A dverti $ er Component manufaCturing

Serving the Structural Building componentS induStry S

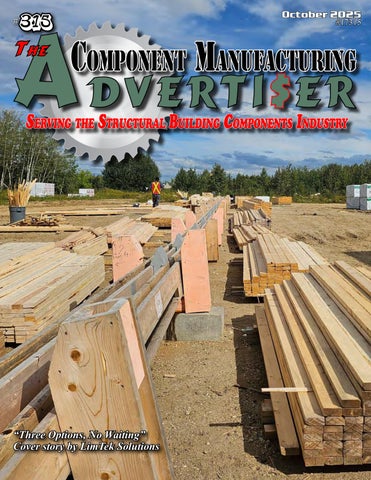

“Three Options, No Waiting” Cover story by LimTek Solutions

A dverti $ er Component manufaCturing

Anna Stamm – Advertiser Forum: Issues, Articles, and Omaha

Joe Kannapell: Home Building Technology, Part X: Competing Connectors

Wendy Boyd – Spida Machinery: What If You Could Build Any Wall on One Line?

Todd Drummond Consulting, LLC: Far More Than Simple Cost Saving with TDC Time Standards Used with Paragon and AppWright

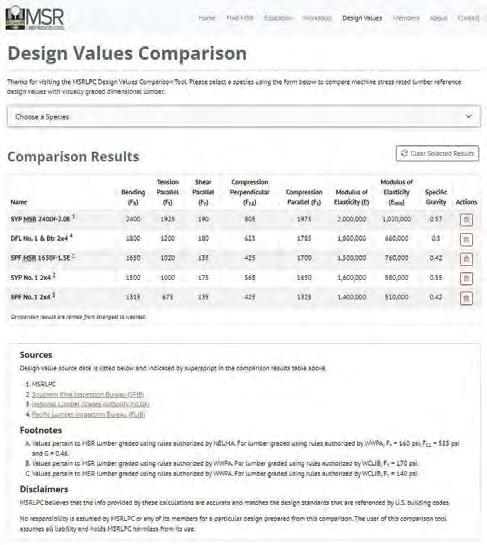

Glenn Traylor: Do You Know Your ANSI/TPI 1 Chapter 3 Numbers?

Ed Lim – LimTek Solutions: Three Options, No Waiting – The RetroC Auto-Feeding SmartConveyor

Jeff Vance, PE – MiTek: Rethinking Shear Transfer at Floor Transitions

Alpine Staff: Alpine Linear Saw 5.0: A New Standard in Small Parts Handling

Jesse Southard – Stiles Machinery: From Sketch to the Production Floor: How Prefabricated Construction Elements Become Reality with WEINMANN Machines

Marco Gagnon – Element Equipment: From Idea to Market: The Journey of Building a New Machine

Jeff Brown – Panels Plus: Solving the Skilled Labor Shortage: How Semi-Automated Equipment is Rebuilding the Construction Workforce

Carl Villella – Acceptance Leasing: Market Confidence and the Building Component Industry

Thomas McAnally – TheJobLine: Hiring-Zone.com: A New Platform Connecting Employers, Job Seekers, and Contractors in the Building Components Industry

Geordie Secord – Design Connections: Training vs. Experience: What Really Builds a Great Designer?

MiTek Staff: Solid Blocking Requirement for Truss Joints

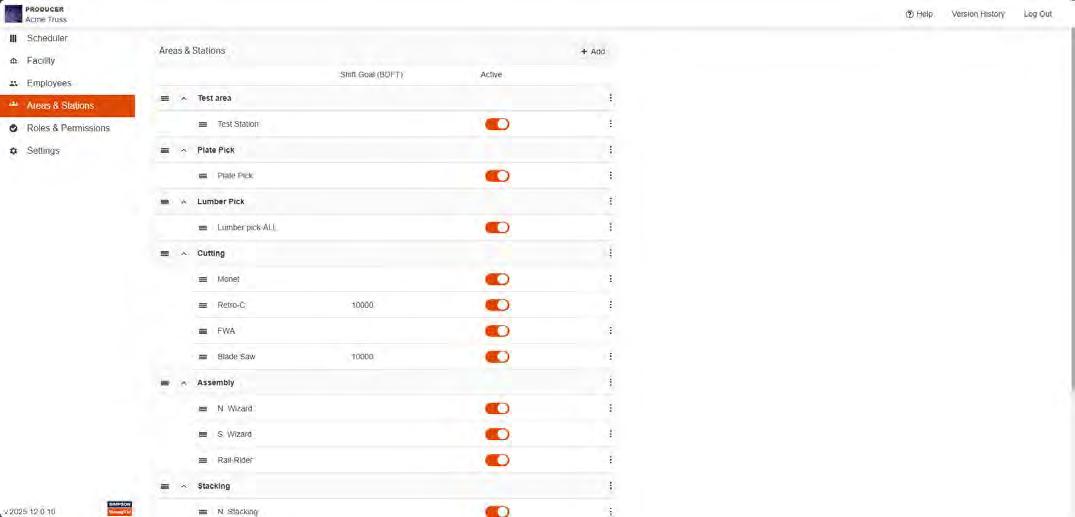

Carolyn O’Hearn – Simpson Strong-Tie: CS Producer™ – A Modern Approach to Truss Production & Management

Joe Kannapell – The Last Word: Housing and Components on the National Mall

A dverti $ er

the Structural Building componentS induStry

New & Used Equipment

Saws

Truss Equipment

Panel Equipment

Trucks & Trailers

Misc. Equipment

Door | Stair | Window Equipment

Safety First

Calendar of Events

TheJobLine - Jobs & Candidates

Industry News

Directory

Hiring-Zone - Jobs & Subcontractors

4Ward Solutions Group

Acceptance Leasing & Financing

Acer, Inc

All Points Technical

Alpine

BuyMetrics

Clark Industries, Inc.

Eagle Metal Products

Eide Machinery Sales, Inc.

Element Equipment

Fitzgerald Group

Hiring-Z one

HOLTEC USA

Hundegger USA

LimTek Solutions

MiTek

Panels Plus

Paragon

Precision Equipment Truss Trailers

ROGworx Automation

Simpson Strong-Tie

Spida USA

Stiles Machinery

The Hain Company

TheJobLine

Timber Products Inspection

Todd Drummond Consulting, LLC

Triad | RUVO | Merrick Machine

Vekta Automation

Wasserman & Associates

West Fraser

Wolf X Machina

Wood Tech Systems

100,101,113,115,116,127,132,135,137,139

Publisher Thomas McAnally twm@componentadvertiser.org

Editor Anna L. Stamm 800-289-5627 x 3 anna@componentadvertiser.org

Distributed FREE Via e-mail subscription Download PDF or Read on line at www.componentadvertiser.com

News of Interest and Advertising inquiries can be submitted to: anna@componentadvertiser.org An Open Forum for many sources.

Deadline 20th of each month. Articles, Trade Names, and Logos are the property of their respective owner or creator unless otherwise noted

Disclaimer: We reserve the right to refuse any advertisement or material that we deem not in the interest of the industry or the Advertiser. Permission to use content is the responsibility of the contributor including permissions to use any likeness of persons.

The Advertiser is provided “As Is” including typographical errors, omissions, and mistakes both intentional and unintentional.

Believe it at your own risk!

Copyright 2008-2025

Component Manufacturing Advertiser

The Advertiser 7586 Becks Grove Road Freetown, Indiana 47235 no reproduction in whole or in part without permission from the component manufacturing advertiser

Archive Copies Available On Line www.componentadvertiser.com

Anna L. Stamm Director of Communications and Marketing Component Manufacturing Advertiser.

Advertiser Forum

Issues, Articles, and Omaha

If you’re like me, you’re away from your computer on the first day of October, choosing instead to attend the industry’s annual trade show, the Building Component Manufacturers Conference (BCMC). Held in Omaha, Nebraska this year, it has promised to be an exciting event.

To Publish or To Wait

Although we could have held back this October issue so we could include photos from the big show, we realize that not everyone is able to attend. We know there are many readers still in the office this week, by choice or necessity. Plus, we always aim to publish on the first of the month, which has been the tradition since Thom switched to monthly issues way back in January 2013.

Always Another Month in View

Always aiming for the first of the month highlights a very important benefit of our magazine –there’s always another issue on the horizon. Although that could be seen as a burden, it’s actually an opportunity. It means that we’re always ready to accept more news, updates, and stories, so if you miss one deadline, you can shoot for the next!

This fall marks 10 years for me at The Advertiser. Yes, my first issue was December 2015! Many things have changed over the years…but many things remain the same. Our industry is still filled with hard-working, dedicated professionals who are committed to doing a good job for themselves, their companies, and their customers. We have much to be proud of, and to celebrate, in our industry. So, let’s hear more of it! Please send me your thoughts and let everyone know what you would like to say in our open forum. Do you have a story from BCMC you would like to share? Is there someone at your company who deserves recognition? Are you looking for feedback or have suggestions to give?

Importantly, The Advertiser will fit into your schedule when you’re ready to contribute. If you aim for one month and fall behind – not to worry, another month will be coming up next. On the road or in the office, we’ll be here for you. What will you say in our pages?

Monet DeSauw FWA 500 Floor Web Cutter

• Push Button Powered Blade Angulations

• Single Push Button Setting for 2 Blades per Side

• Electronic Digital Readouts

• Backup Mechanical Indicators

• Cuts 4 Angle Webs, Cantilever Webs (2 piece webs) & Square Blocks

• Magazine Lumber Feed for 3x2, 4x2 and 6x2 Lumber 12 1/2” to 48 1/2” Length Capacity (7” Minimum on Square Blocks)

• 60 Pieces per Minute

• (4) Internal 16” Blades & (1) External 16” Cut-Off Blade

• Pneumatic Blade Brake on External Blade

• Dust Hoods

• Belt Waste Conveyor (under saw)

• Add $4,300 for 12’ Incline Waste Conveyor (adjacent to saw)

• Add $2,100 for Extra Set of Blades

• 480 Volt / 3 Phase FOBMO Call For Pricing

• Automated (Truss Design Software Download) or SemiAutomated (Touch Screen Entry) Operation

• All Movements are Computer & PLC Controlled

• Comprehensive Setup Screens Display Each Piece with Setup Data

• 22” x 40 Tooth Blade on PAE Cut 1 or 2 Boards up to 20’ (2 Second Plunge Cut)

• Cut Chords, Webs, Rafters, Wedges & Stair Stringers

• Cut Long Scarfs by MultiPlunging

• Servo Positioning on Infeed, Angle & Outfeed Pusher

• Over Travel Protection

• Ink Jet Printer

• Lumber Optimization Program

• Belt Waste Conveyor

• 480 Volt / 3 Phase / 60 Amp

• Includes 5 Day Onsite Installation & Training

• Optional Monet DeSauw Live Deck, Bunk Feeder & Incline Belt Waste Conveyor FOB MO Call For Pricing

• Touch Screen User Interface with Backup Mechanical Controls

• 3 Operating Modes: Auto, SemiAuto & Manual

• All 20 Axes of Movements are Computer & PLC Controlled

• Comprehensive Setup Screens Display Each Piece with Setup Data

• Anti-Collision & Optimizing Programming

• Auto Calibration Productivity & Time Tracking

• Maintenance Diagnostics

• Variable Speed Conveyor (0-50 Flights per Minute)with Powered Hold Downs

• (1) 30” x 80 Tooth Blade (27 3/4” Scarf on PAE)

• (4) 16” x 40 Tooth Blades (13 1/2” Scarf on Centerline)

• Pneumatic Blade Brakes on all 5 Blades

• 16 1/2” to 20’ Length Capacity (11” Minimum on Square End Blocks)

• Vibrating Waste Conveyor Under Saw

• 480 Volt / 3 Phase

• Includes 4 Day Onsite Installation & Training

• Add $2,900 for Extra Set of Blades

• Optional Live Deck, Label Printer, Ink Jet Printer, Catcher Display & Incline Belt Waste Conveyor.

