Introduction

Foreword

Thismanualiswrittenforanexperiencedtechnician. Essentialtoolsrequiredinperformingcertainservice workareidentifiedinthismanualandare recommendedforuse.

Livewithsafety:Readthesafetymessagesinthe introductionofthismanualandthecautionspresented throughoutthetextofthemanual.

Thisisthesafety-alertsymbol.Whenyouseethis symbolonthemachineorinthismanual,bealertto thepotentialforpersonalinjury.

Technicalmanualsaredividedintwoparts:repairand operationandtests.Repairsectionstellhowtorepair thecomponents.Operationandtestssectionshelpyou identifythemajorityofroutinefailuresquickly.

Informationisorganizedingroupsforthevarious componentsrequiringserviceinstruction.Atthe beginningofeachgrouparesummarylistingsofall applicableessentialtools,serviceequipmentandtools, othermaterialsneededtodothejob,servicepartskits, specifications,weartolerances,andtorquevalues.

TechnicalManualsareconciseguidesforspecific machines.Theyareon-the-jobguidescontainingonly thevitalinformationneededfordiagnosis,analysis, testing,andrepair.

Fundamentalserviceinformationisavailablefrom othersourcescoveringbasictheoryofoperation, fundamentalsoftroubleshooting,generalmaintenance, andbasictypeoffailuresandtheircauses.

DX,TMIFC–19–29SEP98–1/1

SECTION10—General Group16—HydraulicValveStack(S.N.—715300) Group17—HydraulicValveStack(S.N.715301—)

Group05—Safety Group10—SpecificationsGroup20—HydraulicCylinders Group25—Motors Group15—Tune-UpandAdjustment Group20—FuelsandLubricantsGroup30—Accumulator

SECTION20—Engine

SECTION80—SeparatorShell Group05—RemoveandInstallEngine Group05—GullWingDoors Group10—CoolingSystem Group15—LowerEngineRepair

SECTION90—OperatorStationRepair Group05—AirConditioningSystem(R134a)

SECTION30—FuelandAirRepair Group10—SystemComponents Group05—AirIntakeSystem Group15—Cab Group10—DieselFuelSystem

SECTION40—ElectricalSystem

SECTION110—FeederHouseRepair

Group05—Conveyor Group05—Batteries Group10—TopShaftandSlipClutch Group10—HarnessandConnectorRepair Group15—FeederHouseDrivesandReverser Group15—WireHarnessRouting GearCase Group20—Fuses,CircuitBreakersandRelays Group20—CONTOURMASTERTiltCylinder Group25—Lighting Group25—CONTOURMASTERTiltFrame Group30—OperatorsStation Group35—SensorsandSwitches

SECTION120—Separator Group40—Wiper Group05—SeparatorRepair Group45—Alternator Group10—SeparatorDrives Group50—StartingMotor Group15—ResidueDisposal Group55—ElectricalEngineControl

Group20—ConveyorAugers,CleaningFanAnd Group60—GREENSTARComponents ChafferAndSieveFrame Group25—TailingsElevatorandAugers

SECTION50—PowerTrainRepair Group30—PrimaryCountershaftGearCase

Group05—TransmissionandDifferential Group35—HeaderElectromagneticClutch Group10—SingleReductionFinalDrive—Heavy Duty

Group15—HydrostaticSystem

SECTION130—GrainTankandUnloadingSystem Group20—CamLobeMotor Repair Group25—TiresandWheels Group05—GrainTankCrossAugers Group10—UnloadingAugerSystemDrives

SECTION60—PowerSteeringandBrakes

Group15—VerticalUnloadingAugerandLower Group05—Steering GearCase Group10—Brakes Group20—HorizontalUnloadingAugerandGear Case Group25—CleanGrainElevator

SECTION70—HydraulicRepair Group05—HydraulicReservoirGroup30—GrainTankandExtensions Group10—HydraulicPumps Group15—HydraulicValves

Allinformation,illustrationsandspecificationsinthismanualarebasedon thelatestinformationavailableatthetimeofpublication.Therightis reservedtomakechangesatanytimewithoutnotice.

