The generation 8

The strengths of the new generation of crawler excavators include: increased engine power, higher digging forces, large bucket capacities, at the same time, reduced fuel consumption and simplified maintenance work. www.liebherr.ca

The strengths of the new generation of crawler excavators include: increased engine power, higher digging forces, large bucket capacities, at the same time, reduced fuel consumption and simplified maintenance work. www.liebherr.ca

Rotate 360°, tilt 45° each way, and get more done — with less machine movement, fuel, and downtime.

Your excavator becomes a multi-tool with engcon’s tiltrotator system. Dig from any angle, work in tight spaces, and tackle complex jobs without constant repositioning.

Tiltrotators have already transformed excavation across Europe.

Now it’s Canada’s turn.

FEATURE STORY

L. WALTER & SONS MARKS 60 YEARS IN BUSINESS WITH A MILESTONE LIEBHERR MACHINE

KOMATSU’S NEW TECHLOADED EXCAVATOR

COVER PHOTO: LINK-BELT’S 260 X4S EXCAVATOR.

CONNECT WITH US @HeavyEquipGuide

Do you have a job site story, innovation, or industry concern that our readers should know about? We’d like to hear from you.

EDITOR IN CHIEF Kaitlyn Till ktill@baumpub.com 604-291-9900 ext. 330

DIRECTOR OF DIGITAL STRATEGY

Slone Fox sfox@baumpub.com 604-291-9900 ext. 335

SENIOR WRITER Meghan Barton mbarton@baumpub.com 604-291-9900 ext. 305

ASSOCIATE EDITOR Stephanie Bontorin sbontorin@baumpub.com 604-291-9900

VICE PRESIDENT OF SALES/ ASSOCIATE PUBLISHER Sam Esmaili sam@baumpub.com 604-291-9900 ext. 110

ADVERTISING

PRODUCTION MANAGER Tina Anderson tanderson@baumpub.com 604-291-9900 ext. 222

DESIGN & PRODUCTION

Morena Zanotto morena@baumpub.com 604-291-9900 ext. 325

PRESIDENT/PUBLISHER Ken Singer ksinger@baumpub.com 604-291-9900 ext. 226

VICE PRESIDENT/CONTROLLER Melvin Date Chong mdatechong@baumpub.com

FOUNDER

Engelbert J. Baum

Published by: Baum Publications Ltd. 124 - 2323 Boundary Road Vancouver, BC, Canada V5M 4V8

Tel: 604-291-9900

Toll-free: 1-888-286-3630 Fax: 604-291-1906 www.baumpub.com www.heavyequipmentguide.ca @HeavyEquipGuide

FOR ALL CIRCULATION INQUIRIES

Toll-free: 1-866-764-0227 email: heg@mysubscription.ca

Contact: Editor in Chief Kaitlyn Till at ktill@baumpub.com or 604-291-9900 ext. 330 EXCAVATORS 2025 | VOLUME 1 • NUMBER 1

Subscription: To subscribe, renew your subscription, or change your address or other information, go to: http://mysubscription.ca/heg/

Heavy Equipment Guide serves the Canadian engineered construction industry including: roadbuilding and maintenance; highways, bridges, tunnels; grading and excavating; earthmoving; crushing; trucking and hauling; underground utilities; trenching; concrete paving; asphalt paving; demolition; aggregates production; fleet maintenance; and asset security and management. The magazine is distributed to key industry personnel involved in these sectors.

Subscription Price: In Canada, CDN $91.00; Outside Canada, US$149. Heavy Equipment Guide is published eight times a year in January/ February, March, April, May/June, July/August, September, October, and November/December.

Heavy Equipment Guide accepts no responsibility or liability for reported claims made by manufacturers and/or distributors for products or services; the views and opinions expressed are those of the authors and not necessarily those of Baum Publications Ltd.

Copyright 2025, Baum Publications Ltd. No portion of this publication may be reproduced without permission of the publishers.

We acknowledge the financial support of the Government of Canada.

Printed on paper made of FSC®-certified and other controlled material. ISSN 1715-7013.

PUBLICATIONS MAIL AGREEMENT NO. 40069270

Return undeliverable Canadian addresses to: Circulation Dept., 8799 Highway 89, Alliston, ON L9R 1V1 email: heg@mysubscription.ca / Toll-free: 1-866-764-0227

Whether you’re digging, loading, moving, placing – or all of the above – you need reliable, performance-driven equipment to get the job done right. Wacker Neuson o ers a powerful line of material handling models designed for jobsite e ciency and operator comfort. From excavators and dumpers to compact track loaders, telehandlers and wheel loaders, Wacker Neuson has all it takes for the challenges you face.

Welcome to Heavy Equipment Guide’s first-ever special edition: Excavators. In this inaugural special issue, we explore the entire world of excavators, from mini machines to massive earthmovers, and we’re enthusiastic about all of them.

The excavator is an incredibly diverse and adaptable machine. Specialty configurations can take a base machine and transform it for incredible additional reach, or demolition power, or quarrying might. Electric machines can venture where no excavator has gone before, and wheeled excavators give operators independence to hop from site to site with minimal logistics to manage. We take a look at each of these types of excavators throughout the issue via themed sections and featured models.

For our feature story, Heavy Equipment Guide’s Meghan Barton sat down with a long-time Liebherr–Canada customer to discuss why the contractor has remained loyal to the OEM for decades and learn about its purchase of the first Liebherr R 992 Litronic excavator in North America. It’s a story about a long-term relationship, the importance of collaboration between the OEM and the customer, and the value of a handshake.

Today’s excavators are made even more versatile by the technology on them. Machine control and safety technologies have come a long way in recent years, and you’ll learn about the latest cutting edge features that will keep your operators productive and your workers, equipment, and property safe.

Finally, at the back of the book you can check out specs for

From mini machines to massive earthmovers, we’re enthusiastic about excavators.

nearly 400 excavator models available in North America. This comprehensive spec guide presents the range of available machines for every size class.

We had a lot of fun diving deep into the world of excavators this year, and we hope you enjoy this special edition as much as we did producing it for you.

Kaitlyn Till Editor In Chief

ktill@baumpub.com

When your operators are happy and have what they need to perform at their best, your jobsite hums and your entire operation reaps the rewards. That’s the thinking behind the all-new Komatsu PC220LC-12 and PC220LCi-12 — to design machines that empower operators. Exceptional comfort, customizable controls and the latest intelligent machine control technology (IMC 3.0) in the PC220LCi-12 help your operators tailor the machine to get the job done easier and faster.

BY MEGHAN BARTON, SENIOR WRITER

THE DELIVERY OF a new Liebherr R 992 Litronic to Canadian contractor L. Walter & Sons Excavating Ltd. in June 2025 was no ordinary handover. This delivery was both fortuitous and especially significant, marking the company’s 60th Liebherr machine purchased and its 60th year in operation. As the first R 992 Litronic excavator delivered to a North American customer, the machine symbolizes a legacy of brand loyalty and a way of doing business that has remained remarkably consistent across four generations.

President Steve, Vice President Matt, and operator Quinten, three generations of Walters, were joined for the handover by Liebherr key account manager Mike Koen, whose own family has also served the OEM for decades. The moment highlighted a partnership defined as much by loyalty across generations as by the iron itself.

L. Walter & Sons Excavating was founded in 1965 by Ludwig Walter, a German immigrant who knew Hans Liebherr personally. Ludwig’s connection to Hans and his confidence in Liebherr equipment’s durability left him certain of his choice when the time came to invest in his first machine in Canada. Ludwig’s son, Steve, grew up in the business. By his teens, he was running backhoes between classes, learning to move earth before he was old enough to drive. Today, Steve still spends his days in the cab, leading by example as president.

L. Walter & Sons focuses on heavy application work such as landfill cell construction and quarry overburden removal. These projects demand reliable equipment and operators who know how to get the most out of it.

“We specialize in just moving bulk dirt, breaking rock. We don’t get into everything. We do what we know best,” says Steve.

That focus is shared by the next generations. Steve’s son, Matt, oversees major projects in the Niagara region, while his grandson, Quinten, operates a dozer full-time at just 25. For Quinten, joining the family business was never in doubt. “I want to do my best, live up to the family name,” he says. “I’m in it for the long haul.”

The Walters’ fleet is dominated by Liebherr excavators, with loaders and dozers rounding out the lineup. The 90-ton R 992 Litronic was chosen for its digging power, stability, and operator comfort.

Matt says the decision to buy the Liebherr machine was straightforward. With heavy landfill and quarry projects on the horizon, they needed an excavator that could handle intense digging cycles with minimal downtime. “We bought the machine for the sheer digging force. And comfort obviously is huge,” he explains.

For Steve, it comes down to long-term reliability. “Nothing digs like a Liebherr,” he says.

Behind the machines is a service model that has kept the relationship strong. Burlington, Ontario, home to Liebherr–Canada’s head office, parts warehouse, and service hub, is based near L. Walter & Sons’ primary operations. That proximity, combined with a dedicated account team, means downtime is measured in hours, not days. It’s a carry-over of the support the Walters first experienced in the early years, when technicians would show up on the job site at 2 a.m. to ensure equipment was ready for a 5 a.m. start.