EZ-SET AUTO JIGGING EXCLUSIVE & PATENTED DESIGN

Automatic Truss Jigging System to drastically reduce setup times. Allows for 100% embedment on the table, with top & bottom chord pucks in the same slot. TopSider or standard configurations available for conventional kick-leg, walk-thru, or our new trackless 8' and 10' continuous table systems. Systems for other roller & hydraulic gantries are coming soon. Available in new machine installations or for retro-fitting your existing table. The TopSider is exclusively applicable for “kick or flip leg” style truss presses such as the Tri-Axis & Lumbermater®

FEATURES / APPLICATIONS

• Capable of 100% On-Table Nail Plate Embedment

• Two Pucks Per Slot

• 24", 26", and/or 30" Spacing

• Compatible with all current major design software

• Multiple Simultaneous Layouts

Sub Component Nailer

By Joe Kannapell

Home Building Technology, Part X: Competing Connectors

In multiple jurisdictions across the country, building code authorities questioned the viability of the curiously shaped metal plates being used on trusses during the last half of the 1950s. In South Florida, for example, four radically different looking plates appeared, with different supporting data. One was applied on the jobsite, while the others arrived at the jobsite already installed on trusses. Building inspectors did not know how to make sure that these products met Code requirements, as they were able to do with conventionally framed roofs. Such was the level of uncertainty in the building business as metal plate connectors proliferated in the market.

This uncertainty could not be tolerated by the main guarantor of home loans, the Federal Housing Administration (FHA). In late May 1960, FHA gave plate manufacturers 60 days to submit a uniform design criterion, otherwise plated trusses would no longer be allowed on homes insured by their agency. Fortunately, the plate business had grown just fast enough to attract individuals with sufficient depth to respond to this imposing threat, and they met together in early June.

Three of the respondents were engineers who had already earned their stripes satisfying the concerns of building officials – Cal Jureit, Bill McAlpine, and Jerry Akdoruk – and a fourth attendee, Charles McAdam, had the longest experience providing connectors. Although I’ve discussed the pinnacle meeting of 12 men in The Development of the Truss Plate, Part V: Frenetic First GetTogether, it is worth underscoring the unique contributions of these industry legends.

Cal Jureit had 20 years of entrepreneurial engineering experience, including his stint in the U.S. Navy Construction Engineers in World War II. After the war, he went on to develop two brand new engineering design methods, and to shepherd them through to approval by the City of Miami’s stringent code authorities. When Jureit subsequently entered the plate business, he knew that he would need broad-based product approvals, and he had already begun developing a relationship with FHA officials in Washington prior to the imposition of FHA’s deadline.

Bill McAlpine had only two years overseeing truss designers when he came to the meeting, but he arrived at Carol Sanford’s business with five years of prior professional engineering experience. There he was handed a core group of truss designers who had produced an impressive body of work (for more on this, see also Home Building Technology, Part VIII: The Engineering Advantage). Undoubtedly, it was McAlpine who suggested that they should fashion the new truss design standard after the code of the Steel Joist Institute (SJI), because both trusses and steel joists were built offsite and both were subjected to similar loadings and site conditions. Also of assistance was the fact that the SJI Code had been accepted by national codes for over 25 years and provided an ideal template.

Yilmaz “Jerry” Akdoruk had emigrated from Turkey as a young engineer, along with a cohort of others who had settled in South Florida. Perhaps because Jerry had to learn a second language to pass the engineering exam in the U.S., he was able to become a prolific trainer of young designers, including Mehmet Ilter. At Ronel, Inc., Jerry had developed the first roller plate that required no supplementary nails, challenging Sanford’s Grip-Plate on his home turf.

Little is known about Charles McAdam and the H-Brace company, except that their H-Brace connector had attracted a considerable following in the Southeast, mainly because no machinery was required to apply it. This connector, shaped like the letter “H”, could be nailed onto trusses like Sanford’s, but due to its unique configuration, it required far fewer nails than Sanford’s Grip-Plate.

With only three weeks remaining to meet FHA’s deadline, these four individuals assembled a reasonably comprehensive draft code, disseminated it to other aspiring plate manufacturers, and invited them to discuss it at a July 9 meeting in Miami. Nine companies agreed to send representatives. Four were from South Florida, four from the Midwest, and one was from the West. Five of them were already producing their own plates, but their design methods were as yet unknown. The similarity of their offerings to the plates patented by the meeting organizers opened the possibility of future contention.

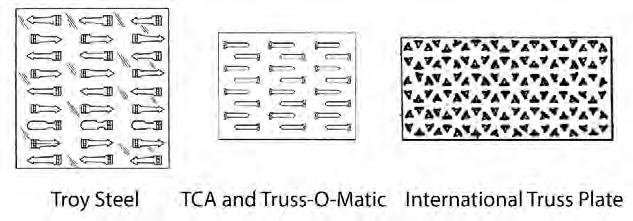

Adams and International Truss Plate used the same short, wedge-shaped teeth as Sanford, but with much increased density and without nail holes. Troy Steel and Truss-O-Matic mimicked the long Gang-Nail teeth, but with slightly different shapes. Templin, however, introduced a unique plate that had two nails struck from the same slot, presaging the future of connector plate design. Even though this first meeting brought together present and future competitors, their differences would have to be temporarily set aside to establish their credibility and protect their future business opportunities.

Next Month: Rapid Growth and Competition

Transforming Your Experience

When it comes to protecting profits and staying green lit for the work ahead, count on your trusted partner for what matters most.

MAXIMIZE OPERATIONAL PRODUCTIVITY

GAIN RELIABLE SOFTWARE ACCESS EXPERIENCE HIGH-TOUCH TECHNICAL SUPPORT

Visit our booth to experience what’s new and improved— including hands-on demos and insights—only at BCMC.

September 29 - October 3, 2025 | Omaha, NE

MII.COM/BCMC

Free MiTek training sessions on software, services, and other educational topics are available.

Equip your customers for faster framing.

Introducing the Simpson Strong-Tie ® EasyFrame automated marking system. A combination saw and printer, EasyFrame cuts detailed wall panel framing members that are pre-marked for fast, accurate assembly. Designed for efficiency, EasyFrame prints framing plans directly onto lumber, including locations of boards, connectors, wiring and more. It can be paired with a manual or automated saw, and features a blade enclosure for safety. Powerful software also lets you ensure precision and optimize material use. EasyFrame is supported by our installation and onboarding services, training and technical expertise. It’s a smart way to equip customers for wall panel jobs while setting your business apart.

Add EasyFrame to your lumber sales area. To learn more, visit go.strongtie.com/easyframe or call (800) 999-5099.

INTRODUCING THE PICKFEEDER...

FLEXIBLE, AUTOMATED PICKING & DELIVERY SYSTEM

NEW INNOVATION

FOR TRADE STORES & FABRICATION PLANTS

Slowly gathering and organizing loose lumber manually is now a thing of the past. Stand-alone automated picking is here!

With a compact footprint and newly developed software, Vekta’s fully customizable PickFeeder system is built to fit your needs.

It intelligently scans, selects, and delivers lumber to the stack at lightning speed – eliminating downtime, fatigue, and costly errors.

You can even combine multiple PackFeeders into your PickFeeder system to increase volume or range of product.

Learn more at BCMC 2025 — Booth 811

— Roy Bedient Manager/ Production Manager, Warman Truss

with 16' TigerStop

• 10 HP (480 Volt/3 Phase) Lauderdale Hamilton Up-Cut Saw with 24” Blade

• 6” x 13 1/2” Capacity

• Foot Pedal Operation

• Dust Outlet

• TigerStop 16’ Programmable Stop

• Automatic Positioning of Stop via Simple and Intuitive Controls

• Infeed/Outfeed Plastic Top Tables with stands

• Excludes: Dust Collector and Adjacent Computer in Orange Cabinet $13,500 FOB NE Wasserman & Associates 800-382-0329 www.wasserman-associates.com

PC controls, all available spare blades and shaker side-pans. 460 volt, 3 phase, 60 Amp electrical required. As-is, Where-is

$29,997 NOW $26,997 FOB MB Wood Tech Systems 765-751-9990 www.woodtechsystems.com

Our team is available to chat all things frame and truss, listen to your pain points and requirements and then recommend solutions that provide real benefits.

Wendy Boyd Chief Customer Officer Machinery Group Spida Machinery

What If You Could Build Any Wall on One Line?

Wall frame fabricators across North America are facing tighter timelines, fewer skilled workers, rising material costs, and increasing variation in project build types (from single-family homes to large-scale multi-unit developments). All of this comes while they strive to maintain quality and throughput. And when it comes to raked (or sloped) wall frames? Things can get even more complicated.

While standard wall panels have benefited from years of automation, raked walls often remain the bottleneck. They can be time-consuming, are highly manual for many, and require a level of precision that many shops struggle to maintain at scale. These factors, alongside the extra complexity, cost, risk, and labor required have resulted in some fabricators limiting the number of raked wall jobs they take on or they avoid them all together.

But what if you didn’t have to choose between precision and efficiency? What if you could produce both standard and raked wall frames on the same line – with one machine?

What are the Challenges with Raked Wall Production Today?

Let’s face it, producing raked wall panels isn’t easy, especially when you’re doing it manually. The nonstandard angles mean specialized manual work and constant measuring, and the skilled labor that’s increasingly hard to come by is required. Even with the right team, your output is still limited by how much lumber/stud components the operator can lift and place in a shift. The key issues are:

• Precision and Quality Control: Raked panels demand exacting accuracy, but getting consistent results manually is tough.

• Production Delays: Intricate job files, rework, and material waste can throw off your schedule.

• Labor Shortages: Skilled operators are hard to find and then retaining them can be challenging.

• Space: Often producing raked walls happens on a separate line or separate area of the factory and often causes issues with smooth workflow and material handling.

The result? Missed deadlines, rising costs, and often a lost opportunity. But it doesn’t have to be this way.

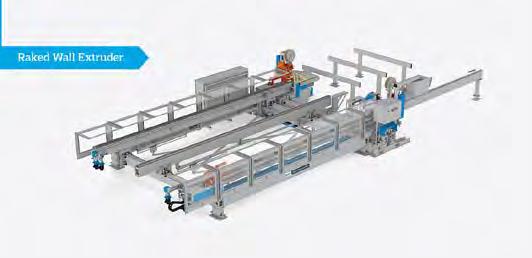

Meet the Spida Raked Wall Extruder

The Spida Raked Wall Extruder is changing the game for wall frame manufacturers. It’s purpose-built to simplify and streamline the process of producing raked AND standard wall panels – using the same equipment, same line, and the same operator. It’s one machine that produces both wall types, with no extra effort required.

The Raked Wall Extruder works like this:

• Automation: The machine automatically adjusts for differing wall heights to match the design on your job file. No manual measuring or setup needed.

• Two-Handed Freedom: With top and bottom plates clamped securely, the operator is able to position studs and components against the stud pins with precision. Then, the four nail guns automatically nail the studs, up to 8” lumber.

