SCHUTTE

When consistent output, tight particle size control, and maximum uptime are critical, the Schutte Hammer mill RAS Dual-Stage Hammer Mill delivers. Built on decades of expertise, RAS combines a powerf mary reduction stage with a precision fine-grinding stage in one compact, production-ready system.

WHY RAS?

Single-pass systems often force a tradeoff between capacity and quality. RAS eliminates the compromise: the first stage reduces bulky feedstock, while the second fine-tunes the grind to spec, even sub-2 mm, with fewer recirculations, less handling, and lower cost per ton.

CUSTOM-CONFIGURED

Each RAS is tailored: power, rotor, screens, liners and feeders, to your material, particle size, and throughput goals.

PROVEN RESULTS

Higher throughput at target spec with predictable quality. Minimal downtime with quick-change parts and monitoring.

READY TO TIGHTEN YOUR PARTICLE SIZE AND YOUR PROCESS?

Let’s map your material, spec, and line layout to the right RAS configuration. Contact Schutte Hammermill today for a quote tailored to your production targets.

N

S T RONG PE OPLE .

S T RONG PR ODU C TS . S T RONG T IE S .

Accent W ire Tie is the largest supplier of baling wire and wire tier technology in the recycling and waste industry. Our leading line of bale packaging equipment includes the Accent 470® W ire Tier, featured on balers around the world and the Envirobale® bagging system for solid waste containment. Accent W ire Ties’ sales and service technicians teams have hands-on experience and stay up-to-date on the latest industry trends. Accent W ire Tie has forged the strongest ties in the industry since 1986.

DESIGNED FOR TWO-RAM BALERS

FE A T U RE S & B E N EF IT S

Four-wheel drive design for exceptional performance and reliability

Pivot-out or removable parts cartridge cutting maintenance time from hours to minutes

No mechanical or hydraulic adjustments needed, allowing for trouble-free operation

Meets ANSI, CSA standards and is CE compliant

FROM THE COVER

Technology plays a vital role in modern recycling by improving material recovery, enhancing worker safety, and helping facilities meet market demands through automation, AI, and advanced sorting systems that make recycling more sustainable, profitable, and scalable for the future.

EDITOR & DIRECTOR OF DIGITAL STRATEGY

Slone Fox sfox@baumpub.com 604-291-9900 ext. 335

EDITOR IN CHIEF Kaitlyn Till ktill@baumpub.com 604-291-9900 ext. 330

SENIOR WRITER

Meghan Barton mbarton@baumpub.com 604-291-9900 ext. 305

ASSOCIATE EDITOR Stephanie Bontorin sbontorin@baumpub.com 604-291-9900

VICE PRESIDENT OF SALES/ ASSOCIATE PUBLISHER Sam Esmaili sam@baumpub.com 604-291-9900 ext. 110

ADVERTISING PRODUCTION MANAGER Tina Anderson production@baumpub.com 604-291-9900 ext. 222

DESIGN & PRODUCTION

Morena Zanotto morena@baumpub.com 604-291-9900 ext. 325

PRESIDENT/PUBLISHER Ken Singer ksinger@baumpub.com 604-291-9900 ext. 226

VICE PRESIDENT/CONTROLLER

Melvin Date Chong mdatechong@baumpub.com

FOUNDER

Engelbert J. Baum

Published by: Baum Publications Ltd.

124 - 2323 Boundary Road Vancouver, BC, Canada V5M 4V8

Tel: 604-291-9900

Toll-free: 1-888-286-3630 Fax: 604-291-1906 www.baumpub.com www.recyclingproductnews.com

@RecyclingPN

FOR ALL CIRCULATION INQUIRIES

Toll-free: 1-866-764-0227 email: rpn@mysubscription.ca

Subscription: To subscribe, renew your subscription, or change your address or other information, go to: https://www.recyclingproductnews.com/ mysubscription/subscribe

CONNECT WITH US @RecyclingPN

WE’D LIKE TO HEAR FROM YOU

Do you have a story, equipment, or technology innovation, commentary, or news that our readers in the recycling industry should know about? Drop us a line any time.

Contact: Editor Slone Fox at sfox@baumpub.com or 604-291-9900 ext. 335

Recycling Product News is published six times yearly: January/February, March/April, May/June, July/August, September/October, November/ December. Advertising closes at the beginning of the issue month.

One year subscription rates for others: Canada $33.50 + 1.68 GST = $35.18; U.S.A. $40; other countries $63.50. Single copies $6.00 + 0.30 GST = $6.30; outside Canada $7.00. All prices are in Canadian funds.

Recycling Product News accepts no responsibility or liability for reported claims made by manufacturers and/or distributors for products or services; the views and opinions expressed are those of the authors and not necessarily those of Baum Publications Ltd.

We acknowledge the financial support of the Government of Canada.

Copyright 2025 Baum Publications Ltd. No portion of this publication may be reproduced without permission of the publishers.

Printed on paper made of FSC®-certified and other controlled material. ISSN 1715-7013. PUBLICATIONS MAIL AGREEMENT NO. 40069270.

Return undeliverable Canadian addresses to: Circulation Dept., 8799 Highway 89, Alliston, ON L9R 1V1 email: rpn@mysubscription.ca Toll-free: 1-866-764-0227

• 42 years of experience

FROM THE EDITOR

RECYCLING RUNS ON TECHNOLOGY

Recycling facilities are dealing with a lot right now. MRFs are juggling increasingly complex waste streams while still being asked to deliver cleaner material. Scrapyards are facing the constant risk of lithium-ion batteries showing up where they shouldn’t. And processors across the board are expected to meet market demand with fewer people on the floor.

The challenges keep coming, and the technology to solve them has to move just as fast. From the way material recovery facilities are designed, to how commodities are traded, to how we keep fires at bay, technology is now at the centre of almost every conversation in the industry.

That’s why Recycling Product News is dedicating this issue entirely to technology. Our first-ever special edition brings together the tools, systems, and digital innovations that redefine what efficiency, safety, and sustainability look like for recyclers. Across the board, technology is no longer seen as nice to have; it’s a necessity for survival, growth, and competitiveness.

MRFs, for example, are leaning on automation and AI to boost recovery and cut contamination. Robots and smart vision systems spot materials with precision that even the best human sorters can’t match, while real-time analytics keep operations running smoothly. Technology is also stepping up on the safety front, with advanced fire detection and suppression systems addressing the growing risk of lithium-ion battery fires before they escalate into disasters. And beyond the plant floor, trading software is streamlining how material moves through the market, giving buyers and sellers faster, smarter, and more transparent ways to connect.

At the end of the day, technology isn’t about replacing people — it’s about supporting them. Technology enables human ingenuity to focus on the areas where it matters most. The future of recycling will always be built on people, but the right tools help their efforts reach further.

As we release our first technology special issue, we see it as

the beginning of an ongoing conversation. Technology is not static. What feels groundbreaking today will soon be standard tomorrow. As new challenges emerge, from extended pro ducer responsibility to the circular economy, the next wave of innovation is already on the horizon.

News will follow those changes closely, and we’re excited to see how recyclers continue to adapt, lead, and thrive with the tools of tomorrow.

PAIRING AI WITH AIREJECTOR SYSTEMS

A NEW APPROACH TO QC AUTOMATION HELPS MRFS TACKLE LABOUR SHORTAGES AND ADAPT ACROSS PLANT SIZES

Automation has been accelerating significantly over the past five years. The industry consensus is that automated material recovery facilities (MRFs) provide higher throughputs, improved product quality, and enhanced safety for employees on the factory floor.

Many new large MRFs now feature completely automated container and fibre lines where manual labour is only required for the sorting of oversized items like OCC, non-program material, bulky rigid plastics, and wood — especially at the beginning of the sort system on either the pre-sort or auger screen post-sort stations.

However, existing facilities and new small-to-medium plants are not in a position to justify the higher amount of capital expenditure required. They still depend on manual labour for quality control functions, such as for PET, HDPE, aluminum, and fibre grades. Hiring and retaining manual sorters in the waste management and recycling industry has been a persistent challenge ever since the pandemic, and it isn’t getting easier.

NIR OPTICAL SORTER LIMITATIONS

From a technical standpoint, conventional automated sorting technologies, including near-infrared (NIR) and colour sensors, could be used to automate quality control functions.

However, those machines are designed for large mass sorting functions (up to 10 feet wide) at high speeds of up to 1,000 feet per minute and are large in size and higher in cost. While this can work for new large facilities, the space and capital expenditures may not be practical in retrofit situations or for new small- to medium-sized plants.

