1 GENERAL INFORMA TION

2 SAFETY INFORMA TION

RIGHT - HAND SIDE CONTROLS

EXTERIOR CONTROLS

PREP ARING FOR ROAD TRANSPOR T

PREP ARING FOR ROAD TRANSPOR T

Loader backhoes B95C - B95CTC - B95CLR - 10C have been designed perform most earth - moving

you use this machine for duties involving the use special consult your dealer make sure that the adaptations modifications carried out are conformity with the s technical specifications and with current regulations safety .

Any modifications adaptations which are not approved the manufacturer may invalidate the s original conformity with safety

1

This machine has been built with the most advanced nology and accordance with recognized safety

The machine must used according its intended use, respecting the safety and precautionary rules and strictly following the operating Any functional especially those fecting the safety the should therefore rectified immediately

A void injury!

Using the machine for purposes other than beyond the intended use not allowed; for example:

- for the transportation persons,

- a working platform,

- for pulling attached

- for pulling transporting loads without the intended working equipment.

Failure comply could result death serious injury .

Any modifications adaptations which are not approved the manufacturer may invalidate the s original conformity with safety requirements.

NOTICE: The engine and fuel system your machine are designed and built government emissions dards. T ampering dealers, customers, operators and users strictly prohibited law Failure comply with this prohibition could result government rework invalid warranty , legal action and possible fiscation the machine until rework original condition completed. Engine service and / repairs must carried out a certified technician only

Before entrusting this machine operator , make sure that:

• The operator qualified operate the machine rectly and safely

• The operator has read and fully understood the structions given this manual.

The manufacturer / supplier cannot held responsible for any damage resulting from unintended use. The risk volved such misuse lies entirely with the user

A TTENTION: For clarity some figures this manual show the machine with protection panels ers Never operate the machine with any tection panels covers

Consult your dealer obtain extra manuals manuals other languages.

Y our dealer your disposal for any further information you may need.

A TTENTION: absolutely forbidden tamper with and / change the setting any the hydraulic system valves avoid damaging machine with a consequent risk for personal safety

The current operator ’ s manual the user ’ s guide for rect run - use and maintenance the

Carefully read this operator ’ s manual and store the cab for quick location and

Instructions concerning safety , operation and nance have been developed permit safe service and operation this

the event queries suggestions relevant your machine not hesitate address your dealer ers have qualified and trained personnel disposal well original means and equipment suitable carry out all necessary maintenance.

The - spare parts have not been checked and authorized the manufacturer The assembly and / use such products may have negative fects the machine design features and could impair its operation safety The manufacturer not liable for any damage caused - spare parts

This machine under warranty according the lations force your country and compliance with the sales agreement drawn with the dealer The ranty , however , expires the operation and maintenance instruction for this machine and contained this manual, have not been

not use this machine for any applications purposes other than those described this manual. you use this machine for duties involving the use special consult your dealer make sure that the adaptations modifications carried out are conformity with the s technical specifications and with current regulations safety

NOTE: Each machine supplied complete with a copy this manual. Descriptions and illustrations provided herein are not The manufacturer , provided that the basic characteristics machine types described and shown this manual remain the reserves the right change parts and accessories supplied without any commitment timely update this publication, and this any time deems convenient for improvement purposes due commercial manufacturing ments. For exact information, please consult your dealer contact the manufacturer ’ s branch who remain your disposal for further

Manuals are available from your dealer for the operation, service, and repair your machine. For prompt convenient contact your dealer for assistance obtaining the manuals for your

Y our dealer can expedite your order for Manuals, Parts Catalogs, Service Manuals, and maintenance

Always give the machine and product identification number (PIN) your machine your dealer can provide the correct manuals for your

The company continually striving improve its products and therefore reserves the right make improvements and changes when becomes practical and possible so, without incurring any obligation make changes additions the equipment sold previously

All data given this manual subject production

NOTICE: Operating and service messages displayed the electronic operating panel may vary from what shown the Should this occur , adhere the latest instruction the electronic operating

Dimensions and weights are approximate only and the illustrations not necessarily show the machine standard For exact information about any particular consult your dealer

Interference may arise a result add ‐ equipment which may not necessarily meet the required standards. such interference can result serious malfunction the unit and / create unsafe you must observe the following:

• The maximum power emission equipment must not exceed the limits imposed the national authorities the country where you use the

• The electro ‐ magnetic field generated the add ‐ system should not exceed V / m any time and any location the proximity electronic

• The add ‐ equipment must not interfere with the functioning the board electronics. Failure comply with these rules will render the warranty null and

Read this manual before you start the engine operate the machine. you need more information, see your NEW HOLLAND CONSTRUCTION dealer

This manual contains important information about the safe operation, adjustment, and maintenance your loader This manual divided into chapters outlined the table

Refer the index the end this manual for locating specific items about your The loader backhoe conforms current safety

Read this manual carefully , paying particular attention the instructions concerning safety , operation and nance avoid the risk injury while operating servicing the The machine has been designed and manufactured according the strictest quality standards. However , the risk accidents can never completely That why essential observe elementary safety rules and

NOT operate permit anyone operate service this machine until you the other persons have read and understand the safety , and maintenance instructions this Use only trained operators who have demonstrated the ability operate and service this machine correctly and safely