The consistency of Liebherr’s service is a natural fit for a company that has built its own reputation on doing things the same way, year after year.

What sets L. Walter & Sons apart is commitment to a more traditional way of conducting business. Word of mouth and personal connections rule. Trust and collaboration are the focus. Jobs are secured face-to-face, often on reputation alone. In an industry where corporatization and marketing budgets dominate, the Walters prefer a handshake.

We bought the machine for the sheer digging force.

Matt Walter Vice President, L. Walter & Sons Excavating

The company’s first encounter with Liebherr machinery came in the 1970s, just as the manufacturer began to establish its Canadian presence. Ludwig tested a demo unit in 1975, purchased one at auction in 1977, and bought his first new Liebherr machine, a 944, in 1978. He was drawn to the build quality and hydraulic performance. For a German immigrant, buying German equipment felt natural.

By the time Liebherr was fully established in Canada, the Walters were already long-term customers. That history created a unique bond between the contractor and the OEM.

For Koen, the partnership is personal. His uncle worked for Liebherr for 40 years and looked after the L. Walter & Sons account. His father led Liebherr–Canada as president for nearly four decades, and Mike has carried that torch for 17 years.

“We share the same values. A handshake means a lot,” he says.

“We don’t really advertise. If we get slow, we just go out and find work, and a few weeks later, we get a job,” Steve says. This approach keeps the company nimble and ready to work.

That doesn’t mean they’re behind on the job site. GPS and GNSS systems are standard on their fleet, and Matt is quick to point out that their operational workflows are current. For them, technology adoption is about value. If technology helps move dirt faster or more precisely, it’s in. If it only adds complexity, it stays out.

Koen describes the approach as a balance of “old school and new world.” Spec’ing new equipment happens not through PDFs but through trips to the factory where the Walters can see machines being built and test them live. The result is iron tailored to their work, not purchased from a catalogue.

Rather than chasing rapid expansion, the Walters focus on keeping operations steady and efficient. The company employs about 45 people, a size that feels sustainable for them. Machines are staged at multiple sites to avoid the delays of moving permits. And growth is measured in uptime, not in headcount.

For Matt, the formula is straightforward: “You have to innovate or die. We’re very competitive.” Innovation, in this context, doesn’t mean splashy marketing. It means investing in iron and tools that keep operators productive and comfortable.

By the time Liebherr was fully established in Canada, the Walters were already long-term customers. That history created a unique bond between the contractor and the OEM.

The next chapter is already in motion. A new Liebherr PR 746 Litronic crawler dozer is in production, with delivery planned for early summer 2026 to avoid seasonal road restrictions. To finalize the order, the Walters are travelling to Europe with Koen to visit Liebherr’s factories, a practice that has become part of their relationship with the OEM. Like the R 992 Litronic excavator, the dozer won’t just be selected off the shelf. It will be tailored on the factory floor, with input from Quinten, who will run it every day. For the Walters, the trip is both a chance to shape the machine to their needs and to reinforce the personal connections that have always defined their partnership with Liebherr.

As Steve sees it, the future is secure. “I’m convinced that

Matthew will continue dealing with Liebherr after I’m done,” he says. “And Quinten will grow into a leader.”

Koen shares that confidence, noting the value of continuity on both sides. “It’s great to have Quinten coming on board at his age. Getting that buy-in at an early age is important for us.” He adds that partnerships like this endure because they balance trust in people with trust in the product. “In today’s marketplace, equipment is very expensive. There needs to be the quality of the machine, quality service, longevity, and dependability.”

Landfills will continue to need cells. Quarries will continue to need overburden stripped. And L. Walter & Sons will continue to choose machines they trust, backed by the team at Liebherr who have supported their work through the generations. HEG

The Liebherr R 992 Litronic crawler excavator replaces the R 976. Built with quarry operators in mind, the model combines raw digging strength, fuel efficiency, and operator-focused design in a package engineered for the extreme demands of hard rock excavation.

Fuel consumption continues to impact operating costs and emissions in quarrying. The R 992 addresses both concerns. Even in demanding environments, the machine consumes less than 60 litres per hour, a savings of around 10 percent compared to its predecessor. This efficiency comes from the proprietary Liebherr Power Efficiency (LPE) system, which continually adjusts engine speed and hydraulic oil flow to match each stage of the digging cycle. This reduces unnecessary energy losses, lowers fuel use, and is intended to lower mechanical stress on critical components without compromising productivity.

The R 992 Litronic benefits from Liebherr’s Bucket Fill Assist (BFA), an operator-assistance function that makes loading easier and more consistent. By sensing resistance, the system prevents the bucket from binding against the material and keeps the digging cycle smooth. With operators increasingly hard to find, the semi-automatic mode helps new hires achieve consistent performance sooner, improving productivity and reducing training time. The result is higher bucket fill factors, faster cycle times, and a noticeable reduction in vibration that reduces fatigue and operating costs.

Durability is another hallmark of the R 992. Its welded structure is reinforced with cast steel components, and the heavy-duty undercarriage is designed to provide stability and a long service life. For abrasive applications, the excavator can be equipped with a reinforced 5.2-cubic-metre HDV bucket with guide rails for a drop

ball, along with piston rod guards for additional protection.

Operator comfort is prioritized with a spacious, quiet cab fitted with ergonomic controls and a high-resolution touchscreen interface. Seats provide standard heating and pneumatic shock absorption, and optional features, such as air conditioning and protective guards, adapt the machine to climate and application. With smooth hydraulic response and reduced vibration from the assistance systems, operators are better able to maintain focus and productivity throughout the workday.

The R 992 also has practical improvements in visibility, safety, and serviceability. Cameras provide panoramic views around the machine, and impact-resistant glazing offers additional protection in tough conditions. Entry and exit are made safer with retractable consoles, and optional cab risers improve the line of sight when loading. On the service side, access platforms and wide catwalks make daily maintenance tasks safer and more ergonomic. An automatic, factory-installed central lubrication system (supplied and warranted directly through Liebherr), and a standard shut-off valve on the hydraulic tank outlet (all Liebherr parts) add further convenience and reliability, eliminating the need for aftermarket installations.

For quarry operators, the R 992 Litronic represents a balance between the sheer force required for bulk excavation and the efficiencies that help reduce cost and emissions. It is a machine designed to dig deeper and with greater force, while preserving uptime, reducing fatigue, and lowering the total cost of operation. As the successor to the R 976, the R 992 signals how Liebherr is striving to combine power and precision with systems that make the work more efficient and the operator’s job more manageable.

The new 370X slots into the 35- to 40-ton class with a focus on productivity and durability.

Powered by a 322-hp Cummins L9 diesel engine, the 370X operates at hydraulic pressures up to 5,511 psi to deliver improved digging and lifting performance while maintaining low engine revolutions for reduced fuel consumption and noise. The latest generation valve block and reversible cooling fan streamline hydraulic performance.

The 370X is equipped with JCB’s UX operator interface, featuring a 10-inch colour touchscreen and integrated 360-degree camera option. LED work lighting is standard, and the cab can be configured with multiple seat and control options.

Reinforced structures and a heavier counterweight enhance stability, with larger hydraulic lines and higher pressures increasing power and service life at the dig end and reinforced boom and pivot points allow for higher load capacity.

The 370X is equipped with a 21-foot (6.45-metre) monoboom available with several arm options (8.6 feet to 13.2 feet), as well as new 2.75- and 3.2cubic-yard heavy-duty buckets and a dedicated HM330T hydraulic breaker.