• Dual Functionality: From straight panels to complex rakes, the switch is seamless – load the job file and let the software and machine do the rest.

• Design Integration: The intelligent software reads your job files and builds to spec with unmatched accuracy and consistency. The Raked Wall Extruder supports all major job formats.

• Seamless Workflow: Both wall types run down the same production line. No extra steps, no extra machines, and no rework are required.

Your operator doesn’t need to learn a new process for each wall type either, they simply follow familiar onscreen prompts. It’s the same workflow, just a smarter output. Watch the Spida Raked Wall Extruder in action to learn more.

Built for Fabricators Who Don’t Slow Down

The Spida Raked Wall Extruder is engineered for speed (it’s one of the fastest wall extruders on the market), power, and precision. It supports C, L, and U stud assemblies and the operator can position the different assemblies with confidence. Longer studs for raked walls? No problem. The machine automatically adjusts.

Whether you’re producing walls for residential builds or large-scale commercial jobs, this machine keeps your line running at full tilt – day in, day out. You can move from job to job, without missing a beat.

Why It Matters

Let’s talk bottom line. With the Spida Raked Wall Extruder, you’re not just adding equipment to your shop floor, you’re unlocking serious benefits:

• Increased Efficiency: Keep production moving by removing the raked wall bottleneck.

• Reduced Labor Costs: Less manual handling and fewer skilled hands required – complete raked and standard wall frames with the same extruder operator.

• Consistent Quality: Every wall panel, raked or straight, is built to exacting standards.

• Scalability: One machine allows you to scale up production without adding complexity.

• Cost Effective: No need for multiple extruders or dedicated wall lines because one machine does it all.

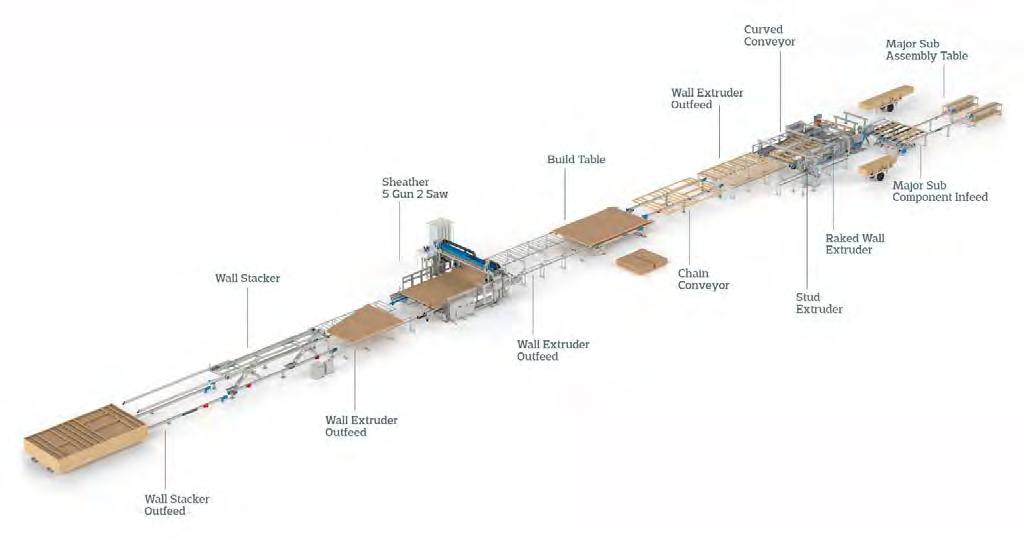

Fits Seamlessly in the Spida Frame Line

The Raked Wall Extruder fits seamlessly into our wall frame line too! To achieve even greater efficiencies, increased productivity (without adding extra labor), streamlined processes, and reduced manual handling and worker fatigue, add the Raked Wall Extruder to a line.

Forget!

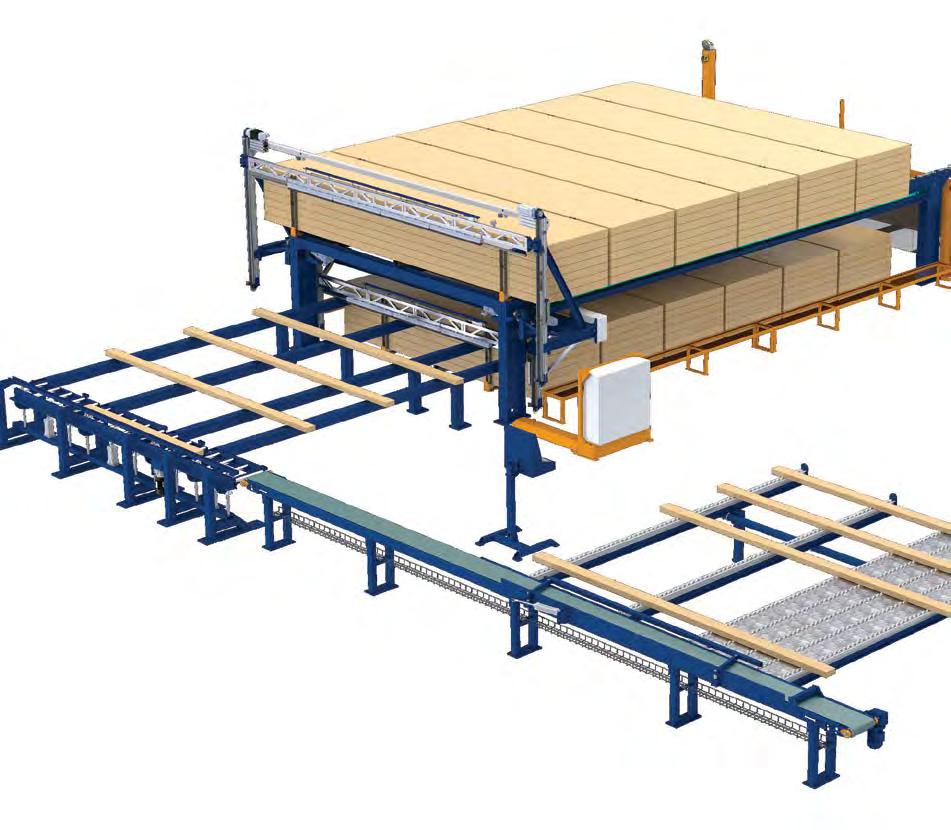

From the Stud Extruder (assemble C, L and U studs along with the nailing of fireblocks to studs) through to the Curved Conveyor (transfer studs and minor sub-assemblies from the assembly point to the extruder) and the Wall Stacker Outfeed (accumulate finished frames ready for loading) and everything in between – our Spida wall frame lines are built to meet your manufacturing needs, factory footprint, automation goals, and budget.

Learn more about our full wall line solutions on our website.

Don’t Just Keep Up – Get Ahead

At Spida, we believe in simplifying the complex because wall framing doesn’t need to be harder than it has to be. That’s why we’ve engineered solutions like the Raked Wall Extruder to work with your team, not against it.

The Raked Wall Extruder is a game changer – no more lost time switching lines or setting up for unique wall types, no hesitation when a custom rake comes through the door – simply load the job and build.

Talk to Us

If you’re looking to redefine your wall framing process, and finally put raked wall headaches behind you, then please get in touch. Let’s explore how the Spida Raked Wall Extruder can fit seamlessly into your operation and help you build smarter, faster, and safer.

Custom Cutting & Material Solutions For Your Plant

UC LINEAR SAW SERIES

The ProCut™ UC Linear Saw Series is your perfect cutting solution for roof, floor, and wall panel components, from webs, chords, sliders, and wedges. Its 6-position clamping squares and holds lumber securely, ensuring spot-on accuracy for up to four boards high. The ProCut™ UC Linear Saw Series is configurable to any assembly line; providing a safe, accurate way to cut your lumber, while keeping your materials moving to your line.

ProCut™ UC Linear Saw

For all Roof, Floor, & Wall Panel Components; up to 4-boards high! Hands-free controls & cuts flawless heels, angles, & lengths.

ProDeck™ Lumber Infeed

Material Handling

Provide a steady supply of lumber to your saw. The ProDeck™ accumulates & dispenses the lumber to the sawyer for processing. Our line of custom Material Handling Systems optimizes material flow & delivers cut parts directly to assembly stations.

Cut, deliver, and build with ProCut™ UC Linear Saw Series, designed to meet the demands of modern component manufacturing.

Hain Systems Framer

The Hain Systems Framer (HSF) will help you build square and accurate wall panels for residential or commercial construction applications. It will help you cut building costs by saving time and improving your quality. It’s a reliable, efficient and proven system that features a ruggedly simple design. The HSF is based on a proven design with over 20 years of actual production use and maintenance experience. It comes fully assembled and is designed for portable job site framing or in-plant permanent installation. The table has many optional attachments and will support Mylar Tape wall layout or any other type of layout. The optional gun rails can also be retro-fit to any table.

Details:

Table Construction: Thick-wall Structural Steel Tubing, Jig Welded for Accuracy

Height: 12 inches

(720”)

Air Supply: 90 psi (10 CFM Air Flow Recommended)

Depth: 12 inches

Electrical Supply: 120 VAC

Powder Coat: Industrial Gray

Dimensions: Height: 43”

Length: 16’ or 20’

Width: Adjustable 8’ to 10’ or 8’ to 12’

Shipping Weight: 3000 lbs

If you are looking for the fastest, most consistent way to measure and cut your product, then the Hain Measuring System (MEA) is your answer. The MEA changes from one length t any length instantly, up to 60’, without changing the operator’s position on the line. It is also highly accurate (+/- .010) and quickly moves from one length to the next in seconds. The MEA is designed for quick and easy setup and is simple to use. Even a first time user will be productive with little or no training required. It can adapt to any saw and can be mounted to any surface so that you can integrate the MEA with your existing setup. The MEA is versatile allowing “left” or “right” handed operation and measurement in “feet and inches” or “inches” depending on your preference. The MEA is also available in a “Skid Mounted” version.

2

Save Costs While Connecting Everything Online

LFar More Than Simple Cost Saving with TDC Time Standards Used with Paragon and AppWright

ast month’s article, “Pure Online Magic with Paragon, TDC Time Standards, and AppWright Job Management,” introduced the new and powerful synergy of Paragon and AppWright, which includes the TDC time standards offering. TDC time standards (R.E., S.U., or Man-Hours based on time and motion) are not widely understood and, quite frankly, are seriously underestimated in terms of how beneficial they are for your wood truss operation. It is far better than board foot, piece count, or cost markups. Here is a quick summary of why this matters so much for your company to gain a competitive advantage using properly developed time standards.

Board Foot (BF) Example: Typical client statement, “Todd, I’ve been in this industry for decades, and we have always used board foot per man-hour.” My reply: “So how does that work out for a low-board-foot project (hip roof) with many setups compared to a high-board-foot (AG trusses), low-setup project?” The response is never enlightening because BF/Man-Hour does not work consistently for every project. Everyone makes adjustments, but these adjustments are never consistent. Think of a shotgun approach, not a rifle, for estimations.

Piece Count Example: A somewhat newer trend is to use piece count, but this works only for run or assembly time with no setup time estimations. They try to get around the setup time by applying an “average” setup time to each piece. Using an average setup time for every piece will skew the labor too high or too low, depending on the piece count.

