ABOUT US

When you think of world-class manufacturing and design, think of Bergan Marine Systems. We are dedicated to providing outstanding customer service, innovation, and excellence. From design to installation - we have you protected.

Bergan Marine Systems manufactures most of its components in-house using CNC metal working machinery including lathes, mills and plasma cutting equipment. Our custom electronic manufacturing facility allows us to rapidly produce systems designed for our customers’ individual needs.

It’s a standard of excellence we’re proud of, and has been since 1975 when Ian-Conrad Bergan began his adventure in Norway. Over the years, we’ve built an incredible team of engineers, sales support, and customer service employees dedicated to serve you, our customers, and our associates. We’ve expanded into Houston and San Diego to provide faster service with lower costs.

And we’re always a step ahead of the competition. Ahead of the innovation curve-the float level alarm sensors or radar level gauges that we can tailor-make to your

specifications or critical sensor data equipment that transmits wireless to desktops and handheld devices-we have you covered.

Our many trailblazing products, like our trademark Guard Level® alarm system and monitoring sensors, provide that security and peace of mind: safeguarding precious lives, the environment, and your investment.

Welcome to our catalog. We know you’ll find costeffective and reliable tools, technologies, and solutions to make a difference in your organization’s profitability and competitive edge. And we look forward to a great working relationship.

Top: Bergan Marine Systems Company Headquarters Located in Pensacola, FL.

Bottom: The Bergan Marine Systems Team.

850.434.1286

CONTROL PANELS & DISPLAYS

In the next few pages, we present our industry-leading tank monitoring and alarm panel products and available modifications. We’re certain you’ll find quality, reliable, and innovative design essential for building your alarm monitoring system.

In order to fit modular internal building block, Bergan Marine System’s designs custom cabinets made to order in virtually any size for Cleaning Plants, Drilling Mud Processing Plants, Terminal Shut Down Systems, or Custom Portable Solutions - just to name a few examples.

We can also retrofit our system into your existing console - even if it was built by another manufacturer - keeping you ahead of the curve without costly replacements.

For 50 years, the professional team at Bergan Marine Systems has been designing and manufacturing high-quality marine instrumentation and equipment built to the highest standards required to guard life, property and the environment, and consistently exceeding expectations.

Alarm Monitoring Unit

The GUARD LEVEL® Alarm Monitoring Unit (AMU) is an independently powered, main alarm control unit for detection of High Level (HL) and Overfill Level (HHL) sensors providing superior control with smart features including voltage-free relay for external signals, cable monitoring for each circuit, individual alarm blocking and a built-in power fail alarm.

This versatile, compact device has 32 digital outputs and can monitor any 4-20mA/HART loop sensor (open and short circuit). All programmed settings are stored in non-volatile Electrically Erasable Programmable Read-Only Memory (EEPROM) memory, with exception being blocking code, so all channels are automatically enabled when the unit is rebooted.

Since the AMU utilizes high precision A/D conversion for all channel measurements, cable shorts and a cable break on individual channels are detected and alarmed. Individual LED indication and custom nameplate is provided for each channel. All measured data as well as remote acknowledgment is handled from the

GUARD LEVEL® Master Control Unit (MCU) and associated GUARD LEVEL® Cargo Management System Plus with the built-in RS422 communication port. With the digital output option, the AMU can be supplied without a front panel. In this case, all alarm indications are on the discreet LEDs on the MCU – or in a customer provided console.

INDEPENDENT ALARM MONITORING.

CABLE MONITORING FOR EACH CIRCUIT (OPEN AND SHORT CIRCUIT).

VOLTAGE FREE RELAY FOR EXTERNAL SIGNALS.

SERIAL COMMUNICATION.

SYSTEM TEST BUTTON.

32 DIGITAL OUTPUTS AVAILABLE.

INDIVIDUAL ALARM BLOCKING.

ALARM DELAY FUNCTION.

BUILT-IN POWER FAIL ALARM.

ALARMS ACKNOWLEDGE BUTTON.

GUARD LEVEL®

Master Control Unit

The GUARD LEVEL® Master Control Unit (MCU) is the core of a reliable monitoring and alarm system working in harmony with a number of Bergan products. The MCU guarantees ultimate performance and top-rated safety in tanks, vessels and in potentially hazardous work areas.

This “go to” Intrinsically Safe and versatile unit supports up to three completely independent systems; High Level (HL) and Overfill Level (HHL) and tank gauging. It’s also available in three physical sizes depending upon required number of I/O.

The HL and HHL’s well-designed mimic panels are comprised of bright amber and red LEDs for easy visibility, as well as a separate alarm acknowledge switch and differing frequency piezo buzzers with adjustable volume control. The gauging section’s hardened and extended temperature-rated embedded computer with the powerful (Intel) i7 processor runs both Windows 10 operating software and GUARD LEVEL® Cargo Management System Plus (CMS+).

This CMS+ user interface is intuitive with a highly configurable 19-inch LCD touchscreen display that can also be console mounted.

The GUARD LEVEL® MCU can be connected to our Guard Power® Uninterrupted Power Source (UPS) and, optionally, a Wi-Fi for remote slave display. Plus, the MCU provides multiple communication ports capable of Ethernet broadcast and Modbus communication over serial or Ethernet connections, meeting and exceeding your communication needs.

Options include a touch panel that can be console mounted.

MULTIPLE COMMUNICATION PORTS CAPABLE OF ETHERNET BROADCAST AND MODBUS COMMUNICATION OVER SERIAL OR ETHERNET.

EXTERNAL USB PORT FOR EASY DATA DOWNLOAD.

PRINTER PORT FOR AUTO ALARM PRINT AND DATA LOG PRINT.

19-INCH COLOR TOUCH PANEL FOR DISPLAY, CONTROL, AND MONITORING OF GAUGING SYSTEMS.

HIGH LEVEL (HL) AND OVERFILL LEVEL (HHL) MIMIC PANEL WITH BRIGHT RED AND AMBER LEDS.

THREE FULLY INDEPENDENT SOUNDERS OF DIFFERENT FREQUENCIES WITH ADJUSTABLE VOLUME CONTROL.

THREE FULLY INDEPENDENT SYSTEMS, HIGH LEVEL (HL), OVERFILL LEVEL (HHL), AND GAUGING ALL POWERED FROM THE GUARD POWER® UNINTERRUPTED POWER SUPPLY (UPS-400) REDUNDANT POWER SOURCE.

Deck Alarm Cabinet+

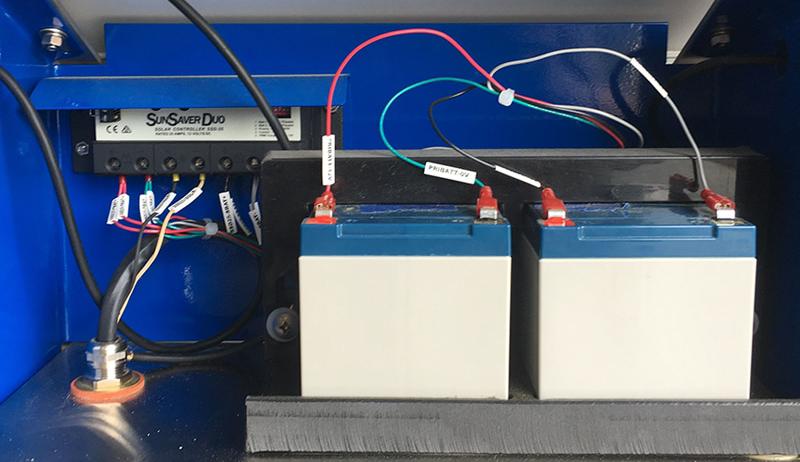

The GUARD LEVEL® Deck Alarm Cabinet (DAC+) is a durable solar-powered monitor and alarm panel that forms the building block for our SMARTBARGE® integration and other inventory control systems. The GUARD LEVEL DAC+’s rugged design is ideal for open deck mounting onboard river and coastal tank barges.

With Independent High Level (HL) and Overfill Level (HHL) level alarms for up to 12 tanks, the GUARD LEVEL® DAC+ is also a match for land-based tank batteries or other remote locations when power is not easily accessible.

Add a PLC (programmable logic controller) capability and the DAC+ becomes a data collection central unit for any 4-20mA/HART type of sensor signals including level, temperature, pressure, and oxygen levels. In addition, the PLC option can communicate with a remote explosion-proof display, like our GUARD LEVEL® MTDE (Multifunction Tank Display Extension).

Set up a wireless modem to transmit data and collect associated alarms together with time stamp, GPS location and system status. Status readings include battery percentage, solar panel voltage and solar charge for all power sources plus the DAC+ total system draw. A wireless transmission can be conveniently set for fixed intervals, event or GPS driven.

Options include hardware to integrate with Bergan Connect, an interface to tank level sensors, an interface to GUARD LEVEL® MTDE deck display, a fail safe shore connect, and an iridium satcom modem and GPS.

INDEPENDENT HIGH LEVEL (HL) AND OVERFILL LEVEL (HHL) ALARMS FOR UP TO 12 TANKS.

ALL SS NEMA 4X (IP67) ENCLOSURE.

LOW POWER 24VDC DECK ALARM CABINET.

175,000 CP STROBE LIGHTS AND 108dB HORNS.

SEPARATE EXTERNAL BATTERY BOX WITH 2EA. 12V 55AH DEEP CYCLE LEAD ACID BATTERIES.

BRIGHT YELLOW AND RED LONG-LASTING LEDS PROVIDE TANK ALARM STATUS.

DUAL 80W SOLAR PAN

GUARD POWER™ Deck Alarm Cabinet

GUARD LEVEL® Deck Alarm Cabinet (DAC) is a solar powered, energy efficient High Level (HL) and Overfill Level (HHL) alarm panel made for open deck mounting on board river and coastal tank barges.

The sunlight-readable LEDs (amber and red) clearly show individual alarm status of up to eight cargo compartments. This energy-efficient design provides fail-safe shore-connect contacts and auto-shutdown after 24 hours protecting battery life.

The alarm features piezo buzzers and strobe lights, as well as power fail warning for tank overfill protection.

A single 20W 12V solar array with independent 12V sealed lead acid batteries provide reliable power and all Intrinsically Safe barrier circuits.

In case of system or power failure, tank loading operation can continue by switching the built-in bypass switch. When the bypass is switched, the alarm sensors are series connected and wired directly to the API receptacles.

Options include hardware to integrate with Bergan Connect, composite fiberglass and NEMA 4 IP67 enclosure.

sales@berganmarinesystems.com

BUILT IN DIAGNOSTICS AND REDUNDANCY PROVIDE MAXIMUM ABILITY.

INDEPENDENT HIGH LEVEL (HL) AND OVERFILL LEVEL (HHL) ALARMS FOR UP TO 8 TANKS.

175,000 CP STROBE LIGHTS AND 10dB HORNS

FAIL-SAFE SHORE CONNECT CONTACTS.

BRIGHT YELLOW AND RED LONG-LASTING LEDS PROVIDE TANK ALARM STATUS.

SEPARATE 2EA. 12V 14AH BATTERY 12V OPERATION AND ONE AS BACK-UP THROUGH SWAP SWITCH INSIDE THE CABINET.

LOW COST AND LOW POWER DECK ALARM CABINET.

AUTO-SHUTDOWN AFTER 24 HOURS PROTECTS BATTERIES.

SMALL SINGLE SOLAR PANEL AND FRAME INCLUDED.

