Get smooth, more responsive control with Hyundai's EPFC (Electric Positive Flow Control), hydraulic flow work modes, designed to accommodate operator preferences, specific applications, and attachments.

See better with a raised, 8’ 2” elevating cabin that provides ideal visibility when loading and unloading trucks and containers in scrap and waste yards.

Cummins engine, ZF axles and transmission, Kawasaki MCV and pump provide the industry leading assurance along with 3-yrs / 3,000 hours of factory warranty.

Side bumpers, AAVM (All Around View Monitoring), 2nd monitor, rear radar, air vent seat and many others ensure safety and comfort for your operation.

No wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, or na.hd-hyundaice.com.

innovation, and industry progress.

Read more on page 18.

EDITOR IN CHIEF Kaitlyn Till ktill@baumpub.com 604-291-9900 ext. 330

EDITOR Slone Fox sfox@baumpub.com 604-291-9900 ext. 335

SENIOR WRITER Meghan Barton mbarton@baumpub.com 604-291-9900 ext. 305

ASSOCIATE PUBLISHER/ VICE PRESIDENT OF SALES Sam Esmaili sam@baumpub.com 604-291-9900 ext. 110

ADVERTISING PRODUCTION MANAGER Tina Anderson production@baumpub.com 604-291-9900 ext. 222

DESIGN & PRODUCTION Morena Zanotto morena@baumpub.com 604-291-9900 ext. 325

PRESIDENT/PUBLISHER Ken Singer ksinger@baumpub.com 604-291-9900 ext. 226

VICE PRESIDENT/CONTROLLER Melvin Date Chong mdatechong@baumpub.com

FOUNDER

Engelbert J. Baum

Published by: Baum Publications Ltd. 124 - 2323 Boundary Road Vancouver, BC, Canada V5M 4V8

Tel: 604-291-9900

Toll-free: 1-888-286-3630 Fax: 604-291-1906 www.baumpub.com www.recyclingproductnews.com

Toll-free: 1-866-764-0227 email: rpn@mysubscription.ca @RecyclingPN

FOR ALL CIRCULATION INQUIRIES

Subscription: To subscribe, renew your subscription, or change your address or other information, go to: https://www.recyclingproductnews.com/ mysubscription/subscribe

Recycling Product News is published six times yearly: January/February, March/April, May/June, July/August, September/October, November/ December. Advertising closes at the beginning of the issue month.

YOU

Do you have a story, equipment, or technology innovation, commentary, or news that our readers in the recycling industry should know about? Drop us a line any time.

Contact: Editor Slone Fox at sfox@baumpub.com or 604-291-9900 ext. 335

Recycling Product News accepts no responsibility or liability for reported claims made by manufacturers and/or distributors for products or services; the views and opinions expressed are those of the authors and not necessarily those of Baum Publications Ltd.

We acknowledge the financial support of the Government of Canada.

Copyright 2025 Baum Publications Ltd. No portion of this publication may be reproduced without permission of the publishers. Printed on paper made of FSC®-certified and other

Return undeliverable Canadian addresses to: Circulation Dept., 8799 Highway 89, Alliston, ON L9R 1V1 email: rpn@mysubscription.ca Toll-free: 1-866-764-0227

For multi-purpose vehicles operating in municipality and maintenance applications, BKT has designed MULTIMAX MP 540. Thanks to the All Steel casing, MULTIMAX MP 540 enables to carry heavy loads during on and off-road applications. Another key feature is the block pattern design, that provides outstanding stability and durability to this tire.

Joe Dias

Eastern Zone Manager

Directeur Régional, Est du Canada

BKT Tires (Canada) Inc.

Cell: 514-792-9220 Web: www.bkt-tires.com

As it turns out, even 384,000 kilometres from Earth, taking out the garbage is an unavoidable chore. As NASA gears up for a long-term presence on the moon as part of its Artemis program, it faces an age-old question: what do we do with all this trash?

To help tackle this, NASA launched the $3 million LunaRecycle Challenge. The idea is to develop systems that can turn mission waste into something useful right there on the moon without having to transport it back to Earth.

Back in June, the agency announced the first round of winners, showing off some early-stage concepts that could change how we deal with space waste. Packaging scraps might become raw material for 3D-printed tools, for example. Wornout clothing could be reprocessed into new textiles. Leftover experiment materials might be transformed into materials for future repairs. The ultimate goal is to recover not just physical materials, but also resources like oxygen, water, and metals which are all essential for long-duration survival.

What I find especially interesting is how this feeds back into our own industry. The technology being developed to recycle in space has real implications for the recycling world here on Earth. The same closed-loop systems that help astronauts reuse materials could one day make recycling more efficient in remote areas or disaster zones.

We’re also seeing the inverse: recycled materials from Earth are being engineered into components durable enough to withstand outer space. Aluminum alloys recovered from scrap, recycled carbon fibres, and reclaimed rare earth magnets are already deeply embedded in aerospace manufacturing. They’re being used in airframes, engine housings, brackets, and structural components. These aren’t secondary, low-risk parts. These are critical systems, built from scrap and performing at a high level.

Space agencies and commercial aerospace manufacturers are rethinking every stage of the material life cycle, too. Whether it’s building launch components from recycled metals or designing spacesuits with end-of-life recycling in mind, the waste

The lessons learned on the moon about efficiency and designing smarter systems will inevitably feed back into how we build our cities, infrastructure, and industries here on Earth.

loop is tightening. Recycling is no longer just about managing materials once they’re discarded — it’s about designing with recovery in mind from the very beginning.

This is where space recycling loops back into something bigger. The lessons learned on the moon about efficiency and designing smarter systems will inevitably feed back into how we build our cities, infrastructure, and industries here on Earth. Because if we can recycle in space, there’s no excuse for not doing a better job of it down here.

SLONE FOX Editor

sfox@baumpub.com

With the Eggersmann Recycling Technology product lines of screens, shredders and self-propelled windrow turners, EggersmannNorthAmericaInc.providesleadingtechnologyofmobileandstationaryrecyclingequipmentforalmost all kinds of applications where shredding, screening or turning is required. The company pays attention to the customer’sneedsandprovidesinnovativesolutionsbysupplyingfullsupportandpartsavailability.Ourgrowingdealer networkthroughoutNorthAmericatakescareofourcustomersandrepresentsourequipmentlinesintheirterritories.

O’Mara

Phone:(517)-206-4450

E-Mail:somara@aisequip.com

MI

Booe Phone:(308)-991-9285 Email:pbooe@booemachinery.com

Phone:(443)-883-0325

(317)-448-0414

dloughran@iegproducts.com

jesse@columbusequipment.com

Doğa PET, a new recycling venture by Doğa Holding, will use TOMRA Recycling’s sensor-based sorting solutions to produce high-quality PET flakes and rPET granules suitable for food and textile applications.

Located in northwestern Turkey, Doğa PET’s plant currently processes more than 4,200 metric tons of PET bottles monthly, producing 1,000 metric tons of PET flakes and 2,000 metric tons of rPET granules. Depending on requirements, the flakes are used for PET sheet production, while the rPET granules are mainly aimed at bottle-to-bottle recycling and high-quality textile applications. The company plans to export its recycled products, primarily to European countries.

Doğa PET is required to prove that less than five percent of the input material for its washing process consists of nonfood-grade PET to produce food-grade pellets. To meet this requirement and enhance material recovery across its sorting lines, the company has invested in a waste analyzer that uses cameras for real-time material analysis and classification at key points in the sorting plant. It continuously monitors and analyzes the quantity of non-food-grade PET bottles destined for the washing line.

By providing data per batch or shift, the analyzer enables Doğa PET to certify the food-grade quality of material from each specific production period, offering crucial reassurance to both its customers and relevant certification bodies.

New research by Novelis and TOMRA Recycling highlights the transformative impact of the latest sorting technologies on aluminum scrap, outlining the business opportunities these innovations present for aluminum recyclers and processors.

Experts examined the typical challenges in aluminum recycling and how the latest technologies — X-ray transmission (XRT), dynamic LIBS, and deep learning — are optimizing sorting processes, enhancing the purity of aluminum scrap fractions, and creating new market opportunities.

