tm1926 - 330CLC and 370C Excavator

Technical Manual

Main Sections

Foreword

Technical Information Feedback Form

General Information

Safety

Operational Checkout Procedure

Operational Checkout Procedure

Engine

Theory of Operation

Diagnostic Information

Tests

Electrical System

System Information

System Diagrams

Sub-System Diagnostics

References

Power Train

Theory of Operation

Diagnostic Information

Hydraulic System

Theory Of Operation

Diagnostic Information

Heating and Air Conditioning

Theory Of Operation

Diagnostic Information

Tests

Dealer Fabricated Tools

Dealer Fabricated Tools

Information

Follow Safety Instructions

Operate Only If Qualified

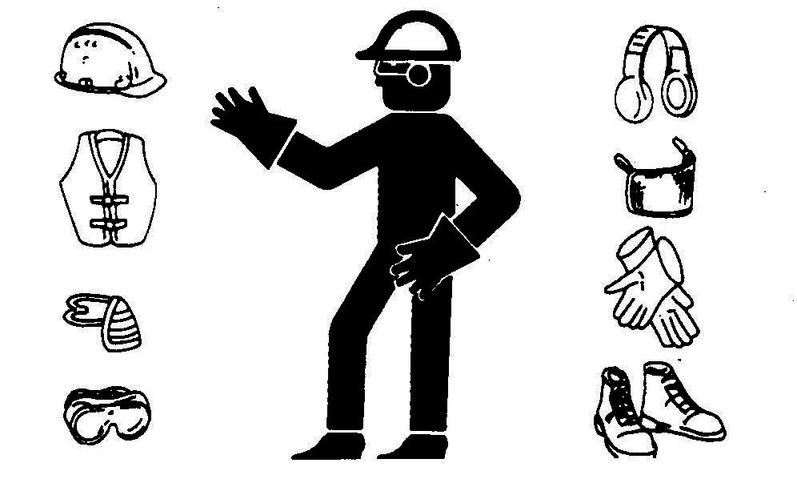

Wear Protective Equipment

Avoid Unauthorized Machine

Modifications Add Cab Guarding for

Special Uses

Inspect Machine

Stay Clear of Moving Parts

Avoid High-Pressure Oils

Beware of Exhaust Fumes

Prevent Fires

Prevent Battery Explosions

Handle Chemical Products Safely

Dispose of Waste Properly

Prepare for Emergencies

Use Steps and Handholds Correctly

Start Only From Operator's Seat

Use and Maintain Seat Belt

Prevent Unintended Machine Movement

Avoid Work Site Hazards

Keep Riders Off Machine

Avoid Backover Accidents

Avoid Machine Tip Over

Use Special Care When Lifting Objects

Add and Operate Attachments Safely

Park and Prepare for Service Safely

Service Cooling System Safely

Remove Paint Before Welding or Heating

Make Welding Repairs Safely

Drive Metal Pins Safely

Engine Speed Control System Operation

Diagnose Engine Malfunctions

Engine Speed Test

Fuel Line Leakage Test

Air Filter Restriction Indicator Switch Test

Air Intake System Leakage Test

Radiator Air Flow Test

Engine Power Test Using Turbocharger Boost Pressure

Electrical Diagram Information

Explanation of Wire Markings

Fuse Specifications

System Functional Schematic and Master Legend

Overall Machine Harnesses Component Location Diagram

Cab Harness (W1) and Alternator Relay Sub-Harness (W11) Component Location Diagram

Cab Harness (W1) and Alternator Relay Sub-Harness (W11) Component Location Diagram Harness Connectors

Engine Harness (W2) Component Location Diagram

Engine Harness (W2) Component Location Diagram Harness Connectors

Monitor Harness (W3) and Windshield Wiper Motor Sub-Harness (W6) Component Location Diagram

Monitor Harness (W3) and Windshield Wiper Motor Sub-Harness (W6) Component Location Diagram Harness Connectors