Group05—Safety 10-05-1

SAEFourBoltFlangeCapScrewTorque Values—HighPressureApplications ...... 10-10-36 ExternalHexagonPortPlugTorqueChart...10-10-37

Group10—Specifications PreventHydraulicSystemContamination 10-10-38

GroundSpeeds(FastIdle)TwoSpeedFour CheckOilLinesandFittings 10-10-39 WheelDrive 10-10-1

BasicElectricalComponentHandling/ TurningRadius ......................... 10-10-2 PrecautionsForVehiclesEquippedWith

Specifications—9560STSCombine 10-10-5

OperatingSpeeds—9560STS ............. 10-10-3 ComputerControlledSystems 10-10-40

Dimensions—9560STSCombine 10-10-7

Group15—Tune-UpandAdjustment

DimensionReferencePoints—9560STS Tune-UpandAdjustment 10-15-1 Combine 10-10-8 CareandMaintenanceofBelts 10-15-2

OperatingSpeeds—9660STS,9760STS DefectiveBelts 10-15-4 Combines 10-10-9

Specifications—9660STSCombine 10-10-11

Specifications—9760STSCombine 10-10-13

Dimensions—9660STS,9760STS

Group20—FuelsandLubricants HandleFuelSafely—AvoidFires ............ 10-20-1

DimensionReferencePoints—9660STS, 9760STSCombines 10-10-17Bio-DieselFuel

OperatingSpeeds—9860STSCombine 10-10-18

Specifications—9860STSCombine(S.N.—TestingDieselFuel

715700) 10-10-20

Specifications—9860STSCombine(S.N.OperatinginWarmTemperatureClimates

SupplementalCoolantAdditives 10-20-7 715701—) 10-10-22

Dimensions—9860STSCombine 10-10-24AdditionalInformationAboutDiesel EngineCoolantsandSupplementalCoolant DimensionReferencePoints—9860STS Combine ........................... 10-10-25Additives

MetricBoltandScrewTorqueValues ....... 10-10-26

UnifiedInchBoltandScrewTorqueDieselEngineBreak-InOil 10-20-10 DieselEngineOil 10-20-11 Values 10-10-27

SealantsandAdhesivesCross-ReferenceExtendedDieselEngineOilService Intervals 10-20-12 Chart 10-10-28

FaceSealFittingsAssemblyandOILSCANandCOOLSCAN 10-20-12 HydrostaticDriveSystem,MainHydraulic Installation—AllPressureApplications 10-10-29

MetricFaceSealFittingTorqueSystemandMainEngineGearCase Oils ............................... 10-20-13 Chart—StandardPressureApplications .... 10-10-30

MetricFaceSealFittingTorqueChart—HighTransmission,FinalDrives,FeederHouse Reverser,LoadingAuger,Primary PressureApplications ................. 10-10-31

SAEFaceSealFittingTorqueCountershaftandTwo-SpeedSeparator DriveGearCases 10-20-14 Chart—StandardPressureApplications 10-10-32

SAEFaceSealFittingTorqueChart—HighGrease 10-20-15 BrakeFluid 10-20-15 PressureApplications 10-10-33

FourBoltFlangeFittingsAssemblyandLubricantStorage 10-20-16 AlternativeandSyntheticLubricants 10-20-16 Installation—AllPressureApplications 10-10-34

SAEFourBoltFlangeCapScrewTorque Continuedonnextpage Values—StandardPressureApplications...10-10-35