A key takeaway from the collaboration is the critical need to maximize both the utilization of aluminum scrap and the capacity for high scrap input in production and recycling processes. Success hinges not only on incoming material quality, but also on effectively generating the necessary scrap qualities. Consequently, material quality is emerging as a central focus in product development and operational strategies.

TOMRA and Novelis also shared findings from various results conducted at TOMRA’s Test Center and in the field, which showed a successful reduction of individual elements in Twitch using different sorting technologies. The optimal sequence for the best overall results was found to be XRT first, then deep learning, followed by dynamic LIBS. From 100 percent Twitch — a widely available yet challenging scrap type due to its complex composition — 40 percent of wrought aluminum was successfully extracted as exceptionally highquality 5xxx and 6xxx alloys. The test results further highlight the future potential for recovering a broader range of aluminum alloys, including the 2xxx, 3xxx, 7xxx, and 8xxx series.

INSIDE ONE OF THE WORLD’S

NOVA Chemicals has opened SYNDIGO1, its first mechanical recycling plant, in Connersville, Indiana. The facility is one of the world’s largest dedicated to polyethylene film recycling. Once fully operational, SYNDIGO1 is expected to repurpose 145,000 bales of plastic film annually and produce more than 110 million pounds of recycled polyethylene by 2026. The plant has also received certification from the U.S. Food and Drug Administration and GreenBlue, ensuring the recycled resin meets safety and sustainability standards.

Spanning 450,000 square feet, SYNDIGO1 is equipped to process a large volume of end-of-life polyethylene film. The recycled material includes recycled linear low-density polyethylene (rLLDPE) suitable for both food and non-food packaging. The recycled rLLDPE is processed into high-quality pellets used in applications ranging from trash can liners to food-grade packaging.

To ensure a consistent and clean input stream, SYNDIGO1 partners with major retailers and distribution centres across the country to source back-of-store polyethylene film. The facility processes an average of 400 bales of film per day, or about 14,000 bales per month. Over the course of a year, the volume diverted from landfills is equivalent to filling four professional football fields to the top of the goalposts.

The facility will support approximately 125 local jobs and play a key role in reducing landfill-bound plastic waste. Plastic film collected from residents, businesses, and commercial partners will be processed into 100 percent post-consumer recycled polyethylene, helping meet growing demand for sustainable packaging materials.

A recent survey by NOVA Chemicals also found that 75 percent of consumers believe companies should increase the use of packaging made from recycled materials, a sign that sustainability is now a key driver in purchasing decisions.

HD Hyundai will merge its construction equipment divisions to create a new company, tentatively named HD Construction Equipment, effective January 1, 2026. The merger will combine HD Hyundai Infracore (DEVELON) and HD Hyundai Construction Equipment. The two companies currently operate independently in North America through distinct dealer networks. The independent brand and dealer network structure will remain in place, and the Hyundai and DEVELON brands will continue to coexist.

Pending shareholder approval and regulatory review, the

merger will create a stronger global construction equipment business while maintaining the success of DEVELON and Hyundai in North America. The advantages of merging the two companies include providing greater price competitiveness, speeding up innovation in smart and electrified equipment, enhancing supply chain and product quality, expanding aftermarket support, and growing the product lineup from compact to ultra-large machines.

DEVELON North America has also appointed a new CEO, Woohyun Kim, to lead heavy and compact construction equipment. Kim brings extensive experience in leadership, sales, and finance to his new role.

The Association of Plastic Recyclers’ new initiative, Recycling in Action, increases visibility into the plastic recycling process as well as its economic and environmental benefits.

Material recovery facilities across the U.S. opened their doors to the public for tours and information sessions to showcase what happens after recyclables are picked up from the curb. This shows the public how manufacturing products with recycled plastics instead of virgin materials reduces the reliance on fossil fuels, uses less energy, and cuts greenhouse gas emissions.

cling facilities to the casting of major automakers. REPURPOSED traces the life cycle of aluminum in places like Toyota’s manufacturing plant in Troy, Missouri, and Missouri Smelting Technology, a key supplier to the automotive industry. With each stop, the series demonstrates how recycled aluminum is not only more sustainable than virgin material but essential to making engine blocks, transmission housings, and wheels found in millions of cars on the road today.

Sierra International Machinery has launched season three of REPURPOSED. The third season of the documentary series is hosted by recycled metals advocate and industry leader John Sacco, who takes a deep dive into the innovations and advancements driving the sector. The newest season, REPURPOSED: Aluminum, takes viewers deep inside the critical, high-stakes role that recycled aluminum plays in powering the U.S. automotive industry, from recy-

Autocar Trucks president, James “Jimmy” Johnston, has been inducted into the National Waste and Recycling Association Hall of Fame. Johnston has been an active member since 1987 and has led Autocar Trucks since 2003.

Robotics manufacturer Glacier has completed a $16 million Series A funding round. The investment caps a breakthrough period for the company, which has expanded its presence across the U.S. in major markets like San Francisco, Los Angeles, Chicago, Detroit, and Phoenix. The investment will accelerate Glacier’s nationwide deployment of AI recycling robots, expansion of its team, and continued innovation in product development.

Bulk Handling Systems (BHS) has been commissioned to design, manufacture, and install the NextGen Integrated Processing System at the Sunnyvale Materials Recovery and Transfer (SMaRT) Station as part of a $34.5 million contract. The NextGen System replaces existing equipment with a modern high-efficiency processing line capable of handling 100 tons per hour of municipal solid waste and 20 tons per hour of source-separated recyclables.

STADLER Anlagenbau has appointed Julia Stadler as cochief executive officer. Julia will strengthen STADLER’s long-standing tradition of family leadership. The leadership team now consists of two co-CEOs, Willi and Julia Stadler, along with CFO Claus Maier. The team combines generational experience and innovation, ensuring a unified strategic vision.

Julia Stadler joined STADLER in 2023 and has served as chief digital officer for the past two years. In this role, she has led the company’s digital transformation, driving initiatives in automa-

tion, integrated data systems, and AI, positioning STADLER for long-term global competitiveness. Her leadership in this role, combined with her prior international consulting experience, has equipped her with a deep understanding of global business dynamics, making her well-prepared to assume the role.

Bridgestone has brought an entirely new tire concept to the market, made with 70 percent recycled and renewable materials throughout the supply chain. The recycled and renewable demonstration tire is based on the Bridgestone M870, a high-scrub, all-position radial waste and recycling tire specifically designed for urban waste collection fleets. The tire uses circular synthetic rubber, like butadiene and halobutyl rubber, circular carbon black, and natural rubber.

Goodbye envelopes, wrapping paper and brown paper bags. GAINnext™ is a game-changing solution that utilizes deep learning technology to produce clean, high quality recovered paper for recycling.

Brandt’s BMH60A material handler is designed to meet the demands of North American scrap, steel, and recycling operations with a machine that’s locally sourced and supported. Purpose-built for heavy-duty applications, the BMH60A delivers the power, uptime, and efficiency needed across dynamic job sites. Its boom and arm are engineered for precise scrap handling, while steel hydraulic lines throughout the machine boost durability and extend service life.

The BMH60A material handler is built with John Deere components which makes it easier and faster to source and replace wear parts. Additional features include rapid cycle times that allow for faster work and an enhanced energy system that incorporates auto-idle and shutdown that maximizes fuel efficiency. Along with the ultra-configurable straight boom and dipper-style (droop nose) arm, the sensitive joystick steering allows the operator to steer the machine with a high level of accuracy.

Full perimeter handrails on top of the machine and cab platform have clear ground access on all four sides, allowing for secure maintenance on the go. The dual underslung boom and arm cylinders with anti-fracture check valves prevent load drop when moving heavy materials like steel and other scrap metal materials. Removable arm hydraulic line guarding allows for easy attachment switching while protecting lines. Factory-programmed rotary arm encoders ensure the grapple doesn’t hit the cab while working.

With easy access and ergonomic machine controls, comfort is customizable for every operator and every site while also reducing hand movement and daily fatigue. Heated and cooled adjustable air ride seats keep the driver comfortable and safe. The cab riser moves the operator up to allow for clear sightlines into rail cars or trailers, enhancing visibility when moving large materials. The standard rear and boom-side cameras minimize operator blind spots, and dedicated view screens eliminate the need to toggle between camera views.

