RemoveAndInstallEngine

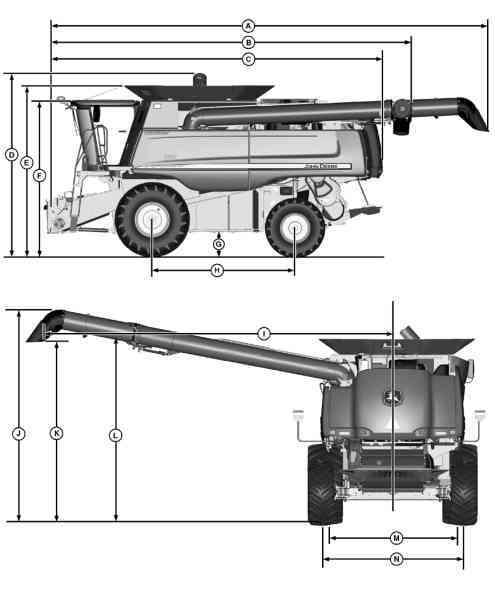

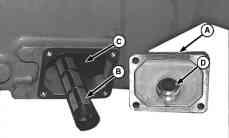

6.Removebatterycables(C)fromstartermotor.

7.Removevariabledrivesheavesupportjamnut(A).

8.Loosenvariabledrivesheavesupportjamnut(F).

9.Removeretainingpin(G)andsupportrod(B).

10.Removecapscrews(D)andsheavesupportbracket (E).

NOTE:Capandplugalllinesandhoses.

11.Disconnect:

• Radiatorandheaterhoses

• Enginewiringharness

• Coldweatherstartaid

• Rotaryscreendrivebelt

• Fuelsupplyandreturnlines

• Engineoildrainhose

12.Remove:

• Mufflerassembly

• Bothchargeairtubes

NOTE:DONOTdisconnectrefrigerantlines.

• Alternator

• Airconditioningcompressor

• Upperandlowerfanshroud

• Coolingfan,spacer,washerandsheave

A—VariableDriveSheave SupportJamNut B—SupportRod C—BatteryCables(4used) D—CapScrew(2used)

E—SheaveSupportBracket F—VariableDriveSheave SupportJamNut G—RetainingPin

OUO6083,00004E61926MAY102/5

13.InstallliftingstrapsJD2441(A)andJD2442(B)on engine.

CAUTION:Usecarewhenliftingengine andNEVERpermitanypartofthebodytobe positionedunderaloadbeingliftedorsuspended.

CAUTION:Theapproximateweightofthe 6068engineis711kg(1568lb).

Specification

Engine—6.8L—Weight..................................................................711kg (1568lb.)

14.Removefrontenginemount(A)fromenginerail.

15.Removegearcasetoenginecapscrews(B).

16.Carefullymoveengineawayfromgearcase.Lift engineoutofcombine.

A—CapScrew(4used)B—CapScrew(4used)

OUO6083,00004E61926MAY104/5

17.Removecapscrews(A)andseparateenginegear casecouplerfromflywheel(B).

18.Repairorreplaceasnecessary.

A—CapScrew(6used) B—Flywheel

OUO6083,00004E61926MAY105/5

InstallEngine—6.8L

1.Inspectbearing(A)inflywheel(B).Replaceasneeded (SeeRemoveAndInstallFlywheelPilotBearingin Section20,Group05.).

A—Bearing B—Flywheel

OUO6083,00004E71926MAY101/4

2.ApplyPM37477ThreadLockandSealer(Medium Strength)tocapscrews(A)andinstallenginegear casecouplertoflywheel(B).Tightentospecification.

Specification

EngineGearCase

CouplerCap Screws—6.8L Engine—Torque.............................................................................55N∙m (41lb.ft.)

A—CapScrew(6used) B—Flywheel

Continuedonnextpage

OUO6083,00004E71926MAY102/4

CAUTION:Usecarewhenliftingengine andNEVERpermitanypartofthebodytobe positionedunderaloadbeingliftedorsuspended.

CAUTION:Theapproximateweightofthe 6068engineis711kg(1568lb).

IMPORTANT:UseonlyaliftingslingliketheJDG23 whichhasaspreaderbar.Othertypesoflifting slingscoulddamagethecylinderhead.

3.Carefullylowerenginetoalignwithenginegearcase.

4.Install:

• Gearcasetoenginecapscrews;tightento specification

Specification

GearCasetoEngine

CapScrews—Torque..................................................................340N∙m (250lb.ft.)

• Frontenginemountcapscrews;tightento specification

Specification

FrontEngine

MounttoEngineRail

CapScrews—Torque..................................................................123N∙m (90lb.ft.)

5.Removeliftingsling(C)andliftingstraps(AandB).

6.Installvariabledrivesupportbracketusingcaps screws.Tightencapscrewstospecification.

Specification

VariableDrive

SupporttoEngineCap

Screws—Torque..........................................................................350N∙m (255lb.ft.)

7.Installvariabledrivesupportrodusingretainingpin.

8.Tightenvariabledrivesheavesupportjamnutto sheavesupportbracket.

9.Installjamnutontosupportrodandtightento specification.

Specification

VariableSheave SupportJam NuttoSheaveSupport Bracket—Torque..........................................................................250N∙m (185lb.ft.)

10.Installairconditioningcompressorandtightencap screwstospecification.

Specification

AirConditioning CompressorCap

Screws—Torque............................................................................35N∙m (26lb.ft.)

NOTE:Fabricatetwodowelpins,6mm(1/4in.)x180 mm(7in.)long,toaidinaligningthefanassembly.

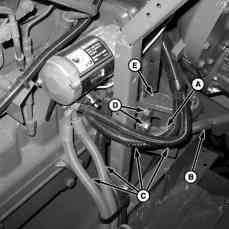

11.Installsheave(D),washer(C),spacer(B),andfan(A) ontohub(E)usingdowelpinstoaidinalignment.

12.Installfourcapscrewsfingertight;thenremovedowel pins.Installremainingcapscrews,andtightento specification.

Specification

FantoFanHubCap Screws—Torque............................................................................80N∙m (60lb.ft.)

13.Install:

• Twopiecefanshroud

• Upperandlowerradiatorhosesandsurgetank hose;tightentospecification

Specification

RadiatorHose Clamps—Torque............................................................................11N∙m (97lb.in.)

• Bothchargeairtubes:tightentospecification

Specification

ChargeAirCoolerTube Clamps—Torque............................................................................11N∙m (97lb.in.)

• Heaterhoses

• Alternator

• Fandriveandrotaryscreendrivebelts

• Exhausttubeandmufflerassembly

14.Connect:

• Enginewiringharness

• Coldweatherstartaid

• Fuelsupplyandreturnlines

• Engineoildrainhose

• Batterycablestostartermotor

15.Installenginecoversandshields.

