BUILD MORE WITH A TEAM THAT HAS YOUR BACK.

At SMS Equipment, we’re more than machines from trusted brands like Komatsu. No matter your project, we’re the people beside you—today and every day—bringing industry-leading technology and expertise to your job site.

Because the right partnership makes

WPS 62 (i): The WPS 62(i) placer/spreader rounds of f WIRTGEN’s slipform paving product portfolio. It is always called for in situations where high productivity is required when paving over pre-placed steel rebar or when concrete can only be supplied from the side. Field-tested and proven slipform pavers like the SP 62(i) compact the concrete placed and spread before them and pave it true to grade and slope A texture curing machine like the TCM 180(i) can produce a transverse, diagonal or longitudinal surface texture and spray a homogeneous coating of a curing agent onto the concrete surface The result is a concrete surface that fulfils even the highest quality standards Take advantage of the innovative solutions from the technology leader in the road construction segment.

18

30 HIGHLIGHTS FROM BAUMA 2025

38 COVER STORY REACHING NEW HEIGHTS: TELEHANDLERS FOR CONSTRUCTION

FIELD REPORT: JOHN DEERE CONSTRUCTION

FIELD DAYS 2025

THE LATEST CRANE INTRODUCTIONS & TECHNOLOGY

WE’D LIKE TO HEAR FROM YOU

Do you have a job site story, innovation, or industry concern that our readers should know about? We’d like to hear from you.

DESIGN & PRODUCTION

Morena Zanotto morena@baumpub.com 604-291-9900 ext. 325

PRESIDENT/PUBLISHER

Ken Singer ksinger@baumpub.com 604-291-9900 ext. 226

VICE PRESIDENT/CONTROLLER

Melvin Date Chong mdatechong@baumpub.com

FOUNDER

Engelbert J. Baum

Published by: Baum Publications Ltd.

Contact: Editor in Chief Kaitlyn Till at ktill@baumpub.com or 604-291-9900 ext. 330 JULY/AUGUST 2025 | VOLUME 40 • NUMBER 5

Subscription: To subscribe, renew your subscription, or change your address or other information, go to: http://mysubscription.ca/heg/ serves the Canadian engineered construction industry including: roadbuilding and maintenance; highways, bridges, tunnels; grading and excavating; earthmoving; crushing; trucking and hauling; underground utilities; trenching; concrete paving; asphalt paving; demolition; aggregates production; fleet maintenance; and asset security and management. The magazine is distributed to key industry personnel involved in these sectors.

Subscription Price: In Canada, CDN $91.00; Outside Canada, US$149. Heavy Equipment Guide is published eight times a year in January/ February, March, April, May/June, July/August, September, October, and November/December.

Heavy Equipment Guide accepts no responsibility or liability for reported claims made by manufacturers and/or distributors for products or services; the views and opinions expressed are those of the authors and not necessarily those of Baum Publications Ltd.

Copyright 2025, Baum Publications Ltd. No portion of this publication may be reproduced without permission of the publishers.

We acknowledge the financial support of the Government of Canada.

Printed on paper made of FSC®-certified and other controlled material. ISSN 1715-7013.

PUBLICATIONS MAIL AGREEMENT NO. 40069270

Return undeliverable Canadian addresses to: Circulation Dept., 8799 Highway 89, Alliston, ON L9R 1V1 email: heg@mysubscription.ca Toll-free: 1-866-764-0227

POWER COUPLE

Whether you’re digging, loading, moving, placing – or all of the above – you need reliable, performance-driven equipment to get the job done right. Wacker Neuson o ers a powerful line of material handling models designed for jobsite e ciency and operator comfort. From excavators and dumpers to compact track loaders, and wheel loaders, Wacker Neuson has all it takes for the challenges you face.

EXCAVATORS | LOADERS | DUMPERS

FAYAT GROUP ACQUIRES MECALAC AND LEEBOY

FAYAT Group has expanded its business with two new acquisitions and has opened a new 100,000-square-foot distribution centre to increase localized production of equipment for North America.

Earlier this year, FAYAT Group signed an agreement with ST Engineering for the acquisition of LeeBoy, a U.S.-based company specializing in the design and manufacturing of road construction equipment. Specifically, LeeBoy offers a range of pavers, compact motor graders, and road maintenance equipment. The acquisition is pending regulatory approval and is expected to close in Q4 2025. FAYAT Group says that it intends to maintain the LeeBoy brand.

FAYAT Group has also acquired a 100 percent stake in the Mecalac Group, which offers a wide range of construction equipment for urban worksites, including excavators, loaders, dumpers, and backhoe loaders.

The Mecalac Group joins the Fayat Road Equipment Division and will strengthen its offerings, particularly for urban projects worldwide. The Division now has 29 production sites in Europe, Asia, and the Americas.

Within the Group, Mecalac will retain its autonomy, offering its clients advanced technological solutions marketed under the Mecalac brand. Mecalac will collaborate with other FAYAT Group entities to develop future technologies and expand its distribution network.

In addition to expanding the company’s presence with new acquisitions, FAYAT Group has also invested in a brand-new 100,000-square-foot parts distribution centre in Fairfield County, South Carolina. The $13.7 million facility will expand FAYAT’s operations for its Road Equipment Division and will improve its aftersales support for contractors throughout North America. The project will also enable FAYAT to increase localized production for its road machinery and enhance its training capabilities.

The new FAYAT parts distribution centre is scheduled to be operational in Q4 2025.

VOLVO CE STRENGTHENS EXCAVATOR PRODUCTION, SELLS STAKE IN SDLG

VDEVELON AND HD HYUNDAI TO MERGE

olvo Construction Equipment is making a significant investment to expand excavator production worldwide. Three facilities will have approximately $261 million invested to expand crawler excavator production to meet growing contractor demands, mitigate supply chain risks, and reduce reliance on long-distance logistics. These facilities include Shippensburg, Pennsylvania, U.S.; Changwon, South Korea; and a location in Sweden.

By expanding production capabilities in key markets, Volvo CE will reduce dependency on any single manufacturing facility and become less reliant on long-distance logistics. Supply chain risks will also be mitigated by expanding domestic supplier bases, allowing Volvo to more nimbly manage any economic or regulatory challenges.

Additionally, it aims to lower carbon emissions by minimizing transportation distances while relying on local suppliers and fostering stronger connections with domestic supplier bases.

Volvo CE has also signed a contract to sell its ownership in China-based Shandong Lingong Construction Machinery Co. (SDLG) for 8 billion SEK (USD 837 million), with closing expected in the second half of 2025. Going forward, Volvo CE says it will target focused business segments in China and enhance its utilization of the Chinese supplier ecosystem. The company will maintain its strategic focus on developing sustainable solutions in the Chinese construction industry, targeting key segments such as mining, quarry, aggregates, and heavy infrastructure.

HD Hyundai will merge its construction equipment divisions to create a new company, tentatively named HD Construction Equipment, effective January 1, 2026.

The merger will combine HD Hyundai Infracore (DEVELON) and HD Hyundai Construction Equipment. Hyundai and DEVELON brands will continue to coexist. The two companies currently operate independently in North America through distinct dealer networks, and that independent brand and dealer network structure will remain in place.

Pending shareholder approval and regulatory review, HD Hyundai says that the merger will create a stronger global construction equipment business while maintaining the success of DEVELON and Hyundai in North America.