ROBOTIC ARM EXTRACTION

Some facilities have addressed this challenge by adding robots in manual sort positions. Over the past seven to eight years, several hundred robotic units have been installed in the U.S. Robotic arms are often considered in retrofit projects

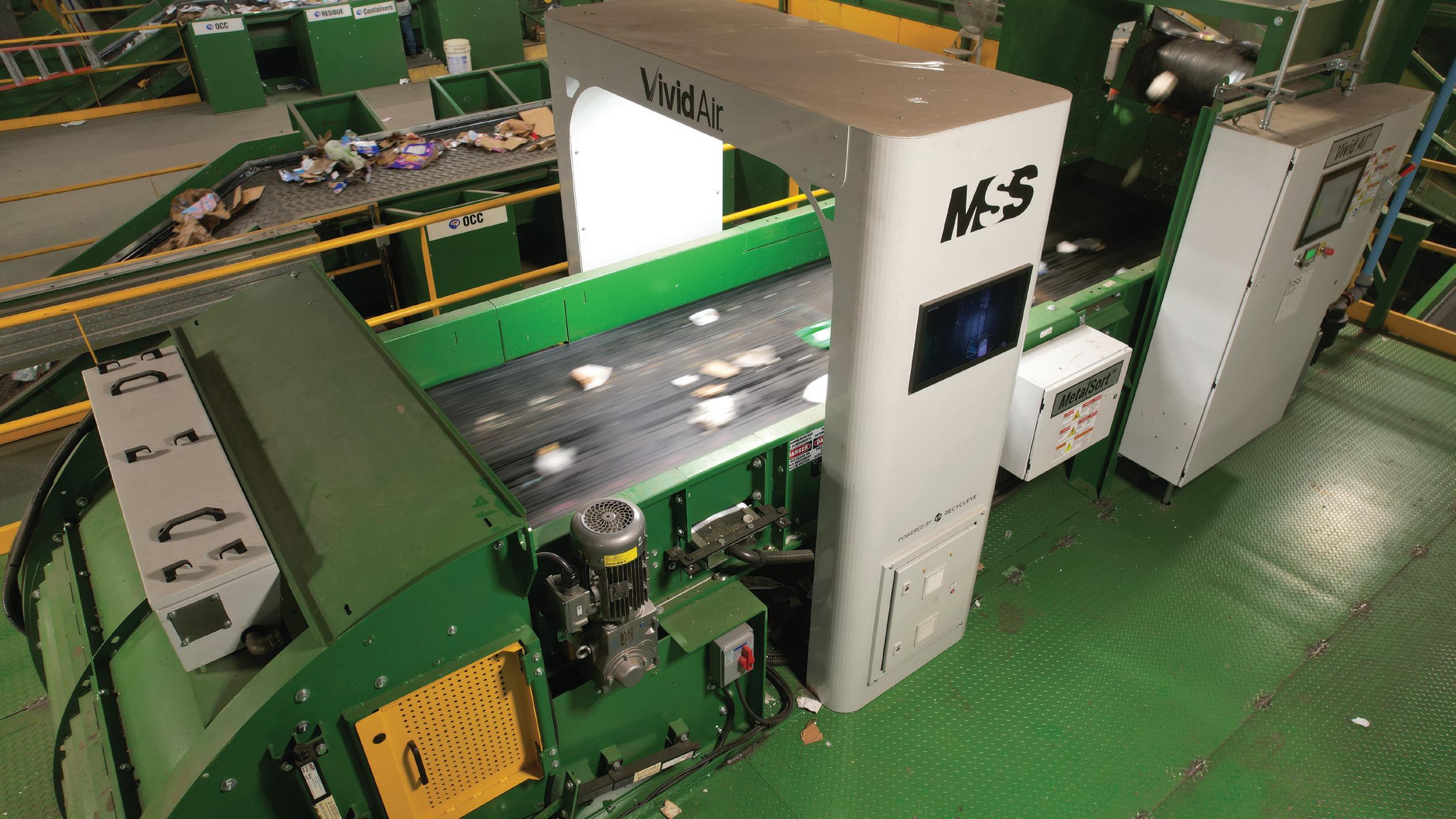

The compact Vivid Air system can be retrofitted onto existing conveyors or installed in new designs with minimal footprint.

where space is limited, but robotic extraction technology presents a number of technical considerations.

Speed and efficiency: Delta robots can complete up to 80 movements per minute, while multi-axis robots average around 30 movements per minute. Vacuum-based end effectors typically achieve 65 to 75 percent efficiency under ideal conditions. This translates into effective pick rates of about 55 picks per minute for delta robots and around 21 picks per minute for multi-axis robots. By comparison, a human sorter averages about 45 items per minute.

Material spread: Robots perform best when the material is evenly distributed. If target items arrive in surges or increase in frequency, robotic systems may capture fewer items. If multiple items pass simultaneously, not all may be recovered, which can affect both recovery and purity levels.

Cost per pick: Bellows-style suction cups used in robotic picking typically need replacement once per shift for $15–20 per cup. The vacuum systems that power these effectors require significant compressed air — approximately 10 times more than positive-pressure air jets. This results in operating costs that can be much higher than air jet systems.

Maintenance requirements: Robotic arms require regular checks throughout the shift. While some automated monitoring is available, facilities with multiple robots often dedicate personnel to oversee their operation and maintenance.

VIVID AIR

Recognizing the need for a compact solution that combines sensor technology with fast and efficient extraction, MSS developed Vivid Air, the first air-ejector-based sorting solution to use AI sensing technology. The compact solution can be easily integrated into a new system design or retrofitted onto existing manual sort conveyors, and its slightly lower

The growing variety of tools available means facilities have more options than ever.

conveyor speed allows for the use of much shorter conveyors compared to conventional NIR optical sorters

According to MSS, the cost per pick is also 12 times lower than that of robotic arms due to the replacement costs of suction cup effectors. Compressed air valves require virtually no maintenance in comparison, and the compressed air usage is about 10 times lower per pick.

EXPANDING OPTIONS FOR MRFS

The pairing of AI with proven extraction methods reflects the broader trend toward flexible, scalable technologies that can be adapted to different plant sizes and budgets. The growing variety of tools available means facilities have more options than ever to improve throughput, product quality, and workforce safety as the industry continues to modernize.

By reducing or eliminating manual quality control stations, MRF operators can use air ejector-based sorting solutions as an additional technology tool to address the challenge of hiring and retaining manual labour and automate one of the last areas in MRFs where manual sorters are mostly still required.

Vivid Air delivers high recovery rates with low compressed air use, helping MRFs improve efficiency and reduce operating costs.

SMALL ROBOTS

DELIVER BIG GAINS

PLUG-AND-PLAY ROBOTICS

UPGRADE MRFS WITHOUT DISRUPTION OR DOWNTIME

BY SLONE FOX, EDITOR

Modern recycling facilities are expected to process an ever-changing stream of packaging, meet stricter purity standards, and do it all with fewer workers on the floor. At the same time, incoming waste streams are more complex than ever, with flexible plastics, multi-layer packaging, and contamination testing the limits of traditional systems. Adding more manual sorters to combat this has also become a less viable option. High turnover, safety risks, and escalating costs make it difficult to sustain a workforce capable of keeping pace with today’s demands. Large-scale retrofits or full-facility rebuilds are often even more out of reach, creating an urgent need for solutions that can boost efficiency without the need to overhaul infrastructure.

RETROFITTING WITHOUT REDESIGN

Rather than forcing facilities to redesign around new systems, the latest generation of equipment is being built to adapt to the realities on the ground. Plug-and-play robotics can be installed directly into existing lines, bringing automation to places where space, cost, or downtime once made it impossible. This makes advanced sorting accessible not only to stateof-the-art facilities, but to older plants that need efficiency gains the most.

For many MRFs, space is the most limiting factor when it comes to upgrading technology. Buildings designed decades ago often operate with narrow conveyor layouts and little room to add new equipment. Plus, traditional robotic systems often require larger footprints, higher ceilings, and longer installation times.

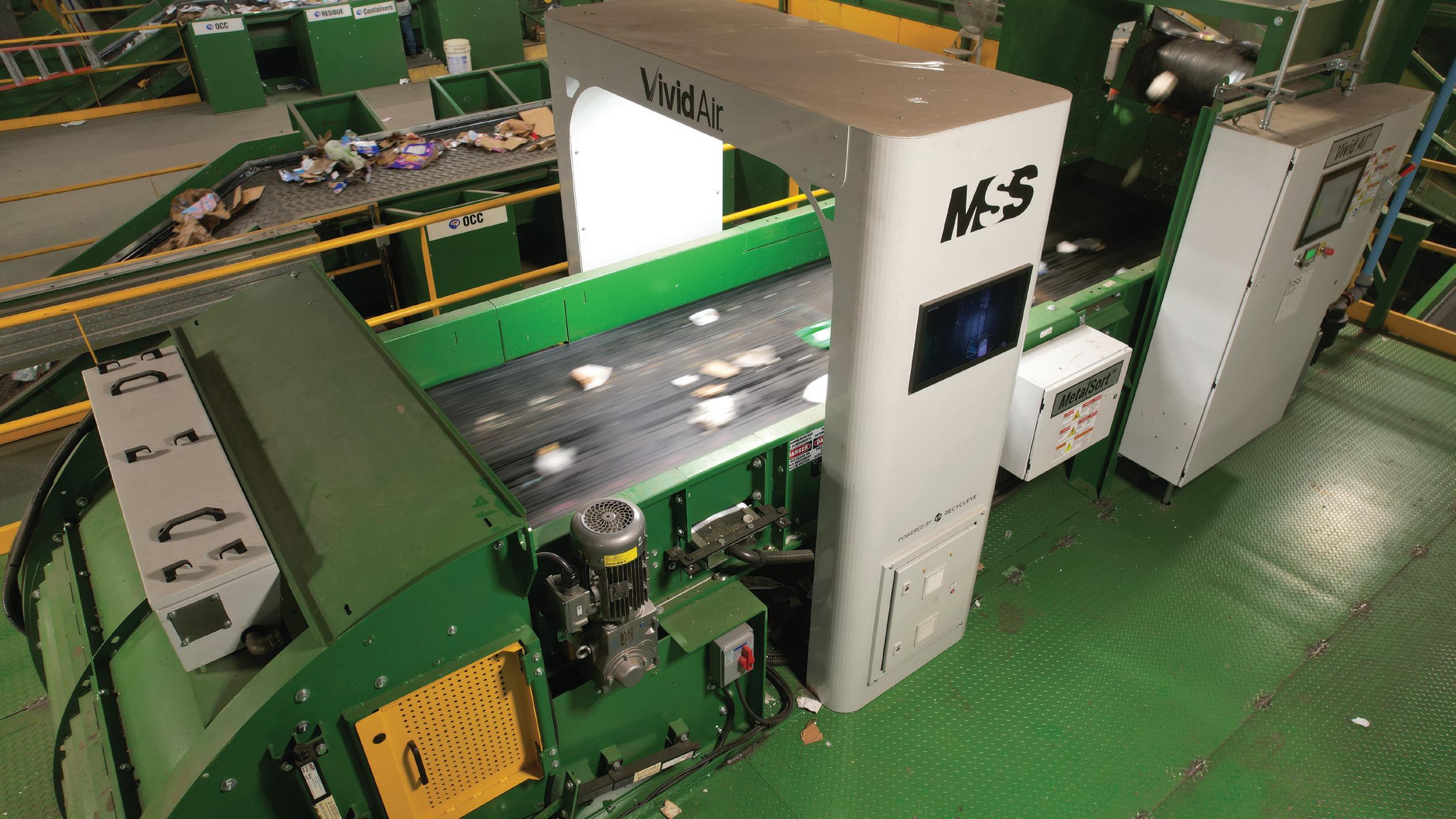

Technologies that can be integrated quickly and without disruptive installation are proving essential to maintaining performance while meeting the demands of modern recycling. Machinex’s latest sorting robot, the SamurAI Optima, is engineered for facilities with ceiling heights as low as eight feet, removing one of the biggest barriers to introducing robotics in older facilities. Mounted directly onto a conveyor, it can be up and running within a day.