16.Fill:

• Enginewithcorrectoil(SeeOperator’sManual)

IMPORTANT:FollowBleedAirFromCoolantSystem procedureinrelevantCTM.

• Coolingsystemwithcoolant

17.Openfuelsupplyvalveonbottomoftank.

18.Turnbatterydisconnectswitchto“I”onposition.

19.FollowenginebreakinprocedureinrelevantCTM.

OUO6083,00004E71926MAY104/4

A—Fan B—Spacer C—Washer

D—Sheave E—Hub

SetHydrostaticPumpDriveGearBacklash

NOTE:Donotusemorethanoneplasticshim.

1.Selectshimstoprovidebacklash(dimensiononend ofsmallergearto+0.1to0.0mm(+0.004to0.0in.) attightestconditionofgearmesh.

2.InstallshimsandOringonpilotdiameterofbearing housing.Tightencapscrewstospecification.

Specification

HydrostaticPump DrivetoGearCase CapScrews—Torque...................................................................50N∙m (40lbft)

Shimsavailableare:

• 0.08mm(0.003in.)

DisassembleandAssembleOilScreen

NOTE:Whenevergears,shafts,orbearingshave beenreplaced,cleanoilscreen.

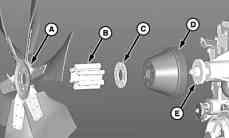

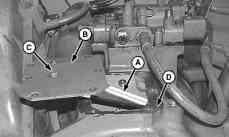

1.Removecover(A)withgasket.

2.Cleanoilscreen(B).

3.Thoroughlycleansumparea(C).

4.Installoilscreen.Besureclosedendofscreenfits inrecessonoppositeside.Pilot(D)mustbeDOWN topositionscreenlowinsump.Tightencoverbolts tospecification.

Specification

EngineGearCase OilScreenCoverCap Screws—Torque............................................................................25N∙m (216lbin.)

• 0.13mm(0.005in.)

• 0.25mm(0.010in.)

• 0.50mm(0.020in.)

AG,OUO6022,3801925JUL001/1

NarrowBodyOilScreenShown

A—Cover B—OilScreen C—Reservoir D—Pilot

RG53986,0000EE31908FEB101/1

DisassembleandAssembleOilTrough

NOTE:Removehose(E)fromfittingifequippedwith 5speedfeederhousegearcase.

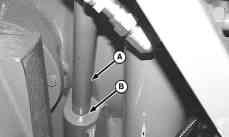

1.Removeoiltrough(A)withcover(B).

IMPORTANT:Correctlocknutsmustbeusedoncap screws(C).Standardnutsmaycomeloose, fallintogearcaseandcausedamage.

IMPORTANT:Becertaintroughisattachedtocoveras shownoroilwillnotbedeliveredtobearings.

2.Replaceifdamaged.

3.Applyathinbeadofsealantallaroundsurface(D).

4.Installoiltrough.Tightencapscrewstospecification.

Specification

OilTroughCoverCap

Screws—Torque......................................................................25±5N∙m (221±44lbin.)

A—OilTrough B—Surface C—CapScrew

D—Surface E—Hose

DisassembleandAssembleDipstickTube

NOTE:Removedipsticktubeonlyifdamaged.

1.Removedipsticktube(A).Tubeisatightfit.

2.Applyacoatofthreadlockandsealerinbore(B).

3.Driveintubeuntilitseats.

A—DipstickTube B—Bore

RG53986,0000EE41908FEB101/1

AG,OUO6022,2971905AUG051/1

RemoveandInstallFilter

1.Turnfilter(A)counterclockwiseandremove.

2.Installfilter(A).

3.Fillgearcasetocapacity.(SeeOperator’sManual.)

4.Checkoillevelafterengagingdrives.

RG53986,0000D111925JAN101/1

RemoveandInstallPressureRegulating Valve

CAUTION:Escapingfluidunderpressurecan penetratetheskincausingseriousinjury. Avoidthehazardbyrelievingpressurebefore disconnectinghydraulicorotherlines.Tighten allconnectionsbeforeapplyingpressure.Search forleakswithapieceofcardboard.Protecthands andbodyfromhighpressurefluids.

Ifanaccidentoccurs,seeadoctorimmediately. Anyfluidinjectedintotheskinmustbe surgicallyremovedwithinafewhoursor gangrenemayresult.Doctorsunfamiliarwith thistypeofinjurymaycallDeere&Company MedicalDepartmentinMoline,Illinois,orother knowledgeablemedicalsource.

1.Fullylowerheaderandreeltogroundandcontinue todepressswitchfor5secondstorelievehydraulic systempressure.Shutoffengineandclose accumulator.Removekey.

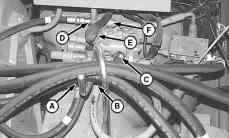

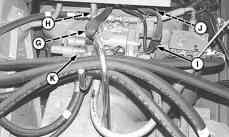

2.Disconnectlines(A—F).

3.Disconnectwiresleads(G—J).

4.Removecapscrews(K)andremovevalve.

5.Inspectforwearordamage.Replaceasnecessary.

NOTE:Donotusesealerongasket.

6.Installvalve.Tightencapscrewstospecification.

Specification

PressureRegulating

ValveCap

Screws—Torque............................................................................25N∙m

7.Connectwires(G—J).

8.Connectlines(A—F).

A—HydraulicHose

B—HydraulicHose

C—HydraulicHose

D—HydraulicHose

E—HydraulicHose

F—HydraulicHose

G—Connector

H—Connector

I—Connector

J—Connector

K—CapScrews(7used)

AG,OUO6022,2941925JUL001/1

Accumulator

Brakecharging

Prechargepressure........................................70303

Checkingheaderfloatsystem............................70302

Essentialorrecommendedtools........................70301

Fivespeedfeederhousedrivegearcase

Prechargepressure........................................70303

Generalinformation...........................................70301

headerfloatprechargepressure........................70303

Shutoffvalve

Removeandinstall.......................................701516

Twospeedautomatictransmission

Prechargepressure........................................70303

Accumulatorshutoffvalve

Removeandinstall..........................................701516

Actuator

Fanspeed

Adjust.........................................................1202022

Foldingauger

Removeandinstall.....................................1302013

Adhesivesandsealants.......................................101023

AHCpump

Install................................................................701011

Mark...................................................................70103

Remove..............................................................70102

Airconditioningsystem

Blowermotor

Removeandinstall.........................................90103

Charge.............................................................900522

Checkrefrigerantoilcharge.............................900522

Clutchhubclearance,check............................900513

Compressorclutch,disassembleand assemble........................................................900512