Air Conditioner and Heater Harness (W7) Component Location

Air Conditioner and Heater Harness (W7) Wiring Diagram

Pump Harness (W12) Component Location Diagram

Pump Harness (W12) Component Location Diagram Harness Connectors

Engine Control Unit Harness (W19) Component Location Diagram

Engine Control Unit Harness (W19) Component Location Diagram Harness Connectors

Engine Control Unit Engine Harness (W20) Component Location Diagram

Engine Control Unit Engine Harness (W20) Component Location Harness Connectors

Fuel Injector Harness (W22) Component Location Diagram

Fuel Injector Harness (W22) Component Location Diagram Harness Connectors Starting

Diagnostic Display Unit (DDU) Operation

Engine Service Codes

Laptop Computer Connection To Engine Control Unit Using Service ADVISOR

Laptop Computer Connection To Pump and Valve Controller Using Service ADVISOR or Excavator Diagnostic Program

Excavator Diagnostic Program General Description and Overview

Reading Service Codes Without Laptop Computer

Monitor Display Diagnostic System Operation

Monitor Data Items

Pump and Valve Controller Service Codes

Alternator Test Procedure

Fuse Test

Pump and Valve Controller Pressure Sensors Test

Pump and Valve Controller Solenoids Test

Pump and Valve Controller Temperature Sensor Test

Engine Control Unit Pressure Sensors and Solenoids Test

Engine Control Unit Temperature Sensors Test

Engine Control Unit Speed Sensors Test

Engine Speed (N) Sensor Test

Electrical Component Checks

Remove and Install Batteries

Remove and Install Propel Alarm Cancel Switch

Remove and Install Key Switch

Remove and Install Travel Alarm

Remove and Install Windshield Wiper Enable Switch

Remove and Install Rear Cover

Remove and Install Switch Panel (A4)

Remove and Install Monitor Controller and Display (A5)

Disconnect Tab Retainer Connectors

Disconnecting Spring Wire Clip Connectors

Replace DEUTSCH DEUTSCH is a trademark of the Deutsch Co Connectors

Install DEUTSCH DEUTSCH is a trademark of the Deutsch Co Contacts

Replace WEATHER PACK WEATHER PACK is a trademark of Packard Electric Connector

Install WEATHER PACK WEATHER PACK is a trademark of Packard Electric Contacts

Remove Connector Body from Blade Terminals

Section 9020: Power Train

Group 05: Theory of Operation

Track Adjuster And Recoil Spring Operation

Propel Gearbox Operation 330CLC (S N 082518)

Propel Gearbox Operation 330CLC (S N 082519 )

Propel Gearbox Operation 370C

Group 15: Diagnostic Information

Diagnose Undercarriage Components Malfunctions

Measure Swing Bearing Wear

Section 9025: Hydraulic System

Group 05: Theory Of Operation

Hydraulic System Diagram and Operation

Pilot System Diagram and Operation

Pilot Pump, Pressure Regulating Valve, and Filter Operation

Pilot Shut-Off Valve Operation

Pilot Controller Operation

Propel Pilot Controller Operation

Flow Regulator Valve and Warm-Up Circuit Operation

Hydraulic Pumps and Drive Gearbox Operation

Hydraulic Pump Regulator Operation

Engine Speed Sensing Control Circuit Operation

Control Valve Operation

Control Valve Check Valves Identification and Operation

System Relief and Power Boost Valve Circuit Operation

Circuit Relief and Anticavitation Valve Operation

Pump Control Valve Operation

Propel Flow Combiner Valve Circuit Operation

Arm Regenerative Valve Circuit Operation

Boom Regenerative Valve Operation

Bucket Regenerative Valve Circuit Operation

Arm Rod End and Boom Reduced Leakage Valves Operation

Arm Head End Reduced Leakage Valve Operation

Boom Manual Lower Needle Valve Operation

Bucket Flow Rate Valve Operation

Propel Flow Rate Valve Operation

Bypass Shut-Off Valve Operation

Swing Gearbox Operation

Swing Motor, Crossover Relief Valve and Make-up Valve Operation

Swing Motor Park Brake Release Valve Operation

Rotary Manifold Operation

Propel Motor and Park Brake Valve Operation 330CLC (S N 082518)