For facilities that can’t afford weeks of downtime or lack the physical space for a full robotic system, this type of design is especially significant. Operators can add automated sorting in stages, addressing the most labour-intensive or contami-

A Machinex SamurAI Optima sorting robot.

nation-prone areas first. The design flexibility gives facilities control over how and where automation enters their process.

For operators weighing the cost and complexity of robotics, these design choices lower the threshold for adoption. Instead of seeing robotics as an all-or-nothing investment, facilities can introduce automation incrementally, adding a robot where it makes the most sense and scaling up as operations evolve.

AI ON THE LINE

The appeal of plug-and-play robotics extends beyond quick installation — it lies in operational simplicity. The SamurAI Optima requires no daily maintenance, keeping uptime high and reducing dependence on specialized staff.

Despite its smaller footprint, the Optima retains the same AI-driven intelligence as the full-size SamurAI. It can achieve comparable pick rates, recognize materials in a wide range of conditions, and reduce reliance on manual labour, all while fitting into facilities where traditional robotic systems would never physically fit.

Continuous software updates through the MACH Cloud subscription allow it to adapt to new packaging and materials automatically, without the need for on-site interventions. In practice, that means that the robots can handle dirty, commingled, and unpredictable inputs, while continuing to recognize new packaging types through regular AI updates. For operators, it’s not just about speed — it’s about maintaining reliable recovery and quality control without constantly retraining staff.

ACCESSIBLE, SMARTER SORTING

Plug-and-play robotics like the SamurAI Optima show that even facilities with tight spaces, older layouts, or limited budgets can take advantage of advanced sorting technology. The real game-changer isn’t just speed or pick rates; it’s the ability to integrate seamlessly, adapt to changing material streams, and operate reliably with minimal intervention.

For MRFs, that means more consistent recovery, better quality control, and the flexibility to scale automation as needs evolve. The future of sorting isn’t measured in square footage or ceiling height — it’s measured in how effectively a facility can use the space it already has. And with compact, plug-and-play robotics, smarter sorting is more accessible than ever. RPN

Continuous software updates allow the SamurAI Optima to adapt to new packaging and materials automatically.

Mounted directly onto a conveyor, the SamurAI Optima can be up and running within a day.

With the Eggersmann Recycling Technology product lines of screens, shredders and self-propelled windrow turners, Eggersmann North America Inc. provides leading technology of mobile and stationary recycling equipment for almost all kinds of applications where shredding, screening or turning is required. The company pays attention to the customer’sneedsandprovidesinnovativesolutionsbysupplyingfullsupportandpartsavailability.Ourgrowingdealer networkthroughoutNorthAmericatakescareofourcustomersandrepresentsourequipmentlinesintheirterritories.

SHREDDING

SMART SORTING AND SYSTEM ENHANCEMENTS STRENGTHEN

MRF PERFORMANCE

EQUIPMENT ADD-ONS HELP FACILITIES BOOST CONSISTENCY AND REDUCE MISSORTS

Recycling facilities are adapting to rising material complexity, evolving packaging streams, and heightened quality demands. Technology is playing a growing role in addressing these pressures, and VAN DYK Recycling Solutions has been working with operators to implement equipment and system designs that respond to these changing demands.

OPTICAL SORTING: SMARTER DECISIONS WITH AI

Optical sorting has long been the backbone of modern MRFs and plastics recovery facilities. VAN DYK’s optical sorting partners are building on this foundation with systems that combine AI-powered add-ons and integrate with proven NIR detection to address sorting challenges that have traditionally been difficult for the industry to resolve.

To identify and eject black plastics, TOMRA uses a laser technology called DEEP LAISER, and Pellenc ST uses Profile Detection for the same task. On the AI front, TOMRA’s GAINnext introduces a series of capabilities not available with traditional NIR to clean up paper, plastic, and used beverage cans (UBCs). Pellenc ST has a similar lineup that includes AISORT and CNS BRAIN.

These AI technologies analyze images of incoming material to intelligently detect common contamination like non-foodgrade resins, non-UBC aluminum, and white or coated cardboard, leading to higher purity levels in the fibre and container line output. Both companies continue to push development further at their respective material and technology test centres, where AI models are trained on real-world materials to refine accuracy over time.

Recycling facilities are turning to technology to keep pace with complex materials and stricter quality demands.

ENHANCED PERFORMANCE WITH SYSTEM ADD-ONS

VAN DYK works with operators to enhance the performance of optical sorters through equipment add-ons designed to improve consistency and accuracy. Disc spreaders ensure material is evenly distributed across the belt for maximum visibility and enhanced sorting performance. Optical acceleration belts can be outfitted with air assist technology to prevent light materials from floating around, improving ejection accuracy and reducing missorts. These enhancements translate directly into cleaner commodities and stronger plant economics.

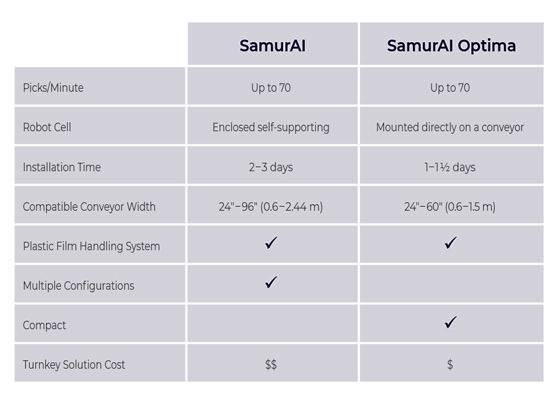

DATA INTELLIGENCE IN REAL TIME

VAN DYK’s exclusive partnership with Greyparrot brings a high-resolution, AI-powered analytics platform to MRFs. By providing minute-to-minute insights into inbound and outbound material streams, Greyparrot analyzers monitor sorting performance on each commodity. Greyparrot flags inefficien-

cies instantly so operators can take action before valuable materials — and profits — are lost. Greyparrot’s AI has been trained to identify 111 waste categories and is continually learning more. This technology is poised to transform how facilities track, analyze, and optimize performance in real time.

RETHINKING THE PRESORT WITH SPLITTER TECHNOLOGY

Upstream, the Günther SPLITTER is a non-wrapping, maintenance-free spiral shaft screen for front-end sizing in a MRF. Ideal for size separation in this setting, the SPLITTER is customizable and can be built with six different axle distances and 11 different auger sizes. This means the SPLITTER screen can be built 33 different ways to properly size and separate materials. Its original shaft technology screens out hazards, boosts safety, and eliminates the need for manual sorters in hazardous areas of the plant. By removing problematic items early, downstream equipment performs more efficiently and sustains less wear.

Optical acceleration belts can be outfitted with air assist technology to prevent light materials from floating around, improving ejection accuracy and reducing missorts.

The Günther SPLITTER is a non-wrapping, maintenance-free spiral shaft screen.

Pellenc ST uses Profile Detection to sort black plastics and advanced AI tools like AISORT and CNS BRAIN to improve paper, plastic, and UBC recovery.

SMARTER COLOUR SORTING

FOR SCRAP

AI-POWERED TECHNOLOGY ENABLES ACCURATE SORTING EVEN WHEN OBJECTS ARE THE SAME COLOUR AS THE BELT

TOMRA Recycling’s FINDER COLOR is designed to meet the evolving needs of the scrap metal recycling and e-scrap processing industries. The colour sorting system is engineered to deliver enhanced purity and recovery levels at high throughput across a broad spectrum of metals sorting tasks.

FINDER COLOR is ideal for recovering valuable materials such as copper and brass from mixed heavy metals, cleaning stainless steel fractions (including those from end-of-life vehicles) and achieving high-level purification of printed circuit boards (PCBs) from mixed e-scrap. It is capable of processing grain sizes from 0.2 to 4.7 inches (6 to 120 millimetres) and delivering throughput of up to 22.4 tons (20 tonnes) per hour on zorba material.

ADVANCED AI ALGORITHMS

The FINDER COLOR combines hardware and software with advanced AI algorithms to adapt to changing material streams and market demands. Its core features an ultra-precise RGB camera and advanced AI-powered object singulation technology, enabling accurate, object-level sorting down to a few millimetres, even when objects are overlapping, adjacent, or the same colour as the belt. This single-camera system sorts materials by colour, size, and shape, providing operators with full control and accuracy.

For enhanced purification, an optional electromagnetic (EM) sensor can be added. This is particularly useful for sorting materials with similar colours. The optional high-sensitivity EM sensor enhances metal recovery from mixed streams in batch mode, supporting PCB classification in e-scrap, or complementing the RGB sensor to add an extra purification layer against plastic contamination.

The system also offers easy configuration for both batch and continuous flow sorting, with fast switching between different fractions. This allows operators to quickly change which material they are sorting, such as switching from copper one day to brass the next.

INTEGRATION INTO EXISTING SORTING LINES

FINDER COLOR’s compact and simple design ensures easy integration into existing sorting lines, while its maintenance platform and accessible

valve block are engineered for simple and efficient servicing. The machine can be connected for optimized, data-driven sorting through TOMRA Insight, an optional cloud-based data platform.