The advantages of merging the two companies include: providing greater price competitiveness through increased sales; speeding up innovation in smart and electrified equipment; enhanced supply chain efficiency and product quality; expanding aftermarket support; growing the product lineup, from compact to ultra-large machines; and building on the growth of engine sales and aftermarket services.

HIGHLIGHTS FROM BAUMA 2025

Innovative new equipment and concept machines for earthmoving.

Turn to page 30.

CATERPILLAR CELEBRATES ITS CENTENNIAL THROUGHOUT 2025

THE COMPANY MARKS THE MILESTONE WITH SPECIAL EDITION MACHINES AND AN INVESTMENT IN THE FUTURE

BY STEPHANIE BONTORIN, ASSOCIATE EDITOR

Caterpillar is marking one hundred years in business with a series of special events, celebrations, and limited edition machinery revealed throughout 2025. During these celebrations the company is reflecting on its achievements, innovations, and commitment to heavy equipment and the industries it has served over the past century while looking ahead to the next 100 years.

Special events have taken place in Sanford, North Carolina; Peoria, Illinois; and at Caterpillar’s headquarters in Irving, Texas, where employees and the families of founders C.L. Best and Benjamin Holt gathered to look back at one hundred years of achievements and goals for the future.

TRAILBLAZING INNOVATIONS

Caterpillar was founded in 1925 as a result of the merger between the Holt Manufacturing Company and C.L. Best Tractor Company.

The Holt Manufacturing Company invented the steam-powered track-type tractor in California in 1904, and Holt found international success selling these tracked machines to farmers. Equipment that had formerly been wheeled could now undulate across muddy soil on tracks. During the First World War,

Holt supplied the U.S. Army with these manoeuvrable tractors to transport heavy equipment and supplies through the muddy fields of Europe.

While Holt focused on the war effort, the C.L. Best Tractor Company gained a customer base across the U.S. with new tractor designs focused on the combustion engine. Following the war, Holt had a global reputation and modern manufacturing facilities, while Best enjoyed a domestic presence, an advanced dealer network, and an expanded product line. The merger of the two companies combined their funds and technological resources for investment in new machine designs, which revolutionized agricultural equipment. A family member of Holt had noted the similarities between the tracked agricultural machine and the waving crawl of a caterpillar, so in 1925 the new company was named the Caterpillar Tractor Co.

The Caterpillar Tractor Co.’s first official product melded the proven functions of Holt’s and Best’s previous machines into an entirely new design: the Twenty Track-Type Tractor. Released in 1927, it was named the “Twenty” because of its 20-horsepower rating. The success of this original track-type tractor laid the groundwork for the iconic Cat dozer line that remains central in the company’s equipment lineup to this day.

CATERPILLAR IS CELEBRATING ITS INNOVATIONS, PAST AND PRESENT, THROUGHOUT 2025.

LIMITED EDITION CENTENNIAL GREY EQUIPMENT

To kick off the centennial celebration, Cat released a limited edition Centennial Grey paint colour for select equipment, starting with a D8 dozer. The new paint scheme is a throwback to the original machines and the more subdued palette from the early days of the brand. Cat’s first Hi-Way Yellow machines were introduced in 1931. The original yellow was discontinued in the 1970s and replaced with Caterpillar Yellow in 1979; the company has kept this iconic colour which is now associated with construction equipment across the globe. Throughout 2025 the Centennial Grey paint has been spotted on skid-steer loaders, wheel loaders, mini excavators, and more.

CATERPILLAR AT BAUMA 2025

At bauma 2025, Caterpillar celebrated with the theme “The Next 100 Years,” highlighting its commitment to innovation and sustainability. The 9,000-square-metre exhibit featured 48 machines, including 17 brand-new models or upgrades. These included equipment from the battery electric lineup, expansions to next-generation machine lineups, and additions to the demolition, waste handling, and recycling portfolios.

CAT TRIAL 14: AFTER HOURS

The Cat Trials began as a way for the company to put its best products, services, and technology on display in entertaining short videos, showing contractors that Cat equipment can conquer any challenge.

Past trials include using large and medium excavators, wheeled excavators, and telehandlers to stack giant Jenga blocks; a life-sized game board where skilled operators remotely operated Cat mini excavators to play PAC-MAN; and the infamous trial where a mini excavator was tasked with driving through a china shop without breaking any of the dishes.

To celebrate its centennial, Cat’s 14th trial showcased a century of machine advancements and achievements during a nighttime spectacle. Cat Trial 14: After Hours included demonstrations of equipment from Caterpillar’s past, like the Holt T-35, a tractor released in 1921, as well as milestone machines like the Cat 797B, the company’s first 400-ton truck.

COMMITMENT TO THE WORKFORCE

To further mark its centennial, Caterpillar is making a massive investment in a resource that will be vital to its success over the next 100 years: people. As part of the ongoing celebrations, the company pledged $100 million over the next five years to help equip the workforce of the future with the skills they need, leveraging technology to meet global market demands as the world undergoes a rapid digital transformation.

Caterpillar’s work to help close the growing skills gap in the industry includes ThinkBIG, a two-year program that pays students while they train to become machine technicians, and the company’s STEM outreach programs that introduce K–12 students to different careers in manufacturing.

As the job market continues to evolve, skill sets will need to keep up with advancements in artificial intelligence, automation, data analytics, and more. Caterpillar says it intends to keep pace with technological growth across sectors to remain competitive.

ward-looking designs, advanced technologies, and global workforce development.

Next year, Caterpillar will display its newest machines at CONEXPO-CON/AGG 2026 in Las Vegas, with a larger-than-life exhibit and competitions. Cat will host the third Global Operator Challenge to test operators’ agility, resilience, and versatility on a wide range of construction equipment and technology. The company will also host the first-ever Dealer Technician Challenge to demonstrate this high-tech, high-impact, and high-demand career.

Since 1925, Caterpillar has driven a century of change in the construction industry, and, as the company looks ahead to the next 100 years, it takes the role of engaging newcomers and attracting talent to the equipment manufacturing, service, and construction industries seriously while continuing to deliver equipment solutions that will meet the needs of the industries it serves — from the biggest quarries to backyard DIY hobbyists. HEG

CAT HAS RELEASED A LINEUP OF LIMITED EDITION CENTENNIAL GREY MACHINES IN 2025, INCLUDING MINI EXCAVATORS.

THE CENTENNIAL GREY CAT D8 DOZER.

NATIONAL EQUIPMENT OPERATOR CHAMPIONSHIPS TO BE HELD AT THE UTILITY EXPO

The National Equipment Operator Championships will bring together skilled operators from across the country to compete in a series of hands-on events designed to test precision, control, and safety in utility-related tasks. Events will include games like hole-in-one putting, soccer, cornhole, and a pipe placement challenge, all with construction equipment.

The competition will span two days, with qualifying rounds at The Utility Expo 2025 on October 8 and the championship prize

will be awarded on October 9. Participants will rotate in a bracket-style format. Finalists will be ranked by cumulative points and time, with a sudden-death round in the event of a tie.

CANADIAN RENTAL ASSOCIATION AND MARKETPLACE EVENTS COLLABORATE

Anew partnership between Marketplace Events (MPE) and the Canadian Rental Association (CRA) will reinforce both groups’ commitment to advancing Canada’s heavy equipment and rental industries. The partnership will focus on educational initiatives, increased member visibility, and stronger industry engagement. This collaboration will span four major events, beginning with two in 2026:

The Atlantic Heavy Equipment Show (AHES) will take place from March 26 to 27 in Moncton, New Brunswick. Celebrating 40 years of driving heavy industry in Atlantic Canada, AHES has over 200,000 square feet of indoor and outdoor exhibits and attracts 10,000+ professionals.

