Manure Handling

boumatic.com

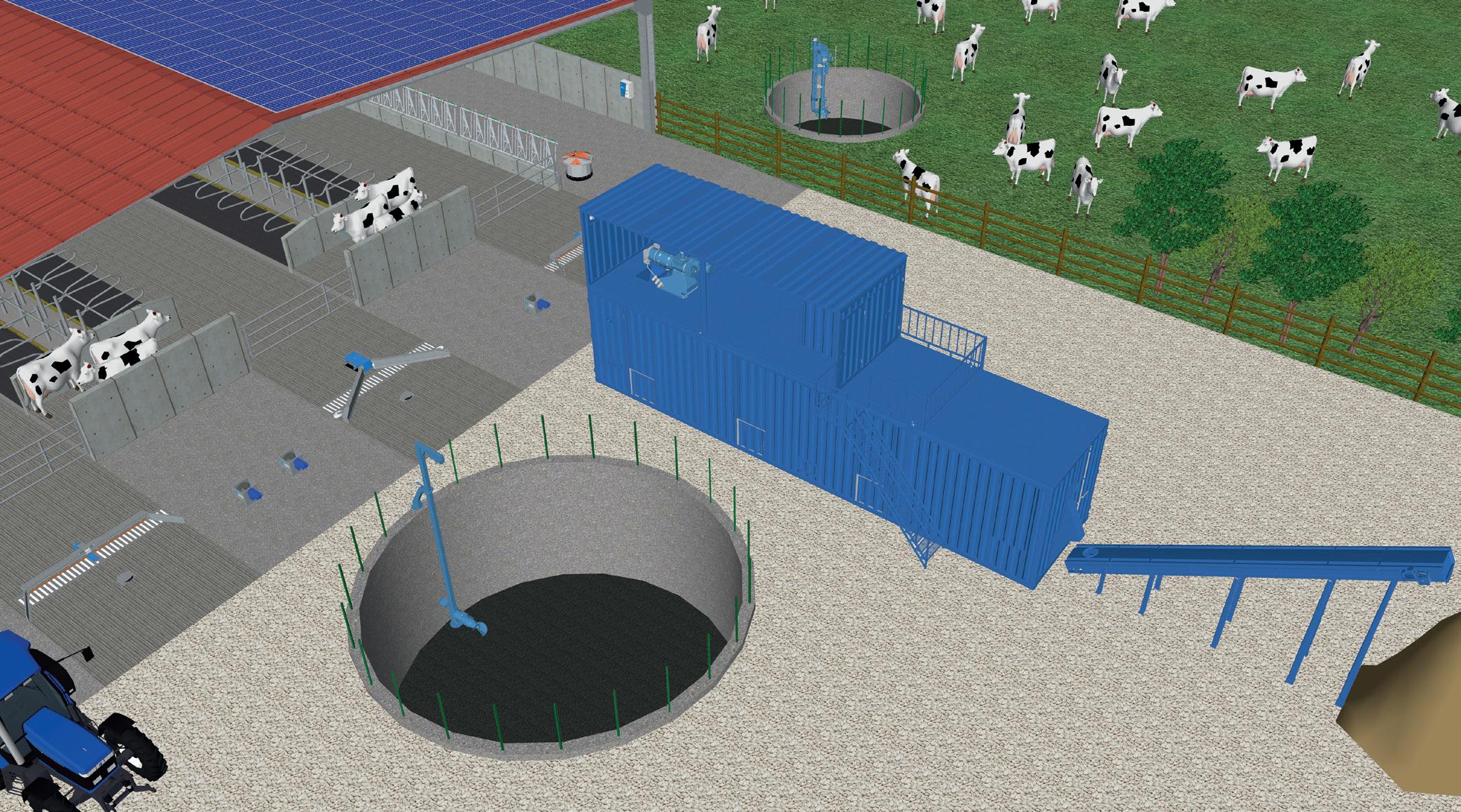

Our environmental approach

With over 50 years of experience in manure handling, BouMatic is an indispensable contributor to the environmental transition.

Manure handling in agriculture is a very demanding task and requires robust, high-performance equipment.

On the strength of its expertise, BouMatic is keen to accompany you in your own environmental transition by providing you with the tools you need to recycle your organic waste.

Our mission

The wide range offered by BouMatic ensures you have a robust, technical and economical solution at your disposal for handling organic waste. In order to achieve this, our experts are constantly searching for solutions to respond to future demands.

3

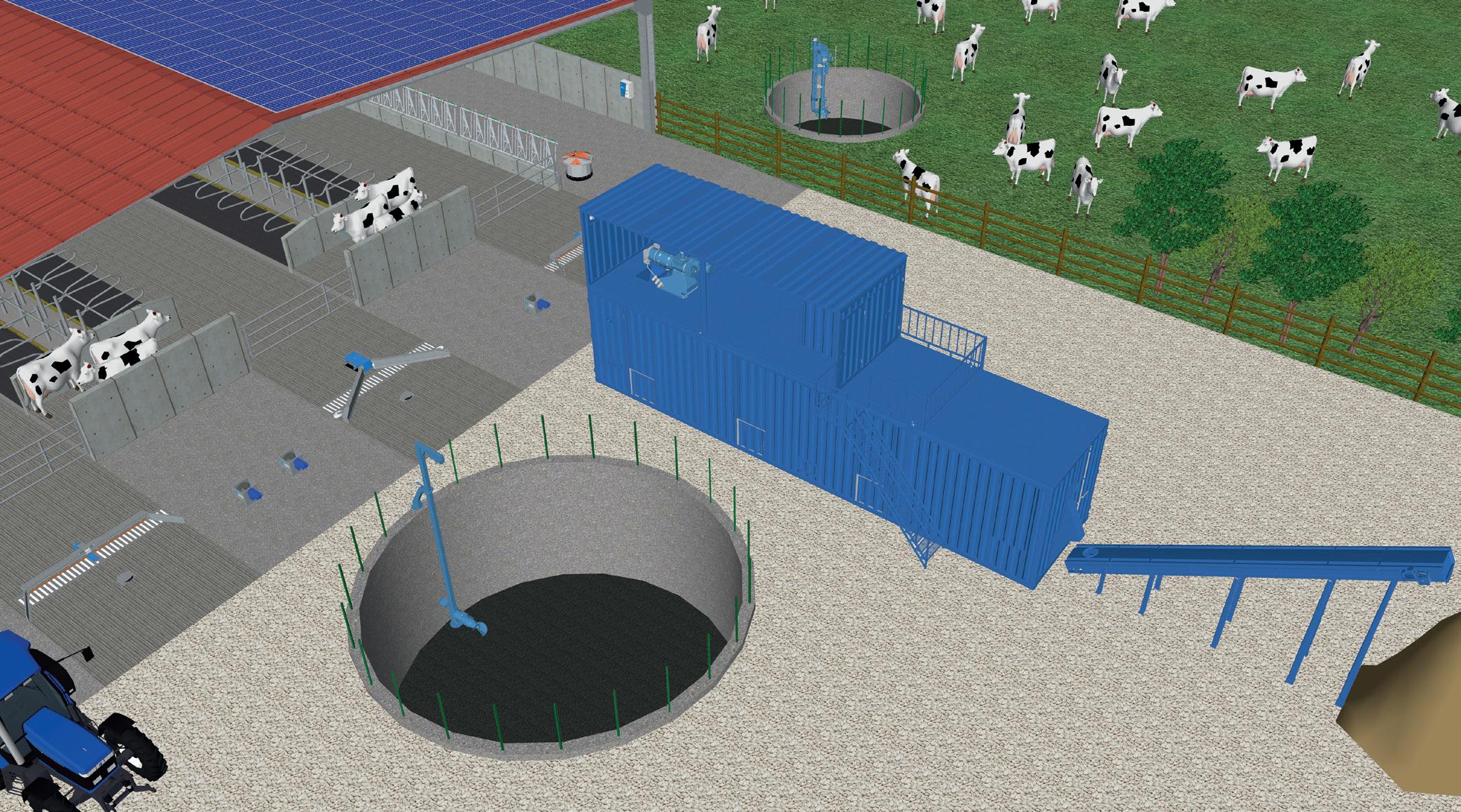

Be ENVIRONMENTALLY responsible

OUR VISION

Heat Energy Gas Organic fertiliser Bedding

6

7 INDEX Manure Handling Vertical pump ........................................................................... 8 MP shredding pump............................................................ 10 VM pump ................................................................................. 11 MPG vertical pump .............................................................. 12 Submersible shredding pump ......................................... 16 DG heavy flow macerator pump ..................................... 20 Flushing.................................................................................... 23 FP flushing pump ................................................................. 25 MPT gravity-fed macerator pump .................................. 26 Piston pump ........................................................................... 28 DK submersible agitator .................................................... 32 POP ............................................................................................ 37 AXP ............................................................................................ 38 POD ............................................................................................ 40 Lagoon agitator..................................................................... 41 Cyclone ..................................................................................... 42 Separator ................................................................................. 48 Platform ................................................................................... 53 Mobile separator ................................................................... 54 BCS ............................................................................................ 56 Falcon cross ............................................................................ 60 Manure conveyor .................................................................. 62 INDEX

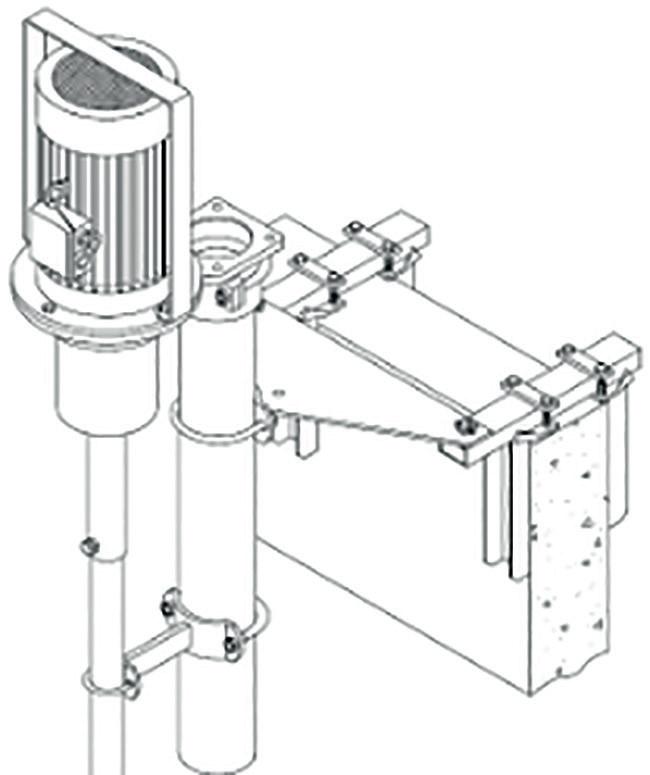

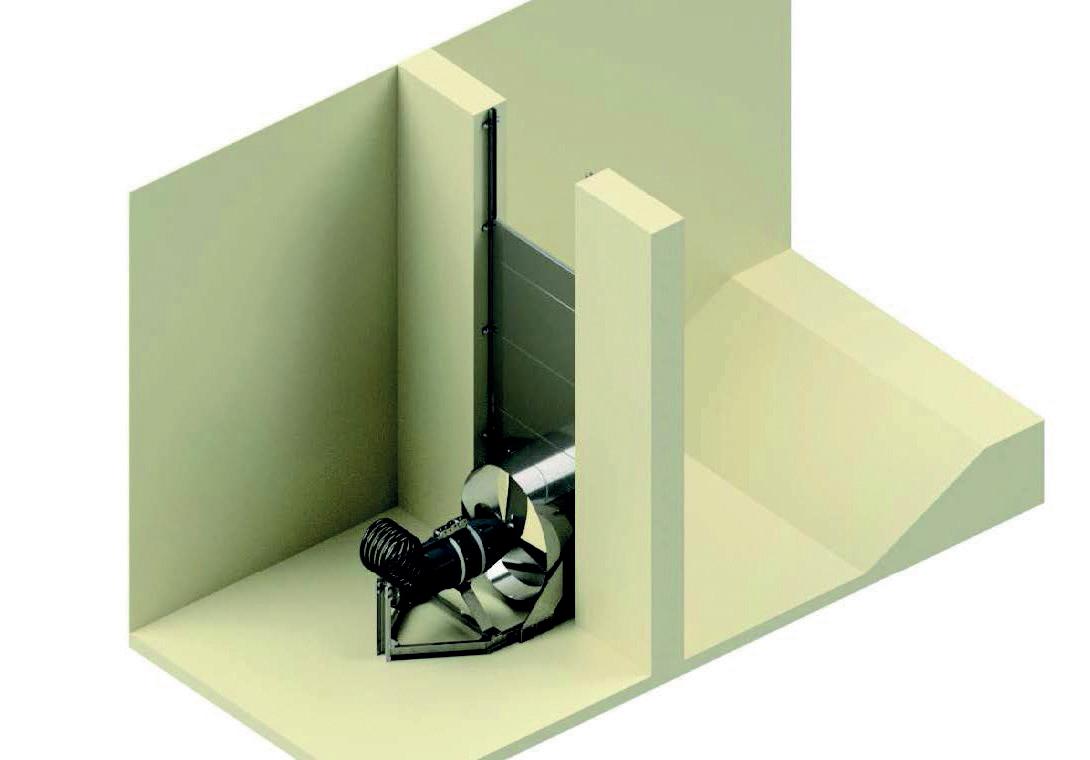

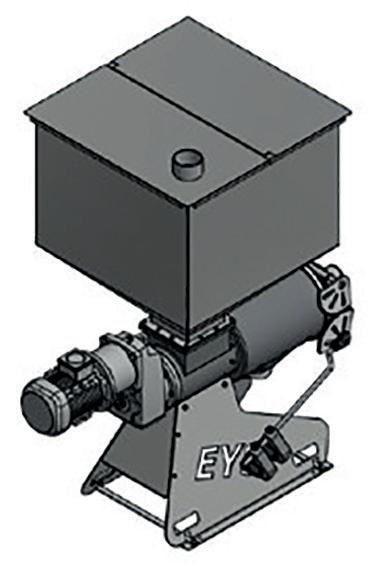

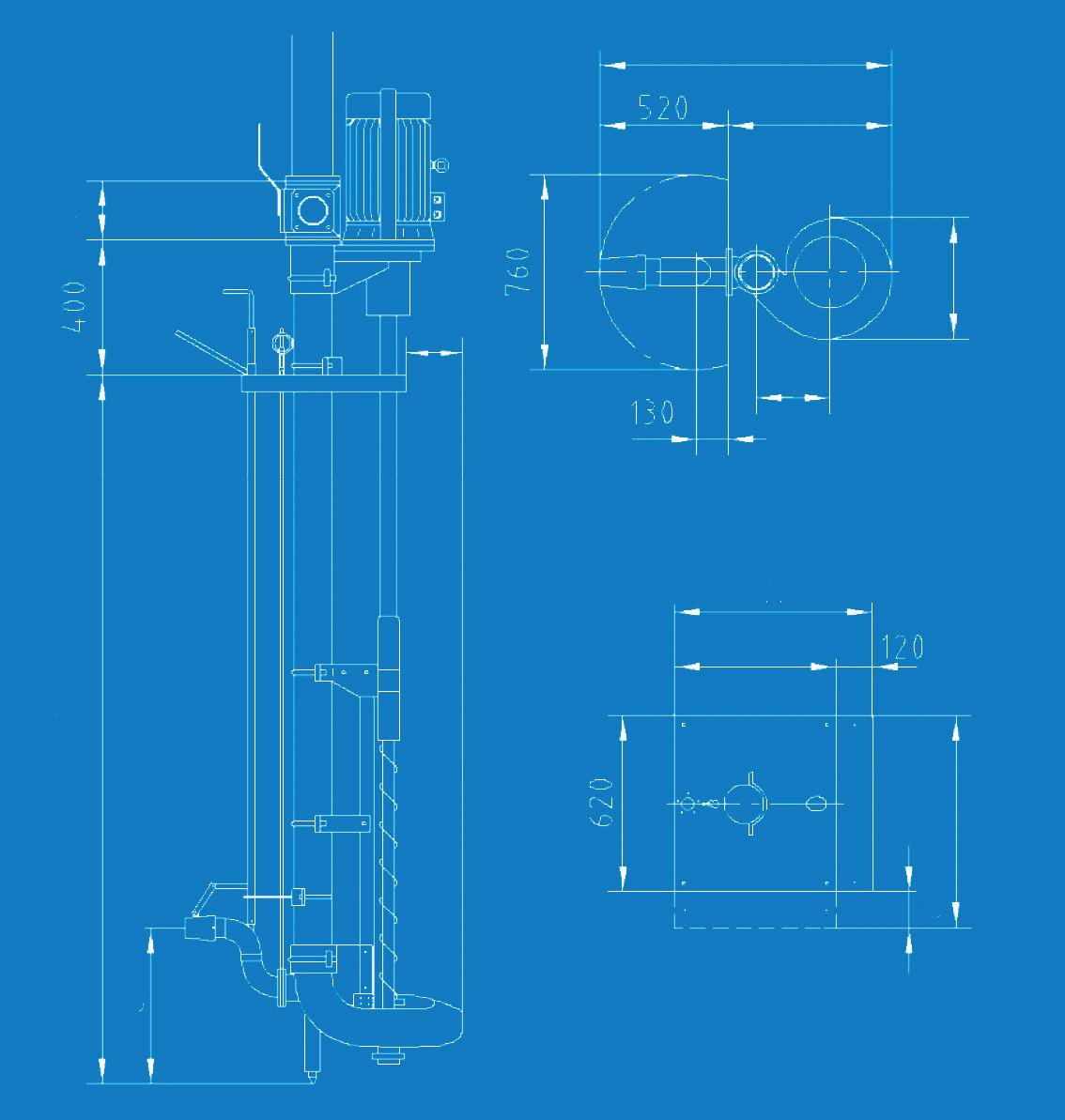

VERTICAL PUMP

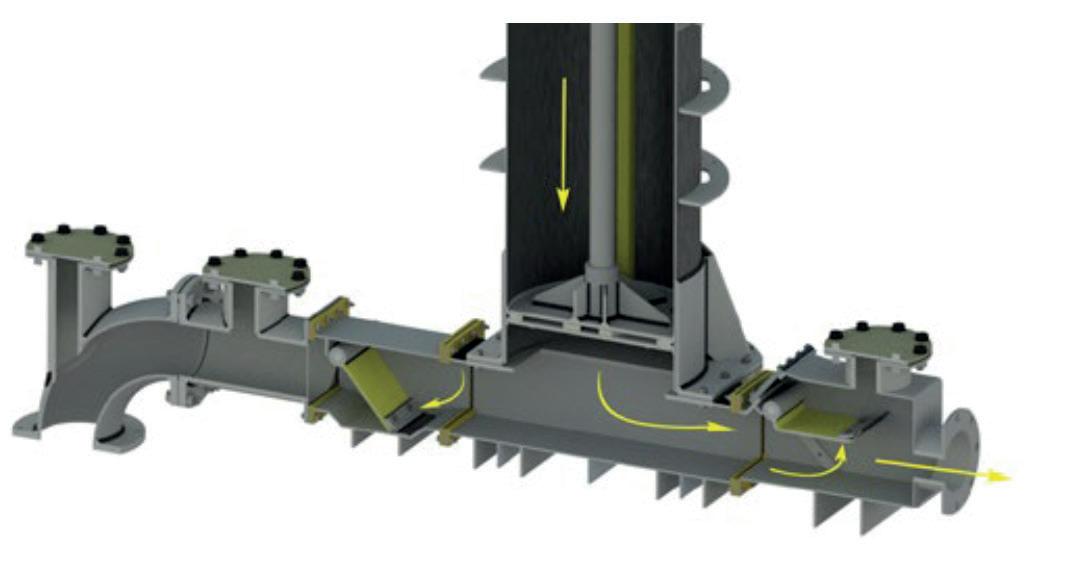

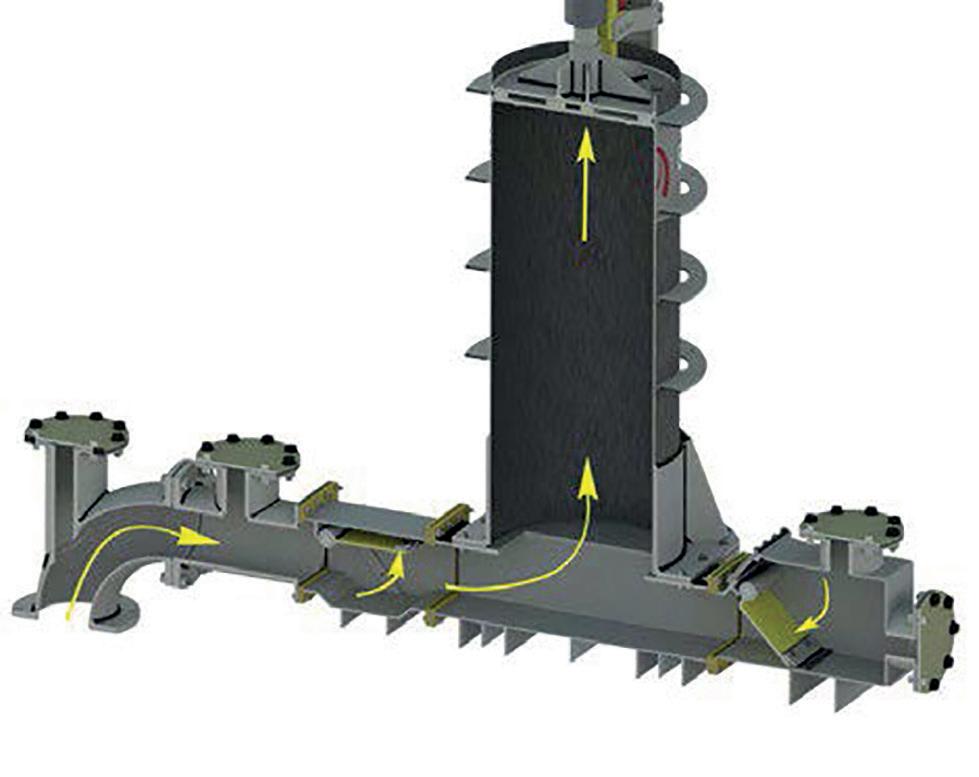

The compact system: 4 in 1

The combi-pump offers a compact but complete solution for slurry handling in the pit.

Our range enables you to

1 2 3 4

Pump Blend Transfer Mix

The pump is equipped with a 400-mm propeller to blend hardened manure before pumping it. The pump is also driven by trapezoidal belts to guarantee additional safety.

The pump’s propeller and its simple design provide it with superior durability over time.

When the outlet valve is opened, it allows you to transfer manure towards your desired destination. The transfer rate depends on the pump’s power rating.

When the outlet valve is closed, the manure is guided towards the mixing nose, causing movement within the pit depending on the desired orientation (+60° or – 60°). The mixing nose enables you to mix the manure evenly throughout the pit. The blend rate depends on the pump’s power rating.

8

5” discharge column

Electric motor with belt drive

Wall mounting kit to aid installation

Adjustable recirculation nozzle with shut-off valve

400-mm blending propeller with contra-rotating blade

Bevel gearbox Robust

Advantages

4-in-1 solution: Pump(1)Blend (2) - Transfer(3)/Mix(4)

Pump inlet propeller: Shred solidified manure to avoid the risk of breakage

Spraying nozzle: Enables you to mix the slurry evenly Centralised lubrication

Orientation of +60° or -60° enabled by the mixing nose

Quick and easy installation

9

MP PUMP

The MP BouMatic Mix-Pump range enables you to mix and pump at the same time.

The BouMatic Mix-Pump is driven by a trapezoidal belt mechanism. The mixer propeller and the pump work with the same gearbox.

The slurry collected in the pit can be consistently pumped to the desired location. If you just want to mix the slurry in the pit, the pump outlet can be shut off by a valve.

The pump rate and mixing efficiency vary depending on the type of motor.

Pit depth of 2 to 5 m

Power from 11 to 30 kW

10 A L B

Type |A| (mm) |B| (mm) |L| (mm) Weight (kg) MP-6 2070 2215 2000 473 MP-8 2670 2815 2600 513 MP-10 3270 3415 3200 554 MP-12 3870 4015 3800 534 MP-14 4470 4615 4400 634 MP-16 5070 5215 5000 674

VM PUMP

The BouMatic Verti-Mix is used to consistently mix slurry in pits. An electrical motor drives a trapezoidal belt mechanism, which drives the vertical shaft. The vertical shaft then drives the mixer propeller and mixing commences. The mixing efficiency varies depending on the type of motor.

410 mm propeller diameter for 5.5 kW VM

610 mm propeller diameter for ratings of 7.5 to 22 kW

Intensity of 5.5 to 22 kW

11 A L

Type |A| (mm) |L| (mm) Weight (kg) VM-6 2070 2000 379 VM-8 2670 2600 407 VM-10 3270 3200 435 VM-12 3870 3800 464 VM-14 4470 4400 492 VM-16 5070 5000 520