The information this manual provided the basis information that was available the time that the manual was part and other items can These changes can fect the service that given the machine. Ensure that you have the complete and most current information from your dealer before you start any machine

The Manual stored the manual compartment equipped this machine. Make sure this manual complete and good Consult your dealer obtain additional manuals manuals other AEM safety booklet included with each T ake the time read the booklet and understand its

Contact your dealer for any further information assistance about your Y our dealer has Corporation proved service Y our dealer has technicians with special training that know the best methods repair and maintenance for your

Improper operation this machine can cause death serious injury . Before using the machine, make certain that every operator

• instructed safe and proper use the

• reads and understands the manual(s) pertaining the

• reads and understands all safety decals the

• clears the area other persons and domestic

• learns and practices safe use machine controls a clear area before operating this machine a job your responsibility observe pertinent laws and regulations and follow CNH Italia S.p.A. instructions machine operation and maintenance.

Keep the Manual the storage compartment provided the rear the operator ’ s The Manual must available for use all

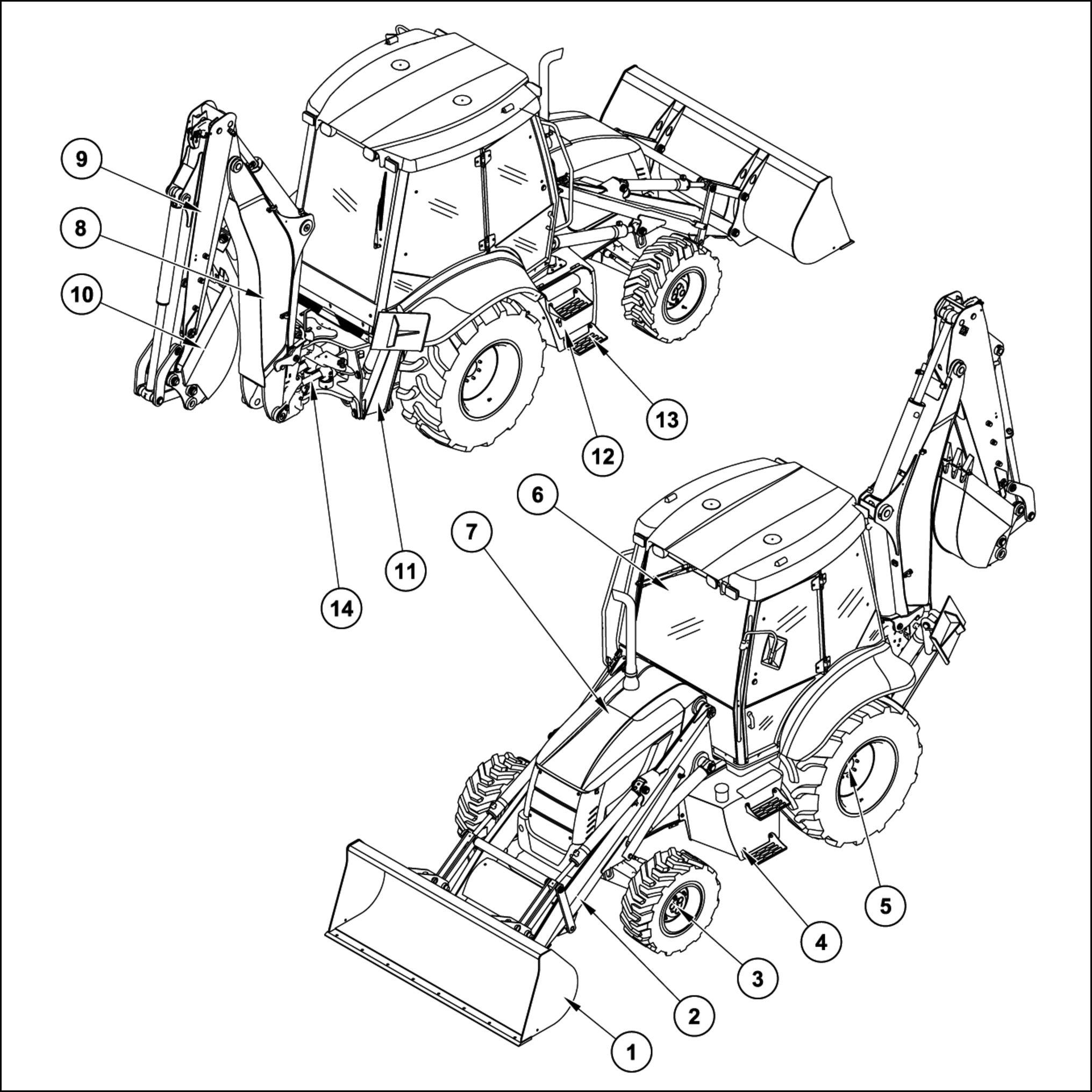

Loader bucket

Loader arm

Front axle

Fuel tank 1

Backhoe attachment boom

Dipper telescopic dipper

Backhoe bucket

Stabilizers

Rear axle Battery box

Operator ’ s compartment - Cab

Hydraulic oil tank

Engine guard Swing cylinders

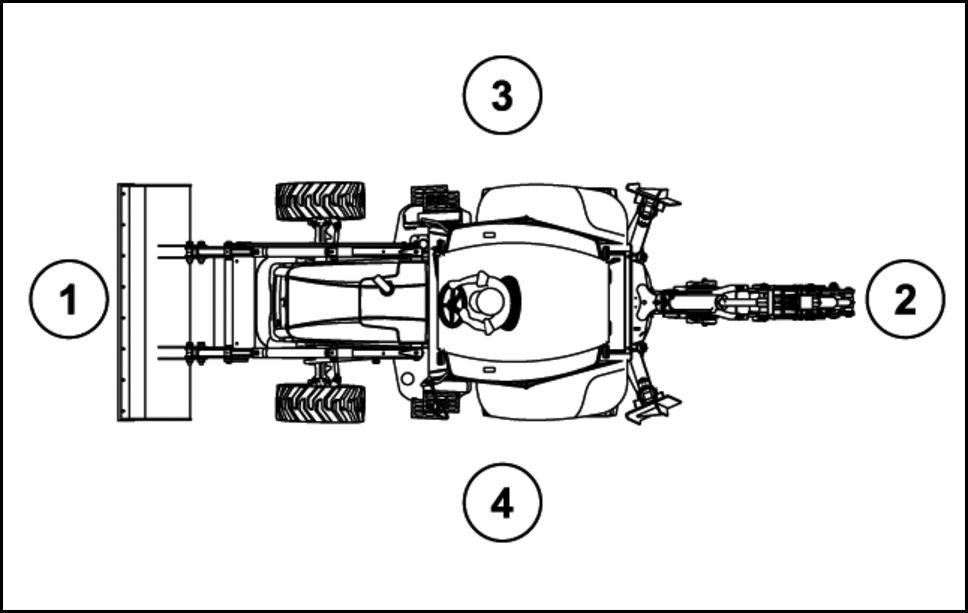

Right, left, front and rear the machine

Machine sides

The terms “right”, “left”, and “rear”, when used this indicate the sides the machine seen from the operator ’ s