ALL SS NEMA 4X ENCLOSURE.

Simple Deck Alarm Cabinet

The GUARD POWER™ Simple Deck Alarm Cabinet (SDAC) is a solar-powered, low-cost High Level (HL) and Overfill Level (HHL) alarm panel ideal for open deck mounting onboard coastal and river barges and other shore facilities. The SDAC is cleverly built to detect a series of connected alarm sensors sounding a common HL and HHL audible and visual local alarm with two Independent Alarm Control Units.

External alarms include red and amber strobe lighting, an electronic sounder with distinct tones and a blue LED power fail low voltage indicator. A built-in power fail alarm function and a low power level warning are included.

The panel also comes with Intrinsically Safe shore alarm connection relays (voltage free) for API shore connect receptacles. The built-in solar panel charges a primary and secondary power source either of which can be used as the power fail source.

With its solid-state design, built-in Intrinsically Safe barrier circuits and the automatic by-pass switch, the SDAC assures safe loading under all conditions. Options include hardware to integrate with Bergan Connect.

850.434.1286

LOW COST LOW POWER DECK ALARM CABINET.

SMALL SINGLE SOLAR PANEL AND FRAME INCLUDED.

ALL SS NEMA 4X (IP67) ENCLOSURE.

TWO INDEPENDENT ALARM CONTROL UNITS.

SERIES CONNECTED HIGH LEVEL (HL) AND OVERFILL LEVEL (HHL) ALARMS.

TWO 12VDC SEALED BATTERIES PROVIDE PRIMARY 12V OPERATION AND ONE AS BACK-UP THROUGH SWAP SWITCH INSIDE CABINET.

FAIL SAFE SHORE CONNECT CONTACTS.

175,000 CP STROBE LIGHTS AND 108dB HORNS.

BRIGHT YELLOW AND RED LONG-LASTING LEDS PROVIDE TANK ALARM STATUS.

GUARD LEVEL®

Multi Tank Display Explosion-Proof

The GUARD LEVEL® Multi Tank Display Explosion-Proof (MTDE) is a heavy-duty explosion-proof remote display when used with existing GUARD LEVEL® Master Control Unit (MCU) and GUARD LEVEL® Deck Alarm Cabinet (DAC+) control panels providing a complete tank and alarm display in hazardous areas.

Smartly designed large LED displays are readable up to 30 feet or more for ullage, level, volume, pressure, tank temperature and independent High Level (HL) and Overfill Levels (HHL). Multiple MTDE’s can be daisy-chained with a 4C cable (Power & Data) and are ideal for on-deck or manifold area displays.

Acknowledging the alarm from any MTDE or the unit can be configured to only accept acknowledgment from the MTDE located near the tank in alarm.

ALL UNITS CHANGE TO TANK IN LEVEL ALARM, AND THEN AFTER PRESET TIME DEFAULT BACK TO ASSIGNED TANK AFTER ACKNOWLEDGMENT.

CAST BRONZE HOUSING AND STAINLESS SUN SHADE.

EXPLOSION PROOF CLASS 1, DIV. 1 DEVICE.

POWERED BY 24VDC SOURCE.

LARGE LED DISPLAYS ARE READABLE TO 30FT OR MORE FOR ULLAGE, LEVEL, VOLUME, PRESSURE, TANK TEMPERATURE, AND INDEPENDENT HIGH LEVEL (HL) AND OVERFILL LEVEL (HHL) ALARMS.

TANKERMAN CAN READ AND ACKNOWLEDGE ALARMS OF ALL TANKS FROM ONE UNIT.

GUARD LEVEL® Remote Display Unit Series

The GUARD LEVEL® Remote Display Unit (RDU) is a series of rugged remote display instruments made in two distinct models – RDU-81 and RDU-82 – with different connection options.

The RDU-81 is specifically designed for the CARGORADAR® units and uses a 4-wire connection. The RDU-82 is similar to the RDU-81 except it is designed as a universal display for any 4-20mA/HART type 2wire sensor making it ideal for remote display for the Hydrostatic Pressure Transducer (HPT) series of pressure sensors.

Each display can be mounted up to 82 feet (25 meters) away from the radar sensor and contains a full graphic LCD display for level, volume pressure or temperature with a light for nighttime viewing and imperial or metric options. Both displays have a rugged cast stainless steel 316L housing with a viewing window and is suitable for classified “Safe” and, when requested, “Hazardous” area usage. Choose optional Bluetooth functionality for easy wireless setup.

RUGGED REMOTE DISPLAY FOR GENERIC 4-20MA AND CARGORADAR® SENSORS (UP TO 25M / 82 FT AWAY)

GRAPHIC LCD DISPLAY WITH LIGHT FOR NIGHTTIME VIEWING.

ENGLISH OR METRIC DISPLAY.

OPTIONAL BLUETOOTH FOR EASY WIRELESS SET-UP.

CHOOSE LEVEL, VOLUME, PRESSURE, OR TEMPERATURE DISPLAY.

ALL 316L STAINLESS-STEEL CONSTRUCTION.

IP66/68 NEMA 4X TYPE 6P ENCLOSURE.

GUARD POWER™ Uninterruptible Power Supply

The GUARD POWER™ Uninterruptible Power Supply400W (UPS-400) is a high-performance, quiet, fan-less unit specifically designed to work with the GUARD LEVEL® Master Control Unit (MCU) series of control panels that guarantees control of key emergency functions such as power failure alerts, push-button shut downs and battery operated backup alarms. It’s a crucial part of the Bergan family of monitoring and alarm systems.

The UPS-400’s ON/OFF push button serves as the MCU ON/OFF switch and provides for handshake and controlled shut down of the GUARD LEVEL® Cargo Management System Plus (CMS+). The MCU also provides for full galvanic isolation on MAIN and AUX input to output and has a power fail alarm with corresponding LED visual indicator. The panel also has an easily accessible power fail acknowledge switch.

The Dual Power fail output circuits for external alarm annunciation (Horn and Strobe) further ensure emergency readiness. This enables one circuit to stay on until power fail has been corrected significantly adding to system stability.

Additionally, the UPS-400 has battery backup options –a built-in sealed lead acid battery and an auxiliary input for external batteries for specified extended UPS running time – so power continues to flow.

DUAL POWER FAIL OUTPUT CIRCUITS FOR EXTERNAL ALARM ANNUNCIATION AND THE ABILITY OF ONE CIRCUIT (STROBE LIGHT) TO STAY ON UNTIL POWER FAIL HAS BEEN CORRECTED.

POWER FAIL ACKNOWLEDGE SWITCH.

SIX INDIVIDUAL SYSTEM 10A BREAKERS ADJUSTABLE POWER FAIL ALARM WITH CORRESPONDING LED VISUAL INDICATOR.

INTERNAL GEL CELL BATTERIES FOR 30 MIN EMERGENCY BACKUP.

BULKHEAD MOUNTED AND FAN-LESS, QUIET DESIGN.

850.434.1286

Work Station Unit

The GUARD LEVEL® Work Station Unit (WSU) is an ergonomically designed compact graphical display designed for ease of use and convenience all around.

Its painted steel enclosure comes with a hinged door for easy internal access and is idea for housing Load Computer software. Its hardened and extended temperature-rated embedded computer with the powerful (Intel) i7 processor runs both Windows 10 operating software and GUARD LEVEL® Cargo Management System Plus (CMS+).

This CMS+ user interface is intuitive with a highly configurable 19-inch high resolution LCD touchscreen display. The WSU can be used as a redundant slave display for the GUARD LEVEL® Master Control Unit (MCU) or the WSU can replace the MCU when configured without an LCD display.

ERGONOMIC COMPACT DESIGN FOR DESKTOP OR BULKHEAD MOUNTING.

PAINTED STEEL ENCLOSURE WITH HINGED DOOR FOR EASY INTERNAL ACCESS.

19” HIGH RESOLUTION LCD TOUCH SCREEN DISPLAY.

MASTER SLAVE CONFIGURATION.

IDEAL HARDWARE FOR LOAD COMPUTER SOFTWARE.

MULTIPLE WSU IN NETWORK FOR SIMPLE ETHERNET HOOK-UP.

USB PORT FOR EASY DATA LOGGING DOWNLOAD.

PRINTER PORT FOR AVAILABLE ALARM LOGGING.

RADAR LEVEL GAUGING SENSORS

Bergan Marine Systems has been the premier supplier of radar sensors for tank level measurement since 1993, and we now have 2400+ gauges in service around the globe.

Under our exclusive OEM with Vega Americas, we offer the full breadth of high reliable radar gauges built by one of the world’s most respected instrument manufacturers. This partnership gives us the unique ability to offer a variety of stateof-the-art radar gauges tailor-made to your requirements.

For cargo tank applications, we can incorporate tank pressure measurement for a clean and simple design. In deep tanks and/or tanks in which no temperature measurements are needed, our radar sensors set the industry standard for level measurement.

For 50 years, the professional team at Bergan Marine Systems has been designing and manufacturing high-quality marine instrumentation and equipment built to the highest standards required to guard life, property, and the environment, and consistently exceeding expectations.

sales@berganmarinesystems.com

CARGORADAR®

The CARGORADAR® series is a mainstay for your tank gauging needs. Through our OEM Vega Americas’ partnership, we’ve produced a high tech, high accuracy (+/-2mm) non-contact ullage measuring instrument.

From 26GHz to the latest 80GHz tightly focused Frequency Modulated Continuous Wave (FMCW) radar transceiver, the CARGORADAR® is perfect for any tank gauging applications with multiple mounting options. This transceiver also yields a tight beam-width, allowing smooth installation without in-tank structure interference in over-crowded tanks.

Add a built-in tank pressure sensor, or interface with tank temperature sensors for inherently low power consumption – all while assuring reliability and high performance.

FULL DEPTH TANK GAUGING.

INTEGRAL LCD READOUT IN US OR METRIC UNITS OF MEASUREMENT.

AVAILABLE FOR ALL PRODUCTS CLEAN TO ASPHALT.

ALL STAINLESS STEEL CONSTRUCTION.

REQUIRES INTRINSICALLY SAFE DC POWER SOURCE, 24VDC LOOP POWERED, 4-20MA/HART, 2-WIRE CONNECTION.

26GHZ - 80GHZ VERSIONS.

316L HORN & TEFLON ANTENNA.

8” (200MM) FLANGE STANDARD.

HYDROSTATIC LEVEL GAUGING & PRESSURE

Our VEGABAR series of pressure instruments are not only highly accurate, but also feature ceramic measurement cells and HART compatibility for easy ranging and scaling. It’s another great example of our advanced sensor technology through our OEM Vega Americas partnership.

Whether you’re measuring a tank’s vapor pressure or checking water and fuel levels with a submersible sensor, we set the industry standard with our hydrostatic level gauging and pressure sensors.

For 50 years, the professional team at Bergan Marine Systems has been designing and manufacturing high-quality marine instrumentation and equipment built to the highest standards required to guard life, property and the environment, and consistently exceeding expectations.