Compressorholdingfixture

DFRW20airconditioningsystem.................199051

Compressormanifold,inspect.........................900513

Compressoroilinformation..............................900521

Compressorreliefvalve,removeand install..............................................................900516

Compressor,disassemble,inspectand assemble........................................................900514

Compressor,removeandinstall........................90056

Correctoilcharge.............................................900521

Discharge/recoverrefrigerant............................90055

Evacuate..........................................................900520

Flush................................................................900518

Hoseandtubingconnectiontorques.................90055

Othermaterial....................................................90054

Purge...............................................................900519

Recirculatorfanmotordriver

Removeandinstall.........................................90103

Recirculatormotor

Removeandinstall.........................................90104

Serviceequipmentandtools..............................90053

Servicepartskits................................................90055

Specifications.....................................................90054

Systeminformation..........................................900517

Temperaturecontroldooractuator

Removeandinstall.........................................90104

Testshaftsealleakage....................................900511

Testvolumetricefficiency...................................90058 Airconditioningsystem(R134a)

Essentialorrecommendedtools........................90051 Airconditioningsystemwithprecleaner

Generalinformation...........................................90102

Airfilter

Restrictionswitch

Removeandinstall.......................................403521

Airintakesystem

Othermaterials..................................................30051

Specifications.....................................................30051 Turbochargerrepair...........................................30052

Airtemperaturesensors

Replace............................................................901012

Alternator

Pulley

Removeandinstall.........................................40453

Removeandinstall............................................40452

Specification.......................................................40451 Alternatorbelt

Removeandinstalll............................................40452

Alternatorrepair

Engineaccessories............................................40452

Armrestcontrolpivot

Removeandinstall..........................................901537 Armrestdisplayunit

Removeandinstall..........................................403016 Auger

Cleangrainloading

Removeandinstall.....................................1302519

Foldingaugerrings

Removeandinstall...................1302014,1302015

Foldinghorizontalauger

Explodedview............................................1302011

Foldinghorizontalaugerpivot

Explodedview............................................1302012

Fronthorizontalunloading

Install..........................................................1302018

Remove....................................1302016,1302017

Horizontalunloading

Elbow

Install......................................................1302029

Remove..................................................1302027

Gearcase

Install......................................................1302024

Remove..................................................1302020

Highunloadrate...........................................130204

Install............................................................130207

Regularunloadrate......................................130203

Remove........................................................130206

Tube

Install......................................................1302025

Remove..................................................1302024

Continuedonnextpage

Outerfoldingaugerassembly

Removeandinstall.....................................1302013

Rearhorizontalfolding

Install..........................................................1302019

Remove......................................................1302015

Augerdrivecountershaft

Install................................................................130102

Remove............................................................130102

Axlebearingsandseals

Removeandinstall..........................................503539

Axleextensiontubes

Install..................................................................50409

B

Backupalarm

9570,9670,9770.............................................403536

9870.................................................................403535

Switch

Removeandinstall.......................................403534

Backlightingdriver

Removeandinstall..........................................403018

Basicelectricalcomponenthandling

Safety.................................................101032,10156

Batteries

Charging............................................................40056

Connectingboosterbatteries.............................40055

Connectingcables.............................................40057

Electricalsystemsafety.....................................40052

Electrolytespecificgravity

Check.............................................................40053

Preventbatteryexplosions.................................40051

Removeandinstall............................................40054

Battery

Replacement......................................................40054

Bearing

Primarycountershaft

Removeandinstall.......................................120109

Rotor

Removeandinstall.....................................1200525

Bearings

Hydrostaticgearset,preload.........................1400546

Belt

Unloadingaugerdrive

Removeandinstall.......................................130101

Beltreplacement

Cleangrainelevator

Remove........................................................130253

Cleangrainelvator

Install............................................................130259

Belts

Adjusting

Feederhousevariablespeed.....................1101565

Bladeinserts

Cleaningfan

Removeandinstall.....................................1202027

Blowermotor

Removeandinstall............................................90103

Boltandscrewtorquevalues

Metric...............................................................101021

Unifiedinch......................................................101022

Brakeassemblies

Tworangeautomatictransmission

Assemble......................................................501535

Disassemble.................................................501530

Install............................................................501541

Remove........................................................501528

Brakedisks

Tworangeautomatictransmission

Checkthickness...........................................601510

Repair...........................................................601511

Brakefluid............................................................102011

Brakefluidreservoir.............................................601011

Brakemodule

Shrinkringinstallationtool

DFHXT5.......................................................199055

Brakepedals,disassembleandassemble

Tworangeautomatictransmission....................60154

Brakes

Assemble...........................................................60108

Bleeding(doublebleedscrew)........................601012

Brakepedals,assemble...................................601016

Brakepedals,disassemble..............................601016

Deglazinglinings................................................60103

Druminstallation................................................60108

Drumremoval....................................................60103

Fluidreservoir..................................................601011

Mastercylinderinstallation.................................60109

Mastercylinderremoval.....................................60109

Mastercylinder,assemble...............................601010

Mastercylinder,disassemble...........................601010

Othermaterial....................................................60101

Parkingpedal,assemble..................................601022

Parkingpedal,disassemble.............................601022

Removebrakeshoe...........................................60104

Repair................................................................60105

Serviceequipmentandtools..............................60101

Slavecylinder,assemble.................................601015

Slavecylinder,disassemble.............................601015

Slavecylinder,install........................................601014

Slavecylinder,remove.....................................601014

Specifications.....................................................60102

Breakinengineoil.................................................10207

Bulb

Cleaningshoelight

Replace..........................................................40256

Frontturnsignal

Taillight

Replacement...............................................40256

Hazard/warninglight

Replace..........................................................40256

Maximumtiltindicator

Replace..........................................................40257

Sidelight

Replacement..................................................40256

Turnsignal

Replace..........................................................40257

Continuedonnextpage

Bulbs

Safetyruleswhenreplacing

Highintensitydischarge(Xenon)...................40251

Bulkhead

Conveyorauger

Removeandinstall.....................................1202011

Rotordrive Alignment.................................................12005102

Cab Install................................................................901522

Operator'sseat

Removeandinstall.......................................901533

Remove..............................................90156,901514

Cabdoor

Disassembleandassemble.............................901548

Latchstriker

Removeandinstall.......................................901549

Removeandinstall..........................................901546

Cabinnerroof

Removeandinstall..........................................901529

Cabpowermodule(CPM)

Removeandinstall............................................40203

Cabroof

Removeandinstall..........................................901528

Camandpistoncarrier

Removeandinstall..........................................503530

Camlobemotor

Controlvalve,disassembleand assemble........................................................503512