Propel Motor and Park Brake Valve Operation 330CLC (S N 082519 )

Propel Speed Control Circuit Operation 330CLC

Propel Motor and Park Brake Valve Operation 370C

Propel Speed Control Circuit Operation 370C

Cylinder Operation

Hydraulic System Circuit Symbols

Hydraulic System Schematic

Group 15: Diagnostic Information

Diagnostic Procedure

Diagnose Electronic and Control Valve Component Malfunctions

Diagnose Hydraulic System Malfunctions

Diagnose Pilot Circuit Malfunctions

Diagnose Dig Circuit Malfunctions

Diagnose Swing Circuit Malfunctions

Diagnose Propel System Malfunctions

Control Valve Line Identification

Main Hydraulic System Component Location

Pilot Controllers-to-Flow Regulator Valve Component Location Excavator Pattern

Pilot Controllers-to-Flow Regulator Valve Component Location Backhoe Pattern

Pilot Flow Regulator Valve-to-Control Valve Component Location

Propel Hydraulic System Component Location

JT05801 Clamp-On Electronic Tachometer Installation

JT05800 Digital Thermometer Installation

JT02156A Digital Pressure/Temperature Analyzer Installation

Hydraulic Oil Filter Inspection Procedure

Hydraulic Oil Cleanup Procedure Using Portable Filter Caddy

Hydraulic System Warm-Up Procedure

Cylinder Drift Test Boom Arm and Bucket

Pilot Pressure Regulating Valve Test and Adjustment

Control Valve Spool Pilot Actuation Pressure Test

System Relief and Power Boost Valve Test and Adjustment

Arm Reduced Leakage Relief Valve Test And Adjustment

Circuit Relief Valve Test and Adjustment

Swing Motor Crossover Relief Valve Test and Adjustment

Propel Motor Crossover Relief Valve Test and Adjustment 330CLC (S N 082518)

Propel Motor Crossover Relief Valve Test and Adjustment 330CLC (S N 082519 )

Propel Motor Crossover Relief Valve Test and Adjustment 370C

Power Boost Propel Speed and Arm Regenerative Solenoid Valve Test and Adjustment

Pump Control Valve Test

Hydraulic Pump Regulator Test and Adjustment Minimum Flow 330CLC

Hydraulic Pump Regulator Test and Adjustment Minimum Flow 370C

Hydraulic Pump Regulator Test and Adjustment Maximum Flow 330CLC

Hydraulic Pump Regulator Test and Adjustment Maximum Flow 370C

Hydraulic Pump Regulator Test and Adjustment Engine Pulldown

Hydraulic Pump Flow Test

Swing Motor Leakage Test

Propel Motor Leakage Test 330CLC (S N 082518)

Propel Motor Leakage Test 330CLC (S N 082519 )