850.434.1286

GUARD LEVEL®

Hydrostatic Pressure Transducer

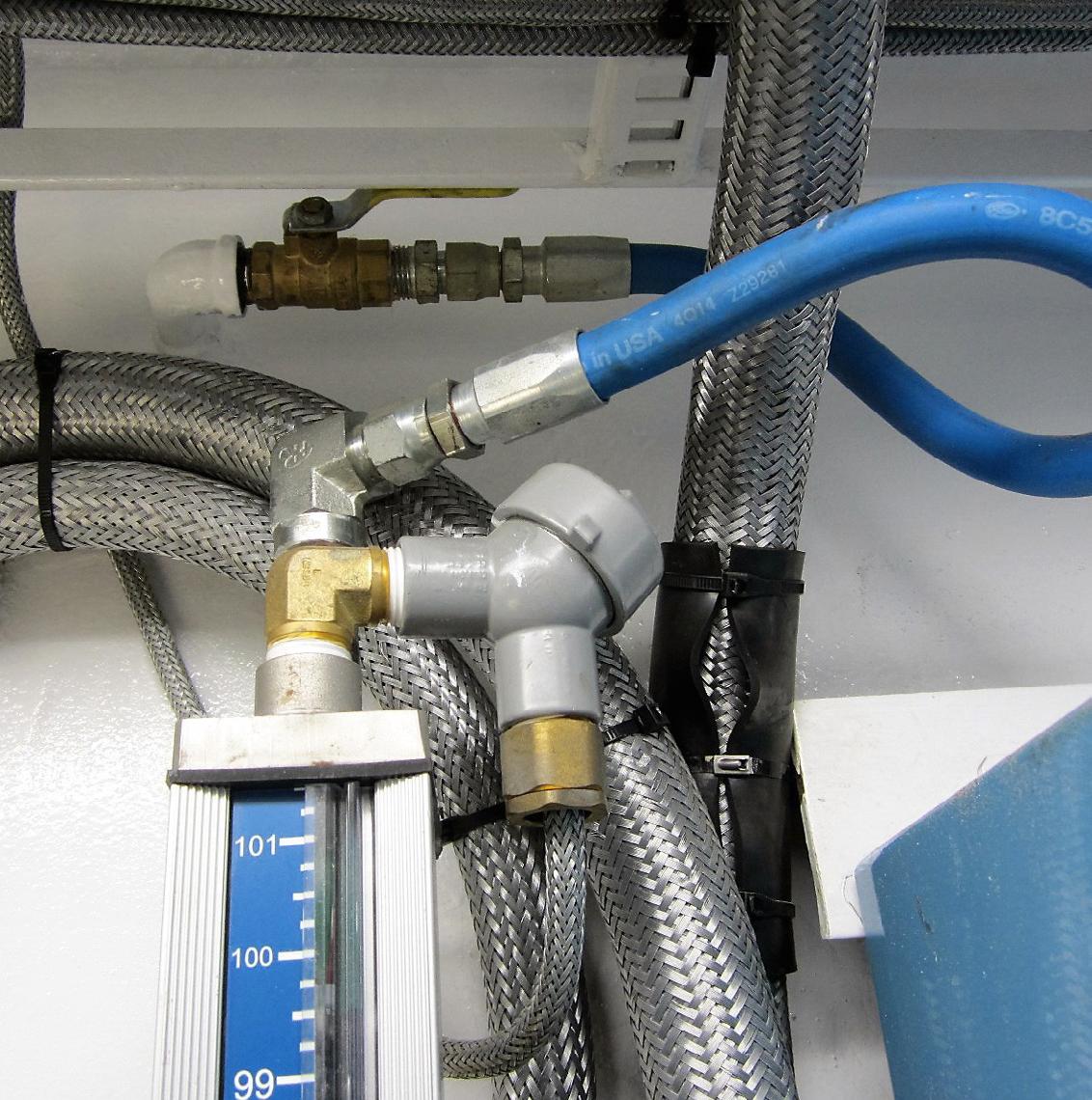

The GUARD LEVEL® Hydrostatic Pressure Transducer (HPT) series are rugged stainless steel, Intrinsically Safe sensors that easily and accurately measure pressure readings in any tank environment. From high pressure full fuel oil tanks to tank vapor line lower pressure situations, the sensors work to assure ease and high accuracy, with safety first on the list. And, for all sensors, pressure ranges can be set according to your exact specifications.

With its unique construction, the sensor can be installed or removed without tank entry and most importantly, can be performed without need of emptying the tank – a major safety advantage. The attached polyurethane cable is suitable for fuel and diesel oil submersion and is simply cut to length depending upon tank height.

Sensor termination can be done with the associated HPT-3 (NEMA 4X IP67) deck junction box. The electrical connection is a simple 2-core cable with an industry standard 4-20mA/HART output signal.

Options include 5” and 6” flange sizes, extended lengths and high temp (asphalt).

ALL STAINLESS-STEEL JUNCTION BOX WITH 2” (50MM FLANGE).

DUPLEX SS HOUSING WITH CERAMIC SENSOR (HPT-3 ONLY)

TANK LEVEL INDICATION BALLAST, FO, LO, AND DRAFT GAUGING.

CHEMICALLY RESISTANT SUBMERSIBLE EXTENSION CABLE.

SERVICEABLE SENSOR WITHOUT TANK ENTRY.

PRESSURE RANGE PER APPLICATION.

FITTED INTO SHIPYARD SUPPLIED 2” PIPE WITH COUNTER FLANGE FOR EASY INSTALLATION AND REMOVAL.

OPTIONAL BUILT IN TEMPERATURE SENSOR.

4-20MA/HART 2-WIRE CONNECTION.

INTRINSICALLY SAFE.

TEMPERATURE SENSORS

Now more than ever you need to safely and accurately measure cargo temperature in tanks and pipelines. Environmental concerns make manual gauging a challenging task, and until recently, a sometimes impossible feat. Our GUARD TEMP™ Barge

Temperature Sensor is a reliable, cutting-edge solution that requires absolutely no cabling or wiring to precisely measure in-tank cargo temperature. Bergan’s Portable Readout Unit allows your crew to easily monitor tank temperature up to three points at a time, safely and efficiently.

For 50 years, the professional team at Bergan Marine Systems has been designing and manufacturing high-quality marine instrumentation and equipment built to the highest standards required to guard life, property and the environment, and consistently exceeding expectations.

sales@berganmarinesystems.com

GUARD TEMP™

Digital Temperature Gauge

The GUARD TEMP™ Digital Temperature Gauge (DTG) is a fully digital tank temperature sensor designed for tank ships and tank barges that significantly saves on deck cabling, IS barriers and I/O cost. The simple 2-wire connection from the cargo tank to main control panel for allthreemeasurementpointsisoneadvantagethatmakes this possible. Also adding value, GUARD TEMP™ DTG has three digital temperature sensors (daisy chained) per cargo tank. These digital temperature sensors connect to a sensor collection unit (SCU) with an optional LCD for local display.

The unit is certified Intrinsically Safe and is typically fitted into a shipyard provided thermowell or a FRAMO style deep well pump. Multiple mounting options are available with a one-inch minimum thermowell size. And, it can connect directly to CARGORADAR® or separately run to CCR with our 2-core cable.

Options include LCD readout at junction box.

ALL 316L STAINLESS STEEL JUNCTION BOX.

MOUNTING OPTIONS INCLUDE FRAMO PUMP FLANGE OR 50MM (2”) UNIVERSAL. 850.434.1286

THREE INTRINSICALLY SAFE DIGITAL TANK TEMPERATURE SENSORS PER CARGO TANK.

CAN CONNECT DIRECTLY TO CARGORADAR® OR SEPARATELY RUN TO CCR WITH 2-CORE CABLE.

1-PAIR (2 WIRE) CONNECTION FOR 3 POINTS.

RANGE: -20C TO +100C

GUARD TEMP™

Single Temperature Sensor

The GUARD TEMP™ Single Temperature Sensor (STS) series of tank temperature sensors are designed for tank ships and tank barges and can be fitted at one, two or three points per tank – with pump thermo well flange or high temp asphalt options.

Choose from a normal cargo temperature using a neoprene cable (STS-100 or the high- temp version with a Teflon jacketed cable (STS-200.) The Platinum1000 (PT-1000) wire wound platinum Resistance Temperature Detection (RTD) type temperature sensors are wired into the associated temperature deck junction box containing one to three RTD to 4-20mA Intrinsically Safe certified converters.

Options include high-temp (asphalt) and pump thermo well flange.

HIGH-TEMP EXTENSION CABLES AND PLATINUM WIRE TEMPERATURE SENSORS (STS-200).

CARGO TEMPERATURE SENSORS AT 1, 2, OR 3 POINTS PER TANK.

INTRINSICALLY SAFE ALL STAINLESS-STEEL JUNCTION BOX.

4-20MA TRANSMITTER W/ 2-WIRE CONNECTION PER TEMP POINT.

2” (50MM) FLANGE

FITTED ONTO YARD SUPPLIED CLOSED THERMO WELLS WITH 2” COUNTER FLANGE.

EXTENSION CABLES WITH PLATINUM WIRE TEMPERATURE SENSORS AND 316L STAINLESS STEEL HOUSING (STS100).

RANGE: PER APPLICATION

GUARD TEMP™

Single Point Sensor

The GUARD TEMP™ Single Point Sensor (SPS-100) is a rugged stainless-steel insertion-type sensor for tank wall or typical cargo piping connections offering a number of options – including for small tanks.

The unit’s removable PT-1000 wire wound platinum

Resistant Temperature Detection (RTD) type temperature sensors are fitted into an RTD to 4-20mA

Intrinsically Safe certified converter. Probe length is customizable, while process connections can be either screw-on or flange connection. Cabling is required, and temperature readings are displayed on a console and/or a deck display.

Our Barge Temperature Sensor is a reliable, cutting- edge solution that gives your crew the ability to easily monitor tank temperature up to three points at a time, safely and efficiently.

Options include portable handheld readout PTRU.

ALL STAINLESS-STEEL CONSTRUCTION.

3/4” NPT (OR) FLANGE CONNECTION.

INTRINSICALLY SAFE.

2-WIRE OUT 4-20 MA TRANSMITTER (OR) 3-WIRE OUT.

REPLACEABLE TEMPERATURE SENSOR ELEMENT WITHOUT REMOVING SENSOR AND EXPOSING LINE.

PLATINUM WIRE TEMPERATURE SENSOR IN 316L STAINLESS STEEL THERMOWELL.

SINGLE POINT TEMPERATURE SENSOR IN PIPING AND SMALL TANKS.

Barge Cargo Temperature Unit

The GUARD TEMP™ Barge Cargo Temperature Unit (BCTU) is a rugged low-cost stainless-steel tank temperature sensor designed for tank barges providing fast, accurate measurements and – the biggest advantage – no more mess. To add to the convenience, the unit requires no permanent cabling and is easily installed in any tank opening of two inches or larger.

The GUARD TEMP™ BCTU is also highly adaptable. Choose from individual thermo wells of up to three different temperature measurement points. The PT1000 platinum wire wound temperature sensors are wired directly to a connector on top of the junction box. Instantaneous temperature measurements are taken with a GUARD TEMP™ Portable Temperature Display Unit (PTDU) – a separate unit connected to the BCTU.

Options include fitted with or without sensor pipes into existing thermal well and fitted on GUARD LEVEL® Twin Alarm Sensor.

SUITABLE FOR ALL CARGOS REFINED TO ASPHALT.

UNIVERSAL FLANGE (OR) NPT COUPLING.

ALL STAINLESS-STEEL CONSTRUCTION.

CARGO TEMPERATURE GAUGING WITH NO POWER AVAILABLE.

JUNCTION BOX ALLOWS FOR EASY REPLACEMENT OF TEMP PROBES WITHOUT EXPOSING CARGO.

1, 2, OR 3 TEMP POINTS PER TANK.

SENSOR LENGTH MADE TO ORDER.