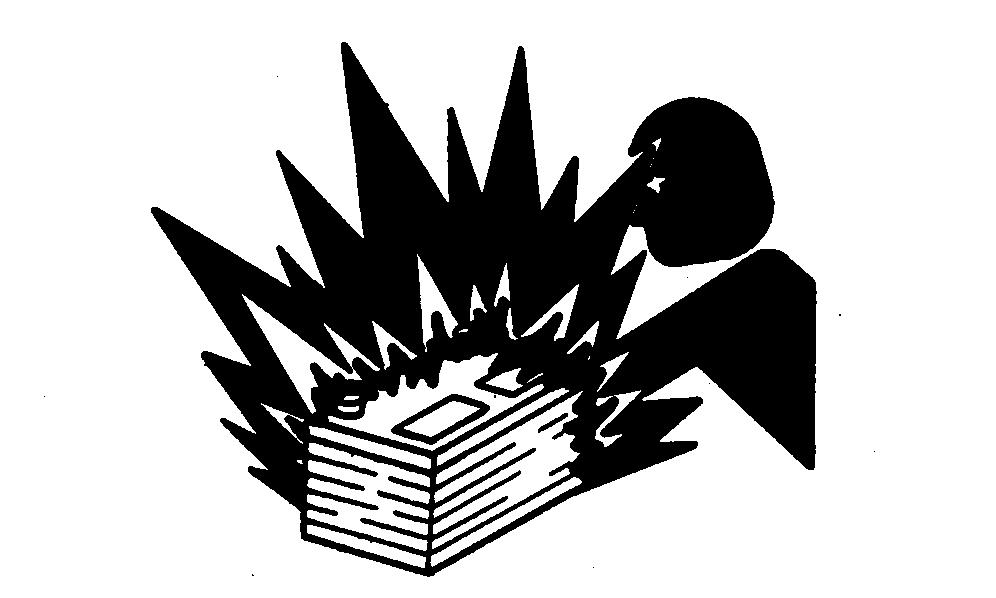

PreventBatteryExplosions

Keepsparks,lightedmatches,andopenflameawayfrom thetopofbattery.Batterygascanexplode.

Nevercheckbatterychargebyplacingametalobject acrosstheposts.Useavolt-meterorhydrometer.

Donotchargeafrozenbattery;itmayexplode.Warm batteryto16°C(60°F).

AvoidHeatingNearPressurizedFluidLines

Flammablespraycanbegeneratedbyheatingnear pressurizedfluidlines,resultinginsevereburnsto yourselfandbystanders.Donotheatbywelding, soldering,orusingatorchnearpressurizedfluidlinesor otherflammablematerials.Pressurizedlinescan accidentallyburstwhenheatgoesbeyondtheimmediate flamearea.