Controlvalve,removeandinstall.......................50358

Install..................................................................50358

Othermaterials..................................................50355

Remove..............................................................50357

Serviceequipmentandtools..............................50354

Specifications.....................................................50356

Stackvalveseals

Removeandinstall.......................................503535

Camposition

Sensor

Removeandinstall 13.5L........................................................403525

Careandmaintenanceofbelts

Tuneupandadjustment....................................10152

Carrierbearing

Primarydriveshaft

Replace......................................................1201022

Chaffer

Chafferframe

Removeandinstall

Chafferframe(withselfleveling shoe).....................................................1202056

ChafferFrame

Removeandinstall

Chafferframe(withoutselfleveling shoe).....................................................1202054

Openinggaugecalibration.............................1202030

Page

Withremoteshoe.......................................1202034

Removeandinstall......................1202030,1202034

Chaffer/sieveframeclevis(selfleveling shoe).........................................................1202029

Chain

Cleangrainelevator

Adjustment...................................................130251

Chargeaircooler

Clean..................................................................30055

Removeandinstall............................................30053

Chargehousing

Unloadingauger

Install..........................................................1302033

Remove......................................................1302031

Chargepump

Removeandinstall..........................................501071

Repair..............................................................501073

Chopper

Bladereplacementandconfiguration

9570STS...................................................1201512

9670,9770and9870STS.........................1201514

Rotorbearing(lefthand)

Replace......................................................1201521

Rotorbearing(righthand) Replace......................................................1201523

Chopperraise/loweractuator

Removeandinstall..........................................120158

Cleangrainauger,lower Removeandinstall........................................1302520

Cleangrainelevator Chain

Cleangrainelevatorbeltreplacement

Cleangrainloadingauger

Cleangrainpaddle

Cleangrainpaddlechain

Cleaningfan Actuator Adjust.........................................................1202022

Continuedonnextpage

Remove......................................................1202017

Drivejackshaft

Disassembleandassemble.......................1202019

Removeandinstall........................................1202023

Speedcontrol.................................................1202016

Cleaningfanbearing

Removeandinstall........................................1202012

Cleaningfansheave

Removeandinstall........................................1202012

ClimaTrak

Switch

Airconditioningcontrol

Removeandinstall.....................................40306

Heatercontrol

Removeandinstall.....................................40306

Clutch

Electromagnetic

Header

Explodedview...........................................120353

Header

Removeandinstall.......................................120351

Clutch,slip

Conveyorauger

Removeandinstall.....................................1202010

Coldweatherstartingaid

Removeandinstall............................................30107

Replacecan.......................................................30107

CommandTouchconsole

Consolecontrols..............................................403014

Multifunctionhandle

Removeandinstall.......................................403024

Removeandinstall..........................................403015

Switches

Activeheadercontrol

Removeandinstall...................................403019

DialASpeed

Removeandinstall...................................403019

Compositestylepanels

Repair................................................................80053

Pulledoutstud................................................80053

Ribscracked...................................................80053

Compressorholdingfixture

DFRW20airconditioningsystem.....................199051

Concave

Adjustingmotor

Removeandinstall.....................................1200584

Adjustingtube

Removeandinstall.....................................1200584

Level

Adjust.........................................................1200579

Removeandinstall........................................1200572

Concavepositionsensor

Removeandinstall............................................40359

Condenser

Install..................................................................90107

Remove..............................................................90105

Repair................................................................90107

Connectorrepair

RArepairprocedure.........................................40108

RAErepairprocedure.....................................401039

RAFrepairprocedure.....................................401041

RAGrepairprocedure.....................................401044

RAHrepairprocedure.....................................401046

RAIrepairprocedure......................................401047

RAJrepairprocedure......................................401048

RAKrepairprocedure.....................................401051

RALrepairprocedure.....................................401053

RBrepairprocedure.......................................401012

RCrepairprocedure.......................................401014

RDrepairprocedure.......................................401017

RErepairprocedure.......................................401019

RFrepairprocedure........................................401021

RGrepairprocedure.......................................401024

RIrepairprocedure.........................................401025

RJrepairprocedure........................................401027

RKrepairprocedure.......................................401032

RMrepairprocedure.......................................401034

RNrepairprocedure.......................................401036

Connectors

HandlingandRepair..........................................40107

Console

CommandTouch

Removeandinstall.......................................403015

Consoleswitchpanel

Removeandinstall..........................................403020

Controlcable

Hydrostaticpump.............................................501074 Adjust...........................................................501075

ControlUnits

Programming.....................................................10157

Controlsandinstruments

Identification.......................................................40302

Conveyor Chain

Adjust...........................................................110053

Measurechainwear.....................................110056

Removeandinstall.......................................110054

Chainlink

Remove........................................................110056

Drivechaintightenerandguides

Disassembleandassemble.......................1101564

Drum

Adjustheight...............................................1100510

Removeandinstall....................1100511,1100513

Wearstrips

Replace........................................................110058

Conveyorauger

Bulkhead

Removeandinstall.....................................1202011

Driveshaft

Removeandinstall.......................................120204

Removeandinstall..........................................120207

Slipclutch

Removeandinstall.....................................1202010

Trough

Removeandinstall.......................................120208

Othermaterial....................................................40105 Page

Continuedonnextpage

Conveyorchain

Adjusting..........................................................110054

Conveyorchainslat

Feederhouse

Remove........................................................110057

Coolant

Additionalinformation........................................10206

Dieselengine.....................................................10204

Supplementaladditives......................................10205

Testing................................................................10207

Warmtemperatureclimates...............................10205

Coolanttemperature

Sensor

Removeandinstall.......................................403518

Coolingsystem

Installradiator

9.0L.............................................................201018

Removeradiator

13.5L...........................................................201016

6.8L.............................................201010,201013

9.0L.............................................................201016

Replacethermostats........................................201021

Rotaryscreen

Removeandinstall.........................................20108

Rotaryscreendrive............................................20104

Rotaryscreenknifecomb

Adjust...........................................................201010

Specifications.....................................................20102

Testradiator.....................................................201020

Testradiatorcap..............................................201021

Waterpump

Repairorreplace..........................................201021

Cornerpost

Removedigitaltachometermodule.................403013

Removeheadercontrolmodule.......................403013

RemoveVisionTrakmodule.............................403013

Cornerpostmaincircuitboard

Replace..............................................................40309

Countershaft

Tworangeautomatictransmission

Explodedview..............................................501591

Install............................................................501592

Remove........................................................501587

Repair...........................................................501589

Cover

Separatortop

Removeandinstall.....................................1200513

Cropdiverter

Removeandinstall........................................1201518

Crossaugercountershafthub

Install................................................................130102

Remove............................................................130102

Crossaugercountershaftshearbolt

Install................................................................130102

Remove............................................................130102

Crossaugers

Install..............................................130054,1300510

Remove............................................130051,130057

Cylinder

Headerlift

Disassembleandassemble.....70203, 70204

Steeringcylinder

Disassembleandassemble...........................70209

Unloadingaugerdrive

Removeandinstall.........................................70208

Unloadingaugerswing

Adjust.............................................................70207

Removeandinstall.........................................70205

Unloadingaugerswingcylinder

Explodedview................................................70206

Cylinder,master

Adjust...............................................................601011

Defectivebelts

Tuneupandadjustment....................................10153 Dieselfuel................................................10201,10202 Dieselfuelsystem