FINDER COLOR can be used as a standalone machine following magnetic separation or to extract value from heavy metals removed by XRT technology, such as TOMRA’s X-TRACT. It is also a last-step sorting solution for extracting value from PCBs in e-scrap and can be used to sort stainless steel and wire from material recovered using TOMRA’s FINDER unit. These integration options optimize the entire sorting process, reducing operational complexity.

TOMRA Recycling’s FINDER COLOR is designed to meet the evolving needs of the scrap metal recycling and e-scrap processing industries.

With a flexible design, the system can adapt to changing material streams and market demands.

FINDER COLOR recovers copper/ brass, cleans stainless steel, and purifies PCBs from mixed e-scrap.

AFFORDABLE AI SYSTEMS HELP CAPTURE MORE VALUE FROM THE STREAM

CAN AUTOMATION AND ACTIONABLE DATA HELP MRFS

FROM WASTE SORTING TO CIRCULAR MANUFACTURING?

BY MEGHAN BARTON, SENIOR WRITER

Anew era is emerging in recycling, where environmental goals meet the precision and efficiency of advanced manufacturing. Material recovery facilities across the U.S. are starting to adopt AI-driven systems that offer real-time operational insights, transforming recycling from a labour-intensive, inconsistent process into a streamlined, data-rich operation.

Among the innovators shaping this transition is Glacier, a San Francisco–based startup leveraging affordable AI robotics to help recyclers improve recovery rates, enhance bale purity, and unlock new value from the waste stream.

“Recycling is manufacturing,” says Rebecca Hu-Thrams, Glacier co-founder and CEO. “These MRFs are responsible for taking in raw feedstocks, producing a certain yield, producing at a certain quality bar. At the end of the day, you’re making new stuff out of raw materials.”

FROM RECYCLING TO CIRCULAR MANUFACTURING

Glacier’s approach uses AI not just to sort recyclables more efficiently, but to reframe how facilities view their role: as manufacturers operating complex, data-driven production lines. Their AI vision systems offer real-time reporting on the composition and quality of material streams, allowing MRFs to track recovery rates and contamination with enhanced accuracy.

“One of the incredible things about this type of AI technology is its ability to continually learn and improve,” explains Hu-Thrams. “Unlike other types of legacy sorting equipment, where once you install it, that’s kind of the job that it does until it becomes obsolete, we can actually teach our AI model to recognize [new packaging] very quickly. Suddenly, the robot is picking stuff that wasn’t even around when it was installed.”

MAKING SMART RECYCLING AFFORDABLE AND SCALABLE

A major barrier to automation in recycling has traditionally been cost and complexity. Glacier set out to remove those obstacles by striving to design a solution that is faster, cheaper, and easier to implement than conventional systems. According to Glacier, their system costs less than standard options, requires just three feet of conveyor space, and can be installed in one day or less, avoiding facility downtime.

“A typical install is extremely fast, all things considered. It usually takes less than a day,” says Hu-Thrams. “We usually go in on the weekend when the MRF is not running, so there’s literally zero downtime for that installation.”

THE FUTURE OF SMARTER, MORE PROFITABLE RECYCLING

Glacier’s broader ambition is not limited to robotics. “Glacier’s mission from the start was never to be a robotics company or an AI company,” says Hu-Thrams. “It’s really to build what we call circular manufacturing.”

The company envisions expanding its AI and vision technologies into adjacent waste streams, including electronic waste, organics, and construction and demolition materials.

“One of the really wonderful advantages about a sort of purpose-built technology stack for recycling is that we’ve designed our technology with the anticipation of being able to scale it into numerous adjacent waste streams in the future,” says Hu-Thrams.

The company is also investing in expanding its AI capabilities. “We’re investing in making our AI model capable of detecting increasingly more and more different types of commodities,” says Hu-Thrams. “We’re already able to detect about 90 percent of the curbside recycling stream, so we’re tackling that long tail of 10 percent.” RPN

The sorting units can be installed in a single day with minimal downtime.

PACKAGING DESIGN MEETS THE SORTING LINE

GREYPARROT’S

DEEPNEST IS HELPING BRANDS OPTIMIZE FOR DETECTION, NOT JUST RECYCLABILITY

BY MEGHAN BARTON, SENIOR WRITER

Designing for recyclability means little if the packaging doesn’t survive recycling systems. Brands have had very limited visibility into how their products are sorted, recovered, or lost at recycling facilities. The missing piece? Real-world data demonstrating how packaging performs once it enters the waste stream.

Greyparrot, best known for its AI-driven material recognition tools for optimizing sorting operations, has launched a new platform called Deepnest to help provide that insight.

A NEW AUDIENCE FOR WASTE INTELLIGENCE

Unlike Greyparrot’s Analyzer hardware and Sync platform, which deliver data and operational insights directly to waste managers and facility operators, Deepnest is designed for a different audience: brands and packaging producers. It leverages the same data collected by Analyzers at MRFs but reframes and repackages it for those making upstream packaging decisions.

“Deepnest is the world’s first waste intelligence platform built for brands and packaging producers,” says Gaspard Duthilleul, COO of Greyparrot. “We’ve been working for six years with waste managers . . . and realized that some of the most critical decisions affecting recycling outcomes are made far upstream by brands, by packaging producers.”

“[We also] realized we have the data, we have the means to tell the brands what happens to their packaging and to help them understand how to optimize [design],” explains Duthilleul. “We built Deepnest to give visibility to brands, to help them understand the end of life of the packaging. [Deepnest can show brands] how design decisions might impact the sorting of this packaging in real life and how to benchmark themselves against other [anonymized] brands to really understand the impact.”

REAL DATA ON REAL-WORLD PERFORMANCE

Through Analyzers installed in facilities across more than 20 countries, Greyparrot now detects over 40 billion waste items each year. By mapping each stage of the recovery process, Deepnest gives brands a clear view of their packaging’s journey through the recovery system, highlighting where it’s captured, where it’s missed, and why.

Instead of relying on assumptions or lab-based recyclability tests, Deepnest offers brands a product-level view of how their specific packaging formats perform in real-world recycling systems. It can identify what packaging is captured consistently, what fails due to material choices or label interference, and how performance varies by region.

For example, packaging that uses full-body plastic sleeves often isn’t recognized by optical sorters, especially if the sleeve

Using data from AI-powered cameras, Deepnest identifies individual packaging items as they move through the sorting line.

is made from a different polymer than the container itself. Dark plastics, long known to be problematic, continue to elude detection by infrared-based sorters. Deepnest brings these issues into focus with tangible data.

Packaging that performs well in one country may fail in another due to differences in infrastructure, policies, or sorting technology. According to Duthilleul, gaining visibility into those regional realities allows brands to design packaging that works at scale, not just in theory, but in practice.

“As a brand, if you’re going to launch a product, how do you make sure that it’ll work in your target market?” says Duthilleul. “And should you do different versions based on how the ecosystem is set up?”

For MRFs, more detectable packaging translates to lower residue rates, fewer sorting errors, and cleaner bales; these benefits support both operational efficiency and downstream market value.

TOP 5 PACKAGING DESIGN PITFALLS IDENTIFIED BY DEEPNEST

1. Full-body shrink sleeves (especially mixedpolymer).

2. Black plastics undetectable by NIR sorters.

3. Small, lightweight, flexible packaging that falls through screens.

4. Asymmetrical designs that affect how packaging lands on sorters.

5. Non-standard labels and adhesives that interfere with detection.

FROM RECYCLABLE TO DETECTABLE

This shift from “designing for recyclability” to “designing for detection” is a major theme behind Deepnest’s development. As Duthilleul puts it, packaging that technically meets recyclability criteria may still be effectively unrecyclable if it can’t be accurately sorted at scale. Size, weight, material composition, and even how an item falls on a conveyor belt can all impact recovery outcomes.

“We’ve seen brands shift materials, adjust label coverage, or change form factors based on this kind of insight,” says Duthilleul. “It’s the kind of thing you can’t fully simulate in a lab.”

HOW DEEPNEST WORKS

The Deepnest platform is built around a dashboard that displays data specific to a brand’s products, including packaging type, volume, geographic performance, and sortability scores. Brands can filter by product lines, compare different packaging formats, and benchmark against anonymized industry norms.

Deepnest does not disclose competitor data or identify specific waste facilities. “We want each stakeholder to benefit from this data and use it to improve,” explains Duthilleul. “A Coca-Cola user will see their own product-level data and how it compares to industry benchmarks like all PET bottles or aluminum cans, but not to another brand’s performance.”

Greyparrot retains ownership of the data, since it is collected via its installed systems, but allows brand partners to access tailored views that support actionable insights. Unlike traditional packaging audits, which can be slow and expensive, Deepnest offers near real-time feedback at scale.

ENABLING CROSS-SECTOR COLLABORATION

While Deepnest is built for brands, it also supports deeper collaboration between recyclers and packaging producers.

With shared visibility into packaging performance, stakeholders across the value chain can move from blame-shifting to co-design.

Brands often argue that they’ve improved their packaging designs, while waste managers point to infrastructure limitations that still prevent effective sorting. According to Duthilleul, Deepnest introduces objective data into these conversations, helping both sides move past blame and toward collaborative solutions.

In some cases, Greyparrot facilitates direct conversations between brands and MRFs to test new packaging or identify regional sorting limitations together. The company is already seeing interest in pilot projects that connect waste managers and brand owners around specific packaging redesigns.

A NEW TOOL FOR EPR AND CIRCULAR ECONOMY GOALS

Deepnest launches at a moment when brands are facing increasing pressure to comply with Extended Producer Responsibility (EPR) laws and circular economy targets. As financial and regulatory accountability grows, companies need to ensure that their packaging choices translate into measurable recovery.

“We don’t want them to try one thing and then try another one and then try another one without [getting] data fast enough to drive these changes,” says Duthilleul. “AI is enabling us to move faster . . . so [brands are] able to make a decision, see the impact quite quickly after, at scale. That’s really the power of Deepnest.”