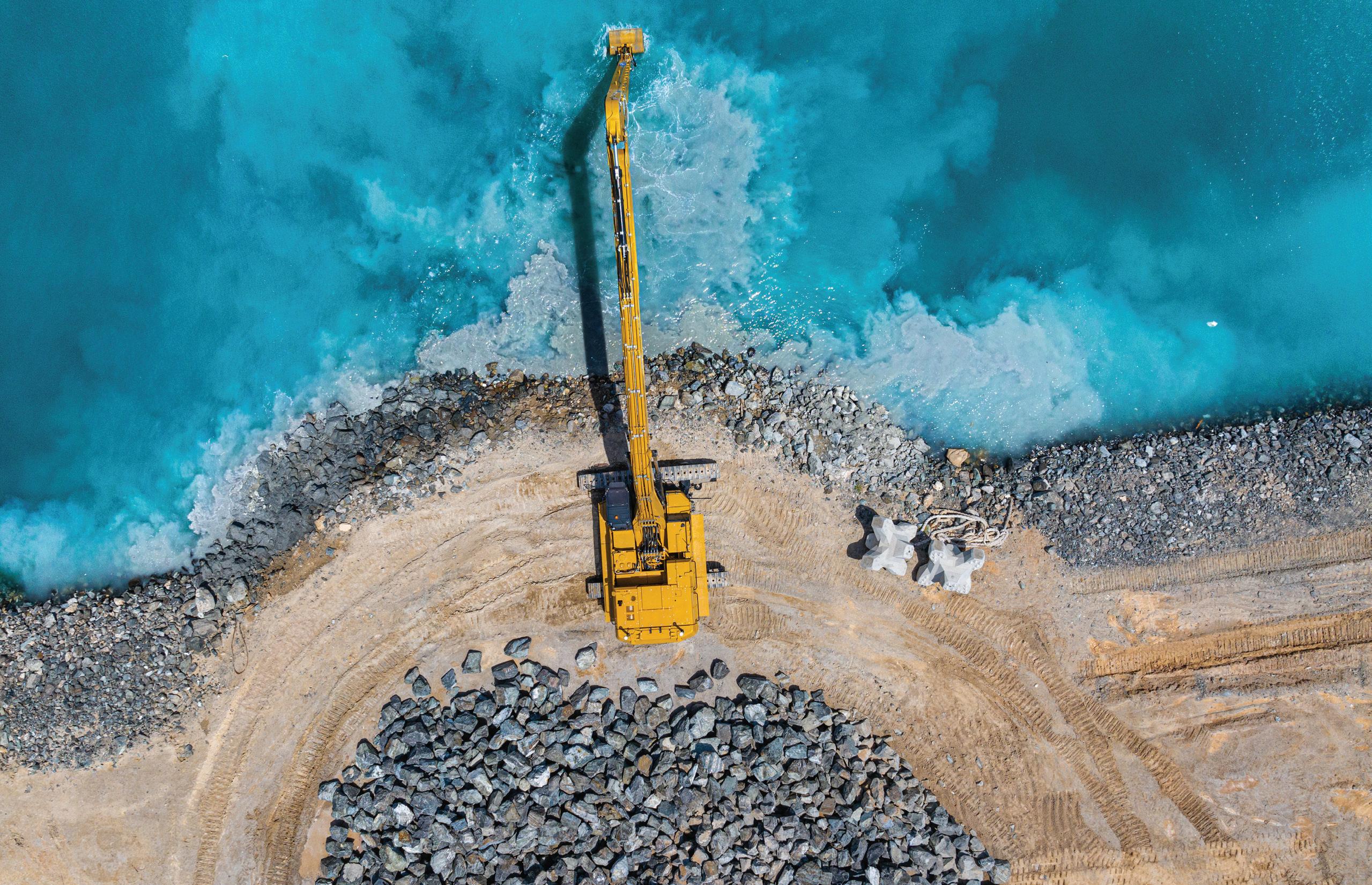

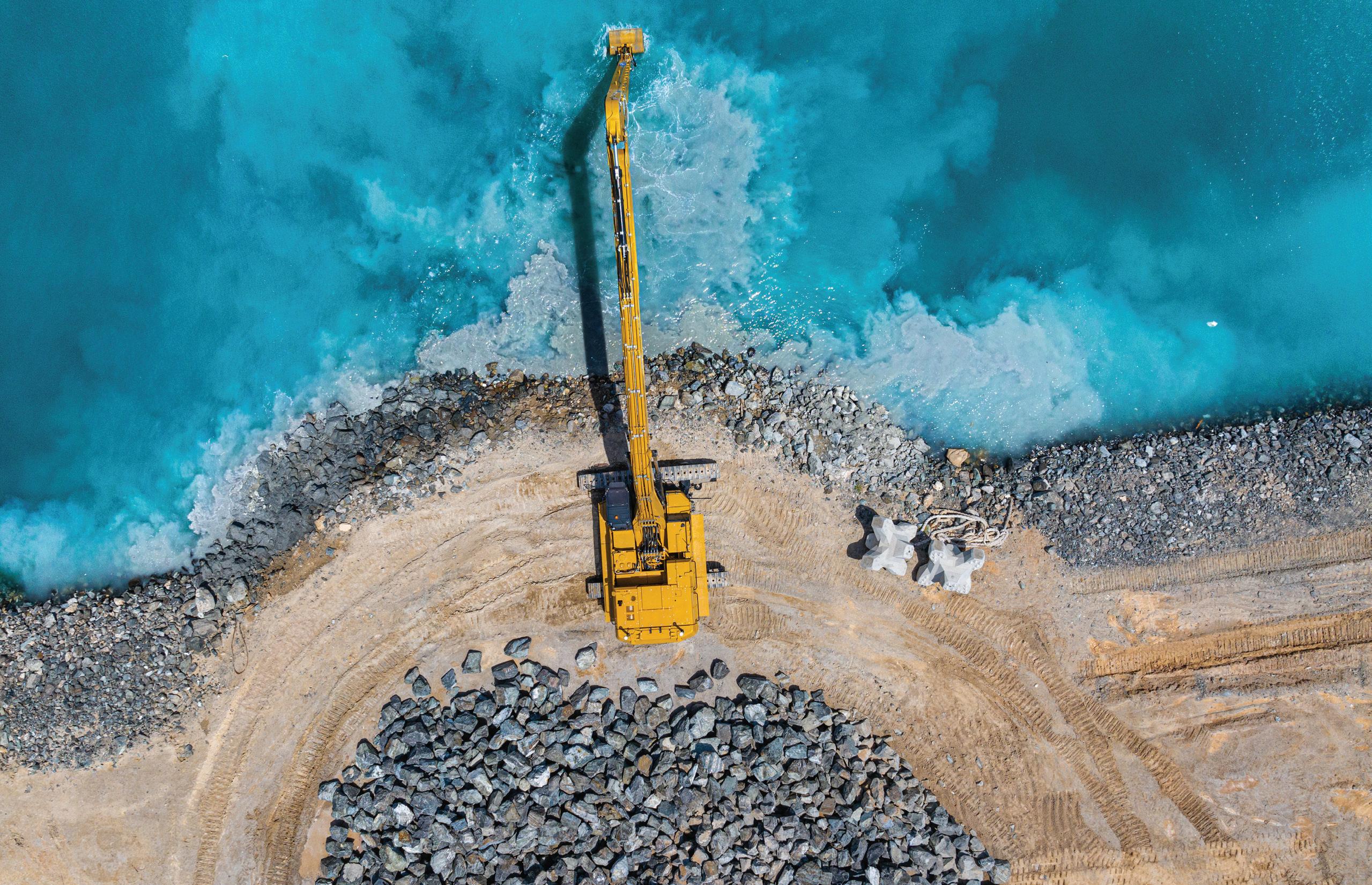

FOR DEEP EXCAVATION, DITCH CLEANING, CANAL AND WATERWAY MAINTENANCE & MORE

Cat’s new 395 LRE kit boosts the Cat 395 excavator’s maximum digging depth to nearly 22 metres and ground-level reach to 28 metres. This super-long-reach kit can be retrofitted to any 395 model to create a highly specialized machine.

The aftermarket kit includes an 11.8-metre stick, a 15.5-metre boom, and a CV linkage adapted for the new stick and boom. Boom cylinders form part of the kit, and the specially designed bucket offers capacity for up to 2 cubic metres.

The kit also includes fully waterproofed sensor boxes to allow continued operation of the full range of next-generation technologies, such as Cat Payload Management System, Cat 2D Grade control system, and Cat 2D E-fence, in underwater applications.

Additional features include an undercarriage upgrade providing greater stability and clearance and a bigger counterweight that still preserves the 395’s tail dimensions.

The 54,900-pound ZX210LC-7H Super Long Front (SLF) excavator provides 50 feet 4 inches (15.35 metres) of reach at ground level and a 39-foot 2-inch (11.94-metre) dig depth. This dedicated long-front machine includes an upgraded swing motor to maximize reach and control and a heavier counterweight. An updated hydraulic control valve provides an immediate response, even when operating at or near maximum extension. Two work modes (Economy and Power) allow operators to tailor operations to job site conditions.

Hitachi’s AERIAL ANGLE camera gives the operator a 270-degree bird’s-eye view on an 8-inch (20.32-cm) antiglare LCD monitor.

Link-Belt’s three new long-front excavators — the 220, 260, and 370 X4S LF — are designed to handle specialized tasks that require extended reach and precision. The 52,000-pound 220 reaches up to 50 feet 10 inches, the 63,900-pound 260 model reaches 59 feet 9 inches, and the heavy-duty 88,400-pound 370 provides the greatest reach at 60 feet 10 inches.

The 220 can dig up to 39 feet 5 inches, the 260 model can dig up to 47 feet 9 inches, and the 370 offers a maximum digging depth of 46 feet 3 inches.

These machines are precision-grade ready,

equipped with factory-welded brackets and pre-installed connectors. The 220 and 370 X4S Long Front can be ordered with machine-control technology factory installed. This technology is designed for operators working on underwater slopes or sediment removal projects, allowing them to achieve the desired grade.

The new X4S lineup features a refined hydraulic system, including an electronically controlled hydraulic pump and an SSC (Spool Stroke Control) system. This system optimizes hydraulic pressure distribution, so power is directed where needed based on real-time machine activity.

At Kubota, we build equipment for those who do. No matter the job on the build site, ambitious plans can become reality with the help of tough, versatile equipment and attachments from Kubota. THERE ARE DREAMERS, AND THERE ARE DO-ERS.

When tight schedules meet cooler ground and active jobsites, precision equipment can make all the difference. The Kubota KX040-5, a robust four-ton compact excavator is engineered to elevate your productivity even in the toughest conditions.

HYDRAULIC SYSTEM FOR REAL-WORLD EFFICIENCY

At the heart of the KX040-5 lies an improved hydraulic system designed to maximize engine horsepower and deliver optimal performance. This system efficiently increases flow rate, enabling operators to use hydraulic attachments and maneuver other functions simultaneously without sacrificing power. The result is a machine that adapts seamlessly to demanding tasks, improving productivity and reducing downtime on any jobsite.