Fueltankshutoffvalve

Removeandinstall 9870............................................................30105

Fueltankshutoffvalveanddrainvalve

Removeandinstall

9570,9670,9770........................................30103

Removeandinstallfueltank..............................30101

Dieselfuelsystems

Othermaterials..................................................30101

Specifications.....................................................30101

Differentialmodule

Tworangeautomatictransmission

Assemble......................................................501552 Disassemble.................................................501546 Explodedview..............................................501550 Install............................................................501558 Remove........................................................501543

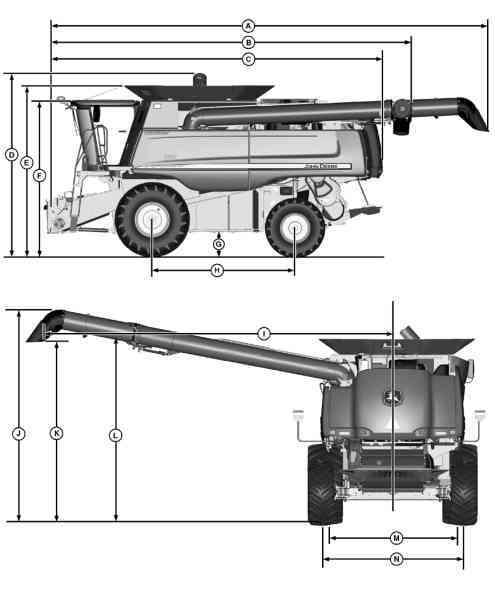

Dimensions

9570STScombine............................................10105

9670STS,9770STS.......................................101013

9870STScombine..........................................101019

Referencepoints

9570STScombine.........................................10106

9670STS,9770STS...................................101014

9870STScombine.......................................101020

Dipsticktube

Disassembleandassemble...........................1400560

Dischargebeater

Dischargebeatergrateframe

Removeandinstall.....................................1200557

Removeandinstall........................................1200561

Wings Removeandinstall.....................................1200561

Dischargebeaterdrivehub

Removeandinstall........................................1200568

Continuedonnextpage

Dischargebeatergrate

Gratesection

Removeandinstall.....................................1200553

Dischargebeaterhousing

Removeandinstall........................................1200568

Displacementcontrolvalve

Removeandinstall..........................................503527

Displayunit

Armrest

Removeandinstall.......................................403016

Domelight

Replace..............................................................40257

Drainoil

Tworangeautomatictransmission..................501514

Drivecylinder

Unloadingauger

Removeandinstall.........................................70208

Drivepump

Disassemble....................................................501039

Reel/belt

Removeandinstall.......................................701015

Drivepump,assemble.........................................501051

Driveshaft

Carrierbearing

Replace......................................................1201022

Primarycountershaftgearcase.....................1201022

Removeandinstall

StyleA....................................................1201015

StyleB....................................................1201018

Removeandinstall

StyleA........................................................1201015

StyleB........................................................1201018

Drivewheel

Bolttorque

Dualwheel......................................................50408

Singlewheel...................................................50407

Drives

Poweredrearwheelassist

Flushing..........................................................50357

Strawchopper

Jackshaft,remove

StyleA....................................................1201524

Dualwheels

Install................................................................504012

Dualwheelsandtrussrod

Install................................................................504012

Elbow

Horizontalunloadingauger

Install..........................................................1302029

Remove......................................................1302027

Unloadingauger

Removeandinstall.....................................1302026

Electrical

Batteries

Preventdamagetoelectrical systems........................................................40052

Safety.............................................................40051

Componenthandlingprecautions......................40106

Visualinspection................................................40106

Electricalsystem

Batteries

Changingbatteries.........................................40056

Operatorsstation

CommandTouchconsoleswitchpanel

Removeandinstall...................................403020

Cornerpostmaincircuitboard

Replace.......................................................40309

Headerandseparatorengageswitch

Removeandinstall...................................403017

Neutralsafetyswitch

Replace.....................................................403022

Sensorsandswitches

GreenStarmassflowsensor

Removeandinstall.....................................40552

Groundspeed

Removeandinstall.....................................40354

Lateraltiltcontrolsensor

Removeandinstall...................................403510

Positionreceiver

Disassembleandassemble......................405525

Removeandinstall...................................405526

Wiper

Windshieldwiper

Adjust..........................................................40404

Wipermotor

Removeandinstall.....................................40401

Electrolytespecificgravity

Checking............................................................40053

Electromagneticclutch

Header

Explodedview..............................................120353

Electronicdisplacementcontrolvalve

Neutraladjustment...........................................501069

Elevator

Cleangrain

Install............................................................130259

Remove........................................................130253

Tailings

Install..........................................................1202519

Remove......................................................1202512

Engine

Flywheel...........................................................200521

Gearcase

Removeandinstall.......................................140058

Install

13.5L...........................................................200519 6.8L...............................................................20056

9.0L.............................................................200512

Remove 13.5L...........................................................200515 9.0L.................................................20053,20059

Repair...................................20053,20103,30052

Enginegearcase

Chopper/unloadingsystemdrive

Disassembleandassemble.......................1400548

Continuedonnextpage

Dipsticktube

Disassembleandassemble.......................1400560

Generalinformatiion.........................................140057

Hydrostaticgearset

Disassembleandassemble.......................1400544

Preloadbearings........................................1400546

Setgearposition........................................1400545

Hydrostaticpumpdrive

Disassembleandassemble.......................1400557

Preloadbearings........................................1400558

Hydrostaticpumpdrivegear

Setbacklash...............................................1400559

Oilfilter

Removeandinstall.....................................1400561

Oilscreen

Disassembleandassemble.......................1400559

Oiltrough

Disassembleandassemble.......................1400560

Pressureregulatingvalve

Disassembleandassemble.......................1400564

Removeandinstall.....................................1400562

Removeandinstall..........................................140058

Separatordrive

Disassembleandassemble.......................1400553

Preloadbearings........................................1400555

Setgearbacklash.......................................1400556

Separatordrivewetclutch

Disassembleandassemble.......................1400534

Separatorgear

Preloadbearings........................................1400552

Setseparatorgearposition............................1400551

Specifications.................................................1400515

Transfergearcase

Disassembleandassemble.......................1400530

Enginegearcaseandvalve

Essentialorrecommendedtools......................140051

Othermaterial..................................................140054

Specifications...................................................140055

Engineoil

BreakIn.............................................................10207

Engineoilpressure

Sensor

Removeandinstall.......................................403524

Enginespeedsensor

Sensor

Removeandinstall.......................................403526

Essentialorrecommendedtools

Accumulator.......................................................70301

Airconditiongsystemcomponents....................90101

Airconditioningsystem(R134a)........................90051

Coolingsystem..................................................20101

Enginegearcaseandvalve.............................140051

Feederhousedrivesandreversergear case................................................................110151