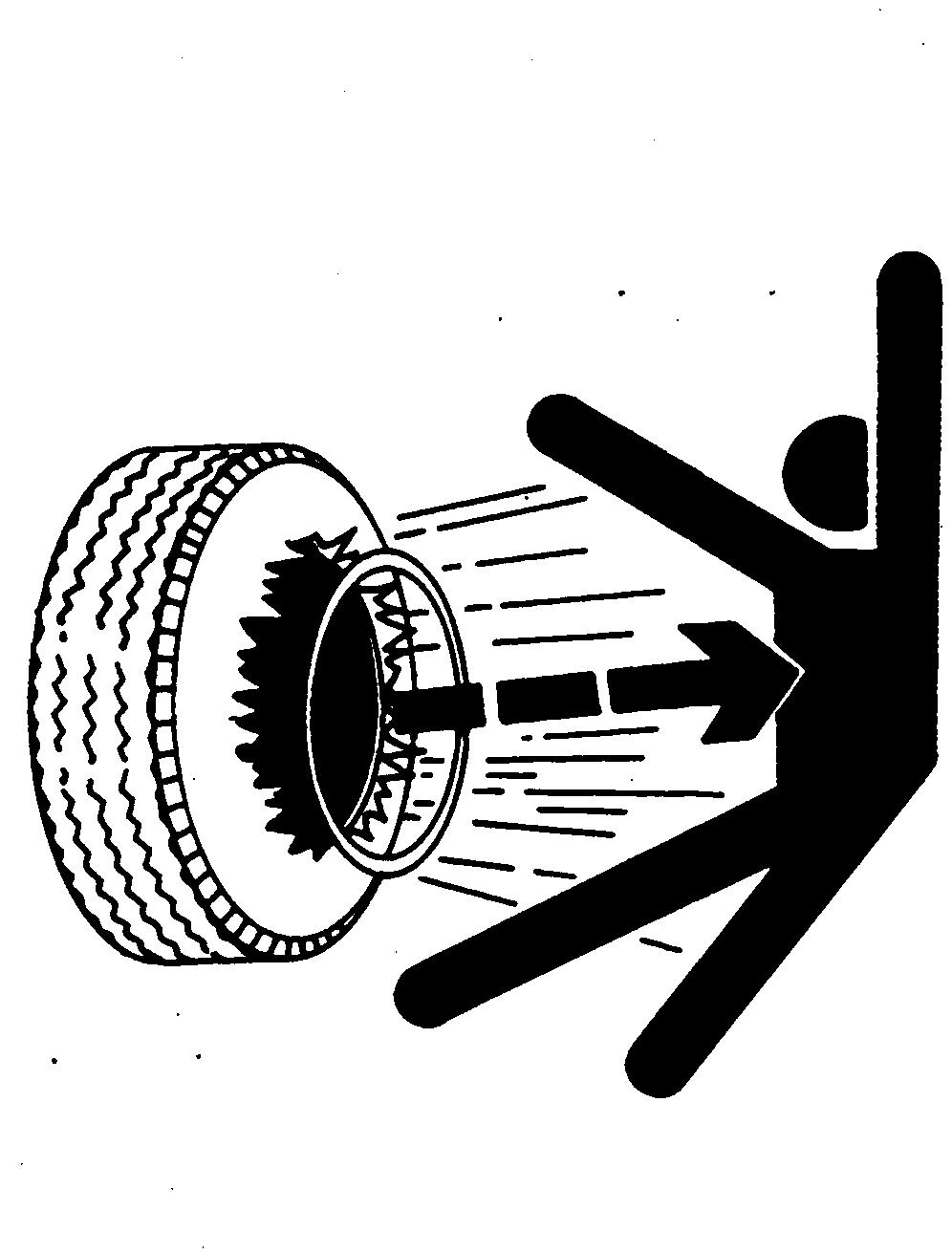

ServiceTiresSafely

Explosiveseparationofatireandrimpartscancause seriousinjuryordeath.

Donotattempttomountatireunlessyouhavetheproper equipmentandexperiencetoperformthejob.

Alwaysmaintainthecorrecttirepressure.Donotinflate thetiresabovetherecommendedpressure.Neverweldor heatawheelandtireassembly.Theheatcancausean increaseinairpressureresultinginatireexplosion. Weldingcanstructurallyweakenordeformthewheel.

Wheninflatingtires,useaclip-onchuckandextension hoselongenoughtoallowyoutostandtoonesideand NOTinfrontoforoverthetireassembly.Useasafety cageifavailable.

Checkwheelsforlowpressure,cuts,bubbles,damaged rimsormissinglugboltsandnuts.

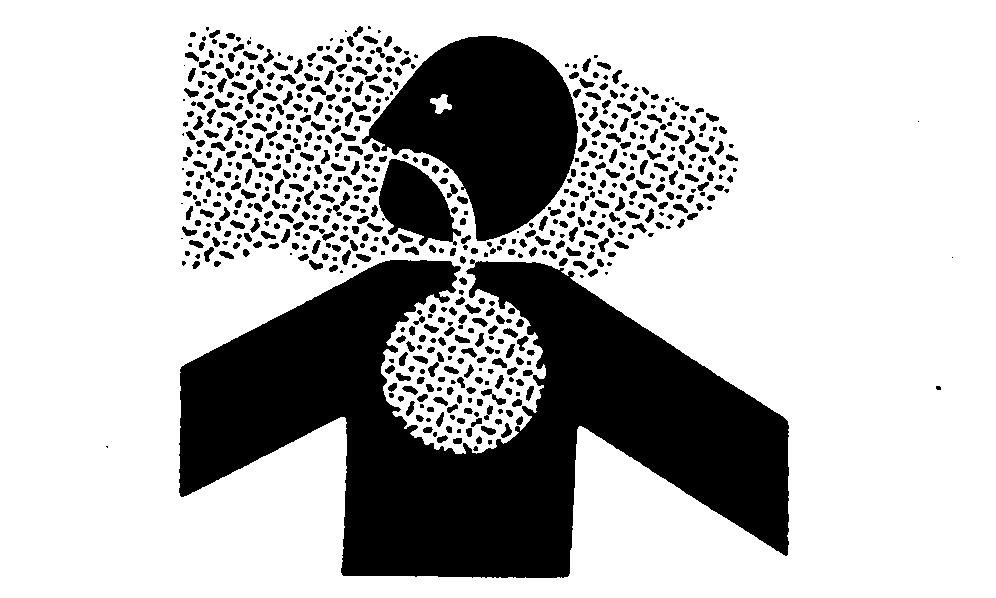

AvoidHarmfulAsbestosDust

Avoidbreathingdustthatmaybegeneratedwhen handlingcomponentscontainingasbestosfibers.Inhaled asbestosfibersmaycauselungcancer.

Componentsinproductsthatmaycontainasbestosfibers arebrakepads,brakebandandliningassemblies,clutch plates,andsomegaskets.Theasbestosusedinthese componentsisusuallyfoundinaresinorsealedinsome way.Normalhandlingisnothazardousaslongas airbornedustcontainingasbestosisnotgenerated.

Avoidcreatingdust.Neverusecompressedairfor cleaning.Avoidbrushingorgrindingmaterialcontaining asbestos.Whenservicing,wearanapprovedrespirator.A specialvacuumcleanerisrecommendedtoclean asbestos.Ifnotavailable,applyamistofoilorwateron thematerialcontainingasbestos.