RICHARD S. BURNS & CO. SHOWS THAT RECOVERY AND TRANSPARENCY CAN GO HAND IN HAND

BY SLONE FOX, EDITOR

Richard S. Burns & Co. built its business on doing things the right way, long before LEED points, zero-waste targets, or third-party certifications became standard practice. Since the 1960s, the Philadelphia-based company has grown from a one-man cleanout and hauling operation into a full-scale construction and demolition (C&D) recycling facility capable of processing up to 1,500 tons of material every day. The company also offers a dumpster service supported by its own fleet of trucks to handle pickups and deliveries.

Earlier this year, the Construction & Demolition Recycling Association (CDRA) named Richard S. Burns & Co. Recycler of the Year, recognizing leadership in diversion, innovation, and industry progress. But what does it really take to earn that title?

One of Richard S. Burns & Co.’s standout innovations is the company’s TOMMYcart system, a barcoded cart-based collection method that allows for precise tracking, clean collection, and enhanced diversion analytics. Here’s how it works:

• The company delivers barcoded TOMMYcarts to construction or demolition sites to collect commingled recyclable materials.

While most facilities have shifted toward automation, Richard S. Burns & Co. has doubled down on manual sorting. After trying conveyor systems in the 1990s, they found that as they pushed more material through, recovery rates dropped and contamination rose — so they returned to hand sorting.

“You’re destroying the material, and then you’re trying to get clean material. The analogy is kind of like you’re making beef stew and then trying to get a sirloin at the end. It’s just not going to work,” says owner Allen Burns. “Our cardboard got so dirty we could barely sell it. We almost had to pay to get rid of it. And our plasterboard just turned to dust.”

The process proved inefficient. Contamination stayed high, and materials were often handled more than once, adding unnecessary cost and complexity.

“After a long enough period of time — and I’m a slow learner, so maybe 20 years — we said, hey, rather than buying all this equipment, just sort it on the ground,” says Burns. “We did so much better.”

That decision led to the development of a manual ground-sorting system using “Sortie Carts” — bins reminiscent of giant wheelbarrows, which are moved directly to the appropriate piles for processing. Burns says this approach has resulted in a contamination rate as low as four percent.

You’re destroying the material, and then you’re trying to get clean material. The analogy is kind of like you’re making beef stew and then trying to get a sirloin at the end. It’s just not going to work.

Allen Burns

Owner, Richard S. Burns & Co.

• Commingled materials are placed directly into the carts by workers on site.

• Full carts are collected and transported to the recycling facility in standard 26-foot box trucks. A set of 21 TOMMYcarts can replace a traditional 30-yard dumpster.

• Upon arrival, the barcode on each cart is scanned to identify the job site, linking each commingled load to its origin for job-specific reporting.

• A Richard S. Burns & Co. employee hand sorts the contents into scaled bins for specific recyclable materials like wood, metal, or drywall.

• The weight of each recovered material is recorded and linked back to the original ticket using the cart’s barcode data. Transparency is a core tenet of Richard S. Burns & Co., especially when it comes to diversion rates. The company achieves up to 90 percent diversion on its TOMMYcart line for new construction projects by using a sorting method that challenges today’s industry norms.

The TOMMYcart line at the Richard S. Burns & Co. facility recently earned a Recycling Certification Institute (RCI) certification, making it the first company in Pennsylvania — and one of the first in the U.S. — to do so. RCI certification is becoming increasingly important for recyclers working on LEED projects, especially under the newest v5 standard.

To earn a credit under LEED v5, a project must use a recycling facility certified by a third party. This is where RCI plays a key role by providing independent verification of diversion rates through strict reporting protocols, transparent data tracking, and on-site evaluations.

Promoting the TOMMYcart system has involved more than launching a new product — it has meant shifting a mindset. “It’s a cultural change for customers. Going from dumpsters to carts, it’s a whole different concept,” says Burns. “It took us probably about a year to get some of our customers educated and trained on how the carts work versus dumpsters. It’s a little bit more involved.”

Burns views RCI certification as a way to distinguish itself in the market, using it both to build credibility and as a key selling point. Being RCI certified gives them an edge, and not only supports their diversion claims but also makes them more appealing to those seeking an extra point.

Burns isn’t shy about sharing his perspective on current C&D recycling reporting. In his view, much of the system still relies heavily on trust rather than independent verification. He says that some recyclers have shifted responsibility to customers for separating materials instead of building more robust sorting systems.

“If you’re going to teach your customer how to separate the stuff, what does he need you for? He can just go to the cardboard guy or the iron guy directly. You’re supposed to bring that expertise to the table,” says Burns.

Burns is working to prove that high recovery rates and traceability can be achieved without outsourcing the job, and sees TOMMYcart’s RCI certification as the first step toward wider standardization in C&D recovery. By digitizing and barcoding more of the facility’s operations, Burns plans to certify additional processes, like the Sortie Carts, and eventually the entire facility.

Rather than building a national footprint alone, the company is looking to partner with like-minded recyclers who want to adopt the system. TOMMYcarts have recently been deployed in Chicago, IL; Austin and San Antonio, TX; Pittsburgh, PA; and Nashville, TN, with interest from other major markets across the U.S. Burns hopes this will push the industry away from visual reporting and toward more verifiable diversion tracking, changing what responsible recovery looks like in the industry.

This focus on accountability and quality also extends to how the company manages its workforce. “We have a hundred people here, and we treat everybody like family. We’ve got guys that have been here 35 to 38, or maybe even more, years,” says Burns. “There’s not much attrition here. When people come aboard and they’re good, and if they don’t get fired, very rarely do we get people who want to leave.”

Many employees have worked at the company for decades, moving up from entry-level sorting roles into skilled trades like welding, mechanics, and construction through in-house training and trade school support. This investment translates into a low-turnover, high-trust environment where employees are empowered to take ownership of their roles.

The manual sort model creates hands-on roles that require skill and accountability, making employees a key part of the company’s success. With more eyes on the material, there’s greater engagement across the board, and employees are directly involved in maintaining both quality and safety.

“We don’t micromanage people, and we’re not standing over people. You don’t have a quota, you don’t have to pick so much per hour or anything like that,” says Burns. “We understand guys have bad days. Some days they do better than they did the day before. Sometimes they’re having a bad week. As long as everything gets done, we’re pretty good with it.”

That practical mindset guides how Richard S. Burns & Co. tackles environmental responsibility, focusing on solutions that are effective and sustainable without added complexity. Rather than investing in heavy infrastructure, the company emphasizes simple, durable systems that last.

Many of their TOMMYcarts and other equipment have been in use for over a decade without needing replacement. Built for longevity, the carts reduce waste, conserve materials, and lower the environmental costs associated with manufacturing new equipment.

The facility also operates with a lean fleet of box trucks instead of specialized or oversized vehicles, keeping transportation emissions and fuel use low. Heavy machinery like loaders and excavators is used sparingly. The TOMMYcart system itself is also designed with emissions in mind: while roll-off

containers require large, fuel-intensive trucks, TOMMYcarts are hauled using standard box trucks. This smaller equipment footprint continues inside the facility, where material flow is managed with minimal machinery and greater human oversight.

Design also plays a major role in keeping workers safe. Safety is built into the daily workflow, starting with manual ground sorting. This method allows employees to work at a steady pace, with full visibility and hands-on control over the materials they’re handling. Paired with a company-wide focus on consistency rather than quotas, this approach has helped Richard S. Burns & Co. maintain a low workers’ comp rate of around one.

That same attention to safety extends to the equipment itself. TOMMYcarts are built with sealed steel to prevent leaks and spills, reflective tape for improved visibility, and floor stops to keep carts stable during loading and unloading. It’s designed with daily use in mind, balancing durability with safety to create a system that protects both people and materials.

The company is continuing to develop its processes with the goal of achieving full-facility RCI certification and expanding tracking to its Sortie Carts to match the TOMMYcart system. Richard S. Burns & Co.’s approach combines practical innovation and long-term focus, aiming to scale its systems while maintaining accountability.