DECK SPOOL PIECE HEIGHT TO ORDER.

SOFTWARE

Designed with reliability and high functionality in mind, our standard software solutions include new releases as well as regular upgrades. Our system utilizes a non-volatile memory hard disk for fast and reliable performance in even the harshest of conditions. Custom interfaces with Modbus are available, created to fit any makers automation system. If you do not find what you need in these pages, our software developers can meet your unique request.

For 50 years, the professional team at Bergan Marine Systems has been designing and manufacturing high-quality marine instrumentation and equipment built to the higest standards required to guard life, property, and the environment, and consistently exceeding expectations.

850.434.1286

GUARD LEVEL® Bergan Connect

At Bergan, we are constantly striving to leverage current technology to deliver innovative solutions to our customers. Bergan Connect is our cloud-based data platform for wired and wireless systems, providing data for any vessel.

Bergan Connect brings together data from multiple sources into a single, user-friendly platform, easily accessible via any device with an internet connection. A custom dashboard allows you to see your most essential data at a glance, including data from any sensors with specific applications.

With Bergan Connect, monitor and track:

• Flow meters, fuel consumption , cargo data, emissions, loading and discharge.

• Tank level sensors, including pressure sensors, temperature sensors, and radars.

• Alarm status and alarm history.

• Battery voltage and charge.

• System and engine data.

• GPS location.

• And so much more

Through our partnerships with leading maritime analytic companies, you have a variety of data and analysis tools at your fingertips. Turn your data into actionable insights with tools from Spinergie, ioCurrents, Helm CONNECT, and Herbert-ABS.

Bergan Connect can be retrofitted into any existing wired system. Our Barge Connect cabinet brings Bergan Connect capabilities to your system. We also offer communication equipment that allows your sensors to transmit wirelessly. Our Bergan Connect API allows for easy integration with any of your preferred platforms.

And this is just the beginning. Bergan Connect promises a future of updates that brings the latest in maritime innovation.

To see how your operations can be enhanced by Bergan Connect, please reach out to us at 850.434.1286 or info@berganmarinesystems.com.

Our Partners

sales@berganmarinesystems.com

Coming soon, integrations with other leading marine software

ACCESSIBLE FROM ANY DEVICE WITH AN INTERNET CONNECTION

CUSTOMIZABLE DASHBOARD

NEAR REAL TIME

ADJUSTABLE HIGH AND LOW STOP GAUGE CHECKS.

ONLINE INTERFACE WITH LOAD CALCULATOR.

TREND ARROW FUELING/DISCHARGING

LOADING AND DISCHARGE RATES.

TIME TILL FULL AND EMPTY.

Cargo Management System+

Our GUARD LEVEL® Cargo Management System Plus (CMS+) is an embedded alarm and monitoring software providing a highly functional and user-friendly graphical software experience. CMS+ guarantees safe loading, monitoring and control of cargo, ballast and fuel tanks. The software comes preloaded onto the Master Control (MCU) and Work Station Units (WSU) or can run separately on an onboard PC. Powered by the advanced Intel i7 processor, this versatile Windows tile-based system makes it easy to configure and set up custom screens to manage your cargo.

While basic overview screens are fabricated with tiles representing cargo High Level (HL) and Overfill Level (HHL), ballast, and service tanks – mix and match and designate tiles for specific loading needs. Cargo can also be color-coded according to customer preference. All monitored parameters are data logged. Choose what element to log and at what frequency.

With the Modbus interface, computer software such as CargoMax® can be loaded allowing for bi-directional

online interface. The CMS+ can be run in master or slave mode accommodating one to multiple secondary displays. Ask our representatives about the outstanding level of CMS+ functionality and specific program requirements.

850.434.1286

SUMMARY SCREENS FOR SYSTEM ALARM, SERVICE TANK, BALLAST TANK, CARGO PRESSURE, PUMP AND MANIFOLD, CARGO ULLAGE, AND CARGO TEMPERATURE.

CARGO LABELS AND USER DEFINED COLOR CODING.

SYSTEM SAFE AND FAULT DISPLAYS.

DATA LOGGING/ USER SELECTED.

ADJUSTABLE HIGH AND LOW STOP GAUGE CHECKS.

ONLINE INTERFACE WITH LOAD CALCULATOR.

TREND ARROW FILLING/ DISCHARGING.

LOADING AND DISCHARGE RATES.

TIME TO FULL AND EMPTY.

GUARD LEVEL®

Fuel Management System

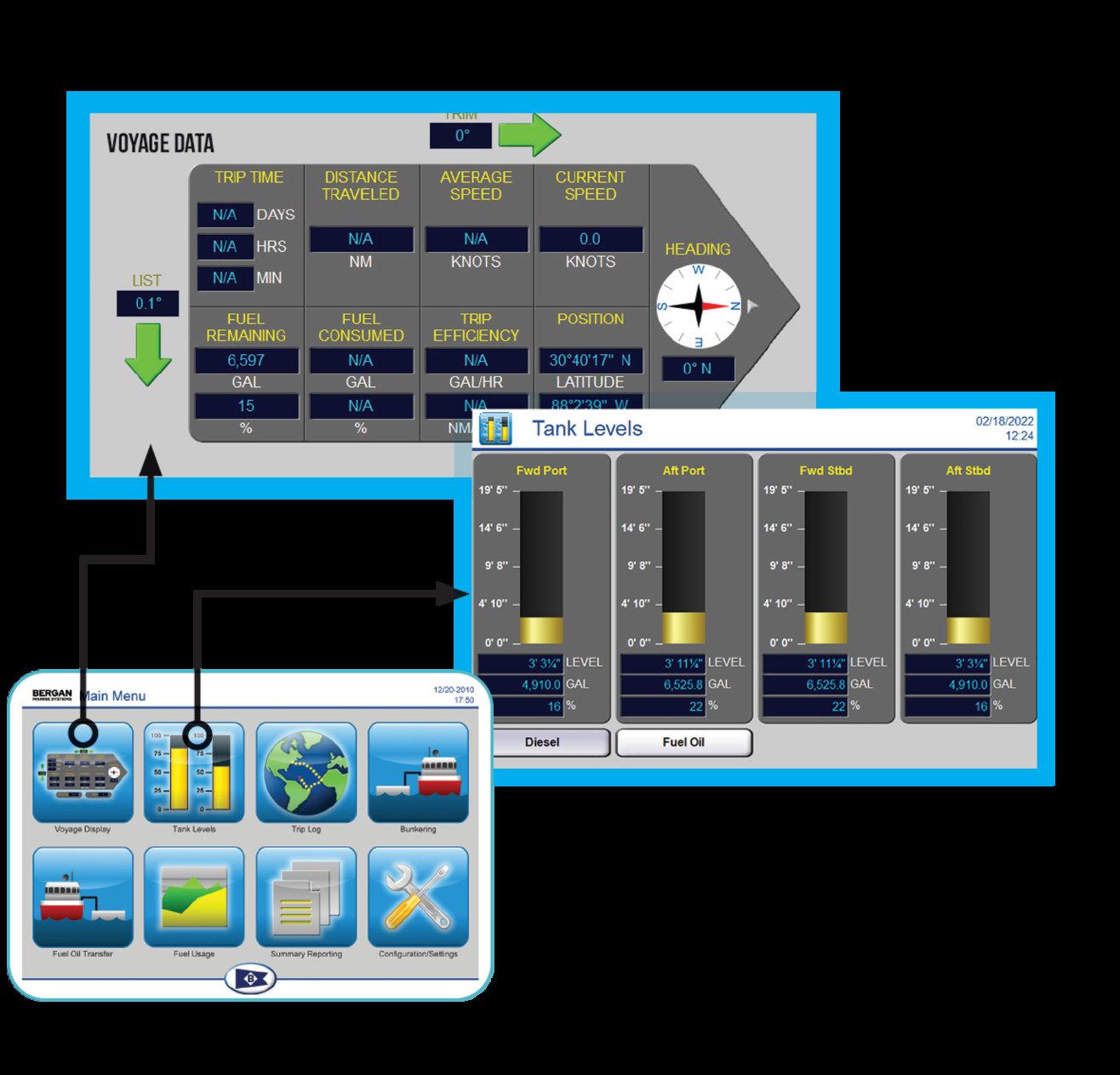

The GUARD LEVEL® Fuel Management System (FMS) is an inventory management system for tug boats and other smaller crafts that produces an audit trail to easily optimize fuel usage and reduce and eliminate fuel pilferage. This intuitive tank gauging system has extended hardware and software capabilities.

The FMS main cabinet and associated CARGORADAR® or GUARD LEVEL® Digital Float Gauge (DFG) combined GPS interface provides for highly accurate daily fuel usage reports. By characterizing the bunker tanks and having these strapped to +/- 0.15% accuracies, highly accurate tank volumes are calculated.

The FMS software generates detailed daily reports and trip data information stored in non-volatile memory. When data communication like a Satcom or 4G system is specified, the daily report can be transmitted directly to your data center or uploaded to our Bergan-provided secure Fleet Reporting Software (FRS) cloud software. With FRS, you have dependable access to the data whenever you need it.

sales@berganmarinesystems.com

CONSUMPTION ANALYSIS WITH GPS COORDINATES FOR ALL INSTRUMENTED BUNKER TANKS.

CONTINUOUS INVENTORY CONTROL OF ALL INSTRUMENTED BUNKER TANKS.

FUEL DISCHARGE REPORT AFTER TUG TO BARGE FUELING TRANSFER.

DATA STORAGE IN NON-VOLATILE MEMORY.

REMOTE MONITORING USING CLOUD BASED FLEET REPORTING SOFTWARE (FRS).

ENGINE FUEL CONSUMPTION (REQUIRES OPTIONAL CORIOLIS FLOW METER).

SHORE VERSUS VESSEL DISCREPANCY REPORT AFTER EACH BUNKER OPERATION.

GUARD LEVEL®

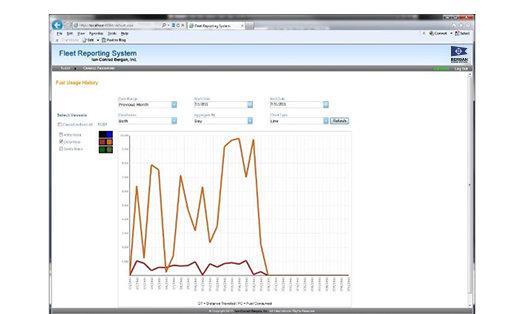

Fleet Reporting Software

GUARD LEVEL® Fleet Reporting Software (FRS) is a lowcost cloud-based software for disseminating fuel data used with the Bergan GUARD LEVEL® Fuel Management System. With the FRS cloud, you have 24/7 access to data. Upload daily fuel reports, download raw data and generate and review graphical presentations of selected data sets.

You own and control your vessel’s proprietary data, which is securely password protected – assuring reliability and peace of mind. The FRS software is a SQL database program that is hosted by a third party.

ACCESSIBLE FROM ANY COMPUTER WITH LOG-ON CREDIENTIALS.

CLOUD BASED SQL DATABASE PROGRAM.

EXPORTING FOR DATA MINING.

SECURE DATA STORAGE.

FUEL MANAGEMENT SOFTWARE (FMS) IN CONJUNCTION WITH FRS PROVIDES AUDIT TRAIL OF VESSEL POSITION, FUEL BURN, AND RELATED DATA.

VESSEL NAME, DATE AND TIME.

TRENDING AND DATA GRAPH.