Keepbystandersawayfromthearea.

DX,DUST–19–15MAR91–1/1

3.RemovelocknutusingJDG666spannerwrench.

4.Removegearfromhousing.

5.Inspectparts.Repairasnecessary.

PreloadHydrostaticPumpDriveBearings

1.Assemblekeyedwasheroverhubofspiralbevelgear andnexttobearingcone.

2.ScrewlocknutusingJDG666SpannerWrenchonto spiralbevelgearhubwithchamferedsideagainst keyedwasher.Tightennuttospecificationtoprovide endplayinbearing.

Specification

HydrostaticPumpDriveGear— EndPlay0.33to0.43mm (0.010to0.020in.) +1/4turntopreload

3.Rapeachendofgearlightlywithsofthammerand rotategearatleastfiverevolutionsbeforetakingend playorrollingtorquemeasurements.Tightennut90 degrees(1/4turn).

4.Assemblelockwasheroverhubofspiralbevelgear withconcavesideoutward.Ifnowashertabalignswith aslotinnut,tightennuttonearestslotalignment.

5.InstalllocknutusingJDG666SpannerWrenchwith chamferedsideagainstlockwasher.

6.Withnutsnugagainstwasher,bendonetabofwasher intoaslotofinnernut.Tightenouternutto specification.

Specification

HydrostaticPumpDriveOuter Nut—Torque70N•m (52lb-ft)

Rollingtorquemustnotexceedspecification.

Specification

HydrostaticDrivePump—Rolling DragTorque28N•cm (40oz-in.)

Ifrollingtorqueistoohigh,removeouternutandlock washerandbackoffinnernut45degrees(1/8turn). Repeatinstallationandadjustment.

Finalassemblymustprovidezeroendplayandlessthan 28N•cm(40oz-in.)rollingtorque.

7.Bendonetabtolockwasherintoslotofouternut.

SetHydrostaticPumpDriveGearBacklash

NOTE:Donotusemorethanoneplasticshim.

1.Selectshimstoprovidebacklash(dimensiononendof smallergearto+0.1to-0.0mm(+0.004to-0.0in.)at tightestconditionofgearmesh.

2.InstallshimsandO-ringonpilotdiameterofbearing housing.Tightencapscrewstospecification.

Specification

HydrostaticPumpDrive-to-Gear CaseCapScrews—Torque50N•m (40lb-ft)

Shimsavailableare:

• 0.08mm(0.003in.)

• 0.13mm(0.005in.)

• 0.25mm(0.010in.)

• 0.50mm(0.020in.)

AG,OUO6022,379–19–25JUL00–2/2

AG,OUO6022,380–19–25JUL00–1/1

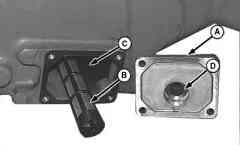

EngineGearCaseandValve

DisassembleandAssembleOilScreen

NOTE:Whenevergears,shafts,orbearingshavebeen replaced,cleanoilscreen.

1.Removecover(A)withgasket.

2.Cleanoilscreen(B).

3.Thoroughlycleansumparea(C).

4.Installoilscreen.Besureclosedendofscreenfitsin recessonoppositeside.Pilot(D)mustbeDOWNto positionscreenlowinsump.Tightencoverboltsto specification.

Specification

EngineGearCaseOilScreen

CoverCapScrews—Torque25N•m (216lb-in.)

A—Cover B—OilScreen

C—Reservoir D—Pilot

DisassembleandAssembleOilTrough

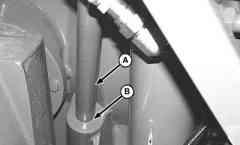

1.Removeoiltrough(A)withcover(B).

IMPORTANT:Correctlocknutsmustbeusedoncap screws(C).Standardnutsmaycome loose,fallintogearcaseandcause damage.

IMPORTANT:Becertaintroughisattachedtocover asshownoroilwillnotbedeliveredto bearings.

2.Replaceifdamaged.

3.Applyathinbeadofsealantallaroundsurface(D).

4.Installoiltrough.Tightencapscrewstospecification.

Specification

OilTroughCoverCapScrews— Torque25 ± 5N•m (221 ± 44lb-in.)

A—OilTrough B—Surface C—Cover D—Surface

DisassembleandAssembleDipstickTube

NOTE:Removedipsticktubeonlyifdamaged.

1.Removedipsticktube(A).Tubeisatightfit.