The recognition of Recycler of the Year goes beyond a title: it confirms that leadership in recycling can be achieved without sacrificing transparency or care. It’s about creating effective systems, sharing results openly, and encouraging higher standards across the industry. RPN

2.9 M square feet of exhibits / 139,000 attendees / 2,000 exhibitors / 150 education sessions

2.9 M square feet of exhibits / 139,000 attendees / 2,000 exhibitors / 150 education sessions

BY CLIFF HOPE

The catalytic converter recycling industry, long defined by metal recovery for end-of-life dismantling, is entering a new phase — one that builds on the traditional model while offering a new part to sell.

Accurate Recycling’s recently launched Certified OEM Converter Program is fully operational with live inventory available to the automotive recycling sector. This development reflects a broader shift within the industry: converters are no longer seen exclusively as scrap commodities. Select units can now be tested, cleaned, and recertified to meet EPA standards, making them suitable for resale as functioning, emissions-compliant auto parts.

Historically, the value of catalytic converters was tied directly to their platinum group metals content. This remains a key part of the industry and continues to serve recyclers well. However, this new program adds an additional layer of opportunity by introducing a compliance-backed resale path for converters that meet strict criteria.

The model is not intended to replace scrap-based refining, but to enhance it by identifying and isolating converters that have remaining life and meet EPA recertification requirements. These units are restored to a resale-ready condition and are catalogued in a virtual inventory system, allowing them to be sold similarly to other used OEM parts.

Under the United States’ Title 40 CFR Part 85, Subpart V of the Clean Air Act, the sale or installation of used catalytic converters is only legal if the unit is properly tested, cleaned, and recertified to meet original emissions standards. Accurate

Recycling, in partnership with its certification and testing providers, is currently the only entity operating under an EPA-approved recertification process.

Each converter in the program is:

• Sourced from known, traceable end-of-life vehicles.

• Matched to a vehicle application via VIN-based identification.

• Cleaned, tested, and labelled to verify EPA compliance.

• Added to a national inventory system with fitment and part number data.

This creates a verified chain of custody and ensures compatibility with the vehicles for which they are recertified.

A key feature of the program is the use of VIN data to identify donor converters before removal. This approach ensures regulatory compliance and enables recyclers to better assess whether a converter should be directed to the scrap stream or held for recertification and resale.

Industry observers note that this method also has potential spillover effects. By focusing on VIN-specific components, recyclers may also begin to identify other high-value OE parts suitable for resale, further expanding the range of what is salvageable beyond converters.

With certified units now catalogued in a cloud-based inventory system, the program enables easier part matching, ordering, and fulfillment. The goal is to integrate converters more seamlessly into the broader used auto parts market.

This shift positions catalytic converters as legitimate components in resale channels historically reserved for engines, transmissions, and body parts, backed by full emissions compliance, part-level documentation, and warranty.

Some recyclers in the industry are advocating for converters to fall under the right to repair law so they can be sold without proper testing. It is critical to consider that converters are not like any other mechanical part. Without the right tools and an EPA-certified process, recyclers are asking for trouble by selling a used, untested converter.

The program creates new legal resale opportunities that avoid the pitfalls of an untested unit. The Environmental Protection Agency has reaffirmed that selling used converters without proper testing and recertification remains a federal violation, carrying penalties of up to $25,000 per occurrence.

Common risks of uncertified converter sales include:

• High failure rates and emissions compliance issues.

• Fitment problems due to a lack of labelling or part tracking.

• Legal liability for non-compliant installations.

• Damage to brand reputation among customers and repair networks.

The Certified OEM approach seeks to address these concerns through rigorous quality control, documentation, and compliance.

This development marks an important milestone in the maturation of the converter recycling industry. By offering a dual-path mode — metal recovery for most units and certified resale for others — recyclers and dismantlers can better align with both environmental goals and emerging revenue opportunities.

As more focus is put on environmental regulations, aftermarket converters are a sub-performing product. They provide only 10 percent of the emissions performance of the OEM units and often don’t even turn off the check engine light. With this new alternative, Certified OEM converters will become an increasingly important option for businesses looking to stay ahead of compliance and value trends.

HOPE is the national sales executive at Accurate Recycling.

Tailored to your material streams

U.K. SECURES BETTER TARIFF TERMS AS EU FACES CHALLENGES UNDER NEW U.S. TRADE DEAL

BY MAYURI PHADNIS

On the heels of the U.S.-U.K. deal, the U.S. government signed a trade deal with the EU to ease tensions. Their terms, however, differ starkly, with the EU metal industry getting the shorter end of the stick. The baseline duties for the U.K. stand at ten percent versus 15 percent for the EU.

The U.S.-U.K. trade agreement has offered more immediate tariff reductions, albeit on limited volumes of goods. In contrast, the U.S.-EU agreement leaves in place substantial tariffs, with ongoing discussions of future reforms.

Although both deals are influenced by the shared goal of addressing Chinese overcapacity, EU metals exporters currently face a significant competitive disadvantage compared to their U.K. counterparts.

In the deal signed with the U.K. in May, the U.S. government reduced car export tariffs from 27.5 percent to 10 percent. Meanwhile, 10 percent tariffs on engines and aircraft parts were removed, benefitting the aerospace sector. The removal also aided companies like Rolls-Royce to become more competitive, according to a statement released by the U.K. government.

For steel and aluminum and their products, the U.S. had plans to set tariff-rate quotas for items originating from the

U.K. These quotas were proposed to be in line with the terms outlined in the Economic Prosperity Deal. Products exceeding these quotas or failing to meet specified requirements will remain subject to the current Section 232 tariffs. The deadline for the deal was set at July 9. However, the two countries were unable to finalize the deal, keeping the existing 25 percent tariffs in place.

Gareth Stace, director general of UK Steel, noted that keeping the tariff at 25 percent benefits shipments already underway, which might have otherwise faced increased charges. However, Stace emphasized ongoing uncertainty about the timing and final tariff decisions, warning that U.S. buyers may hesitate to place new orders from U.K. suppliers. He stressed the urgency for the U.S. and U.K. to finalize the May agreement to remove tariffs fully, especially given the challenging conditions facing the U.K. steel industry.

In 2024, the U.S. represented a crucial export destination for U.K. aluminum, making up 10 percent of the U.K.’s total aluminum exports and valued at £225 million. Members of the Aluminum Federation (ALFED) have observed early indicators of market disruption, such as a clear reduction in order volumes from the U.S., worries about losing contracts, and fears that semi-finished aluminum products that were meant to be

shipped to the U.S. might instead be redirected to the U.K. market. These developments signal significant challenges ahead for U.K. aluminum producers amid changing trade dynamics.

Meanwhile, the U.S. government has kept the tariffs on steel and aluminum imports from the EU unchanged at 50 percent. Other changes, however, include the exemption of airplanes and aircraft parts from any tariffs.

Beyond steel-specific measures, the general 15 percent tariff on EU exports, previously just 2.5 percent, is likely to impact steel demand indirectly. The association added that steel-intensive industries, including automotive and machinery manufacturing, stand to lose heavily. In 2024, the EU exported around 760,000 vehicles to the U.S., representing roughly one million metric tonnes of steel content, much of which now faces a tougher tariff barrier, according to the European Steel Association (EUROFER).

Axel Eggert, director general of EUROFER, indicated that while the effects on the EU steel sector are expected to remain significant, there is optimism regarding potential collaborative efforts between the EU and the U.S. to address the harmful spillover consequences caused by the global steel overcapacity affecting both markets.

European Aluminum believes that the deal indicates a possibility of a reduction in tariffs and the introduction of a quota system for steel and aluminum imports. However, specific details on the implementation timeline, the exact tariff reductions, and how the quota system will operate have not yet been clearly outlined.

In 2024, the U.K. exported 180,000 metric tonnes of semi-finished and finished steel to the U.S., worth £370 million, accounting for seven percent of the U.K.’s total steel exports by volume and nine percent by value, according to UK Steel.

The country exported 300,000 metric tonnes, or £490 million worth of steel to the U.S. in 2017 before Section 232 tariffs were imposed in 2018.

The U.K. exported an average of 200,000 metric tonnes (£320 million) over 2018–2021. The system of tariff rate quotas agreed by the U.S. and the U.K. in 2022 boosted exports slightly to 235,000 metric tonnes (£517 million).