Brands can also submit new product designs to Greyparrot in advance, allowing those products to be added to the recognition database before they reach the recycling stream. This proactive approach speeds up detection and enables targeted testing in specific geographies.

A Greyparrot Analyzer unit scans waste materials, collecting data with AI-driven vision systems and delivering insights through the Deepnest platform.

Greyparrot’s Deepnest platform provides brands with packaging performance insights through a customized dashboard.

WHAT’S NEXT FOR DEEPNEST?

Currently, Deepnest is being used by major brands such as Unilever, Amcor, and Asahi Beverages. Greyparrot’s largest footprint is in the U.S., the U.K., and Europe, and the company is actively expanding in Canada and other global markets.

While Deepnest opens the door to smarter packaging design, widespread adoption will require more brands to commit to transparency and recyclers to engage with standardized data models. Making Deepnest insights actionable across regions will require close alignment between technology providers, policymakers, and local recovery systems.

The long-term goal is to create a unified layer of packaging intelligence that supports both

WHAT DETECTION REALLY MEANS

In the context of recycling, “recyclable” doesn’t always mean “recoverable.” If packaging isn’t detected by the facility’s sorting equipment — due to its size, shape, colour, or labelling — it may never make it into the correct material stream.

Detection depends on:

• Optical recognition by NIR (near-infrared) sensors or AI cameras.

• How an item lands on the conveyor belt (label-side down can obscure recognition).

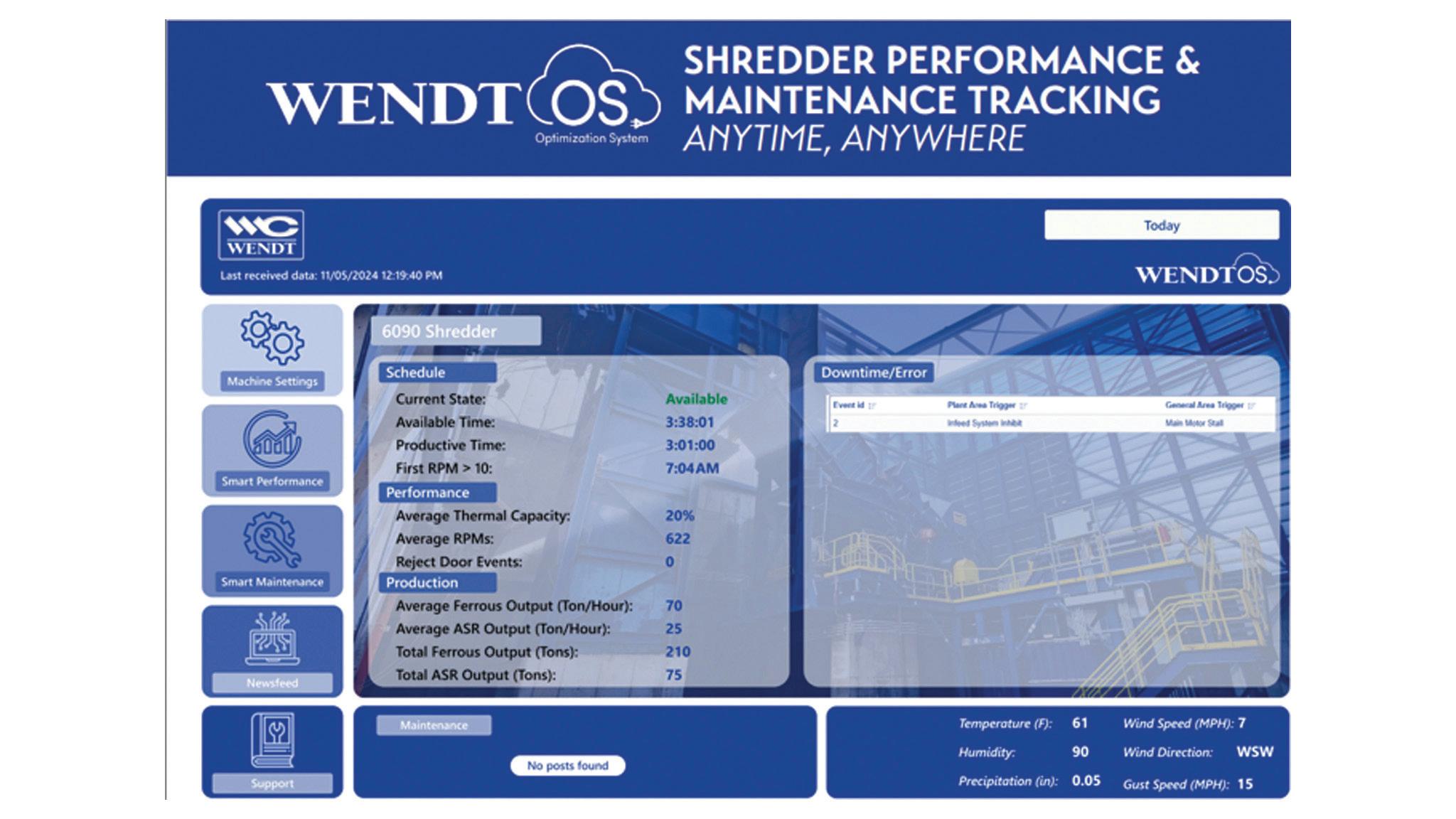

RETHINK SHREDDER PERFORMANCE THROUGH CONNECTED DATA

HOW WENDTOS HELPS SCRAPYARDS MODERNIZE MAINTENANCE, PRODUCTION TRACKING, AND DECISION-MAKING

BY MEGHAN BARTON, SENIOR WRITER

In an industry where every ton counts, visibility into operations can be the difference between incremental gains and missed opportunities. That’s the premise behind WENDTOS, a new software platform from WENDT that is designed to give scrapyard operators powerful insight into shredder performance, wear part life, and downtime events in real time from any web-enabled device.

WENDTOS, short for WENDT Optimization System, launched earlier this year after a multi-year development and beta testing phase. Built from the ground up to meet the specific needs of metal shredding operations, the platform is already being rolled out on all new WENDT shredders, with broader availability for non-WENDT machines and downstream systems in the pipeline.

BRINGING A LAGGING INDUSTRY UP TO SPEED

Digital transformation may have swept through other sectors, but scrap recycling has been slow to follow. When asked why WENDT has chosen to launch its optimization platform now, Justin Kibler, business development manager at WENDT, offers a candid response that reflects urgency and opportunity for the rollout. “Yesterday was the best time,” says Kibler. “Today is the second-best time.”

While industries such as logistics, manufacturing, and energy have forged ahead with tech innovation, many players in scrap recycling have been slower to modernize their data infrastructure. Operators have typically relied on local computers, programmable logic control-

lers (PLCs), or even custom Excel spreadsheets to cobble together insights from disconnected machine signals. For Kibler and his team, that fragmented approach was no longer tenable.

“Our customers struggle to understand the data behind the systems they’re running,” he explains. “What are their throughputs? Something as simple as how much material they’re actually running can be difficult to ascertain.”

WENDTOS is WENDT’s answer to that challenge: a platform that enables operators to track, analyze, and act on shredder performance data in real time. With key performance data, production data, and maintenance data transmitted via an independent cellular signal from an onsite RSS module to WENDT’s servers in Buffalo, New York, the platform provides

WENDTOS is designed to give scrapyard operators powerful insight to track, analyze, and act on shredder performance data in real time.

remote access to shredder metrics with any web-enabled device. Users can monitor multiple shredders across different locations from a single interface.

CORE FEATURES AND FUNCTIONALITY

At its core, WENDTOS provides a series of interconnected dashboards that translate raw sensor data into actionable insight. Among the most frequently used tools are:

Smart Performance which tracks throughput (tons/hour), motor load, thermal capacity, and other key shredder KPIs in real time.

Operational Outline is a calendar-based module to schedule run times, material types, and downtime events.

Smart Maintenance tracks the life cycle of internal wear parts based on tonnage processed, issuing proactive replacement alerts.

Downtime Reporting logs and categorizes all forms of downtime, from scheduled maintenance to unshreddable events, and provides clear insight into efficiency gaps.

Smart Hydraulics monitors oil particulate levels, fluid temperatures, filter

life, and tank levels to support predictive maintenance and prevent equipment damage.

Smart Water tracks water injection flow rates to ensure proper dust suppression and system performance during operation.

Production Reports are automated daily, weekly, and monthly summaries delivered via email and available in-platform for easy-to-access performance reviews.

BUILDING THE RIGHT TOOL

From the start, WENDTOS was designed to do more than just capture data. The goal was to create a flexible, customer-centric system that adapts to the unique needs of different facilities.

Kibler is clear: “Data reporting programs are a dime a dozen. What sets WENDTOS apart is the configurability guided by our industry expertise. We’re working with every customer to make sure they’re seeing data in the way that’s most useful to them.”

This means frequent feedback loops, hands-on training, and one-on-one collaboration throughout the onboarding process. WENDT’s team often holds

We can show you which feedstock runs better, which operator is more efficient, or where there’s a spike in vibration.

Justin Kibler Business Development Manager, WENDT

weekly or bi-weekly sessions with facility managers and operators to walk through data, refine reports, and explain new features. For operators less familiar with digital tools, the learning curve is addressed through step-bystep coaching.

“If we just gave them a login and walked away, they’d probably never use it,” says Kibler. “We make sure they get the most out of it.”

WENDTOS provides a series of interconnected dashboards that can be accessed from any web-enabled device.

INTEGRATION AND SCALABILITY

While WENDTOS comes pre-installed on all new WENDT shredders, the platform is also designed to be adaptable for use on older equipment and third-party systems. For older WENDT equipment, simple upgrades like adding belt scales and vibration sensors can bring machines online with minimal disruption. For non-WENDT systems, integration is handled with completely bespoke solutions.