Operator and seat loader attachment position

Front side Back side Right side Left side

Operator and seat backhoe attachment position

Front side Back side Right side Left side

1

2

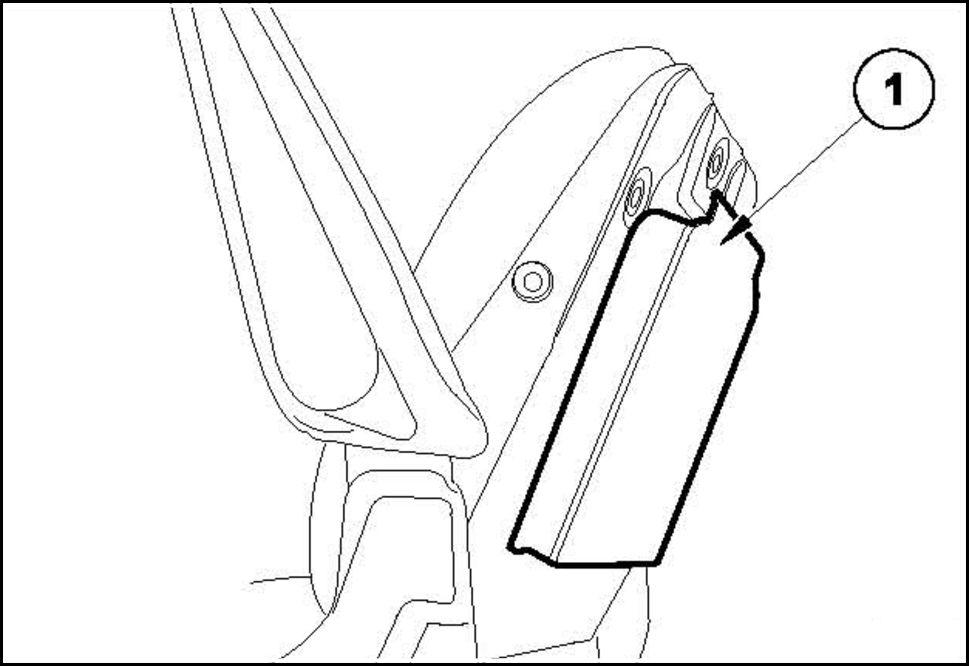

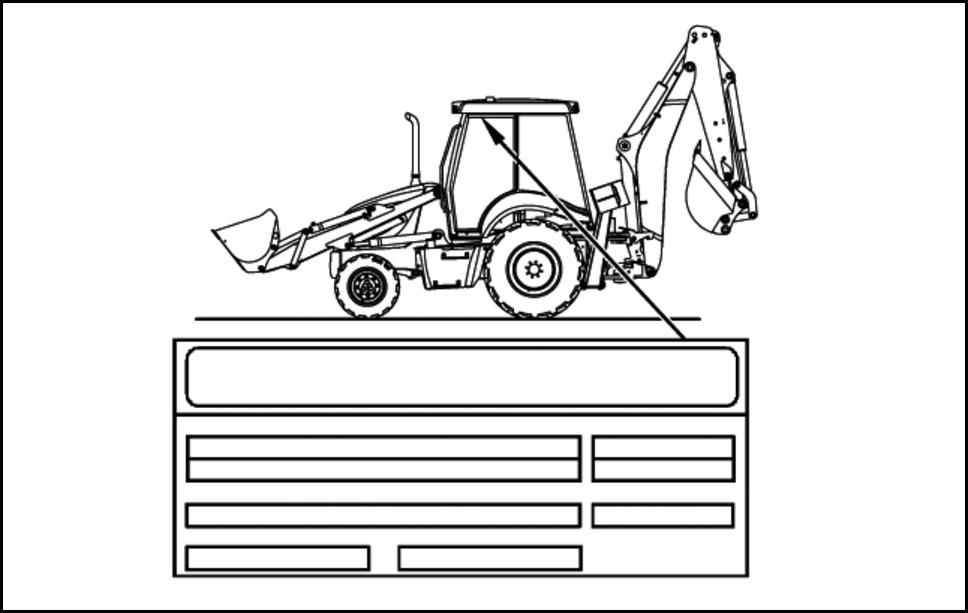