2.Applyacoatofthreadlockandsealerinbore(B).

3.Driveintubeuntilitseats.

A—DipstickTube B—Bore

RemoveandInstallFilter

1.Turnfilter(A)counterclockwiseandremove.

2.Installfilter(A).

3.FillgearcasewithSAE10Woil.Filltocapacity.

AG,OUO6022,297–19–05AUG05–1/1

4.Checkoillevelafterengagingdrives.

OUO6083,0000075–19–21MAY01–1/1

RemoveandInstallPressureRegulating Valve

CAUTION:Escapingfluidunderpressurecan penetratetheskincausingseriousinjury.Avoid thehazardbyrelievingpressurebefore disconnectinghydraulicorotherlines.Tighten allconnectionsbeforeapplyingpressure. Searchforleakswithapieceofcardboard. Protecthandsandbodyfromhighpressure fluids.

Ifanaccidentoccurs,seeadoctorimmediately. Anyfluidinjectedintotheskinmustbe surgicallyremovedwithinafewhoursor gangrenemayresult.Doctorsunfamiliarwith thistypeofinjurymaycallDeere&Company MedicalDepartmentinMoline,Illinois,orother knowledgeablemedicalsource.

1.Fullylowerheaderandreeltogroundandcontinueto depressswitchfor5secondstorelievehydraulic systempressure.Shutoffengineandclose accumulator.Removekey.

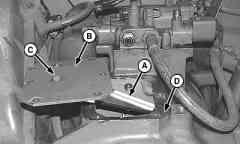

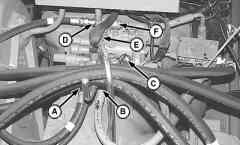

2.Disconnectlines(A—F).

3.Disconnectwiresleads(G—J).

4.Removecapscrews(K)andremovevalve.

5.Inspectforwearordamage.Replaceasnecessary.

NOTE:Donotusesealerongasket.

6.Installvalve.Tightencapscrewstospecification.

Specification

PressureRegulatingValveCap Screws—Torque25N•m (216lb-in.)

7.Connectwires(G—J).

8.Connectlines(A—F).

A—HydraulicHose

B—HydraulicHose

C—HydraulicHose

D—HydraulicHose

E—HydraulicHose

F—HydraulicHose

G—Connector

H—Connector

I—Connector

J—Connector K—CapScrews(7used)