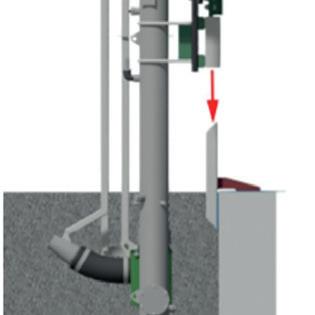

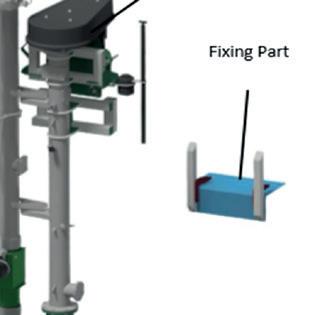

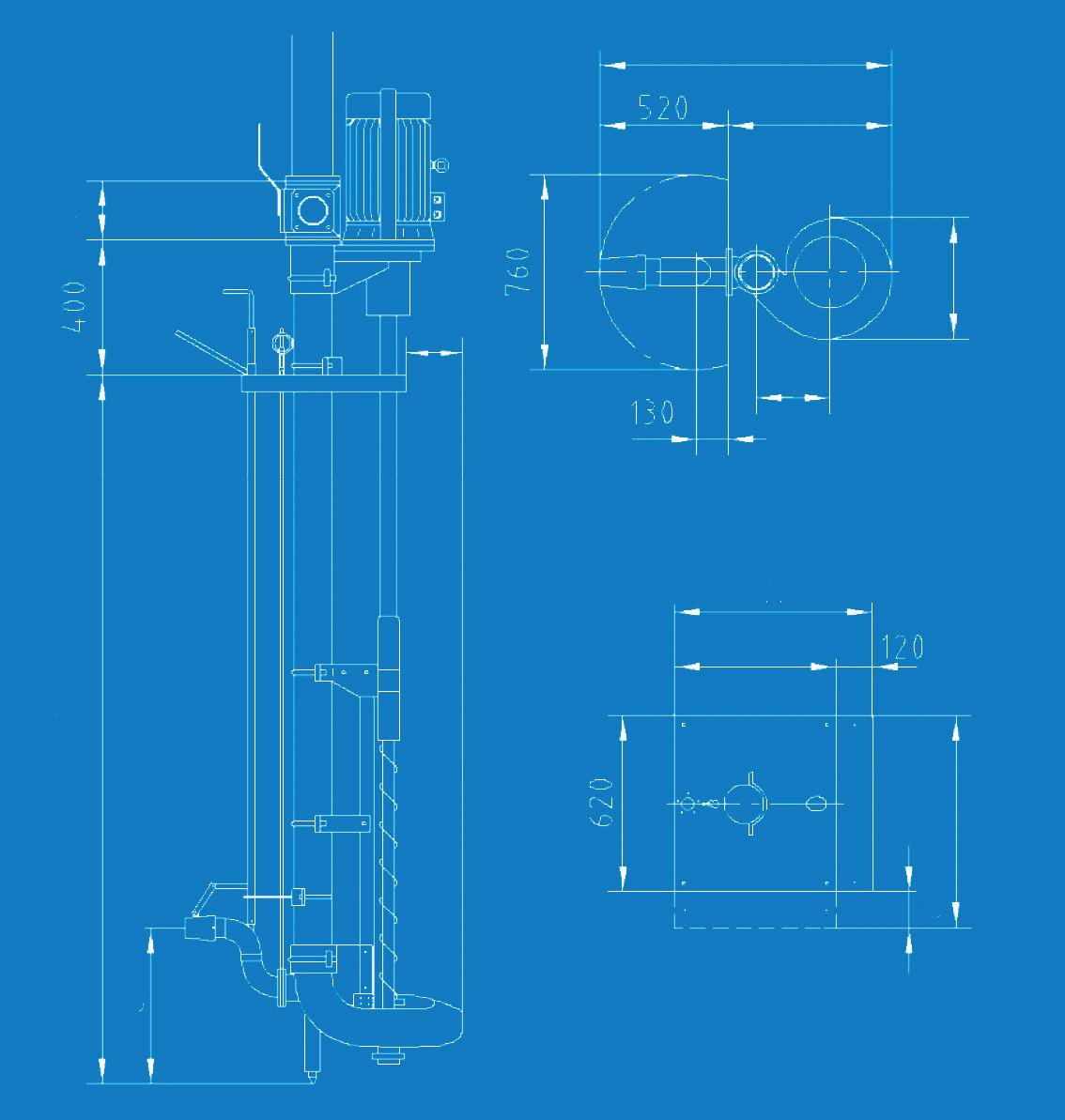

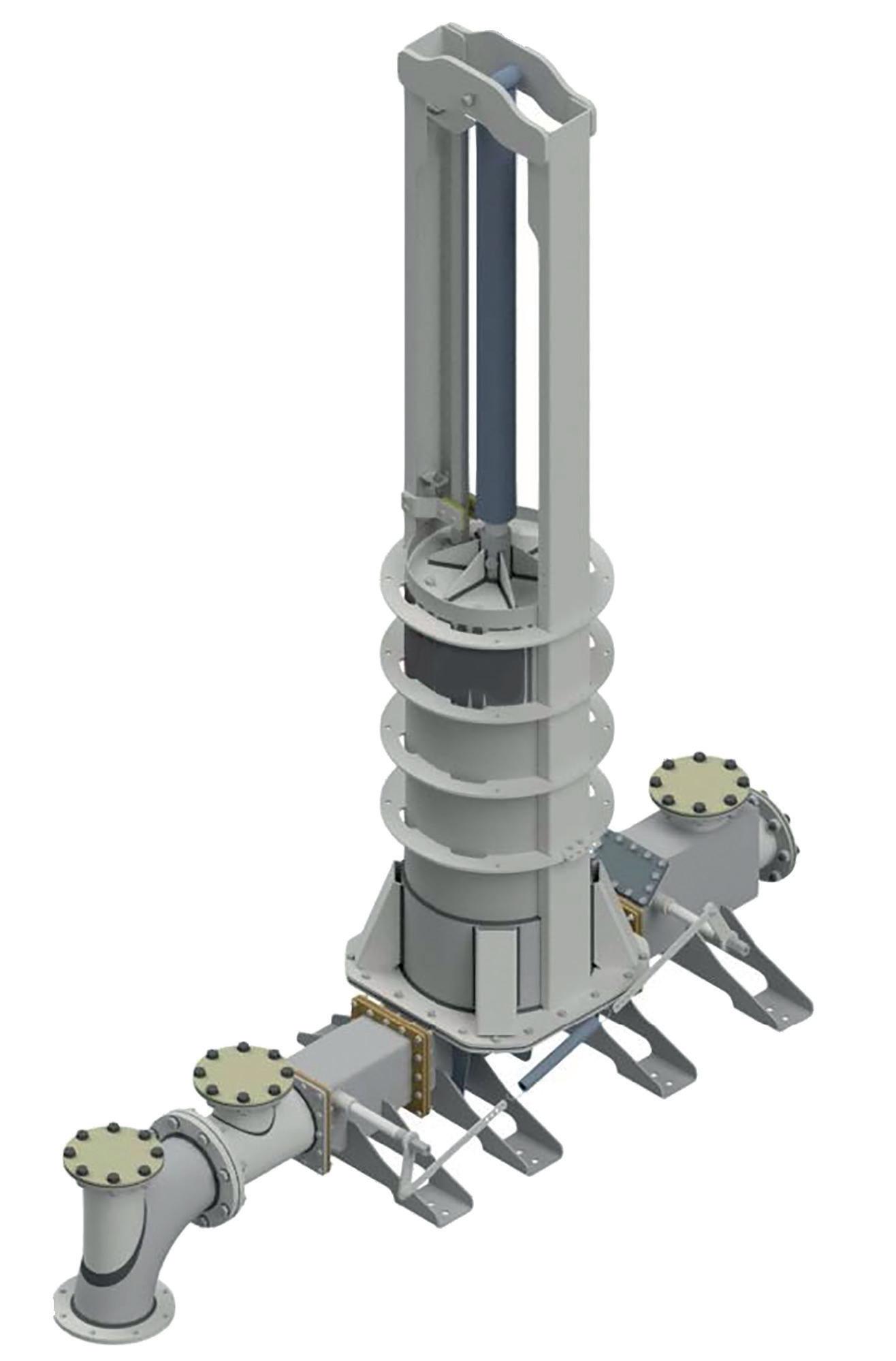

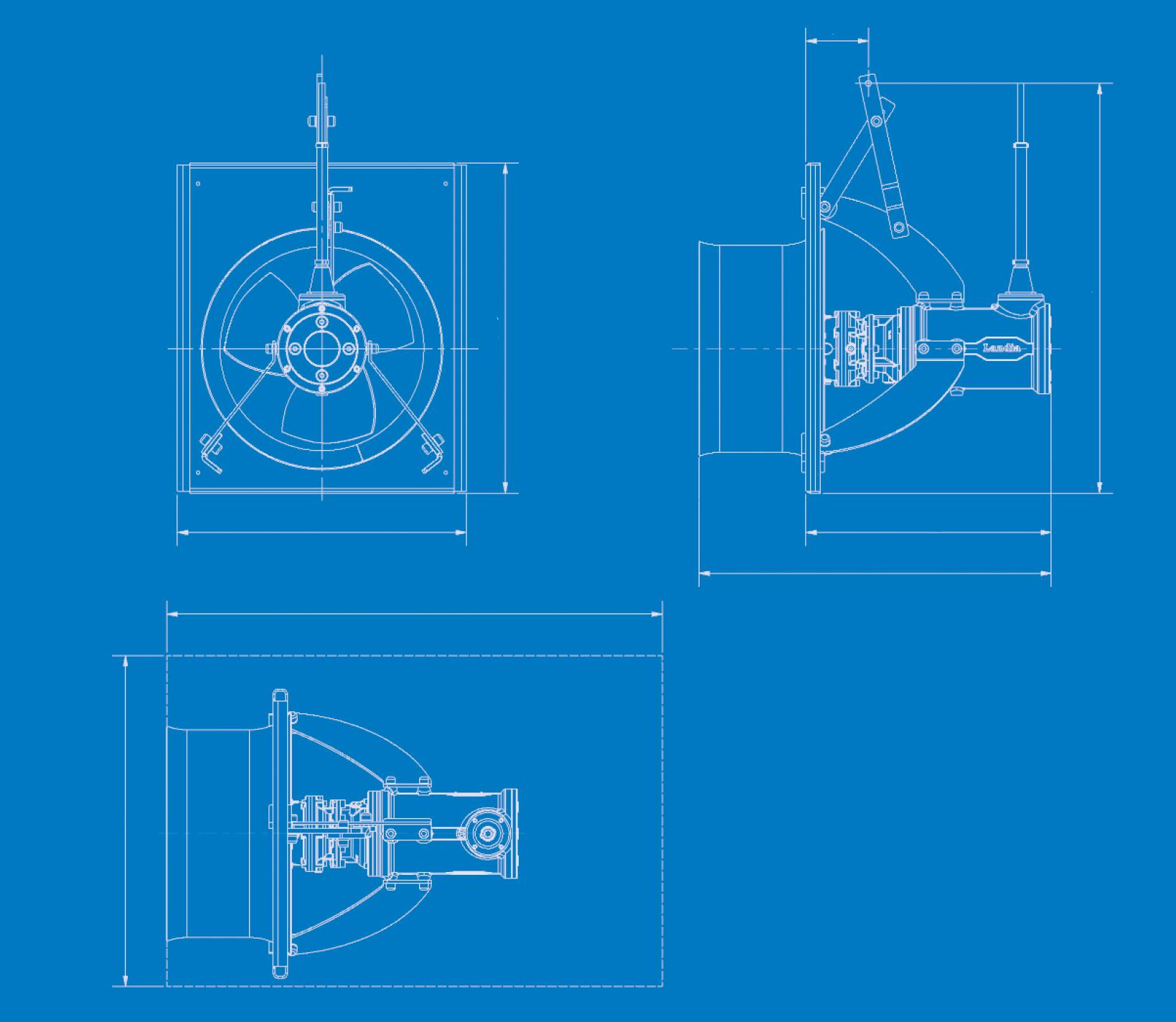

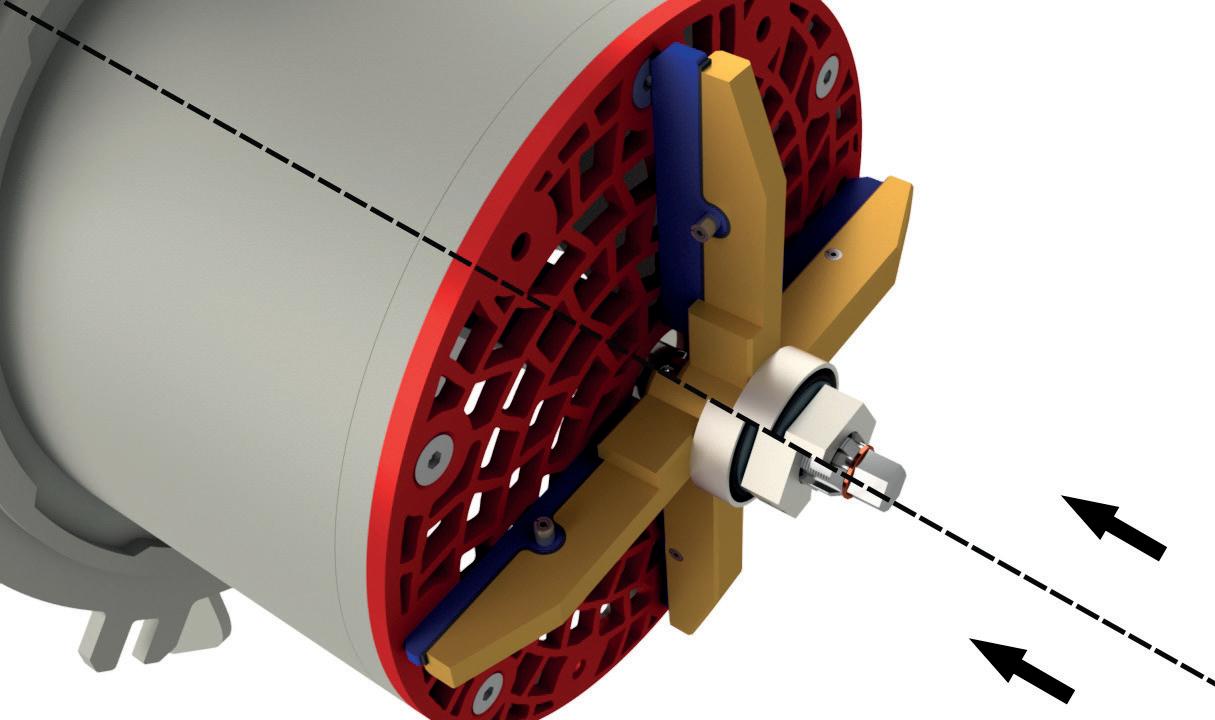

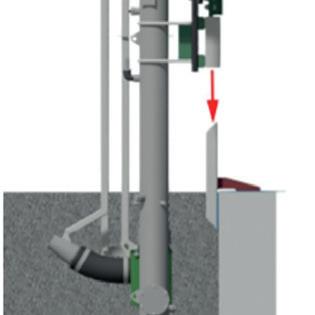

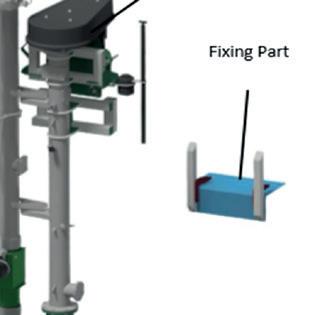

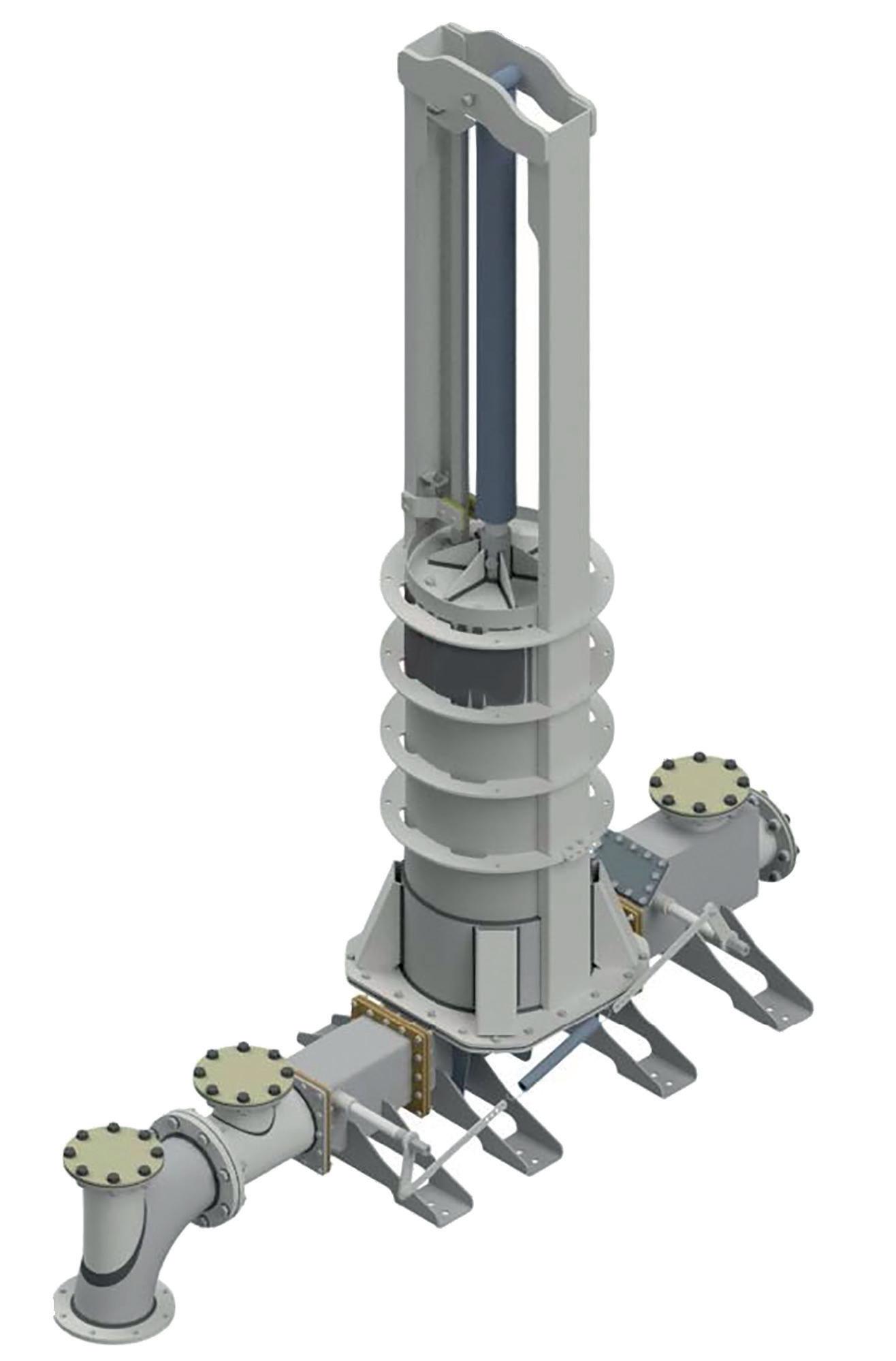

MPG VERTICAL PUMP

BouMatic MPG pumps with a long shaft for MPG-type organic waste (motor-driven pump) are mounted on the edge of a receiving pit or storage pit so that the lower part containing the pump housing is lowered into the liquid and the upper part containing the motor is in the open air.

The long-shafted pump can be supplied with a moving bottom agitator for mixing. Numerous sizes, fittings and pipings are available (4’’ – 5’’ – 6’’).

The hardened steel blade system for shredding coarse elements and the propeller providing consistent access to the pump ensure seamless pumping.

12

Features

Pump housing made of hardened steel that is much better quality than the welded pump housing.

Superior strength, often 10 to 15 years of service without great expense.

Capacity up to 450 m³/h.

Suction via the top of the volute

Inlet auger with contra-rotating blade

Engine sizes from 5.5 to 30.0 kW

Lifting height up to 25 metres

Pump hose 4”, 5” or 6”

Available for pits of 1.8 to 5.4 m in depth

13

14 A B C M M P G F E D X Q Type MPG 4’’ MPG 5’’ MPG 6’’ A (mm) 244 282 322 B (mm) 120 180 218 C (mm) 620 620 722 D (mm) 1050 1155 1330 E (mm) 530 635 810 F (mm) 420 480 600 G (mm) 225 285 355 M (mm) 740 740 842/890 P (mm) - - 270

*Values measured in water

Performance diagram (test conducted using water)

15 0 1000 2000 3000 4000 5000 6000 7000 35 34 33 32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 MPG 5,5/4 MPG 7,5/4 MPG 11/4 MPG 15/4 MPG 18,5/4 MPG 11/5 MPG15/5 MPG 18,5/5 MPG 22/5 MPG 15/6 MPG 18,5/6 MPG22/6 MPG30/6

Capacity (m3/h) Head (m) Type MPG 75/4 MPG 110/4 MPG 150/4 MPG 185/4 MPG 150/5 MPG 185/5 MPG 220/5 MPG 220/6 MPG 300/6 Discharge hose (mm/ inch) 100/4 125/5 150/6 Power (Kw) 7,5 11 15 18,5 15 18,5 22 22 3030 Consumption(A) 15 21,5 29 35 29 35 43 43 5757 Weight 300 350 370 400 Power Liquid (L/mn) 3200 4100 4800 5200 4850 5500 5700 6350 7000 Average (L/mn) 2700 3500 4100 4500 4350 4950 5100 6000 6650 Thick (L/mn) 1600 2050 2400 2550 2900 3300 3400 4450 4900 Max. transfer height (m) 10,5 14,5 17 19,5 17 19,5 20,5 20 21