Kubota understands that operator comfort is key to sustained performance. The KX040-5’s cab boasts an expanded glass area offering 20% more front window visibility than its predecessor and an unobstructed view of the bucket thanks to the removal of roof window slash bars. Inside, the cab features a slim profile with an interior that includes a repositioned 7-inch LCD monitor, more headroom, and increased foot space. The backlit keypad simplifies control even in low-light conditions, while the optional air suspension seat provides superior comfort during long hours of operation.

CUTTING-EDGE TECHNOLOGY BUILT FOR TODAY’S OPERATOR

The KX040-5 is packed with smart features to keep you connected and in control. Keyless start technology supports up to 10 unique operator passwords, enhancing security and customization. KubotaNOW telematics lets you effortlessly monitor machine data—such as accumulated hours, fuel level, and location—via the KubotaNOW app, directly from your smartphone or office. Additional conveniences include LED work lights with turn-off delay, ensuring you leave the site safely illuminated, and an optional rear-view camera to maximize visibility and jobsite safety.

Equipped to compliment Kubota’s versatile attachments like buckets optimized for speed and efficiency, the KX040-5 adapts to a variety of excavation tasks with ease. Whether digging, loading, or site clearing, this excavator combines power, precision, and reliability to ensure your job stays on schedule.

Experience the Kubota KX040-5 in action by visiting your local Kubota dealer today, and discover how the perfect blend of technology, comfort, and power can transform your next project.

The EC500 is the largest model in Volvo CE’s revamped excavator lineup. A newly optimized electro-hydraulic system, along with a smart cooling system and engine speed regulation for higher torque at a lower rpm, add up to a 15 percent improvement in fuel efficiency compared with the previous model. The enhanced hydraulics enable better machine control and the smooth and precise movement of the boom, bucket, and other hydraulic components. Work modes have been expanded to 10 settings, including two specific to power and four specific to automatic ECO modes.

Volvo Smart View with Obstacle Detection gives operators 360-degree visibility of the machine’s surroundings; it combines camera technology and a new radar detection system to distinguish between objects and humans giving operators a heightened level of job site awareness.

The automation of boom and bucket movement with the Volvo Active Control machine control system and an advanced electric control joystick help operators increase productivity.

BOBCAT ENTERS THE 20-TON CLASS WITH HIGH-PERFORMING, FUEL-EFFICIENT EXCAVATORS BUILT FOR TODAY’S JOB SITES

BY MEGHAN BARTON, SENIOR WRITER

Bobcat’s legacy in compact equipment has shaped the industry, but now the company is scaling up. With the release of the 23-ton E220 and the 25-ton E245, Bobcat is moving firmly into the 20-ton class, bringing familiar performance and operator comfort to a larger size of excavators.

“We’ve had an excavator lineup for many years,” says Luke Hill, senior product specialist at Bobcat. “But we had a gap from that 19,000-pound class up to the 30,000- to 40,000-pound range. So really, what we’re doing here is expanding our portfolio to meet more of our customers’ needs.”

As job sites and customer expectations grow, Bobcat is expanding its offerings to match without losing sight of the performance, reliability, and support that built its name in compact equipment.

“Our dealers are excited for the 20-ton excavators and the performance that’s going to come at that price point,” says Hill. These machines represent more than just a new size category. They reflect Bobcat’s long-term strategy to grow alongside its customers, expand its product portfolio, and better serve a broader range of contractors and applications.

While Bobcat already offers larger excavators, such as the E145 and E165, Hill says the E220 and E245 were developed to meet increasing customer demand for machines that deliver more lifting capacity, stronger digging performance, and better fuel economy. The E220 is powered by a 174-hp turbocharged engine and weighs approximately 52,738 pounds in its standard configuration. The E245 features a larger 189-hp diesel engine and weighs in at approximately 56,908 pounds.

“The E220 and E245 are focusing on the core needs of high performance and reliability,” explains Hill. “On the performance side, we have some of the highest lift capacities in the E220 and E245 compared to their competitors in the size class, as well as tremendous breakout forces giving excellent digging power for, honestly, just really good productivity.”

The E220 and E245 are built with job site productivity in

mind. Both models come equipped with performance-focused features designed to support precision, efficiency, and control in a wide range of applications.

Standard features include:

Smart Power Control automatically adjusts engine RPM, hydraulic pump torque, and machine response based on load requirements.

Four selectable power modes (Power+, Power, Standard, Economy) that optimize fuel use or prioritize speed, depending on task demands.

Fine swing mode to reduce sway and spillage when lifting heavy objects into position.

Joystick or foot‑pedal auxiliary control with two-way hydraulic piping for attachments and multi-directional operation.

Side‑ and rear‑view cameras included as standard equipment for enhanced visibility.

“You get into these machines and the first thing you notice is how smooth and responsive they are,” Hill says. “They’re balanced. They feel strong, and they’re intuitive to operate.”

You’ve got great front visibility with the lower window cutout. That’s increasingly important as job sites become more congested and safety becomes even more of a focus.

Luke

Hill

Senior Product Specialist,

Bobcat

Though both machines share key features, Hill notes that the E220 and E245 serve distinct types of work.

E220: Designed for long-term use on large job sites, this model is well-suited to commercial contractors who don’t move machines frequently.

“The E220 will really target those commercial contractors who have machines stationed at larger job sites for longer periods of time,” says Hill.

E245: A reduced-tail-swing model ideal for infrastructure and roadwork in confined spaces.

“We’re going after those roadwork and infrastructure contractors on job sites that have size limitations,” he explains. “It has excellent bucket capacity,” Hill adds, “but then also that reduced tail swing keeps the working area rather tight.”

Both models have a bucket digging force of 35,464 poundfeet. Digging depth ranges from 21 feet 7 inches on the E220 to 21 feet 11 inches on the E245.

Visibility, a long-time Bobcat strength, is also notable in the new excavators. Hill says that the cabs are designed to minimize blind spots and give operators clear sightlines to the work area.

“The visibility in these machines is exceptional,” Hill says. “You’ve got great front visibility with the lower window cutout. That’s increasingly important as job sites become more congested and safety becomes even more of a focus.”

The operator environment also includes premium features like an air-ride seat, touchscreen display, and customizable controls.

“Operators are spending long days in these machines. It’s important that they’re comfortable, and that the cab helps them stay productive,” he adds.

Both machines come ready for grade control and are compatible with third-party systems. This plug-and-play approach to technology appeals to users looking for streamlined integration within their own fleets.

It is also part of what makes the E220 and E245 especially appealing to rental companies, another key market for Bobcat. Hill says their balanced specs and approachable price points make them easy additions to any fleet.

“You get all the productivity benefits of a larger excavator without jumping into the ultra-premium segment,” he explains. “That’s something rental customers are going to respond well to.”

Hill emphasizes that Bobcat’s expansion into heavier size classes isn’t just about offering larger machines. It’s about supporting them properly.

“Our Bobcat dealers are a core identity to the brand, and they offer exceptional service that many people love,” he says. “They’ll now be able to get that service all the way up through the heavy equipment offerings that we now have.”

So far, that opportunity has been met with excitement from dealers and early demo users alike.

“Our dealers are excited to get aggressive and to go after [new] customers and then also to offer our compact customers solutions for their heavy needs.”

He adds that while many customers are just beginning to receive shipments, early impressions are strong.

“I have had the opportunity to have customers come demo these machines,” says Hill. “They’ve stated that these machines do not lack any power. From heavy wet topsoil to digging into the earth and lifting heavy loads, they are absolutely blown away by the power and performance that these machines have.”

Our dealers are excited for the 20-ton excavators and the performance that’s going to come at that price point.

Luke Hill

we get to know the customer’s needs a little bit more, we may branch out into more niche marketplaces within these size classes of machines.”

And for those contractors who haven’t considered Bobcat excavators in the past?

Hill says the brand is ready to go head-to-head with the industry’s top players in the segments where it matters most. Still,

The DX17Z-7 is the smallest model in DEVELON’s excavator lineup. Weighing approximately 4,200 pounds, the 16-hp machine is built for manoeuvrability in confined environments. Its retractable undercarriage narrows to 48 inches for access between structures and expands for added stability when digging or lifting. A collapsible dozer blade supports grading and backfilling in restricted spaces.

The DX17Z-7 features a zero-tail-swing design for close-quarters operation and an open-canopy for visibility. Operators can switch between ISO and backhoe control patterns without tools, and a blade-float function allows the dozer blade to follow ground contours automatically. Auxiliary hydraulics with flush-face couplers and thumb-ready plumbing simplify attachment use, while on-board diagnostics support preventive maintenance.

Cylinder guards protect key components, and the rubber-track undercarriage minimizes ground disturbance on soft or finished surfaces.

THE FIRST PRODUCTION MODEL HAS BEEN DELIVERED TO SUNCOR’S FORT HILLS OPERATION IN ALBERTA

The 900-tonne Komatsu PC9000 is purpose-built for large-scale efficiency in high-production mining. Engineered as a five-pass match for Komatsu’s 980E ultra-class haul trucks, this combination enables fast, double-sided loading and is compatible with autonomous haulage systems (AHS).