850.434.1286

CargoMax®

Through our partnership with Herbert Software Solutions, we provide CargoMax® in conjunction with our cargo management systems.

For over 35 years, CargoMax® has set the standard for shipboard stability and load management software. This proven system combines rigorously tested algorithms with a user-friendly interface to provide quick and consistent results, ensuring that the safety of the vessel is maintained at all times.

For more information go to www.herbert-abs.com.

INTERFACE WITH BERGAN GAUGING SYSTEM.

INTACT AND DAMAGE STABILITY.

LOAD MANAGEMENT.

GROUNDING.

STRENGTH ANALYSIS AND LOCAL SHEAR.

CUSTOM FEATURES AND ALARMS.

TRIM AND DRAFT OPTIMIZATION.

FLOAT LEVEL GAUGING SENSORS

Bergan Marine Systems has a gauge to meet every demand, from our tried-and-true Digital Float Gauge to our new, innovative Digital Level Indicator. These gauges lay the foundation for precise inventory control and fuel management systems - with power consumption so low they can be powered completely with solar energy. Our sensors are accurate so they will never need to be calibrated.

Whether you’re gauging the blazing heat of Papa, New Guinea, or the arctic temperature of Juneau, Alaska, our GUARD LEVEL® DFG is the proven and safe choice.

For 50 years, the professional team at Bergan Marine Systems has been designing and manufacturing high-quality marine instrumentation and equipment built to the highest standards required to guard life, property, and the environment, and consistently exceeding expectations.

GUARD LEVEL® Digital Float Gauge Series

The GUARD LEVEL® Digital Float Gauge (DFG) sensor is a rugged and accurate tank gauge sensor ideal for cargo as well as ballast and service tanks – also available in an ALL-IN-ONE version.

The float magnetically actuates a series of digitally interfaced dry reed switches, physically spaced, assuring absolute accuracy and completely eliminating the need for recalibration during its life.

This adaptable sensor can be supplied in any length of 0.5m increments up to a maximum of 20m. Add an optional 150 or 300lb flange, it is an ideal setup for LPG/ Ethane and other liquefied compressed gas applications.

For cargo tank gauging, the GUARD LEVEL® DFG 250 ALL-IN-ONE version of the DFG is the perfect solution. It combines the level gauging, High Level (HL) and Overfill Level (HHL) alarms, tank pressure, tank temperature (one to three points) and UTI port for MMC or Hermetic style vapor ball valve in a single tank penetration.

With a single 6 or 8-core cable to the MCU, this sensor significantly reduces installation cost and minimizes trip hazards on deck.

And, the local LCD display can be optionally remote mounted. For simplicity, all electrical/electronic parts can be serviced from tank top without exposing tank vapor to the crew –keeping them safe.

Options include digital temperature gauge (max three points) without additional cabling, tank pressure sensor without additional cabling, and an ALL-IN-ONE configuration for cargo tanks.

850.434.1286

SIMPLE AND RELIABLE LEVEL

GAUGE WITH 100% DIGITAL DESIGN.

LIGHTED LCD READOUT FOR CONVENIENT DISPLAY.

ALL STAINLESS-STEEL JUNCTION BOX WITH 2” (50MM) FLANGE.

FULL DEPTH GAUGING AVAILABLE UP TO 20M (64FT).

SIMPLE 2-WIRE CONNECTION.

CALIBRATED FOR LIFE WITH ABSOLUTE ACCURACY OF 5MM (1/4”).

ALL STAINLESS-STEEL CONSTRUCTION.

INTRINSICALLY SAFE.

Digital Level Indicator Series

The GUARD LEVEL® Digital Level Indicator (DLI) is a digitally designed electronic visual sight glass for engine room fuel and service tanks providing not only 100% accuracy, but flexibility.

Because its standard 4-20mA output has HART compatibility, the DLI can be interfaced to any ship’s automation system for remote indication and alarm.

The DLI gauge is clamped onto a two-inch SS316L bridle and, as its magnetically actuated stainless-steel float moves, it activates the adjoining magnetic switch and corresponding LED.

The bridle can be yard or Bergan supplied and connects to the tank wall with either flange or a hose connection.

Options include a custom volume scale, metric version, and 2” 316SSL bridle with isolation valves with flange or hose connection.

sales@berganmarinesystems.com

VISUAL TANK GAUGING WITH STANDARD 4-20MA / HART (LOOP POWERED) OUTPUT.

INTERFACE TO BERGAN OR ANY MAKERS SYSTEM.

ADJUSTABLE HL AND LL ALARM (FROM 4-20MA).

SIMPLE CLAMP-ON BRIDLE DESIGN.

ELIMINATES FRAGILE GLASS TUBES AND LEAKS.

DIGITAL LED INDICATION WITH 1/4” PITCH SPACING.

1/8” LIQUID LEVEL RESOLUTION.

SUITABLE FOR SAFE AREA MACHINERY SPACE.

MEASURING RANGE MAXIMUM 20 FT (6.25M)

ALL STAINLESS STEEL 316L FLOAT (IS FITTED INSIDE BRIDLE).

COMPLIES WITH USCG REGULATIONS FOR TANK GAUGING.

ZERO SENSOR DRIFT AND ABSOLUTE LINEARITY.

FLOAT LEVEL ALARM SENSORS

Bergan Marine Systems has more experience in making reliable float level alarm sensors than any other fabricator in the world. With focus on consistent performance and product longevity, the engineers at Bergan Marine Systems have developed a line of float level alarm sensors that provide industry-leading reliability.

From the hot asphalt to cryogenic temperatures of LNG tanks, we have a device that will deliver for you. Many of our sensors may be customized with optional secondary functions, such as UTI/sampling port, rising gauge stick, tank pressure or even temperature to minimize tank penetrations.

For 50 years, the professional team at Bergan Marine Systems has been designing and manufacturing high-quality marine instrumentation and equipment built to the highest standards required to guard life, property and the environment, and consistently exceeding expectations.

850.434.1286

GUARD LEVEL®

Adjustable Compact Alarm Sensor

The GUARD LEVEL® Adjustable Compact Alarm Sensor (ACAS) is an ingenious way to assure overfill protection on bunker tanks and other small service tanks accommodating a variety of setups. Its rugged stainlesssteel single alarm point level sensor fits into any tank opening of 1.5 inches (G1.5) or greater, while its dry reed switch opening allows for either a Normally Closed (N.C.) or Normally Opened (N.O.), allowing for simple sensor interface to any alarm system.

The level alarm is brilliantly designed so it can easily be adjusted to test proper function while ACLAS’s nonsinkable Nitrophyl float allows the compact level alarm sensor to be suitable for all petroleum products. Like all Bergan products, it is certified Intrinsically Safe due to its Simple Apparatus certification.

Options include longer lengths and flange sizes to order.

LASER ENGRAVED GRADUATION TO SHOW ALARM POINT SETTING.

ALL STAINLESS-STEEL CONSTRUCTION.

EASILY ADJUSTABLE ALARM POINTS WITH A SLIP JOINT COUPLING.

SIMPLE 2 WIRE CONNECTION, N.O OR N.C.

HEAVY-DUTY UNSINKABLE NITROPHYL FLOAT.

INTEGRAL TEST FUNCTION.

IDEAL FOR FUEL, BALLAST AND OTHER SERVICE TANKS (WITH TOP ACCESS).

GUARD LEVEL® MKII

The GUARD LEVEL® 07324 MKII is a highly reliable and simple level alarm sensor for tank barges and tank ships. The MKII has an enviable record of providing the ultimate defense against tank overfill conditions. The alarm sensor can be applied as either a single or dual alarm point (1A or 2A) utilizes the proven principle of a float with magnetic actuation of a highly reliable bi-stable dry switch contact. With a built-in test rod, full functional testing can occur before loading tank.

With outstanding adaptability, the GUARD LEVEL® MKII can be configured to different lengths to fit any alarm points below tank top. An optional extended temperature range alarm switch can be added to secure a wide range of cargo, from cryogenic to boiling bitumen tanks. The GUARD LEVEL® 07324 MKII of course meets all class and IMO regulations.

Options include 5” and 6” flange sizes, extended lengths, and high temp (asphalt).

INDEPENDENT HIGH LEVEL (HL) AND/OR OVERFILL LEVEL (HHL) CARGO ALARMS.

STANDARD 4” (100MM) UNIVERSAL WITH 5” PENETRATION PIPE.

ADJUSTABLE HERMETICALLY SEALED NC LEVEL SWITCHES. ALL STAINLESS-STEEL CONSTRUCTION.

TEST ROD FOR TESTING LEVEL ALARMS.

HEAVY DUTY 316L LEVEL ALARM FLOAT.

GUARD LEVEL®

TWIN Series

Our GUARD LEVEL® 07324 TWIN series (TWIN, TWINSTICK, TRI-STICK, TWIN-RADAR) are highly reliable level alarm sensors for tank barges and tank ships providing the ultimate defense against tank overfill conditions – with a mounted flange that can accommodate optional radar level gauges. Built upon our trailblazing 07324 MKII design and the proven principle of a float with magnetic actuation of a highly reliable bi-stable dry switch contact, the sensors can be applied as a single or dual point alarm sensor (1A or 2A). With a built-in test rod, full functional testing can occur before loading tank.

With outstanding adaptability, The GUARD LEVEL® 07324 TWIN series sensors can be configured to different lengths to fit any alarm points below tank top. The series’ mounting flange size can accommodate optional radar level gauge (TWIN-RADAR), TWIN-DFG, TWIN-STICK AND TRI-STICK as well as an MMC vapor control valves and Hermetic ball valve for a clean deck installation with minimal tank penetration.

Options include radar, pressure, and temp sensor, UTI with MMC

850.434.1286

INDEPENDENT HIGH LEVEL (HL) AND/OR OVERFILL LEVEL (HHL) ALARM.

ADJUSTABLE HERMETICALLY SEALED NC LEVEL SWITCHES.

TEST ROD FOR TESTING LEVEL ALARMS.

HEAVY DUTY 316L ALARM FLOATS.

ALL STAINLESS STEEL CONSTRUCTION.

8” (200MM) ANSI FLANGE.

PORTABLE HANDHELD PRODUCTS

Our hand-held portable devices for measuring cargo temperatures and testing level alarms make monitoring precious cargo possible in any environment. Bergan Marine Systems has a long history of engineering devices that are Intrinsically Safe, batteryoperated, and proven reliable in every category.

For 50 years, the professional team at Bergan Marine Systems has been designing and manufacturing high-quality marine instrumentation and equipment built to the highest standards required to guard life, property, and the environment, and consistently exceeding expectations.

sales@berganmarinesystems.com

SMARTBARGE®

Draft Loading System

Our innovative SMARTBARGE® Draft Loading System allows your tankerman to safely load your barge to a specified draft. With the Draft Loading System, tankerman no longer need to lean over the side to read the draft marks. It increases safety from trips, slips, and falls, reduces heat stress, and overall creates a safer environment by reducing the need to move around the barge.

And, with a total weight of 5.4 LBs, it’s easy to transport. Our Bergan CR31 Radar is accurate to +/-2mm. The wireless transmitter can send data quickly and dependably to an intrinsically safe, rugged tablet.

U.S Provisional Patent Application, Serial No. 63/452,720 entitled: Wireless Freeboard Measurement Device For Ships.

REDUCES CHANCES OF MAN OVERBOARD AND HEAT STRESS ON TANKERMAN.