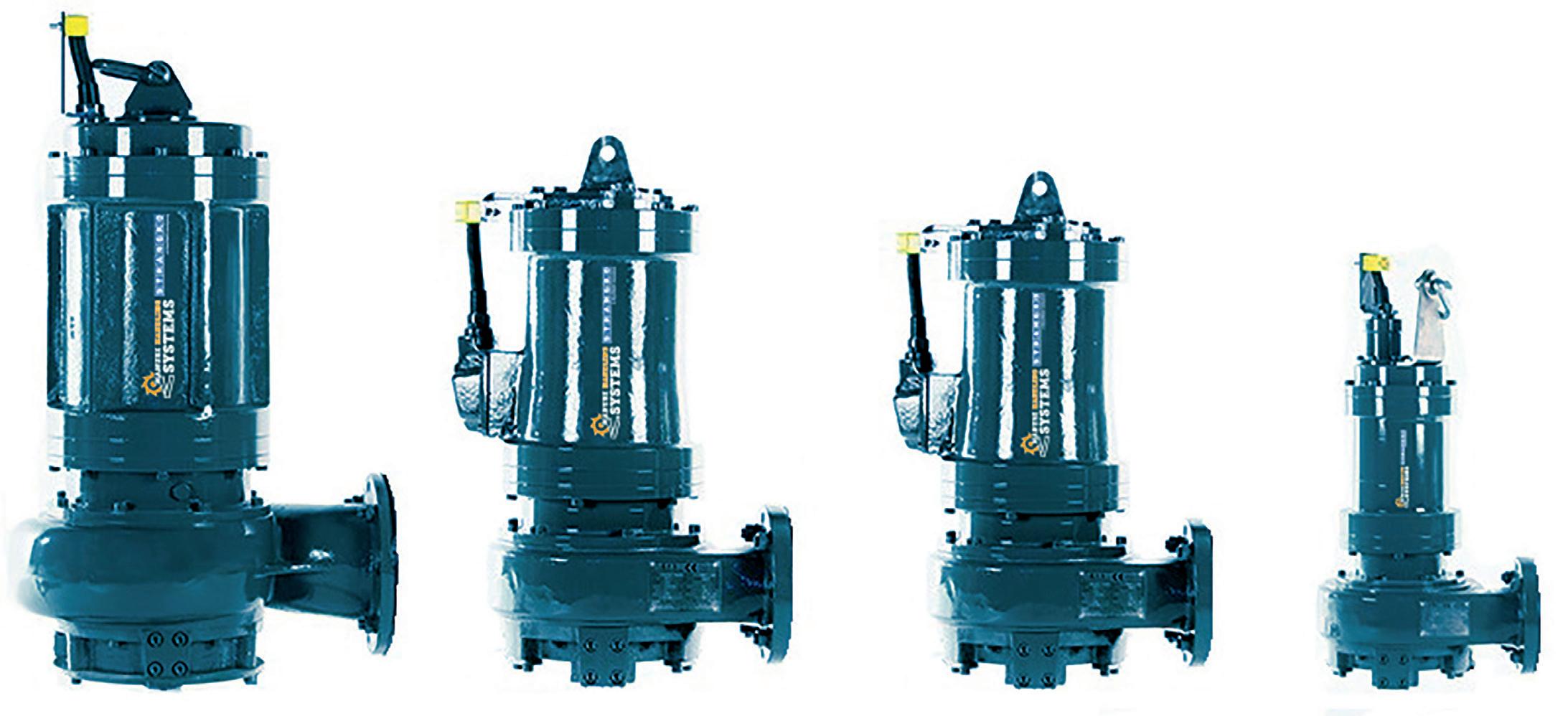

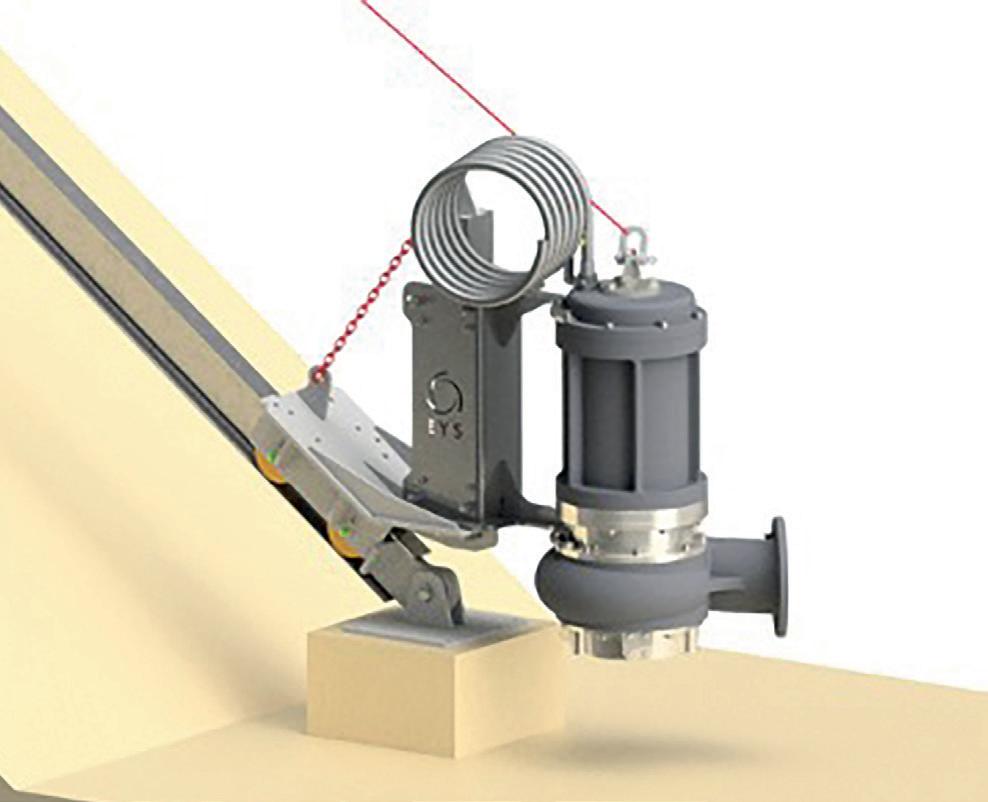

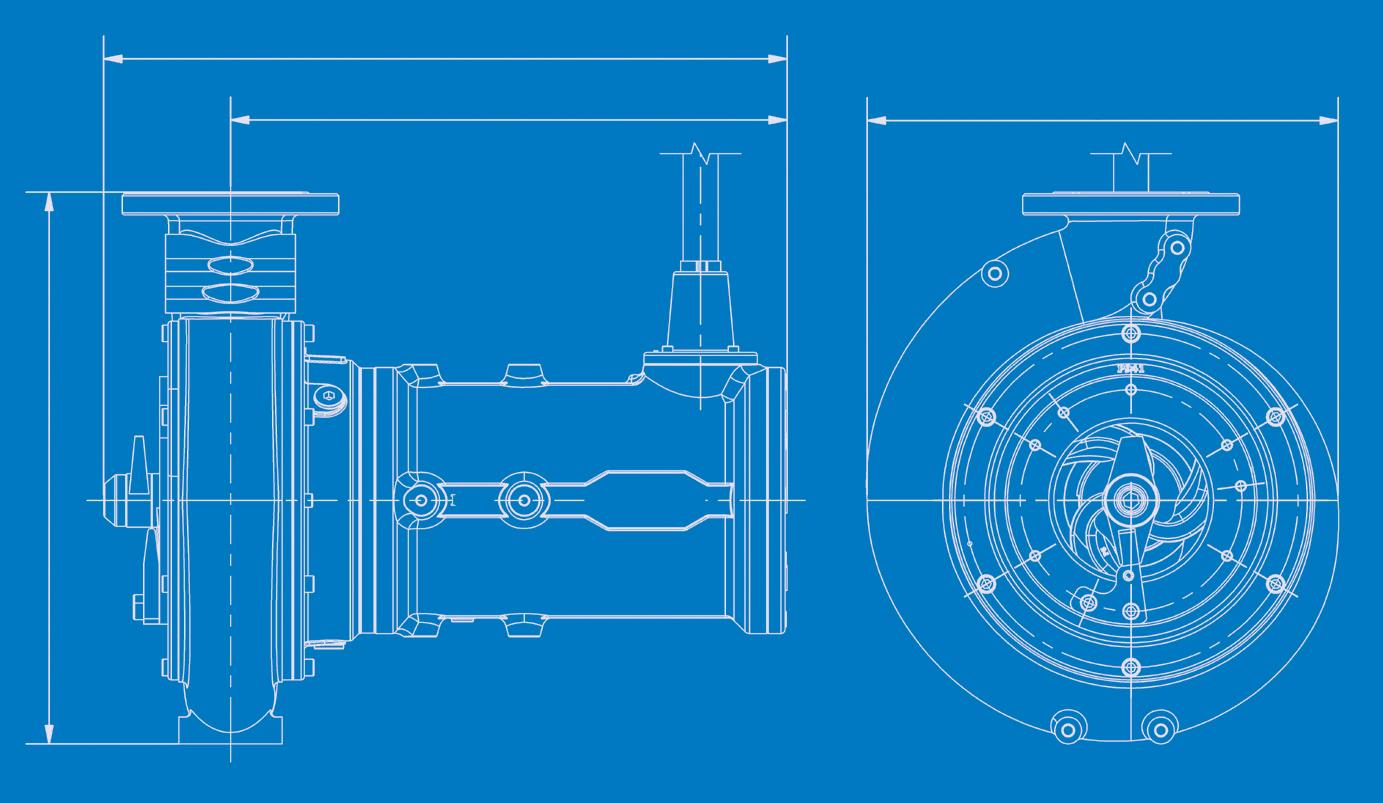

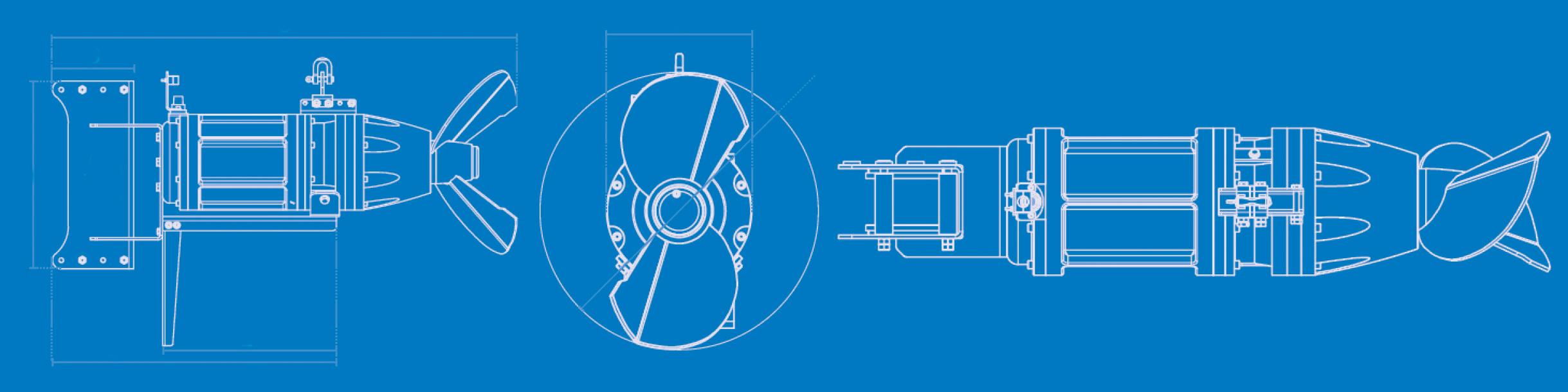

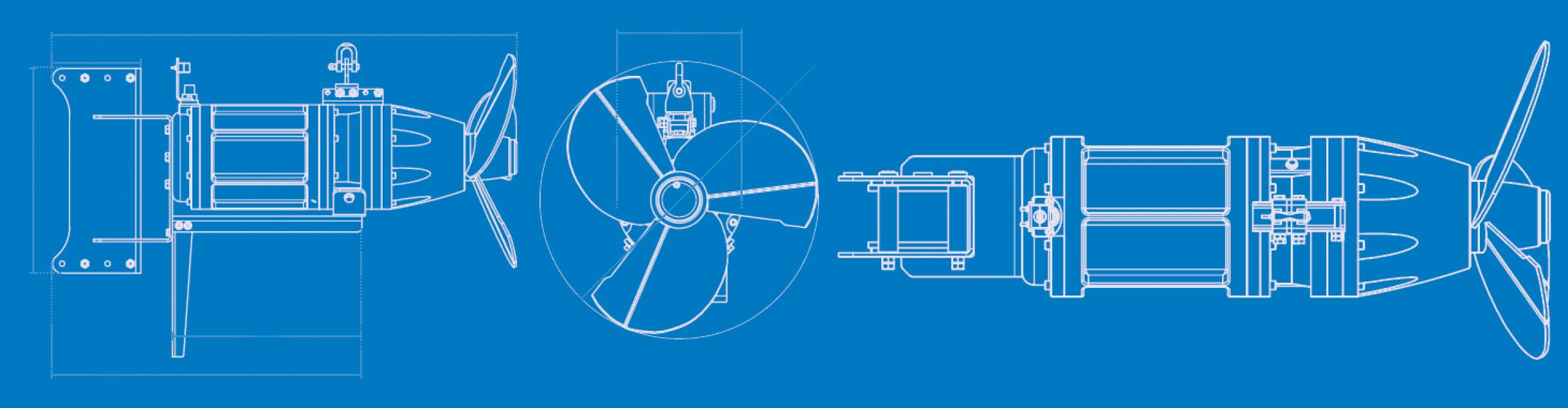

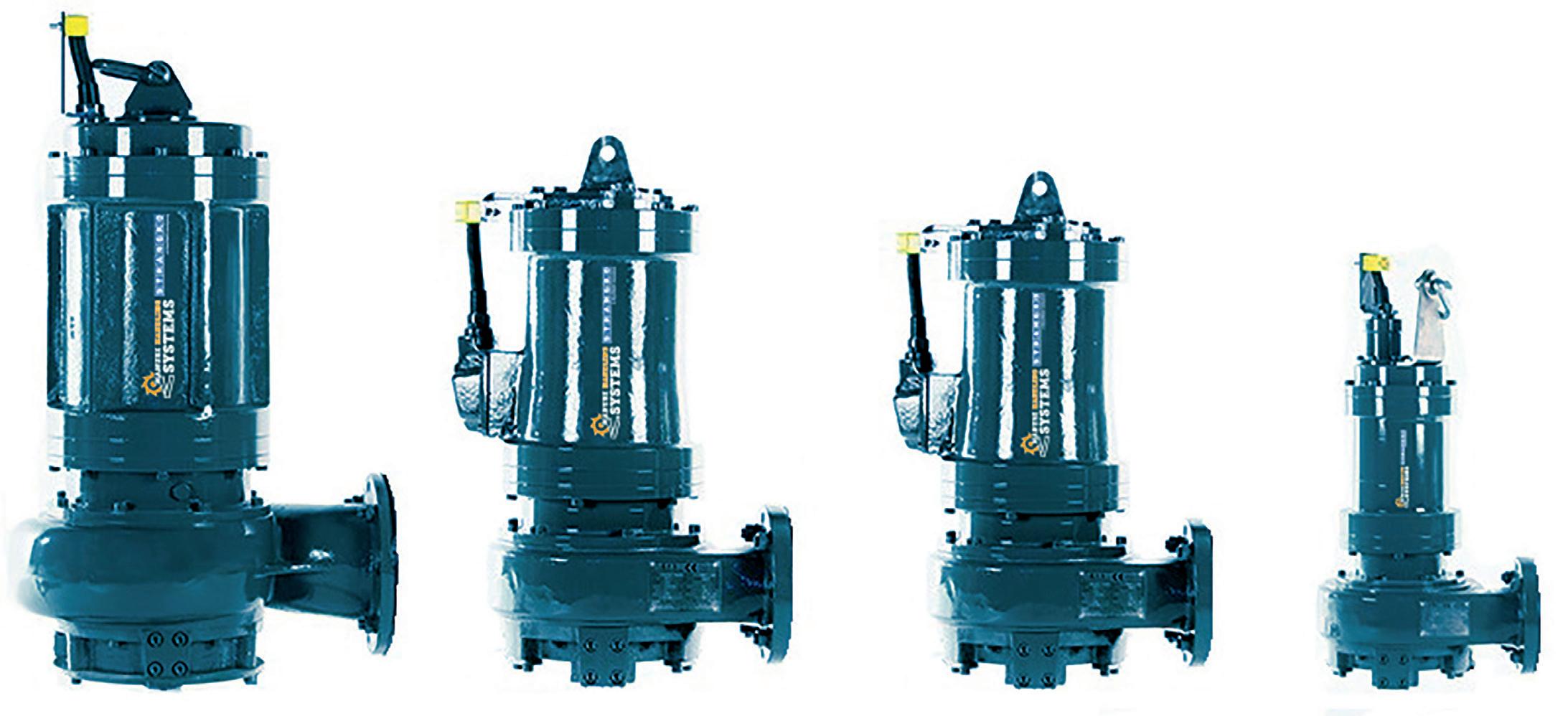

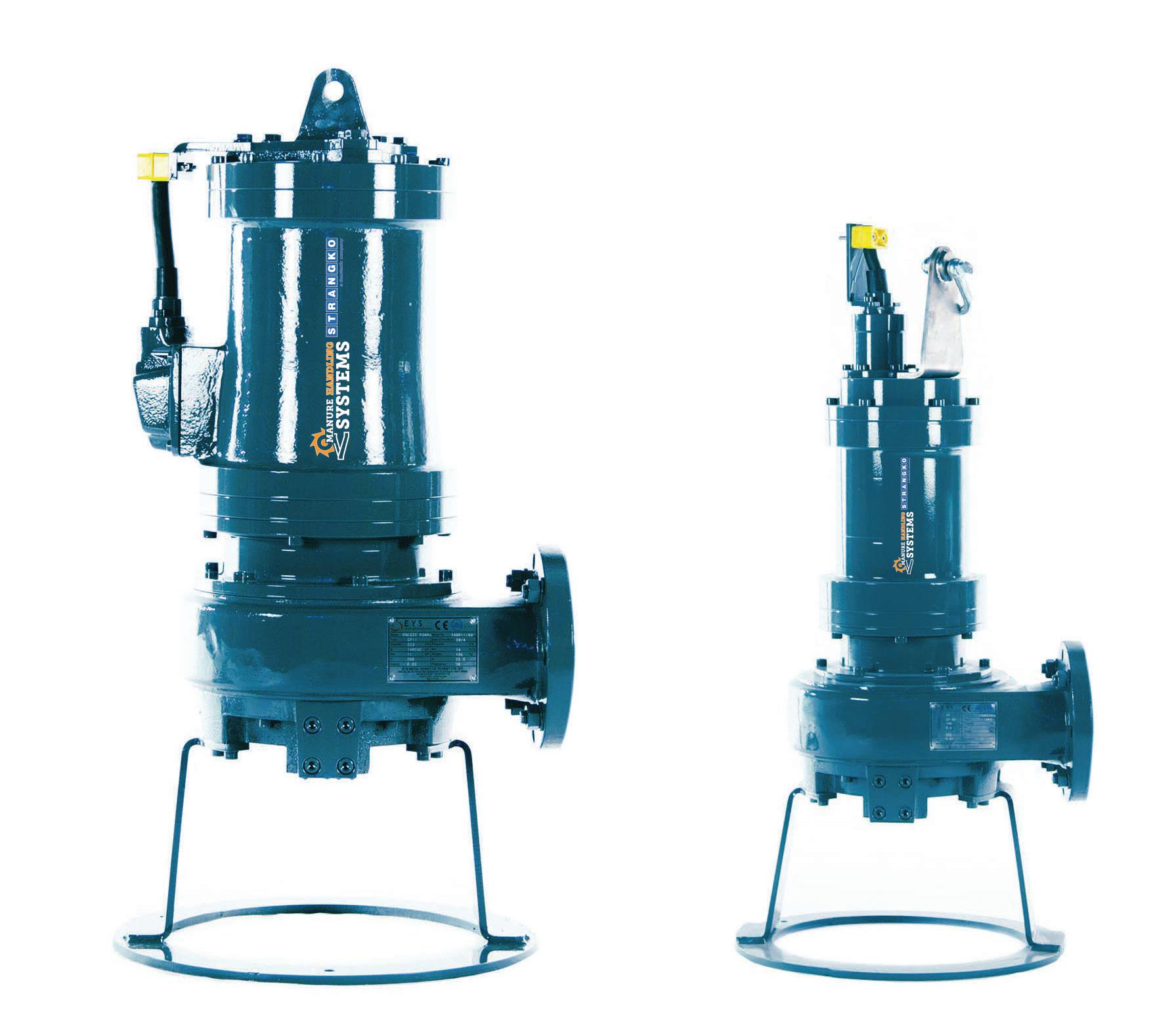

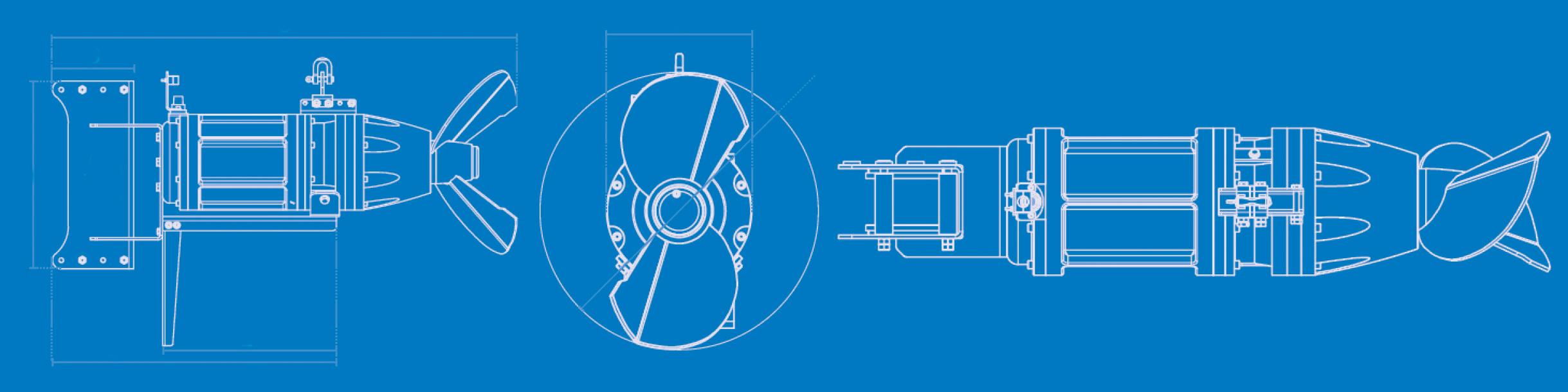

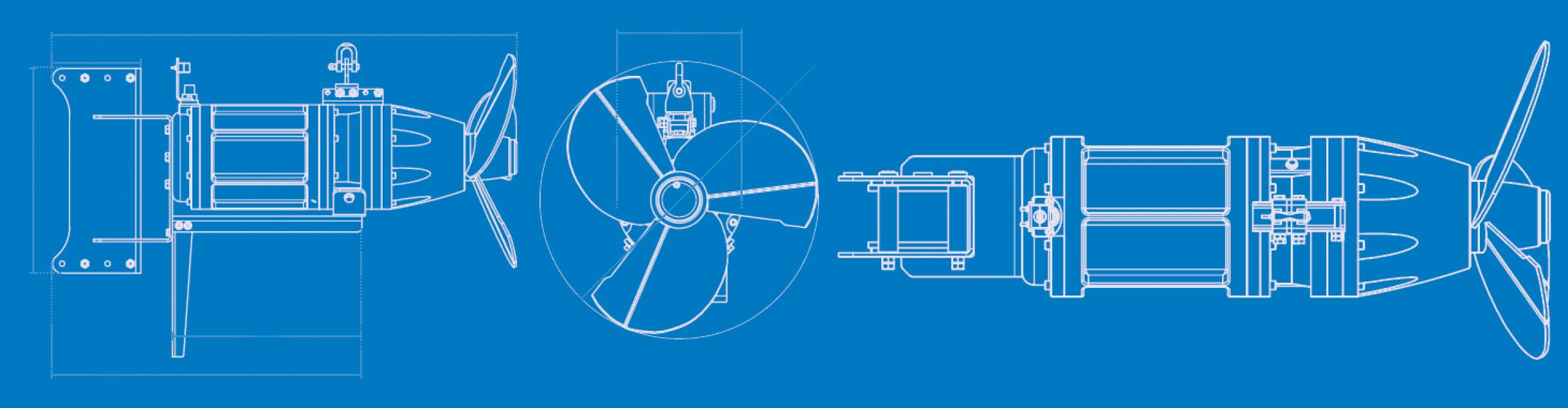

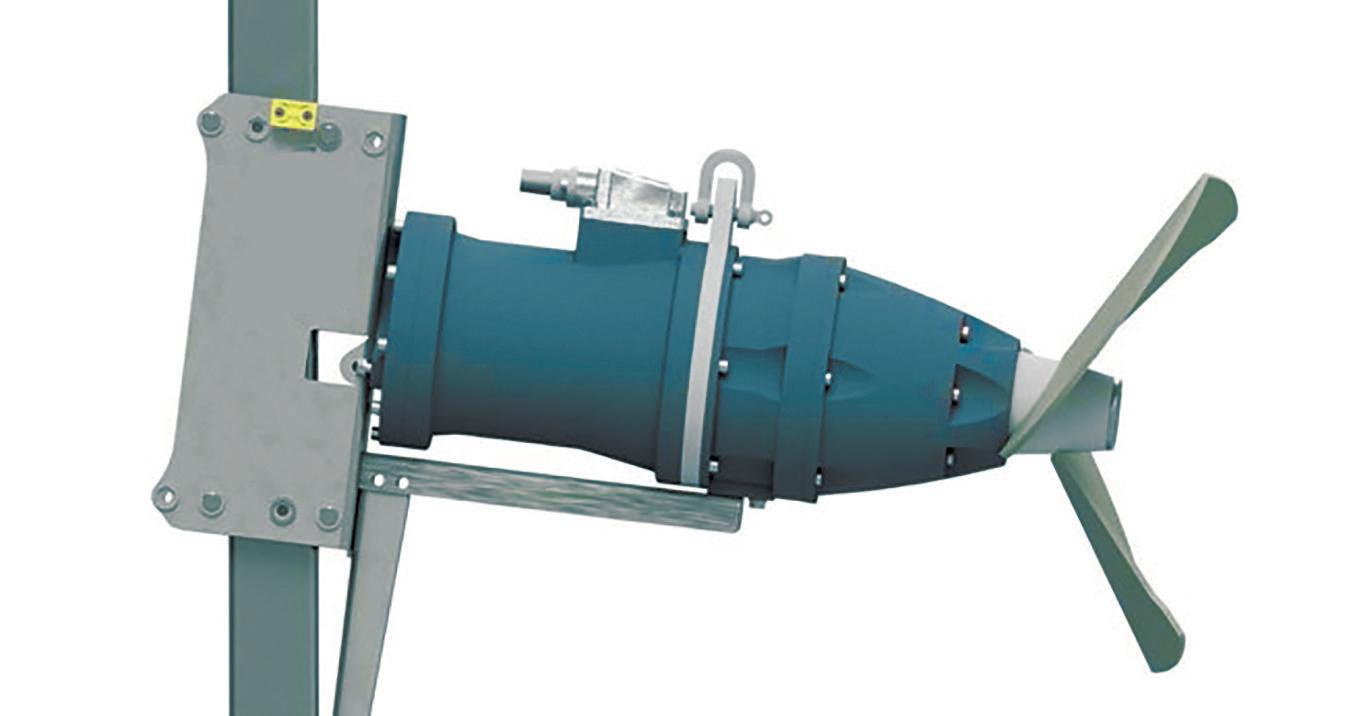

DP SUBMERSIBLE SHREDDING PUMP

The right solution for your farm.

Choose from our wide range of submersible shredding pumps to find the right solution for handling slurry as well as thicker manure. The pump is essentially composed of adjustable blades. Adjusting the contra-rotating blades allows you to shred different-sized fibres contained in manure (e.g. pieces of straw/long fibres).

The special cast alloy pump’s design and its stainless-steel pump shaft ensure the enhanced durability of the pump. The pump body can also be made of stainless steel as optional.

Features

*Values measured in water

16 D 1 D H D 2 N H 1 D 2 D 1 D H N H 1 DP 30/40 DP 55

Type DP30 DP40 DP55 DP75 DP110 DP150 DP185 Power 3 4 5,5 7,5 11 15 18,5 Max. pressure (bar) 0,84 0,88 0,92 1,25 1,4 1,88 2 Max. pump rate 90 98 105 125 135 188 200 Max. counter pressure(bar) 0,5 0,5 0,5 0,7 0,7 1 1 Max. return pressure rate (m3/h) 60 80 82 95 110 140 161 Weight (kg) 70 74 80 153 158 305 305

Which solution is right for you?

6 different power ratings

17 0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 210 220 230 240 250 260 270 280 290 300 310 320 330 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 DP185 DP150 DP110 DP75 DP55 DP30DP40 D 2 D 1 D H D 2 D 1 D H N H 1 N H 1 DP 75/110 DP 150/185

Rate in m3/h Head in m

*Values measured in water Type DP30 DP40 DP55 DP75 DP110 DP150 DP185 H (mm) 595 595 810 730 730 897 897 H1 (mm) 105 105 128 123 123 152 152 N (mm) 343 343 390 392 392 548 548 D (mm) 190 190 220 220 220 265 265 D1 (mm) 150 150 180 180 180 225 225 D2 (mm) 80 80 114 114 114 150 150

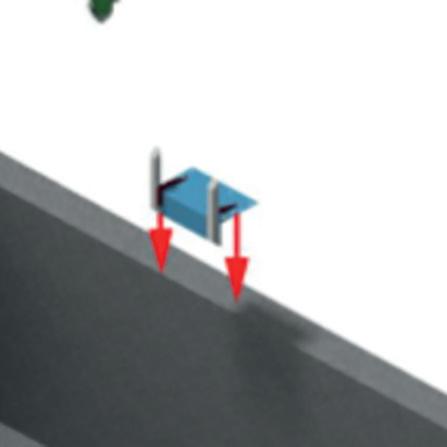

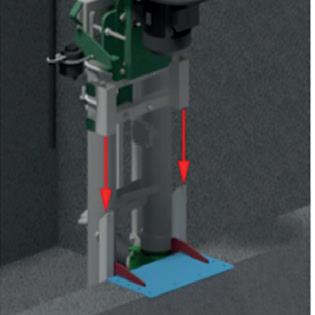

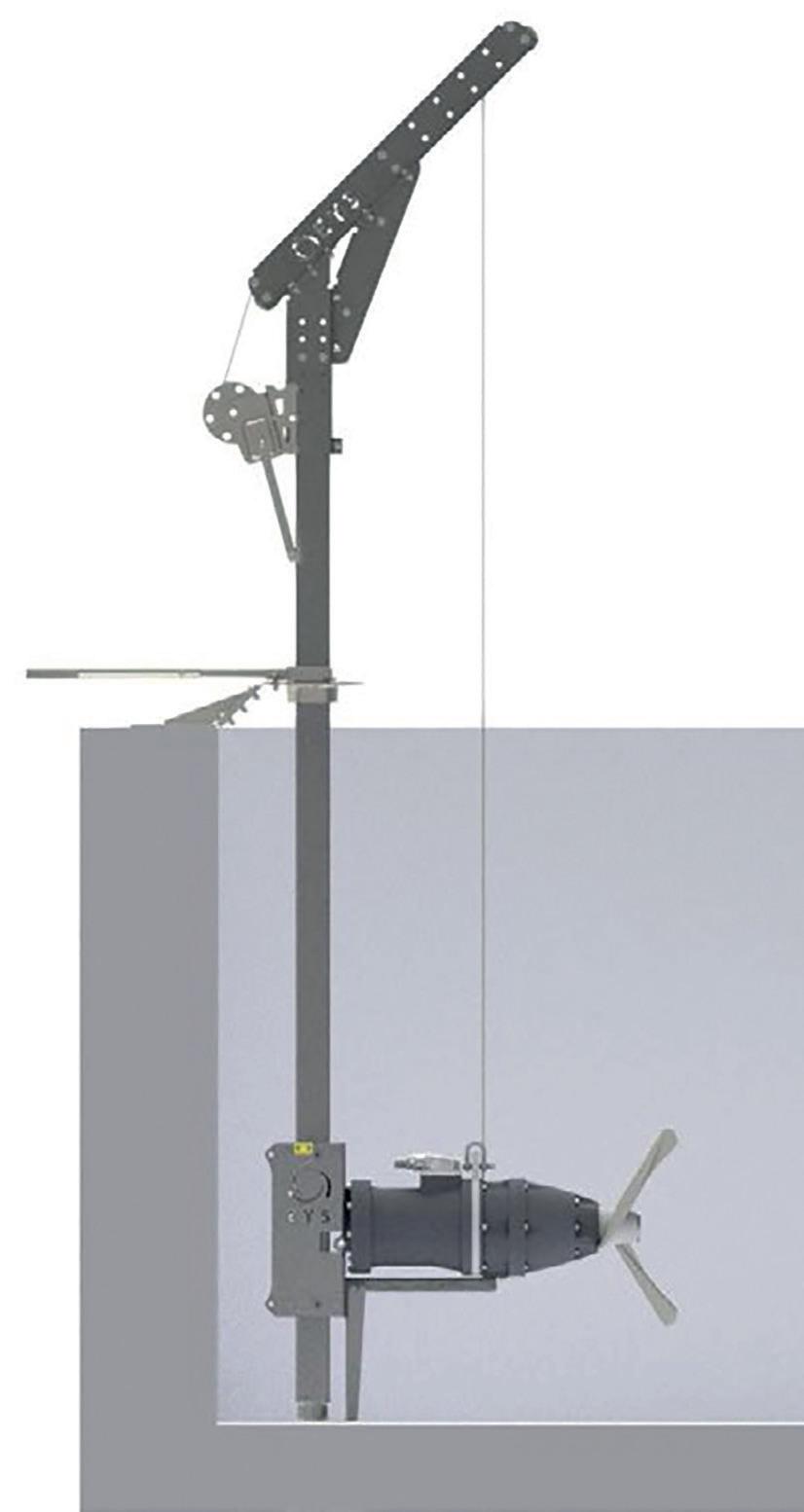

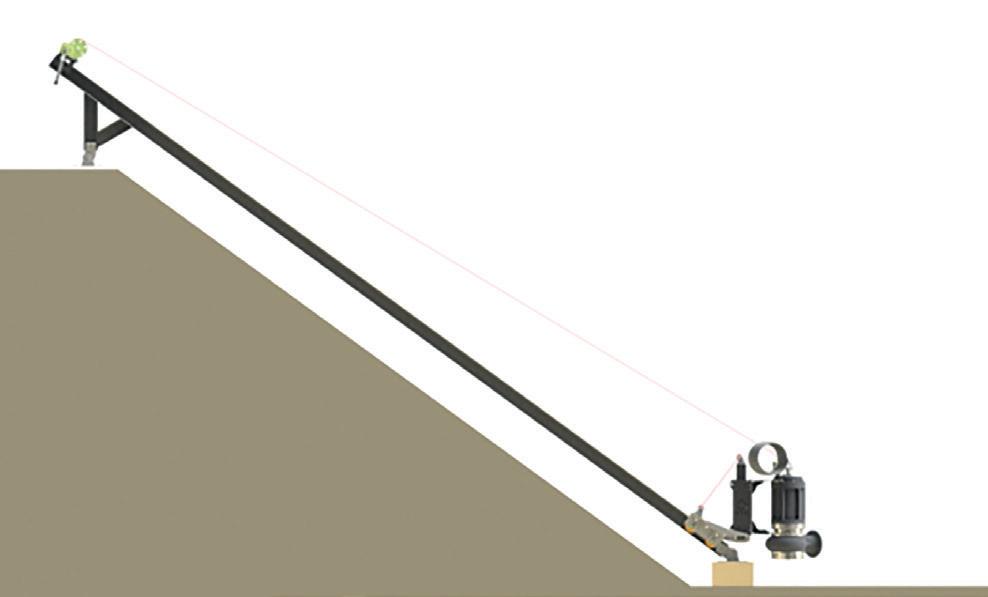

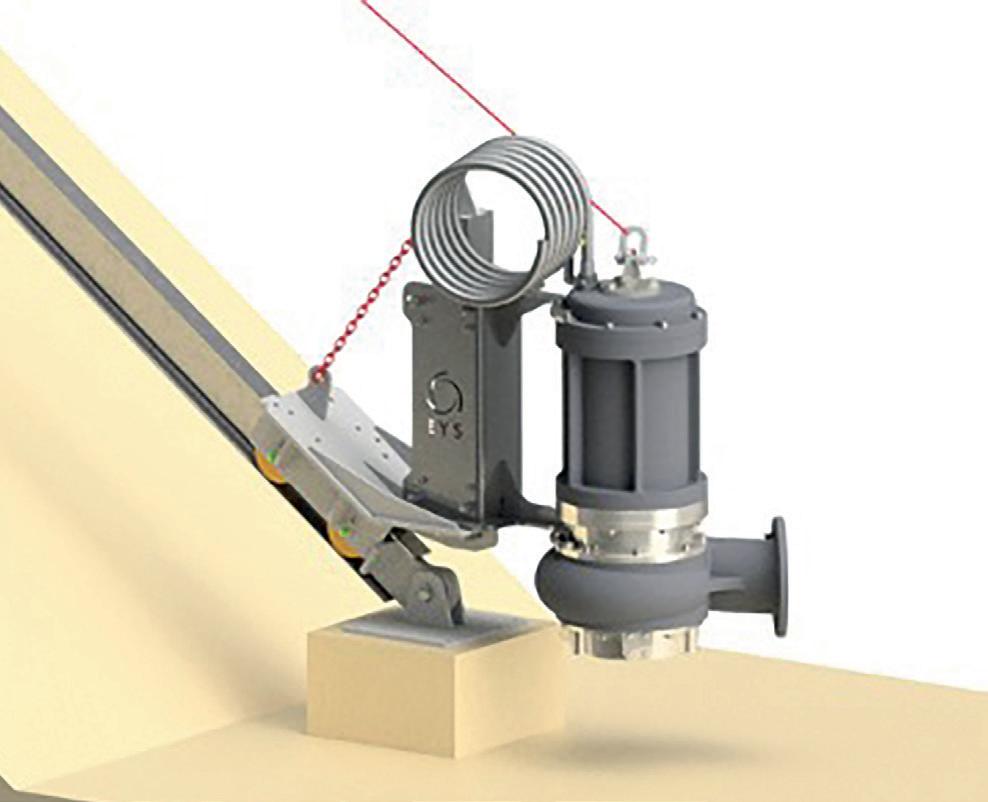

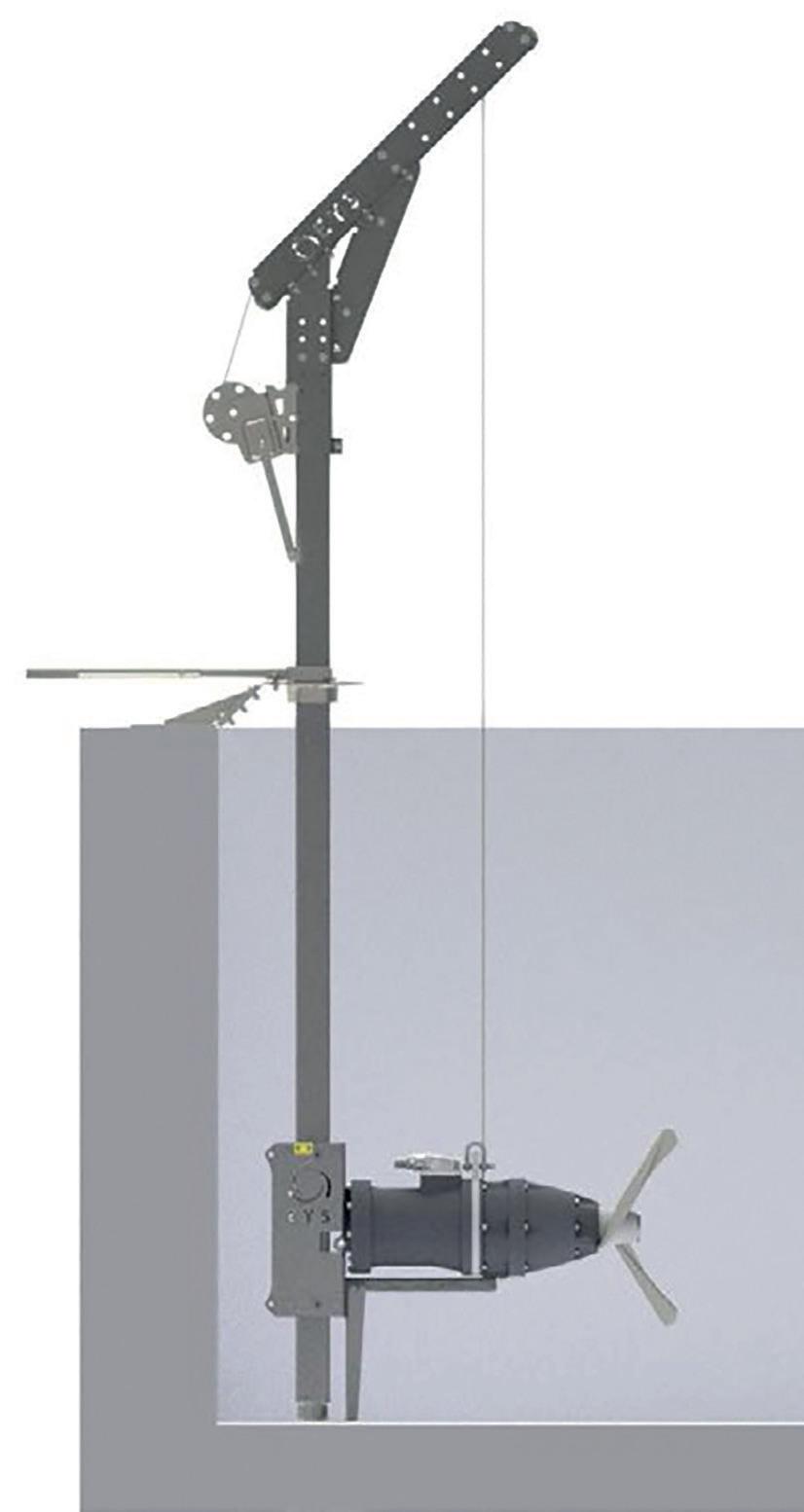

4 mounting options

For each of the mounting options, there are several sizes available to enable it to be optimally adapted to your pit configuration.