With extended reach, higher digging forces, and an oversized bucket that significantly improve cycle times

and lower cost-per-tonne performance, the PC9000 delivers the power and efficiency that mining operations expect.

In addition to its digging and loading capabilities, it features a redesigned hydraulic system aimed at reducing energy consumption and emissions, supporting both sustainability goals and operational efficiency.

The Komatsu PC9000, the company’s largest hydraulic mining excavator, has officially arrived at its final destination. After a highly anticipated international journey from Düsseldorf, Germany, the PC9000 was unveiled during a special handover ceremony at Suncor’s Fort Hills operation in Alberta. It is the first operation worldwide to deploy the PC9000.

The 55-ton-class SK520LC-11 extends KOBELCO’s -11 series with a focus on technology, power, control, and efficiency. With an operating weight of approximately 121,000 pounds, it delivers a bucket digging force of 72,200 pounds and a lifting capacity of 46,540 pounds. The machine is powered by a 463-hp Tier 4 Final Isuzu 6WG1 engine and incorporates the company’s “Independent Travel” hydraulic system, enabling simultaneous movement, lifting, and swinging without power loss.

The excavator can be equipped with an optional counterweight removal system for simplified transport, and multiple working modes allow operators to match hydraulic output to specific tasks. Maintenance points are designed for convenient access, and energy-saving functions, such as automatic idle shutdown, help manage fuel use and emissions.

Inside the cab, a large 10-inch colour monitor displays key operating data and hydraulic settings, while the adjustable, heated air-ride seat, multi-vent air conditioning, and rear and right-side cameras support comfort and visibility. The SK520LC-11 also accommodates a range of attachments, including buckets, hammers, and grapples.

BY CAMERON CLARK

IN AN INDUSTRY KNOWN FOR resisting change, being a leader who encourages out-of-the-box thinking and innovation can be difficult. While it’s no easy feat, trying new things is essential for overcoming challenges and driving growth. At the same time, change doesn’t happen on its own; it requires people like Rory Prendergast who are willing to challenge the status quo.

Prendergast is a machine control and survey superintendent for Amrize Canada. Amrize, which was previously known as LaFarge, delivers a wide range of paving, road, and heavy civil construction work and is a leading supplier of cement, aggregates, ready-mix, precast concrete, and asphalt.

Throughout his career, Prendergast has been a changemaker, driving the adoption and connection of technology and new workflows. His out-of-the-box thinking has been proven to drive value, bring efficiency to day-to-day operations, improve collaboration and streamline project delivery.

“Transferring data fast, but also ensuring everybody is accessing the right piece of data and can access it quickly, is what’s advantageous about connected workflows and connected systems,” he says.

Before joining Amrize, Prendergast led a surveying team on Canada’s largest civil infrastructure project, the Site C dam and hydroelectric generating station on the Peace River in northeast British Columbia. The project began in 2016 and will provide power for 450,000 homes when completed. The volume of earthwork, tunnelling, and concrete required to complete the project is staggering, testing surveyors’ planning, communication, and data management skills and compounding the value of technology-driven efficiencies and cost savings.

Across a footprint of eight square miles, crews on the Site C project will move just shy of 20 million cubic yards of 17 different material types and pour more than 1.6 million cubic yards of concrete. According to Prendergast, the drafting department will turn out close to 4,000 designs over the course of the project.

“Immediately, I saw that we needed a faster communication stream,” says Prendergast. “Surveyors completed scans, exported them to a USB stick, and then drove them back to the office. Because we were working on an expansive job site with a river running through it, getting around the site took half an hour. Hand delivering the file was the biggest and most time-consuming aspect of our work.”

Prendergast envisioned a future state of better data sharing between the office and the field, coupled with connected machine control and guidance, to minimize downtime and increase efficiency. He started by adding SIM cards to the Windows-based controllers so surveyors could immediately transmit scan data to the office. “They would let me know over WhatsApp when they were complete, and I would then process the scan,” he said. “Using Trimble Business Center, I would isolate the high spots and upload the excavation design with cosmetic changes, so the operators could quickly address the area and move to the next excavation. This new workflow radically reduced turnaround time from 90 minutes to 10 to 15 minutes.”

Although this simple improvement significantly improved the field-to-office collaboration, it was just the beginning of data sharing and communication.

The project also required the underwater excavation of a 600- by 200-metre area to a minimum line that would ensure a smooth release from the spillway. The excess raw material removed from the river bottom was also essential to building the dam buttresses.

Prendergast noticed communication barriers were impacting

progress and preventing operators from getting the information needed to do their work efficiently. “We had to confirm the minimum line of excavation, but we also didn’t want to waste each excavator’s time across the day and night shifts,” he explains. “Each operator needed to know where the previous excavator had excavated.”

Each excavator was equipped with Trimble grade control technology, allowing operators to gather data, much like surveyors. “Even with grade control technology on the machines, we were limited to manual data transfer with USB sticks, but WorksManager streamlined that process very quickly,” he says.

Trimble WorksManager is a cloud-based platform that streamlines communication and data management between the office and the field. “The operators manually recorded positions throughout the day,” Prendergast explains. “At the end of the day, I logged directly into the machine grade control using WorksManager, downloaded the data as point files (.PNT) and dropped it into Trimble Business Center, which is Trimble’s constructable modelling, earthwork, and survey software. Each day, I compared the completed work to the 3D model to confirm it was below grade tolerance with the defined safety factor. I sent an updated perimeter model to the operators each morning through WorksManager. I adjusted the perimeter to include the previous day’s excavation, so when the day shift started, they were not reworking an area that had already been excavated to grade.”

With clear information on where to work, operators were confident they could work without stops and starts. “It completely revolutionized the job,” Prendergast says. “We could concentrate on actual survey work rather than overseeing operators and driving around designs from machine to machine.”

Prendergast found that using technology for purposes other than its intended use can bring about positive change.

The company also uses SketchUp, Trimble’s 3D modelling software. “We use SketchUp in a unique way that I don’t think many people would consider,” he says. “Our older-model controllers weren’t 3D-capable. Our foremen and field engineers sometimes struggled to comprehend the complex 3D models, but the 2D plans provided limited help. I thought there had to be a way to display 3D models on a phone or iPad.”

Prendergast’s previous experience using Trimble SketchUp sparked the idea of exporting and sharing the SketchUp model on WhatsApp, where the foremen can view it on a phone or iPad. “This gives them a fully rendered 3D model,” he says. “They can view and manipulate it, turning layers on and off to get the view they need. Once word of this new workflow got around, I would arrive at work and find a stack of iPads with requests from the night shift crew asking me to install

SketchUp. It was the greatest answer to the problem we didn’t know existed.”

Anyone can help shape the future of their business and the construction industry by taking the initiative to drive change. For Prendergast, this meant finding ways to connect, use, and maximize the company’s existing technology for data sharing, which transformed workflows and saved valuable time.

“When everything is connected and an operator, for example, can see the grade and where they need to be, it pushes the company to the next level,” he says. “We’ve seen tremendous time savings from using technology, which equates to revenue. Companies can’t compete on these projects without connected machine control technology. Without it, they would need a never-ending roster of surveyors to constantly check the grade behind the dozer or stake out in front of them. If you’re not on the cutting edge in adopting and using these technologies, you will get left behind.”

CAMERON CLARK is the earthmoving director for the civil construction sector at Trimble. He is focused on delivering machine control innovation to the market.

BY KAITLYN TILL, EDITOR IN CHIEF

Komatsu’s PC220LCi-12 is packed with technology to make operation more accurate and intuitive.

Komatsu’s PC220LCi-12 excavator, which the company bills as “the most advanced excavator ever designed,” has now arrived in Canada and is ready to deliver awesome accuracy and performance on Canadian job sites. The new PC220LCi-12 is front-loaded from the factory with features designed to make operators more proficient, confident, and productive — and includes the debut of Komatsu’s big machine control update.

Komatsu’s flagship technology offering, Intelligent Machine Control (IMC), has entered a new generation with the debut of the PC220LCi-12. IMC 3.0, the successor to IMC 2.0, gives operators the same experience of up to three centimetres of accuracy, but the system has become more responsive and has exciting new automation features.

According to James Barr, manager for Smart Construction Operations at SMS Equipment, the largest independent Canadian dealer for Komatsu’s full line of equipment, the transition from IMC 2.0 to 3.0 brings notable enhancements in speed and performance of the 3D system, along with expanded automation capabilities.

“With IMC 3.0, more functions are now automated,” says Barr. “The operator only has to pull one joystick function, and the automation starts. The boom will go up and down, the bucket will hold its angle, and it will follow the target surface.”

Hitting grade and following a targeted plan isn’t the only excavator function that has received an automation update on the new model: the PC220LCi-12 also boasts a new auto swing feature that simplifies the load and dump process.

The operator sets the swing range and heights. Then they fill the bucket, push two buttons on the joystick, and the machine takes care of automatically lifting the boom and swinging it to the dumping zone where the operator can dump the bucket into the hopper or a truck. Then the operator pushes the joystick

Komatsu’s flagship technology offering, Intelligent Machine Control, has entered a new generation with the debut of the PC220LCi-12.

buttons again to automatically return to the digging location. The cyclical automation streamlines the operator’s inputs for efficient operations. And, when combined with the new factory-integrated advanced payload monitoring system, this excavator is ready to hit targets without under- or overloading.