By then, the EU steel industry had already lost around one million metric tonnes of steel exports to the U.S. since the application of Section 232 in 2018, down from 4.6 million metric tonnes to 3.8 million metric tonnes in 2024, of which around 600,000 metric tonnes were subject to 25 percent tariff. A 50 percent out-of-quota tariff would likely also eliminate those exports, believes EUROFER.

The effects of the latest additional U.S. tariffs on EU steel are already having a further destructive impact on the sector. The European Commission promised in its “Steel and Metals Action Plan” a “highly effective steel trade measure” to be presented by September 2025.

MAYURI PHADNIS is the European Markets editor and ferrous analyst at Davis Index. You can email them at mayuri.phadnis@davisindex.com.

BY MEGHAN BARTON, SENIOR WRITER

As Metro Vancouver braces for the closure of its landfill within the next seven years and rising tipping fees put pressure on contractors, a new pilot program from Light House is drawing attention to one of construction’s most overlooked waste streams: plastic.

Light House, a Vancouver-based non-profit focused on circular and regenerative practices in the built environment, launched its Construction Plastics Initiative (CPI) to tackle this growing issue head-on. “The Construction Plastics Initiative was a recognition that . . . almost no attention has been paid to plastic waste generated by the construction sector,” says Gil Yaron, managing director of circular innovation at Light House. “We wanted to investigate the scope of plastics coming from construction and demonstrate the potential for converting plastic from a waste into a resource.”

While construction waste is widely acknowledged as a significant contributor to landfills, accounting for roughly 40 percent of landfill volume in Metro Vancouver alone, plastics have largely been overlooked in favour of higher-profile materials, such as concrete and steel. Much of this plastic waste comes in the form of protective packaging: plastic film, wrappings, and tarps used to transport new materials to site.

“Up to this point, there’s been virtually no awareness about plastics in the construction sector,” explains Yaron. “Certainly no awareness of the magnitude of the amount being generated.” Without intervention, that plastic either ends up buried on-site or sent directly to landfill.

The CPI is testing a closed-loop system to capture and reuse construction plastic. For this pilot project, Light House will engage with two high-profile Metro Vancouver projects: the PNE Amphitheatre (Freedom Mobile Arch) with EllisDon and the Steveston Community Centre and Library with Scott Construction. Participating sites are required to separate all plastics at the source into dedicated bins.

From there, the material is collected and processed into plastic pellets. These pellets are then purchased by Plascon Plastics and used as feedstock for InfinaNet, a proprietary concrete void system from Infina Technologies that displaces 30 percent of concrete in slab floors.

“Suddenly this plastic, which everyone thinks is a waste product, has value,” says Yaron. “We are . . . reducing the amount of virgin material that’s required. We are eliminating waste from the construction sector. And we are putting it back into the system. Circular economics in action.”

Recognizing that construction timelines are tight and change can be disruptive, Light House designed CPI to minimize interference. A site monitor works directly with the contractor’s lead supervisor, and Light House coordinates bin pickup and downstream logistics.

“We provide a turnkey service . . . it’s really easy,” says Yaron. “Aside from the extra room for the bin, there shouldn’t be much disturbance to the site’s day-to-day operations.”

Yet the benefits extend well beyond waste diversion. The

program also generates valuable data. By tracking the type and quantity of plastics collected, CPI aims to spotlight what has so far remained invisible. This data will inform contractors, producers, and policymakers, especially as Canada’s construction sector prepares for the reporting requirements of the plastics registry in 2026.

“I think the federal plastics registry is going to make the invisible visible,” says Yaron. “Most of the industry is blind to it. It’s something that the industry just doesn’t want to deal with.” Light House strives to ensure that the CPI will represent the most comprehensive effort in Canada to date to understand the scope and impact of plastic waste on construction sites.

By demonstrating that plastics can be separated, processed, and repurposed without disrupting job site operations, CPI is building a case for industry-wide change by showing that circularity is achievable on real-world construction job sites. And while the volume of waste currently captured by the program is small, the infrastructure and the market already exist to scale.

“This is the beginning,” says Yaron. “We have the capacity to manage most plastics coming off the sites on this project. Once we establish the viability of this, and if policy follows that requires the sorting of all plastics, there is capacity. Other plastic manufacturers can handle this material.”

He also noted that the construction sector could eventually benefit financially. As with other post-consumer materials, such as PET bottles, plastic waste from construction may one day have a market value high enough to generate revenue. For now, CPI operates on a cost-neutral basis.

CPI is building a case for industry-wide change by showing that circularity is achievable on real-world construction job sites.

“At this point, [contractors] are doing it because they see the problem, they want to help, and it [doesn’t cost] them,” says Yaron. “At scale, they could actually be making some money.”

While CPI is focused on end-of-life plastic, it’s already raising bigger questions about the materials entering job sites in the first place. Yaron hopes the program’s findings will encourage contractors to pressure suppliers into reducing or rethinking plastic packaging. He says the next phase of the conversation is clear: it’s time to look upstream.

“That is the upstream generation of plastic in the first place . . . Once we show the world the crap that’s coming out of the tail end, then we say, okay, this is where it’s coming from,” he says. “Let’s get the big construction companies to have conversations with their suppliers.”

Ultimately, it’s a call for extended producer responsibility in the construction supply chain. It’s a call for a system where manufacturers design out excess packaging and also take ownership of the waste they create.

It is also estimated that 10 to 15 percent of all materials brought on site are wasted. “Contractors also need to embrace new technologies that allow them to plan better to reduce the amount of waste resulting from over purchasing materials and construction errors that generate plastic waste unnecessarily.”

“Suppliers should be taking back their materials,” adds Yaron. “Just like return programs for pallets or packaging in other industries, we need to rethink what responsibility looks like in construction.”

For Yaron and the Light House team, circularity is just one piece of a broader vision for the built environment.

“Our mission is to build smarter by reducing materials used in construction and eliminating waste in the built environment,” he says. “And to develop buildings that support the health and well-being of their occupants.”

That means changing how buildings are designed, what materials go into them, how they’re used, and what happens when they reach the end of their lifespan.

“We need to start viewing waste as a resource,” Yaron says. “It’s not just about building a structure. It’s about how this structure interacts with our environment.”

From site separation bins to reclaimed plastic pellets, the Construction Plastics Initiative is showing that circular construction isn’t just a theory; it’s a practical, scalable, and increasingly necessary evolution of the way we build. RPN

FROM CHANGING MATERIAL STREAMS TO AGING SORTERS, HERE ARE SOME SIGNS THAT IT MAY BE TIME TO UPGRADE

BY RICK ZETTLER

Maybe your recycling facility isn’t producing the same quantity of saleable product as in the past. It could be that you need to increase the yield of a certain product that is in high demand. Or possibly recyclate quality is not where it needs to be to meet your customers’ needs.

“From product quality to energy consumption to reducing maintenance, recyclers have a range of needs when considering a retrofit or technology upgrade,” explains Gleb Trofimov, area sales manager for TOMRA Recycling. “And, as suppliers, the first thing we consider is the right technical solution to meet the customer’s targets. It could be upgrading to the latest generation of optical sorter, incorporating a deep learning AI solution, or adding a sorter in the line. We consult with recyclers to make sure we offer the right solution to meet their goals.”

Today, sorting automation technology available to material recovery facilities (MRFs) and plastics recovery facilities (PRFs) is rapidly evolving. New versions of optical sorters that are just 10 years old will have updated features that can offer more granular material sorting.

“If yields are dropping, landfilling costs are rising, or manual labour costs are increasing, the facility might benefit from updated technologies or add-ons that could help improve the sort,” Trofimov adds.

Beyond improved sorting performance, looking at retrofits and upgrades to the line can help to lower long-term operating costs. Trofimov points to more recent improvements in newer machines that offer lower energy consumption and use less air. Plus, the reliability and easier maintenance designs help to improve efficiency at the facility. These combine to reduce long-term maintenance and operating costs for a better bottom line.