Five-Blade Component Saw Cutting 2x4 Lumber

Piece Count Example: Setup saw time = 1 man-minute for a crew of 2

Cut rate time per 2x4x8 piece = 0.17 minutes for a crew of 2

Quantity 2 = (1 setup minute) + (0.17 * 2) = 1.34 minutes total = 0.67 each

Quantity 20 = (1 setup minute) + (0.17 * 20) = 4.4 minutes total = 0.22 each

The difference is 3 times! (0.22 * 3.05 = 0.67)

Cost Markup Measure Example: The cost markup method typically includes some form of total material cost (lumber and plates) markup. But only someone hiding under a rock for the past few years would have missed seeing the flaws in using the cost markup method. If material costs (such as lumber) fluctuate or the project has been discounted, does that mean the actual labor needed to complete the project will change the same way too? Of course not.

Incentive Program and Scheduling: Using time units shown as manminutes is a far more effective way of estimating expected labor time when applied correctly. (They can be displayed as R.E. or S.U., which are also time elements) Using properly developed man-hours, many production schedules can be scheduled down to a four-hour window weeks in advance. However, unless you have industrial engineering training and understand how to develop and apply proper time units, you are likely unfamiliar with their effectiveness. Many people mistakenly believe they can derive proper time units using past projects, tracked labor time to establish man-minutes units, and the formulas to calculate the expected man-minutes to input into the estimating programs. But they fail to understand that this is not the proper way to develop efficiency rates, nor will it provide the logic the estimating software needs to calculate the efficiency benchmarks. It is not a simple process, so using already developed and tested man-minute units and labor factors is highly recommended.

Pricing – A gain of 3 to 6 points for net profits using margin per man-minutes is the norm. If you were not selling manufactured components, how would you maximize your gross profit for your manufacturing location? It is pretty simple. You would rent or lease your facility at the maximum dollar rate per time period. Whoever is renting your facility, what they are using it for, and the cost of materials they use to manufacture their products are irrelevant to you. You want the most you can get based on market conditions for the lessee’s agreed time using your facility. How is this different from leasing your manufacturing facility when you sell a manufactured project to your customers? When you manufacture a customer’s project, it uses your facility’s hourly and daily time periods. It should be common sense that every project should be evaluated as a margin rate per man-hour versus the market markup method. Maximizing the margin of dollars earned per shop hour becomes very easy when using man-hours, but impossible when using BF, Piece Count, or Dollar units. Your company must use gross margin per man-minute calculation to make more money with your existing market. Every company that uses the gross margin per man-minute method improves its profits, usually by 3 to 6 points added to the bottom line for net profits. Talk to me at the BCMC show for more details about how this is easily applied.

Paragon, AppWright, and TDC Time standards are coming together to offer your company a serious competitive advantage. Find out how your company can reduce costs, improve manufacturing scheduling and pricing using man-hours, and manage every area, not just wood component manufacturing, with the power of web-based applications working seamlessly.

If your CM operation is ready to explore how your company can save tens of thousands in plate cost and productivity, then it is time to explore what Paragon and AppWright can do for your group.

“If anyone would come after me, he must deny himself and take up his cross daily and follow me.” — Luke 9:23

There is no better value than TDC for getting the best ROI for professional consulting services. TDC is your best source for learning about proven and practical lean manufacturing best practices combined with industrial engineering principles to keep your company at the leading edge of competitiveness. Cost savings and net profit gains that usually take months or years can be accomplished in weeks or months with TDC. No one is better at providing your team with proven results for good employee practices, pricing, truss labor estimation, and so many other best-in-class practices. All areas are addressed, not just manufacturing. Please do not take my word about TDC’s services, though. Read the public testimonials from many current and past clients with decades of expertise and experience.

Website: www.todd-drummond.com • Phone (USA): 603-748-1051

E-mail: todd@todd-drummond.com • Copyrights © 2025 Work Smarter

Sub Component Nailer

Speed Up Your Production of wall panels, windows, doors, and other sub components

Block Sizes: 2x4 & 2x6 framing lumber, any length

Nail Cycle Time: 1 nail 1 sec; 2 nail 2 sec; 3 nail 3 sec

Machine Set Up Time: 1 sec from any prior set up

Air Supply: 125 psi at 30 CFM, nothing less

Electrical Supply: 120 VAC

Frame: 1/4” steel plates mounted to heavy duty roll top tables and 2x2 skids mounted no install

Transfer System: Pneumatic transfer for finished sub component assembly

Covers: 3/16” thick aluminum

Shipping Weight: 1000 lbs including crate

Dimensions: Height 48”, Width 48”, Depth 10” MADE IN AMERICA BY AMERICANS

The truss industry relies on 3rd party quality assurance services to provide random visits to review the plants Quality Assurance program along with their operations. If your plant needs to comply with the IRC, IBC and to those who depend on solid, experienced QA expertise, we ask you to consider selecting Timber Products Inspection, Inc. (TP) as your choice for 3rd party inspections.

Proudly serving the forest products industry for over 50 years, TP brings the expertise you need to ensure your business is successful. As a responsible partner, TP delivers to clients, employees, and the industries we serve the confidence to drive value through the effective use of our diverse professional team.

TP would like to welcome the following authorized agents to our inspection team, each of whom have many years of experience in the truss industry!

Al Coffman

Jean Hart

Curt Holler

Chuck Ray

Glenn Traylor

Elliot Wilson

If you have questions about how you can make this selection, please contact your authorized agent above or Glenn Traylor at 919-280-5905 or trusguy@gmail.com. https://www.tpinspection.com/ https://www.tpinspection.com/auditing-services/truss

By Glenn Traylor

Do You Know Your ANSI/TPI 1

Chapter 3 Numbers?

Inspired by frequent requests for a quick reference, I’ve created a single-sheet ANSI/TPI 1 Chapter 3 guide—similar to a CliffsNotes version of the standard. Please note that important details are omitted; for a complete understanding, consult the full standard, National Design Standard for Metal Plate Connected Wood Truss Construction, available from the Truss Plate Institute website: https://www.tpinst.org/documents

3 inspections per week per shift per station are required (Section 3.3.2)

3/4” variation from design length (Section 3.5.1)

1/2” variation from design height (Section 3.5.1)

1/2” variation truss to truss length (Section 3.5.1)

1/4” variation truss to truss height (Section 3.5.1)

No less than 1 critical joint per truss selected for inspection each week (Section 3.7.1)

1/8” midpoint variation of critical plate if no polygon is present on critical joint (Section 3.7.2.1d)

10% plus or minus is the allowable plate rotation variation unless otherwise noted (Section 3.7.3)

1/32” is the maximum allowable embedment gap of an installed connector (Section 3.7.5.1)

1/8” is the maximum member to member gap except for floor chords (Section 3.7.6.1)

1/16” is the maximum member to member gap for floor chords (Section 3.7.6.1)

3/4” is the minimum width of a shimming metal to correct member to member gap (Section 3.7.6.3)

1/4 of tooth length is the maximum tooth length visible for flattened teeth (Section 3.7.7.1)

0% is the value of the area where wood was removed while removing a connector (Section 3.9.2)

50% is the value of the area where teeth were removed but no wood was removed (Section 3.9.3)

Although a summary sheet may assist in recalling important figures, it should not substitute for a thorough understanding of the standard. I encourage dedicating a few minutes to reading the standard to ensure complete comprehension.

Glenn Traylor

HUNDEGGER

lnnovationen fur den Holzbau

HUNDEGGER

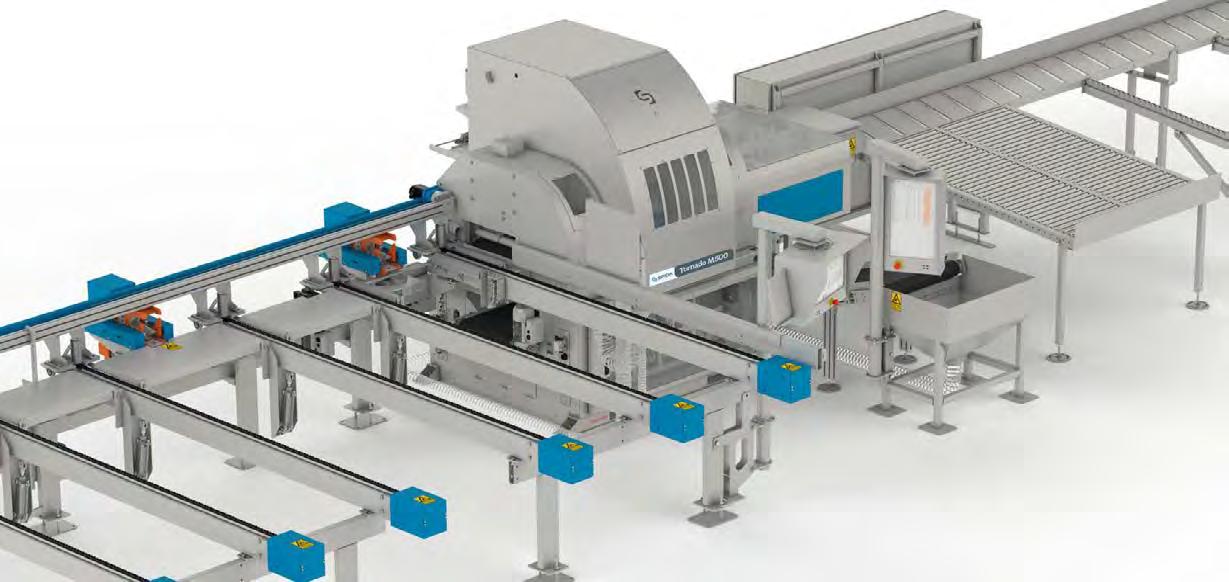

Hundegger leads the way in automation innovation for the truss component industry. Our advanced CAMBIUM software offers cutting-edge automation and digitalization solutions, revolutionizing operations, boosting productivity, and driving sustainable growth for manufacturers like you.

We go beyond standard mechanization; we champion true Automation. The Hundegger TD-II isn't just a saw-it's a transformative, comprehensive solution designed to streamline your production process. From retrieving lumber to optimizing, nesting, stacking, destacking, sorting, buffering, and precise delivery, our system ensures peak efficiency and productivity, tailored specifically to truss component manufacturing.

REVOLUTIONIZE YOUR TRUSS MANUFACTURING WITH THE HUNDEGGER TD-II

Harness the power of data with Hundegger's advanced CAMBIUM TACTICAL software. It meticulously tracks and optimizes your production, ensuring more automated operations and significant productivity gains.

We provide state-of-the-art automation and control solutions that set the industry standard. Our focus on industrial automation and robotics positions Hundegger as the leader in enhancing performance and efficiency in truss component manufacturing and beyond.

Hundegger products are essential for future-proofing your business. Elevate your productivity and secure your competitive edge with our advanced technologies and automation solutions, meticulously designed to meet the unique demands of component manufacturers today and tomorrow.

Don't get left behind. Invest in the future with true automation from Hundegger and see your business thrive.

2000 Alpine AutoMill Component Saw 2000 Alpine AutoMill model 343H, (5) blade component saw, cuts lumber from 2×3 through 2×12, from 18″ to 20′, 4-angle floor webs from 18″. Includes powered length and angulation, digital readouts, (1) 32″, (3) 18″ & (1) 20″ blade, shaker under-saw scrap conveyor, incline, PC with Windows 98 o/s, and outfeed conveyor. Decommissioned in 2018. Stored indoors. 480 volt ,3 phase electrical required.