TOTAL WEIGHT OF 5.4 LBs.

INTRINSICALLY SAFE.

WIRELESS TRANSMISSION OF DATA TO AN INTRINISCALLY SAFE, RUGGED TABLET.

BERGAN CR31 RADAR ACCURATE TO +/- 2MM.

BATTERY POWERED.

850.434.1286

GUARD LEVEL® Portable Alarm Unit

The GUARD LEVEL® Portable Alarm Unit (PAU) is a rugged portable solution for on-board alarm annunciation on inland and coastal river barges. The system monitors and raises alarms through series-connected alarm sensors and gives a unique warning for both High Level (HL) and Overfill Level (HHL). This battery-powered unit plugs into existing tank barge API receptacles. It complies with all CFR regulations for tank overfill control.

Unique features include an automatic by-pass switch allowing for seamless operation when connected to a tank terminal’s alarm system. In case of power failure or system failure, the switch automatically disconnects the PAU from the circuit and by-passes the series-connected sensors directly into the terminal’s alarm system. Battery status and power fail warnings are also included. And, the PAU meets the requirements to be used for TANDEM loading.

The PAU is designed to be located and operated in a barge “safe” area, but all the sensor input and outputs are protected with galvanically isolated safety barriers for complete safety in most shipping locations.

PORTABLE HIGH LEVEL (HL) AND OVERFILL LEVEL (HHL) ALARM BOX FOR SERIES CONNECTED H AND HH LEVEL ALARM SENSORS.

BUILT-IN BATTERY CHARGER AND PLUG WITH LCD BATTERY CHARGE STATUS INDICATOR.

POWERFUL LED LIGHTS AND 117 dB SOUNDERS.

DURABLE HIGH IMPACT MOLDED POLYETHYLENE CARRYING CASE.

RECOMMENDED FOR SMALLER RIVER BARGES WITH NO ELECTRICAL POWER.

WORKS WITH ANY MAKERS SENSORS CONNECTED TO API RECEPTACLE.

TANDEM BARGE LOAD CAPACITY

WEIGHT: 50LBS

GUARD LEVEL®

Portable Testing Unit

The GUARD LEVEL® Portable Testing Unit (PTU) is a rugged, compact, handheld, battery-powered High Level (HL) and Overfill Level (HHL) alarm tester for U.S. inland and coastal barges.

This mobile device is ideal for verifying that the barge level alarms are in the correct working order before arriving at the terminal. This unit has series-connected alarm sensors terminating in port and starboard Application Programming Interface (API) shore alarm connectors. The PTU’s LED indicators and dual-tone piezo buzzer activate when alarm sensors are tested.

PORTABLE HIGH AND OVERFILL ALARM TESTING UNIT FOR SERIES CONNECTED ALARM SENSORS.

WORKS WITH ANY MAKERS SENSORS CONNECTED TO API RECEPTACLE.

INDIVIDUAL LED INDICATION FOR SAFE AND ALARM CONDITION.

RECOMMENDED FOR TESTING LEVEL ALARM SENSORS PRIOR TO LOADING AND CONNECTING TO TERMINAL SHUT DOWN SYSTEM.

DURABLE HIGH IMPACT MOLDED CONSTRUCTION.

USER REPLACEABLE ALKALAINE BATTERIES.

DUAL TONE PIEZO BUZZER.

GUARD LEVEL®

Portable Testing Unit Mobile

The GUARD LEVEL® Portable Testing Unit Mobile (PTU-M) is a rugged, handheld, battery-powered High Level (HL) and Overfill Level (HHL) alarm tester for U.S. inland and coastal barges. It is a useful tool to verify that the barge level alarms are in the correct working order before arriving at the terminal.

This unit has series-connected alarm sensors terminating in port and starboard API shore alarm connectors. Like the Portable Testing Unit (PTU), the PTU-M is equipped with LED indicators and a dual-tone piezo buzzer that activates when alarm sensors are tested, as well as an API plug and a 25-foot extension cord.

PORTABLE HIGH LEVEL (HL) AND OVERFILL LEVEL (HHL) ALARM TESTING UNIT FOR SERIES CONNECTED ALARM SENSORS.

INDIVIDUAL LED INDICATION FOR SAFE AND ALARM CONDITION.

WORKS WITH ANY MAKERS SENSORS CONNECTED TO API RECEPTACLE.

RECOMMENDED FOR TESTING PRIOR TO ARRIVING AT LOADED TERMINAL.

DURABLE HIGH IMPACT MOLDED CONSTRUCTION.

USER REPLACEABLE ALKALINE BATTERIES.

API PLUG AND 25’ EXTENSION CORD.

850.434.1286

GUARD TEMP™

Portable Temperature Display Unit

The GUARD TEMP™ Portable Temperature Display Unit (PTDU) is an Intrinsically Safe battery-operated temperature display device. When connected to the

GUARD TEMP™ Barge Cargo Temperature Unit (BCTU), it provides quick and easy tank temperature indication of up to three measurement points simultaneously.

The BCTU can be configured to display either degrees Fahrenheit or Celsius. With its gold-plated spring connector and coaxial design, the BCTU is easily connected/disconnected to the PTDU.

PORTABLE TEMPERATURE READOUT.

CERTIFIED INTRINSICALLY SAFE.

FOUR AA BATTERY POWERED.

DEGREE IN F OR C.

REPLACES MESSY MANUAL THERMOMETERS WITH CLEAN, ACCURATE TEMP GAUGING.

USED TO READ TEMPERATURES FROM OUR BARGE CARGO TEMPERATURE UNIT (BCTU).

DISPLAYS UP TO THREE SENSORS SIMULTANEOUSLY.

CLASS 1, DIV. 1, GROUPS C & D.

MANUAL GAUGING PRODUCTS

Clear vision. It’s important.

Our entire line of mechanical gauging products allows visual gauging with an unobstructed view into the tank for inland and coastal tank barges, as well as oceangoing tankers.

A manual back-up emphasizes Bergan’s ongoing commitment to customer safety with a guaranteed critical clear line of sight. Ask us about our other unique solutions, such as sight glasses created with specialized German-built fused glass for chemical applications. Our technicians are experts at developing custom solutions to challenging situations and would be glad to talk to you.

That’s what we’ve been doing for 50 years: helping companies protect their vision while safeguarding everything they’ve worked for. And the people that make it possible.

GUARD LEVEL® MDS

The GUARD LEVEL® MDS is a magnetically coupled gauge-stick giving a visual reference on tank barges during loading for designated “Safe” or “Hazardous” areas complying with all Code of Federal Regulations. Its rugged stainless-steel design and simplicity of operation assures safe loading and prevention of tank overfills – with over 14,000 units currently in service.

The tricolor (green, yellow, and red) gauge stick measures the upper one meter (1M) of tank ullage. Longer and shorter stick lengths can be made to order, along with flange sizes. Our high temp (HT) version, also optional, is ideal for safe loading of hot oil and asphalt cargo.

Options include longer and shorter lengths to order, high temperature, and flange sizes to order.

MAGNETICALLY COUPLED TRI-COLOR STICK GAUGE WITH ULLAGE TAPE.

CARGO GAUGING TOP METER OF TANK.

850.434.1286

ALL STAINLESS-STEEL CONSTRUCTION.

8” (200 MM) ANSI FLANGE. HEAVY DUTY 316L FLOAT.

Dual Wiper Sight Glass Series

The GUARD LEVEL® Dual Wiper Sight Glass (DWSG) series of powerful sight glasses provide visual aid and fulldepth gauging on coastal tank barges assuring safe loading and prevention of tank overfills. With a 50-inch square viewing area, these sight glasses are vapor-tight and can be mounted on tank hatch domes or expansion trunks.

It complies with the Code of Federal Regulations for full depth manual tank gauging. When placed above the tank sumps, the sight glasses’ visual gauging aids in a tank’s stripping operation. Wiper elements of different types are available for petrochemical as well as chemical applications. The gas-free version is also available and incorporates a hinged design with a flame screen.

Options include mounting truck with hardware and a single teflon chemical wiper.

SINGLE 2-SIDED WIPER FOR SIMULTANEOUS WIPING OF TOP AND UNDERSIDES.

ALL PARTS CAN BE REPLACED WITHOUT REMOVING COMPLETE UNIT

50” SQ. INCH VIEWING AREA

RAISED GLASS FOR EASY CLEANING AND TO ELIMINATE ATER ACCUMULATION

1/2” THICK HEAT TEMPERED VIEWING GLASS

ALL STAINLESS STEEL CONSTRUCTION

GUARD LEVEL® MAXIVIEW

The GUARD LEVEL® MAXIVIEW is a rugged heavy-duty cast stainless-steel sight glass that provides visual aid and full-depth gauging on coastal tank barges assuring safe loading and prevention of tank overfills.

Unique features include the largest wiped surface area of any sight glass made in the industry and a raised- glass design for zero water accumulation. The sight glass is vapor-tight and can be fitted on tank hatch domes or expansion trunks providing unmatched visual precision in full-depth gauging on coastal tank barges.

Naturally, the MAXIVIEW complies with the Code of Federal Regulations for full depth manual tank gauging. When placed above the tank sumps, the sight glasses’ visual gauging aids in a tank’s stripping operation. Wiper elements of different types are available for petrochemical as well as chemical applications. 1/2”-thick tempered glass prevents cracked glass. The MAXIVIEW is a perfect bolt-on replacement for a competitors’ style rectangular sight glass.

LARGEST WIPED VIEWING OF ANY SIGHT GLASS. 30% MORE CLEAN AREA THAN THE NEAREST COMPETITOR.

RAISED GLASS PREVENTS WATER ACCUMULATION AND ALLOWS FOR EASY CLEANING.

ALL STAINLESS STEEL CONSTRUCTION.

FITS ON ERL STYLE RECTANGULAR MOUNTING FLANGE FOR EASY RETROFIT.

WIPER BLADES ARE IN CONSTANT CONTACT DUE TO NOVEL ROLLER GUIDE DESIGN.

1/2” THICK TEMPERED GLASS PREVENTS CRACKED GLASS WHICH OCCUR WITH ERL STYLE RECTANGULAR SIGHT GLASS.

sales@berganmarinesystems.com

Visual Gauge Tree

The GUARD LEVEL® Visual Gauge Tree (VGT) is a radial gauge tree, which when used with sight glasses provides enhanced gauging ability for full depth gauging. Its unique design allows for absolute tank level readings and visual gauging up to 15 feet, clearly marked with ullage or innage flags every six inches or optional metric versions (available with 20cm spacing).

Flag spacing can also be customized to order. Large twoinch by four-inch numbers provide for easy viewing. Its stainless-steel bar stock provides maximum strength and reduces product build-up. Lengths can be custom sized.

GUARD LEVEL® VGT can be set for clockwise or counterclockwise rotation as well as ullage or innage measurements. Top-off flags for 95% and 98% are supplied separately and can be clamped on for the exact tank maximum level.

Options include top-off flag (stop sign), top-off flag with 98% and top-off flag with 95%.

LARGE 2” X 4” NUMBERS PROVIDE FOR EASY VIEWING.

VISUAL GAUGING UP TO 15’ WITH ULLAGE OR INNAGE FLAGS EVERY 6”

MADE OF SOLID STAINLESS-STEEL BAR STOCK, PROVIDING MAXIMUM STRENGTH AND REDUCING PRODUCT BUILD UP.

VALVE CONTROL

The simplicity, reliability, and low cost of manual valve control products makes them the best method of valve control on tank barges and larger ocean-going type ATB tank barge.