The National Heavy Equipment Show (NHES) will be held from April 23 to 24 in Mississauga, Ontario. NHES brings together industry leaders, cutting-edge machinery, and innovative solutions for construction, roadbuilding, and more.

DEPTHS OF INNOVATION

Excavator Boring Shields (EBS) and the EX-50 Excavator support manned-entry tunneling with joystick controls, laser-guided alignment, spoil removal, and sand shelves with hydraulic doors to prevent subsidence.

Volvo Penta recently hosted its Industrial Distributor Meeting in Florida, bringing together partners from across North America to align on strategic priorities and recognize top-performing distributors.

The company’s annual meeting focused on honouring excellence in service and sales as well as achieving continued progress in the industrial segment.

Volvo Penta recognized the following top-performing distributors for their exceptional achievements in 2024:

Distributor of the Year: Wajax

Service Excellence Award: Atlantic Detroit Diesel Allison

Top Sales – Industrial Engines: Interstate Industrial Systems

Top Sales – Industrial Engine Parts: Wajax

Finlay

Electric scalping screen

The Finlay 883+ Electric is a heavy-duty scalping screen engineered for demanding applications in quarrying, mining, C&D waste, and iron ore processing. It features a fully electric drive system that powers the feeder, screenbox, and conveyors, offering compatibility with grid power or a genset. The on-board engine powers the tracks for relocation without external support. A redesigned feeder allows rear feeding with a wheel loader, while hydraulic extensions and a wear-resistant steel hopper improve durability and flexibility. By switching to electric, operators can reduce CO₂ emissions, lower maintenance costs, and enjoy quieter operation.

CASE Construction Equipment Mini excavators

CASE has expanded its mini excavator lineup with four new models: the diesel-powered CX12D, CX19D, and CX60D and the battery-electric CX25EV. Ranging from 2,932 to 13,162 pounds, these machines offer a range of power and features suited to tight job sites and smaller-scale construction tasks. Designed for easy transport, manoeuvrability, and versatility in tight or sensitive job sites, all models feature zero or minimal tail swing, intuitive controls, and simplified maintenance through accessible service points. Two standard auxiliary hydraulic circuits and optional quick couplers support a wide range of attachments. The CX60D includes a long arm and six-way blade compatibility. The CX25EV runs on a 32.3 kWh battery and delivers quiet, emissions-free performance comparable to diesel.

Electric scalping screen

Mini excavator

Telehandlers offer a special kind of flexibility. They deliver heavy materials to hard-to-reach parts of the job site, whether that’s deep within the ground floor of a building, or multiple stories up, but are more flexible than small cranes or forklifts. In addition to forks, telehandlers can use a variety of attachments, such as sweepers for cleanup and buckets for moving dirt and stone, and some are compatible with many skid-steer attachments. There is an incredible range of telehandler options — from more than a dozen OEMs — in North America. Turn the page to explore the defining characteristics of different OEMs’ telehandler lineups and learn about key models.

REACHING NEW HEIGHTS TELEHANDLERS FOR CONSTRUCTION

JCB’s versatile lineup includes compact, mid-range, and high-capac ity models tailored to construction, agriculture, and industrial sites. Operating capacities range from 5,000 to 14,000 pounds and engine options range from 74 to 145 horsepower. Each model is engineered for durability, operator comfort, and productivity. Standard features include climate-controlled cabs with ergonomic controls, all-around visibility, and JCB’s LiveLink telematics for real-time diagnostics. Additional innovations, like the welded U-shaped boom design and the fuel-efficient JCB ECOMAX engine, deliver standout performance. Camera options,

FEATURED MODEL: 510-56

The JCB 510-56 is built for demanding construction applications, including masonry, framing, steel erection, and material staging. With a 10,000-pound lift capacity and high-boom design, it’s ideal for vertical lift tasks on multi-storey job sites. Key features include wide-set stabilizers for excellent stability, a side-mounted engine for simplified service access, and low-effort servo controls arranged in a familiar pattern. A rear cutout delivers expansive rearward visibility, while an integrated lifting hook streamlines material handling. Optional features include air conditioning, work lights, and industrial tires.

Engine power: 109 hp

Lift capacity: 10,000 pounds

Maximum lift height: 56 feet

Lift capacity at maximum height: 3,000 pounds

Maximum reach: 42 feet

Ba variety of demanding applications with lift capacities up to 9,000 pounds and extended reach up to 23 feet. All models feature four steering modes: all-wheel, front-wheel, crab, and semi-crab. Operators will be comfortable in the spacious, high-visibility cabs with intuitive controls, air-suspension seating, and climate control. Bobcat telehandlers offer excellent attachment versatility via the Power Bob-Tach mounting system on the TL519/TL623 and Power Quick-Tach attachment mounting system on the TL723/TL923. Automatic ride control enhances stability and reduces spillage, and the Bobcat engine delivers high-torque performance with a non-DPF design.

Lift capacity at maximum reach: 3,000 pounds

Turning radius: 14 feet 1 inch

FEATURED MODEL: TL623

Bobcat’s TL623 has a compact size (82.7 inches width and 84.3 inches height) that enables the machine to fit into small openings, buildings, and other tight spaces. The TL623 includes five operation modes to give operators the versatility they need for a wide variety of applications. Changing non-hydraulic attachments without leaving the cab is quick and easy with the Power BobTach mounting system. Operators will further appreciate a single, intuitive joystick and fingertip

Engine power: 74 hp

Lift capacity: 6,000 pounds

Maximum lift height: 23 feet

Lift capacity at maximum height: 4,400 pounds

Maximum reach: 13 feet 3 inches

Lift capacity at maximum reach: 2,300 pounds

MAGNI

Magni offers a range of telehandlers, including rotating, fixed, and heavy-duty models. The company has more recently entered the compact telehandler segment. Throughout the range, Magni has focused on producing safe, strong, and reliable models, including the fixed telehandler range which combines craftsmanship with innovation and technology to aim for high-end performance in each application. The TH range is flexible and adapts to a variety of applications, including construction and mining sectors. A standout feature is Magni’s Load Moment Indicator (LMI), which is designed to monitor machine movements, updating and displaying the relevant load data in real time to reduce safety risks and help the operator maintain full control of the machine during lifting operations.

Xmaximum lift heights of up to 56 feet. Standard features include four-wheel drive, three steering modes, and ROPS/FOPS-certified cabs designed for operator safety and comfort. Each model is equipped with high-visibility cabins, load-handling safety systems, and robust boom structures for reliable operation. Intuitive joystick controls and ergonomic layouts enhance productivity across all job site conditions. Optional features include a fuel heating system, foam-filled tires, boom wiring harness, and a variety of fork and carriage configurations tailored to specific industry applications.

FEATURED MODEL: 3,5.9

The new Magni TH 3,5.9 compact telehandler is equipped with Magni’s Load Moment Indicator (LMI) integrated into the Magni Combi Touch System (MCTS) to guarantee operating safety with any compatible attachment. The cab is similar to Magni’s smallest model, but has more space. It offers wide visibility and carefully designed ergonomics to keep the operator safe, comfortable, and alert on the job site. The dual boom extension system keeps the machine dimensions compact, providing excellent lifting height without sacrificing agility.