Propel Motor Leakage Test 370C

Air Conditioning System Cycle Of Operation

Diagnose Air Conditioning System Malfunctions

Diagnose Heater System Malfunctions

Air Conditioner and Heater Diagnostic System Operation

Air Temperature Is Uncontrollable

Vent Control System Is Inoperable

Fresh Air or Recirculated Air Control System is Inoperable

Air Volume is Uncontrollable

Air Conditioner Controller Diagnostic Trouble Codes

21 - Mix Door Open Circuit

-21 - Mix Door Short Circuit

22 - Mode Encoder Open Circuit

23 - In-Cab Ambient Temperature Sensor Open Circuit

-23 - In-Cab Ambient Temperature Sensor Short Circuit

24 - Outdoor Ambient Temperature Sensor Open Circuit

-24 - Outdoor Ambient Temperature Sensor Short Circuit

25 - Coolant Temperature Sensor Open Circuit

-25 - Coolant Temperature Sensor Short Circuit

26 - Solar Radiation Sensor Open Circuit

-26 - Solar Radiation Sensor Short Circuit

Heating and Air Conditioner Component Location

Heating and Air Conditioning System Checks

R134a Air Conditioning System Test

Air Conditioning Compressor Clutch Test

Refrigerant Leak Test

Refrigerant Hoses and Tubing Inspection

Air Conditioner and Heater Sensors Test

Table of Contents

Avoid High-Pressure Oils

Beware of Exhaust Fumes

Prevent Fires

Prevent Battery Explosions

Handle Chemical Products Safely

Dispose of Waste Properly

Prepare for Emergencies

Use Steps and Handholds Correctly

Start Only From Operator's Seat

Use and Maintain Seat Belt

Prevent Unintended Machine Movement

Avoid Work Site Hazards

Keep Riders Off Machine

Avoid Backover Accidents

Avoid Machine Tip Over

Use Special Care When Lifting Objects

Add and Operate Attachments Safely

Park and Prepare for Service Safely

Service Cooling System Safely

Remove Paint Before Welding or Heating

Make Welding Repairs Safely

Drive Metal Pins Safely

Operational Checkout

Operational Checkout

Operational Checkout

Engine Speed Control System Operation

Engine RPM Dial

Hydraulic Oil Warm-up

Engine Speed Control System Operation

Engine RPM Dial

Hydraulic Oil Warm-up

Engine Speed Control System Operation

Engine RPM Dial

Hydraulic Oil Warm-up

Diagnose Engine Malfunctions

Diagnose Engine Malfunctions

Engine Speed Test

Engine Speed Test

Fuel Line Leakage Test

Air

Air

Radiator

Electrical Diagram Information

System Functional Schematic Diagram

Wiring Diagram If Provided

Component Location Diagram

Connector End View Diagram If Provided

Electrical Schematic Symbols

Explanation of Wire Markings247

Explanation of Wire Markings248

Fuse Specifications249

System Functional Schematic and Master Legend251

Overall Machine Harnesses Component Location Diagram259

Cab Harness (W1) and Alternator Relay Sub-Harness (W11) Component Location Diagram261

Cab Harness (W1) and Alternator Relay Sub-Harness (W11) Component Location Diagram

Harness Connectors265

Engine Harness (W2) Component Location Diagram267

Engine Harness (W2) Component Location Diagram Harness Connectors269

Monitor Harness (W3) and Windshield Wiper Motor Sub-Harness (W6) Component Location

Diagram 271

Monitor Harness (W3) and Windshield Wiper Motor Sub-Harness (W6) Component Location

Diagram Harness Connectors274

Air Conditioner and Heater Harness (W7) Component Location276

Air Conditioner and Heater Harness (W7) Wiring Diagram278

Pump Harness (W12) Component Location Diagram279

Pump Harness (W12) Component Location Diagram Harness Connectors281

Engine Control Unit Harness (W19) Component Location Diagram282

Engine Control Unit Harness (W19) Component Location Diagram—Harness Connectors284

Engine Control Unit Engine Harness (W20) Component Location Diagram286

Engine Control Unit Engine Harness (W20) Component Location Harness Connectors288

Fuel Injector Harness (W22) Component Location Diagram289

Fuel Injector Harness (W22) Component Location Diagram Harness Connectors290

Starting and Charging Circuit Theory of Operation291

Starting and Charging Circuit Theory of Operation293

Travel Alarm Circuit Theory of Operation295

Monitor Controller and Display Circuit Theory of Operation297

HOUR METER AND GAUGES

STATUS INDICATORS

Air Filter Restriction Indicator Light (H33)

Fuel Level Indicator Light (H13)

Engine Coolant Temperature Indicator Light (H32) Engine Coolant Temperature Gauge Sender (B9) Engine Oil Pressure Indicator Light (H17)

Engine Coolant Level Indicator Light (H11)

Engine Oil Level Indicator Light (H19)

Alternator Voltage Indicator Light (H18)

Monitor Controller and Display Alarm (H8)

Check Engine Indicator Light (H10)

CONTROL SWITCHES AND INDICATORS

Windshield Wiper and Washer Switch (S9)

Work Light Switch (S6)

Propel Speed Switch (S8) Auto-Idle/Auto-

Acceleration Switch (S13)

(S12)