$10,497 FOB ON Wood Tech Systems

765-751-9990

www.woodtechsystems.com

Striebig Optisaw, model

Optisaw Automatic (Type # 5164) vertical panel saw station, with angled frame supporting material being cut: Max. cutting height (vertical) 5′-4″, max. cutting length (horizontal) 15′-1″, max. cutting thickness 2.36″. Both vertical and horizontal analog measuring scales on frame. Cutting head manually rotates from vertically to horizontally for rip vs. cross-cutting, adjustable spacers for repetitive cuts, 5.25 HP saw motor, 9.84″ diameter blade, guide bearings for travel , push button controls, e-stop button and dust extraction hose (no vacuum included). Overall footprint of station 19′-1″ wide x 4′7″ deep x 7′-10″ height. Sold for $36,000 new. 208 volt, 3 phase electrical required.

$14,490 FOB AZ Wood Tech Systems 765-751-9990 www.woodtechsystems.com

Alpine AutoMill RS Parts

Alpine AutoMill RS Parts per Uploaded PDF

$23,500 NOW $19,500 FOB GA Wasserman & Associates 800-382-0329 www.wasserman-associates.com

NEW Hain 20' Powered Measuring System

Adapts to Any Saw. Left or Right Hand Operation. Feet & Inches System (Stops at 12” Centers) or Inches System (Stops at 10” Centers). Motor: 1/4 HP Linear Actuator (110 Volt). Stop Rail: 2 x 4 x 1/4” Aluminum Extrusion. Stops: Jig Bored Steel. Stop Blocks: Machine Billet Aluminum. Optional Lengths from 5’ to 60’. Optional Gang Stop. Add $890 per 10’ Section of Heavy Duty Roller Conveyor with Stands $8,990

Wasserman & Associates

800-382-0329

www.wasserman-associates.com

Building on Better .

Off-site construction solutions built around your business.

Build higher-quality components and modules more efficiently.

Stiles has been a trusted name in the U.S. woodworking industry for over six decades. Today, we continue to lead the way with a consultative approach to off-site construction, partnering with you to increase speed, precision, and productivity, while providing ongoing parts and service support when you need it.

Invest in equipment built to perform—and last.

Stiles is the exclusive North American provider of WEINMANN, the world’s leading machinery and equipment manufacturer for off-site construction. Whether it’s an individual machine or fully automated system, Germanengineered WEINMANN machines provide innovative solutions that revolutionize your production.

Make your good decisions work even better. Learn More

2004 Alpine Speed Cut Express

• Alpine Metra-Cut Saw

• 5 HP Motor with 16" Blade

• Saw Barrier Guard

• Speed Cut Express Automation with Touch Screen Computer

• Automated Stop and Automated Saw Angulation as directed by Truss Design Software

• Infeed/Outfeed Roller Conveyor with Stands

• ____ Volt / 3 Phase

2 Available at $10,900 Each or Both for $20,000 Wasserman & Associates 800-382-0329

www.wasserman-associates.com

2023 Northfield Model 410 Upcut Saw NEW 2023 Northfield model 410 upcut saw available for immediate shipment. 90/90 degree cuts to 4″ x 10″ capacity (fence forward position) to 2″ x 14″ (fence rearward position). Saw is configured for material from left to right, with 3″ x 6″ air operated cylinder, filter, regulator, lubricator, 10 HP motor, enclosed steel base with cast iron table, magnetic starter and adjustable operating speed from 20 to 60 CPM. Includes optional two-palm controls, additional 4″ dust outlet, NEMA 12 electrics with fused disconnect and two 18″ diameter 60 tooth blades with 1″ diameter bore. 460 volt, 3 phase electrical required.

$18,630 FOB MN Wood Tech Systems 765-751-9990

www.woodtechsystems.com

Whirlwind Model 1000 Cut-Off Saw

• 5 HP Motor with 14" Blade

• 2 3/16" x 8 1/4" Capacity

• Pneumatic Blade Guard/Lumber Clamp

• Foot Pedal Control

• Dust Collection Outlet

• 460 Volt / 3 Phase

• 1 Left Hand & 1 Right Hand Model

Available

$3,500 NOW $2,250 Each FOB NC Wasserman & Associates 800-382-0329

www.wasserman-associates.com

1982 SpeedCut MetraCut Centerline Saw

GOOSENECK ROLL OFF TRUSS TRAILERS

26’, 32’ & 36’ sizes available, Split Rollers available too! 2 YEAR WARRANTY

ALL TRAILERS NOW AVAILABLE WITH OPTIONAL GALVANIZED ROLLERS

Scan the QR Code to take you directly to our website. For more information or to request a quote Call or Email: 1-800-237-5161 sales@precisionequipmfg.com

1982 Speed Cut Metra Cut, model SSA-11, centerline saw, 16″ blade, maximum cutting depth of 6″, maximum cut length of 31″, 164 deg. cutting range and 5 HP motor. Includes push-button on/off controls and analog angle measure on turntable with air stop, 20′ long infeed conveyor with OEM SpeedMeasure, 20′ long outfeed conveyor and one (1) spare blade. 208 volt, 3 phase electrical required (can be converted to 240v/440v).

$6,990 FOB WY Wood Tech Systems 765-751-9990

www.woodtechsystems.com

New Monet DeRobo Linear Saw

New, DeRobo linear saw by Monet organizes "fill" boards to increase optimization of each board, can produce unlimited scarf cuts, cuts 1 or 2 boards at a time and cuts webs, chords, wedges, rafters and open-stair stringers. Works with all major connector plate manufacturer's software. Features include 22 inch blade, left-to-right feed direction standard, lumber push and pull grippers for more accuracy, ink marking on the 1 1/2" face of the incoming boards and small piece capture and delivery to the front of the saw for easy access. Infeed deck and bunk feed are shown as options only. 480 volt, 3phase.

$245,000 FOB MO.

Edmond Lim, P.Eng. LimTek Solutions Inc.

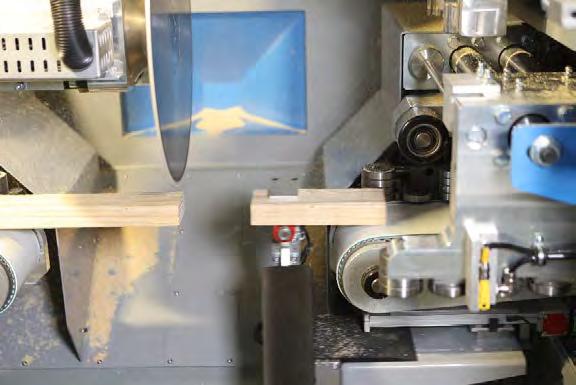

Three Options, No Waiting –The RetroC Auto-Feeding SmartConveyor

More than 120 proud RetroC owners will tell you that the auto-feeding of lumber is the most powerful feature of the Enventek RetroC automated component saw. Auto-feeding is made possible with Enventek’s SmartConveyor integrated with the RetroC’s clamping material feed chains. To that, we add the equally powerful feature of the RetroC – the magic of SpeedCatch with auto-filling carts that can keep up with the RetroC until the carts are filled and ejected to start the next cycle of cart filling. (For more on this feature, see my article, “Accommodating Your Catch As Catch Can.”) With three options, the SmartConveyor can be set up to work in any plant.

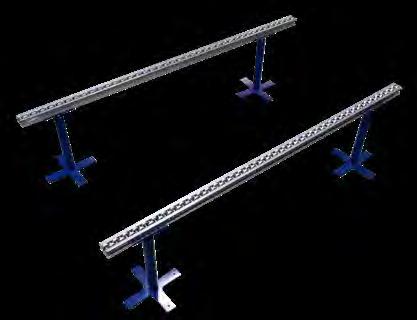

The SmartConveyor (Deck A) is what we refer to as the “sawyers” deck. It is here that the sawyer simply has to re-crown the lumber if necessary and verify the piece order, width, grade, and length before the SmartConveyor takes over and automatically starts feeding lumber into the RetroC. The wear and tear on the sawyer is reduced significantly, because once lumber is flattened onto the SmartConveyor, the sawyer’s handling of the lumber is minimal, regardless of whether it is 2x3 up to 2x12 lumber.

Replacing an existing and traditionally forklift-fed legacy component saw or upgrading to an Enventek Lumber PickLinefed RetroC is exactly the same procedure for the saw operator stationed at Deck A, whether it is an 8 ft long or 70 ft long SmartConveyor. This is the versatility of the RetroC, which enables a “One Size Can Fit All” approach. Shown here is SmartConveyor “Deck A” –the sawyers deck.

Of the three methods to feed a RetroC, let’s start with the simplest way to feed an autofeeding RetroC component saw. Shown here is a forklift spilling and flattening lumber directly onto SmartConveyor Deck A from a bunk of lumber. For long runs of ag trusses, this is a very efficient material handling method.

Next up is a more efficient method of prepping the lumber for Deck A by repurposing an existing live deck, which we refer to as Deck B, to handle and organize the forklift-picked bundles or bunks of lumber that will then be spilled and flattened onto Deck A. Deck B is raised 12 inches above Deck A, and skate wheel roller arms are used as a lumber waterfall to spill the lumber to flatten onto Deck A. The sawyer clears Deck A and then spills the next bundle of lumber from Deck B. This works great for both long runs and for cut-by-truss batches.

Of course, the best way to feed a RetroC is with an Enventek Lumber PickLine. In this scenario, Deck A and Deck B are of equal length and at the same level – so no spilling or flattening of the lumber is required. The lumber comes up to the sawyer at Deck A already flattened by the lumber picker working on the PickLine trough (see photo on cover). More importantly, the lumber is culled and pre-crowned so that the sawyer gets the last look and touch as a final quality control check. The work of the lumber picker has also been checked by the PickLine using sensors to count the boards, verify the correct length, and verify the correct width of board. For more information on how to catch lumber spewing out of a RetroC, see “Batch Cutting vs. Cut By Truss.”

Whether you’re retrofitting or replacing, the time is now to upgrade to a RetroC with SmartConveyor. With three options for setting up the lumber feed, the SmartConveyor will be adapted to your space and your needs.

When you’re ready to Feed Your Beast and see these efficient and effective systems for yourself, let us know! Inside and out, LimTek Process Organization Technology will help you squeeze out more truss production and deliver quality trusses with shorter lead times to better service your customers by organizing your truss fabrication processes to maximize your investment in automation. https://limteksolutions.com/#solutions

BCE-MASTER

NEW!

Terminailer

Price: $237,900

FOB: ND

The Terminailer all but shatters the stereotypical myth that sub-component equipment is essentially peripheral – unimportant. And it does so by quickly and accurately driving far more framing nails in your wall panel jobs than ever before. Whether in your shop or in the field, one operator sets the pace for production and quality, which reduces labor costs and other aspects of overhead.

The new Terminailer V.8 improves on the previous generation Terminailer in several key ways:

All new HMI/Software

• Siemens Pivoting HMI Touchscreen display to operate from either side

• On-screen tutorial for all menu items

• Operator now controls functions such as process speed, nail spacing, nail patterns, etc.

• Simplified input commands

Nail Feed Complete Redesign

• All new frame to allow for redesigned nail coil placement with direct feed path

• EverWin PN90-PAL industrial tools now standard equipment

• New nail guides with spring-loaded tensioners

• Nail coils move with vertical travel of the nail guns

Reengineered air system

• SMC “Soft–Start” Pneumatics

• Simplified air for control to all components: lift–cylinders, triggers, stop–gate, etc.