Optical sorters generate vast amounts of data that can be leveraged to improve overall operational efficiency. In the past, this information was tied to the individual machine, and a worker had to physically be on site to access the machine data for analysis. While this data served to help the one facility, sharing this data across multiple locations was challenging. A recycler can significantly upgrade newer sorter performance by leveraging cloud-based reporting technologies currently offered by manufacturers. “Our secure cloud-based monitoring portal, TOMRA Insight, provides near-real-time sorting data as a strategic management tool that can be safely accessed anywhere an internet connection is available,” says

Trofimov. “And this is not just one machine. The data is offered by machine, by plant, and company-wide, so it provides reporting and monitoring for all TOMRA machines.”

Sorters are now connected devices that transform sorting from an operational process into a strategic management tool. Customizable reports enable key personnel to analyze critical operational data, such as yield, throughput, and purity by sorting machine, by shift, by location, or for all facilities.

Not limited to production details, connected machines assist by reporting machine availability, performance, maintenance information, and active alarms. These alarms serve to keep recyclers ahead of potential issues and optimize sorter performance.

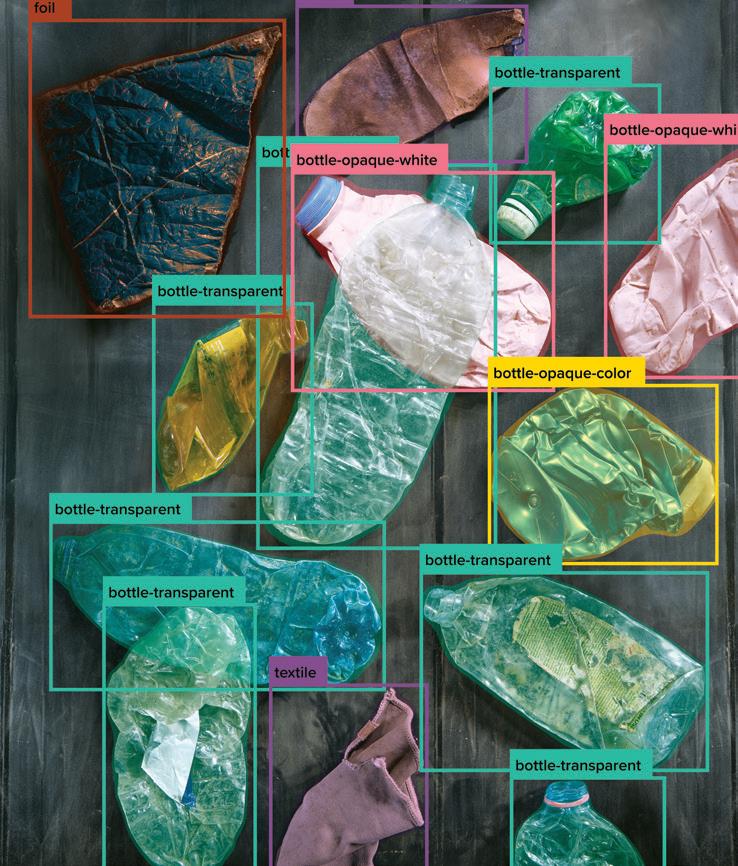

Additionally, newer deep learning artificial intelligence (AI) waste analysis tools like the PolyPerception Analyzer offer further transparency to operations with real-time material monitoring at key points in the sorting process. Every object passing under the camera is analyzed in real-time, and deep learning models quickly adapt to changes in the waste stream. Waste analysis delivers value to the facility through improving sorting efficiency, assessing true material quality for making commercial decisions, and certifying material quality for compliance.

If yields are dropping, landfilling costs are rising, or manual labour costs are increasing, the facility might benefit from updated technologies or add-ons that could help improve the sort.

Gleb Trofimov Area Sales Manager, TOMRA Recycling

AI has grabbed much attention in the recycling industry over the past few years. While AI has been used for material separation with optical sorters for decades, the deep learning subset of AI is now expanding mechanical sorting’s capabilities. The exciting trend is the pairing of these cameras and deep learning algorithms with sensor-based sorting capabilities to provide a granular sorting of materials.

“The basic understanding we need is that both are different sorting technologies, which have their own unique values,” explains Indrajeet Prasad, product manager of deep learning for TOMRA Recycling. “Near infrared (NIR) and other sensors in optical sorters do the sorting based on material types, distinguishing between, for example, polyethylene terephthalate (PET), polyethylene (PE), and polypropylene (PP) in the case of plastics. Deep learning, on the other hand, sorts based on visual information — what the eye can see.”

However, Trofimov advises consulting with the technology provider to ensure the right combination of sensors are employed. “When retrofitting, it may be that upgrading to the latest optical sorter will help to reach established targets, or it might require an additional sorting machine. We are here to help guide recyclers through the considerations to ensure they get the combination right.”

When it comes to machine retrofits, Trofimov explains that recyclers often have a triangular need. “Improvements typically focus on wanting to improve yield, purity, throughput, or a combination of all three.” He also mentions that on the back end, recyclers are looking for easier maintenance and lower energy consumption.

While AI has been used for material separation with optical sorters for decades, the deep learning subset of AI is now expanding mechanical sorting’s capabilities.

Combining the NIR sensors of units like AUTOSORT with GAINnext deep learning AI algorithms is the peanut butter cup of the recycling world that solves sorting tasks once thought difficult or impossible. It addresses several limitations of the camera-based AI solution alone when sorting key materials at the MRF or PRF.

For one, the pairing enables material to be sorted using valve-block technology much faster than robotic arms. “The arms are designed to mimic the picking action of a human, so they offer around 70 or 80 picks per minute,” says Trofimov. “Valve blocks deliver a much higher capacity, and we are seeing purity rates in excess of 95 percent at throughput rates reaching six tons per hour.”

Additionally, pairing sensor-based traditional AI with deep learning offers a more granular sort of plastics. “The camera with deep learning will see colour, shape, and texture of the material on the belt. So, it can recognize a green soda bottle or a clear water bottle, or a milk jug,” adds Prasad. “When combined with the NIR sensor of the optical sorter, we can distinguish that it’s a PET bottle with either a PET or PVC label.”

Deep learning ushers in a new era of sorting capabilities and revenue streams for the recycler, including food-grade plastics sorting, upgrading PET or paper streams, advancing the sorting capabilities for aluminum, and providing a more sophisticated sort of wood materials.

Market changes can prompt recyclers to augment their facilities with newer technologies. Several years ago, thermoforms were not as plentiful in the PET stream as they are today. If a recycler wants to sell material for bottle-to-bottle recycling, PET thermoforms must be removed from the bottles.

“You cannot recycle a thermoform into a bottle, so you need the optical sorter to detect what is PET bottle and PET thermoform,” explains Trofimov. “Just a couple of generations ago, our AUTOSORT units could not make this distinction, but sensor and algorithm updates in our latest generation AUTOSORT can separate PET bottles from PET thermoforms.”

Trofimov recalls working with a plastics recycler in British Columbia, Canada, to replace the company’s older optical sorters to assist in making its recycled plastic pellets. The upgrade to the latest sorters gives the owner real-time data to analyze the sort. Plus, the upgraded circuit incorporates deep learning AI to help further purify the PET stream.

“The owner values the information about the material that passes through the machine,” he explains.

Additionally, a solid waste management company with operations across North America recently replaced its approximately 15-year-old optical sorters at its recovery facility in Ontario, Canada, to improve the recovery and purity of its old corrugated container (OCC) product. The motive, in addition to yield, was for easier machine serviceability.

So, when is it a good time for the MRF or PRF to consider an upgrade? Trofimov says that every facility collects its own statistics and measurements to make the determination. “It could be changing material streams, or the yield of a certain product starts to wane. Normally, it doesn’t happen overnight. These decisions are made over time,” he says.

Regardless of the reason for the upgrade, Trofimov is a proponent of recyclers reaching out to the technology supplier and working together for the solution. “Recyclers have the knowledge about their operations, what is taken in, what can be sorted, and where improvements are needed,” he concludes. “Technology suppliers like TOMRA have vast application experience with machines operating around the world. We have the consultative expertise and will focus on the technical solution to get the right sensor combination to meet established targets.”

RICK ZETTLER is the owner of Z-Comm, a PR and marketing communications company that specializes in equipment coverage.