18

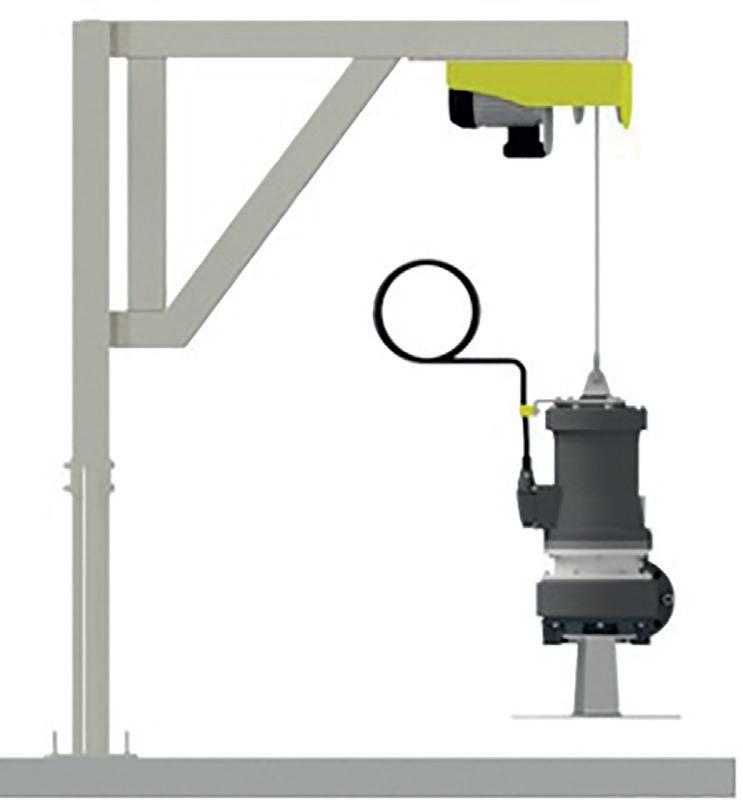

Sur potence avec treuil électrique

On a fixed mast under the slotted floor

On a rotating mast

On an arm with an electric winch Lagoon

Advantages

Contra-rotating blade adjustment enabling you to shred different sizes of fibre

The right solution for the pit: 4 mounting options

The right solution for the farm: 6 different power ratings

High reliability

19

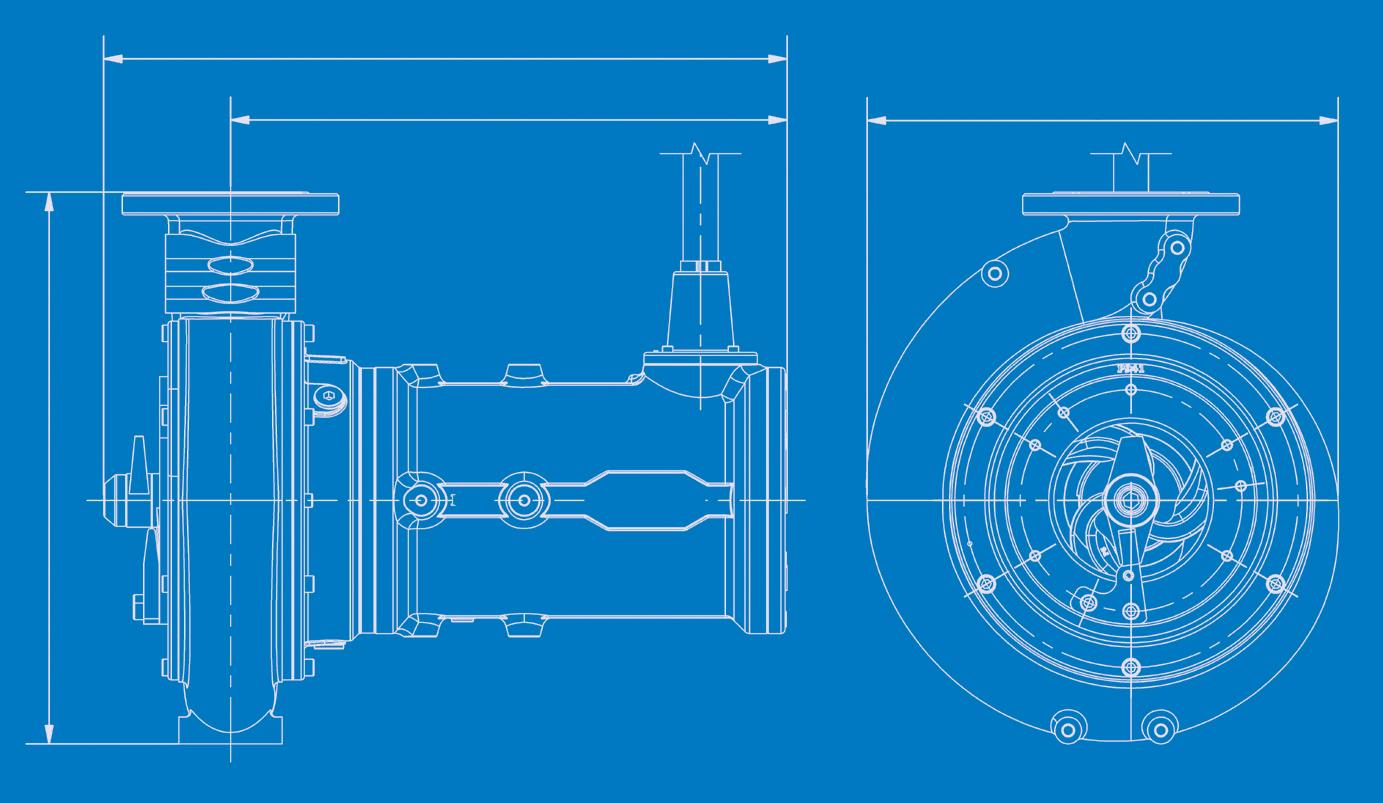

DG HEAVY FLOW MACERATOR PUMP

BouMatic macerator pumps have been designed for the toughest applications. Their reinforced housing for extreme applications (heat-reinforced as optional for use with sand), cast iron body (stainless steel as optional) and blade system, make them the most effective pumps on the market.

The BouMatic DG pump is a high-performance pump that enables you to pump heavy loads at a high rate (350-400 m3/h)

The suction and maceration concept of BouMatic’s DG pumps offers optimum performance:

Macerator blade system comprising up to 3 blades (1 blade supplied as standard, if I’ve understood correctly)

Inlet designed to protect the pump body and seals

Reinforced propeller for unrivalled durability

20

21

3 mounting options

Top wall outlet

Bottom wall outlet

Mounted with a chain and a foot on the pump

Features

*Values measured in water

22 C D A B

Type DG50 DG65 DG80 DG105 DG150 Motor power (KW) 0,55 0,75 1,1 1,5 2,2 3 4 5,5 7,5 11 15 18,5 18,5 22 30 Consumption 3x400V amp. 1,6 2,6 3,4 5,0 6,7 8,8 11 15 21,5 29 35 35 43 57 Opening required for the pump to pass through 550x400 650x500 750x550 850x650 900x650 1000x750 Weight (kg) 25 45 50 55 80 85 100 150 160 200 210 265 325 350 A (mm) 250 320 320 320 370 370 370 460 460 460 460 580 580 580 B (mm) 300 380 380 380 440 440 545 545 545 545 545 754 754 754 C (mm) 365 445 445 450 550 550 580 665 665 710 710 690 820 820 D (mm) 290 361 361 366 445 445 480 540 540 585 585 585,5 715 715

FLUSHING

BouMatic offers two solutions for flushing out waiting areas, passages and scraping aisles:

DG heavy flow pump

Special flushing version of the FP vertical pump

The 160-diameter valves have been specially designed to not stem the flow so that a maximum flow rate can be achieved by reducing the energy.

FLUSHING VALVE

When the pump is off, the valve is closed.

When the pump starts, the flow of liquid causes the valve to lift and send out a spray of water. The water creates a wave that cleans the surface.

FP FLUSHING PUMP

The flushing pump is used to pump liquids with a high flow rate.

The flushing pump is also used for cleaning certain areas with water (e.g. channels, aisles).

The electric motor drives the trapezoidal belt mechanism and the vertical shaft drives the pump’s propeller.

The design of the flushing pump housing reduces the level of pressure, which increases the capacity.

It helps maintain the cleanliness of your aisles by providing a constant and reliable flow of water.

The pump rate varies depending on the type of motor.

Available for pits of 2 to 5 m

Power ratings of 5.5 to 30 kW

24

25 A L B Type |A| (mm) |B| (mm) |L| (mm) Weight (kg) FP-6 2070 2215 2000 546 FP-8 2670 2815 2600 598 FP-10 3270 3415 3200 651 FP-12 3870 4015 3800 703 FP-14 4470 4615 4400 755 FP-16 5070 5215 5000 807

MPT GRAVITY-FED MACERATOR PUMP

Dry configuration pump

BouMatic pumps are equipped with a unique combination of static and rotating blades, making them the ideal solution for finely shredding and transferring organic waste with a high dry matter content.

The blade system and shape of the pump housing ensure the pump’s smooth suction capacity.

Wearing parts such as pump gears and pump housing can be supplied in reinforced material so that wear is reduced by half when pumping sandy slurry or manure containing abrasive elements, for example.

Capacity up to 475 m³/h.

In short

Motor sizes from 0.75 to 30.0 kW

Lifting height up to 50 metres

Compact design

*Values measured in water

30 25 20 15 10 5 0 45 60 75 90 105 120 135 150 0 50 100 150 200 250 300 350 400 450 500 10 15 20 25 30 35 40 0 15 30 45 60 75 90 105 120 135 80 105 A C D B E F 0 I H G J Q[m3/h] H [ m ] Q[l/s] Type MPT 55/80 MPT 75/105 MPT 110/105 MPT 150/105 MPT 185/105 MPT 220/150 MPT 300/150 Power ratings (Kw) 5,5 7,5 11 15 18,5 22 30 Consumption (A) 11 15 21,5 29 35 43 57 Dimensions (LXlXH) (mm) 635x370x540 670 x 457 x 534 720 x 457 x 534 730 x 457 x 534 870 x 580 x 740 Weight 100 140 160 200 210 330 360 Dimensions A (mm) 522 640 640 640 640 822 822 B (mm) 280 340 340 340 340 380 380 C (mm) 635 670 720 730 730 870 870 D (mm) 540 565 615 625 625 725 725 E (mm) 370 460 460 460 460 580 580 F (mm) 205 250 250 250 250 320 320 G (mm) 0192 0 212 0 285 H (mm) 150/160 170/180 240 I (mm) 0 82 0 107 0 152 0 (mm) 4/ 010 J (mm) 10 10 12

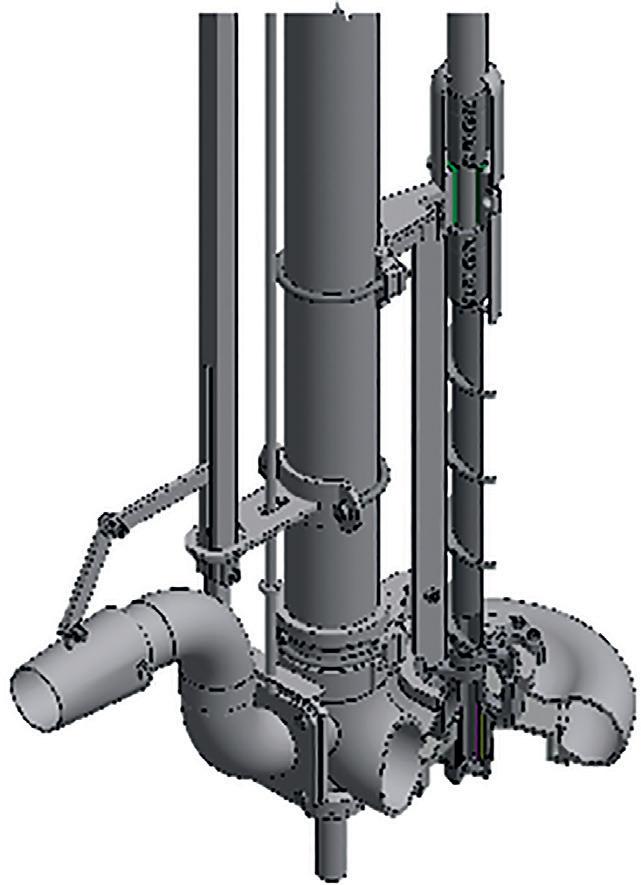

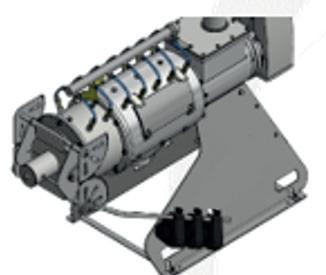

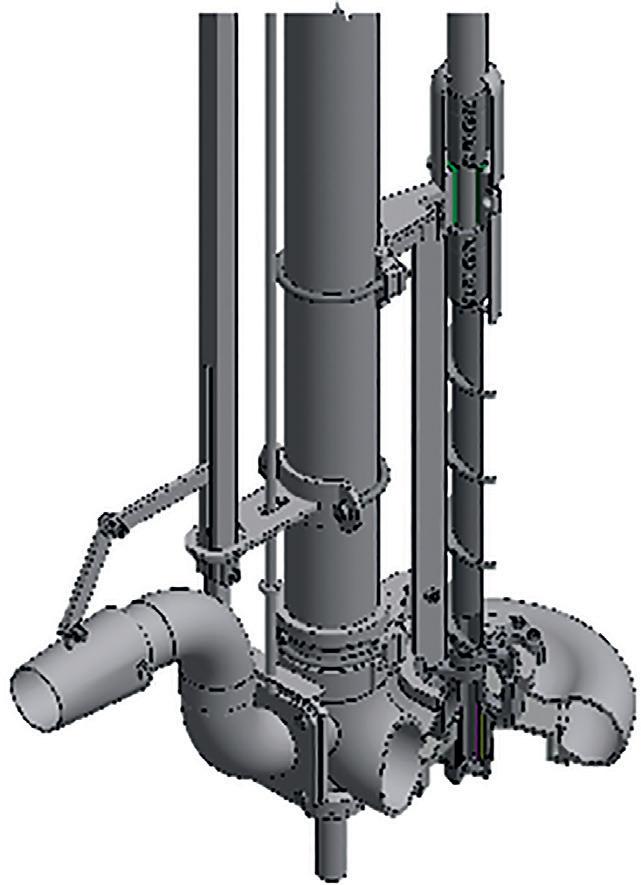

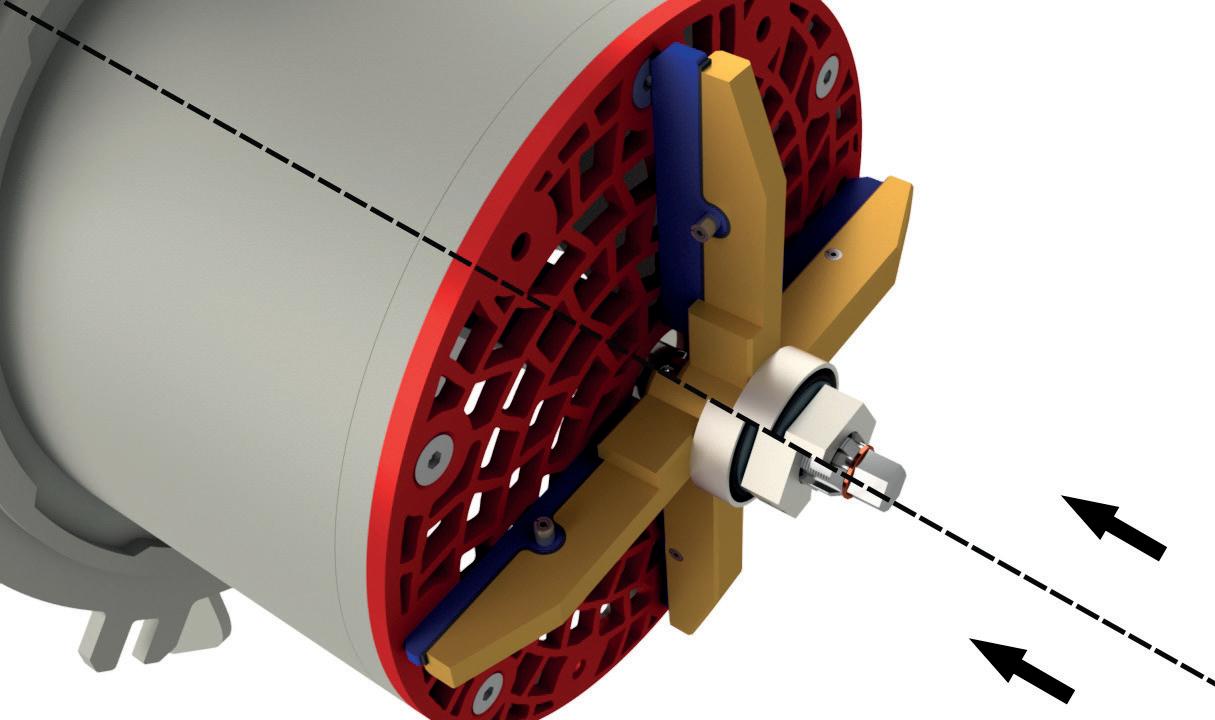

PISTON PUMP

The BouMatic piston pump is a hydraulic drive unit used for pumping slurry, manure, and semi-solid and viscous digestate across long distances with minimal power.

Several configuration options are available:

A hydraulic power unit for one pump

A hydraulic power unit for two pumps; two heights available 3.38 or 2.48 m

Top sensor

Hydraulic cylinder

Bottom sensor

Cleaning flange

Feeding hose

Discharge hose

28

*Values measured in water **The

distance

the pump can even transfer it over a distance

1 kilometre. Type PP55 PP110 PPS55 PPS110 Number of pumps 1 2 1 2 1 2 1 2 Hydraulic power unit rating (kw) 5,5 5,5 11 11 5,5 5,5 11 11 Oil capacity (power unit) (L) 100 100 100 100 125 125 150 150 Pump capacity (cm3) 26 26 36 36 26 26 36 36 Flow (m³/h)* 25 50 50 100 20 45 45 90 Inlet diameter (mm / inch) 200/8 200/8 Outlet diameter (mm / inch) 150/6 150/6 Max. pumping depth**((m) 8 8 Discharge distance*(m) 1000 1000 Max. discharge height 60 60

transfer

and pumping depth vary depending on the consistency of the slurry. If the slurry is well mixed,

of

A simple yet effective mechanism for greater longevity.

Two sensors are integrated into the pump. They are activated by the position of the piston in the chamber. When the sensor at the bottom is activated, a signal is sent to the piston to return to the top.

During this phase, the waste is sucked into the chamber. Conversely, when the sensor at the top is activated, a signal is sent to the piston to return to the bottom. The waste is discharged from the chamber and pumped out.

30 A B C D E F G H I J K L M N O P

With the BouMatic piston pump, you can pump manure without any risk of damaging the internal parts. No mechanical elements are in contact with the product. The pump is designed to have very few parts requiring maintenance. It also consumes less energy (compared to a rotary lobe pump). Its daily usage cost is very low.

Dimensions PP55-PP110 PPS55PPS110 Dimensions PP55PP110 PPS55PPS110 A 2193 I 1458 B 347 J 2684 C 520 K 562 D 449 L 1700 1250 E Ø18,2 M 3378 2477 F 700 N 202 G 820 O Ø650 H 900 P Ø508

