent to saw)

• Video available upon request

• Add $12,500 for 6 Chain Live Deck $16,500 FOB ND Wasserman & Associates 800-382-0329 www.wasserman-associates.com

Safety Speed Manufacturing, model 7400 XL*, vertical panel saw, 3 HP induction motor, 64 inch crosscut, 2 1/8" maximum thickness, accuracy within 0.005 inches, 13 foot long welded steel frame with integrated stand and linear V-guides, enclosed counterweight system, adjustable vertical and horizontal rules. Quick changes from vertical to horizontal cutting. Includes machined aluminum material rollers, hold down bar, wheels, quick stop gauges and material hold downs. Dust collection ready. Options available include digital readouts for vertical cuts, automated length measuring, laser guide, stop bar, vacuum and midway fence. 208-230/460 volt, 3 phase electrical (208-230 single phase, 2 HP power optional +$100.00).

$40,995 FOB QC

2010 Alpine ALS 286A Linear Saw -Linear feed saw model 286A cuts truss parts from lumber up to 12″ nominal depths. Cuts bevels from 90 to 20 degrees, scarf cuts to 60 inches, and optimizes material usage. From OEM literature, “…has 6-axis of automation, self-calibrates at powered startup with 1/32” accuracy”. Includes Matthews InkJet printer (single 3 ½” face), servo motor drive mechanism, 10 HP motor, 20 inch carbide tipped blade, small parts outfeed bin and touch screen control with Windows XP o/s. Includes 18 ft. infeed conveyor, 16′ outfeed conveyor and any available spare parts. Decommissioned in March of 2025. Cutting chamber weighs 8,000 lbs. 230V, 3 phase, 85 Amp electrical required.

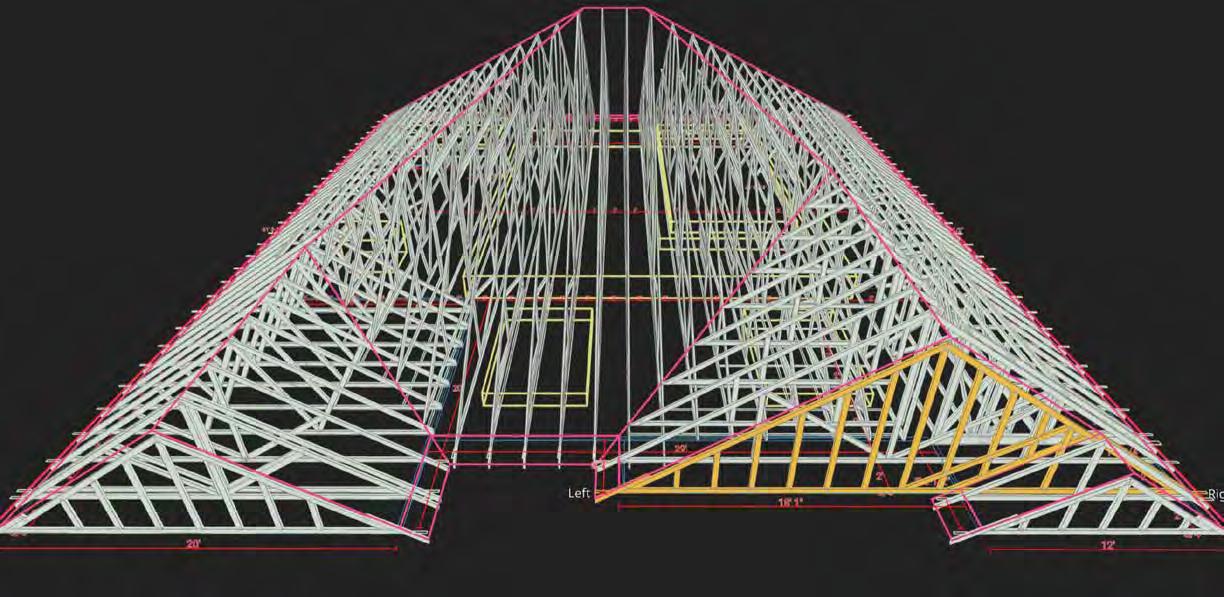

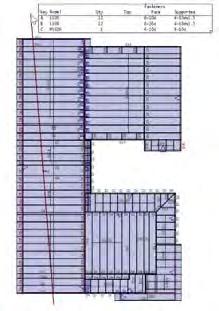

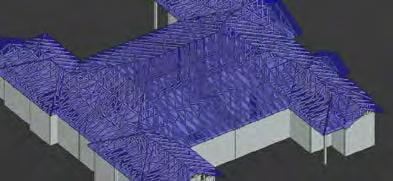

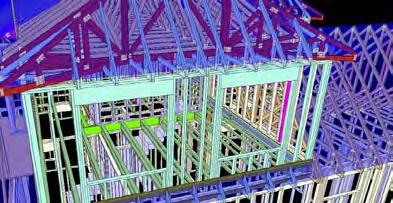

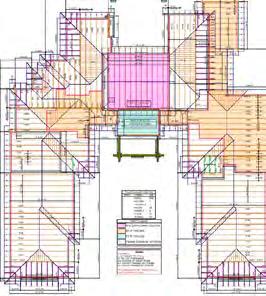

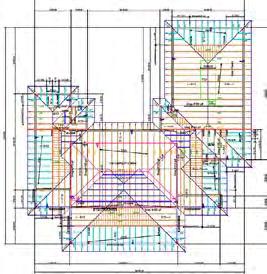

By Landon Boucher Director, Business Design

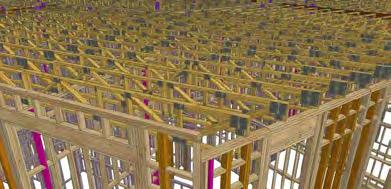

Striking Gold with Posi-Strut in Carson City