Engine power: 75 hp

Lift capacity: 7,700 pounds

Maximum lift height: 29 feet 2 inches

Lift capacity at maximum height: 3,950 pounds

Maximum reach: 19 feet 10 inches

FEATURED MODEL: XT1256U

The XCMG XT1256U is built for heavy-duty lifting, loading, and placement tasks across construction, agriculture, and industrial material handling. Key features include four-wheel drive, three steering modes, a robust telescopic boom, and a ROPS/FOPS-certified cab with wide visibility and a ±10-degree cab levelling system for stability on uneven terrain. For added safety, it can be equipped with a load moment indicator. Optional configurations include boom wire harness, hydraulic port expansion, foam-filled tires, and a fuel heating system. Available attachments include a bucket, hook, and winch.

Engine power: 130 hp

Lift capacity: 12,000 pounds

Maximum lift height: 56 feet

Lift capacity at maximum height: 5,000 pounds

Maximum reach: 43 feet

Lift capacity at maximum reach: 3,500 pounds

Turning radius: 14 feet 1 inch

SANY

As Canadian job sites grow tougher and more complex, contractors need more than performance — they need reliability, versatility, and long-term value. SANY Canada offers a range of telehandlers that are built for real-world demands. From northern winters to tough terrain, SANY telehandlers are made to thrive in Canadian conditions. Buyers have the option to choose between Cummins or Deutz engines. Sany telehandler models feature Dana powertrain components and are supported coast-to-coast by the Sany dealership network. In 2025, Sany Canada will offer its first electric telehandler model, the 625E, which is ideal for quiet, zero-emissions operation indoors and on low-emission job sites.

SKYJACK

Skyjack’s telehandler series is designed with all major service points easily accessible, limiting downtime and increasing customers’ utilization. Skyjack’s FLEXCAB is an innovative cab design that allows fleet operators to easily convert between open and enclosed cabs with simple hand tools. AXLDRIVE is an axle-based drive system with an operator-controlled locking differential on the rear axle and limited slip differential on the front axle. Skyjack’s SkyCODED colour-coded and numbered wiring system allows for straightforward troubleshooting and repair. READYHOOK is a yoke-mounted lifting hook with capacity to match the machine’s maximum lifting capacity. It allows for the safe under-slinging of loads and avoids the practice of using the forks as an underslung lifting device.

FEATURED MODEL: STH1056A

The STH1056A is built for dependable performance across residential, commercial, and industrial job sites. With exceptional visibility, operator comfort, and responsive boom control, the STH1056A is designed to keep productivity high and downtime low. This telehandler also offers excellent visibility as the operator can see all four tires from the seated position. Standard features include wide-angle rear-view camera and reverse sensing system, LED work lights, flashing beacon, and lift hook.

Engine power: 121 or 130 hp

Lift capacity: 10,000 pounds

Maximum lift height: 56 feet 3 inches

Lift capacity at maximum height: 10,000 pounds

Maximum reach: 42 feet 11 inches

Outside turning radius: 14 feet 1 inch

FEATURED MODEL: SJ519 TH

Designed specifically for rental, the SJ519 TH suits numerous applications including material handling in construction, warehouse, and industrial settings. Along with the rest of Skyjack’s TH series, the SJ519 TH has been updated to include maintenancefree (greaseless) main bearings, a dual-tilt compensation cylinder design for load distribution and reliability, a relocated ECU for easier service access, a high-pressure filter system and hydraulic tank design to reduce contamination, rental yard repairable steel engine cowling, and an ergonomic seat.

Engine power: 74 hp

Lift capacity: 5,500 pounds

Maximum lift height: 19 feet 1 inch

Lift capacity at maximum height: 4,440 pounds

Maximum reach: 11 feet 1 inch

Lift capacity at maximum reach: 2,000 pounds

Turning radius: 10 feet 5 inches

FOCUS ON TELEHANDLERS

MANITOU

M1055, MTA 1242 and MTA 1255, with lift capacities ranging from 6,000 to 12,000 pounds and lift heights from 42 to 55 feet. Manitou’s MTA series innovations include a new “SuperView” cab, redesigned engine accessibility, automatic transmission, operator aided pop-ups, EasyStep, 5-speed transmission, and automatic parking brake. The company has since filled out the lineup with more models, including its most compact MTA telehandler, the MTA 519, and variants tailored to the rental market.

FEATURED MODEL: MTA 519

The new Manitou MTA 519 is extremely compact at 5-feet 11-inches wide and 6-feet 4-inches tall, making it small enough to fit through garage doors and down ramps into the lower levels of structures. One of the most important advances on the new MTA 519 is the skid-steer quick attach system, which allows the machine to operate standard flow skid-steer and CTL attachments. Rental businesses can rent out this telehandler with a range of attachments that they already have; it’s also a major convenience for fleet managers who may already own a significant number of attachments.

Engine power: 75 hp

Lift capacity: 5,500 pounds

Maximum lift height: 19 feet 1 inch

Lift capacity at maximum height: 3,000 pounds

Maximum reach: 11 feet

Lift capacity at maximum reach: 1,850 pounds

Turning radius: 11 feet

GENIE

Gmultiple steering modes, and proportional joystick controls for precise handling. Genie telehandlers are compatible with a variety of attachments, including buckets, truss booms, and pallet forks, enhancing their adaptability to various tasks. Optional features, such as the Lift Connect telematics system, rear proximity alarms with camera displays, and hydraulic quick-attach couplers, further improve safety and efficiency. Additional options include climate-controlled cabs, cold weather packages, and Enduro A/T tires.

FEATURED MODEL: GTH-1244

The Genie GTH-1244 telehandler is purpose-built for high-capacity pickand-carry applications, delivering a 12,000-pound lift capacity without stabilizers for faster cycle times. Ideal for steel erection, energy, and industrial maintenance, the GTH-1244 combines a rugged boom with simplified design to reduce maintenance costs. It features a single lift cylinder, 74-hp DEF-free engine, and Enduro A/T foam-filled tires for durability. Operators benefit from 360-degree visibility, a multi-functional joystick, and load adjustment without rear axle locking. Options include rotating, swing, and side-shift fork carriages.

Engine power: 74 or 121 hp

Lift capacity: 12,000 pounds

Maximum lift height: 44 feet 7 inches

Lift capacity at maximum height: 8,000 pounds

Maximum reach: 30 feet 7 inches

Lift capacity at maximum reach: 2,000 pounds (4,000 pounds with optional stabilizers)

Turning radius: 13 feet 11 inches

AUSA

AUSA telehandlers are compact, versatile machines designed for efficient material handling in confined or rugged environments. A side-mounted telescopic boom enhances stability and operator visibility while maintaining a narrow profile for superior manoeuvrability, and the ergonomic cabs offer excellent visibility, intuitive controls, and operator comfort. Advanced steering modes, including front-wheel, fourwheel, and crab steering, provide excellent control on uneven terrain. AUSA telehandlers are compatible with a wide range of attachments, enabling users to tackle various tasks with a single machine. Designed with durability and serviceability in mind, simplified maintenance access reduces downtime.

CATERPILLAR

camera for enhanced visibility, and a load stability indicator system to pro vide visual and audible alerts to the operator regarding forward machine stability during operation. All models feature a pilot-controlled joystick, allowing for predictable and smooth multifunction performance, along with a standard tilt steering column for added operator comfort. Service and maintenance have also been optimized, with extended service intervals reducing downtime and cost. The integrated telematics system provides real-time diagnostics with remote troubleshooting and software flashing capabilities.