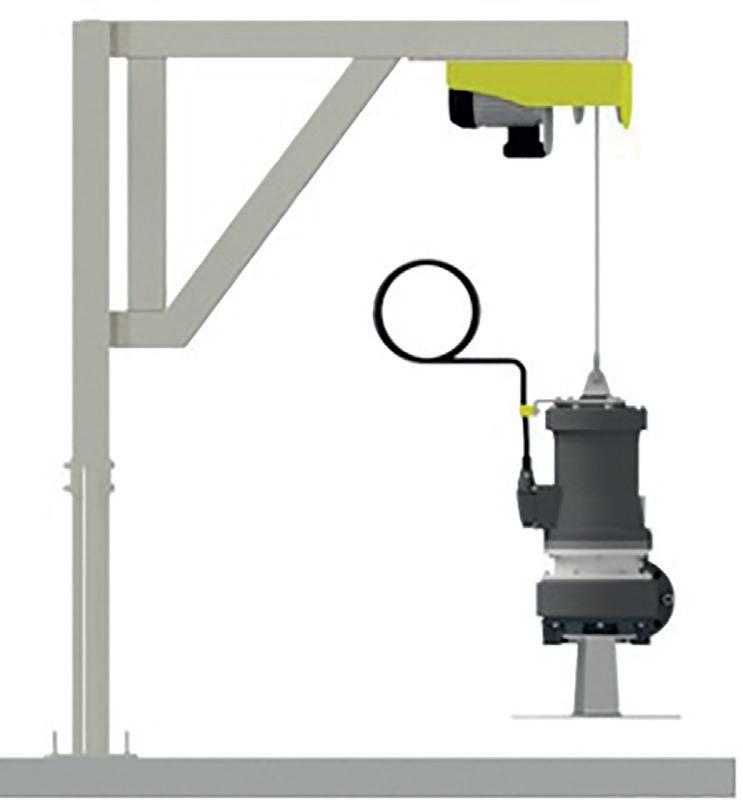

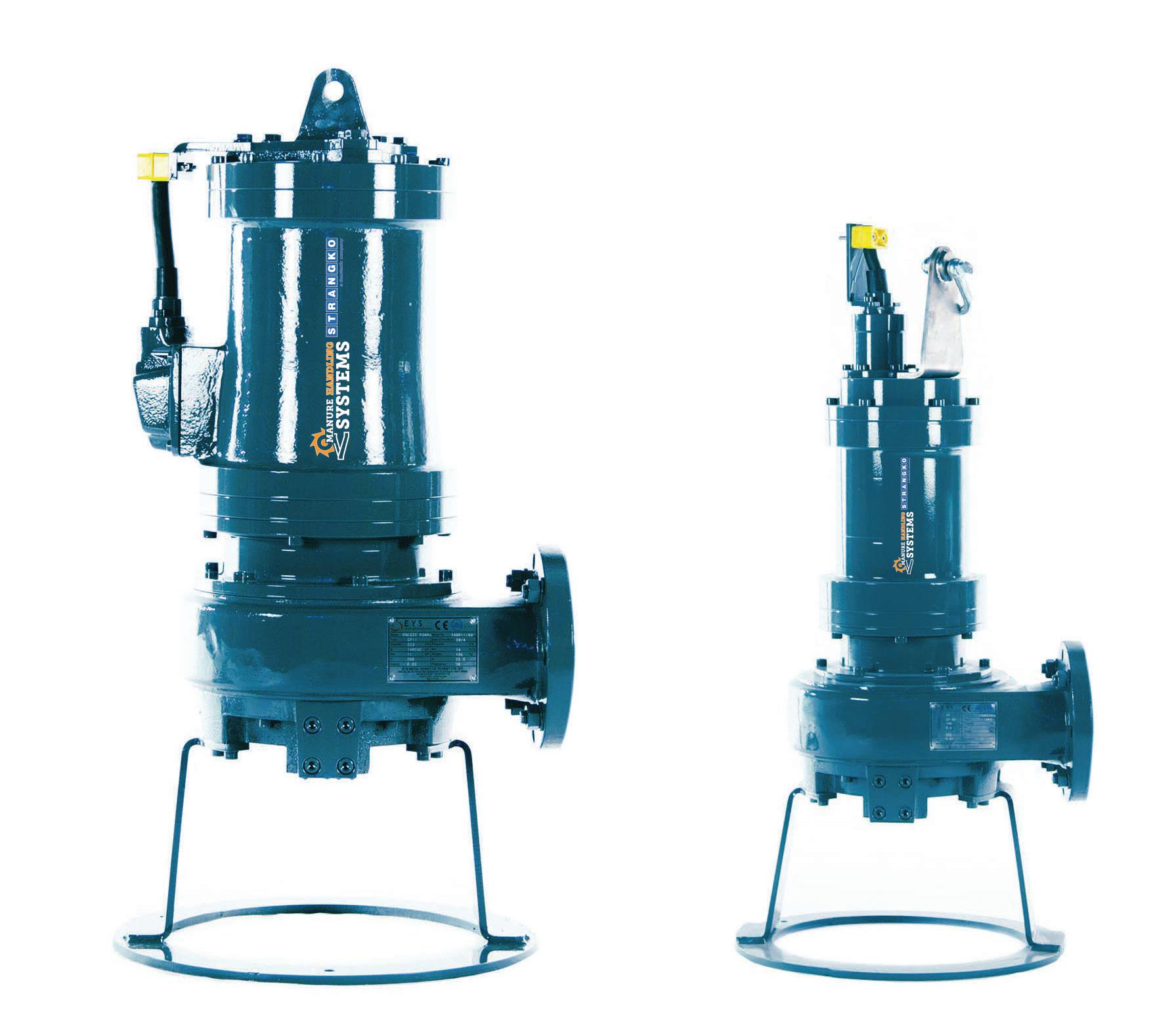

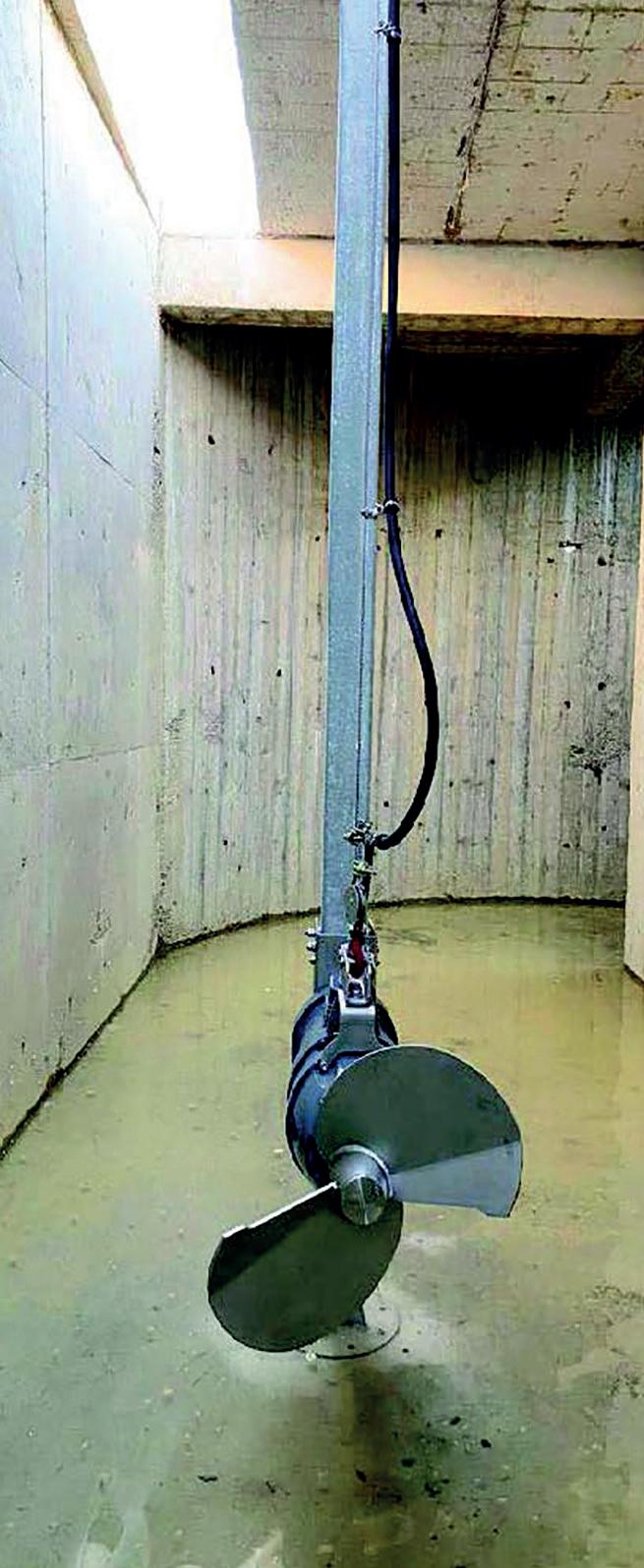

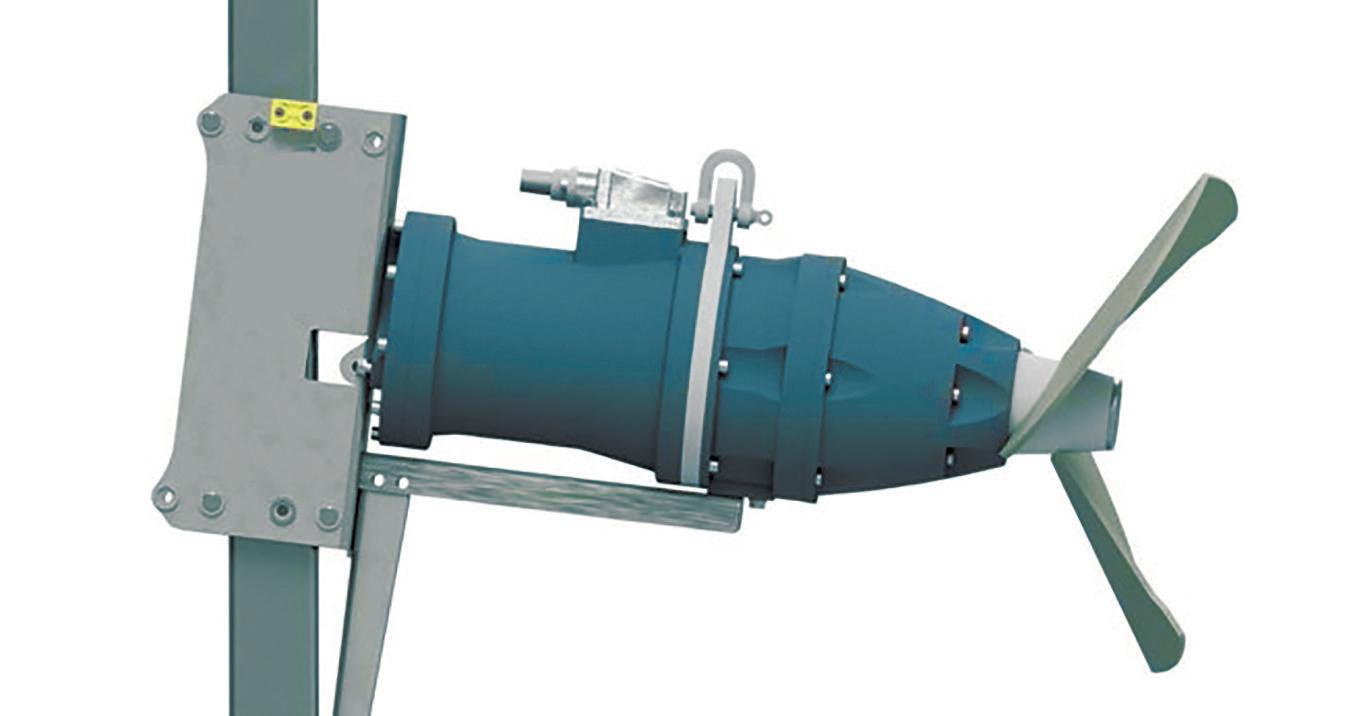

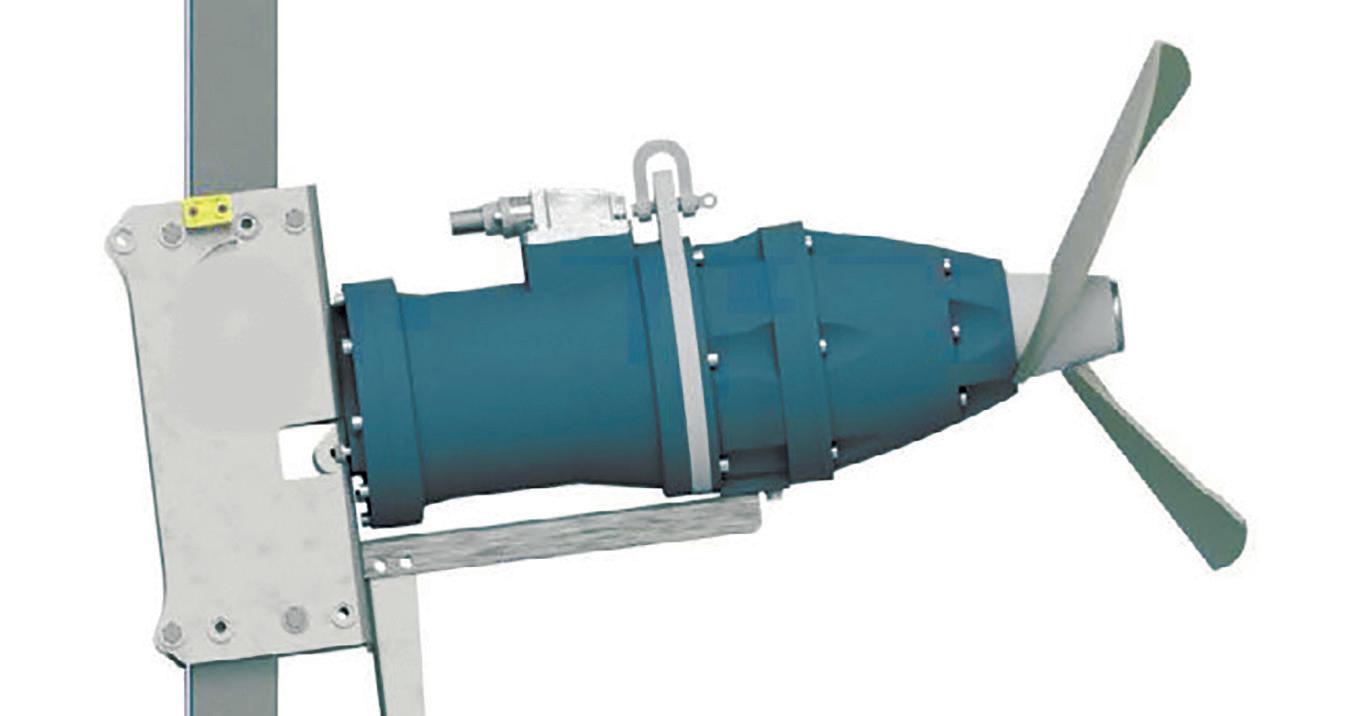

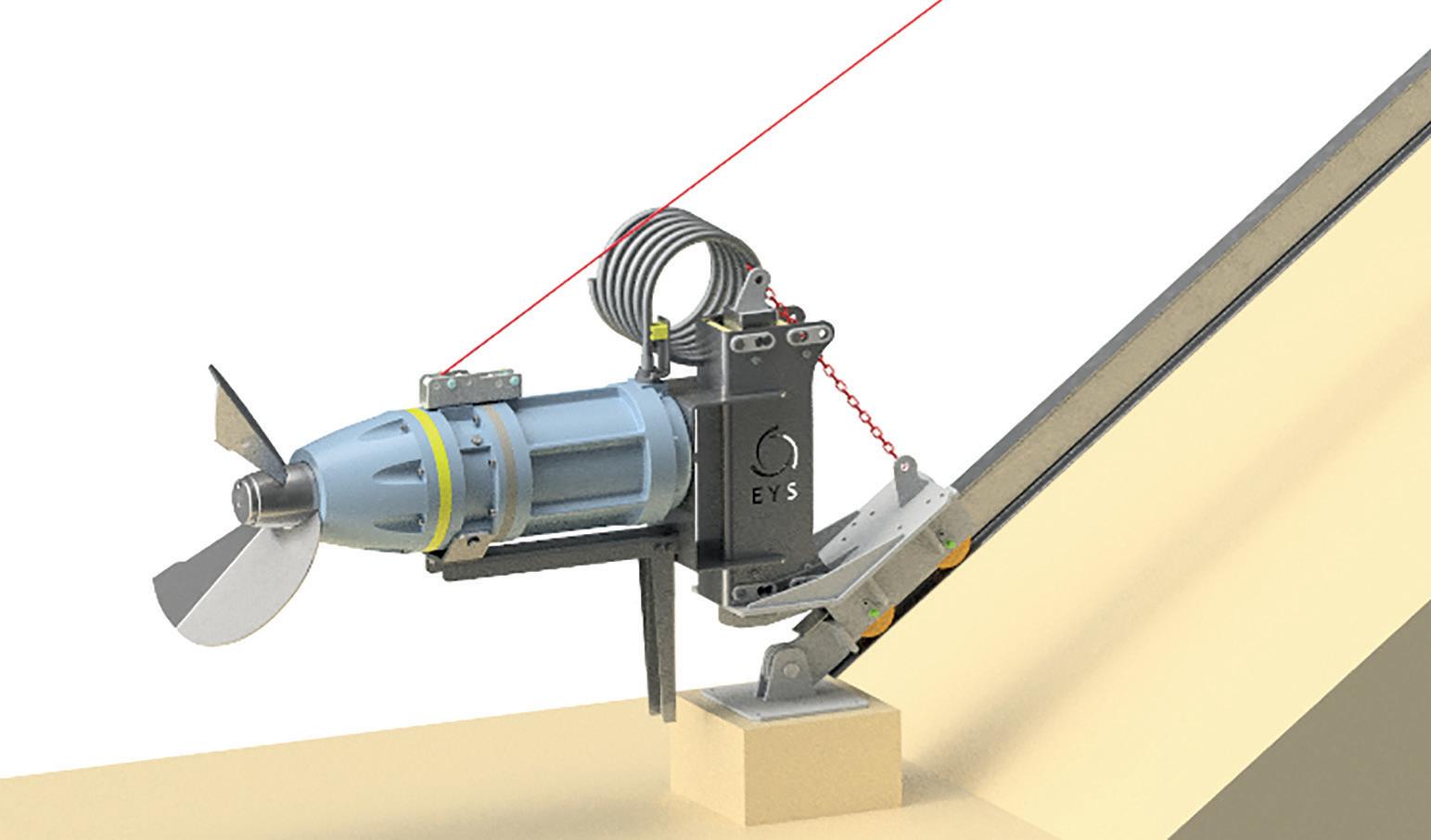

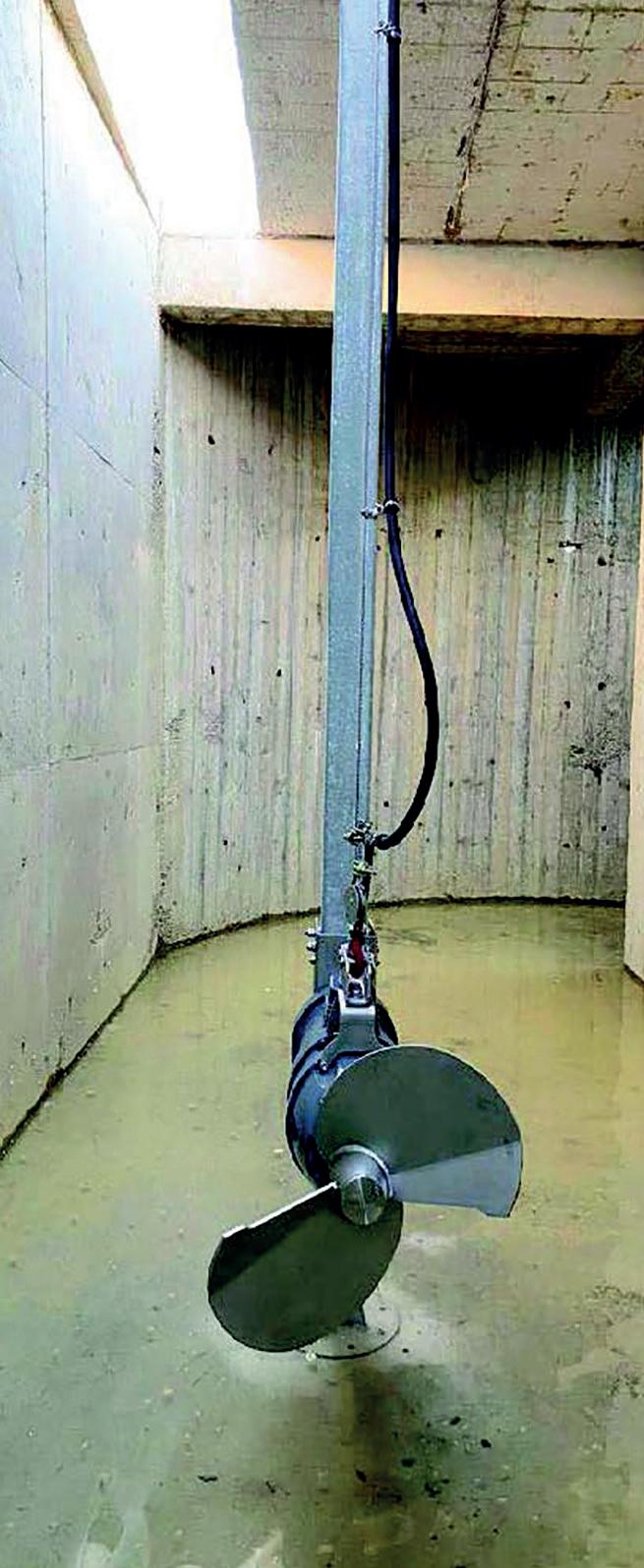

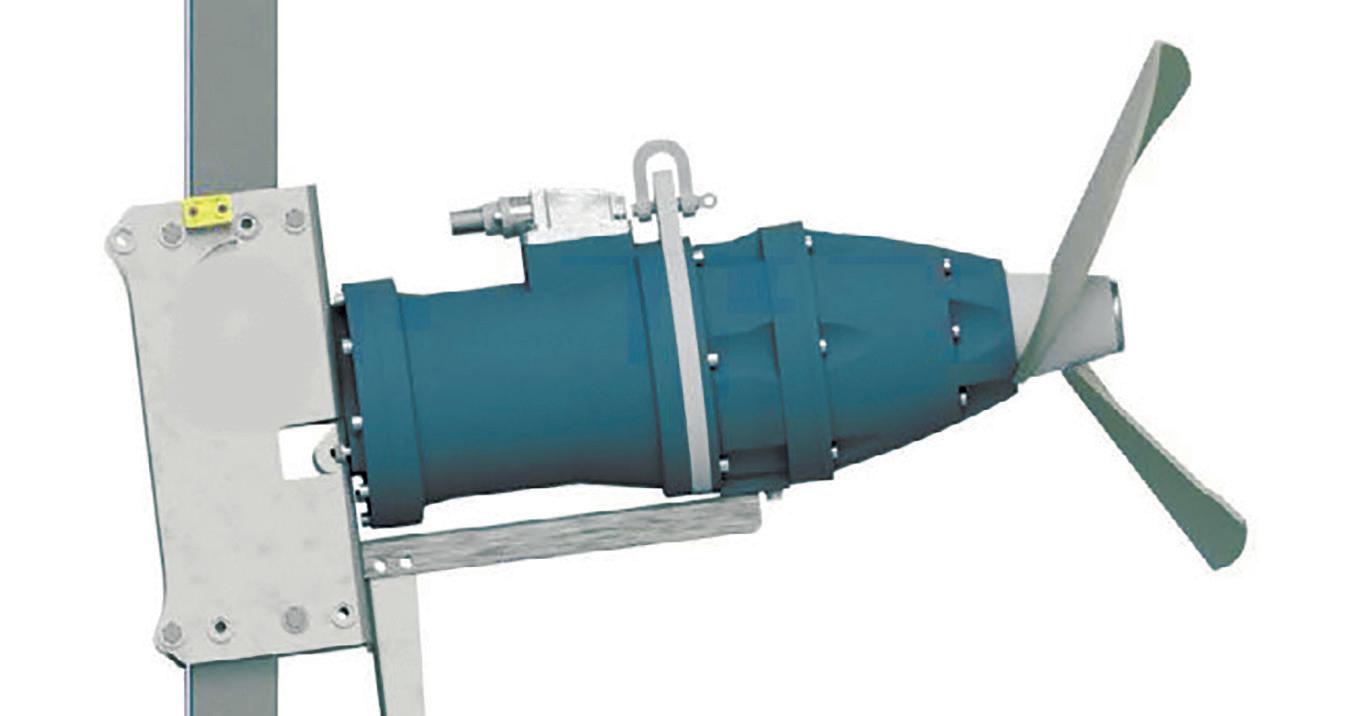

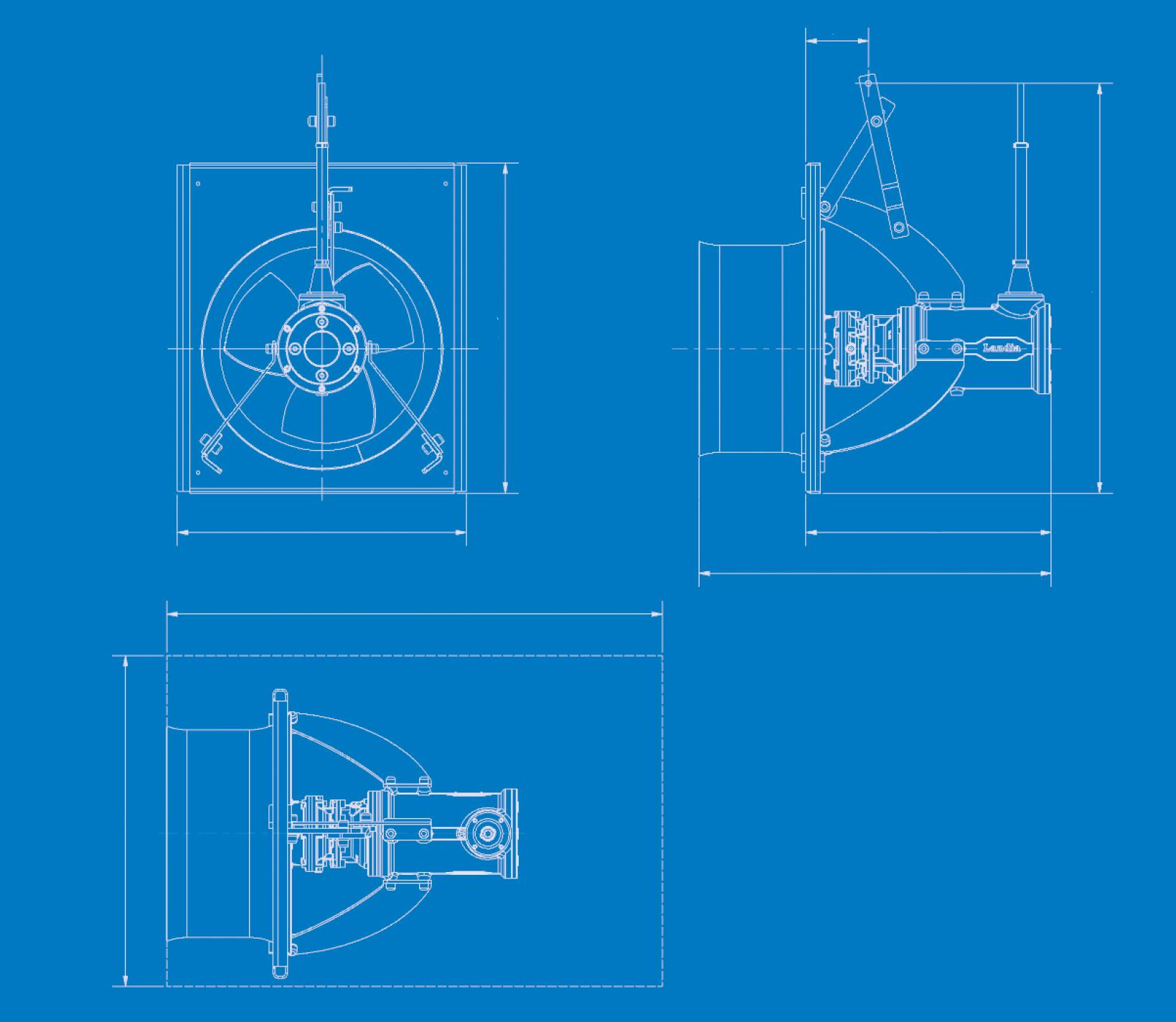

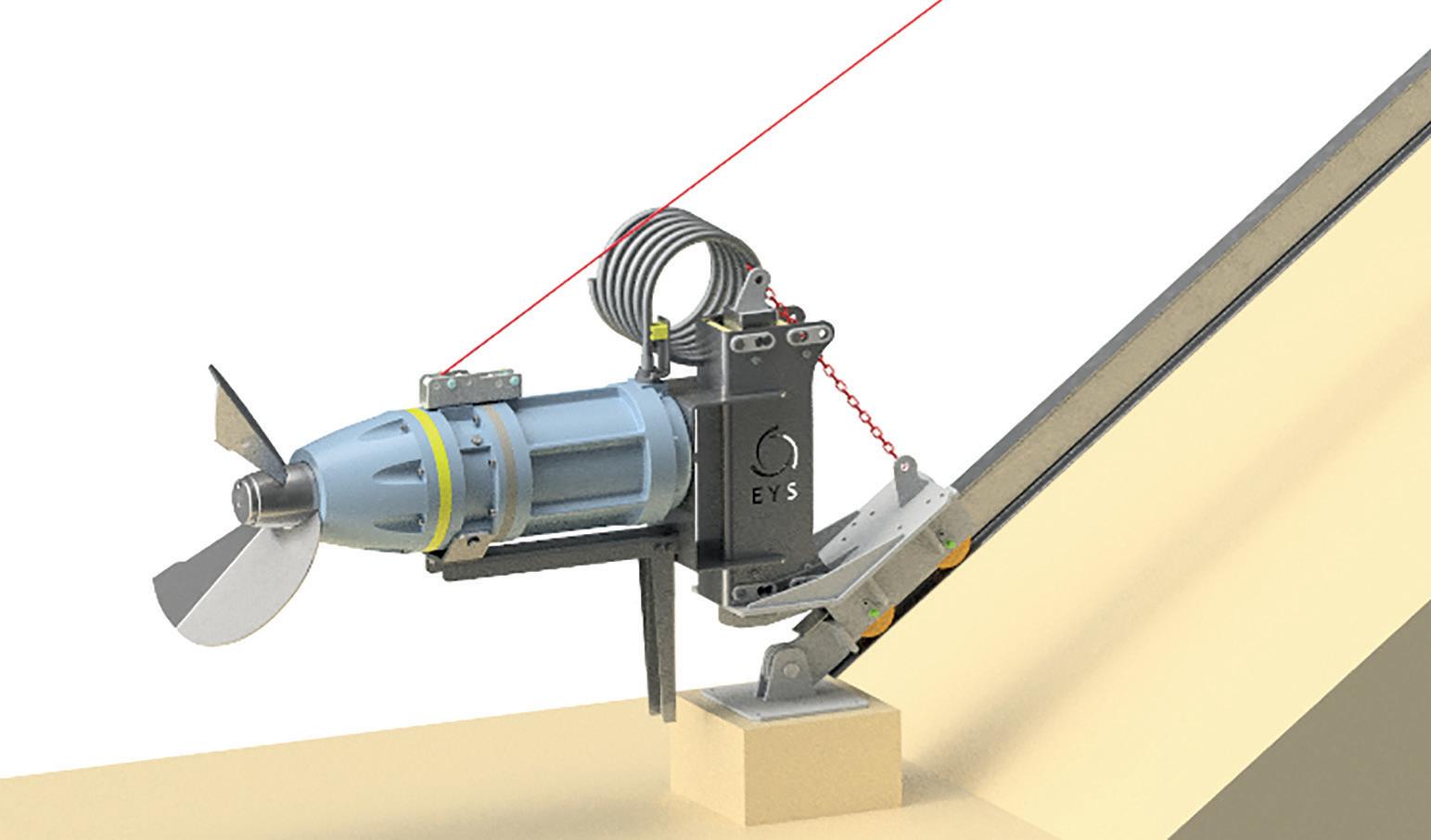

DK SUBMERSIBLE AGITATOR

BouMatic DK and DK EX submersible agitators have a sleek, slim design thanks to their planetary gearboxes. The large propeller blades of the submersible agitator make it ideal for blending/ homogenising manure and biomass in slurry pits, pre-pits, slurry channels, biogas digesters, postdigesters, and so on. Submersible agitators are also suitable for use in industrial plants and waste water treatment plants due to their superior construction and design.

Included in the delivery

Stainless steel screws

IP68 level of protection

Propeller in stainless steel 1.4301

Leak sensor in the gearbox housing

10-m E cable incl. 8 parts

Cable clamp

Thermal sensor in the coils (PTC100)

Mechanical seal between the gear and the fluid

Mechanical seal between the gear and the electric motor

Stainless steel 1.4301 bracket (for 100 x 100-mm mast)

2 directions of travel

32

The stirring power for a homogeneous product.

The BouMatic DK agitator has a three-blade propeller. The advantage of a three-blade agitator is that it stirs a greater volume per hour than a two-blade agitator using the same amount of power. This means faster stirring and an energy saving of up to 15%.

2 directions of travel

The blades can also be used in both directions of travel, i.e. to suck up or discharge the manure. This feature is particularly useful when working with a highly viscose material. Once again, the agitator is designed with maximum longevity and minimal servicing in mind.

33

The BOUMATIC DK range provides impressive working results, practicality and flexibility to meet your high demands for mixing. Its robust construction, attention to detail and high-quality components guarantee the superior mixing results you expect on your farm.

Whether you are using it for aerobic or anaerobic applications. BOUMATIC submersible agitators guarantee a long service life with minimal maintenance.

Whatever the shape or size of your pit, we have the right submersible agitator to suit your needs. With models from 7.5 kW to 18.5 kW, we offer a wide range of submersible agitators to meet all your mixing needs.

4 configuration options

Thanks to its sleek design, the agitator can be used to blend and homogenise organic waste in a diverse range of settings, such as lagoons, channels, fermenters, and so on.

Pit agitators

Option to add a flow concentrator to stir pits or slotted floors

Slalom agitators

34

Features

*Values measured in water

C A B D E F G C A B D E F G MIXEURS IMMERGE STANDARD DK75 DK11 DK15 DK185

Type DK75 DK11 DK15 DK185 Number of propellers 2 3 2 3 2 3 2 3 Power ratings (KW) 7,5 11 15 18,5 Weight (kg) 210 214 220 225 430 435 440 446 Motor speed (T/mn) 1450 Propeller speed (T/mn) 325 Propeller diameter 570 620 610 660 660 730 740 790 Blending capacity 3600 3800 5200 5500 6500 6900 6800 7500 Max. power rating (A) 15,6 22,7 30,4 37,6 Voltage/frequency 380 v /50Hz Dimensions A (mm) 500 500 650 650 B (mm) 215 215 226 226 C (mm) 1130 1070 1170 1115 1550 1420 1570 1436 D (mm) 648 648 926 926 E (mm) 435 435 700 700 F (mm) 284 284 332 332 G (mm) 570 620 610 660 660 730 740 790

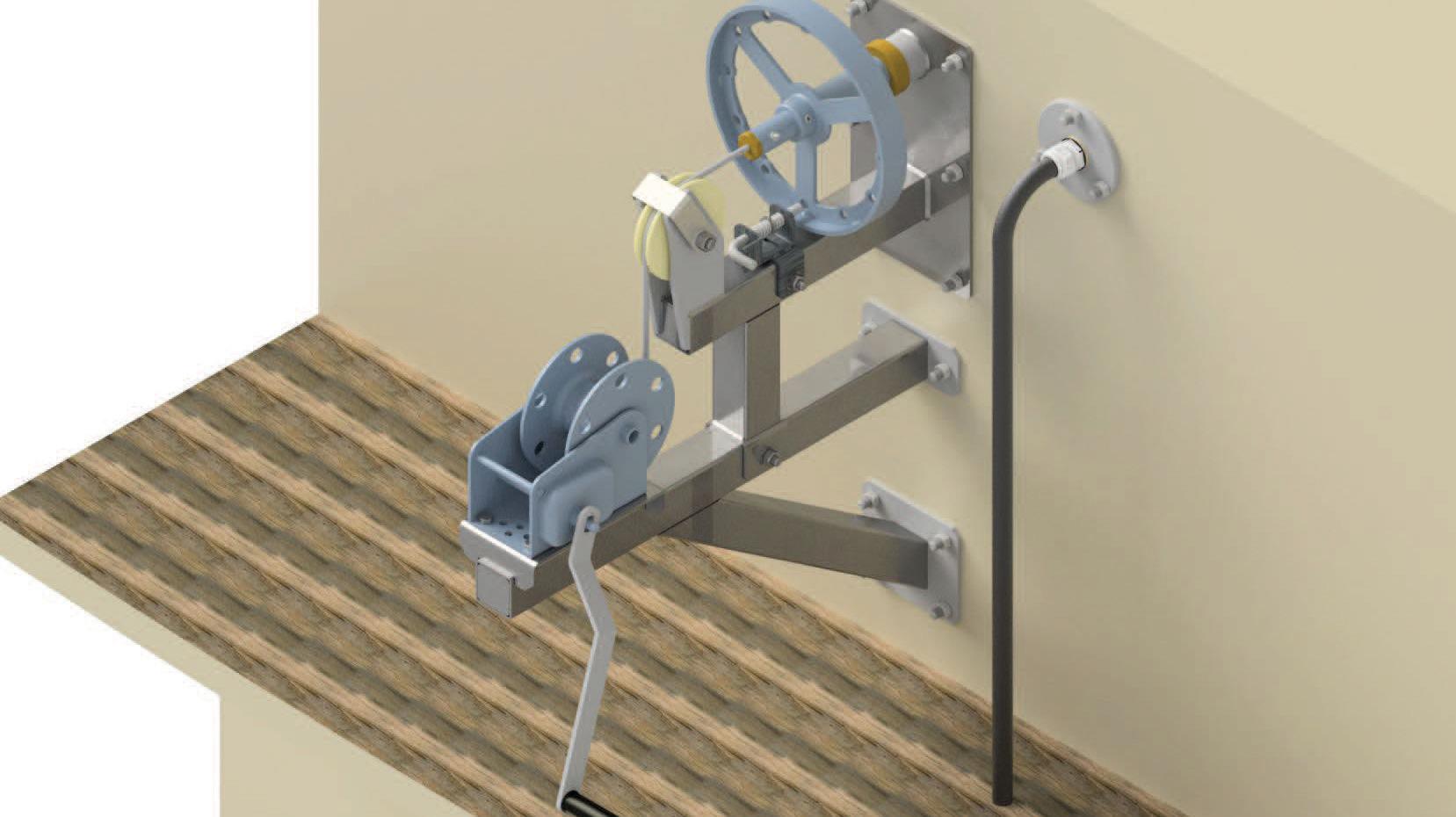

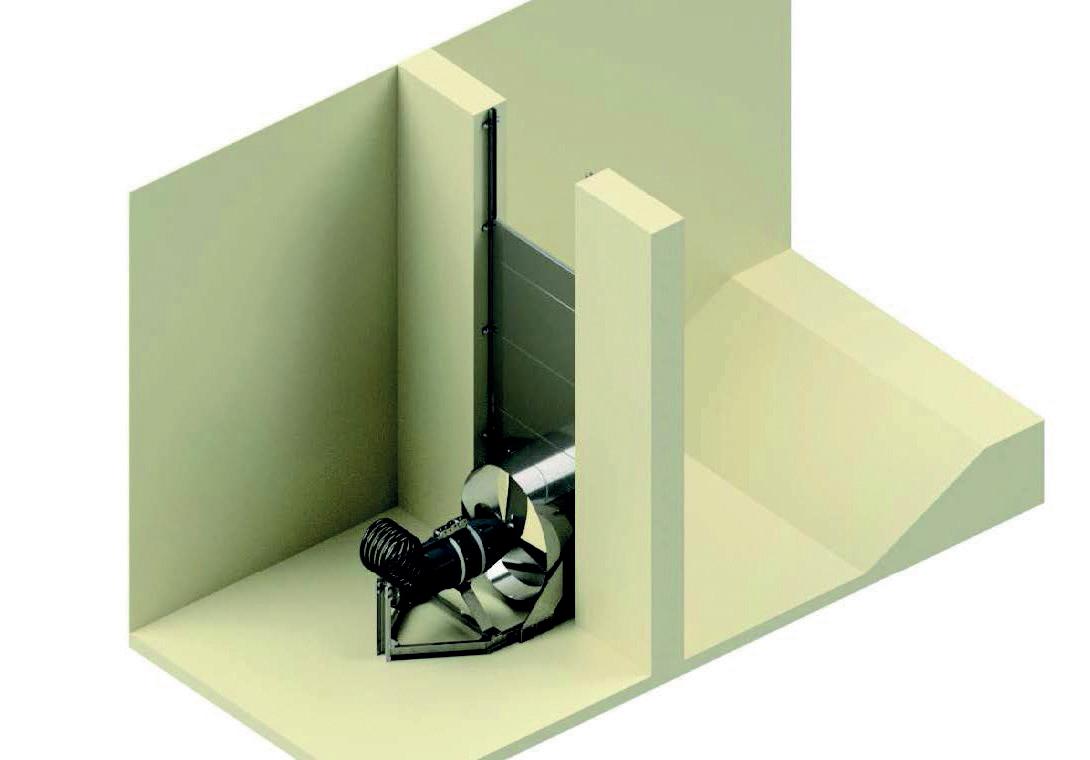

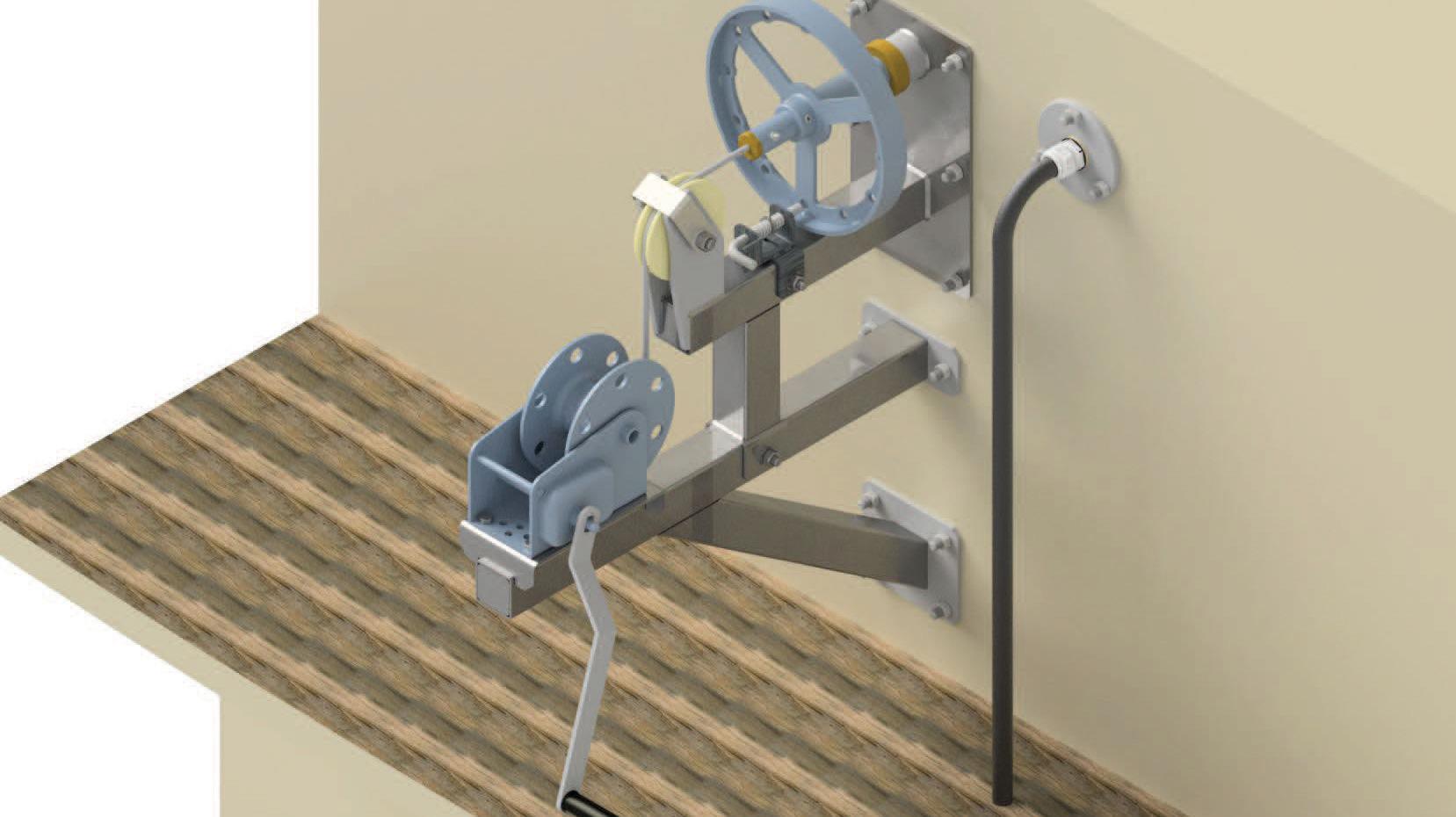

3 mounting options

An agitator platform to enable you to work in complete safety – a custom solution for biogas applications. The unique design of the biogas platform makes it one of the best solutions for checking the agitator settings in complete safety. The areas that come into contact with the manure are made from stainless steel AISI 316. The integrated manual winch enables you to lift the agitator up to the same height as the service window and pivot it horizontally with the aid of a rotation mechanism.