At Bergan Marine Systems, we know the importance of reliability and safety when it comes to valve actuation and have developed the leading valve product line in the industry - GUARD VALVE®.

From its sturdy stainless-steel handwheels with optional speed handle to the high visibility valve position indicator that allows a clean and unambiguous true valve position indication, explore what makes the GUARD VALVE® the preferred choice for shipyards and owner.

For 50 years, the professional team at Bergan Marine Systems has been designing and manufacturing high-quality marine instrumentation and equipment built to the highest standards required to guard life, property, and the environment, and consistently exceeding expectations.

850.434.1286

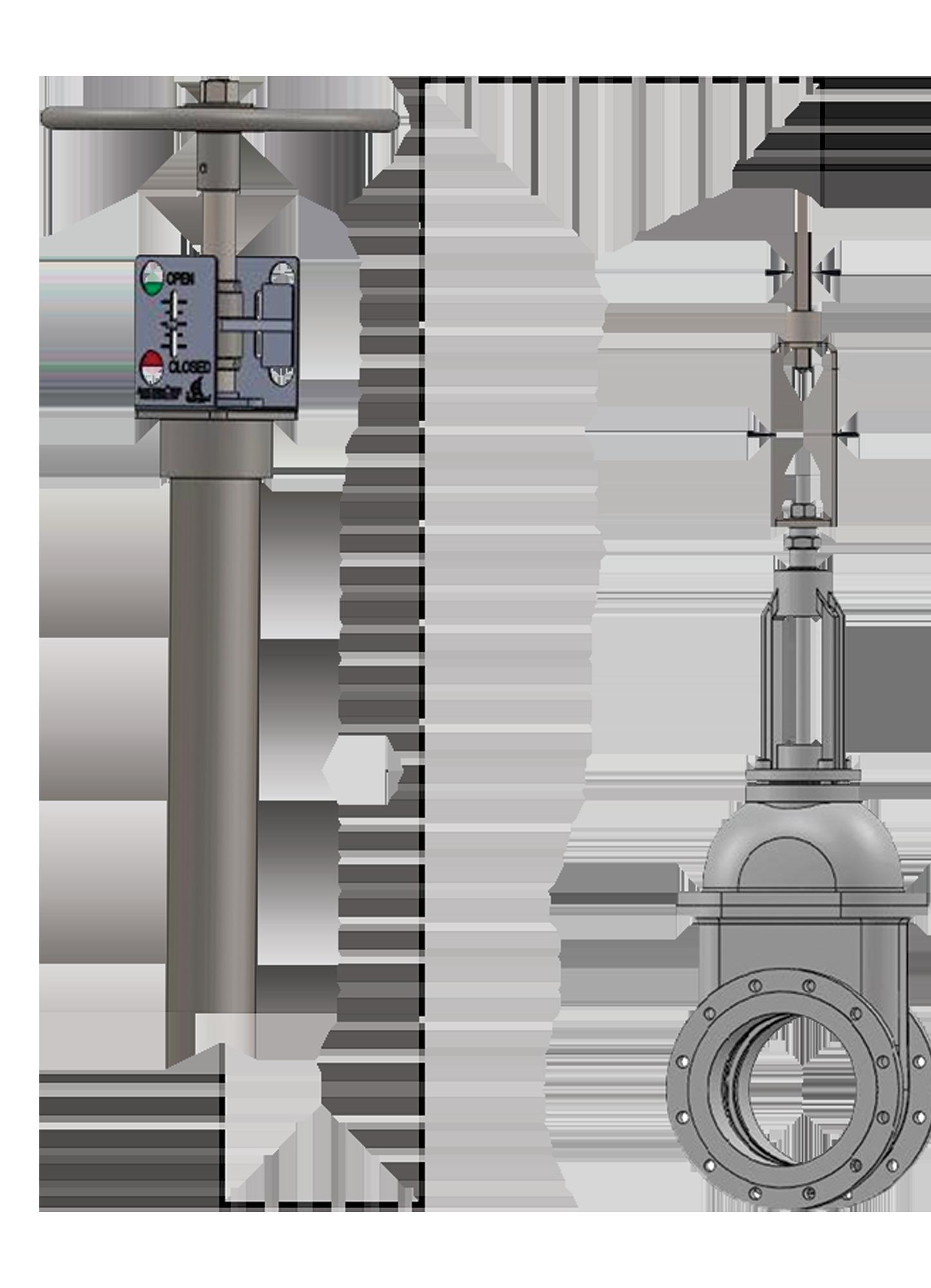

GUARD VALVE® Series

The GUARD VALVE® series of products are designed for manual control of non-rising submerged cargo and ballast valves and give a clear indication of the valve position even from afar.

The main components are a heavy-duty stainless-steel handwheel, a deck stand with attached valve position indication and stuffing box, a reach rod and a stainlesssteel yoke with appropriate sizes for direct fitting to the valve stem. All parts can be customized to meet any requirements.

The deck stand and associated valve position indication can be welded directly to the deck plate or, if required, be fitted for a flanged connection (three or four inches).

Unique features include a DELRIN® thrust bearing which eliminates weight and associated wear on the valve. And, with the sliding yoke assembly design, the valve can be replaced without lifting the reach rod assembly.

sales@berganmarinesystems.com

VALVE CONTROL AND INDICATOR FOR NON-RISING STEM SUBMERGED CARGO AND BALLAST VALVES.

INTEGRAL STUFFING BOX WITH TRIPLE SEAL (TEFLON AND VITON).

COLOR CODED VALVE POSITION INDICATOR WITH REFLECTIVE TAPE FOR ON-THE-SPOT VISUAL VERIFICATION.

ZERO WEIGHT ON VALVE HEAD. ALL WEIGHT IS DISTRIBUTED ON STUFFING BOX, STANDPIPE, AND TANK TOP.

ACCEPTS VALVES WITH 15-25 TURNS.

BERGAN SLIP YOKE ALLOWS FOR THE YOKE TO BE UNBOLTED, SLIPPED OUT OF THE WAY, AND RE-PINNED.

DIRECT WELDING TO 3” OR 4” PIPE.

FLANGE MOUNTING AVAILABLE.

AVAILABLE REACH RODS IN SIZE (1”, 1-1/4”, AND 1-1/2”) STEM ADAPTER AND HAND WHEELS.

SLIP YOKES ALLOW FOR EASY CHANGE OUT OF VALVE.

ACCEPTS VALVES WITH 15-25 TURNS.

PV VALVES & TANK VENTING

Tank high-velocity pressure vacuum valves are critical safety devices. For over 25 years, our simple but technologically innovative deadweight principle PV valves have ensured safe passage for our tank barges and tank ships.

Through our long-term partnership with a world-class manufacturer TankTech, each of our high-quality valves can be supplied in a variety of sizes and materials, all quality-built to the latest IMO and Class requirements.

For our barge customers, we also offer complete vent stack as well as flame screens for gas freeing operations.

Our engineers have set the maritime industry standard - from the basic and simple tools that keep you in business day to day, to the highly complex and groundbreaking methods, designs and systems unmatched by anyone else.

GUARD VALVE®

TOP SAFE SUPER-ISO

GUARD VALVE® TOPSAFE SUPER-ISO high velocity PV valves are high performance dead-weight based valves that meet all international and USCG requirements. The valves are available in a large selection of size and material choice and have a test handle for easy valve verification.

CAST IRON CONSTRUCTION.

SS316 INTERNALS.

SIMPLE DEAD WEIGHT PRINCIPLE.

ACCESSORIES

From API reels at marine terminals to Xenon explosion proof strobe lights, Bergan Marine Systems manufactures and supplied top-notch equipment to the commercial marine and industrial markets.

Through our trusted partners, we are a reseller of the MMC series of UTI (Ullage Temperature Interface) ball valves as well as iridum SATCOM data plans.

Our investment in new technologies plus our years of industry experience ensure we deliver superior products and services. If you don’t see what you need, we can engineer or supply precisely what your operation demands.

For 50 years, the professional team at Bergan Marine Systems has been designing and manufacturing high-quality marine instrumentation and equipment built to the highest standards required to guard life, property, and the environment and consistently exceeding expectations.

GUARD LEVEL® API PIGTAIL

Extend the reach of the terminal alarm connections with this device. Ensures you will be able to load with an active alarm system. Also used to extend the reach of your Portable Alarm Units.

GUARD LEVEL® API

RECEPTACLE

The GUARD LEVEL® API receptacle is a rugged stainless steel enclosure that connects shore alarm systems, portable alarm units, tandem loading boxes, and alarm system testers. Its reinforced 316L NEMA 4X, IP67 enclosure with nickle-plated pin and sleeve contact is guaranteed Intrinsically Safe.

Options include a heavy duty fiberglass enclosure.

850.434.1286

TERMINAL REEL API

Bergan’s terminal reel directly interfaces with our API standard receptacles for transmission of tank data seamlessly to shore personnel.

BATTERIES

All batteries are Marine-grade gel cell, Power-sonic delivers the power you need. The battery box ensure corrosion protection of the batteries. Well vented for safety and performance extending the life of the batteries.

GUARD LEVEL® BARGE TANDEM LOADING BOX

The GUARD LEVEL® Barge Tandem Loading Box (BTLB) allows for safe simultaneous loading of two barges with series-connected level alarms and/or a Bergan deck alarm cabinet. Activation of High Level (HL) or Overfill Level (HHL) switches on either barge will activate a terminal shutdown. The BTLB is equipped with cable storage for easy access (with cable length at 30 feet), a PELICAN style heavy duty watertight carrying cases and two Hubble connections for inboard and outboard barge receptacles.

CENTRAL JUNCTION BOX

All stainless-steel junction boxes for alarm connection in series barges. The labeled terminal connection provides an easy wire connection. Hinged and loc cables for safety and protection.

BARGE CONNECT

Barge Connect is a small cabinet that brings Bergan Connect capabilities to any system.

DATA COMMUNICATIONS

Bergan offers methods of communicating data from our equipment to your personnel. Whether you want cargo data on the bridge of your vessel, a bunker transfer report or fuel consumption data, Bergan Marine Systems has you covered. Let us design a system for you using WiFi, Cell Data, Iridium or LoRa, depending on your needs.

GUARD LEVEL® BOURDON

STYLE PRESSURE GAUGES

The Bergan Pressure gauges are manufactured by Ashcroft - all high quality units manufactured from SS 316L and designed for harsh marine and industrial environments.

The Bergan low pressure gauges are designed for use with air or gas service and are ideal for tank pressure or vapor line measurements on board ships and barges. sales@berganmarinesystems.com

The Bergan high pressure gauges are designed for use with pumps, compressors and hydraulic pressure applications on board ships/barges and industrial.

GUARD LEVEL® SIGNALS

Extended alarms are a core safety feature onboard any marine vessel. Alarms give audio and visual warning, provide pressure/vacuum alarm and system power fail indications and warning, and keep cargo and lives safe.

Our external alarms are constructed in stainless-steel housing and mounting base, utilize a high-strength acrylic lens for additional light protection, and are housed in a watertight NEMA 4X IP67 junction box. Bergan light fixtures are visible at one million Candlepower and 90 flashers per minute.

Our MEDC electric horns are 117 decibles with tone modulators for differing tone frequencies and 316L stainless steel mounting painted to match the associated alarm light color. Explosion-proof electric

horn units and air horns with explosion-proof solenoids are available as well.