FEATURED MODEL: T235H

This compact, all-terrain telehandler is engineered for efficient material handling in confined and rugged environments. Its 4x4x4 drive system and three steering modes enable precise operation on uneven terrain. The hydrostatic transmission, powered by a 44.5-hp Kubota diesel engine, ensures smooth performance with low fuel consumption. An ergonomic cab offers 360-degree visibility and features an intuitive digital display for easy access to controls and diagnostics. Quick-connect hydraulic couplings and compatibility with various attachments enhance its versatility.

Engine power: 44.5 hp

Lift capacity: 5,000 pounds

Maximum lift height: 16 feet 4 inches

Lift capacity at maximum height: 3,970 pounds

Maximum reach: 7 feet 9 inches

Lift capacity at maximum reach: 1,764 pounds

Turning radius: 9 feet 11 inches

FEATURED MODEL: TH1255

The TH1255 is ideal for material handling and heavy lifting in construction, utility, industrial, and landscaping applications. The range of Cat attachments adds to its versatility, and three steering modes provide manoeuvrability in tight spaces. Available with either a canopy or an enclosed cab with air conditioning, standard comfort features include a tilt steering column, dual charging ports, a full suspension seat, and a full-colour LCD monitor. Optional upgrades, including full coverage fenders, cold weather packages, and a top window sunshade, are available.

Engine power: 74 or 115 hp

Lift capacity: 12,000 pounds

Maximum lift height: 54 feet 7 inches

Lift capacity at maximum height: 5,000 pounds

Maximum reach: 41 feet

Lift capacity at maximum reach: 3,500 pounds

Turning radius: 13 feet 1 inch

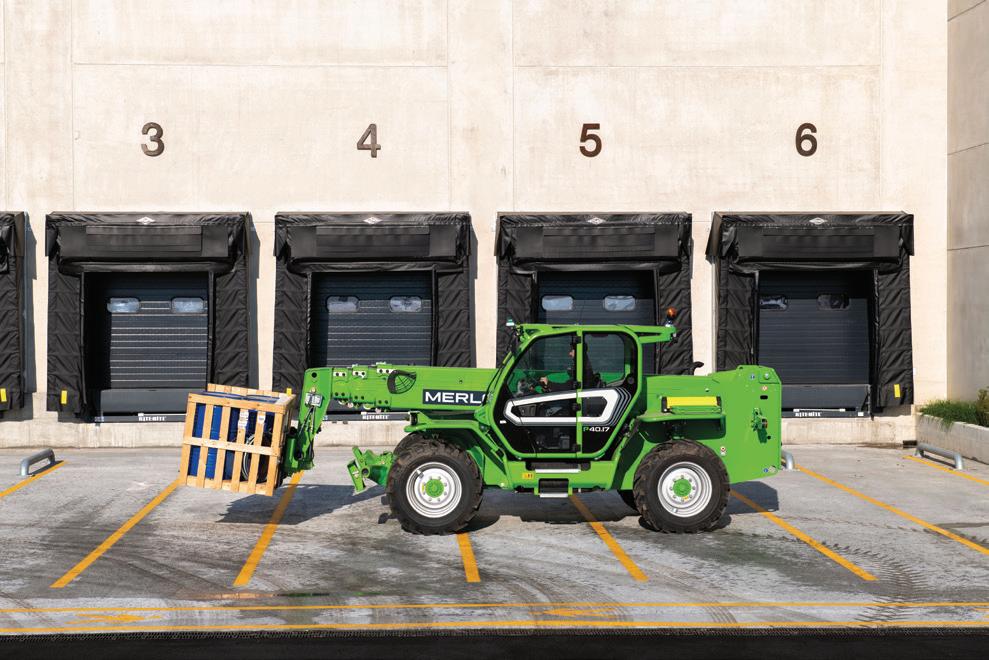

MERLO

Merlo telehandlers feature cutting-edge design, innovative tech nology, and excellent operator comfort. Some of the key standard and distinguishing features include the rapid and precise Swedish steel mast with positive deflection. A Tac-Lock device allows operators to hitch and unhitch attachments without exiting the cab, and Merlo's “Ring of Steel” design provides protection to key components and allows for better weight distribution, eliminating the need for a counterweight. Additional features include a quick access brake system; oversized axles with three anchor points for increased robustness; a low-pressure, highflow hydraulic system; 360-degree visibility from the cab; an anti-tipping system; and all-wheel drive and three steering modes (front, all-wheel, and crab steering).

With lift capacities ranging from 5,000 to over 12,000 pounds and maximum lift heights exceeding 50 feet, JLG telehandlers are ideal for reliable lifting, placing, and transporting of materials in construction, agriculture, and industrial applications. Their advanced hydraulics, all-wheel steering, and spacious operator cabs ensure precise control and operator comfort. Many models include SmartLoad Technology for real-time load monitoring and enhanced safety. Available with a wide range of attachments, such as buckets, truss booms, and forks, JLG telehandlers adapt easily to different tasks, increasing job site productivity. Built with durability and ease of maintenance in mind, they help reduce downtime and total cost of ownership.

FEATURED MODEL: 40.17

The 40.17 is a safe and efficient telehandler that combines boom precision, manoeuvrability, and speed within a uniquely compact frame. Thanks to its quick-attach and Tac-Lock systems, the machine can seamlessly transition from a rotating, remote-controlled work platform to a winch, bucket, or any other attachment needed to get the job done. Merlo’s integrated boom sideshift eliminates the need for machine repositioning. It features a hydrostatic transmission. Compact, fast deploying stabilizers are mounted on the axle. A heated and pressurized cab is available.

Engine power: 115 hp

Lift capacity: 8,800 pounds

Maximum lift height: 54 feet 5 inches

Lift capacity at maximum height: 6,000 pounds

Maximum reach: 41 feet

Lift capacity at maximum reach: 1,300 pounds

FEATURED MODEL: E313 ELECTRIC

The JLG E313 is an ultra-compact, electric telehandler engineered for zero-emission performance in indoor, urban, and noise-sensitive environments. Powered by six maintenance-free 48V lithium-ion batteries, the E313 offers up to four hours of continuous operation and features dual on-board chargers compatible with 110V and 220V outlets. Its two-speed electric transmission provides both two-wheel and four-wheel drive modes for adaptable terrain handling. Safety is enhanced with Load Stability Indication and an Operator Presence system, while a universal skid-steer coupler expands attachment versatility.

Engine power: 8.6 kW electric-drive motor

Lift capacity: 3,500 pounds

Maximum lift height: 13 feet 1 inch

Lift capacity at maximum height: 1,800 pounds

Maximum reach: 7 feet 7 inches

Lift capacity at maximum reach: 1,415 pounds

Turning radius: 11 feet 2 inches

BIG SHOULDERS

It’s a big, heavy world out there — let Manitou do the heavy lifting for you. From compact telehandlers to rotating telehandlers and everything in between: if there’s a way to lift it, Manitou will help you handle the weight of the world.

These easy-to-use, reliable telehandlers have proven themselves around the world, on jobsites big and small. Put the durability of Manitou telehandlers to work for you

Learn more at Manitou.com.