Finaldrives.........................................................50301

Fivespeedfeederhousedrivegear case................................................................110301

Harnessandconnectorrepair......40101, 40451,40501

Horizontalunloadingaugerandgear case................................................................130201

Hydraulicpump..................................................70101

Hydraulicreservoir.............................................70051

Hydraulicvalves.................................................70151

Hydrostaticsystem.............................................50101

Primarycountershaftgearcase.......................120301

SensorsandSwitches.......................................40351

Separatordrives...............................................120101

Separatorrepair...............................................120051

Singlereductionfinaldrive.................................50351

Steering..............................................................60051

Tiresandwheels................................................50401

Topshaftandslipclutch...................................110101

Tworangeautomatictransmission....................50151

Verticalunloadingaugerandlowergear case................................................................130151

Evaporator

Replace..............................................................90109

Evaporatortemperaturesensor

Removeandinstall..........................................901010

Exhaustgasrecirculation

Sensors

Removeandinstall.......................................403527

Exhaustgasrecirculation(EGR)mixedgas temperaturesensor

Sensor

Removeandinstall.......................................403528

Expansionvalve

Replace............................................................901010

Feedaccelerator

Shaft

Remove........................................................120057

Wearstrips

Removeandinstall.....................................1200512 Feedflights

Removeandinstall........................................1200598

Feederhouse

Adjustvariablespeedbelt..............................1101565

Adjusting

Conveyorchain............................................110054 Belt

Fixedspeed

Replace...................................................1101572

Variablespeed

Replace...................................................1101569

Conveyorchain

Adjust...........................................................110053

Measurewear...............................................110056

Removeandinstall.......................................110054

Conveyorchainlink

Remove........................................................110056

Conveyorchainslat

Remove........................................................110057

Conveyordrum

Removeandinstall....................1100511,1100513

Continuedonnextpage

Conveyorwearstrips

Replace........................................................110058

Countershaft

Fixedspeed

Disassembleandassemble....................1101521

Drive

Fivespeedcontrolvalve

Disassembleandassemble........................70157

Drum

Adjust.........................................................1100510

Feedplatesupport

ExplodedView............................................1100524

Fixeddrivesheave

Removeandinstall.....................................1101535

Fixedspeed

Drivetightener

Disassembleandassemble....................1101562

Lowershaft

Removeandinstall.....................................1101560

Midfloorassembly

Removeandinstall...................1100519,1100520

Multicoupler

Disassembleandassemble.........................701516

Inspect..........................................................701516

Mutlispeeddrivebelt

Removeandinstall.....................................1101571

Oilcooler

Removeandinstall.....................................1101537

Othermaterial

Drivesandreversergearcase.....................110152

Tiltframe......................................................110251

Removeandinstall..........................................110052

Reversergearcase........................................1101538

Disassembleandassemble.......................1101539

Oilpump

Disassembleandassemble....................1101553

Removeandinstall.....................................1101536

Reversershiftpiston

Removeandinstall.....................................1101557

Rightforwardvalveblock

Removeandinstall.........................................70155

Singlepointlatching

Levelland

ExplodedView........................................1100520

Specifications

Topshaftandslipclutch...............................110102

Subfloorassembly

Removeandinstall.....................................1100517

Topshaft

Disassembleandassemble........................1101011

Topshaftslipclutch

Disassembleandassemble.........................110103

Install............................................................110106

Remove........................................................110102

Topshaftsupports

Removeandinstall.......................................110107

Variabledrivecountershaft

Disassembleandassemble.......................1101515

Variabledrivesheaves

Cams

Removeandinstall...............1101522,1101533

Repair.....................................................1101526

Feederhousedrivegearcase

Fivespeed

Crosssectional...........................................1103010

Disassemble...............................................1103013

Install............................................................110306

Ouputshaft

Crosssectional.......................................1103012

Feederhousedrivesandreversergearcase

Essentialorrecommendedtools......................110151

Specifications...................................................110153

Feederhouserepair

Conveyor

Conveyorchainslat

Removing..................................................110057

Drumheight

Adjust......................................................1100510

Feederhousedrivesandreversergear case

Conveyordrivechain,tightenerand guides

Disassembleandassemble....................1101564

Fixeddrivesheave

Removeandinstall.................................1101535

Reversergearcase

Removeandinstall.................................1101536

Reversergearcaseoilpump

Disassembleandassemble....................1101553

Variabledrivesheavesandcams

Removeandinstall...............1101522,1101533

Lateraltiltframeandbeam..............................110252

Feederhousereversergearcase

Lubricants........................................................102011

Feederhouse/conveyor

Othermaterial..................................................110051

Specifications...................................................110051

Finaldrive

Assemble...........................................................50308

Disassemble......................................................50308

Removeandinstall............................................50304

Singlereduction

Adjustspindlebearing(alternate method)......................................................503018

Adjustspindlebearing(preferred method)......................................................503017

Finaldrives

Specifications.....................................................50303

Fivespeed

Controlvalve

Disassembleandassemble...........................70157

Fivespeedfeederhousedrivegearcase

Assemble.......................................................1103021

Crosssectional..............................................1103010

Disassemble..................................................1103013

Essentialorrecommendedtools......................110301

Continuedonnextpage

Gear/clutchassemblties

Disassembleandassemble.......................1103018

Outputshaft

Crosssectionalview..................................1103012

Remove............................................................110306

Fivespeedfeederhousegearcase

Othermaterial..................................................110305

Specifications...................................................110305

Flushing

Reel/beltpickupdrivesystem............................70055

Foldingauger Actuator

Removeandinstall.....................................1302013

Foldingaugerrings

Removeandinstall......................1302014,1302015

Foldinghorizontalauger

Auger

Explodedview............................................1302011

Housing

Explodedview..............................................130209

Pivot Explodedview............................................1302012

Foldingunloadingaugerpositionsensor

Removeandinstall..........................................403511

Foreaftframe

Install..............................................................1102514

Foreaftturnbuckles

Adjust..............................................................1102511

Freshairtemperature Sensors

Removeandinstall.......................................403527

Frontbulkhead

Removeandinstall........................................1200588

Frontchafferelement

Elementremoveandinstall............................1202050

Fronthorizontalunloadingauger

Install..............................................................1302018

Remove........................................1302016,1302017

Fuel

Diesel...................................................10201,10202

Handlingandstoring..........................................10201

Lubricity..............................................................10203

Fuelpressure,highandlow

Sensor

Removeandinstall.......................................403522

Fuelpressure,transferpump Sensor

Removeandinstall.......................................403522

Fuelrailpressure Sensor

Removeandinstall 6.8Land9.0Lengines............................403530

Fuelsender

Removeandinstall..........................................403521

Fueltank

Installstrainerandbreather...............................30106

Removeandinstall............................................30101

Sender

Removeandinstall.......................................403521

Fueltankshutoffvalve

Removeandinstall 9870...............................................................30105