“Every competitor system is set up differently, so there is a potential hurdle when integrating into a system that isn’t designed and built by WENDT,” says Kibler. “But we’ve built the framework. It’s all about understanding what’s [already] there and how to talk to it.”

The future road map for WENDTOS includes expanding beyond the shredder to cover non-ferrous systems. Kibler explains that this next phase could involve developing new dashboards tailored to equipment used for recovering materials like aluminum, copper, and stainless

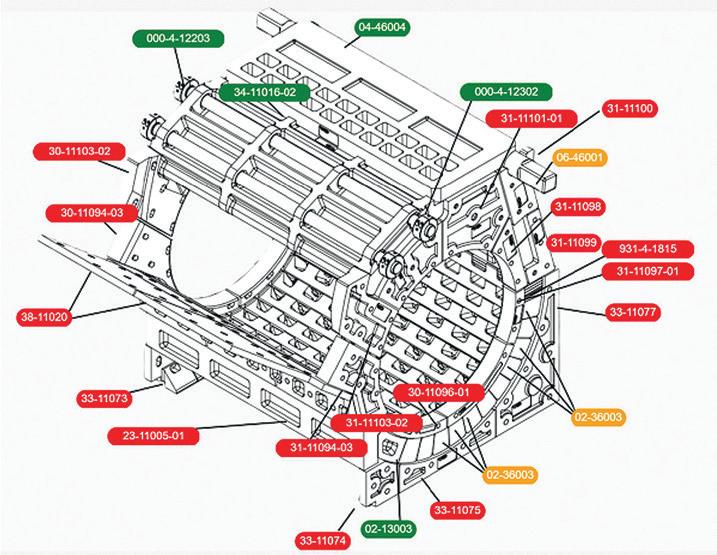

The WENDTOS Smart Maintenance feature tracks the life cycle of internal wear parts and issues proactive replacement alerts.

steel. WENDT also plans to integrate technology from existing partners, like TOMRA, to support this evolution.

SECURITY BY DESIGN

With rising concerns around data privacy and cybersecurity in industrial operations, WENDT took deliberate steps to decouple WENDTOS from a facility’s internal network. Instead of transmitting data via local internet, WENDTOS uses a secure cellular signal through the RSS module, creating a physical barrier between customer systems and WENDT servers. The data only ever flows out of the system with nothing getting sent back to the facility’s site.

“Even if our servers were compromised, there’s no way to access the customer’s shredder system,” says Kibler. “All we’re doing with the connection is reading data. By design, we don’t even have the ability to make changes to the local system or shut things down.”

THE VALUE OF VISIBILITY

When asked about return on investment, Kibler is candid. WENDTOS isn’t a

silver bullet — it’s a tool that empowers operators to make better decisions.

“The ROI depends on what you do with the information,” he says. “We can show you which feedstock runs better, which operator is more efficient, or where there’s a spike in temperature. But it’s up to the management team to act on that.”

Even with early adopters still in the data collection phase, the platform is already delivering insight. Facilities are identifying cost-saving trends, scheduling smarter maintenance, and minimizing downtime.

WHAT’S NEXT?

WENDTOS is still evolving with new features rolling out regularly. Plans include enhanced detection capabilities for radiation and moisture, expanded integration with partner equipment, and predictive analytics based on weather conditions and historical performance.

For scrap recyclers unsure about making the leap to digital, Kibler’s advice is simple: “Try it. Let us show you what

While WENDTOS

WENDT

it can do. Once you’ve experienced this level of data capture, you’ll wonder how you ever operated without it.”

In a market defined by thin margins and operational complexity, smarter shredding starts with better information. WENDTOS is designed to support that transition. RPN

VISIA TRANSFORMS RECYCLING WITH ADVANCED HAZARD DETECTION AND REAL-TIME INSIGHTS

OPTIMIZING OPERATIONS AND PROTECTING WORKERS WITH AI-POWERED MATERIAL TRACKING

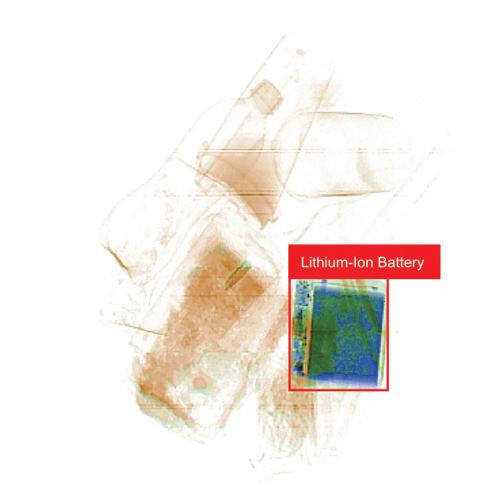

In the world of recycling, hazards are often hidden in plain sight. Lithium-ion batteries, pressurized tanks, and other dangerous materials can slip through manual sorting, triggering thermal events, fires, and operational downtime. As material streams become increasingly more complex and regulatory scrutiny intensifies, traditional sorting and reporting methods can no longer provide the speed, accuracy, or actionable insights operators need to manage risk and optimize operations.

Enter Visia, an innovative technology company driven by a passion for transforming recycling operations. With AI-powered X-ray and machine learning systems, Visia is equipping facilities to detect hazards, improve throughput, and unlock real-time operational insights, all while safeguarding workers and valuable resources.

“I think the thing that really excites us is [there is] an opportunity for us to . . . play a part in redirecting these critical materials where they belong,” says Raghav Mecheri, Visia founder and CEO.

HOW IT ALL BEGAN

Visia’s origin story began as a typical college experiment. “We were 19-year-olds in engineering and design

at Columbia, and we had no idea how recycling really worked,” recalls Mecheri.

The team’s first project was an AI-powered trash can: a self-sorting consumer receptacle that could identify materials by using cameras and drop them into the correct bin. While the device itself wasn’t commercially viable, the experiment sparked a fascination with the industrial side of recycling.

Over the course of a year and a half, they connected with operators, studied facility workflows, and learned that the biggest challenge in recycling was unpredictability: what came in and what went out. That insight became Visia’s mission.

Today, the company deploys imaging systems, including cameras, X-rays, and CT scanners, paired with machine learning models to detect hazards, analyze material streams, and provide real-time operational insights.

Building on that early curiosity, Visia turned insight into impact. The team applied their understanding of material unpredictability to create AI-powered systems that detect hazards, streamline workflows, and give operators real-time control over their facilities. These innovations set the stage for Visia’s first major deployments.

CASE STUDY 1: INNOVATION IN HAZARD DETECTION

After a battery fire destroyed its facility, Rumpke Recycling needed a proactive solution. Relying on manual sorting left hazardous items undetected, exposing both personnel and machinery to potential harm. The solution came in the form of Visia’s AI-powered X-ray system, installed on Rumpke’s pre-sort line.

The system uses machine learning to automatically identify hazardous items, including lithium-ion batteries and gas tanks, through dense piles of materials. A mounted laser pointer alerts sorters to the exact location of flagged items, enabling precise, targeted removal.

Rumpke’s operations team now accesses real-time data through Visia’s dashboard, replacing manual audits with continuous insight. The system learns and improves over time, adapting to the facility’s evolving material stream. Since implementing the technology, Rumpke has detected and removed hazardous items with zero shredder fires, demonstrating the transformative potential of AI in high-risk operations.

Visia uses machine learning to automatically identify hazardous items, including lithium-ion batteries and gas tanks, through dense piles of materials.

CASE STUDY 2: SCALING INSIGHTS FOR C&D RECYCLING

Visia’s impact isn’t limited to hazardous item detection. In construction and demolition (C&D) recycling, reporting and compliance pose major challenges. Premier Recycle, a leading C&D recycler in the Bay Area, needed a scalable solution to deliver accurate diversion data across multiple job sites without slowing operations or creating administrative burdens.

Previously, teams relied on manual photo uploads, spreadsheets, and hand-built reports to meet LEED and CALGreen requirements. The process was labour-intensive, time-consuming, and prone to human error.

By implementing Visia’s AI-powered material characterization system, Premier Recycle transformed this workflow. Using a mobile app, teams capture photos of incoming loads, which the system automatically classifies by material type. Material data is processed in real time, enabling instant, LEED-compliant diversion reporting.

“It’s something that we call forward-deployed engineering, where we literally have a more involved engineering presence with our customer sites, where we work with them to figure out how this data gets used, and all the different ways we can [impact] operations,” says Mecheri.

The results speak for themselves: Premier now achieves 98+ percent data accuracy, has eliminated manual photo review and data entry, and saves approximately 80 payroll hours per month. The digital platform will scale easily for future growth, creating a blueprint for circular construction practices.

CASE STUDY 3: ENHANCING SAFETY AND EFFICIENCY IN E-SCRAP

Visia’s solutions also extend into electronics recycling. PedalPoint Recycling (formerly evTerra) implemented AI-powered hazard detection on pre-sort lines, scanning dense e-scrap loads in real time. The system differentiates battery chemistries, such as lithium-ion and lead–acid, helping facilities optimize downstream processes and comply with strict handling protocols.

Once proven at a single site, the technology quickly expanded across PedalPoint’s national operations, standardizing safety protocols, providing real-time data,

and improving throughput. Each facility benefits from a unified, chemistry-specific detection system, preventing thermal events while allowing PedalPoint to reduce QC staff by 67 percent.

Beyond operational efficiency, the team at Visia sees a bigger picture. By ensuring that valuable resources are recovered and redirected, Visia is supporting operational ROI and the circular economy as a whole.

TRANSFORMATIVE TECHNOLOGY, THOUGHTFUL DEPLOYMENT

It’s not just the technology that sets Visia apart. It’s the philosophy behind its deployment. The team emphasizes selecting the right customers and ensuring readiness for success before expanding to new geographies. This careful approach ensures that facilities get the full benefit of the system, backed by on-site expertise and ongoing support.