A C C E N T ® 4 7 0

DESIGNED FOR TWO-RAM BALERS

S T RONG PE OPLE . S T RONG PR ODU C TS . S T RONG T IE S .

Accent W ire Tie is the largest supplier of baling wire and wire tier technology in the recycling and waste industry. Our leading line of bale packaging equipment includes the Accent 470® W ire Tier, featured on balers around the world and the Envirobale® bagging system for solid waste containment. Accent W ire Ties’ sales and service technicians teams have hands-on experience and stay up-to-date on the latest industry trends. Accent W ire Tie has forged the strongest ties in the industry since 1986.

Four-wheel drive design for exceptional performance and reliability

Pivot-out or removable parts cartridge cutting maintenance time from hours to minutes

No mechanical or hydraulic adjustments needed, allowing for trouble-free operation

Meets ANSI, CSA standards and is CE compliant

BY MEGHAN BARTON, SENIOR WRITER

Vibratory screens are a critical component of material recovery systems, but not all screens are created equal. Beneath the motion lies an important design distinction: whether the screen is powered by a two-mass system or brute force. While both approaches aim to separate material effectively, the way they generate and manage vibration can significantly impact energy use, maintenance, and throughput, especially in demanding environments like scrapyards, C&D facilities, and MRFs.

“When you add weight to a brute force system, performance goes down,” explains Bob Huffer, director of recycling at General Kinematics (GK). “But with a two-mass system, it actually improves.”

Huffer has spent decades helping recycling operators choose the right screen for the right material stream, whether that’s high-tonnage C&D, scrap, or municipal solid waste. While both systems serve the same purpose, the design differences are substantial, and those differences show up in everything from energy efficiency and scalability to how they respond under load.

Brute force systems operate on a simple principle: a motor is mounted to a single mass, essentially a steel box, supported by isolation springs. When powered on, the eccentric motor shakes the entire unit.

“The bigger that box gets, the more energy, the more horsepower you need to drive that,” says Huffer. Additional or larger motors are required to maintain performance.

Two-mass systems take a more engineered approach. Rather than forcing vibration through a single body, they use two masses connected by springs. One mass contains the motor where the vibration is created. That vibratory energy is then amplified through springs into the second mass, where the material is handled. This configuration allows the two-mass system to operate near its natural frequency, where a minimal amount of energy is needed to do the same or more work than a brute force machine. The result is a more efficient transfer of motion and significantly lower energy demand.

“In general, you’re looking at 40 to 60 percent less horsepower [for two-mass] compared to brute force,” says Huffer.

Where the two systems really diverge is in how they respond to changes in material load. In brute force systems, increasing the weight of the load dampens the stroke, essentially reducing the amplitude of the screen’s motion. This results in reduced material movement, slower processing, and lower overall capacity.

Two-mass systems behave differently. As more weight is added, the stroke increases due to the natural frequency effect. This effect makes them better suited for high-volume or heavyload applications, such as C&D recycling, scrap processing, and mining, where material surges are common.

Two-mass systems are a good choice for large-scale, fixed recycling facilities. According to Huffer, GK’s systems can weigh upwards of 85,000 pounds and are designed to handle up to 1,400 tons per day of construction and demolition material. These installations often include custom finger screens and integrated components tailored to the plant’s material flow and space constraints.

Brute force screens are more common in compact or mobile applications, such as aggregate screening trailers or under-crusher feeders. Their simplicity makes them easy to maintain in tight quarters or when weight and space are limiting factors.

“There are still cases where brute force makes sense,” says Huffer. “It’s a simpler design with fewer components, and sometimes that’s what the site demands.”

Designed for high-throughput C&D recycling, the two-mass screen maximizes efficiency and durability in a single-unit configuration.

A two-mass vibratory screen under construction at General Kinematics showcases the company’s focus on scalable, high-efficiency recycling solutions.

Another advantage of the two-mass design is its ability to manage dynamic forces. Because the two masses move in opposite directions, they cancel out a significant portion of the vibration that would otherwise be transmitted to the foundation.

According to Huffer, this cancellation effect can reduce dynamic forces by up to 80 percent. This is a crucial benefit when installing heavy equipment on lighter foundations or in older facilities. It also minimizes the risk of vibration damage to nearby structures or equipment.

Brute force screens offer a simpler mechanical design, with fewer components and no counterbalancing mass. With fewer moving parts and a straightforward drive mechanism, brute force systems are often easier to install, troubleshoot, and maintain in compact or remote set-ups.

However, that doesn’t necessarily equate to longer life or lower maintenance over time. Brute force systems hit design limitations when scaled up, making them less suitable for larger or high-tonnage operations.

Two-mass systems, by contrast, are built for scalability. Their design allows machines to be constructed wider and longer without losing stroke or efficiency. This means operators can process more material in a single unit, increasing throughput without expanding their equipment footprint. It also opens the door to custom configurations tailored to high-tonnage applications, where brute force designs would struggle to maintain consistent performance.

When it comes to wear and maintenance, both systems are comparable, provided they’re processing similar volumes. “Wear is probably equivalent if you’re comparing the same tonnage,” says Huffer.

General Kinematics offers three primary screen designs under the finger screen category: Traditional, Free-Flow, and Velocity (formerly known as FINGER-SCREEN 2.0). Each is built on a two-mass platform but optimized for different materials and system configurations.

Traditional finger screens use a counterbalance beneath the screen to stabilize motion and are ideal for high-volume, rugged applications.

Free-Flow screens eliminate the lower conveying pan, allowing all material to drop through onto a belt. This open-deck design minimizes material buildup and simplifies maintenance, making it especially effective when processing sticky or wet fines.

Velocity screens use multiple screen bodies running outof-phase to maximize stroke and movement, making them well-suited for light or bulky materials like cardboard.

Choosing between screen types depends on feedstock, separation goals, and plant layout. “It’s about the type of material, the size you’re trying to separate, and how much volume you’re dealing with,” says Huffer.

Both systems can be used with wet or sticky materials, but the longer stroke and higher energy of two-mass systems make

them more effective in these scenarios. The increased vibratory energy helps prevent material from clumping or clogging.

When feedstock is inconsistent or surging, as is often the case in MRFs and C&D facilities, the responsive stroke of twomass systems enables them to adapt in real-time, spreading material more evenly and maintaining throughput.

For facilities that currently use brute force systems, upgrading to two-mass can offer a path to greater capacity without increasing footprint. In some cases, a plant can handle significantly more throughput simply by swapping in a two-mass system tuned to the existing space.

Huffer notes that upgrading to a two-mass system is often a natural step for facilities looking to modernize or expand. For operations aiming to boost capacity by 20 to 40 percent, switching to a different screen design can be the most effective solution.

As customer demands evolve, GK is continuing to scale its technology. In 2023, the company built its largest finger screen to date: seven feet wide and 50 feet long, weighing in at 130,000 pounds. It was developed to meet growing demand for high-throughput screening in a single unit.

Increasingly, the company is designing integrated systems that pair shredders, screens, and downstream sorting equipment into cohesive, high-efficiency workflows. According to

For facilities that currently use brute force systems, upgrading to two-mass can offer a path to greater capacity without increasing footprint.

Huffer, the shift reflects a broader trend across the industry: reducing manual labour while maximizing material recovery.

“Whether it’s through robotics, optical sorting, or better front-end screening, customers are looking for ways to reduce headcount while increasing throughput,” he says.

Designing effective recycling systems isn’t just about choosing a screen. It’s about engineering for the feedstock, footprint, and future growth. With two-mass systems, greater efficiency, foundation protection, and scaling potential are clear advantages. But in more compact or mobile applications, the simplicity of brute force still brings value. And for operators evaluating upgrades, the right screening system can be a powerful tool for addressing existing limitations without tearing up the plant. RPN

With the industry’s widest line of granulators and shredders, Herbold has a Size Reduction Solution that’s right for any application. Whether it’s clean or post-consumer materials, our systems quickly and effectively size reduce, PET waste, agricultural film, low bulk density material and even thick walled pipe. No challenge is beyond the capabilities of our equipment.