When ordering parts, requesting information always give your Dealer the model and serial number your machine and component

T ype / Model and Category backhoe B95C (*)

Serial number

B95CLR and 10C

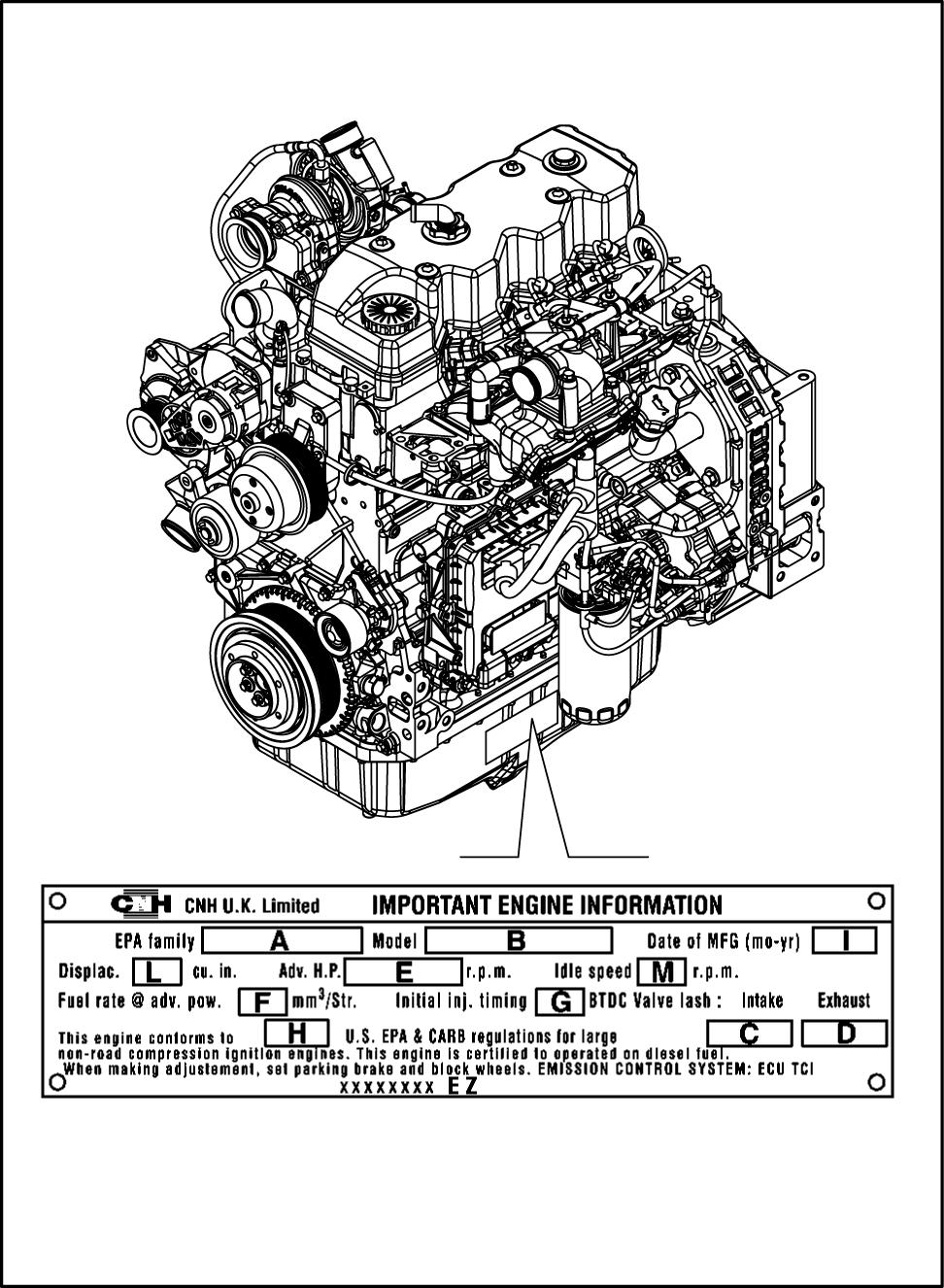

T ype / Model...............................F5HFL413C for B95C (*)