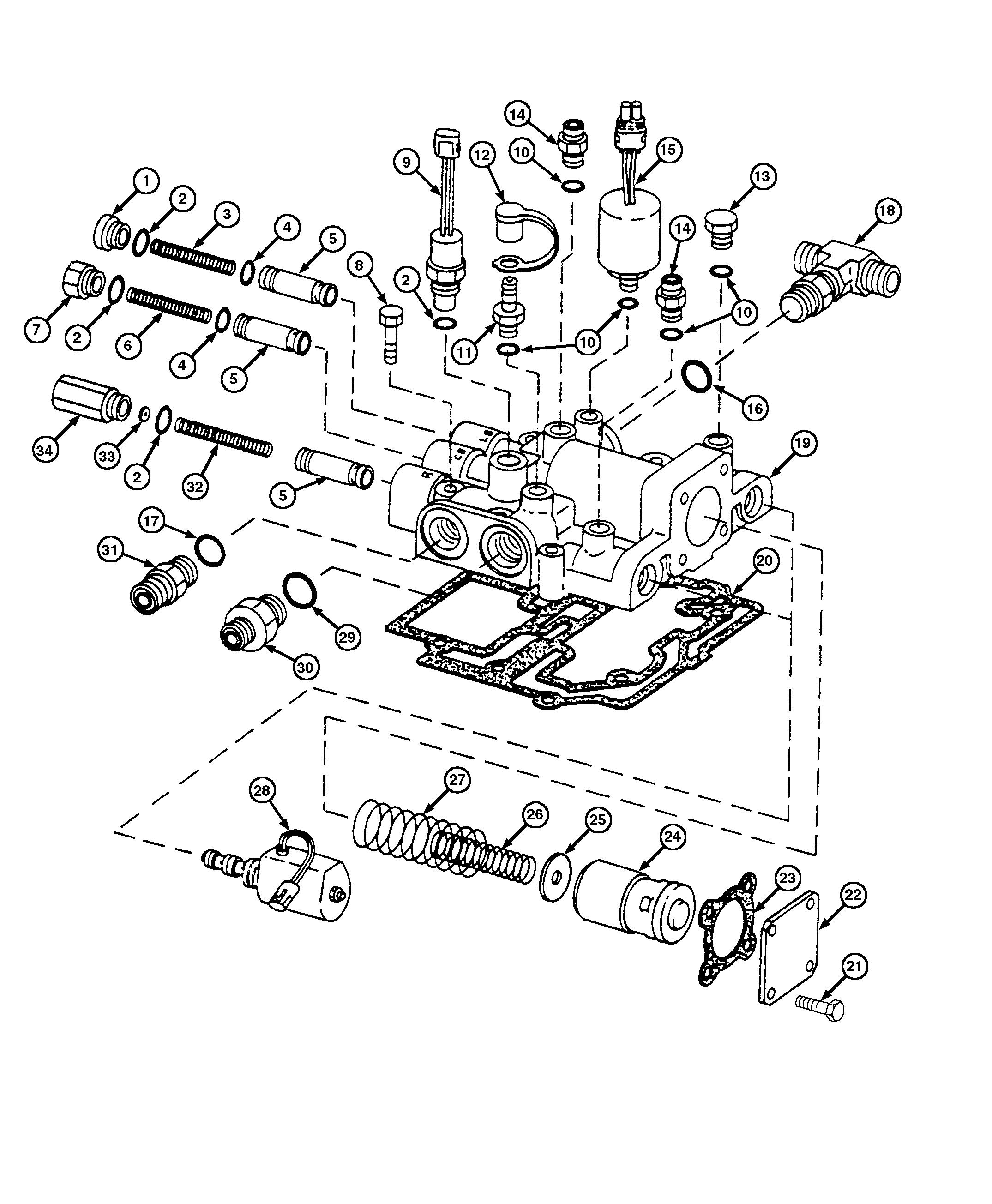

1—Plug10—O-Ring19—ValveHousing27—Spring 2—O-Ring11—TestGaugeFitting20—Gasket28—Solenoid(2used) 3—Spring12—DustCap21—CapScrew(4used)29—O-Ring 4—O-Ring13—Plug22—Cover30—Adapter 5—Valve(3used)14—Adapter23—Gasket31—Adapter 6—Spring15—OilPressureSender24—AccumulatorPiston32—Spring 7—Plug16—O-Ring25—Washer33—Shim 8—CapScrew(7used)17—O-Ring26—Spring34—Fitting 9—WetClutchOilTemperature18—Tee Sender

1.Refertotheexplodedviewfordisassemblyand assembly.

2.Washpartsinsolventanddrythoroughly.

3.Removesmallnicksandburrswithemerycloth. Replacepartsasneeded.Repairkitsarenot available.

NOTE:O-ringsareusedonallspoolsexceptspoolin port“R”.DonotuseanO-ringonspoolinport “R”.

4.Insertcrossdrilledholesonvalves(5)intohousing first.

5.Replacesamequantityofshims(33)thatwere removed.Theyarepre-setatthefactory.However, ifvalvehousing(19)isreplaced,installoriginal shimsandcheckregulatedpressure.Addshimsas necessary.Eachshimwillincreasethepressureby approximately10psi.

6.Temperaturesender(9)goesintoport“TI”. Pressuresender(15)goesintoport“PI”.

Continuedonnextpage

OUO6083,00005C3–19–14MAY03–2/4

A—SeparatorSolenoidB—UnloadingSystem Solenoid

7.Thetwosolenoidsareidentical;(A)engagesthe separatorand(B)engagestheunloadingsystem. Refertotheexplodedviewforrepair.Tightenlarge hexwheninstallingsolenoidcartridgeto specification.

Specification

PressureRegulatingValve SolenoidCartridge—Torque25N•m (216lb-in.)

H57022–UN–24JUN99

8.Donotuseasealerongaskets(20)and(23). Tightenthesevencapscrewstospecification.

Specification

PressureRegulatingValveCap Screws—Torque25N•m (216lb-in.)

OUO6083,00005C3–19–14MAY03–3/4

A—Back-upRingE—SnapRingI—PlungerL—guide B—O-RingF—SpoolJ—SpringM—Nut C—Back-upRingG—SpringPinK—O-RingN—Coil D—O-RingH—O-Ring

OUO6083,00005C3–19–14MAY03–4/4

ValveSolenoid

A—65 ± 2mm(2.559 ± 0.079B—65 ± 10mm(2.559 ± 0.394E—105 ± 10mm(4.134 ± 0.394G—53 ± 2mm(2.087 ± 0.079 in.)in.)1 in.)in.)