36

.

Bottom mixing / -7°

POP SLURRY AGITATOR

The BouMatic POP slurry agitator is a robust and effective full-service agitator. The propeller is specially designed with three low-speed blades, making it ideal for mixing even very thick slurry.

The shape of the propeller produces optimum mixing results. Up to 4000 m3.

Numerous sizes, fittings and hoist systems are available.

Easy to install. Even in a slurry-filled reservoir. Can be repositioned for use in multiple reservoirs.

In short

Motor sizes from 3 to 30.0 kW

Triple-sealed system

Mixing capacity up to 4000 m3

37

BOUMATIC AXP CHANNEL AGITATORS

BouMatic AXP channel agitators are intended for circular stirring and for mixing slurry in the channels beneath slotted floors. They allow you to effectively mix your manure to ensure it is always of a smooth consistency.

The design of the propeller enables it to be adapted to applications such as a channel with low levels of liquid. The agitator is also lightweight, allowing it to be repositioned and used in multiple locations.

The agitator can be mounted onto a mobile trolley.

In short

Engine sizes from 5.5 to 18.5 kW

Number of revolutions: 400 rpm

38

B A G H C D E F Type AXP 500 55 AXP 500 110 Power (KW) 5,5 11 Motor speed (T/mn) 1440 1455 Current rating (400v) (A) 11 21,5 Start-up. Current intensity (DOL) (A) 68 146 COS PHI 0,87 0,84 Degree of effectiveness 84,6 87,9 Weight (kg) 145 195 Dimensions A (mm) 800 B (mm) 700 C (mm) 1200 D (mm) 800 E (mm) 155 230 F (mm) 1000 900 G (mm) 600 655 H (mm) 860 925 *Values measured in water

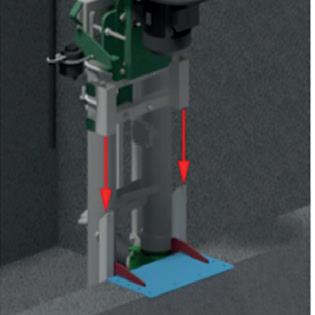

TROLLEY-MOUNTED AGITATOR POD

Power from 2.2 to 11 kW

Area of application:

Stirring slurry beneath slotted floors. Effectively mixing floating sludge and sediment into the liquid phase improves the consistency of the slurry, making it easy to pump.

Push the agitator to the stirring site. Then lift up part of the slotted floor and immerse the agitator into the slurry using the winch. You can also lift, lower and turn the agitator. This allows the slurry to be easily and effectively homogenised in the various parts of the channel.

40

Specifications and performance: Motor, 3x400 V: 2,2 kW 5,5 kW 7,5 kW 11,0 kW Current 5,2 amp. 10,5 amp. 15,0 amp. 21, amp. Propeller revolutions: 1500 t/m 1500 t/m 1500 t/m 1500 t/m Yield 360 m³/h 920 m³/h 1450 m³/h 2000 m³/h

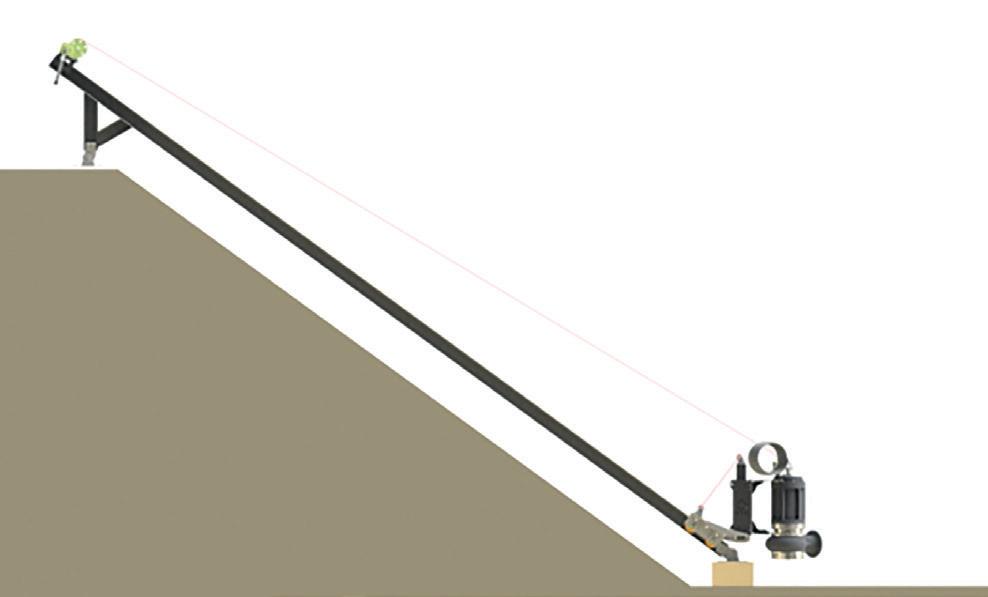

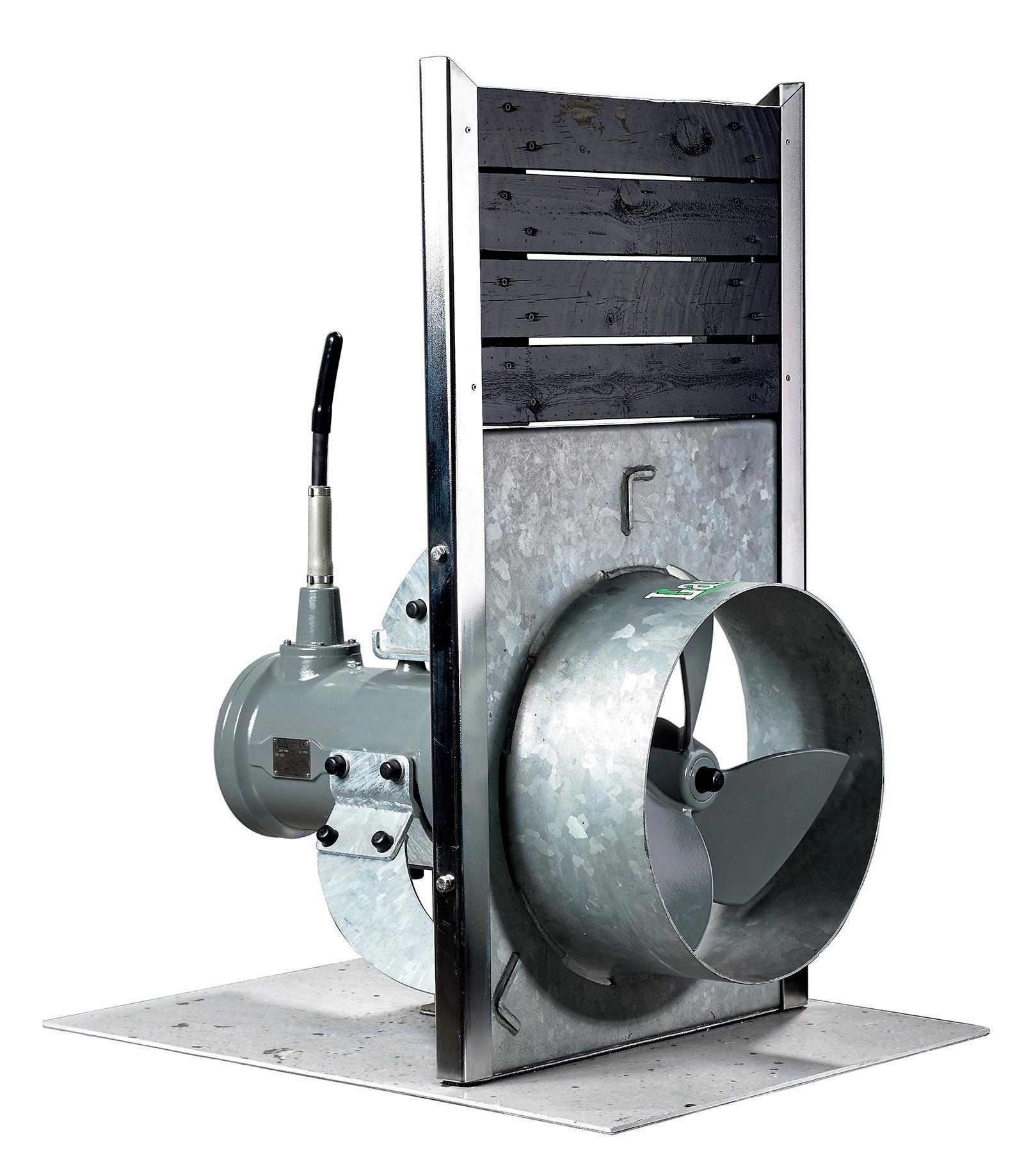

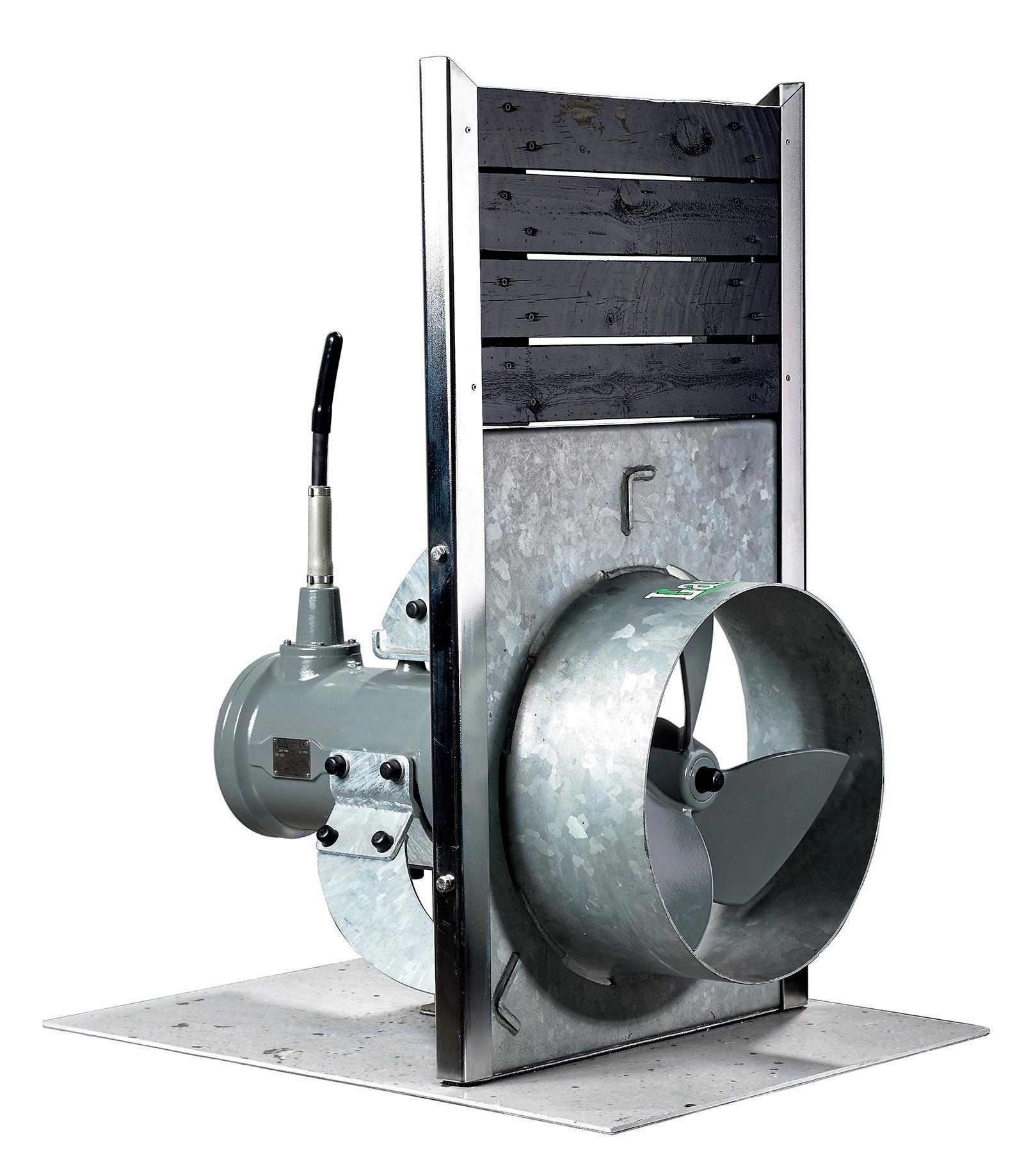

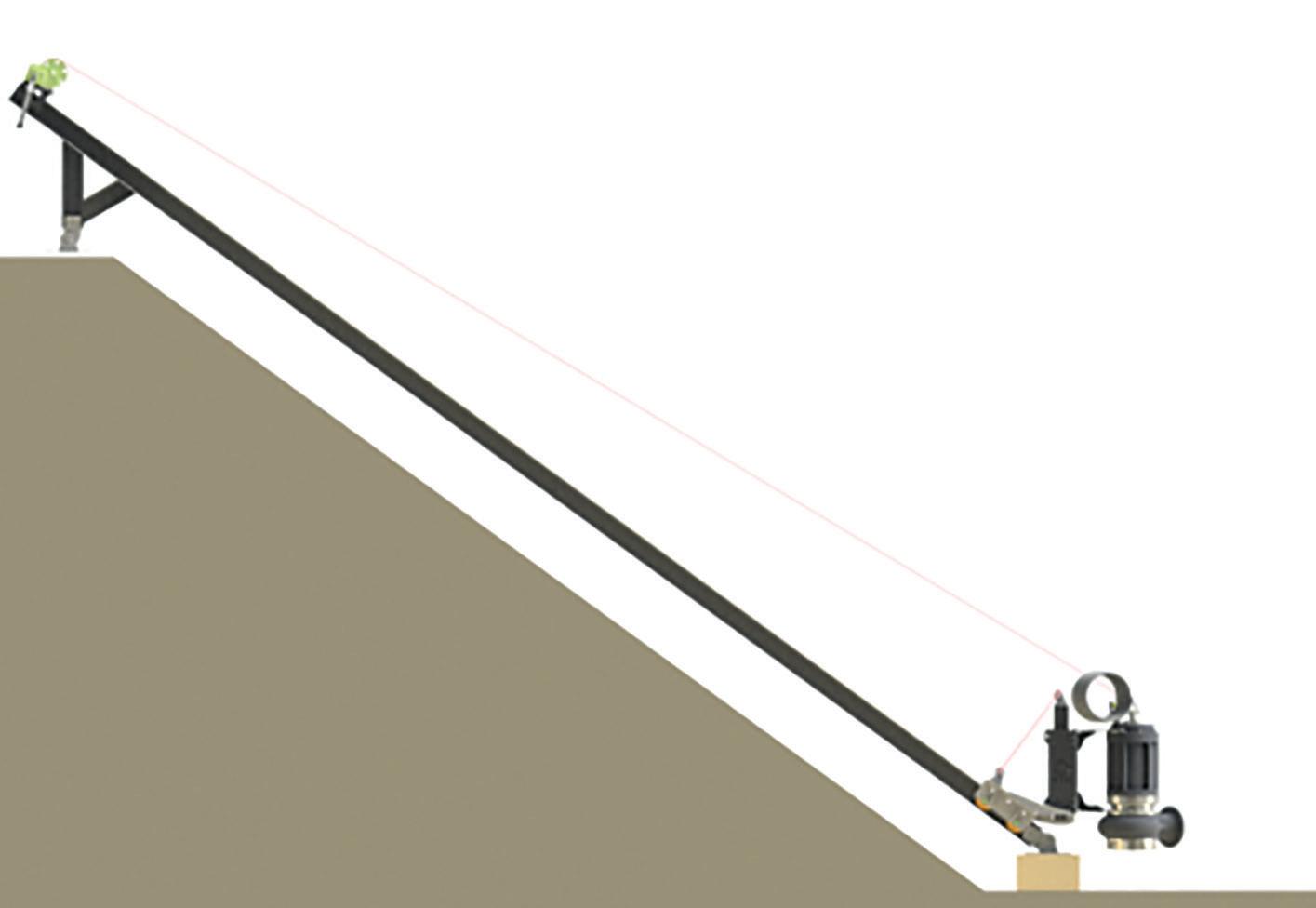

LAGOON AGITATOR

The frame of the lagoon agitator is made entirely of stainless steel for robustness and enhanced durability. The DK agitator series from 7.5 to 18.5 kW is made to fit the frame.

41

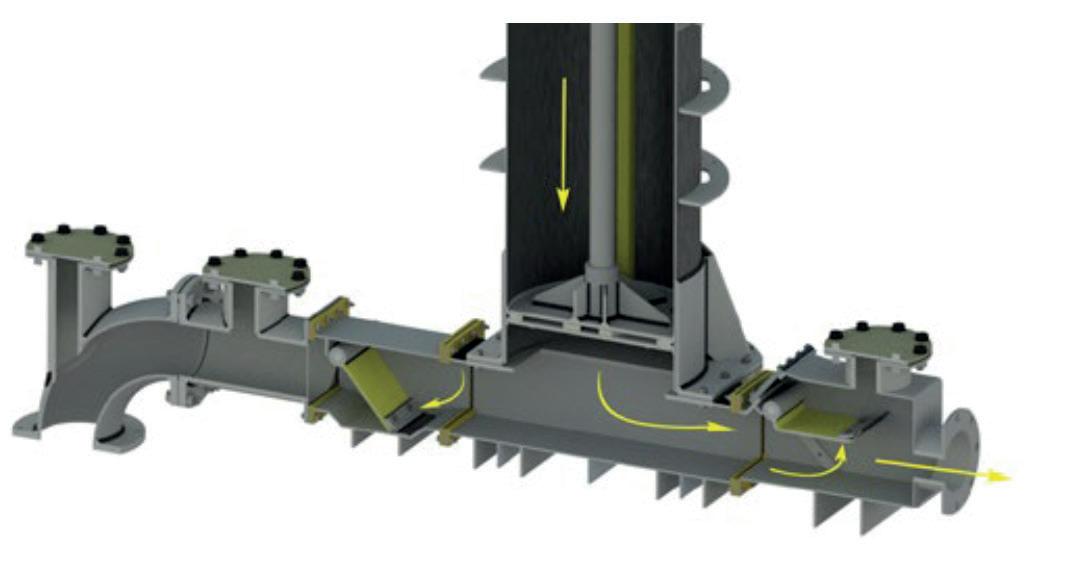

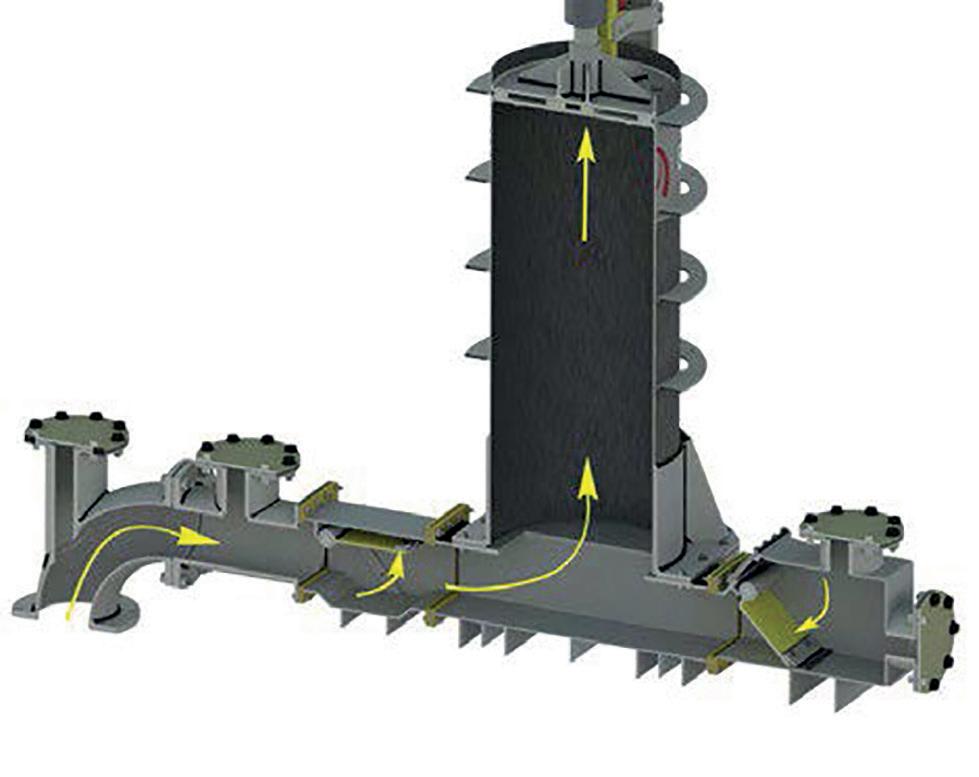

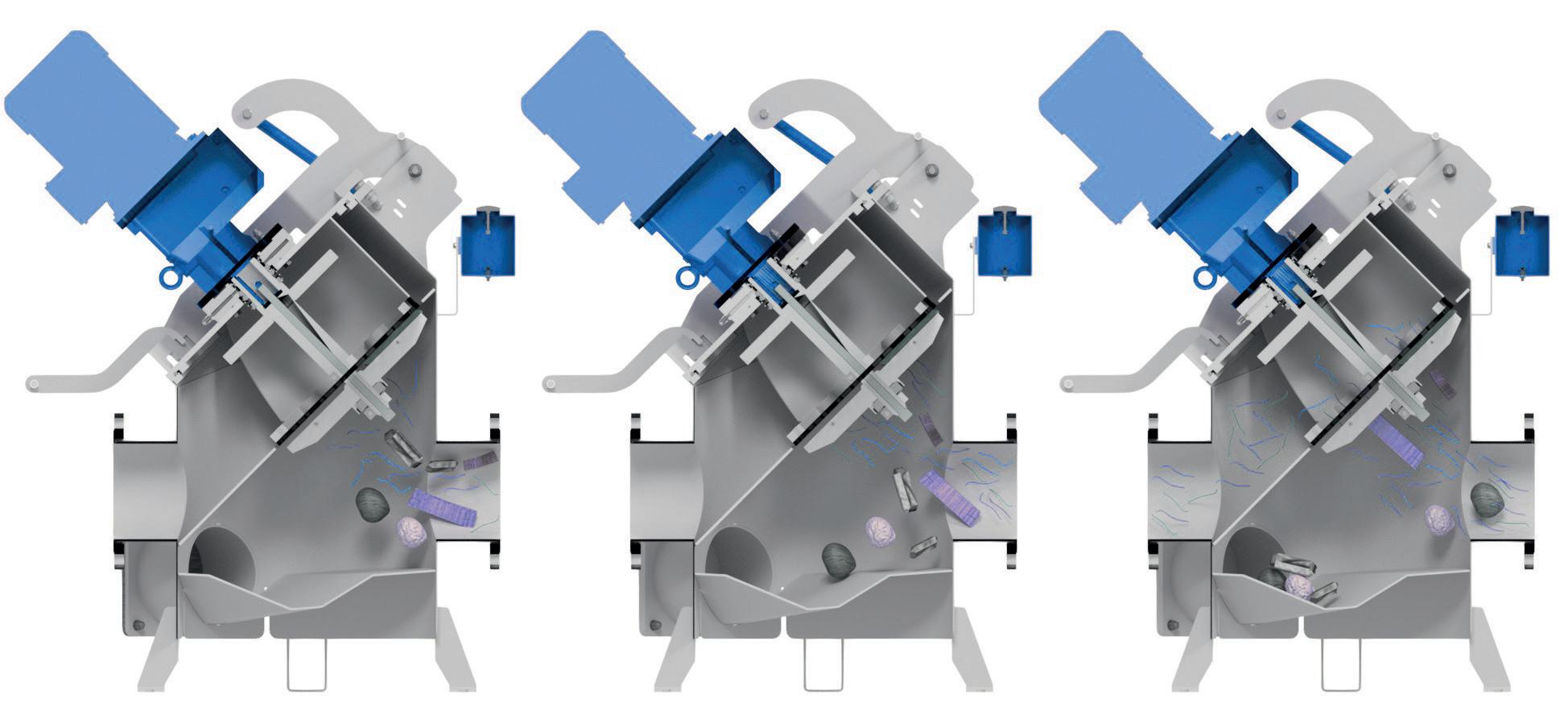

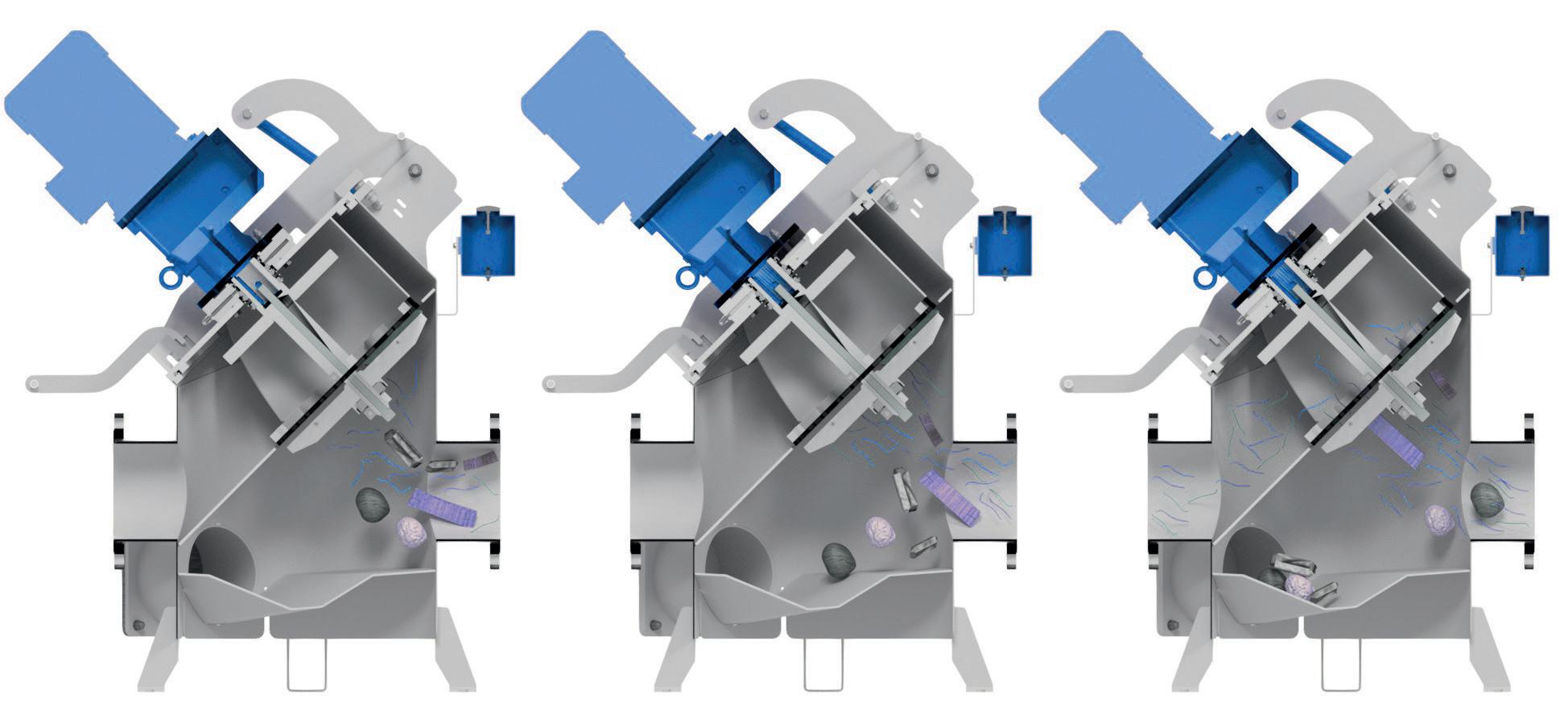

CYCLONE

The core function of the BouMatic CYCLONE is to separate out foreign bodies.

CYCLONE shredders combine both separation and shredding functions. They separate, shred and then discharge the material via a pipe.

As the fluid flows through the machine, heavy and foreign objects such as stones and metal parts are separated out by gravity and settle at the bottom of the body. The lower part of the body acts as a trap for foreign objects. They can then be easily removed via the cleaning flange. All the floating and suspended substances in the fluid (fibrous materials, wood, grass, straw, etc.) are transported by the flow to the cutting screen and chopped up by the self-sharpening blades. The product is also homogenised in the process.