Engine Control Unit Circuit Theory of Operation

High Pressure Fuel Pump (Solenoid 1) (Y7) and High

Electronic Fuel Injectors (Y11 Y16)

Pump and Valve Controller Circuit Theory of Operation

Pump and Valve Controller (A7)

Pump and Valve Controller Sensors

Pump and Valve Controller Solenoids

Fuel Pump (Solenoid 2) (Y8)

Windshield Wiper And Washer Circuit Theory of Operation

Air Conditioner and Heater Controller Circuit Theory of Operation

Diagnostic Display Unit (DDU) Operation

Accessing Menu

Viewing Active Service Codes

Access Stored Codes

Clearing Active Or Stored Service Codes From Diagnostic Display Unit Memory

Diagnostic Display Unit (DDU) Operation

Accessing Menu

Viewing Active Service Codes

Access Stored Codes

Clearing Active Or Stored Service Codes From Diagnostic Display Unit Memory

Engine Service Codes

Laptop Computer Connection To Engine Control Unit Using Service ADVISOR

Laptop Computer Connection To Pump and Valve Controller Using Service ADVISOR or

Excavator Diagnostic Program

Excavator Diagnostic Program General Description and Overview

Troubleshooting Reading

12 V

24 V

Pump and Valve Controller Pressure Sensors Test

Pump and Valve Controller Solenoids Test

Pump and Valve Controller Temperature Sensor Test

Engine Control Unit Pressure Sensors and Solenoids Test

Engine Control Unit Temperature Sensors Test

Engine Control Unit Speed Sensors Test

Engine Speed (N) Sensor Test

Electrical Component Checks

Remove and Install Batteries

Table of Contents

Remove and Install Rear Cover

Remove and Install Switch Panel (A4)

Remove and Install Monitor Controller and Display (A5)

Disconnect Tab Retainer Connectors

Disconnecting Spring Wire Clip Connectors

Replace DEUTSCH ™ Connectors

Install DEUTSCH ™ Contacts

Replace WEATHER PACK ™ Connector

Install WEATHER PACK ™ Contacts

Remove Connector Body from Blade Terminals

Track Adjuster And Recoil Spring Operation

Track Adjuster And Recoil Spring Operation

Track Adjuster And Recoil Spring Operation

Propel Gearbox Operation 330CLC (S.N. 082518)

Propel Gearbox Operation 330CLC (S.N. 082519 )

Propel Gearbox Operation 370C

Diagnose Undercarriage Components Malfunctions

Diagnose Undercarriage Components Malfunctions

Measure

Hydraulic System

Hydraulic

Hydraulic

Hydraulic

Hydraulic System Diagram and Operation

Hydraulic Oil Return Filter

Pilot System Diagram and Operation

Pilot Pump, Pressure Regulating Valve, and Filter Operation

Pilot Shut-Off Valve Operation

Pilot Controller Operation

Propel Pilot Controller Operation

Flow Regulator Valve and Warm-Up Circuit Operation

Flow Regulator Valve

Warm-Up

Hydraulic Pump Regulator Component Identification

Hydraulic Pump Regulator Control by Pump 1 (Front) and Pump 2 (Rear) Control Valve

Decreasing Flow Rate (Displacement)

Hydraulic Pump Regulator Control By Supply Oil Pressure

Hydraulic Pump Regulator Control By Speed Sensing Pilot Oil

Engine Speed Sensing Control Circuit Operation

Control Valve Operation

Control Valve Check Valves Identification and Operation

System Relief and Power Boost Valve Circuit Operation

Boost and Auto-Power Lift Control Circuit Operation Power Boost Solenoid Valve (SG)

Circuit Relief and Anticavitation Valve Operation

Pump Control Valve Operation

Propel Flow Combiner Valve Circuit Operation

Table of Contents

Arm Regenerative Valve Circuit Operation

Arm Regenerative Solenoid Valve (SC)