C—96 ± 1mm(3.78 ± 0.039in.)F—33 ± 2mm(1.299 ± 0.079H—55mm(2.165in.)

D—125 ± 5mm(4.921 ± 0.197)in.)Maximum2

MaterialRequired:

IMPORTANT:Steelmustbe1045FCDQL-2or harder.

NOTE:ODoftoolmustbeaminimumof125mm (4.921in),butmaybelarger.

165mm(2.559in.)istheMAXIMUMODallowedtomaintainproper sidewallthickness.ODmaybemadesmallerthan65mm(2.559 in.).Diametershouldmatchpresscylinderdiametertoaidin centeringtooloverbearing.

255mm(2.165in.)istheMAXIMUMdepthoftopboretomaintain properthickness.Topboredepthmaybelessthan55mm(2.165) butmustbeaMINIMUMof5mm(0.197in.)deep.

• 125mm(4.921in.)RDJDMA01045FCDQL-2 Steel

Augerswingvalvemodule

Automaticcombineadjustmentdisplay

AuxiliarycabmainAUTOTRACwiring

Auxiliaryfieldlights

Axlebearingsandseals

Axleextensiontubes

Cleangrainelevator

Bladeinserts

Removeradiator

9.0L...........................

Crossaugercountershaftshearbolt

Cylinderblock

Dischargebeaterhousing

9.0L...........................

Separatordrive

Evaporator

Disassembleandassemble ......... 140-05-56 Replace Preloadbearings 140-05-59

Separatordrivewetclutch

Separatorgear

Transfergearcase

Disassembleandassemble

Evaporatortemperaturesensor

Exhaustgasrecirculation(EGR)mixedgas

CONTOURMASTERtiltbeam

CONTOURMASTERtiltframe

Conveyor

Foldingaugerrings

Foldinghorizontalauger

Freshairtemperature

FrontHorizontalunloadingauger

Horizontalunloadingaugerandgearcase

Electro-hydraulicfeederhousereverservalve

Hydraulicsolenoidcontrolvalve

Pilotsleeveo-rings

HubIdentification 70-16-8

Twowayreelliftandvariablespeedfeeder

Hydrauliccylinders(S.N.715301--)

(S.N.--715300)

HydraulicpumpSpecifications 70-05-2 Temperaturesensor Assemble 70-10-9 Disassemble 70-10-5Removeandinstall 40-35-16 TierIIIcoolingpacakge 40-35-16 Essentialorrecommendedtools 70-10-1

Accessdoorworklight,bulb

Auxiliaryfieldworklight,bulb

Light,(InfraRed)

Lowshaftspeedsensor

Lowercellassembly GREENSTARmoisturesensor Removeandreplace 40-60-11

Lowerenginerepair RemoveandinstallengineoilpanaccessOilscreen Disassembleandasssemble .......... 140-05-65 sheet ............................20-15-1 LowergearcaseOiltrough Disassembleandassemble 140-05-65

Verticalauger Install 130-15-12Operatingspeeds 9560combine 10-10-3 Remove 130-15-3 Lubricant9660STS,9670STS 10-10-9 9860Combine 10-10-18 Mixing 10-20-17 Storage 10-20-16Operatorsseat Airsuspensionexplodedview 90-15-46

Lubricityofdieselfuel 10-20-4

Essentialorrecommendedtools 120-30-1

Receiver/dryer

Othermaterial 120-30-1 Removeandinstall ...................90-10-4 Removeandinstall .................. 120-30-3

Recirculatorfanmotordriver Specifications 120-30-2 Removeandinstall

Reel/belt

Reelfore/aftvalvemodule .............. 70-16-10

Reel/beltpickup Strawspreader Explodedview 70-10-11 Flowcontrolvalve Reel/beltpickup

Radiator

Reel/beltpickupdrive Disassembleandassemble ........... 70-10-15 R

Reel/beltpickuppump Assemble ......................... 70-10-23

Reel/beltpickuppumpdrive Install 12.5L 20-10-28Removeandinstall 70-10-12

TurbochargerCompressorInlet sieveframe

Shoesupplyaugers,cleaningfanandchafferand

Removeandinstall Fanspeedactuator

Sensors

Threshingbars

Separatorgear

Tierodend

Strawspreader

Warningdisplaypanelandheaderfloatgaugelights