Fueltankshutoffvalveanddrainvalve

Removeandinstall

9570,9670,9770...........................................30103

Fueltankstrainerandbreather

Removeandinstall............................................30106

Fueltemperature Sensor

Removeandinstall.......................................403529

Fuelsandlubricants

Transmissionandfinaldrive............................102010

Fullgraintank Sensor

Removeandinstall.........................................40356

Fuseidentification

Panel..................................................................40201

Gearcase

Cleangrainelevator.......................................1302515

Removeandinstall.....................................1302513

Horizontalunloadingauger

Disassembleandassemble.......................1302021 Install..........................................................1302024 Remove......................................................1302020

Primarycountershaft

Disassembleandassemble.........................120304

Gearshiftplanetarydrive

Tworangeautomatictransmission

Tworangeautomatictransmission

Oilrecommendations.....................................10209

Gearshiftleverandlinkage

Removeandinstall..........................................500524

Gearshiftlinkage Adjust...............................................................500525

Generalrepairprocedures

Fivespeedgearcase.......................................110306

Grainsaverdoor

Unloadingauger

Removeandinstall.......................................130205

Graintank

Crossaugers,install......................130054,1300510

Crossaugers,remove......................130051,130057 Explodedview

Continuedonnextpage

Extensions

9560STSand9650STS.............................130304

Highunloadrate...........................................130304

Regularunloadrate......................................130304

Grates

Separator,removeandinstall........................1200571

Grease

Extremepressureandmultipurpose................102011

GreenStar

Massflowsensor

Removeandinstall.........................................40552

Moisturesensor

Actuator

Removeandinstall.....................................40557

Circuitboard

Removeandinstall...................................405510

Disassembleandassemble...........................40556

Lowercellassembly

Removeandreplace.................................405511

Removeandinstall.........................................40554

GreenStarcomponents

Othermaterial....................................................40551

Specifications.....................................................40551

Groundspeed(fastidle)