• Direct air supply to each nail gun for improved nailing performance

• All pneumatic elements are clearly labeled for EZ service and adjustment

Overall Features

• Pharmaceutical grade assembly, industrial grade durability

• “Block–wheel” redesign for 3X increased applied force

• Approximately 1,200# of applied clamping force resulting in straighter finished

• Subcomponents from even the poorest lumber

• Larger doors for easier access to interior elements including coil–nail spools

Terminailer is an event-driven, sub-component assembler that will quickly and accurately drive 30% to 70% of the framing nails in any wall panel job. In your shop or in the field, one operator sets the pace for production and quality. The Terminailer functions independent of design software, requires zero set-up time when switching between any configuration, and requires no special operator training.

The Terminailer is easy to move around the shop so its location can evolve as your shop evolves. With all of the nailing occurring in the closed main chamber, nail injuries and nail location misfires are eliminated, making your plant that much safer.

With nearly ten years of development from people that know machinery, it is assembled to exacting standards, well supported, and it is easily maintained with shelf-item parts. Terminailer: vetted, tested, and ready to drive maximum productivity for you. Be sure to check out our videos below for a quick review of this revolutionary machine!

208 volt, 3-phase, 21 (full load) Amps, 60 Hz electrical required. 50 SCFM @ 100 PSI air required. Net weight 7,000 lbs..

Bander

•

• Spida Automated 20' Length Stop/ Plate Positioner

• Auto Plate Positioning with Manual Marking

• Control Cabinet Enclosure with Touch Screen Computer

• DeWalt Model DWS780 Miter Saw

• Support Table for DeWalt Saw

• 10' Infeed Roller Conveyor

• Excludes Dust Collector & Spida Annual Support Fee

$19,900 FOB ND

Wasserman & Associates 800-382-0329

www.wasserman-associates.com

Component Saw

Five blades cut lumber from 2″ x 4″ through 2″ x 12″, 4″ x 2″ lengths from 12 inches to 20 feet, including four-angle floor webs from 18 inches. All powered movements. Saw includes (1) 30″, (2) 20″ and (2) 14″ blades, analog scales, chain-drag scrap conveyor with chain-drag scrap incline, and an extra set of blades. Additionally this saw includes an extensive spare parts inventory including: Contacts/Starters, fuses, push buttons, limit switches, crank handles, scales/rulers/dials, angulation, conveyor, and saw motors, universal joints, and arms for outfeeds. 480 volt, 3 phase electrical required.

$17-924 FOB NC Wood Tech Systems 765-751-9990 www.woodtechsystems.com

Monet DeSauw FWA 500 Floor Web Cutter

• Push Button Powered Blade Angulations

• Single Push Button Setting for 2 Blades per Side

• Electronic Digital Readouts

• Backup Mechanical Scales

• Cuts 4 Angle Floor Webs & Square Blocks

• Heavy Duty Feed Conveyor with Hold Downs

• (4) Int ernal 16" Blades & (1) External 16" Cut-Off Blade

• Shaker Pan Waste Conveyor (under saw)

• Excludes Incline Waste Conveyor (adjacent to saw)

• 480 Volt / 3 Phase

• Price is in US Dollars

$55,000 FOB Alberta Canada

• Automated Truss Length and Angle Cutting as directed by Truss Design Software Output

• Di rect Drive 7.5 HP Motor with Automated 160 Degree Angulation & 18" Blade

• Minumum Angle of 10 Degrees with 36" Stroke for Long Scarf Cuts

• Braked Saw Motor , Safe Grip, Variable Stroke Limiter & Plexiglass Shield for Operator Safety

$69,880 FOB WA

• 20' of Steel Framed/MDF Table with Automated 20' Length Stop & 10' Gravity Conveyor

• Workstation, Control Cabinet Enclosure & 21" Touch Screen Integration

• Kufo Dust Collector

• Spare Parts

• Truss Cutting Operating Software

• 480 Volt / 3 Phase

• Lighty Used

• Excludes: Installation/Training & Annual Technical Support Fee

Alpine ALS 276C Linear Saw

$39,990 FOB OH

Cuts wall and truss parts from lumber depths 2×4 through 2×12, 60”+ scarf cuts, internally optimizes material (up to 11 7/8″ x 1.5″ EWP) Includes 20 foot OEM auto-infeed conveyor and 15 foot OEM outfeed conveyor, and under-saw scrap conveyor with belt-type incline. All servo controlled functions, Microsoft Windows XP OS, 7.5 hp motor with 20” carbide tipped blade. Includes spare infeed/outfeed belt and any available spare parts. No printer is included. The door latch needs to be repaired. 220v / 3 ph power, 125 PSI air required.

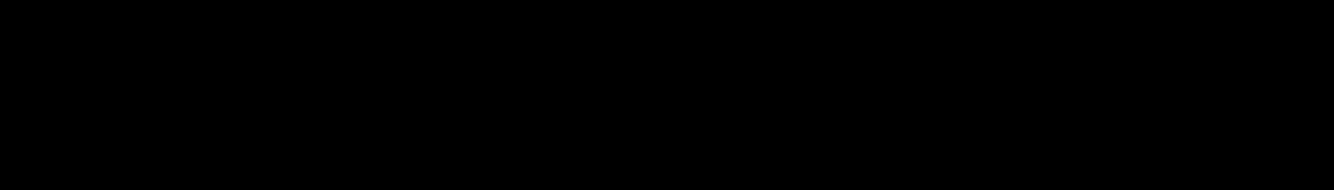

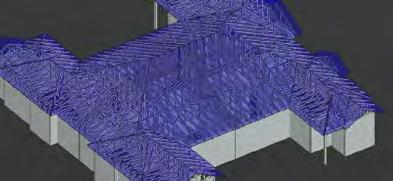

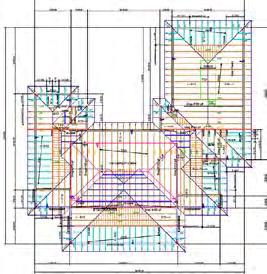

By Jeff Vance, PE Principal Optimization Engineer

Rethinking Shear Transfer at Floor Transitions

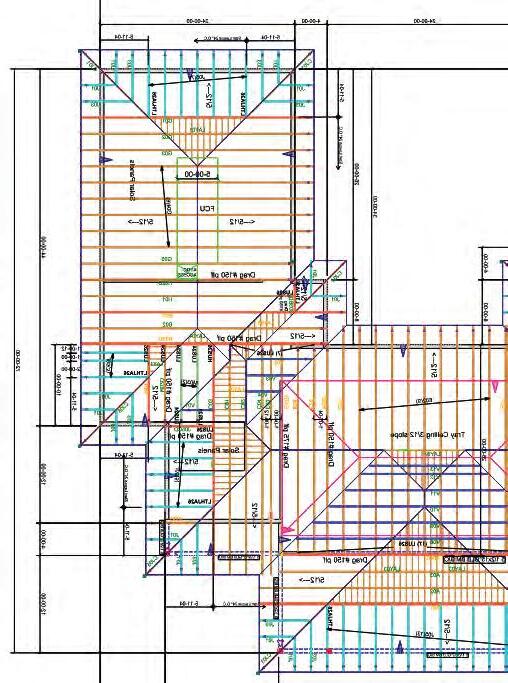

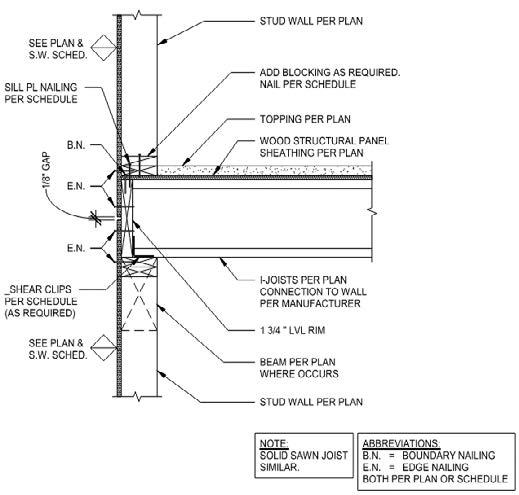

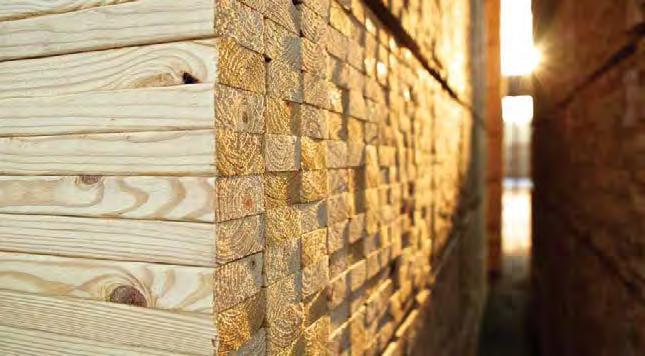

Still defaulting to rim boards at every floor edge? In modern woodframed construction, it’s worth taking a closer look at several detailing options including ribbon boards or top chord bearing detailing. These options can simplify construction and reduce blocking material while still being able to offer a reliable, flexible, and code-compliant alternative for lateral shear transfer, gravity transfer, and floor-to-wall transitions.

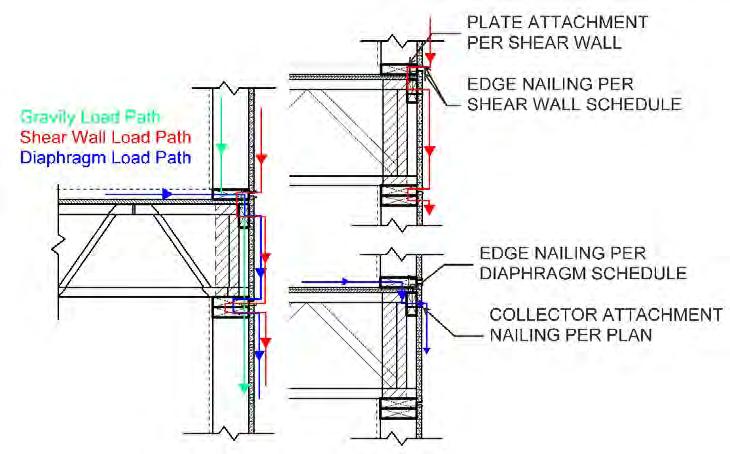

Understanding Lateral and Gravity Load Paths

In any wood structure, gravity and lateral loads must be continuously transferred through structural members to the foundation. Lateral loads from wind or seismic events are picked up first by the horizontal diaphragm (typically floor sheathing), transferred to the walls, and ultimately down to the ground. Similarly, vertical (gravity) loads from roof, walls, and floors must be supported and channeled to structural bearing points.

Rim Boards

Rim boards are a common and reliable method for floor-to-wall transitions. They sit directly on the wall plate and act as full depth framing members, providing a direct bearing surface for both vertical and lateral loads. Floor sheathing is fastened directly to the rim board, and vertical loads from above— including stacked walls or posts—transfer cleanly into the supporting wall below. Rim boards are typically specified as Engineered Lumber such as LVL or LSL and widely used in conventional wood framing due to their simplicity, familiarity, and predictable load path behavior.

However, while rim boards offer clear advantages, they are not the only option available. Designers should consider whether alternative details—such as ribbon board framing with sheathing splices or top chord bearing trusses—could provide similar structural performance with greater flexibility or cost efficiency. In projects where load demands are modest or where floor framing depth and fire-rating conditions are critical, alternative detailing strategies may reduce material use, simplify coordination, or improve constructability.