“We’re really in no rush to deploy,” explains Mecheri. “The goal is to define customers who will see value, where we’ll be able to implement quickly, and who we can support to the standard we believe in.” It’s an approach that balances strategic independence with deep customer partnerships, empowering operators to unlock transformative value from day one.

LOOKING AHEAD

Visia is redefining recycling with AI and machine learning, fuelled by a team passionate about finding smarter, more impactful ways to transform operations. As material streams grow more complex and regulatory requirements tighten, Visia’s technology equips facilities to operate safer, more efficiently, and with greater insight into critical material recovery. At its core, the company’s story is one of innovation, ambition, and the belief that AI can empower recyclers to achieve more than ever before.

www.visia.ai

sales@visia.ai

Visia uses imaging systems paired with machine learning models to give operators actionable insights.

SMART DETECTION AND TARGETED EXTINGUISHING SYSTEMS REVOLUTIONIZE FIRE SAFETY

INTELLIGENT FIRE PREVENTION USES TECHNOLOGY TO SAVE MATERIALS, REDUCE POLLUTION, AND OPTIMIZE OPERATIONS

In the industrial sustainability conversation, waste reduction, resource conservation, and recycling are at the top of the agenda. But, ironically, the very facilities promoting circular economy practices face a major technological and environmental challenge: fires that threaten people, assets, and the environment.

AN UNDERESTIMATED RISK WITH GLOBAL IMPACT

Data from the U.K., the U.S., Germany, and other countries shows that recycling facility fires are not isolated incidents. In the U.K. alone, 670 fire incidents were reported between 2019 and 2020. Many caused massive smoke and toxic emissions, strained emergency services, and led to long-term environmental damage.

At the core of the problem are lithium-ion batteries. Around 80 to 90 percent of documented recycling fires originate from energy cells, with heat, friction, sparks, and self-ignition adding to the risk.

ENVIRONMENTAL DAMAGE FROM SECONDARY EFFECTS

What begins as an effort to protect the environment can, in a worst-case scenario, end in environmental disaster. This makes proactive fire risk control all the more important.

When a fire occurs, consequences extend beyond property loss:

• Air pollution from smoke, soot, and toxic gases

• Water contamination from firefighting runoff containing hazardous substances

• Loss of valuable secondary raw materials

• Production shutdowns, even for neighbouring facilities

• Regulatory penalties or license suspensions

FIRE PROTECTION IS ENVIRONMENTAL PROTECTION

Preventing fires before they start relies on modern technology. Spark and ember detection systems are designed to identify ignition sources within milliseconds and neutralize them automatically before a fire can start.

These systems are now widely used and recommended by insurers — especially in high-risk areas such as shredders, dust extraction units, and conveyor systems. Unlike traditional sprinkler systems, they respond to early warning signs rather than waiting for a full-blown fire.

INTELLIGENCE WHERE IT MATTERS

Fagus-GreCon’s Intelligent Extinguishing Module (IEM) elevates this approach. Continuously monitoring valves, nozzles, and pressure levels, the system detects wear, leaks, or irregularities at an early stage. This reduces unplanned downtime,

extends maintenance intervals, and ensures system availability. The IEM uses extinguishing agents only where needed and in the amount needed. Extinguishing agents are finely atomized and precisely targeted. This reduces water consumption and protects both the environment and stored materials. Due to integrated frost protection and smart heating, the system remains reliable even in freezing temperatures, which is essential for outdoor facilities.

MORE THAN A SAFETY FACTOR

Fire protection systems don’t just provide safety; they provide data.

OverBuilt High Speed Car Crushers

evaluation, identify risk patterns, and guide targeted preventive measures. Fire protection becomes part of process optimization, turning safety into a core element of industrial sustainability strategy.

PREVENTION IS ESSENTIAL

Only Overbuilt offers the Highest Opening in the Industry at 10’ and the Patented High Speed Oil Bypass System minimizing costs and maximizing production.

Fire protection systems don’t just provide safety; they provide data. Integrated with control systems, they enable process

The recycling industry must think in both economic and ecological terms. Smart, data-driven fire prevention safeguards operations, conserves resources, and reduces environmental risk. These technologies are proven and ready to meet today’s challenges. Preventing fires doesn’t just protect assets — it protects the planet.

Fagus-GreCon’s extinguishing unit protects assets by detecting and suppressing sparks before they ignite a fire.

DEBUNKING SEVEN MYTHS ABOUT SCRAP METAL TRADING

HOW TECHNOLOGY IS RESHAPING ONE OF RECYCLING’S MOST OPAQUE MARKETS

Scrap metal has long been the backbone of the recycling industry, with millions of tonnes of material moved each year across domestic and global markets. Yet, for all its importance, the sector has historically operated in a haze of opacity, where price discovery is patchy, information is uneven, and the strength of one’s personal network at any given point in time, in any given market, often determines trading outcomes. But markets move, trading lanes shift, and the ground beneath those relationships is constantly changing.

That lack of clarity isn’t intentional. It’s the byproduct of decades of trading built on relationships, handshake deals, and limited visibility. In a world where information translates into bargaining power, opacity has become accepted as simply “how things are done.”

But technology is showing that it doesn’t have to be this way. With greater transparency, sellers gain access to more buyers and better prices, while buyers gain broader access to supply — creating a healthier, more resilient marketplace for all stakeholders.

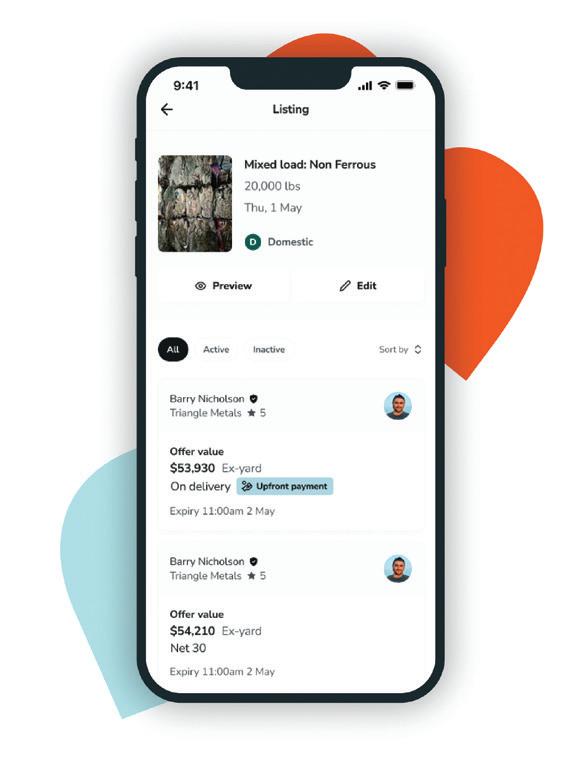

One of the platforms emerging to bring transparency to this space is Buddy, a digital marketplace and trade OS built “for scrappies, by scrappies.” Since its launch, it has given North American recyclers access to a broader set of vetted buyers, helping form and build new relationships and delivering stronger prices. For buyers, Buddy has created access to trusted sources of supply on tap, while simplifying the mechanics of trading.

“Everyone is skeptical at first, and I get it,” says Buddy founder Stu Kagan. “But 100 percent of people understand the value after seeing the platform.”

In this special technology issue of Recycling Product News, we take on seven persistent myths about scrap trading, and explore how transparency and digital tools are transforming the market — for the benefit of both relationships and results.

Scrap metal recyclers can now download the Buddy app on iOS and Android, set up their account, and start trading right away.

THE ROOTS OF OPACITY

Scrap trading has always relied on relationships. For most recyclers, those relationships are with two to four key buyers for each major grade they sell. When markets move, the natural instinct is to pick up the phone: “Hey, what are prices at the moment for commodity X?”

Those conversations remain essential, but they also highlight the industry’s structural imbalance.

Scrap metal recyclers rely on indices such as Comex, AMM, or the LME as important proxies, and they play a vital role in shaping market dynamics and sentiment. However, they don’t provide the full picture when it comes to scrap, which still lacks a transparent, real-time, trade-verified index that reflects secondary material values. That has meant recyclers depend heavily on their buyers to provide pricing signals — signals they also use to set their own buying prices.

Buyers have traditionally filled this role out of necessity. Their scale and reach allow them to aggregate supply, secure better prices, provide market access through their own networks, manage logistics, handle paperwork, and share market intel and advice. What’s shifting now is not the value of those relationships, but the foundation beneath them.

With technology providing real-time, trade-verified data, recyclers no longer have to call a buyer just to ask where the

market is. They already know. That levels the playing field and turns the conversation toward higher-value questions: What terms can we agree on? What volumes make sense? How do we grow this partnership?

MYTH 1: MARKET OPACITY IS UNAVOIDABLE

For decades, opacity was seen as inherent to the way scrap trading was done. Traders relied on fragmented networks where visibility was scarce, and many assumed it had to stay that way. But digital platforms are now aggregating pricing and demand signals, giving sellers confidence in their options and buyers broader access to supply.

Blaine Cash of Recycle Management captures this shift: “It is allowing me to see more buyers. Now I get to see what the real market is instead of just one or two people telling me. I really do not make a deal until I’ve seen five bids now. Before Buddy, we didn’t have five people to choose from.”

MYTH 2: I ALREADY HAVE THE BEST BUYERS

It’s natural for recyclers to trust the buyers they know. Strong relationships are built over time, and those buyers

Buddy founders Stu and Lisa Kagan.

often provide invaluable service beyond pricing. But the assumption that existing buyers always offer the best price is harder to defend.

Markets move quickly. A buyer who locked in a position today might be at a disadvantage compared to one who secures their position later when conditions shift. Relationships will always matter, but transparency ensures that those relationships are based on mutual benefit rather than blind reliance.

Diversifying the buyer base doesn’t mean abandoning trust; it means testing the market to confirm that trust is yielding competitive outcomes. As Conner Wilkinson of Wilkinson Gary Iron & Metal notes: “In my first week, I threw up some aluminum [on Buddy] and got eight offers in a day, from companies I’d never even heard of. I ended up doing business with five of them.”