Komatsu’s focus on technology extends far beyond efficiency and production features. The new PC220LCi-12 is packed with safety technology designed to keep operators, bystanders, and property safe. Leading the lineup of safety features is the camera system around the machine, which includes a forward-facing camera, giving the operator 360 degrees of job site awareness.

The excavator is also able to detect the difference between static objects and people and will issue internal and external alerts if someone is too close to the working machine. Komatsu’s object detection system can be set to stop the machine if a person or object enters the excavator’s line of travel and also activates if the operator starts to swing and something enters the avoidance zone.

These features can be turned on and off as needed, because, as Barr points out, sometimes the detection can’t be used.

“In some applications, such as trenching or pipeline work, operators may temporarily disable the boundary detection system to allow for material placement,” says Barr. “In those cases, material often needs to be placed directly behind or beside the work area, which would normally fall within a restricted zone. The flexibility to adjust these settings allows operators to work efficiently and safely, adapting the system to the conditions on site.”

The flexibility of these safety systems allows operators to assess their application and determine which safety features they need to use to operate as safely as possible. But these features aren’t just nice to have — they have been in demand.

“Some customers working near sensitive areas, such as working parallel to train tracks, have expressed the need for a permanent boundary that prevents the machine from swinging into restricted zones, regardless of its position,” explains Barr. “That capability wasn’t previously available but it is now. You can set a 3D boundary in your design file, and the machine will never be able to pass through the set boundary.”

Every new Komatsu LC-12 machine will come with these safety features standard from the factory.

The cabs of today’s excavators are designed with care to keep operators comfortable and operation intuitive. If either of those standards aren’t met, the operators who run that machine won’t be happy.

To that end, customization is what operators want, and that’s what the new Komatsu cab delivers.

“It’s just like when I get in my car. I like my seat in a certain spot and when I push the button, it sets my seat and my steering wheel and now I’m ready to go. They’re doing that in construction machines too,” says Barr.

On the PC220LCi-12, the cab is 28 percent larger with 30 percent more leg room and 50 percent improved visibility compared to its predecessor, the PC210LC-11.

In this larger cab, the touchscreen is the command centre where the operator has access to their climate control, Bluetooth, and User ID, which ensures that each operator’s preferred settings are saved so when they switch machines they just need to push a button to be ready to get back to work. The PC220LCi-12 features EH controls which are also customizable via the touchscreen.

Upskilling operators is vital for employers, and automation, safety, and comfort features all contribute to make new and experienced operators more proficient, confident, and productive.

According to Barr, contractor interest in technology has increased a lot. Companies that had previously dismissed adding these advanced features to their equipment are recognizing that there is more competition in bidding and more of their peers are using this technology. And, as Barr notes, there are a lot of bids that contractors can’t win without technology on their machines.

“You’re seeing this turn in the industry where a lot of people are recognizing that they need technology on their fleet to maintain a competitive edge,” he says.

On Komatsu’s new PC220LCi-12, that technology is the standard, and it is designed to make the transition as seamless and intuitive as possible.

Barr adds that more customers are reaching out to SMS Equipment to start the conversation about integrating technology into their operations so that they can grow as an organization — and they’re ready to benefit from the dealer’s support on that journey. HEG

The 145 X4S hydraulic excavator is designed to improve fuel efficiency, precision, and operator control. The machine is powered by a DPF-free Isuzu AR-4JJ1X Tier 4 Final engine. Its electronically controlled hydraulic pump and Spool Stroke Control (SSC) system work together to deliver responsive performance and lower fuel consumption. Operators can optimize efficiency with four selectable power modes.

The 145 X4S is available with advanced technology options, including Digital Level, Height and Depth Alarm, and Payload Management. It also comes precision grade–ready for easier integration of machine guidance and control systems. Serviceability is simplified with 500-hour fuel filter intervals and ground-level access to key maintenance points.

Inside the cab, a high-definition, 10-inch, anti-glare monitor is fully customizable to display key operating data, and the WAVES camera technology offers a 230-degree view. The ROPS- and FOPS-certified cab delivers generous legroom and a high-back heated seat with tilt adjustment.

The 24-tonne 922FE electric excavator is designed to eliminate CO2 emissions from job sites without sacrificing the performance that operators expect from a diesel machine.

A 423 kWh battery system drives a robust 165 kW (221 hp) engine, delivering diesel-equivalent digging force and hydraulic responsiveness. This machine is ideal for indoor facilities, urban job sites, or eco-regulated zones. With no fuel costs and simplified maintenance, LiuGong says this excavator offers up to 40 percent lower lifetime operating expenses.

Run time lasts 8 to 10 hours, and the excavator can be recharged in 90 minutes. Operators can monitor the machine via its interactive display, where real-time battery health, performance analytics, and customizable settings are at their fingertips.

The CX25EV electric mini excavator, with an operating weight starting at 5,159 pounds (2,340 kg), offers clean, lownoise operation and excellent control that is well-suited for close-quarters and sensitive environments. This machine includes hydraulic flow settings and up to three auxiliary circuits that can be paired with a quick coupler and a variety of attachments. It’s equipped with electro-hydraulic controls that are fully customizable by the operator, and the short-radius design makes it easy to move around in tight spaces.

The updated 23-ton EC230 Electric is a general purpose machine ideal for medium to heavy-duty applications, such as excavation, demolition, and industrial material handling. The new-generation machine offers an extended run time of seven to eight hours on a single charge. Powered by its 600V lithium-ion battery with a capacity of 450 kWh, operators can now work a full day without interruption. Fast charging capabilities allow the battery to reach from 20 percent to 80 percent in just one hour with a 250-kW charger. The updated EC230 Electric shares many of the hallmark features of Volvo’s recently updated excavator lineup, including a larger cab; intelligent electro-hydraulics for smoother, more precise movements; and a suite of safety features which includes HD Volvo Smart View with People and Object Classification.

Takeuchi’s TB20e electric excavator is now available in a cab configuration. The new 2,125-kg (4,685-pound) cab model is slightly heavier than the 1,930-kg (4,255-pound) canopy model (pictured). Its 12.6 kW electric motor is powered by a 24.7 kWh lithium-ion battery that offers a continuous working range of up to eight hours, depending on application and environment. The TB20e has a maximum dig depth of 2,390 mm (7.8 feet) and a maximum reach of 4,090 mm (13.4 feet). A primary hydraulic circuit delivers 34.0 L/min (9.0 gpm) for running hydraulically driven attachments. It has an independent circuit for the slew function which provides smooth control and improved battery life.

Family-owned Cox Construction, headquartered in Guelph, Ontario, works in various pits and plants across the southeast part of the province and uses two small, 2.5-ton ECR25 Electric excavators to break up oversize rock that is too big to fit in crushing plants.

“The transition from the diesel machine that we had before to the electric has basically been seamless,” says Brandon Crumbie, a crusher foreman at Cox Construction. “I really like it because there’s less warm-up time. You just hit the key and away you go. It’ll do every job you could ever need.”

The ECR25 Electric has the power Cox Construction needs while requiring a fraction of the maintenance performed on the diesel model that used to do the job: there are no engine oil changes and no filter changes, just the hydraulics system to maintain. And, according to the contractor, the vibration of the crusher affects the excavators much less than it affected the previous diesel models because they have far fewer components.

The ECR25 Electric machines run on top of a 600volt crusher, so charging from the generator that powers the crushing set-up is convenient and draws minimal power.

Cox Construction was supported through the ECR25 Electric implementation process by Volvo dealer Nors Construction Equipment Canada.

Sized right for tight spaces. Steel-built for heavy-duty work. With groundbreaking power in a nimble package, Takeuchi Compact Excavators are proof positive that it’s not the size of the machine in the work, it’s the size of the work in the machine.

THE MARK OF TOUGHNESS

EXTENSIVE EXCAVATOR LINEUP: INCLUDES CONVENTIONAL TAIL SWING, SHORT TAIL SWING, SIDE-TO-SIDE (STS) OFFSET BOOM, HYBRID AND FULLY ELECTRIC MODELS.

MINI EXCAVATORS (<6 TONS) MIDI EXCAVATORS (6-10 TONS)

(10-15 TONS)

The 100-ton HX1000A L is designed to meet the needs of high-volume earthmoving, mining, and quarrying applications.

Powered by a 620 net hp (420 kW) engine, the HX1000A L can be configured with various boom and arm options to match the application. Bucket capacity ranges from 7 to 8.9 cubic yards (5.4 to 6.8 cubic metres).

Bucket digging force ratings also reflect the machine’s suitability for heavy-duty applications, with the HX1000A L delivering 88,185 lbf (40,000 kgf).

Operators have selectable power modes and an electronic power-optimizing system to maximize their control over machine power and efficiency. The cab is designed for comfort and safety, featuring Level 2 FOPS protection and advanced vibration-damping mounts. The Hyundai AAVM (All-Around View Monitoring) camera system gives operators a 360-degree view to the worksite around the machine. The 8-inch touchscreen provides easy access to control menus, power settings, and auxiliary hydraulic settings.