FOCUS ON TELEHANDLERS

LIEBHERR

Liebherr’s telehandler lineup is engineered for performance, safety, and efficiency across industries such as construction, agriculture, and waste management. Every model features a hydrostatic drive, automatic parking brake, and a panoramic cab. Safety is built into every detail, including assistance systems that automate load lowering. The operator simply moves the joystick forward, and the telescopic boom lowers and retracts safely. The hill assist, auto parking brake, and inching functions further enhance control on challenging terrain. Robust design, high breakout forces, and responsive joystick operation provide the strength and precision needed for demanding tasks. Optional features include high-flow hydraulics, reversible fans, multiple tire and lighting configurations, and various quick attach systems for compatibility with a wide range of attachments.

The next gen X-Series telehandlers are designed to provide intuitive operation, easier servicing, and reliable performance. Each telehandler has a side pod engine placement that offers quick service access while maintaining curbside visibility from the cab. The X-Series features a hydraulic circuit that offers excellent controllability and smooth operating feel, while enhancing efficiency and cycle speeds. Cylinder cushioning dampens the end of strokes, both extending and retracting. Boom overlap is nearly doubled from previous models to reduce contact forces on wear pads. The X-Series includes eight fixed-boom Extendo models and four Traverse models. Maximum lift heights range from 36 feet to 56 feet 6 inches, and max load capacities range from 9,000 to 16,000 pounds.

FEATURED MODEL: T 60-9S

The T 60-9s telehandler is engineered with strength, precision, and intelligent technology for demanding industrial, construction, and material handling applications. It delivers an ideal balance of strength and reach and features a hydrostatic transmission, a panoramic cab for excellent visibility, and advanced operator assistance systems for safer, more efficient operation. One standout feature is the EcoMotion function, which enables precise, load-free lowering of the boom without increasing engine speed, reducing fuel consumption and wear while enhancing comfort.

Engine power: 156 hp

Lift capacity: 13,228 pounds

Maximum lift height: 28 feet 10 inches

Lift capacity at maximum height: 8,818 pounds

Maximum reach: 16 feet

Lift capacity at maximum reach: 4,409 pounds

Turning radius: 12 feet 6 inches

FEATURED MODEL: TRAVERSE T944X

The Traverse T944X features an extendable, traversing boom that moves loads by sliding forward horizontally up to 70 inches. The sliding boom carriage is mounted to the machine’s chassis with a series of slide pads and is pulled forward with a hydraulic cylinder. This feature allows users to safely place loads at the full specified lift height without coordinating multiple boom functions.

Engine power: 74 or 120-hp

Lift capacity: 9,000 pounds

Maximum lift height: 44 feet 6 inches

Lift capacity at maximum height: 7,000 pounds

Maximum reach: 35 feet 10 inches

carriage forward (30 feet carriage retracted)

Lift capacity at maximum reach: 600 pounds with carriage forward (1,900 pounds with carriage retracted)

Turning radius: 14 feet 1 inch

PETTIBONE

WACKER NEUSON

Wing with a loader arm that can push material, dig below grade, and handle a variety of attachments. This gives operators the benefits of three machines in one: the digging capabilities of a wheel loader, the versatility of a skid-steer loader, and the telescopic lift height of a telehandler. Operators can work efficiently and safely with the Vertical Lift System, a driver assistance system that extends and retracts the boom semi-automatically when lifting or lowering. These telehandlers have three steering modes: all-wheel, front-wheel, and crab steering. From the cab, operators have excellent all-round visibility to the attachment, immediate working area, and machine surroundings. Switches and

FEATURED MODEL: TH625

The compact TH625 telehandler offers operators a comfortable cab with excellent ergonomics and all-round visibility, electronically controlled travel drive with various travel modes, robust telescopic arm with excellent view of the attachment, and a wide range of options all within a modern machine design. The transversely installed motor and the optimized arrangement of components ensure excellent maintenance accessibility. The integrated Vertical Lift System ensures safety and also increases operating comfort.

Engine power: 60 hp

Lift capacity: 5,512 pounds

Maximum lift height: 20 feet 1 inch

Maximum reach: 4 feet 4 inches

Lift capacity at maximum reach: 2,205 pounds

Turning radius: 8 feet 8 inches

HIGHLIGHTS FROM BAUMA 2025

NEW

EQUIPMENT, TECHNOLOGY & CONCEPT

MACHINES

BY KAITLYN TILL, EDITOR IN CHIEF

VOLVO CONSTRUCTION EQUIPMENT

UNVEILS THE WORLD’S FIRST ELECTRIC ARTICULATED DUMP

TRUCKS AT BAUMA 2025

THE A30 AND A40 ELECTRIC ARE AMBITIOUS NEW ADDITIONS TO VOLVO’S EXTENSIVE BATTERY-ELECTRIC LINEUP

When Volvo CE recently overhauled its full line of articulated dump trucks, the most common question the company received was, “Why didn’t you include an electric hauler?”

At bauma 2025, Volvo answered that question with a big reveal on day two, dropping a curtain to introduce the world’s first serial production, full-size battery-electric articulated dump trucks, the A30 and A40 Electric.

The A30 Electric was the centrepiece of Volvo CE’s bauma booth — its first all-electric presentation at a trade show. Surrounded by the company’s electric excavators, wheel loaders, and more, the new ADT made a statement: Volvo’s commitment to sustainable propulsion solutions is here to stay, and it’s here to go big.

SEASONED VOLVO ADT OPERATORS WILL BE FAMILIAR WITH CO-PILOT, ALSO AVAILABLE ON THE ELECTRIC ADTS.

VOLVO CE’S MELKER JERNBERG REVEALED THE WORLD’S FIRST ELECTRIC ARTICULATED DUMP TRUCKS AT BAUMA 2025.

Before making the reveal, Melker Jernberg, president of Volvo CE, teased, “It’s something that not even we thought we were able to do just a couple of years back, and now we see it. I’m extremely proud of our leadership and I’m extremely proud of my team that has done this.”

ALL-NEW ELECTRIC ADTS ARE BUILT ON A FAMILIAR PLATFORM

With payloads of 29 and 39 tons, the A30 and A40 Electric ADTs are among Volvo CE’s largest electric machines. The new zero-emissions options are suited to a range of segments, including quarrying, mining, and construction, and they are designed to give operators the same performance as their diesel-powered counterparts.

The electric ADTs offer a runtime of 4–4.5 hours across most applications, but Volvo says that high-energy jobs may require more frequent recharging. They can run up to seven hours in some conditions. Ideal applications include downhill load carrying and uphill empty runs, tunnel work, and quarries and underground operations. Fast charging from 20 to 80 percent in around one hour can be done with a DC charging solution with a maximum charging capacity of 350 kW. Operators can check the charging status, machine hours, and energy consumption using Volvo CE’s My Equipment app.

They are built on the same new-generation platform as the rest of the 2025 Volvo ADT lineup, which includes advanced operator support systems to reduce accident risk, improved visibility for safer operation, and simplified servicing for quicker and easier maintenance. The electric machines deliver the added benefits of quieter operation and reduced vibration to

the operator, in addition to improved air quality around the machine.

Operators will find easy access to media, cameras, climate control, and machine status via the integrated Volvo Co-Pilot, and vital equipment data is quickly viewable on the instrument cluster. Volvo has repositioned the door, provided guided entry lighting, and designed new handrails to ensure that getting in and out of ADTs is safer than ever.

Operators that use Volvo’s Haul Assist will get the most productivity and efficiency from the hauler and will reduce energy consumption and machine wear.