Serial number (*) B95CTC and B95CLR

T ype / for 10C

Serial number

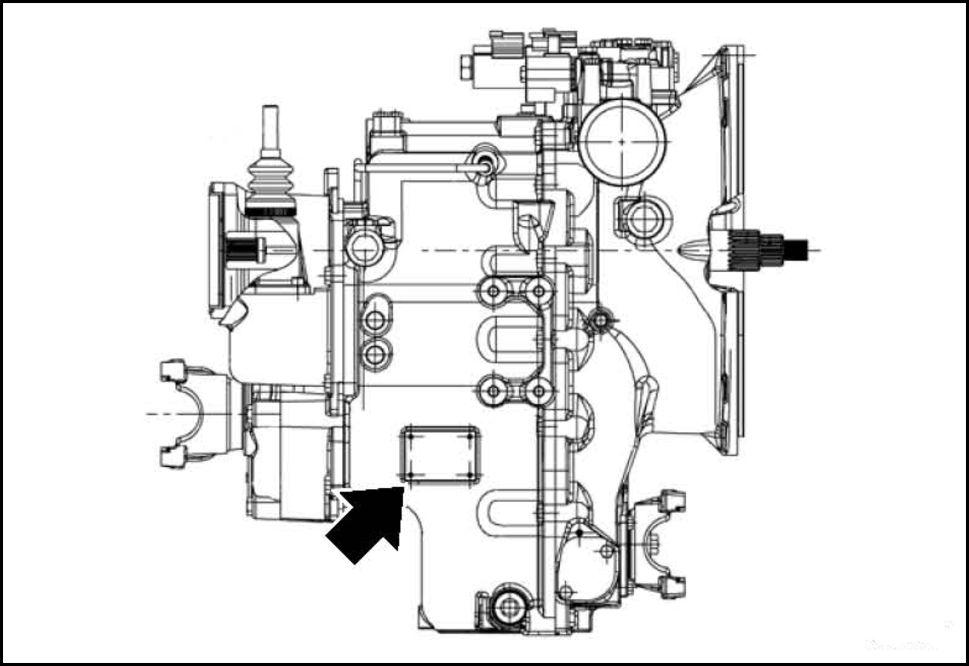

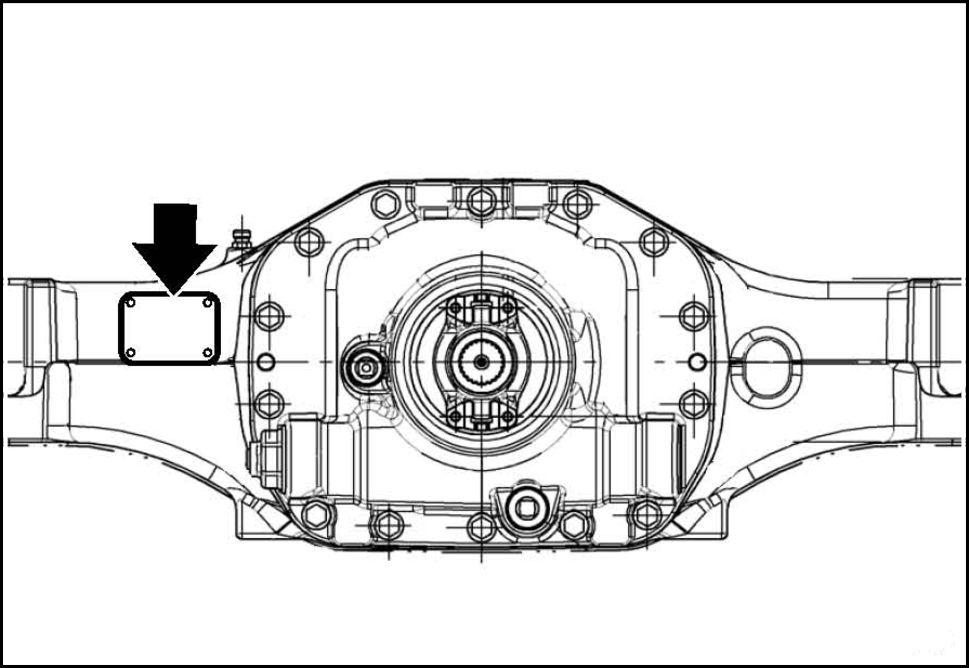

LEEN1 1T0340AA 3 POWERSHIFT - TRANSMISSION

Serial number

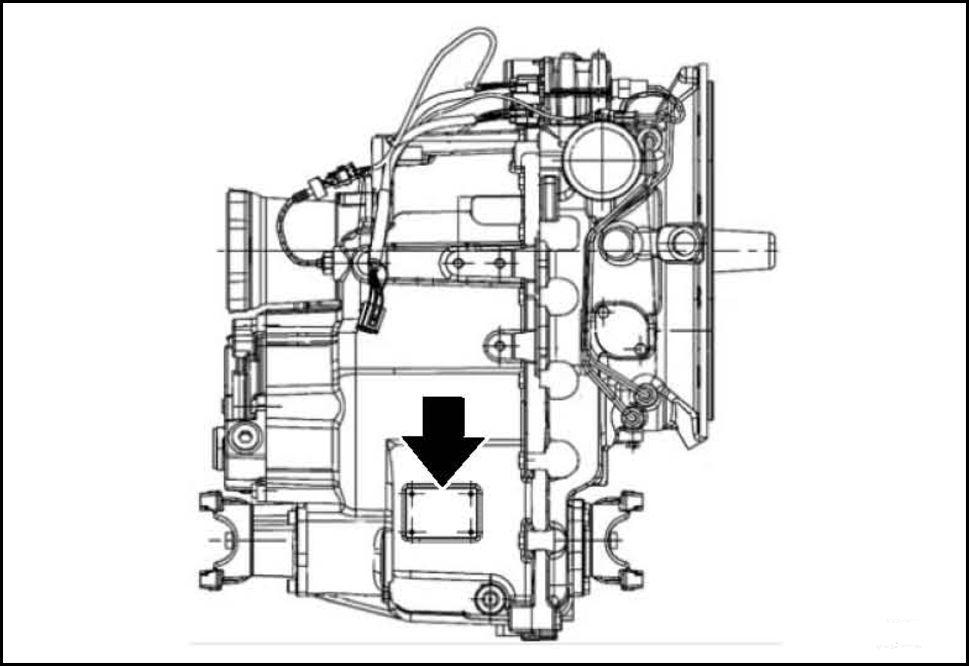

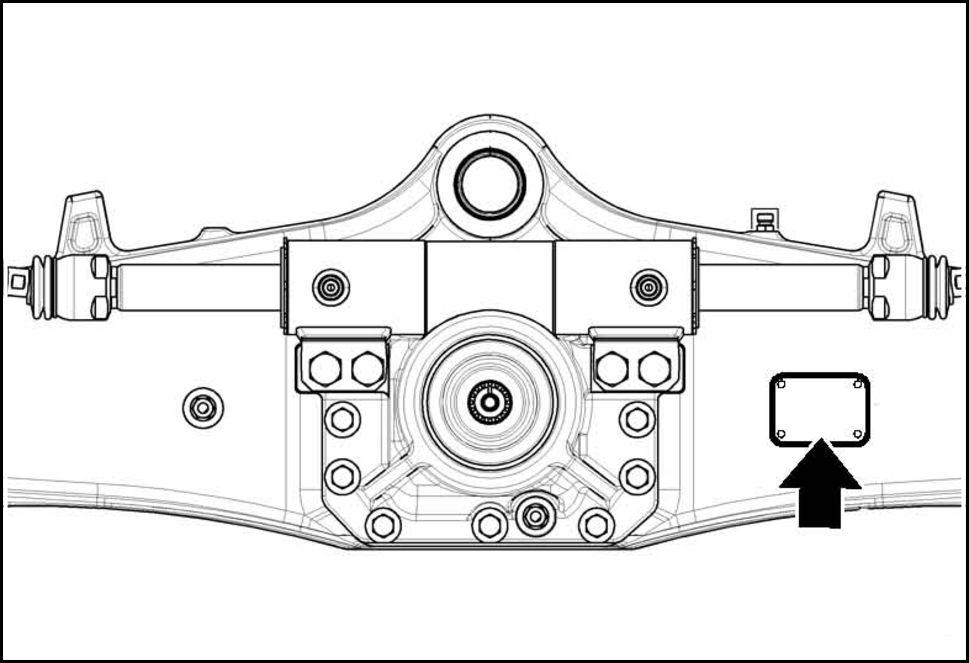

LEEN1 1T0341AA 4 FRONT AXLE

Serial number

LEEN1 1T0342AA 5

Serial number

Safety rules and signal word definitions

Personal safety

This the safety alert used alert you potential personal injury Obey all safety messages that follow this symbol avoid possible death injury

Throughout this manual and machine you will find the signal words W and CAUTION followed special instructions. These precautions are intended for the personal safety you and those working with

Read and understand all the safety messages this manual before you operate service the machine.

DANGER indicates a hazardous situation not will result death serious injury The color associated with DANGER

W ARNING indicates a hazardous situation not could result death serious injury The color associated with W ARNING

used with the safety alert indicates a hazardous situation not could result minor moderate injury . The color associated with CAUTION YELLOW .

Machine safety

NOTICE: Notice indicates a situation not could result machine property The color associated with Notice

Throughout this manual you will find the signal word Notice followed special instructions prevent machine property The word Notice used address practices not related personal safety

Information

NOTE: Note indicates additional information which clarifies other information this

Throughout this manual you will find the word Note followed additional information about a other information the The word Note not intended address personal safety property