The next-generation E20 compact excavator has a 1,098-pound rated lift capacity and delivers 24 percent more arm digging force and 26 percent more lifting capacity over the blade than the previous model.

It features a zero-tail-swing design, in-track swing frame, and retractable undercarriage. An optional enclosed cab with heat is available. Features include a Bluetooth radio, auto idle, auto shift, 3D grab handles, and reduced noise levels.

Other highlights include a closed-centre hydraulic system with a new load-sensing pump and larger boom and blade cylinders to boost digging performance and lift capacity; a standard long arm that increases maximum reach, digging depth, and dump height; a standard long blade for improved grading and backfilling; and joysticks with fingertip controls for precise boom swing and auxiliary movement control.

BY SEJONG KO

Hybrid technology has been around for more than a century in the auto industry — the first hybrid car was introduced in 1899 by Porsche. The introduction of Ford’s automobile assembly line in the early 1900s led to an increase in the production of gas-powered vehicles, making hybrids basically obsolete for several decades. But a resurgence in the 1970s brought them back, and now hybrid technology is taking hold in the construction industry.

For passenger vehicles, “hybrid” typically refers to powering the movement of the vehicle. But hybrid technology in construction equipment — specifically, excavators — is about powering the hydraulics.

So what is a hydraulic hybrid excavator? And in which applications do they make the most sense?

There

are no electronics

to program and no additional control systems because the technology is not meant to “generate” electricity or store it in batteries — it’s just about optimizing hydraulic flow.

The word “hybrid” might make you think of a complicated system that takes hours of operator training, extra components to monitor and replace, and so on. But that isn’t the case.

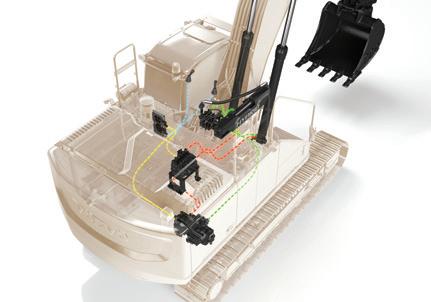

While most construction equipment manufacturers with hybrid technology use the swing motion to capture energy for the hydraulics, Volvo CE is doing it a little differently, capitalizing on the upand-down motion of the boom instead.

This is accomplished by mounting a hydraulic accumulator just behind the boom, so as the boom goes down, the high-pressure oil used to slow that movement goes into the accumulator instead of the tank. This charge is then routed through assist motors and pushed back

into the cylinders on the upswing.

The best part for the operator? The entire process is controlled automatically. They simply see a symbol on the dash that indicates when the accumulator is charging and discharging.

Using the energy generated by the boom-down motion to assist the boomup motion makes sense because that is where you need most of the pressure and power during operation.

In 2020, Volvo CE launched its first hydraulic hybrid excavator, the 30-ton EC300E Hybrid. Today, they offer five hydraulic hybrid excavators ranging from 26 to 50 tons. The newest models deliver up to 20 percent better fuel efficiency than their internal combustion engine

(ICE) equivalents and a 10 to 15 percent reduction in CO2 emissions, all without sacrificing performance specs.

A lot of the benefits come from reducing fuel consumption. A hydraulic hybrid excavator uses 15 to 20 percent less fuel than an ICE model because it requires less work from the engine. When used in high-production applications, the fuel-saving payback is approximately two years (depending on fuel prices). As an added benefit, this also means a 12 to 15 percent decrease in CO₂ emissions com-

pared to a conventional machine.

There are no electronics to program and no additional control systems because the technology is not meant to “generate” electricity or store it in batteries — it’s just about optimizing hydraulic flow.

The 26- to 50-ton hybrid models that Volvo currently offers are most often used in “dig and dump” applications like construction site prep and quarrying.

The stop-and-go nature of site prep (especially in urban areas) can burn fuel quickly, so hybrid technology offers a

big advantage. And in quarrying, where machines need to work reliably and efficiently all day, the ability to conserve fuel adds up fast.

Plus, as more project owners consider environmental factors and more governments pass clean air regulations, emission-reducing capabilities are increasingly valuable. Many contractors aren’t ready to make the switch to battery-electric machines until prices come down further and/or charging options improve. In that case, hybrid technology is a great way to bridge the gap.

For a more in-depth look at how Volvo’s hydraulic hybrid technology works, this example is based on the EC300, a 30-ton crawler.

The Volvo D8M Tier 4 Final (Stage V) engine uses Volvo Advanced Combustion Technology, which means precise, high-pressure fuel injectors, a turbo charger, an air-to-air intercooler, and electronic engine controls to optimize performance.

A 20-litre hydraulic accumulator just behind the boom harvests “free” energy generated by the downward motion and uses it to supercharge the engine system.

As the boom goes down, the high-pressure oil used to retard the boom dropping goes into the accumulator instead of being routed to the tank.

The accumulator delivers this energy to drive the hydraulic assist motor that helps power the engine system.

Any stored energy is also used to drive the assist motor, lowering the torque requirement on the engine.

SEJONG KO is the excavator product manager at Volvo CE.

The new CX380E excavator is built to maximize power for clearing land, trenching, craning pipes, or breaking rock. Weighing in at 83,114 pounds and with a 268 hp engine, this machine delivers fast cycle times and empowers operators to tailor its performance to their task. Four fuel-efficient work modes and ten throttle settings are available. Eco mode lowers fuel consumption by up to 18 percent compared to previous CASE excavators.

Operators can store settings for up to ten attachments via the touchscreen, and the intelligent Hydraulic Flow Control Balance makes the excavator more responsive by customizing the priority of hydraulic flow. Selectable free swing functionality gives operators more stability and improved safety with less fatigue when lifting and placing swinging loads, working on uneven terrain, or loading trucks.

Kubota's 8-ton KX080-5 is an update of the KX080-4. The machine features a two-pump load-sensing hydraulic system that enables smooth, simultaneous operations. An auto-shift function automatically adjusts travel speed based on terrain and traction.

Powered by Kubota’s fuel-efficient engine with a common rail system (CRS) and diesel particulate filter (DPF), the KX080-5 delivers over 15 feet of digging depth, a 17-foot dumping height, and a 24-foot digging radius. Its powerful bucket force is paired with automatic idle and engine stop functions to improve fuel efficiency and reduce engine wear.

Operators will appreciate a larger cab with improved visibility, reduced noise, and increased foot space. An ergonomically positioned, 7-inch LCD monitor integrates key functions, such as the rear-view camera and hydraulic controls, while standard LED lighting with turnoff delay keeps the job site visible. The updated design also includes a double-adjustable air-suspension seat and simplified controls for improved comfort and ease of operation.

Volvo Construction Equipment has updated its demolition range with the EC400 High Reach and EC500 High Reach, replacing the EC380EHR and EC480EHR models. These new machines feature a next-generation design that improve fuel efficiency by up to 15 percent through engine-pump optimization and extended service intervals. Ground-level service access, refined electro-hydraulic controls, and a quieter cab environment will be appreciated by operators.

Developed specifically for high-reach demolition, the EC400 and EC500 High Reach incorporate an extension-boom concept that expands working range and accommodates heavier attachments. Hydraulic lines have been re-engineered with an enlarged X1 return line and dedicated drain line to reduce back pressure and improve oil flow to rotating tools.

Operator assistance features include Volvo’s Demolition Assist system, providing visual and audible alerts for working-range and stability limits, and Smart View with optional obstacle detection for a safer working environment. The reinforced, high-visibility cab offers tilting capability, P5A-rated windows, and integrated front-view HD cameras. Both models are compatible with a wide range of attachments and can convert from ultra-high-reach to standard digging configurations for added versatility.

The Cat 330 UHD (Ultra High Demolition) excavator is a 46-ton machine engineered for demolition versatility in applications ranging from 5 to 6 storeys. With a reach of up to 20 metres (65 feet 6 inches) and a tool capacity of 3,300 kilograms (7,275 pounds), the machine can be configured with one-piece or two-piece retrofit booms to suit site requirements. Fifteen-minute boom swaps are possible with the hydraulic quick disconnect system. Operators can select a fixed or hydraulic-variable undercarriage for a 3-metre (9-foot 10-inch) transport width or 3.4-metre (11-foot 3-inch) working width for added stability.

The 330 UHD features integrated technologies, including Cat Payload, Cat 2D Grade, and Cat 2D E-Fence, and a stability-monitoring system on a 10-inch touchscreen. Powered by a Cat C7.1 engine compliant with Tier 4 Final standards, the machine offers automatic hydraulic oil warmup and ground-level service access.

A tilting demolition cab improves sightlines for height work and incorporates P5A-rated glass, front and roof operator protective guards, and standard side and rear-view cameras. Inside, operators benefit from programmable controls, a heated and cooled seat, and compatibility with Cat’s VisionLink and Remote Flash support systems.

The 51-tonne SENNEBOGEN 830 E Demolition Vario Tool combines three machine configurations into one platform, offering flexibility for high-reach, below-grade, and earthmoving applications. Operators can switch between the two-part AB17 boom with a 17-metre reach, the three-part AB23 long-front boom with a 23-metre reach, and the EA12 digging boom with a 12-metre reach. This versatility enables a single machine to perform demolition and earthmoving tasks across various site conditions.