SIGNAGE

SOLAR PANELS

Bergan Marine Systems has the most experience in solar systems in the world for marine applications. Solar panels are a heavy-duty consistent source of charge life for your batteries. Setups available for all shore and vessel applications. When you need onsite charging for your batteries trust Bergan Marine Systems for your solar needs.

GUARD LEVEL® TANDEM LOAD SWITCH

The GUARD LEVEL® Tandem Load Swtich links seriesconnected alarm sensors in both an inboard and outboard barge. Once the two barges connect, the link continues through the inboard barge to activate the terminal shut-down system. The terminal alarms when an Overfull alarm is activated on either the inboard or outboard barge.

The tandem load switch retro fits to any inland tank barge. For new construction, the tandem load switch can be built into the central junction box.

VAPORGUARD

Fail-safe adapter for all High Level (HL) and Overfill Level (HHL) alarm test rods. Vapor guard screws onto existing test rod, eliminating vapor leaks due to non-tightened test rods. Allows for testing alarms without loosening test rod bushing, safely preventing vapor leaks.

850.434.1286

WIRELESS NODE

Our powerful wireless nodes bridge the gap between you and your vessel by transmitting your sensor’s data. It is compatible of interfacing with a variety of inputs.

CUSTOM SYSTEMS

Do you have a specific vessel that is in need of gauging equipment? Alarm sensors? Portable handheld products? We have exactly what you need. However, if off-theshelf products don’t suffice, we specialize in creating custom solutions that solve your vessel’s unique needs. Our products work cohesively in a system that safeguards your life, property, and the environment.

The following pages show example how a custom system would function on vessels such as a Tank Ship ATB, an Inland towboat, a Tank Barge, a Pressure Barge, and a Service Barge. If you have questions about another vessel, contact us to learn how we can develop a custom system that suits your vessel’s unique needs.

For 50 years, the professional team at Bergan Marine Systems has been designing and manufacturing high-quality marine instrumentation and equipment built to the highest standards required to guard life, property, and the environment and consistently exceeding expectations.

sales@berganmarinesystems.com

GUARD LEVEL®

BargeWatch System

Handling hazardous cargo requires constant vigilance to ensure the safety of personnel, the vessel, and the surrounding environment. Even a momentary lapse in attention during loading or discharge can lead to serious consequences. Continuous monitoring is essential for mitigating risks and maintaining operational safety.

BargeWatch provides real-time vessel monitoring, enhancing communication between deck and shore personnel. By integrating seamlessly with existing tank levelandalarmsystems,itensuresthatallsafetyprotocols are being followed.

With Bergan Connect serving as the central hub, shore personnel can remotely oversee operations, ensuring compliance and safety. The system utilizes timers and wireless acknowledgment buttons mounted on the deck to verify that tankermen are actively monitoring the barge. If proper monitoring lapses, an automatic notification is sent to shore, preventing unnoticed overfill incidents.

Stay ahead of safety risks with BargeWatch. Ensure compliance, improve communication, and protect your

crew with a reliable monitoring system designed for the most demanding marine environments. Contact us today to learn how BargeWatch can enhance your vessel’s safety operations.

LEGEND

To navigate to a specific product page, click on the corresponding product below.

1. Guard Level® Twin Series

2. CargoRadar® Series

3. Wireless Acknowledgement Button

4. Flow Meter

5. Guard Level® Deck Alarm Cabinet+

6. Timers

7. Strobe Light and Horn

8. Bergan Connect

850.434.1286

Tank Ship ATB

LEGEND

To navigate to a specific product page, click on the corresponding product below.

1. GUARD LEVEL® Hydrostatic Pressure Transducer -3

2. HVPV Valve

3. Guard Level® Twin Series

4. Multi Tank Display Explosion Proof

5. CARGORADAR®

6. LVPV

7. MMC Ball Valve

8. Guard Level® Dual Wiper Sight Glass Options also include a GUARD LEVEL® Maxiview.

9. GUARD TEMP™ Digital Temperature Gauge

10.All-In-One Gauge

11. GUARD LEVEL® Digital Float Gauge

12.Manual Valve Control

13.Remote Valve Control

14.IPS Deepwell Pump

15.GUARD LEVEL® Hydrostatic Pressure Transducer - 2

16.LNRV

17. GUARD LEVEL® Work Station Unit

18.GUARD POWER™ Uninterruptible Power Supply-400

Uninterruptible Power Supply can also connect to ship’s power.

19.GUARD LEVEL® Master Control Unit

Master Control Unit can also connect to Modbus and Satcom/Wifi

20. Strobe Light And Horns

21. Compact GUARD LEVEL® Master Control Unit

22. Custom Console

23. Bergan Connect

sales@berganmarinesystems.com

Inland Towboat

GUARD LEVEL® FUEL MANAGEMENT SYSTEM (FMS)

• Fuel discharge report after tug to fueling transfer.

• Consumption analysis with gps coordinates for all instrumented bunker tanks.

• Continuous inventory control of all instrumented bunker tanks.

• Engine fuel consumption (requires optional coriolis flow meter).

• Data storage in non-volatile memory.

• Remote monitoring using cloud based fleet reporting software (frs).

• Shore versus vessel discrepancy report after each bunker operation.

• Tank strapping services provides accurate tank tables.

GUARD LEVEL® FLEET REPORTING SOFTWARE (FRS)

• Cloud based sql database program.

• Accessible from any computer with log-on credentials.

• Fms in conjunction with frs provides audit trail of vessel position, fuel burn, and related data.

• Secured data storage.

• Fuel burn and related data.

• Vessel name, date, and time.

• Trending data graph.

• Exporting for data mining.

850.434.1286

LEGEND

1. Ballast Tank

2. Potable

3. Lube Oil Tank

4. Fuel Tanks

5. Wash Water Tank

Tank Barge

LEGEND

To navigate to a specific product page, click on the corresponding product below.

1. 40-Ton Winch

2. GUARD TEMP™ Barge Cargo Temperature Unit

3. GUARD LEVEL® MDS

4. GUARD LEVEL® TWIN Series

5. GUARD TANK® LVPV

6. MMC Ball Valve

7. GUARD LEVEL® Visual Gauge Tree

8. GUARD LEVEL® Dual Wiper Sight Glass Options also include a GUARD LEVEL® MAXIVIEW.

9. HVPV Valve

10. Vent Stack

11. GUARD LEVEL® TRI-STICK

12. Manual Valve Control

13. Engine Monitoring

14. IPS Pump

15. Drip Pan

16. 40-Ton Winch

17. GUARD LEVEL® Portable Alarm Unit

18. Port API

19. Central Junction Box

20. STBD API

21. GUARD LEVEL® Simple Deck Alarm Cabinet

22. GUARD LEVEL® Deck Alarm Cabinet

23. GUARD LEVEL® Deck Alarm Cabinet +

24. Bergan Connect

25. Solar Array

sales@berganmarinesystems.com

Pressure Barge

LEGEND

To navigate to a specific product page, click on the corresponding product below.

1. 40-Ton Winch

2. GUARD LEVEL® Digital Float Gauge

3. GUARD LEVEL® Hydrostatic Pressure Transducer-2

4. Battery Box

5. CARGORADAR®

6. GUARD LEVEL® Multi Tank Display Explosion Proof

7. GUARD LEVEL® MDS Trio (Long)

8. GUARD LEVEL® MDS Trio (Medium)

9. GUARD LEVEL® MDS Trio (Short)

10. 40-Ton Winch

11. GUARD LEVEL® Master Control Unit

12. Bergan Connect

850.434.1286

Service Tank

LEGEND

To navigate to a specific product page, click on the corresponding product below.

1. GUARD LEVEL® Hydrostatic Pressure Transducer-3

2. GUARD LEVEL® Hydrostatic Pressure Transducer-2

3. LNRV

4. CARGORADAR®

5. CARGORADAR®

6. GUARD LEVEL® Digital Float Gauge

7. DFG REMOTE DISPLAY

8. GUARD LEVEL® DLI

sales@berganmarinesystems.com

HYDROSTATIC

AFTERMARKET SUPPORT

A product is only as good as the company behind it.

Bergan Marine Systems’ unwavering commitment to after-sales support has been one of our crowning acheivements since 1975. Our experienced service teams are ready to customize a maintenance plan that will keep your equipment running in shipshape condition for years to come. Our teams assure that you operate under the highest safety levels while reducing replacement costs.

In addition to our Pensacola home base, we’ve not only expanded our Houston presence, but also opened our San Diego service stations for faster service. Bergan Marine Systems’ after-sales service engineers and staff are fully trained and ready to go the distance.

Most importantly we warrant our work to protect your investment - wherever it takes you.

Remote Support

When you have a pressing need that cannot wait, we provide remote support on specific products and systems.

Our proprietary Bergan Guard Level® Remote Data Acquisition system allows level, volume, pressure, temperature, and alarm activation data to be collected by the Cargo Management System Plus (CMS+) software, and in turn makes it available to other software entities.

With your data at our fingertips, our Field Service Technicians can effectively solve problems and walk you through solutions.

As technology changes, our service will continue to evolve. Our commitment to developing personal relationships with our customers will always remain our highest priority. If you’re interested in exploring how our Remote Support Program can benefit you now and into the future, contact our Service Manager and let’s schedule a conversation. We look forward to understanding of your unique needs.

Customer Training

Post commission, Bergan Marine Systems works on contract basis with end users to provide extensive, ongoing training for product and system sales. Because it is critically important that owners and operators understand how our specialized equipment works, we are pleased to provide face-to-face training for our CMS software, alarms, and more upon first load of cargo.

Because each vessel has unique configurations, our training programs are highly customized after assessing your vessel’s equipment as well as your specific needs. We will work together with you to design a training program that keeps your vessel on course and on budget.

EXTENDED SERVICES

Preventative Maintenance EXTENDED SERVICE

Aftermarket Parts

Marine industry customers understand that their success and profitability is ensured by the consistent performance of highly specialized products like those offered by Bergan Marine Systems.

Any vessel that experiences downtime can be costly to our end users as well as the customers they serve. An effective Preventative Maintenance Program will provide the support you demand and the peace of mind you desire.

Our Preventative Maintenance Program requires a nominal enrollment fee equal to one visit by one of our expert Field Service Technicians. You will receive:

• Free Vessel Inspection

• Proactively identifying potential issues.

• Reduced rate for additional inspection and support requests.

• Annual discount on parts and services.

To ensure that our customers experience full use of our quality equipment, we have put systems in place to ensure the availability of after-market parts along with speedy, 24/7 service and support.

In addition to our home base in Pensacola, our satellite offices in Houston and San Diego are staffed with the industry’s most highly trained and experienced technicians. The strategic positioning of our personnel allows us to provide spare parts and service solutions in days or weeks instead of months or years.

Of course, we warranty all of our equipment, and can even negotiate a custom warranty at the time of sale that extends beyond the standard 12 months from delivery of equipment. For equipment defects that appear within one year of purchase, we will replace the defective parts free of charge.

850.434.1286

EXTENDED SERVICES

Installation & Commissioning

While aftermarket/spare parts and service represent a large part of our business, Bergan Marine Systems Field Service Technicians are often relied upon for both the installation of parts and commissioning of new vessels.

Often,customsystemsthatincludeourindustry-leading products are installed by shipyard engineers. In these cases, we are sometimes called upon for general installation assistance and support. When working hard to meet critical deadlines, our customers can rely on our professional technicians around the clock to ensure that they receive the service that they need, exactly when they need it.