VOLVO CE STANDS BEHIND BIG AMBITIONS WHILE SUPPORTING CUSTOMERS WHERE THEY ARE AT

The company continues to reinforce its commitment to supporting customers wherever they are on their emissions-reduction journey, including with its diesel-combustion-powered equipment, but the Volvo booth was a bold statement that assures customers that the company stands behind its electric ambitions in a big way.

“This zero-emission lineup is a marker of our commitment to drive change,” said Jernberg. “Together with our pioneering service, solutions, and updated portfolio of conventional machine variants, we show that we stand alongside our customers to support them across every stage of their journey. We show that we are committed to our ambitions, not just because we can, but because it is the right thing to do.”

The A30 and A40 Electric ADTs will be available in Europe in 2026, with global introductions to follow.

LANDCROS One is Hitachi’s concept for the future of job site interaction between machines, operators, and the broader digital construction ecosystem. This concept seamlessly integrates physical controls with digital interfaces to create an intuitive operator environment designed to appeal to the next generation of operators by gamifying operations and integrating AI-assisted interfaces. Assistance tools will automate some tasks, reducing operator fatigue and aiding novice operators. The concept can be used to control machines remotely from anywhere, opening up opportunities for a global workforce that expands the reach of operators

HYUNDAI DEMOS CONCEPT HYDROGEN EXCAVATOR

Hyundai Construction Equipment demonstrated its HW155H hydrogen fuel-cell-powered wheeled excavator concept. A hydrogen fuel cell uses a chemical reaction between hydrogen that is carried on board and oxygen in the atmosphere to generate electricity. The only emission is water vapour. The fuel cell delivers power on demand to drive the machine, either through electric motors, or via electrically driven hydraulic pumps.

The HW155H is equipped with a single fuel cell with a maximum output of 90 kW. The hydrogen storage on board has the capacity to provide a full 12 hours of operation.

VOLVO’S A40 ELECTRIC ARTICULATED DUMP TRUCK.

2.9 M square feet of exhibits / 139,000 attendees / 2,000 exhibitors / 150 education sessions

M square feet of exhibits / 139,000 attendees / 2,000 exhibitors / 150 education sessions

2023 Attendee Dylan Mercier, D2

2.9

LIEBHERR AUTONOMOUS OPERATIONS DEMONSTRATED AT BAUMA

LIEBHERR WON THE BAUMA INNOVATION AWARD FOR DIGITALISATION

The centrepiece of Liebherr’s demonstration at bauma 2025 was Liebherr Autonomous Operations, the bauma Innovation Award–winning autonomous wheel loader concept that automates repetitive wheel loader tasks. Liebherr Autonomous Operations took home the prize in the Digitalisation category.

LIEBHERR AUTONOMOUS OPERATIONS

Developed by Liebherr-Werk Bischofshofen GmbH, the company says that Liebherr Autonomous Operations is the result of many years of intensive work. With this system, the repetitive and monotonous tasks of a wheel loader can be completed without a driver. This helps counteract the difficulty of finding staff for routine tasks and frees workers to focus their skills on more complex work. Liebherr says that it does not require any specialist IT knowledge.

Liebherr showed off the system at the massive Liebherr stand; it demonstrated its capability by moving aggregate from a stockpile to load a hopper for crushing.

LIEBHERR SHORTLISTED FOR ADDITIONAL INNOVATION AWARDS

The bauma Innovation Awards are held at the start of each bauma to honour groundbreaking developments across five categories, and Liebherr Autonomous Operations wasn’t the company’s only representation at this year’s bauma Innovation Awards.

Liebherr was also a finalist in the Machine Technology category with two innovations: Positioning Pilot, a driver assistance system for crane operators, and the S1 Vision, a single-axle truck that reimagines the mining hauler.

The Positioning Pilot driver assistance system enables semi-automated, sway-free crane operation. The intelligent

LIEBHERR’S S1 VISION CONCEPT HAULER.

KOMATSU’S PC220LCI-12 EXCAVATOR IS LOADED WITH TECHNOLOGY TO MAXIMIZE OPERATOR PRODUCTIVITY AND ACCURACY IN DIGGING OPERATIONS.

THE MOST ADVANCED EXCAVATOR EVER?

KOMATSU’S PC220LCI-12 EXCAVATOR IS OPTIMIZED FROM THE HEART OUT TO SEAMLESSLY INTEGRATE MECHANICAL INNOVATION WITH CUTTINGEDGE DIGITAL TECHNOLOGY

Komatsu calls its next generation PC220LCi-12 excavator introduced at bauma “the most advanced excavator ever designed.” The PC220LCi-12 is packed with technology features to make that case: it introduces Komatsu’s intelligent Machine Control 3.0 (iMC 3.0) on an excavator that is optimized from the heart out to produce seamless performance. To do this, Komatsu has introduced a new high-torque, 129kW engine; a new electronically controlled, high-efficiency hydraulics system; and a new P+ operating mode that delivers an 18 percent increase in productivity.

The new engine and hydraulics system pair to give operators a significant reduction in fuel consumption and an increase in arm and bucket forces that make digging and movement easier, producing sharp response with zero lag.

KOMATSU INTRODUCES INTELLIGENT

MACHINE CONTROL 3.0

We were treated to a preview of Komatsu’s iMC 3.0 at bauma. It offers several new features, including 3D Boundary Control, Tiltrotator integration and control, Auto Swing, Swing-to-line, Travel-along-line, and Advanced Payload Meter.

Project managers will also appreciate the extensive range of iMC 3.0 features that help operators stay on design, instilling confidence that they will get the job done right the first time.

Auto-Stop Control stops the bucket edge on the design surface during boom, arm, or bucket operation and eliminates over-digging past the desired grade.

Auto Grade Assist automatically raises the boom, and the bucket edge precisely traces the design surface. The operator just controls the grading speed.

Minimum Distance Control calibrates the bucket to the excavator so that the iMC system can always calculate the bucket’s nearest point or the “minimum distance” to the design model.

Auto Tilt Control adjusts the bucket to the design surface and keeps the bucket edge exactly on the grade throughout the grading pass.

Bucket Angle Hold enables the operator to automatically set the bucket grading or digging angle.

Track Volume Progress automatically logs the lowest point of the bucket edge. This data can be used to create an upto-date terrain surface that reflects recent digging progress on the job site. This progress can be viewed on the Komatsu Smart Construction dashboard.

KOMATSU SMART CONSTRUCTION

SOLUTIONS ARE INTEGRATED INTO THE NEW EXCAVATOR

Komatsu’s Smart Construction offers several solutions that integrate with the PC220LCi-12, including Smart Construction Remote, which facilitates file transfer to the machine in addition to remote troubleshooting. Smart Construction Fleet Lite connects to the advanced payload system so that the project manager can download productivity data to ensure that the project is on target.

AN ALL-NEW CAB MAXIMIZES OPERATOR COMFORT AND PRODUCTIVITY

Komatsu’s new cab gives operators 30 percent more legroom than previous models, and a premium seat option is available. Komatsu has improved visibility to the right side of the machine, and overhead cooling vents and joystick steering are standard. On the 8-inch touchscreen monitor the operator will have access to all of the operator assist technology packed into this excavator. The versatile, programmable electronic control levers and customizable hydraulic settings give the operator freedom to set their preferences. HEG

FIELD REPORT

JOHN DEERE CONSTRUCTION FIELD

DAYS 2025

BY KAITLYN TILL, EDITOR IN CHIEF

John Deere Construction Field Days 2025, held at John Deere’s proving grounds in sunny Arizona, was an opportunity to get up close to and operate a range of new John Deere equipment including a wheel loader, dozer, ADT, and backhoe loader.