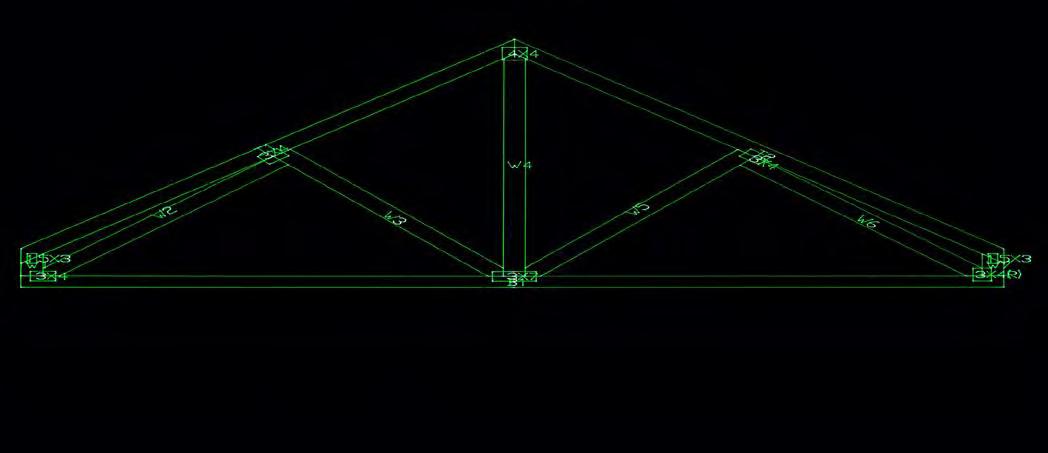

Figure 1: Typical Rim Joist Detailing

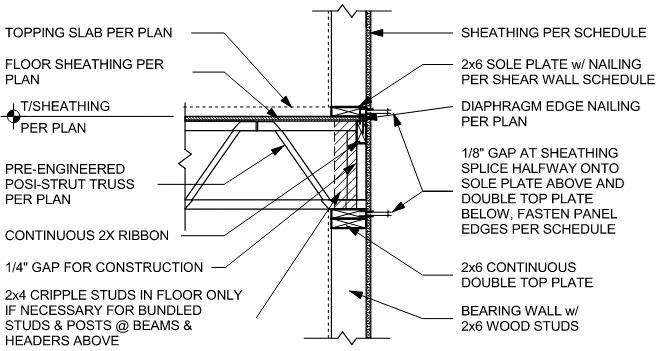

Ribbon Boards

Ribbon boards are a practical solution for light-frame construction, especially in 1- to 2-story buildings where vertical loads are relatively low and don’t accumulate significantly from above. This makes them an ideal fit for single-family homes, garages, and small accessory structures.

Ribbon boards are set within the depth of a floor truss and do not typically align directly over the wall plate. When properly designed and detailed for gravity loading, ribbon boards can be used to transfer vertical loads. In most standard installations, ribbon boards serve as alignment and lateral support elements. If gravity loads are not specifically designed to bear on the ribbon, supplemental blocking should be added to transfer those loads to appropriate bearing supports.

Figure 2 shows a separate sheathing panel to bridge the gap between the upper and lower levels. The gravity load path begins at the studs in the upper wall and is transferred through the sill plate to the ribbon board or blocking. From there, the load is redirected into the adjacent floor trusses, through the truss bearing, and ultimately down to the top plate of the supporting wall below, completing the vertical load path to the foundation.

To ensure lateral load continuity, the additional sheathing panel is connected to the sill plate of the upper wall and the top plate of the lower wall or floor framing using proper shear wall edge nailing. This splice allows lateral loads—such as wind or seismic forces—to transfer across the floor assembly, preserving diaphragm continuity and maintaining the effectiveness of the overall shear wall system.

Edge nailing at both upper and lower wall plates is essential to maintain the integrity of this lateral force-resisting path. Lateral loads from the diaphragm are first transferred into the ribbon board through diaphragm edge nailing, then into the sheathing via the fasteners connecting the sheathing panel to the ribbon. From there, the sheathing transfers those loads into the adjacent shear wall system below. This layered connection ensures a continuous and code-compliant lateral load path.

This approach maintains the integrity of the gravity and lateral load path and is a well-established method in wood-framed construction. Though it involves an additional sheathing step compared to using a rim board, ribbon detailing offers greater flexibility in truss layout and material usage—key factors in both design efficiency and cost control.

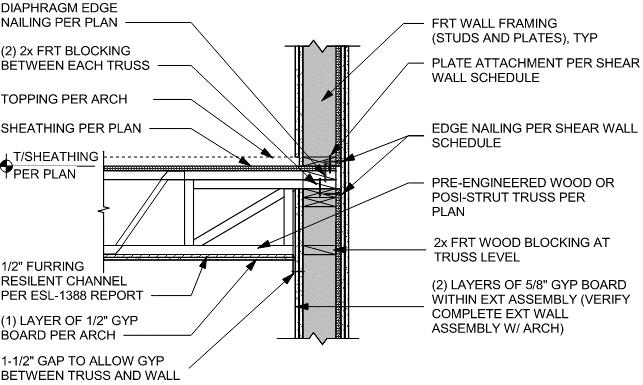

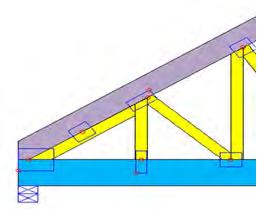

Top Chord Bearing Conditions

Top chord bearing trusses make more sense in multi-story or multi-family buildings, where loads are greater due to accumulated loading. At exterior walls, code requirements for fire resistance add another layer of complexity. In many jurisdictions, blocking within trusses at exterior walls must be fire-treated, which can increase material costs and complicate detailing. By contrast, top chord bearing trusses may avoid fire treatment requirements in the floor assembly, as clarified in resources like DCA-3 (Design by Code Acceptance by the American Wood Council) and the International Building Code 2024, particularly when the top chord is fully embedded and shielded by rated assemblies.

In multi-story construction, top chord bearing trusses provide a highly effective floor-to-wall transition. Here, the top chord of the truss sits directly on the wall plate, allowing the floor sheathing to span continuously across the truss. This creates a clean and direct gravity load path and often eliminates the need for a separate rim or ribbon board.

Figure 3 illustrates a simplified gravity load path where vertical loads from the wall studs above transfer directly through 2x blocking and top chord bearing trusses into the supporting wall below. Because the top chord rests directly on the wall plate, this detail eliminates the need for intermediate framing elements like ribbon or rim boards, streamlining vertical load transfer.

The lateral load path is also simplified in this configuration. Lateral forces from the wall above are transmitted through the top chords and 2x blocking using either nailed shear transfer connections or mechanical hardware. This direct path enables clean diaphragm continuity and reduces detailing complexity, making top chord bearing conditions especially effective for multi-story and fire-rated assemblies.

Design Recommendations

Figures 4 and 5 are detailing examples for both ribbon board detailing and top chord bearing detailing. To ensure performance in either lateral or gravity load transfer, we recommend:

• In clude notes for ‘diaphragm nailing per plan’ at all critical interfaces.

• Ensure ribbon boards are properly designed if they are to support gravity loads.

• Provide sheathing splices or extended sheathing where diaphragm continuity is needed.

• Plan for blocking where vertical loads align with ribbon boards.

Conclusion

Selecting the right truss end detail— whether it’s a rim board, ribbon board, or top chord bearing condition—should be a deliberate decision informed by structural needs, code requirements, construction priorities, and cost considerations. At MiTek, we understand that good detailing isn’t just about following tradition; it’s about critically evaluating each project’s unique demands and identifying opportunities to simplify framing and reduce material use while delivering improved building performance. Early coordination between designers, engineers, truss manufacturers, and contractors creates more options for smarter, more efficient solutions—especially when fire ratings, load paths, and framing layouts intersect.

By engaging with MiTek during the development of your construction drawings, you will be able to unlock the power of Offsite Construction through our collaborative network of Design Make Build partners and achieve optimized results. We aim to come alongside the engineering community to enable a more thoughtful and holistic approach to design, considering all detailing strategies, to deliver better results for wood framed construction. Choosing the right detail isn’t just good engineering—it’s good building. The best solutions come from understanding how systems work together, asking the right questions at the right time, and pushing framing practices forward, one thoughtful decision at a time.

Interested in collaborating with MiTek and our partners on your next project? Email DesignEngagement@ mii.com.

Sources

American Wood Council. WFCM: Wood Frame Construction Manual for One- and Two-Family Dwellings, 2021 Edition. American Wood Council, 2021. https://awc.org/publications/wfcm-2021.

WoodWorks – Wood Products Council. Detailing Floor-to-Exterior Wall Conditions in Type III Projects. WoodWorks, 2023, https://www.woodworks.org/resources/detailing-floor-to-exterior-wall-conditions-in-type-iii-projects/ Accessed 21 Apr 2025.

American Wood Council. DCA 3: Fire-Resistance-Rated Wood-Frame Wall and Floor/Ceiling Assemblies. 4th ed., American Wood Council, 2021. https://awc.org/publications/dca3.

International Code Council. “Section 705.7.1: Projections.” International Building Code 2024. International Code Council, 2023.

Used Hain Quick Rafter Cutter

• Reconditioned in December 2020

• Board Sizes: 2x4 and 2x6

• Motors: Two 1 HP / 220 Volt or 440 Volt / 3 Phase

• Saw Blades: 7 1/4" Carbide Tipped (set at 45 degrees)

• Angle Adjustment: Manual Rotation with Air Brake

• Air Supply: 90 PSI

• Carriage: Steel Rails with Steel Dual V Rollers

• Pedestal: 3/16" Formed Steel

• Saw Housing: 1/2" Billet Aluminum

• Covers: 10 Gauge (1/8" thick) Steel

• Fully Enclosed for Safety

$12,500 NOW $9,900 FOB AZ Wasserman & Associates 800-382-0329 www.wasserman-associates.com

work)

• 230 Volt / 3 Phase

• Excludes: Outfeed Queue Rollers & Waste Conveyor

$29,900 NOW $14,900 FOB AZ Wasserman & Associates 800-382-0329 www.wasserman-associates.com

manufaCturing

In answer to the demands of high-volume customers comes the Monet DeSauw FWA 500 CA (Automated Controls) floor web saw. The 500 CA is perfect for component manufacturers who routinely run floor trusses in high volumes with variable web geometry. Another primary feature is enhanced safety through automation which eliminates the need to open the saw motor cabinets other than for periodic service. The 500 CA includes automation for all blades, including the fixed cut-off blade for minimal waste. Lumber infeed speed is variable up to sixty (60) boards per minute, while the powered carriage utilizes rack and pinion drive with airlock for set accuracy throughout the production run. Your operator will easily download batches to the 500 CA saw from your design software via an ethernet connection to a MS Windows 10 industrial PC with a 17″ monitor housed in a stand-alone console. If you frequently batch floor web cutting, and if enhanced safety with increased productivity are a concern, then an automated Monet FWA 500 CA may be the right selection for you. More information Here

Price based on configuration.

That'sallthetimeittakes todrillstudsforrunningRomexorotherelectricalwireinthewallpanels Work Smar ter 2Seconds

Motor: HeavyDuty5HP-3phase-220vor440v(Pleasespecifywhenordering)

MotorcarriagebearingandspindleassemblymountedonBlanchardgroundsteelplate LinealmotionishardenedandgroundVbearingsandrails

BlockSizes: 2x4through2x12infiniteheightsettingtocenter

AirSupply: 100psi10CFM

Drills: 2wing3/4'”CarbideTippedcanaccommodatesmallerorlarger

Spindles: AlloySteelpolishedandgroundprecisionshafting

Frame: 2"SteelWithPowderCoatFinish

Covers: 10Gauge(1/8"Thick)Aluminumremovable

Dimensions: Height-60inches,Width-33inches,Depth-33inches

Shippingweight: 750lbs.-(Includingcrate)

MADEINAMERICABYAMERICANS

Quality components and meticulous assembly minimize downtime.