A strong partner will want recyclers to secure the best deal for their long-term sustainability, even if that means losing a particular load. Technology helps prove out those dynamics, keeping relationships anchored in transparency and longterm value.

MYTH 3: A HANDFUL OF STRONG RELATIONSHIPS IS ENOUGH

It’s tempting to believe that a few trusted buyers will always be enough to keep material moving. Strong relationships are vital, but markets are never static. Export tariffs,

AI may be the buzzword of the moment, but it’s important to understand the foundation

beneath it: data. Data is to AI what shredder feed is to a shredder. Without it,

there’s nothing to process.

Lisa Kagan Co-founder, Buddy

shipping disruptions, and sudden demand swings have all left recyclers scrambling to find outlets when traditional lanes closed.

The only constant in scrap trading is change. Technology widens the circle, ensuring recyclers always have a home for their metal without sacrificing the depth of existing partnerships.

With technology providing real-time, trade-verified data, recyclers no longer have to call a buyer just to ask where the market is. They already know.

MYTH 4: TECHNOLOGY ERODES RELATIONSHIPS

Some fear that digital tools could depersonalize the business, replacing the handshake with a cold algorithm. But in reality, transparency strengthens trust. When both sides see the same data, expectations align more easily. Technology doesn’t replace relationships; it reinforces them.

“Buddy hasn’t changed the trust in our industry,” says Wilkinson. “It has reinforced it. Everyone’s vetted and hitting confirm feels like the digital handshake.”

MYTH 5: NEGOTIATION IS ONLY ABOUT PRICE

Negotiation is central to scrap trading, but it has never been just about price. Skilled negotiation weaves together material quality, logistics, payment terms, and trust between buyer and seller.

Historically, proving material quality often required years of trading together. Technology now helps shorten that curve. By using trade-verified data to build a reputation for consistent quality, sellers can give lesser-known buyers the confidence to price their material more competitively, without waiting years to establish that trust.

MYTH 6: A GUT FEELING ALONE IS ENOUGH

Unlike primary metals, scrap has never had a true system of record for trade data. A price only formally exists when a deal is struck and payment is made. In reality, though, every negotiation contains valuable signals that traditionally vanish into the ether once a load is sold.

By using a marketplace to trade, recyclers begin generating data-rich profiles — not just on their own material quality, but also on buyer responsiveness, reliability, and how their deals compare to broader market trends. Over time, this builds a living system of record that helps sellers drive better trading outcomes in real time.

Lisa Kagan, co-founder of Buddy, puts it this way: “AI may be

GAINnext™ AI –high purity PET performance

Take PET Sorting to the next level!

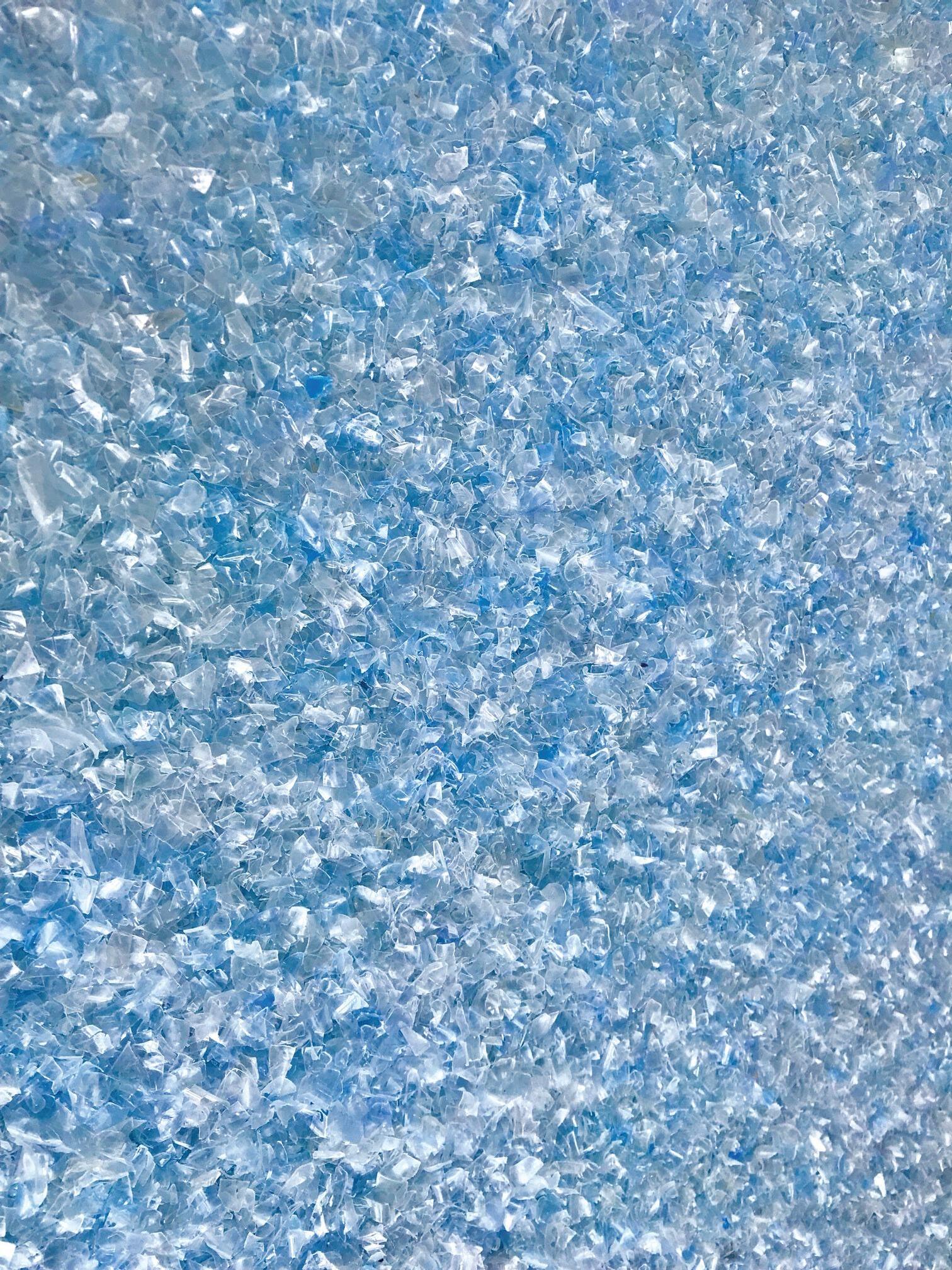

Developed specifically for North American recyclers, TOMRA’s GAINnext™ PET Cleaner leverages deep learning AI visual recognition to boost PET recovery and purity. PET Cleaner allows you to:

• Separate opaque white packaging, textiles and foils from PET

• Remove over 92% of opaque objects with titanium dioxide protection

• Enhance sorting of clear and color PET

• Unlock new revenue streams

the buzzword of the moment, but it’s important to understand the foundation beneath it: data. Data is to AI what shredder feed is to a shredder. Without it, there’s nothing to process. This is a watershed moment for the industry — one that will only reach its full potential if recyclers embrace a more data-driven approach.”

MYTH 7: CHANGE IS HARD

Scrap trading has a reputation for being slow to adapt, but change doesn’t have to be painful. Modern platforms are designed with usability front and centre, making the leap easier than many expect.

In Buddy’s case, the app was intentionally designed to be intuitive: “So easy, even your dad can use it.” Recyclers who once hesitated are finding that listing a load, comparing offers, and closing deals takes just a few taps.

“It’s so simple,” says Derrick Brion of Clayton County Recycling. “Simplicity and time savings.”

Those gains matter in a business where hours saved are money earned.

FROM OPACITY TO CLARITY

The opacity of scrap trading may have once felt inevitable, but technology is proving otherwise. Marketplaces that provide transparency, competition, and standardization are changing the way recyclers do business.

And, as Wilkinson points out, the impact goes beyond numbers: “When you feel cornered into choosing between the lesser of two evils, Buddy gives you fresh options. There’s

always someone else bidding.”

The shift to transparency is not about dismantling the relationships that have always defined this industry — it’s about strengthening them. By removing unnecessary uncertainty, technology allows traders to focus on what matters most: trust, service, and sustainable long-term growth.

That shift is accelerating. In September, Buddy launched its domestic trading platform, giving recyclers the ability to connect with more vetted buyers across North America.

“Having seen the impact we made on the export side of things, I believe domestic U.S. trading is going to be a game changer for all involved,” says Stu.

Buddy’s business model reflects its commitment to sellers by making it free for recyclers to list and sell material. Buddy earns its revenue on the buy side, with a take rate of 0.25–0.5 percent of transaction value. That structure has helped ensure that vetted buyers on the platform continue competing aggressively, helping them win business by outbidding those still operating off-platform.

In the end, the myths fall away, and a clearer, more resilient market takes shape — one where relationships endure, prices are transparent, and recyclers enter every conversation with confidence.

BUDDY was founded by Stu Kagan, who spent nearly three decades as an operator and trader in the scrap industry, and his wife, Lisa Kagan, who has a background in emerging and disruptive tech and venture creation.

◊ Rugged construction

◊ An adjustable internal

Accent Wire Tie

Benlee Trailers

Buddy

Bulk Handling Systems (BHS)

CP Group

Dings Co. Magnetic Group

Eggersmann North

America Inc. ..............................................

Harris American

Industrial Magnetics, Inc.

Industrial Netting .................................

Machinex Industries Inc.

New West Gypsum

Recycling Inc. ............................................

OVB Holdings LLC

Schutte Hammermill

ScrapWare Corp. .....................................

TOMRA Recycling Inc.

VAN DYK Recycling Solutions

Visia ........................................................

CONNECT WITH US @RecyclingPN

Processing Solutions Capable of Closing the Loop

Turnkey processing, washing, and extrusion systems