A fully hydraulic quick-change system enables fast transitions between booms and attachments, including grabs, shears, and buckets, without leaving the cab. The undercarriage provides a 4.5-metre maximum track width for stability, and transport is simplified through a counterweight that lowers hydraulically at the touch of a button.

The 830 E features SENNEBOGEN’s Maxcab, which can elevate 2.8 metres and tilt 30 degrees to improve visibility and operator comfort. Roof and front protection guards are standard, and optional bulletproof glazing is available for added safety.

John Deere’s new 510 P-Tier Excavator replaces the 470 P-Tier offering greater performance, increased fuel efficiency, and lower operating costs.

With a 9.0L John Deere Power Systems engine, the 510 P-Tier delivers the same net horsepower and responsive performance as the 470 P-Tier’s larger 13.5L engine while reducing fuel consumption. John Deere says that this efficiency gain is driven in part by a new electronic, ondemand cooling system that replaces traditional hydraulic fans, reducing engine load. The cooling package features ten electric fans (E-Fans) that optimize airflow, while maintaining adequate cooling performance.

Contractors can empower their operators to reach grade faster and achieve more points on grade, helping eliminate costly rework and additional job site inputs caused by over-excavation, by adding optional 2D Grade Guidance, 2D SmartGrade Ready Control, or full 3D SmartGrade. A right, rear, and left camera system with LED surround lighting comes standard and is integrated into the main monitor of the machine.

Blue Diamond’s new hydraulic breaker lineup consists of 12 models for excavators up to 55 tons. These breakers are loaded with features ready to tackle construction, quarry, and demolition applications, including underwater demolition work. The breakers have four tool configurations: a moil point, a chisel tool, a pyramid tool, and a blunt tool. Tools are easily interchangeable with minimal downtime, allowing operators to select and change the tool in the field without additional wrenches or keys.

A solid monoblock design reduces maintenance downtime, and a vibration dampening system consisting of a polyurethane shell wraps around the mo-

no-block and sits inside the Hardox steel outer casing. This reduces noise for the operator and vibration transfer to the excavator.

A self-regulating valve protects the breakers from over pressurization, excessive flow, and back pressure. It also eliminates the need to test the machine’s hydraulic pressure and flow before operation. Anti-blank firing prevents internal damage from dry firing while the attachment is not engaged with material.

Interchangeable mounting brackets, available on many of the models, allow a single breaker to be moved between different host machines, including from excavators to skid steers.

The FAE BL0/EX-100 is a fixedtooth mulcher designed for 5-ton excavators. Featuring Bite Limiter technology, the head is ideal for high-productivity vegetation management. With its compact frame for ample manoeuvrability, the mulcher is capable of shredding light vegetation, shrubs, and trees up to three inches in diameter in tight areas, like railroad

Choose from 2-ton (open or closed cab), 4-ton, and 6-ton mini excavators

All machines are backed by 3 years of warranty and local after-sales support you can rely on Mini Excavators, Backhoes & Wheel Loaders In Stock

ALLU’s new Asphalt Bucket is available for 25- to 45-ton excavators. This hybrid-screening solution is designed to process cold-milled asphalt and reclaimed asphalt pavement — crushing clumps, screening fines, and separating oversized particles — in a single pass.

With screen sizes of 12, 16, and 25 millimetres, the bucket can deliver up to 250 tons per hour with the rapid drum change-outs. The hybrid blade configuration mixes screening and crushing blades, allowing operators to process cold-milled asphalt directly at the source without additional equipment.

The bucket can produce 95 percent of finished material below target size, reducing reprocessing needs and turning milled material into a high-quality resource directly on site.

Introducing ZELIOX NEO

Zeliox is the all-in-one mobile power solution for tools, appliances, and accessories—anywhere you work. Compact, plug-and-play, and built for service vans, trailers, and remote sites, it delivers clean, reliable energy with three charging capabilities:

Shore power

Solar Alternator

This integrated heating solution is engineered for offhighway machines. Tied to the engine’s coolant loop, it keeps cabs warm, windows clear, and engines ready, even when your machine is parked and off. Rugged, quiet, efficient, and fuel-smart—Hydronic delivers dependable warmth across the job site.

www.eberspaecher-utility-cargo.com

MB Crusher’s new MB-P and MB-PT demolition pulverizers for excavators, backhoe loaders, and skid-steer loaders from 1.5 to 25 tons are built for primary and secondary crushing with 360-degree continuous hydraulic rotation that allows for the precise, manoeuvrable positioning of the attachment. Five models are available. The attachments come in two versions and can be outfitted with a single-cylinder or double-cylinder depending on the power needed. Both versions were installed on different machines and tested by contractors while keeping the weight-to-power ratio in an optimal range. The design is adapted to the hydraulics of mid-size machines to ensure an even performance when crushing reinforced concrete.

Key features of the MB-P and MB-PT demolition pulverizers include an optimal design for rapid opening and closing of the jaws, tilted rotating head to increase the working range, increased transverse tearing power with the option of a double-motor, an enhanced lever system, reversible and interchangeable blades, interchangeable teeth, and a sturdy slewing ring and protected cylinders.

Steelwrist’s next-generation QuantumConnect control system platform combines advanced ergonomics, intelligent integration, and always-on connectivity to give operators a seamless installation and operating experience.

It features new A9 joysticks for improved ergonomics and functionality. Operators can choose between two or three rollers, benefit from a five-way mini joystick switch, and enjoy additional features, such as heated handles. Haptic feedback gives the operator instant tactile signals from the system.

Steelwrist says that the modular system design makes it easy to adapt QuantumConnect to any excavator brand or model. Purpose-built modules, such as the QIO modules, convert CAN data to analog and digital signals, enabling smooth integration with machine functions and external systems. The tiltrotator control module, integrated directly into the tiltrotator, ensures precise control of valves and sensors, while the AUX module offers flexibility to manage additional hydraulic functions such as blades, outriggers, or offset booms.

The new Connectivity Gateway module ensures wireless communication with sensors and components, while also managing 4G connections for cloud

backup, over-the-air software updates, and remote diagnostics.

The new InstallMate app guides technicians step by step. Predefined templates for each excavator brand and model ensure that system configuration is straightforward, while cloud-based storage allows machine settings to be securely saved, cloned, and restored across multiple excavators.

From powerful digging to effortless positioning, DEVELON excavators are built to help you do more work in less time. Add in our superior standard warranty and local dealer support and you’ll conquer every challenge with confidence.

See how we stack up.

Matt Quinnell of Advanced Wall Structures, a retaining wall construction contractor based in Minnesota, uses Engcon tiltrotators paired with DEVELON excavators, including the DX140LCR, to construct boulder retaining walls. Engcon’s EC-Oil automatic quick coupler system enables quick switching between attachments, such as grapples, buckets, and compactors, empowering one operator with one machine to quickly execute several different tasks on the job site.

The zero-tail-swing CX85E is designed for work in confined spaces. Weighing 19,467 pounds (8,830 kilograms), it is powered by a 72-hp diesel engine and delivers the hydraulic performance needed for digging, lifting, and loading in residential, utility, and urban applications. The fixed-boom design facilitates full rotation close to structures for improved access where larger machines cannot operate.

A comprehensive hydraulic package includes standard auxiliary, drain-to-tank, and quick-coupler circuits for operating a variety of attachments, including buckets, thumbs, hammers, and grapples. Electro-hydraulic controls allow operators to adjust lift and tilt responsiveness to match specific tools or job site conditions.

Inside the cab, a 7-inch LCD monitor, ergonomic joystick controls, and a heated air-suspension seat enhance comfort and precision. Maintenance access is simplified through wide service compartments, swing-out panels, and a tilting cab.

READY TO EFFICIENTLY

The TB395W is Takeuchi’s first wheeled excavator available in North America. It weighs 23,424 pounds when equipped with outriggers and a blade and is powered by a 114-hp Tier 4 Final engine. A closed-loop, load-sensing hydraulic system delivers smooth control of the work equipment and a wide range of hydraulic attachments. The TB395W is equipped with three auxiliary circuits that cater to different hydraulic requirements. The primary circuit delivers 32 gpm, the secondary circuit provides 14.5 gpm, and the third auxiliary circuit is designed for use with a hydraulic quick coupler.

The TB395W features two steering modes, 2WS (two-wheel steering) and 4WSC (four-wheel with crab steering). A two-piece boom with a long arm allows for greater clearance between the bucket and dozer blade. This design allows the operator to pull the bucket all the way back to the dozer blade.

With Auto Cruise operators can set and adjust their travel speeds with a toggle switch; Auto Cruise is also designed for use with attachments that require a consistent, repeatable travel speed, such as a mulcher, mower, or trencher.

The 25,000-pound DX100W-7 is compact, speedy, and agile for navigating cramped job sites and travelling between projects. It is equipped with three steering models, including two wheel, four wheel, and four wheel crab, and four work modes, including One-way mode, Two-way mode, Digging mode, and Lifting mode. Four power modes, including Power+ mode, Power mode, Standard mode, and Economy mode, allow operators to tailor machine power to the task.