Boom Regenerative Valve Operation

Bucket Regenerative Valve Circuit Operation

Arm Rod End and Boom Reduced Leakage Valves Operation

Arm Head End Reduced Leakage Valve Operation

Boom Manual Lower Needle Valve Operation

Bucket Flow Rate Valve Operation

Propel Flow Rate Valve Operation

Bypass Shut-Off Valve Operation

Swing Gearbox Operation

Swing Motor, Crossover Relief Valve and Make-up Valve Operation

Swing Motor Park Brake Release Valve Operation

Rotary Manifold Operation

Propel Motor and Park Brake Valve Operation 330CLC (S.N. 082518)

Propel Motor and Park Brake Valve

Propel Motor Slow and Fast Speed

Propel Motor Park Brake Release Circuit

Propel Motor Counterbalance Valve

Propel Motor and Park Brake Valve Operation 330CLC (S.N. 082519 )

Propel Motor Slow Speed Operation

Propel Motor Fast Speed Operation

Propel Speed Solenoid Valve (SI)

Propel Motor and Park Brake Valve Operation 370C

Propel Motor and Park Brake Valve Housing

Propel Motor and Park Brake Valve Components

Propel Motor Slow Speed Operation

Propel Motor Fast Speed Operation

Counterbalance Valve

Propel Motor Crossover Relief Valves

Propel Motor Park Brake

Propel Speed Control Circuit Operation 370C

Propel Speed Control Circuit Operation—330CLC Cylinder Operation

Pilot Controllers-to-Flow Regulator Valve Component Location Excavator Pattern

Pilot Controllers-to-Flow Regulator Valve Component Location Backhoe Pattern

JT05801 Clamp-On Electronic Tachometer Installation

JT05801 Clamp-On Electronic Tachometer Installation

JT05800 Digital Thermometer Installation

JT02156A Digital Pressure/Temperature Analyzer Installation

Hydraulic Oil Filter Inspection Procedure

Hydraulic Oil Cleanup Procedure Using Portable Filter Caddy

Hydraulic System Warm-Up Procedure

Cylinder Drift Test Boom, Arm and Bucket

Pilot Pressure Regulating Valve Test and Adjustment

Control Valve Spool Pilot Actuation Pressure Test

System Relief and Power Boost Valve Test and Adjustment

Arm Reduced Leakage Relief Valve Test And Adjustment

Circuit Relief Valve Test and Adjustment

Swing Motor Crossover Relief Valve Test and Adjustment

Propel Motor Crossover Relief Valve Test and Adjustment 330CLC (S.N. 082518)

Propel Motor Crossover Relief Valve Test and Adjustment 330CLC (S.N. 082519 )

Propel Motor Crossover Relief Valve Test and Adjustment 370C

Power Boost, Propel Speed, and Arm Regenerative Solenoid Valve Test and Adjustment

Pump Control Valve Test

Hydraulic Pump Regulator Test and Adjustment—Minimum Flow—330CLC

Hydraulic Pump Regulator Test and Adjustment Minimum Flow 370C

Hydraulic Pump Regulator Test and Adjustment Maximum Flow 330CLC

Hydraulic Pump Regulator Test and Adjustment Maximum Flow 370C

Hydraulic Pump Regulator Test and Adjustment Engine Pulldown

Hydraulic Pump Flow Test

Swing Motor Leakage Test

Propel Motor Leakage Test—330CLC (S N —082518)

Propel Motor Leakage Test 330CLC (S N 082519 )

Propel Motor Leakage Test 370C

Air Conditioning System Cycle Of Operation

Air Conditioning System Cycle Of Operation

Air Conditioning System Cycle Of Operation

Diagnose Air Conditioning System Malfunctions

Diagnose Air Conditioning System Malfunctions

Diagnose

Air Conditioner Controller Diagnostic Trouble Codes

Heating and Air Conditioner Component Location

Heating and Air Conditioning System Checks Table of

R134a Air Conditioning System Test

Air Conditioning Compressor Clutch Test

Refrigerant Leak Test

Refrigerant Hoses and Tubing

Inspection Air Conditioner and Heater

Sensors Test DFT1218 Split Flange

Hose Cap DFT1218 Split Flange Hose Cap DFT1218