After comprehensive testing , each Ranger is carefully packed for shipping

Infeed deck assembly versions available for 5 saw brands

Rangers can be installed in one day. Modular construction and thorough labeling of cables and components make the job easy.

2012 Vista "Angle Boss" Saw with 20' TigerStop

• 2012 Vista Model M-20 AutoSet Cut-Off Saw

• 0 to 75 Degree Left & Right Blade Rotation

• 10 HP/460 Volt Motor with 20" Blade

• 10' Infeed Roller Conveyor & 20' Outfeed Roller Conveyor

• 2012 TigerStop (250" Cut Length)

• TigerStop Software Version 5.30

• Excludes Dust Collector

• Video available upon request

• Price in US Dollars

$18,880 FOB MB Wasserman & Associates 800-382-0329 www.wasserman-associates.com

Safety Speed Manufacturing Model 7400 XL Panel Saw

Safety Speed Manufacturing, model 7400 XL*, vertical panel saw, 3 HP induction motor, 64 inch crosscut, 2 1/8" maximum thickness, accuracy within 0.005 inches, 13 foot long welded steel frame with integrated stand and linear V-guides, enclosed counterweight system, adjustable vertical and horizontal rules. Quick changes from vertical to horizontal cutting. Includes machined aluminum material rollers, hold down bar, wheels, quick stop gauges and material hold downs. Dust collection ready. Options available include digital readouts for vertical cuts, automated length measuring, laser guide, stop bar, vacuum and midway fence. 208-230/460 volt, 3 phase electrical (208-230 single phase, 2 HP power optional +$100.00).

$14,499 Base, FOB MN. Wood Tech Systems 765-751-9990 www.woodtechsystems.com

Saws

• Automated Component & Linear Saws (2010 & Newer)

• Monet DeSauw or TimberMill Manual Component Saws

• Floor Web Saws

• Spida (Apollo) Saws with Truss Automation

• Bunk Cutters Truss Equipment

• Roller Gantry & Hydraulic Press Systems

• Finish Rollers

• Truss Stackers

• Floor Truss Machines

• Lumber Splicers

• Jack Tables

• C-Clamp Presses

Stretch Roll-Off Trailers • Go oseneck Roll-Off Trailers

Pacific Automation or MiTek Mobile Home Press

Safety Speed Cut Model 7000 Panel Saw

Safety Speed Manufacturing model 7000, vertical panel saw, 3 HP induction motor, 64 inch crosscut, 2 inch maximum thickness, accuracy within 1/64th of an inch, 10 foot welded steel frame with integrated stand and linear V-guides, enclosed counterweight system, adjustable vertical and horizontal rules. Quick changes from vertical to horizontal cutting. Includes machined aluminum material rollers, hold down bar, wheels, quick stop gauges and material hold downs. Dust collection ready. Options available include lower frame extensions, digital readouts, laser guide, stop bar, vacuum and midway fence. 208-230/460 volt, 3 phase electrical (208-230 single phase, 2 HP power optional +$100.00). $10,199 Base, FOB MN.

•

Together the PieceGiver and PieceMaker streamline production, boost efficiency and reduce manual labor – all with just ONE operator.

Is truss cutting your bottleneck? Get in touch to learn how the power duo can transform your workflow!

The PieceMaker

An automated linear saw that cuts, prints and optimizes.

The PieceGiver

A high speed, fully automatic lumber loading system.

$349,000 Location: MO

New, Monet DeSawyer 2000, computerized, five-bladed component saw, sets up in 15 to 17 seconds, can run in manual mode, downloads projects from a network or manually using display screen controls. Features all powered movements, cuts from 15" 90/90 cuts to 20 foot length, 2 x 3" to 2 x 12" lumber depths and internal brakes are standard. Options include enhanced servo controls featuring autocalibration, catcher's display and either shaker or belt scrap conveyor and incline. 440 volt, 3 phase electrical.

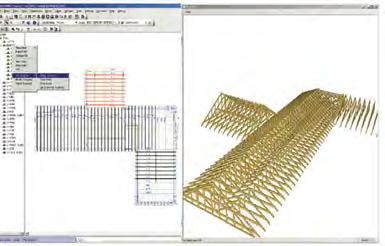

IntelliVIEW Suite Manage. Design. Build.

The industry’s most powerful integrated component design, engineering, and management software for steel and wood-framed structures.

iCommand

Manage projects, customers, materials, pricing & inventory

iModel

Design truss layout & profiles

iDesign

Optimize material usage & engineer trusses

iPanel

Design wall layouts, panelize, bundle, break & stack

eShop

Maximize crew productivity & improve manufacturing efficiency

The IntelliVIEW Suite is a fully integrated software solution for the layout and design of a building’s rough framing elements—including roof and floor trusses, wall panels, solid sawn, EWP, sheathing and various ancillaries.

The IntelliVIEW Suite provides the industry’s most complete analysis of the design, cost information and bill of materials—promoting increased profits by reducing plate and lumber use.

Ask those who know. They’ll tell you about the people at Alpine who make a difference.

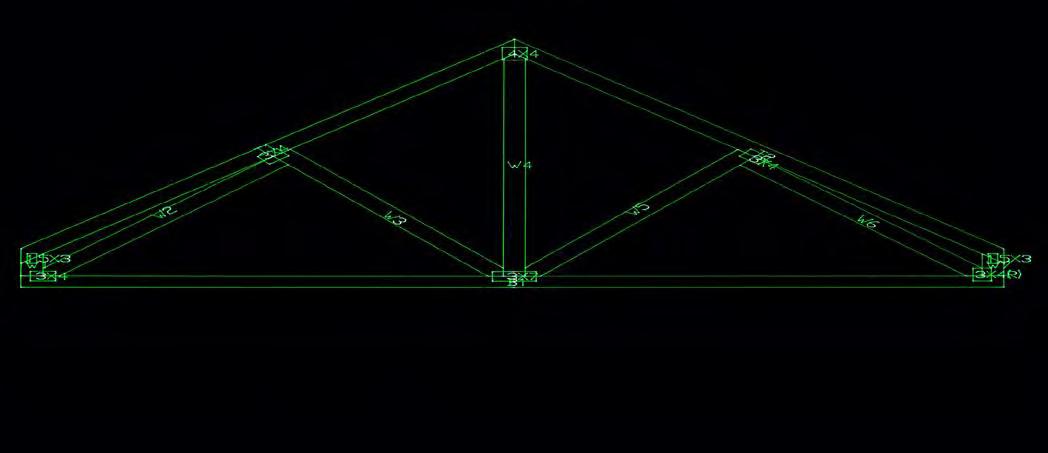

Alpine Linear Saw 5.0: A New Standard in Small Parts Handling

By Alpine Staff

Building on the legacy of over two decades of proven reliability and precision, the latest version of the Alpine Linear Saw (ALS) continues Alpine’s proud tradition of innovation. Designed and engineered to optimize cutting and material handling workflow, the ALS introduces a key innovation – the Small Parts Handler (SPH) – improving efficiency, accuracy, and speed throughout the cutting process. This new feature provides component manufacturers with an efficient transfer of components as small as a 6-inch-long 2x4 square cut block.

Smaller parts often disrupt production, as sawyers must manually retrieve components from a dedicated bin or waste, leading to delays in production, errors, and lost components.

Small Parts Handler

The SPH addresses workflow bottlenecks and improves overall plant efficiency. It uses an articulated arm with a gripper and roller that operates simultaneously with the cutting process. After the leading-edge cuts are completed and before trailing cuts are performed, the arm grips the component adjacent to the saw blade.

Once the piece is cut, the arm seamlessly transfers the component onto the belt, which is delivered directly to the outfeed roll case – saving time and freeing up sawyers for other tasks, improving overall plant throughput.

Ergonomic Impact

Continuing Alpine’s focus on innovation and streamlining workflow, the SPH enhancement improves plant ergonomics by reducing the need for repetitive lifting, bending, and manual sorting of small parts while minimizing risk and maintaining productivity in the plant.

Sawyers can customize the small part handling system to fit their workflow through user-defined settings to meet the plant’s operating requirements. The result is a unified outfeed system that helps simplify stacking and organization for table delivery, eliminating the need for manual sorting by using the arm to deliver small parts directly to the outfeed – keeping them separated from waste.

The ALS 5.0 sets a new standard in linear saw performance. Combining reliability with innovative solutions, this next-generation saw is ready to enhance productivity and improve the efficiency of the plant environment. Contact your local Alpine Sales Representative or email info@alpineitw.com to learn more.

Truss solutions from idea to installation.

Transform your truss operation with an integrated solution from Simpson Strong-Tie. The industry leader in truss plates now brings you a full suite of software, equipment, hardware and services to drive truss component manufacturing from idea to installation. Start with CS Director™ , CS Truss Studio™ , CS EWP Studio™ and CS Producer™ for design, layout, production and project management. Use our powerful Monet DeSauw industrial saws to cut webs, chords, stair stringers, rafters and wedges with speed and precision. Specify the optimal connectors, anchors and Strong-Drive ® structural fasteners for every project. You can also complement your team with our professional truss design services at any time. Altogether, you have a smart solution made to increase productivity, ensure high quality and take your business to the next level.

To learn more, contact your representative at (800) 999-5099 or visit

• 5 Blade Automated Component

• Cuts

• Waste Conveyor (under saw)

• E xcludes Incline Waste Conveyor (adjacent to saw)

• Video available upon request

• Add $12,500 for 6 Chain Live Deck $16,500 FOB ND Wasserman & Associates 800-382-0329 www.wasserman-associates.com

Safety Speed Manufacturing, model 7400 XL*, vertical panel saw, 3 HP induction motor, 64 inch crosscut, 2 1/8" maximum thickness, accuracy within 0.005 inches, 13 foot long welded steel frame with integrated stand and linear V-guides, enclosed counterweight system, adjustable vertical and horizontal rules. Quick changes from vertical to horizontal cutting. Includes machined aluminum material rollers, hold down bar, wheels, quick stop gauges and material hold downs. Dust collection ready. Options available include digital readouts for vertical cuts, automated length measuring, laser guide, stop bar, vacuum and midway fence. 208-230/460 volt, 3 phase electrical (208-230 single phase, 2 HP power optional +$100.00).

The Auto-Feeding RetroC

The Amazing RetroC by Enventek

A complete wood processing system proven to profitably feed cut lumber to truss plants of all sizes.

Easy to use, simple robust automation that is scalable with less labor. A RetroC holds calibration.

Out Produces Any Saw in Batch Cut or Cut by Truss Mode

Auto-Feeding, no upper hold-downs (just 15 automation axes) with electronic braking. Efficient material handling that will significantly increase cut piece production with reduced operating costs and improve truss build times with consistently accurate cut pieces.

The Magic of SpeedCatch - No Catching Labor

Catching labor is eliminated with our optional SpeedCatch cart system. Sophisticated SpeedCatch software enhances the efficiency of truss production by effectively collating and organizing the lumber at the truss tables. SpeedCatch upgrades the RetroC to a comprehensive one-person (sawyer) wood processing system.

Monet B500 5-Blade Component Saw $54,908 NOW $48,900

NC