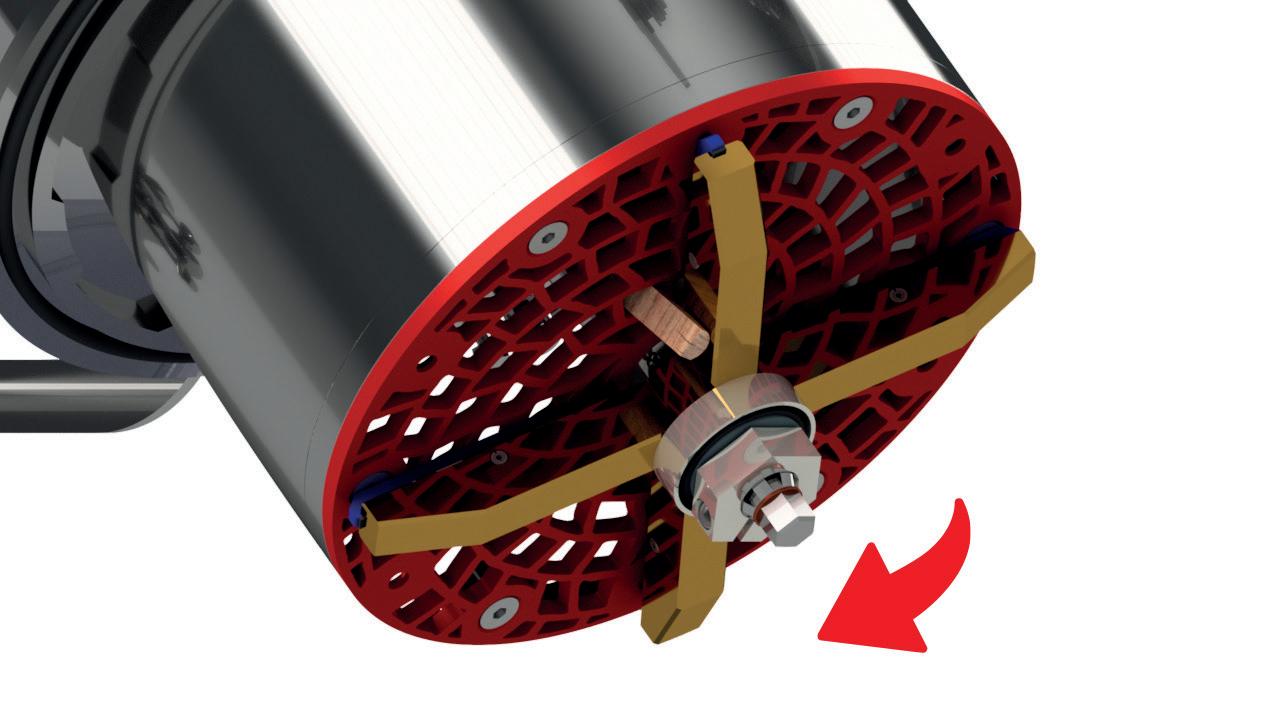

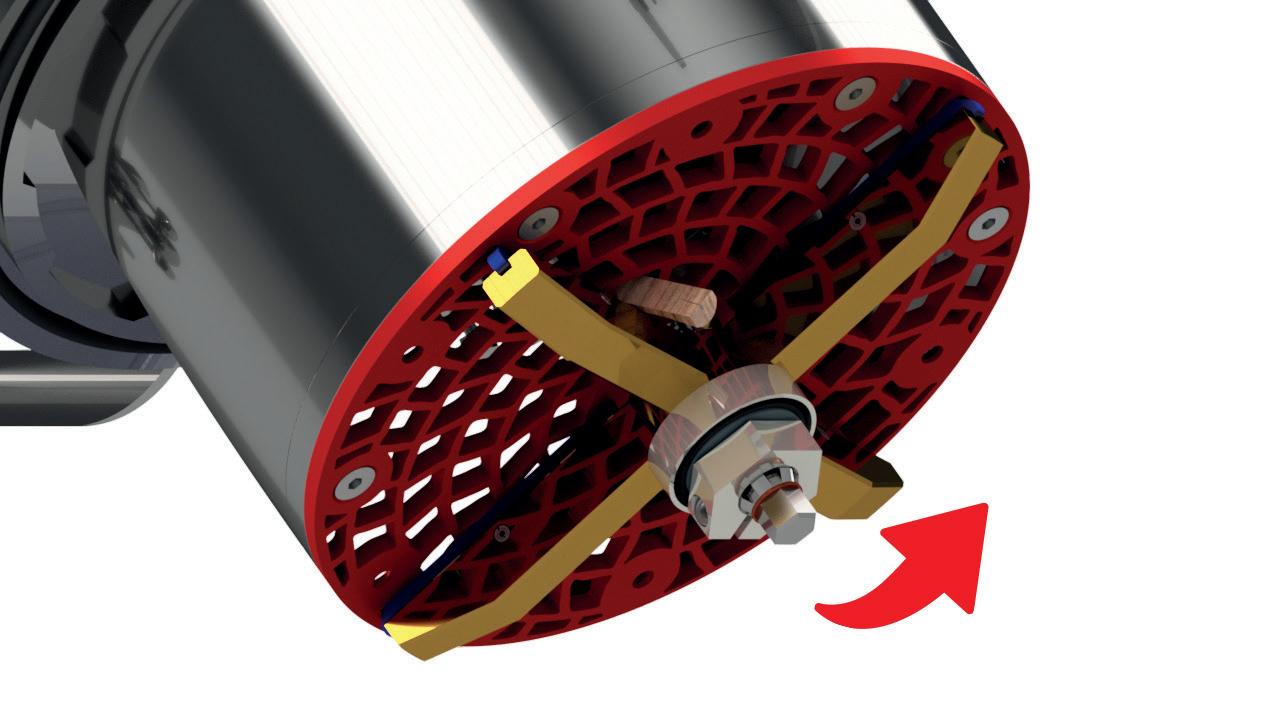

The system automatically detects blockages caused by contact with coarse, hard foreign objects and reverses the rotation direction of the blade rotor. The shredder also attempts to chop up the disruptive material from the other side. The same process is repeated until the blockage material has been penetrated. The automatic inversion function also helps to maintain the cutting edges used on the sieve and sharpened blades, which enables the user to benefit from optimum cutting performance and reduced energy consumption.

The cutting blades of the BouMatic CYCLONE are wear resistant and have a long service life. If the blades wear out over time, the position of the blade mechanism can be easily adjusted. Thus, the blades can be used until they are completely worn out.

Cutting blade in new state [blue].

Cutting blade close to wear

43 CYCLONE

Features

44 B A D C H

Type IM3 IM5 IM10 Motor power 2,2 3 5,5 11 15 Voltage & frequency 400/50 RPM 183 256,8 273 Max. flow m3/h 180 300 600 Max. pressure (Bar) 1,5<x<2 Cutting diameter (mm) 4<x<28 4<x<30 4<x<38 Bin volume (l) 40 85 140 Inlet and outlet diameter (mm) 125/5’’ 150/6’’ 200/8’’ Access cover diameter Stainless steel type AISI 304 *Values measured in water

BouMatic’s in-line CYCLONES work with spiral pumps or piston pumps. The CYCLONE is placed downstream of the pump. This enables it to trap foreign bodies to prevent them from damaging the pump or the separator.

The BouMatic CYCLONE comes in three different models, making it the ultimate solution to meet your shredding needs.

Dimensions with cover open

Dimensions with cover closed

45 G F E CYCLONE

Type A (mm) B (mm) C (mm) D (mm) H (mm) IM3 541 1483 917 1454 486 IM5 646 1635 1152 1615 578 IM10 769 2077 1171 2057 681 Type E (mm) F (mm) G (mm) I (mm) IM3 1150 923 374 546 IM5 1271 1039 464 566 IM10 1435 1109 566 840

The BouMatic CYCLONE is designed to be easy to maintain. All the wearing parts are easily accessible and can be replaced in very little time.

Advantages of an in-line macerator

Protection from foreign bodies for all machines positioned after the CYCLONE.

Perfect shredding of fibrous, coarse materials.

Fully automatic operation, easy maintenance and low servicing requirements.

Reduces the energy required by the pump due to the material being more consistent and fluid.

Energy efficient.

Self-sharpening blade

Reversible cutting grid

Made entirely from stainless steel

Outlet flange

Inlet flange

Cleaning flange

46

CYCLONE shredders are designed to effectively shred and separate out foreign bodies in slurry or digestate to enable the smooth functioning of biogas, waste water and slurry treatment plants on farms. The BouMatic CYCLONE is the best option for this purpose.

47

PHASE SEPARATORS

48

49

on

headland

Consistency of the compost transport andspreading Recycle manure

30% more storage capacity

Reduce odours Obtain a dry product that you can store

the

Aids

by 100%

PHASE SEPARATORS

Phase separators are designed to separate slurry into 2 elements:

• Solid : Easy to transport, less bulky to store, odour-free, excellent as fertiliser or bedding. The phase separator allows heavily polluting phosphorus and nitrogen to be concentrated in the compost. The resulting product has a dry matter content ranging from 25% to over 40%.

• Liquid : Easy to pump and spread (using a slurry tank or irrigation system). Depending on local regulations, it can enable greater flexibility in spreading.

Ultra-resistant gear

Adjustment system

Access cover

Liquid discharge

Weight adjustment on the arms to slow down the compost outlet

SP400 SP600 SP800 SP600HD SP800HD 1100HD Motor 2,2kW 5,5kW 5,5kW 5,5kW 11kW 11kW Auger (t/mn) 26,6 33 33 11,7 24,4 24,4 Sieve dimensions 0,65mm 0,65mm 0,65mm 1,00mm 1,00mm 1,00mm Ø sieve Ø180mm Ø258mm Ø258mm Ø258mm Ø258mm Ø258mm Sieve length 1x L:380mm 1x L:516mm 1x L:516mm 1x L:258mm 1x L:516mm 1x L:516mm 1x L:258mm 2x L:516mm Sieve available Optional model available: 0,5mm - 1,00mm

Auger reinforced with tungsten

Which separator best meets the needs of your farm?

• Standard : This model is the first choice for farms wanting to gain up to 30% more storage volume in their slurry pit. The solid residue is then used for spreading on crops as a fertiliser.

• HD : The HD model of phase separator is recommended for farms that wish to use the solid material as bedding or compost. In this case, the aim is to obtain a product with a high dry matter content and to have a stable product after fermentation.

FERTILISER STANDARD

Product with a 25 to 30% solid matter content

BEDDING

HD Product with a 30 to 40% solid matter content

51 SEPARATEURS CYCLONE

Performance SP400, SP600, SP800 and SP1100 Separator Standard Grid: 0,65mm / 25% - 30% MS SP400 SP600 SP800 SP1100 % dry matter Capacity no. of animals Capacity no. of animals Capacity no. of animals Capacity no. of animals Cattle slurry 3-5% 4-10m3/h 150 12-18m3/h 800 15-24m3/h 1500 20-35m3/h 2000 6-9% 3-6m3/h 100 7-12m3/h 600 10-18m3/h 1200 16-26m3/h 1500 10-12% 1-4m3/h 60 5-10m3/h 500 7-12m3/h 800 11-20m3/h 1200 Pig slurry 3-6% 4-12m3/h 240* 18-40m3/h 800 22-46m3/h 920 27-58m3/h 2000

Performance

Separator HD Grid: 1mm / 35% - 40% MS SP600HD SP800HD SP1100HD % dry matter Capacity no. of animals Capacity no. of animals Capacity no. of animals Cattle slurry 3-5% 9-15m3/h 500 12-22m3/h 700 16-30m3/h 850 6-9% 6-10m3/h 400 9-15m3/h 600 12-20m3/h 750 10-12% 4-7m3/h 350 6-10m3/h 500 8-13m3/h 600

*Sow + offspring (post-weaning and fattening = 18.4 m3/year)

SP600HD, SP800HD and SP1100HD

Options

If it is not possible to have a return, this tank comes on top of the separator and works with a pressure sensor that regulates the pump (VSD).

Be ENVIRONMENTALLY responsible

Back wash : Allows the sieve to be cleaned automatically.

Our environmental approach

The phase separator forms part of BouMatic’s commitment to an agro-environmental approach.

Air pollution is reduced as a result of using the phase separator –phosphorus and nitrogen are concentrated in the solid phase. This reduces the extent to which these two highly polluting components are released into the atmosphere.

Reduction in olfactory pollution.

100% slurry recycling – the solid phase is recycled into fertiliser, bedding or compost

Reduction in CO2 levels (faster spreading, PM 2.5)

52

N2O

NH3

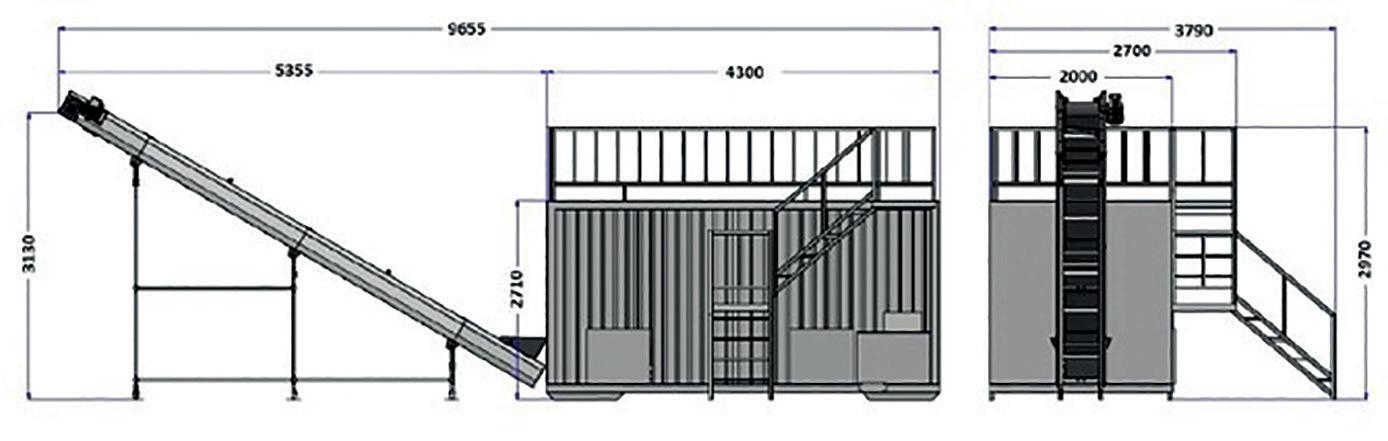

PLATFORM

Features

Galvanised steel

Handrail for safety

Trapezoidal type sheets for side walls and roof

Screws and dowels included

Potential for multiple mounting

Option to screw to the mounting area

Disassembled transport with assembly instructions

Height and dimensions available for single and double separator

53 7720 3700 3850 4150 4000 5275 765 4100 3500 3620 905

The phase separator can be placed on a raised platform below which the dry matter can be stored. The platform can contain 1 or 2 separators.

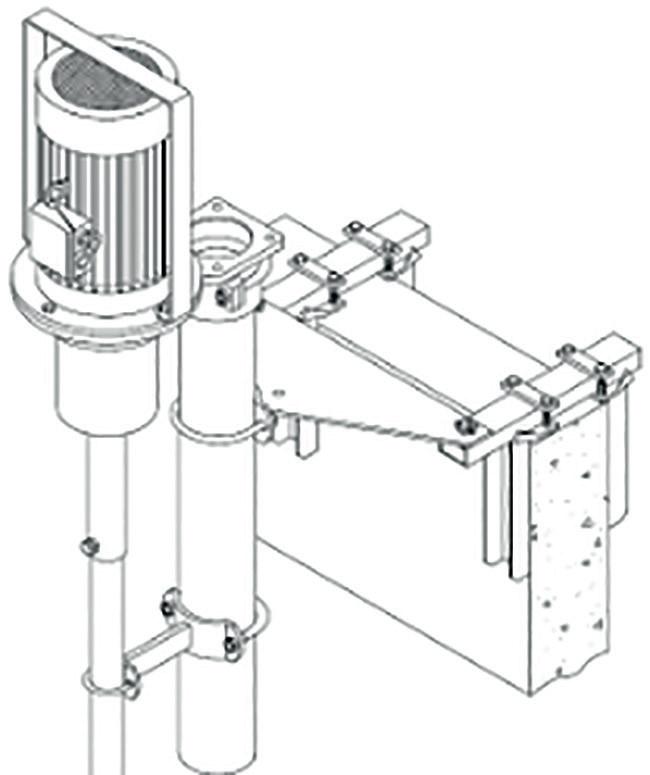

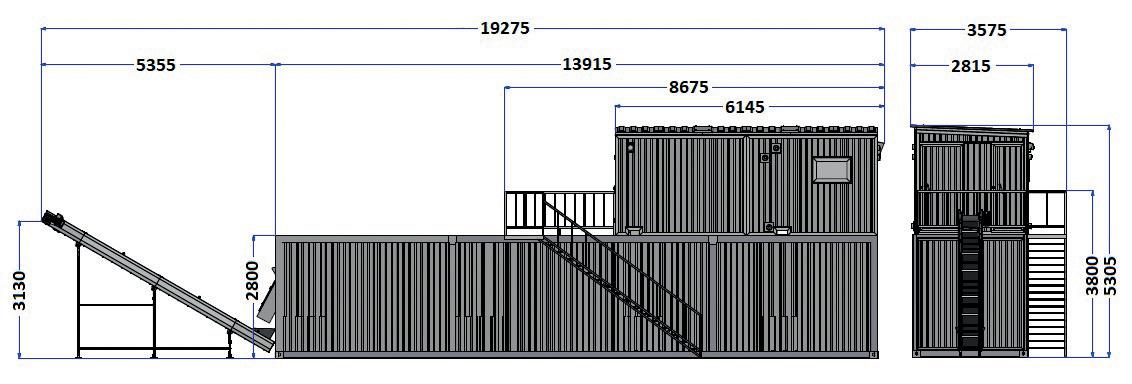

MOBILE PHASE SEPARATORS

BouMatic has developed a solution that is specially adapted to phase separation work carried out by machinery syndicates. In essence, this range has been designed to permit easier mobility. The separator’s design has been adjusted to enable this:

• Plug & Play: Once the separator is on site, simply plug it into the electrical socket and the circuits that will feed in the slurry and send the liquid phase to the pit. Then simply start up the system.

• Built-in conveyor : Once the manure has been separated into two phases, a conveyor transports the solid phase to the operator’s desired location. The length of the conveyor is X metres. Once the task is complete, the conveyor can be folded up to save on space.

• Compact : The separator has been designed to incorporate all the best features of a separator in a compact version to make it easier to transport.

Which separator best meets the needs of your farm?

Standard : This model is the first choice for farms wanting to gain up to 30% more storage space in the pit. The solid residue is then used for spreading on crops as a fertiliser.

HD : The HD model of phase separator is recommended for farms wanting to use the solid material as bedding or compost. In this case, the aim is to obtain a product with a high dry matter content and to have a stable product after fermentation.

54

FERTILISER STANDARD Product with a 25 to 30% solid matter content HD Product with a 30 to 40% solid matter content BEDDING

MOBILE PHASE SEPARATORS SP STANDARD Type Power Weight Sieve d. S2G-600 18,0 kW 2.225 kg Ø:258 mm S2G-800 18,0 kW 2.380 kg Ø:258 mm S2G-1100 20,0 kW 2.685 kg Ø:258 mm MOBILE PHASE SEPARATORS SP HD Type Power Weight Sieve d. S2G-600HD 18,0 kW 2500kg Ø:258 mm