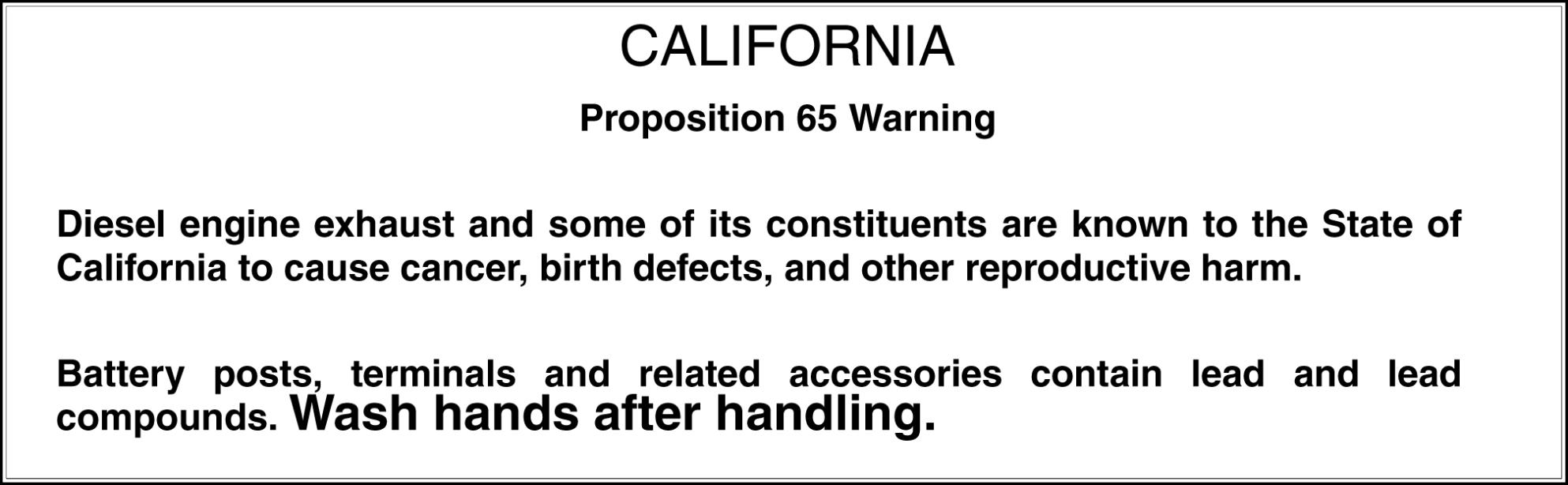

Safety rules - California Proposition W arning

RCIL08CCH001EAA 1

California Proposition W arning

Diesel engine exhaust and some its constituents are known the State California cause cancer , birth and other reproductive

Battery posts, terminals and related accessories contain lead and lead W ash hands after

Understand that your safety and the safety other workers bystanders measured how you service and ate this Know the positions and operation all controls before you try CHECK ALL CONTROLS

READ THIS MANUAL COMPLETEL Y and make sure you understand the All equipment has a Make sure you understand the stability , and load characteristics this machine before you start operate.

Most accidents involving machine operation and maintenance can avoided following basic safety rules and precautions. Read and understand all the safety messages this manual, the safety manual and the safety decals the machine before you operate service the See your dealer you have any

The safety information given this manual does not replace safety codes, insurance needs, federal, state, and local Make sure your machine has the correct equipment according these rules

CNH Italia continuing work for your safety making loader backhoes with better protection and viding rules for safe

• not W not

• Dirty slippery walkways and forms can cause Make sure these surfaces remain clean and clear debris.

• W ear the seat belt maximize the protection pability the cab Inspect the mounting bolts for the seat belt and the a daily basis ensure their integrity .

• not permit riders the machine

• W ear protective equipment when Hard hats, protective glasses, protective shoes, gloves, reflector type and ear protection are examples equipment that may

• Remove all loose objects stored the machine. Remove all objects which not belong the machine and its

• Certain protective equipment should replaced and renewed upon age and wear Old hard hats may not ford the original intention. Faded and soiled vest are longer highly visible original See the s

• not operate this machine perform nance work you have not had appropriate and read and fully understand the instructions and warnings this

• The air conditioning system under high not disconnect any The release high pressure can cause serious injury

• Only a trained service technician shall pair , recharge the air condition

• Always wear safety protection when working around the liquid The refrigerant can cause rious injury eyes and

Escaping fluid!

Hydraulic fluid diesel fuel leaking under pressure can penetrate the skin and cause infection other injury T o prevent personal injury: Relieve all pressure before disconnecting fluid lines performing work the hydraulic system. Before applying pressure, make sure all connections are tight and all components are good Never use your hand check for suspected leaks under pressure. Use a piece cardboard wood for this purpose. injured leaking fluid, see your doctor immediately .

Failure comply could result death serious injury

Some components may continue run down after disengaging drive systems. Make sure all drive systems are fully

Failure comply could result death serious injury .

• Always check the operating and the road safety the machine before

• Always make sure the working area clear other domestic before you start operating the

Never operate the machine with the shields Always close access doors panel fore operating the

• Before starting the sure all operating controls are the neutral park lock

• Another worker bystander within the operating area a machine can struck crushed the machine its NOT allow anyone enter the work

• Always sound horn before starting the

• Never operate the engine enclosed spaces harmful exhaust gases may build up.

• Start the engine only from the operator ’ s

• Operate controls only when seated the except for those controls expressly intended for use from other

• not allow other persons ride the machine attachment /

• Operate and drive the machine with care and speed compatible with Use extra caution when operating over rough ground, slopes, and when

• Check and other machine control devices accordance with maintenance prior starting Observe all gauges warning instruments for proper ate all controls ensure proper any malfunctions are remove the key and attach a Not tag the machine until the function

• a failure that causes loss control such service engine stop the chine motion quickly Make sure the machine securely parked. Remove the key and attach a Not tag the machine until the malfunction corrected the machine can safely towed.