The Herbold Advantage

n Double Cross Cutting Action – Reduces Jams and Material Fines

n Adjustable Bed and Rotor Knives –Maintain Constant Cutting Circle

n Easy Access to the Grinding Chamber –Improved Maintenance, Screen Changes and Machine Cleanout

n Replaceable Armor Plating Inside the Cutting Chamber

n Faster, Safer Knife Changes – Adjustments Made in Jig Outside of Granulator

n Available Force Feed Mechanisms –Increase Throughput by up to 80% While Reducing Energy Consumption

BY MEGHAN BARTON, SENIOR WRITER

Moving on without proper post-fire assessment could have long-term operational and financial consequences.

When a lithium-ion battery ignites in a scrapyard or material recovery facility (MRF), most operators focus on the visible danger: the flames, the smoke, the rush to extinguish. But Randy Narine, president and CEO of Clean Core Research and an active firefighter, wants the recycling industry to understand a deeper truth. Lithium-ion battery fires behave differently from traditional fires and require entirely different suppression methods.

“You know, this is the biggest education point that I’m trying to get out there,” says Narine. “The fire is one piece. The structure collapse is another. The biggest concern for me is the actual chemical release; identifying what’s been exposed, cleaning it up, and mitigating that risk.”

Through extensive research, Narine and his team have confirmed what many recyclers may not realize: the combustion byproducts from lithium-ion batteries, including hydrofluoric acid, hydrogen chloride, and other volatile organic compounds (VOCs), can corrode metals, saturate protective gear, damage sensitive equipment, and even compromise the quality of outgoing recycled materials. And that’s just the beginning.

How common are lithium-ion fires becoming? “That’s the number we’re trying to get a hold of,” says Narine. “I can tell you that the fires have increased. I think the number that was

I’ve seen stuff reacting a month later. We don’t have an answer to how long it keeps acting for. It could be forever. That’s the research we’re trying to do right now.

Randy Narine

President

and CEO, Clean Core Research

given was close to 40 percent year over year [in Toronto].” That increase is attributed 100 percent to lithium-ion battery fires.

And yet, many scrapyards and recyclers continue to treat battery-related fires like any other type of fire incident.

“A lot of them aren’t even going through insurance anymore,” Narine explains. “They know if they have another insurance claim this year, their insurance is going up. So they’re not even bothering. The fire’s out, and they move on.”

But as Narine makes clear, moving on without proper postfire assessment could have long-term operational and financial consequences.

In 2024, Clean Core Research conducted an investigation following a lithium battery fire in a residential setting. The fire had been extinguished quickly, but within days, electrical panels began showing signs of corrosion, even in parts of the home that hadn’t been touched by flames. Tools rusted. Outlets degraded. HVAC systems tested positive for chemical contamination.

That same kind of hidden damage, Narine says, can occur in scrapyards and MRFs.

“The byproducts create some serious oxidation,” he explains. “And it will rust metal at an astronomical rate.”

Even worse, those byproducts can infiltrate every corner of a facility. In one case, following an e-bike battery fire in an indoor facility, Clean Core investigators found contamination levels as high as 17 grams per square metre, even 100 metres from the burn site, far above the National Institute for Occupational Safety and Health (NIOSH) working limit of 0.5. “That is dangerously deadly,” says Narine.

In line with common practice, the insurance provider did not require a comprehensive decontamination, and within days, several staff members working in the area became ill.

Narine says MRF and scrapyard operators often overlook how soot and residue from these fires cling to soft goods and sensitive materials.

“There are metal particulates, VOCs, and carcinogens that [become] embedded into fabrics,” he says. That includes gloves, coveralls, high-vis vests, seating upholstery in cab equipment, HVAC filters, and even foam packaging in incoming e-waste.

“Standard PPE laundering isn’t enough. You can’t just wipe it off,” he says. “You’re going to need proper decontamination. Otherwise, your gear is still toxic. And if you’re putting that on again the next day, you’re breathing it in.”

Narine emphasizes that the corrosive effects of lithium fire residue are ongoing. “I’ve seen stuff reacting a month later,” he says. “We don’t have an answer to how long it keeps acting for. It could be forever. That’s the research we’re trying to do right now.”

He adds that recyclers, in particular, need to understand how these fires can compromise material quality. When lithium-ion batteries combust, the corrosive byproducts don’t just settle on surfaces; they actively degrade them. Metals exposed to soot and gases like hydrofluoric acid and hydrogen chloride begin to oxidize rapidly, often within hours or days. This can result in pitting, rust, and structural weakening, rendering high-value ferrous and non-ferrous materials less marketable or entirely unusable.

Even more concerning is that affected materials may leave the facility before the damage becomes apparent. In some cases, contaminated scrap has been shipped to clients, only to be returned or rejected due to unexpected corrosion, damaging both business relationships and a recycler’s reputation. For facilities that rely on the resale of clean, high-quality recovered metals, these types of incidents can have a lasting financial impact.

And it’s not just metals. Residue from lithium fires can also compromise the integrity of plastics, rubbers, coatings, and composite materials often found in e-waste and automotive components. Without proper testing and decontamination, these materials may continue to degrade even after they’ve been processed and sold.

So, realistically, what should facilities be doing?

For Narine, it all starts with a mindset shift. “Dealing with batteries is not hard. It’s actually really easy. It’s a fundamental shift in thinking,” he says. These fires follow a different chemistry than conventional ones and demand a tailored response.

Step one is risk assessment. “A basic assessment will minimize your risk,” he says. “We come in and identify the [specific battery-related risks]. Then we create procedures for how to deal with [those risks], how to store materials safely, and how to keep them in your operation in a way that doesn’t hinder your workflow, but also doesn’t shut you down if there’s an incident.”

Containment is critical. In the case of lithium-ion battery fires, the goal is not always to extinguish the flames immediately but to prevent the spread of heat, gases, and corrosive by-products to surrounding materials and structures. Proper containment solutions can buy valuable time for safe evacuation and emergency response while minimizing the extent of environmental and equipment damage.

“The keyword is containment, not extinguishment, because most times we just let it burn out by keeping it contained,” Narine explains. “But I would never tell any company out there to have their staff do this. [Their role] is creating a safe environment for [their team] to get out and for the first responders to come in.”

After a fire, the next steps should include more than replacing damaged items or sweeping ash. Residue from lithium-ion battery fires can be chemically active long after the flames are out, and failing to address it can lead to contamination, equipment failure, or regulatory violations.

“Soil sampling is a major component of it, especially if you’ve given water to the fire,” says Narine. “Environment Canada is taking this seriously. We had one case where six dump trucks of soil had to be dug up and sent out for disposal.”

But soil is only the beginning. Recyclers should also test HVAC systems for contamination, inspect electrical panels and wiring for corrosion, and assess whether soft goods like PPE, seat upholstery, and filters need to be removed or replaced. Materials in the immediate and surrounding areas may need to be swabbed or scanned for chemical residue, even if they appear visually undamaged. Air quality testing, corrosion monitoring, and moisture level assessments are also recommended, particularly in enclosed or poorly ventilated spaces.

Narine explains that many operators are unaware that Transport Canada and Environment Canada may inspect their site after a lithium fire. “You don’t want them to start sampling, because that’s when the fines come in, and they get heavy.” In some cases, failure to act quickly or document proper cleanup can trigger long-term liability concerns.

For recyclers trying to stay operational, Clean Core Research provides detailed site assessments, cleanup guidance, and coordination support without pushing products. “We’re not there to sell anything. We’re there to work with companies. We’re trying to do the right thing and do so within their budget,” says Narine. “A basic assessment can go a long way in helping stay ahead of this.

While Narine frequently works with major manufacturers and energy clients, he’s equally committed to supporting small and mid-sized operators. “I always say, even Bob’s junkyard needs to know this stuff,” he says.

Narine urges recyclers and scrapyards to take proactive steps before a lithium-ion battery fire forces their hand. Too often, facilities only implement safety protocols after an incident. But by then, the damage is done. From risk assessments and containment strategies to proper staff training, early action is key to minimizing risk, avoiding regulatory penalties, and protecting long-term operations.

“Companies need to adapt, and they need to adapt now,” he says.

What’s the one thing he wishes every recycler and scrapyard operator understood?

“The event is not over just because the fire is out.” RPN

Boost Performance. Prevent Incidents. Lead with Confidence.