55

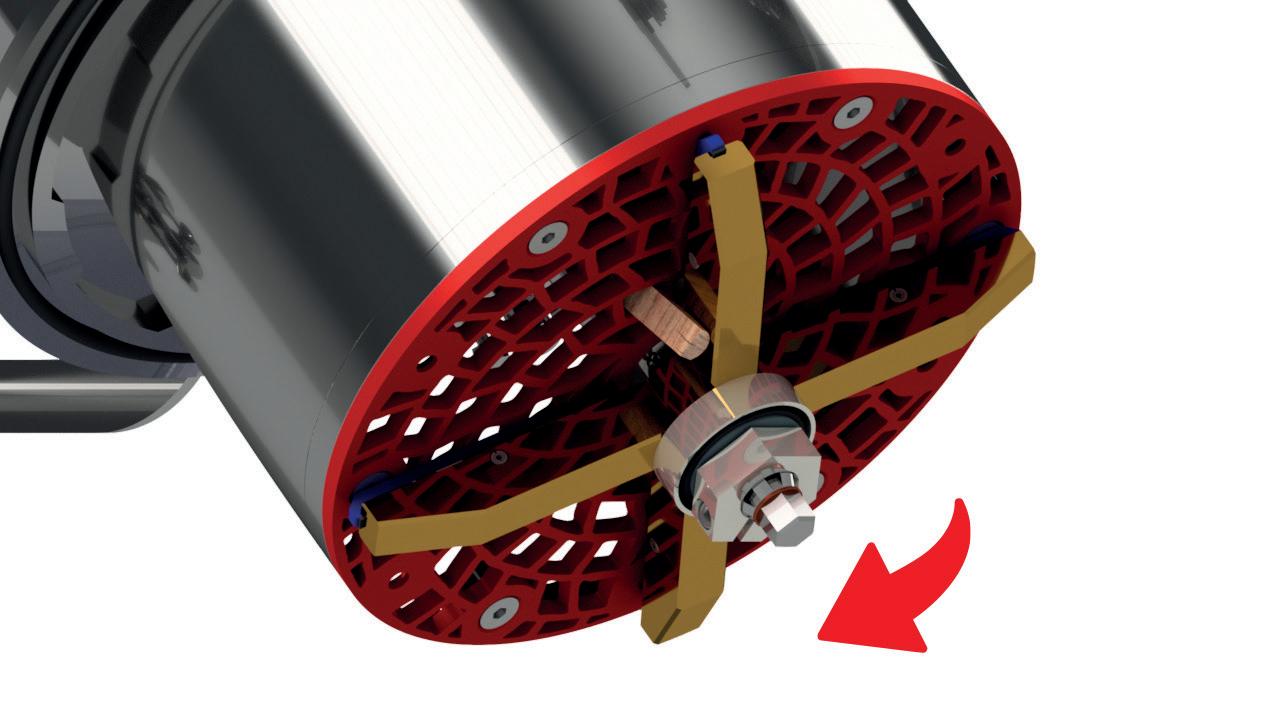

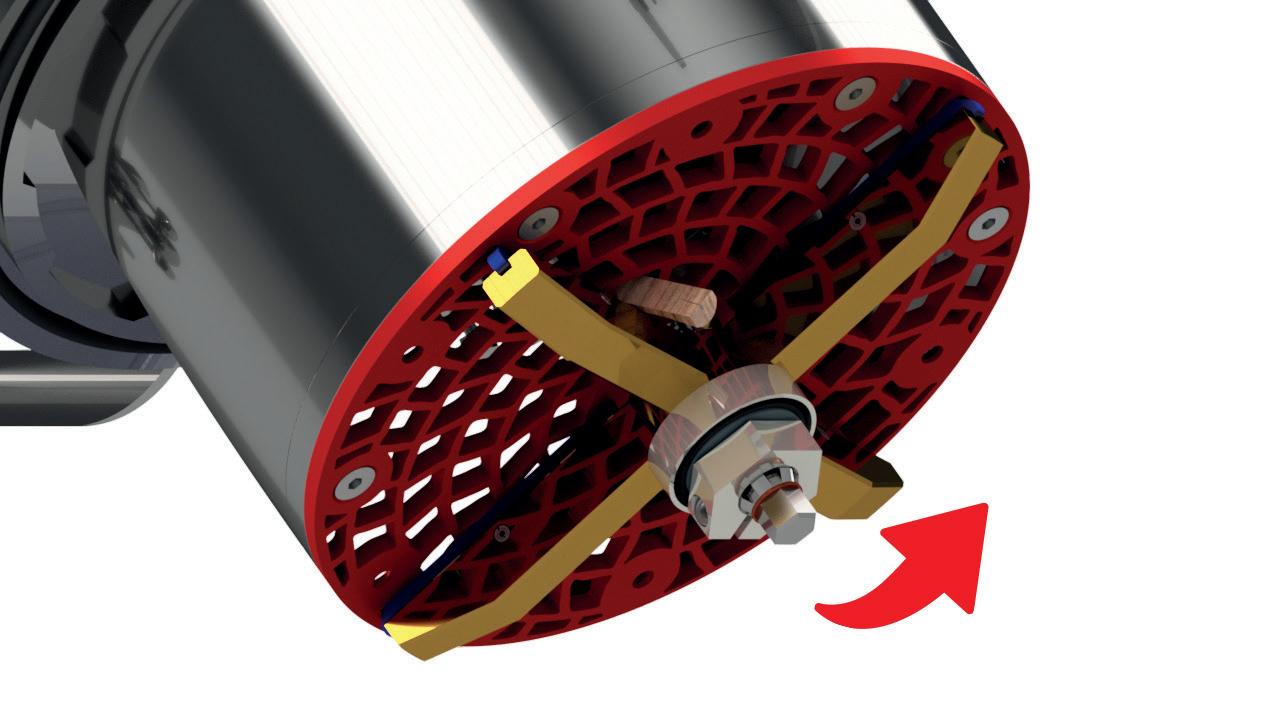

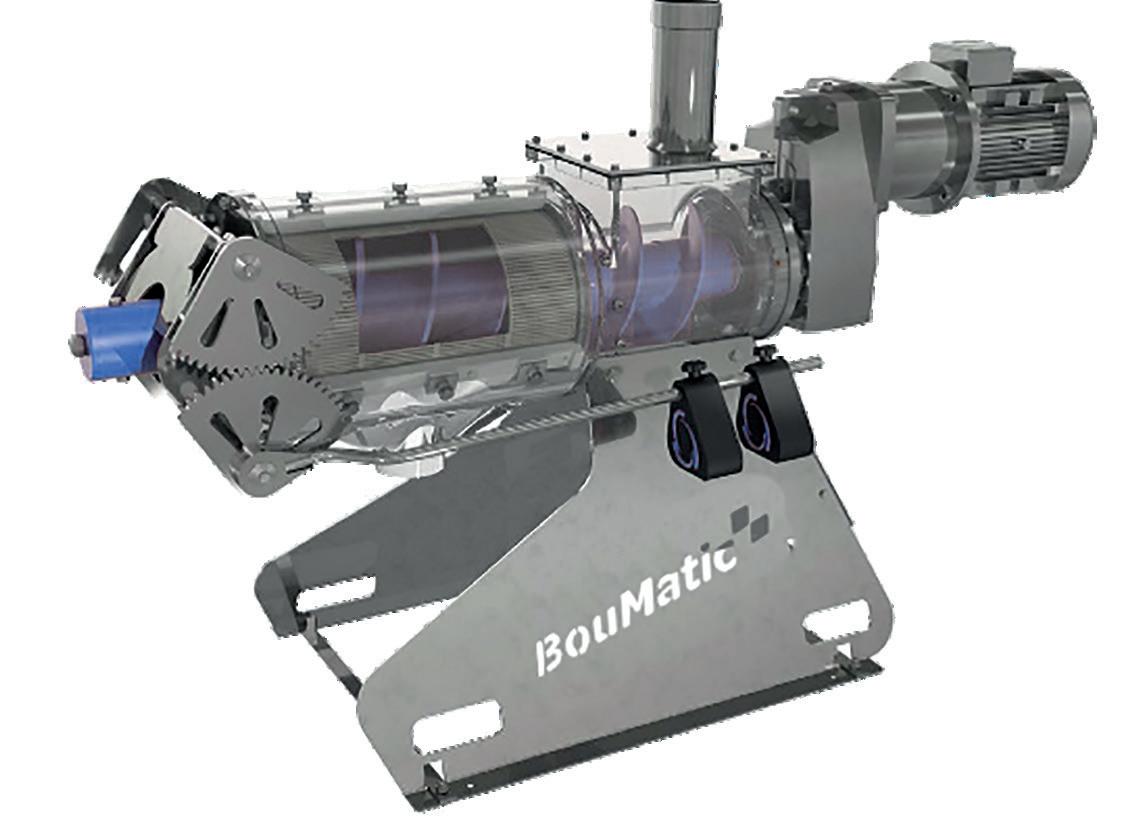

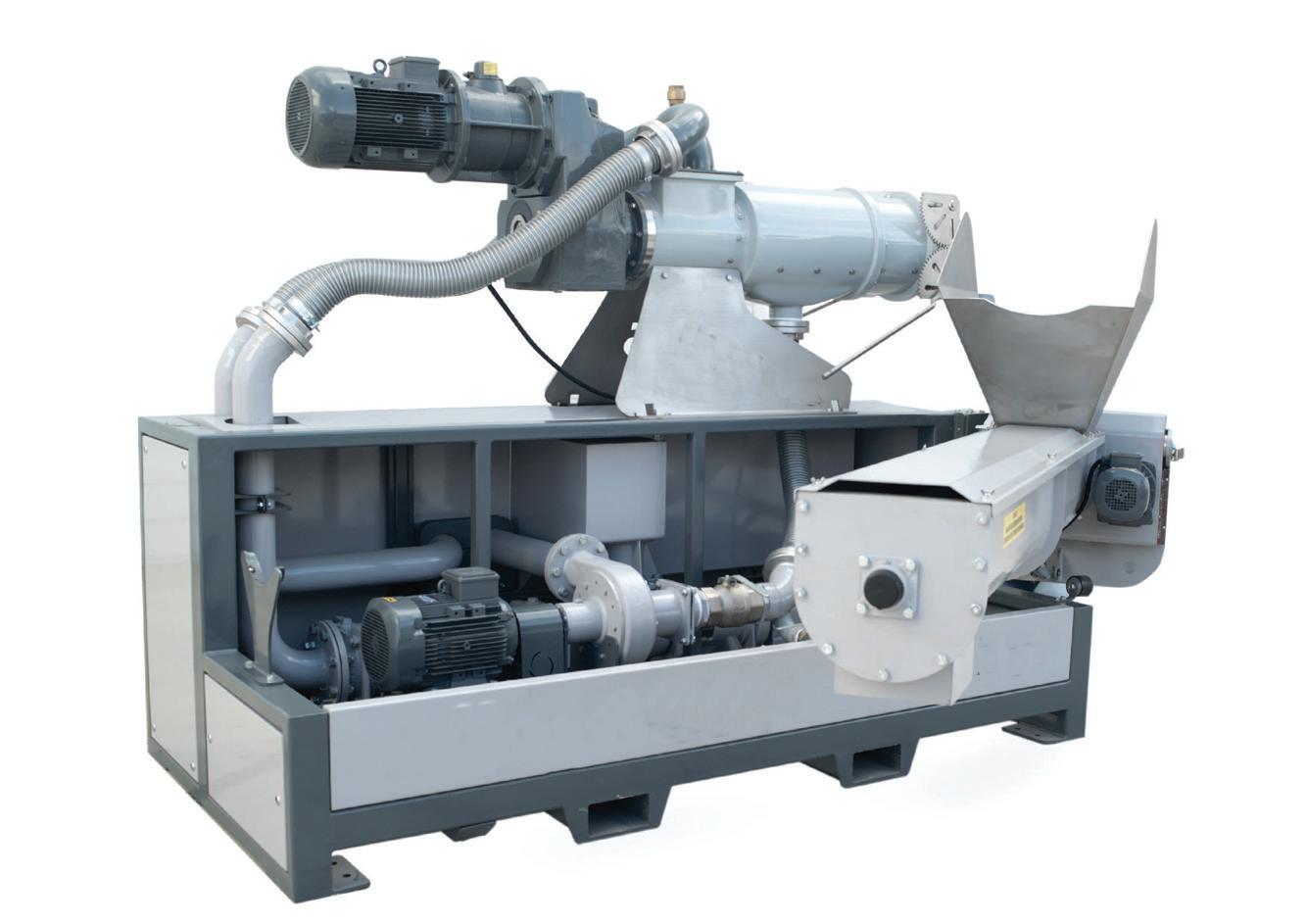

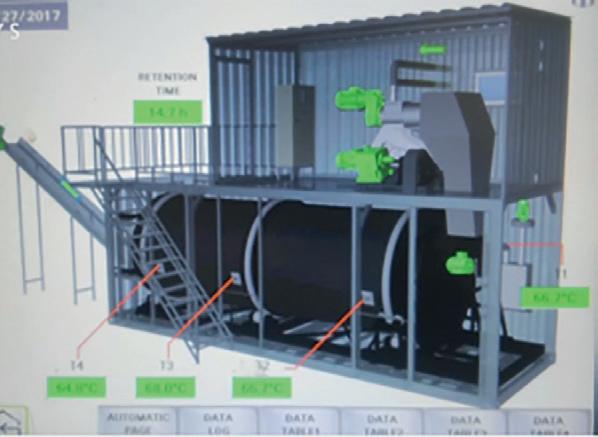

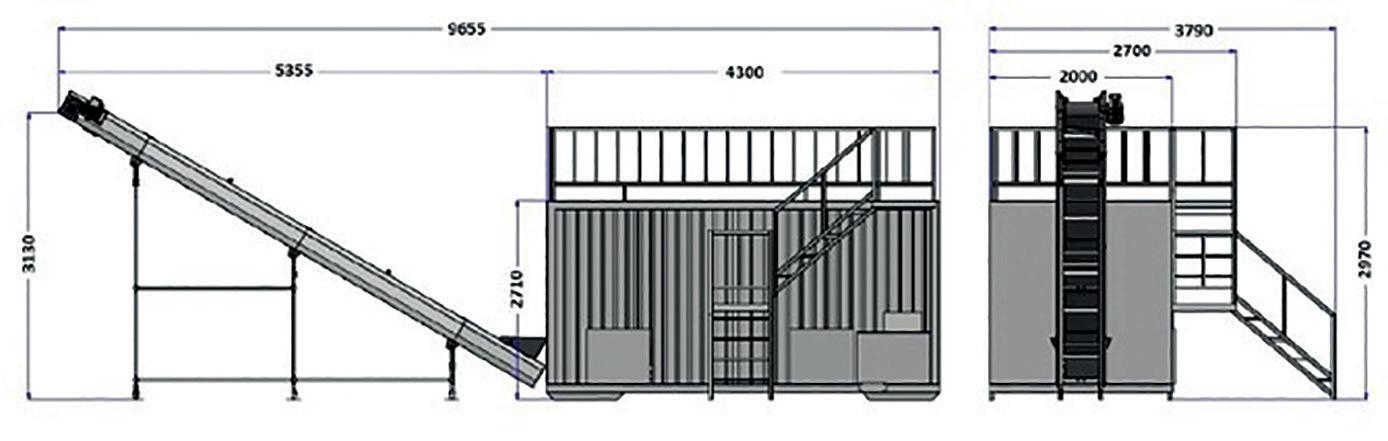

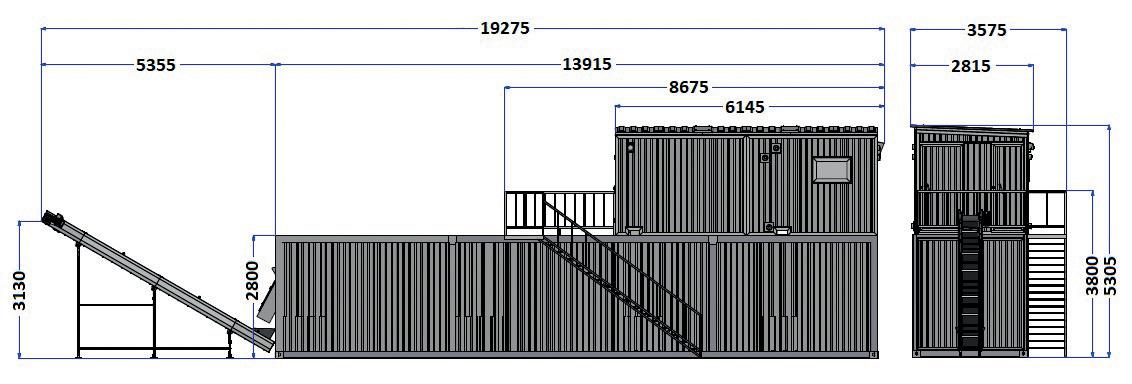

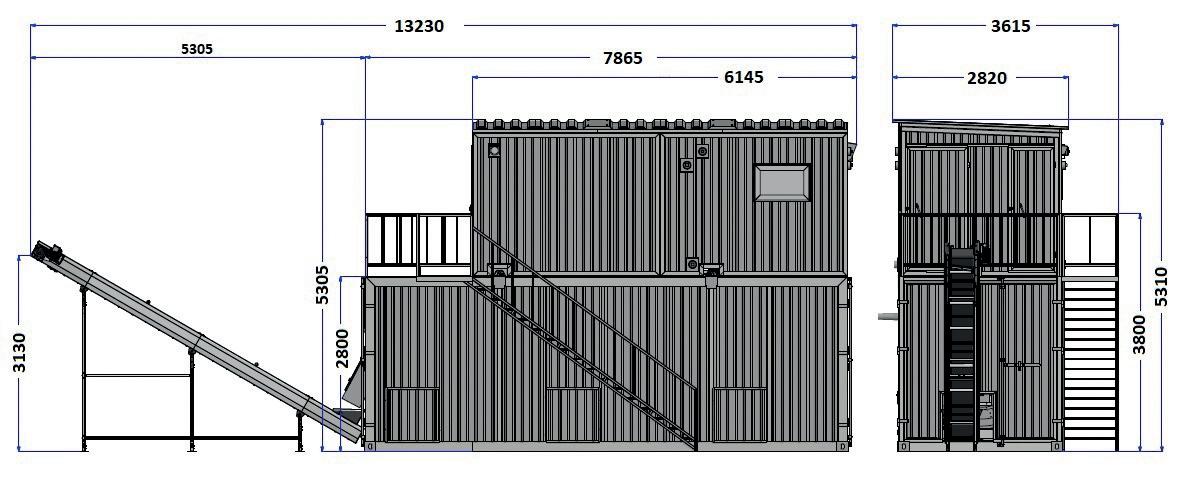

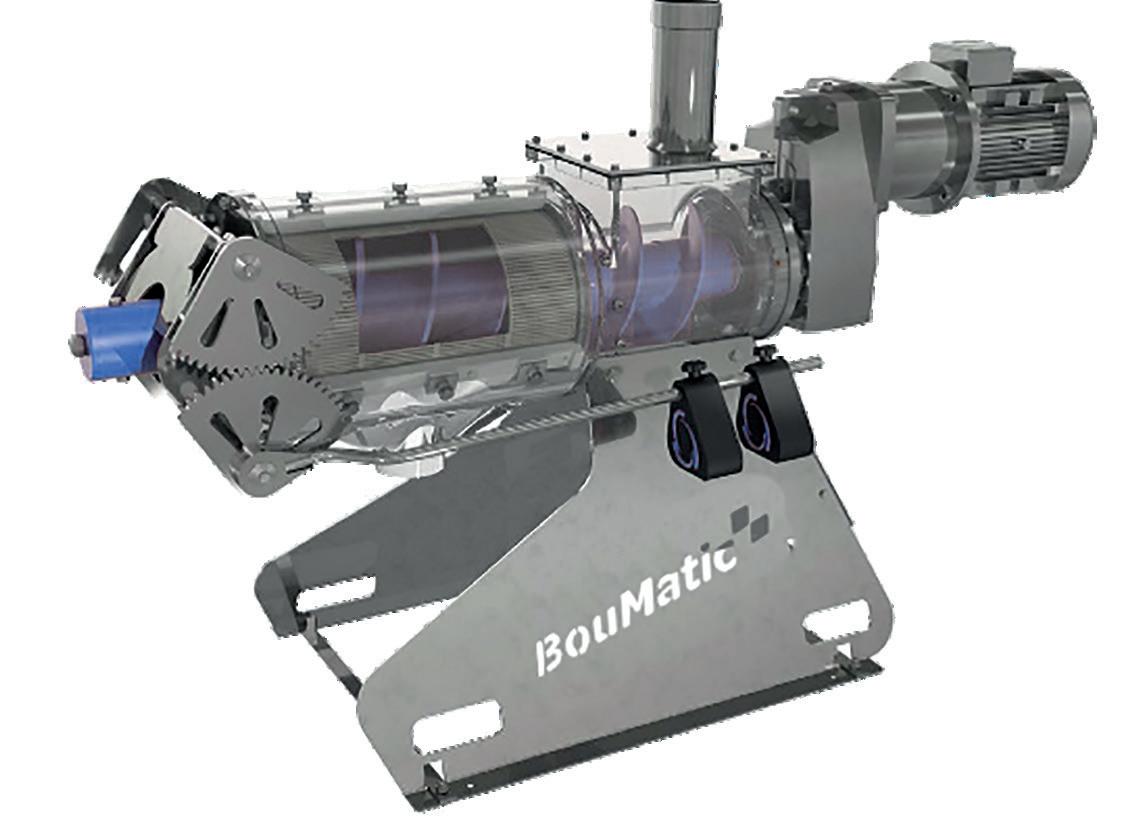

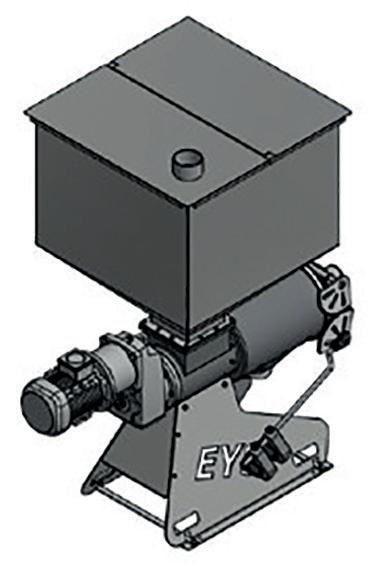

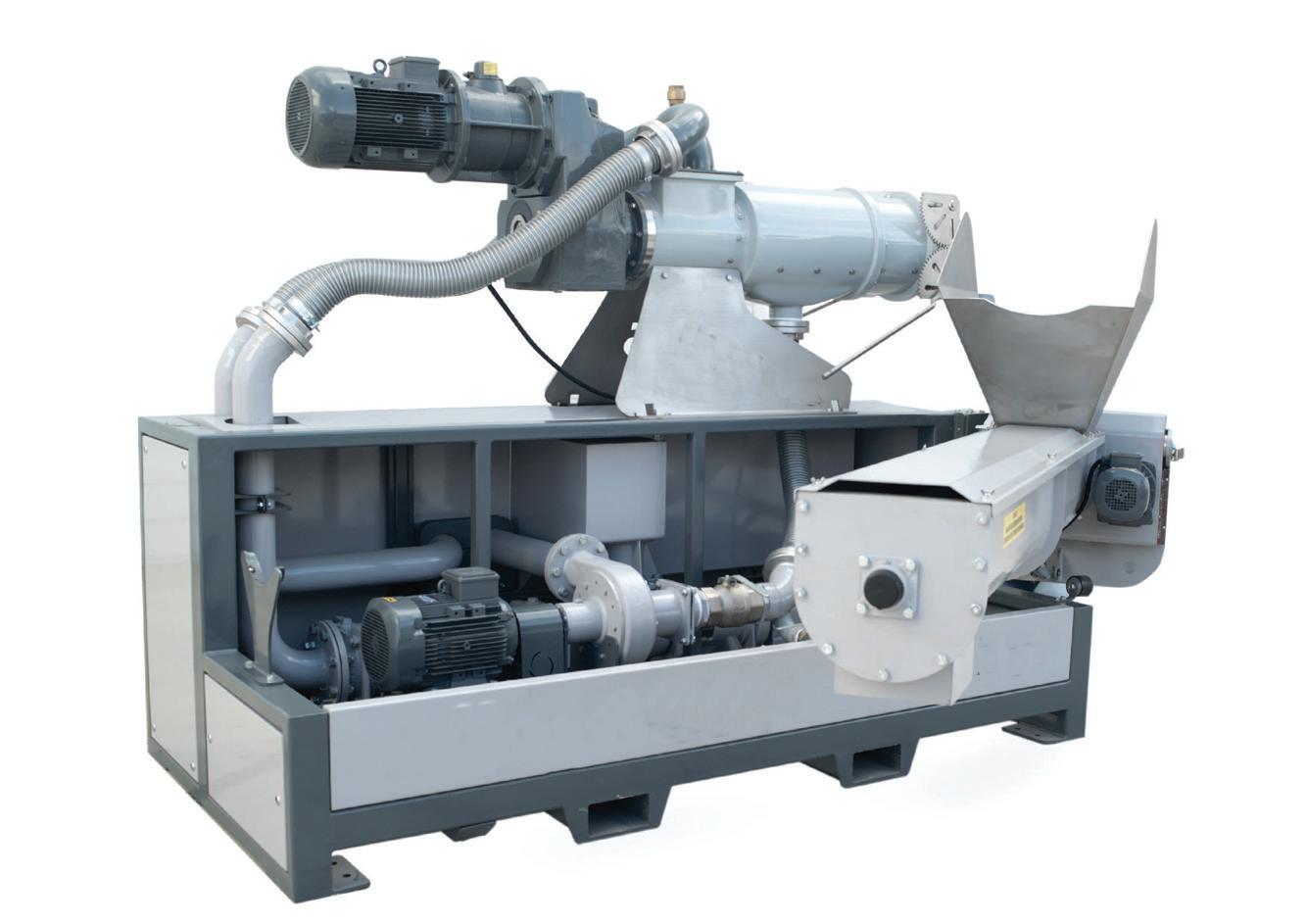

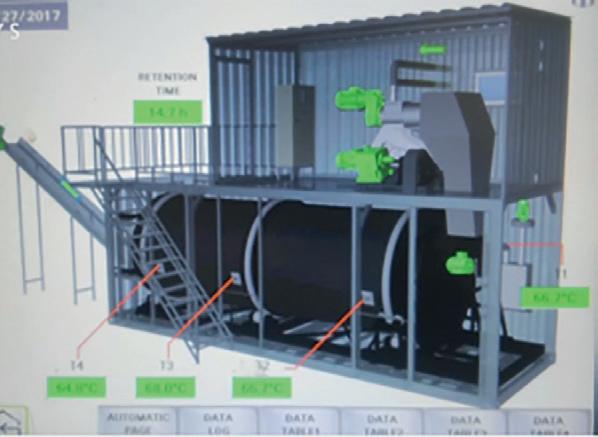

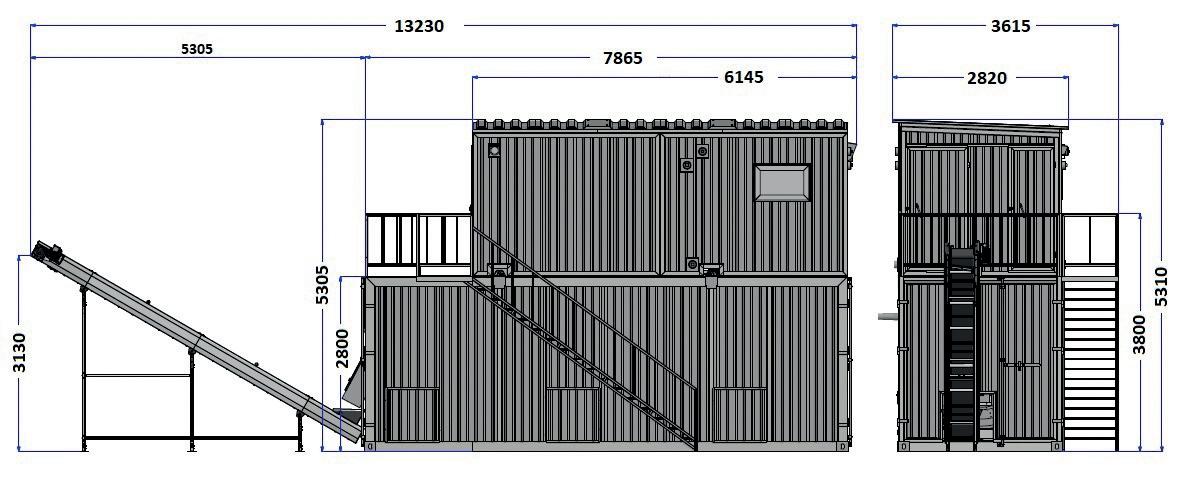

BCS BOUMATIC COMPOSTER SOLUTION

Our composter is a state-of-the-art composting drum that significantly accelerates the aerobic fermentation process. It creates the ideal environment for aerobic bacteria to grow and mineralise organic compounds.

All we do is help natural bacteria do their job - but FASTER!

No external heat is supplied to the system for the fermentation process

The solid matter heats up to 70°C by itself via exothermic aerobic fermentation in line with European regulations on hygienisation.

Low amounts of electricity are required to obtain a high-quality, healthy product.

The BC-series composting system comprises a special heavy-duty (HD) separator that separates solids up to a specific humidity level and a DM content of around 40%.

56

The separated solids are then automatically introduced into the special polymer drum, where they are held for 24 to 72 hours. During this time, the system’s computerised control unit adjusts the temperature, humidity and oxygen levels inside the drum.

The composting parameters can be easily monitored and adjusted from the touchscreen control unit, even via a web browser or smartphone

57

Our system enables compliance with the EU’s hygienisation requirements* without having to invest in a heat treatment system. We use the self-heating fermentation process to reach 70°C while continuously monitoring and recording the temperature.

Whether you are a compost manufacturer or a slurry processor, you can count on the bedding composter for your hygienisation needs.

58

HD separator

Control room

HDPE drum

Wireless temperature sensor

Elevator options: 2m - 4m – 6m – 8m – 10m – 12m Type BCS5 BCS10 BCS20 BCS40 Capacity (m3) 4 10 20 40 Required power rating (kw) 8,5 10,5 12 18,5 Average consumption (Kw/h) 5 7 9 15 Separator SP 600 HD SP 600 HD SP 600 HD 2 x SP 600 HD 1 x SP 1100 HD Separator (Kw) 5,5 5,5 5,5 2 x 5,5 1 x 11 Drum drive (Kw) 2,2 4 5,5 11 Ventilator 0,55 0,55 0,55 1,1 Weight (excl. elevator) (Kg) 750 3000 6000 8000 Laden weight (excl. elevator) (Kg) 5000 14700 19700 29000 CAPACITY (m³/day)/BEDDING 4 10 20 40 MAX. NUMBER OF COWS 150 600 1200 2500 CAPACITY (m³/day)/compost use 1 3 7 13

Dairy farmers are well aware of the advantages of deep beds made up of ergonomic bedding material. Cows are healthier and give more milk when they are on kept on deep bedding. The solid matter obtained from properly composted slurry makes an excellent bedding material. - In contains low levels of bacteria, no mastitis-inducing pathogens, and is drier than separated solids. It allows you to make significant savings compared to bought-in straw bedding, which means you can apply more bedding per cow. But above all, cows love it!

59

10

BCS

20

40

5

BCS

BCS

BCS

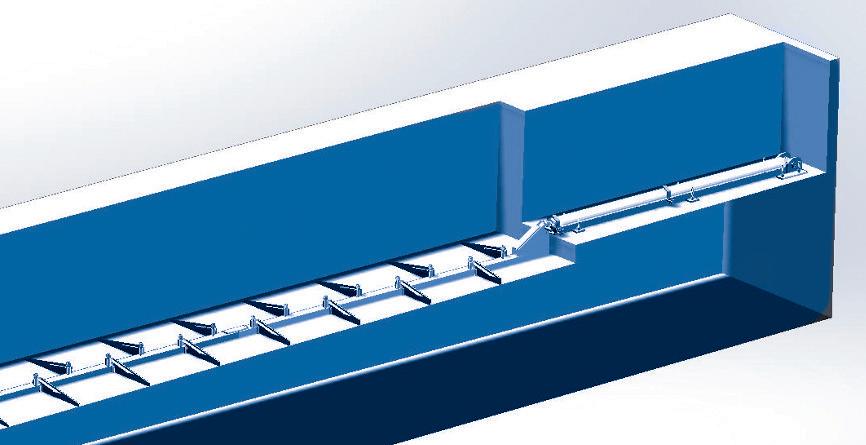

FALCON CROSS

The Falcon cross is capable of pushing the heaviest loads. In a 1.15-m channel for the double row or 0.635-m channel for the single row, it will push the manure that the scraper has discharged.

The Falcon cross is used in a compact straw and manure system.

The cylinder pushes and retracts causing the traction rail to move back and forth. The scrapers move forward and backward, allowing the manure to be pushed forward. One-way claws positioned in the races prevent the manure from returning when the scrapers retract. This allows the manure to be conveyed to the manure pit.

It can be supplied as an add-on to the ELEVATOR.

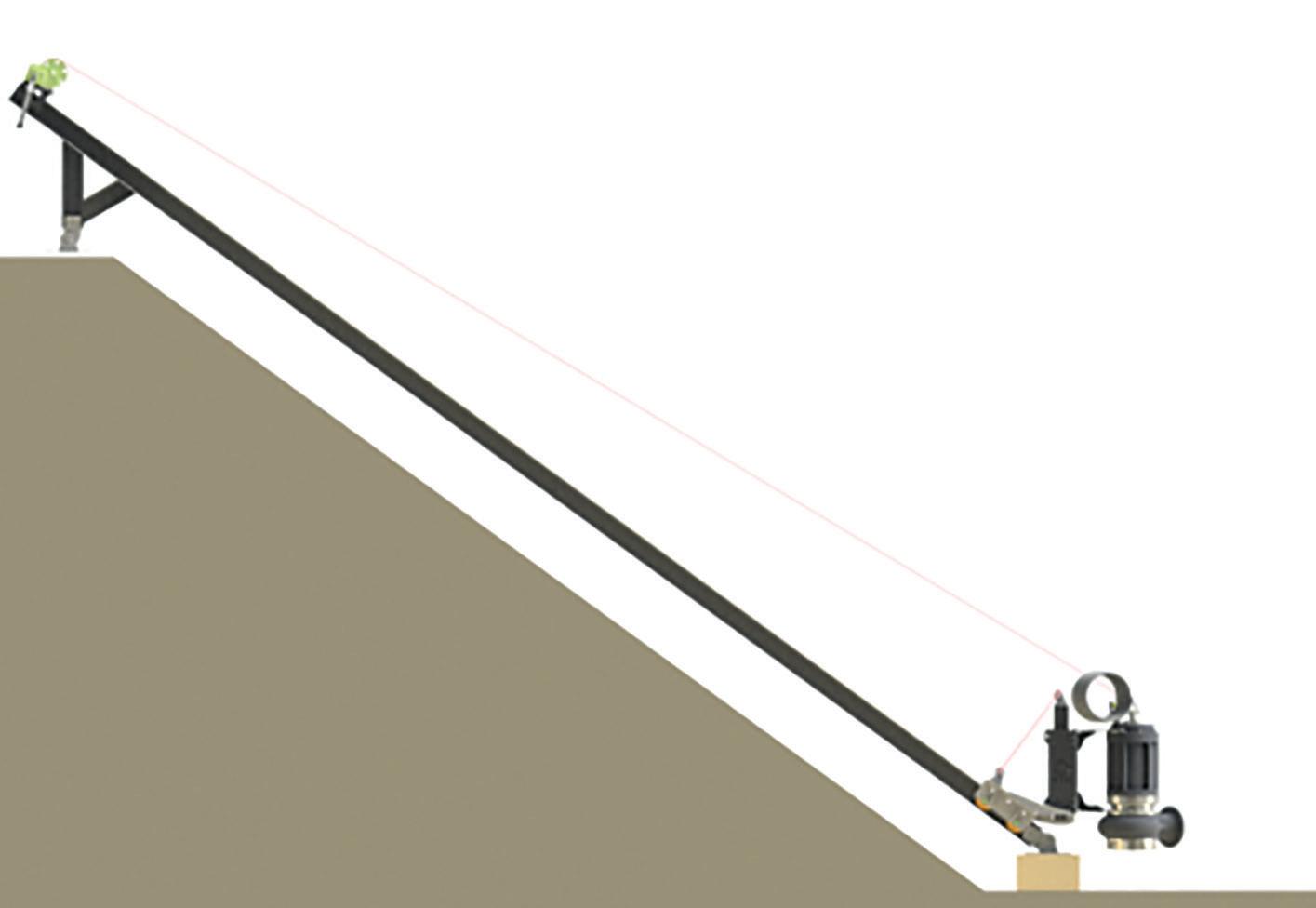

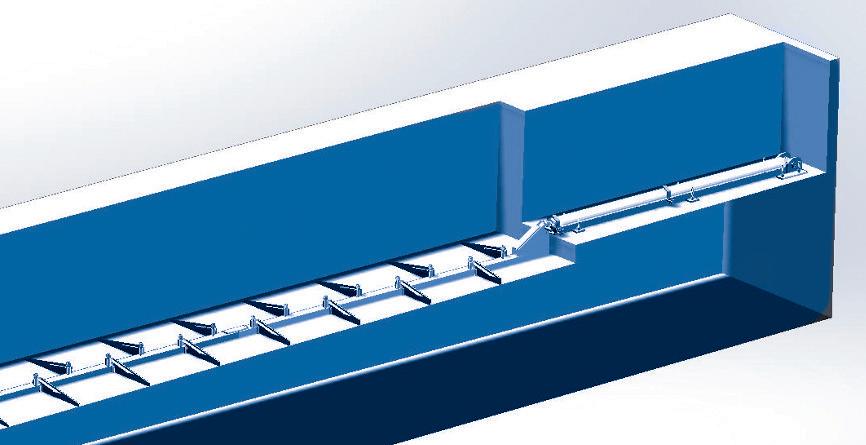

ELEVATOR

The BouMatic elevator can transport manure up to 70 m. The sturdy square chain and scraper have been tried and tested and will serve you for many years.

Ramp models from 2 to 12 metres are available. It comprises two 0.5-m parallel gutters separated by a 0.2-m central wall.

The drive is positioned at the top of the ramp to pull the load, which puts less strain on the gearbox. The drive unit has a power rating of 3 kW. The 180° bevel gearbox pulley is mounted on a high-strength bronze ring.

It is located at the end of the gutter and allows the chain to rotate effortlessly.

It can be synchronised with the scrapers to automate the transportation of manure.

62

63 A B

X 33° 28° L = ml A H B C A H B C 12 6,3 4,1 9,65 6,25 6,6 3,51 10,15 5,4 10 5 3,3 8 5,2 5,3 2,82 8,39 4,46 8 3,8 2,5 6,3 4,1 4 2,13 6,62 3,52 6 2,7 1,7 4,6 3 2,65 1,41 4,86 2,58 5 2,1 1,4 3,8 2,45 2,21 1,17 3,97 2,11 4 1,7 1,1 2,95 1,9 1,77 0,94 3,09 1,64 3 1,25 1,1 2,1 1,35 1,32 0,7 2,21 1,17 2 0,84 0,55 1,25 0,82 0,88 0,47 1,32 0,7

(scarico )

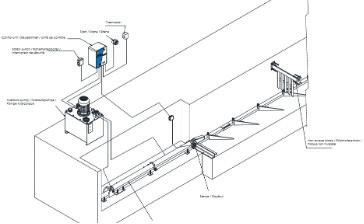

EXAMPLE 1:

Receiving pit:

Two TYPHOON BSC scrapers (brush scrapers).

A slalom receiving pit with AXP mixer.

The slurry is pumped by the piston pump and transferred to the separator.

The separated solid part is stored on the platform and the separated liquid part in the storage pit.

64 1 1 2 3 4 5 6 SIMULATION

1 2 3 4 5 6

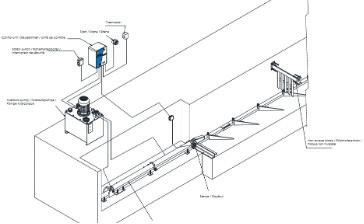

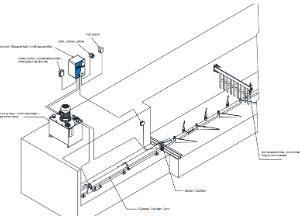

EXAMPLE 2:

Slalom receiving pit:

Two TYPHOON BSC scrapers (brush scrapers).

A slalom receiving pit with AXP mixer. The slurry is pumped by the piston pump and transferred to the separator. The separated solid part is stored on the platform and the separated liquid part in the lagoon.

65 1 1 2 3 4 5 6

1 2 3 4 5 6

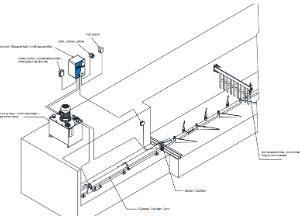

EXAMPLE 3:

Hygienisation: Installation with a flushing channel and an end receiving pit with a vertical pump for flushing.

Hygienisation of the slurry with the ECOBEDDER to reuse the compost in the stalls. A straight TYPHOON scraper and a «V» scraper.

A mixer

placed in the brown water pit.

66 1 2 3 4 6 5

1 2 3 4 5 6

is

EXAMPLE 4:

Solid-liquid separation:

The separated liquid part falls into the channel and is discharged into the cylindrical pit.

In the pit there is a vertical shaft pump for flushing and a mixer to homogenise the slurry.

The solid part is pushed onto the platform. The straight Typhoon scraper is along the feed alley and the V-shaped scraper is between the two rows of cubicles.

67 1 4 5 6 2 3 1

1 2 3 4 5 6

A PARTNERSHIP FOR SUCCESS

Dealers and service

At BouMatic, we are proud of the longterm relationships that we have with our users from around the world. As the largest privately-owned company in the sector, we focus all our energy on our customers.

In all our dealings and on all levels, we work for you, our customers, because your success is our success.

The company has access to a global network of dealers. Thanks to them, BouMatic is able to offer its customers the expertise and experience of a multinational combined with the proximity of local experts. Targeted training is offered to customers with each purchase.

OUR PHILOSOPHY

From our modest beginnings, we have always stayed true to the core values of our founders.

Today, as an industry leader, those values have become our guiding principles.

Animal health Engagement in scientific research Profitability

Your dealer:

68 Siège social 2001 S Stoughton Rd, Madison, WI 53716 T: (608) 222-3484 F: (608) 222-9314 BouMatic Europe - Belgique Rue Jules Mélotte 31 4350 Remicourt Belgique T: 0032 (0) 19 54 42 66 F: 0032 (0) 19 54 55 44 BouMatic A/S Jernvej 2 Skjern 6900 Danemark T: 0045 75 26 02 11 info@boumatic.com www.boumatic.com

© 2022 BouMatic. LIT00426EN - All rights reserved.