• Make sure all components are good condition and tighten all connections before starting the engine pressurizing the

• Make sure all guards and shields are good dition and properly installed before operating

• your machine has a make sure that all dows are clean and that the windshield wipers work correctly

• Dust, fog, smoke, etc., can decrease your vision and cause Stop the machine crease the speed until you can

• Understand the machine limitations and keep the machine under

• Before you operate check that all lamps

• Select a gear that will prevent excessive speed when going not coast

• NOT attempt remove material from any part the machine while being operated nents are

• When using the backhoe:

• Position the stabilizer pads for maximum bility

• Before leaving the vehicle:

• Park the vehicle a level

• Put all controls neutral park lock

• Install a guard rail and warning signs keep other persons away from the machine ating area with reduced visibility , such a building.

• Place the direction control lever and the mission neutral and apply the parking brake before turning the seat around the backhoe

• Ensure the seat locked into position.

• Know which control pattern engaged before actuating the hydraulics (pilot control chines

• Use caution when swinging the backhoe pletely the side prevent contact with the

• Engage the parking brake; use wheel chocks

• Lower all hydraulic attachments / implements tools, the ground.

• Shut down the engine and remove the key

• a rare circumstance when the engine must running without operator the take these precautions:

• Reduce engine speed low

• Disengage all drive

• Put the transmission

• Apply the parking

Battery acid causes burns. Batteries contain sulfuric acid. A void contact with skin, eyes clothing. Antidote (external): Flush with water . Antidote (eyes): flush with water for minutes and seek medical attention immediately Antidote (internal): Drink large quantities water milk. not induce vomiting. Seek medical attention immediately . Failure comply could result death serious injury

• Follow instructions when storing and handling

• Always wear eye protection when working with a battery

• not create sparks have open flame near the battery .

• not smoke near a battery

• V entilate when charging using a battery closed

• When using auxiliary batteries connecting booster cables start the use the dure shown this NOT short across

• When working around storage remember that all the exposed metal parts are “live”. Never lay a metal object across the terminals because a short personal injury may

• When disconnecting the battery terminals, remove the negative ( cable first; then remove the positive (+) When connecting the battery connect the positive (+) cable first; then connect the negative (

• Disconnect the battery (both terminals) before ing any part the Failure may cause damage sensitive electrical For additional welding refer this chapter

• Frozen electrolyte can cause the battery not charge a frozen battery use a frozen tery booster start the Always keep the battery full charge prevent the electrolyte from

• Keep batteries out reach children and other unauthorized persons.

• Battery and related accessories contain lead and lead compounds. W ash hands after

• operate machine during electrical

• you are the ground during electrical stay away from machinery and Seek shelter a protected

• electrical storm should strike during remain the not leave cab not make contact with the ground objects outside the machine.

• Leaked spilled fuel / oil hot surfaces electrical components can cause a

• Sparks from the electrical system engine haust can cause explosion and Before you operate the machine area with flammable dust vapors, use good ventilation remove the flammable dust

• Engine fuel can cause explosion not fill the fuel tank with the engine you are near open you are etc.

cleaning the machine may necessary ing the operating environment and

• the machine has hydraulic fluid always repair the leak and clean the area before

• Keep the cooling system clean and maintain the rect coolant

• not store oily rags other flammable materials the

• Inspect the electrical system for loose connections frayed Repair replace loose aged

• not weld flame cut any items that contain flammable Clean items thoroughly with non - flammable solvent before welding flame

• Promptly investigate any unusual smells odors that may occur during operation the

• Always have a fire extinguisher near the Make sure the fire extinguisher(s) maintained and serviced according the manufacturer ’ s

• you use a cutting torch the chine:

• Clean the area

• Disconnect isolate the drive train controller

• a fire extinguisher has been always recharge replace the fire extinguisher before operating the

• not expose the machine flames, burning

• Keep the ground cable from the welder near the work area possible.

• Sparks flame can cause the hydrogen gas a battery explode. T o prevent explosion:

• least once each day , and the end the day , remove all trash and debris from the machine cially around hot components such mission, exhaust, battery , etc. More frequent ing the machine may necessary depending the operating environment and

• Connect the negative ( cable

• When connecting booster cables start the use the procedure shown this

• not short circuit the battery posts with metal

• least once each day , remove debris accumulation around moving components such leys, belts, gears, cleaning fan, etc. More frequent

• not weld, grind, smoke near the battery .

• not smoke permit open flames while fueling near fueling

• not fill the fuel tank completely the Allow room for

• T ighten the fuel tank cap securely Should the fuel cap replace only with the original approved Use a non - approved cap without proper venting may result pressurization the

• Clean spilled fuel immediately and dispose contaminated material environmentally correct manner

• Never use fuel for cleaning purposes.

• Use the correct fuel grade for the operating

• you are exposed come contact ardous chemicals you can seriously The required for the function the machine can They may attractive and harmful mestic animals well

• Material Safety Data Sheets (MSDS) provide mation about chemical substances within a uct, safe handling first aid and procedures taken the event a spill accidental MSDS are available from your dealer

information the well the information this manual when servicing the

• Dispose all and containers vironmentally safe manner according local laws and regulations. Check with local environmental and recycling centers your dealer for correct posal

• Store fluids and filter accordance with local laws and Use only appropriate containers for the storage chemicals petrochemical

• Before you service the check the MSDS for each used the This information indicates the associated risks and will help you service the machine safely . Follow the

• Keep out reach children other unauthorized