Twospeedfourwheeldrive

Specification...................................................10101

Groundspeedsensor

Removeandinstall............................................40354

Gullwingdoors

Align...................................................................80055

Othermaterial....................................................80051

Removeandinstall............................................80051

Specifications.....................................................80051

Halogenbulbs

Safetyrules........................................................40251

Handlingbatteriessafely

Safety...................................................10052,40051

Hardwaretorquevalues

Metric...............................................................101021

Unifiedinch......................................................101022

Harness

Replace..............................................................40151

Header Electromagneticclutch

Explodedview..............................................120353

Install............................................................120353

Removal.......................................................120351

Headerandseparatorswitches

Removeandinstall..........................................403017

Headerelectromagneticclutch

Install................................................................120353

Removal...........................................................120351

Headerheightcontrolvalve

Removeandinstall..........................................701515

Headerheightsensor

Removeandinstall..........................................403510

HeaderLiftCylinder

Removeandinstall............................................70202

Headermagneticclutch

Specifications...................................................120351

Headliner

Removeandinstall..........................................901532

Heatercore

Removeandinstall............................................90105

HIDXenonballasts

Removeandinstall............................................40255

HIDXenonlighting

Removeandinstallballast.................................40253

Removeandinstalllight.....................................40253

Highpressureswitch

Replace............................................................901011

Highunloadrate

Horizontalunloadauger...................................130204

Horizontalunloadingauger

Elbow

Install..........................................................1302029

Remove......................................................1302027

Gearcase

Disassembleandassemble.......................1302021

Install..........................................................1302024

Remove......................................................1302020

Inspect.............................................................130202

Install................................................................130207

Remove............................................................130206

Tube Install..........................................................1302025

Remove......................................................1302024

Horizontalunloadingaugerandgearcase

Essentialorrecommendedtools......................130201

Othermaterial..................................................130201

Horn Switch

Removeandinstall.......................................403027

Housing Foldinghorizontalauger

Explodedview..............................................130209

Hub

Crossaugercountershaft

Install............................................................130102

Remove........................................................130102

Hydrauliccylinder

Headerlift

Disassembleandreassemble..70203, 70204

Removeandinstall.........................................70202

Hydrauliccylinders

Specifications.....................................................70201

Hydraulicpump

Assemble...........................................70109,701010

Disassemble......................................................70104

Essentialorrecommendedtools........................70101

Install................................................................701011

Main

Remove..........................................................70102

Mark...................................................................70103

Continuedonnextpage

Othermaterial....................................................70101

Reel/belt

Strawspreader

Explodedview...........................................701014

Seal

Replace..........................................................70105

Serviceequipmentandtools..............................70101

Specifications.....................................................70102

Hydraulicrepair

Hydraulicreservoir

Hydraulicsystem

Flushing......................................................70055

Reel/beltpickupandstrawspreader pump

Assemble..................................................701025

Reel/beltpickupdrivesystem

Flushing......................................................70055

Hydraulicreservoir

Essentialorrecommendedtools........................70051

Removeandinstall............................................70052

Specifications.....................................................70051

Temperaturesensor

Removeandinstall.......................................403518

Hydraulicsystem

Essentialorrecommendedtools........................50101

Flush..................................................................70055

Serviceequipmentandtools..............................50101

Specifications.....................................................50103

Hydraulicvalvestack

Disassambleandassemble.............................701513

Removeandinstall..........................................701511

Hydraulicvalves

Essentialorrecommendedtools........................70151

Othermaterial....................................................70151

Serviceequipmentandtools..............................70151

Hydrochargepressure

Switch

Removeandinstall.......................................403523

Hydrostaticdrivemotor

Controlbodyseals,replace...............................50255

Coverplateseal,replace...................................50254

Essentialorrecommendedtools........................50251

Generalview......................................................50253

Inspectionnotes...............................................502516

Portplate,assemble........................................502511

Portplate,disassemble......................................50257

Removeandinstall............................................50252

Rotarygroup,adjust.........................................502523

Rotarygroup,assemble...................................502518

Rotarygroup,disassemble..............................502513

Specifications.....................................................50251

Hydrostaticdrivepump

Assemble.........................................................502028

Boostpressurevalveseals,replace................502013

Boostpumpseal,replace..................................50208

Cleanpump........................................................50202

Controlpistoncoverseals,replace..................502010

Controlpiston,disassemble.............................502023

Cylinderassembly,disassemble......................502022

Disassemble....................................................502018

Driveshaftseal,replace....................................50205

Generalview......................................................50201

Inspectionnotes...............................................502025

Pressurecutoffvalveseals,replace...............502014

Removeandinstall............................................50203

Rotarygroup,install.........................................502032

Serialnumberplate............................................50202

Specifications.....................................................50201

Swashplateholdingtool

DFHXT3.......................................................199053

Zeroposition,adjust.........................................502036

Hydrostaticgearset

Disassembleandassemble...........................1400544

Preloadbearings............................................1400546

Setgearpositiion...........................................1400545

Hydrostaticmotor

Assemble.........................................................501028

Bearingplate

Inspect..........................................................501019

Cylinderblock

Inspect..........................................................501019

Cylinderblockspring

Replace........................................................501027

Disassemble......................................................50108 Driveshaft

Inspect..........................................................501027

Fixedswashplate

Inspect..........................................................501016

Inspect.............................................................501014 Inspectbearingandrace.................................501026 Inspectservopiston.........................................501026

Motorvalveblock(manifold)

Removeandinstall.......................................501036

Hydrostaticmotorandpump

Hydrostaticpump

Displacementvalvewithfeedrate

Explodedview..............................................501068

Electronicdisplacementcontrolvalve Neutraladjustment.......................................501069

Controlunit,removeandinstall.......................502015 Page

Continuedonnextpage

Endcover

Diassembleandassemble...........................501065

Orings

Replace........................................................501064

Removeandinstall..........................................501038

Hydrostaticpumpdrive

Disassembleandassemble...........................1400557

Hydrostaticpumpdrivebearings

Preload...........................................................1400558

Hydrostaticpumpdrivegear

Setbacklash..................................................1400559

Hydrostaticsystem

Abrasivecontamination....................................501014

Cavitation.........................................................501015

Controlcable

Adjust...........................................................501075

Removeandinstall.......................................501074

Flushing.............................................................50106

Hydrostaticmotor

Disassemble...................................................50108

Fixedswashplate

Inspect......................................................501016

Inspectparts.................................................501014

Removeandinstall.........................................50107

Thrustplate

Inspect......................................................501015

Hydrostaticmotorandpump

Lackoflubrication........................................501014

Motorandpump

Clean..............................................................50106

Overspeeding..................................................501015

Serialnumberplate............................................50106

Specifications.....................................................50104

Startupprocedure...........................................501076

Hydrostaticsystemrepair

Startupprocedure.............................................70056

Inserts

ThreadedRIVNUT

Removeandreplace..................................1200596

Instrumentsandcontrols

Identification.......................................................40302

Intakemanifoldpressuresensor

Sensor

Removeandinstall.......................................403528

Lateraltiltbeam

Removeandinstall..........................................110255

Lateraltiltcylinder

Explodedview..................................................110202

Fittings.............................................................110201

Hoses...............................................................110201

Removeandinstall..........................................110203

Lateraltiltframe

Removeandinstall..........................................110253

Lateraltiltsensor

Removeandinstall..........................................403510

Leaktestingairconditioningsystem

Withdye...........................................................900510

Leftfrontvalveblock

Removeandinstall............................................70153

Leftfrontvavleblock

Disassembleandassemble...............................70154

Leftpowermodule

Removeandinstall............................................40203

Light

Accessdoorworklight,bulb

Replace..........................................................40255

Auxiliaryfieldworklight,bulb

Replace..........................................................40255

Cleaningshoe

Replace..........................................................40256

Dome

Replace..........................................................40257

Frontturnsignal

Tail

Replacement...............................................40256

Hazard/warning,bulb

Replace..........................................................40256

Sidefinder(optional)lightbulb

replacement.....................................................40255

Sidelight

Replacement..................................................40256

Lightpaneldimmer

Switch

Removeandinstall.........................................40304

Light,(InfraRed)

Cabheadlightbulbreplacementand adjustment........................................................40252

Lights

Backlightingdriver

Removeandinstall.......................................403018

Lowpressureswitch

Replace............................................................901011

Lowshaftspeedsensor

Removeandinstall............................................40355

Lowercellassembly

GreenStarmoisturesensor

Removeandreplace....................................405511

Lowergearcase

Verticalauger

Removeandinstall.....................................1201518

Install..........................................................1301513

Continuedonnextpage

Remove........................................................130152

Lowershaft

Feederhouse

Removeandinstall.....................................1101560

Lubricant

Mixing...............................................................102012

Storage............................................................102012

Lubricityofdieselfuel............................................10203 M

Mainhydraulicpump

Install................................................................701011

Remove..............................................................70102

Mastercylinder

Adjust...............................................................601011

Disassembleandassemble.............................601010

Removeandinstall............................................60109

Mechanicaldisplacementcontrolvalve

Neutral,adjust..................................................501075

Metricboltandscrewtorquevalues....................101021

MetricORingTorqueChart

TorqueChartORingMetric.............................101025

Midfloorassembly

Removeandinstall......................1100519,1100520

Mirror

Switch

Removeandinstall.......................................403028

Mirrors

Removeandinstall..........................................403027

Mixinglubricants..................................................102012

Module

Cabpower..........................................................40203

Leftpower..........................................................40203

Removeheadercontrol....................................403013

Rightpower........................................................40203

Motor

Concaveadjust

Removeandinstall.....................................1200584

Motorvalveblock(manifold)

Removeandinstall..........................................501036

Motor,hydrostaticdrive

Controlbodyseals,replace...............................50255

Coverplateseal,replace...................................50254

Essentialorrecommendedtools........................50251

Generalview......................................................50253

Inspectionnotes...............................................502516

Portplate,assemble........................................502511

Portplate,disassemble......................................50257

Removeandinstall............................................50252

Rotarygroup,adjust.........................................502523

Rotarygroup,assemble...................................502518

Rotarygroup,disassemble..............................502513

Specifications.....................................................50251

Multicoupler

Feederhouse

Disassembleandassemble.........................701516

Inspect..........................................................701516

Valveidentification........................................701516

Multifunctionhandle

Feedratesensor

Removeandinstall.......................................403513

Removeandinstall..........................................403024

Neutralsafetyswitch

Replace............................................................403022

O

Oilpressureregulatingvalve

Tworangeautomatictransmission

Disassembleandassemble...........................60156

Oilscreen