IN THE OPERATOR’S SEAT

I had the opportunity to jump in the cab of the new 850 X-Tier dozer, and, while I can assure you that my operating skills are not fantastic, using SmartGrade tech on this smooth riding dozer kept me out of ruts and on grade.

John Deere is introducing all-new backhoe loaders this summer and I had the chance to check out a pre-production model — and operate it — at Construction Field Days. Once in the cab, I immediately noticed the great view to the front of the machine. John Deere has prioritized visibility to the working tool and designed a comfortable work station that made it easy to focus on the task.

NEW JOHN DEERE MACHINES PUT THROUGH

Two new direct hitch scrapers, the 3012 Direct Hitch (DH) Scraper and the 3812 Direct Hitch (DH) Scraper, are the largest scrapers in the John Deere lineup with 30- and 38-cubic-yard capacities. Self-loading scrapers allow loading, spreading, and transport to be completed by a single operator.

There’s an impossible-to-ignore new feature on John Deere wheel loaders. SmartDetect Digital for select mid-size and large wheel loaders provides audible and visual alerts when bystanders are too close to the wheel loader, issuing escalating warnings as the wheel loader gets closer to the object. I can vouch that the alert was so annoying when I walked directly behind the machine that I had no desire to get too close to it again! SmartDetect Digital is more than just a proximity alarm. It also sends data to the John Deere Operations Center giving managers insight into the job site layout and traffic — it’s a new tool to help with risk management and job site efficiency improvements.

MORE VISIBILITY, MORE ROOM & MORE OPTIONS KEEP OPERATORS PRODUCTIVE IN JOHN DEERE’S NEW BACKHOE LOADER CAB

Operators will appreciate the expansive view, the spacious cab, and the industry-first rear-view camera on John Deere’s upgraded backhoe loaders. The updates are available for five models: the 310 G-Tier and P-Tier and the 320, 410, and 710 P-Tier.

“There are three key areas that people are going to notice differences in: visibility, operator comfort, and the controls,” said Emily Pagura, product marketing manager at John Deere, at Construction Field Days.

These new features, which follow recent updates that include Optional Heavy Lift and Pressure Compensated Load Sensing (PCLS) hydraulics on the 320, 410, and 710 P-Tier, make the new backhoe loaders versatile and comfortable for any application, according to the company.

CLEARER SIGHTLINES AND A NEW REAR-VIEW CAMERA MAXIMIZE JOB SITE AWARENESS

With two side posts consolidated to one, the new John Deere backhoe cab provides an expanded field of view, particularly for truck loading and trenching operations. A new overhead rear window system offers an unobstructed view of trenches and tight spaces, increasing accuracy in underground applications and reducing exposure of the window to dust and debris, keeping it cleaner.

The rear camera system, displayed on a dedicated 8-inch touchscreen, improves overall job site awareness. The operator can adjust their view to just the left side, just the right side, or to show a full view of the rear of the machine. Upgraded LED work lights and LED turn signals enhance visibility in low-light conditions.

OPERATORS WILL GET COMFORTABLE IN THE NEW CAB

Operators with longer legs will be enthusiastic about the cab of these upgraded backhoe loaders. The redesigned cab gives them five more inches of leg room when swivelling the seat.

A heated and vented seat is optional

and, when paired with the upgraded HVAC system that delivers 10 percent more airflow, ensures optimal climate control in all working conditions.

New storage solutions, including an updated tool box on the outside of the machine, offer better organization for tools and personal items.

REDESIGNED AND RELOCATED CONTROLS KEEP FOCUS WHERE IT SHOULD BE

A redesigned palm-on-top loader grip helps support the operator’s hand to keep them comfortable on long work days.

“We’ve gone with an ergonomic, restyour-hand-on-top style, which is really comfortable because you just rest your hand there and you’re not at a weird angle. It’s

CONTROLS HAVE BEEN RELOCATED TO THE OPERATOR’S LINE OF SIGHT. THE ROOMY CAB GIVES TALL OPERATORS LOTS OF SPACE TO TRANSITION THE SEAT. 1 2 3 1

A PRE-PRODUCTION MODEL OF JOHN DEERE’S NEW 320 P-TIER BACKHOE LOADER.

2

3

really easy on the arm,” explained Pagura. Controls that were previously located in the lower right hand area have also been moved to a new single post where they remain in the operator’s line of sight and are easy to reach.

MORE OPTIONS AVAILABLE FOR JOHN DEERE BACKHOE LOADERS

Optional manual stabilizer locks and a stabilizer position warning system that keeps the operator informed of stabilizer position during transport are available for all models. A new pull-down front sunshade with more surface area to shield the operator from sun while in loader mode is optional for John Deere P-Tier backhoe loaders. HEG

Join us at Trimble Dimensions User Conference 2025

At Dimensions 2025, connection is magnetic.

Plug into a powerful network of industry experts, unlock hidden potential within your Trimble solutions, and master the latest techniques driving the future of your work. Discover innovative workflows and solutions, and solve your toughest challenges alongside peers, partners and Trimble professionals.

Trimble.com/Dimensions Get the best rate on registration before July 31, 2025

LARGE EXCAVATOR BUILT FOR HEAVYDUTY TASKS

CASE Construction Equipment’s latest large crawler excavator is built to marry strength with intelligence for maximum production on a variety of job sites and in applications that include land clearing, trenching, craning pipes, and breaking rock.

The new CX380E large excavator has a 268-hp engine and weighs 83,114 pounds (37,700 kg).

AN EXCAVATOR BUILT TO DELIVER PRECISE POWER

The CX380E is built for heavy-duty tasks, with 56,000 pounds of breakout force and fast cycle times. Operators can adjust the power to the task with four fuel-efficient work modes and up to 10 throttle settings:

Super Power for the maximum possible power; Power for a hard-working mode suitable for daily operation; Eco for more fuel efficiency; and Lifting for maximum control during lifting and craning tasks. CASE says that Eco mode lowers fuel consumption by up to 18 percent compared to its previous excavators. In addition, CASE telematics and software provide precise data to measure fuel usage and other metrics to further improve efficiency.

CUSTOMIZABLE TO THE OPERATOR’S PREFERENCES

The CX380E’s advanced controls and customizable sensitivity settings give operators the control to dial in responses exactly to their preference. The 10-inch touchscreen lets operators store set-

tings for up to 10 attachments (one-way and two-way), making it simple to change attachments in seconds at the touch of a button.

The intelligent Hydraulic Flow Control Balance also makes the excavator even more responsive and efficient by customizing the priority of hydraulic flow used for movements like arm in and boom up as well as arm in and swinging.

For added control, the CX380E features selectable free swing functionality, giving operators more stability and improved safety with less fatigue when lifting and placing swinging loads, working on uneven terrain, or loading trucks. Along with advanced controls, operators can also work more confidently using the 270-degree camera which provides a bird’s-eye view via the display screen for improved visibility and safer operation, as well as setting up arm and swing preferences.

ALL-DAY COMFORT IN THE CAB

Heated, air-suspension seating and lots of legroom will keep operators comfortable all day. A suspended operator station locks the seat and console together so no matter the operator’s size, they have the same experience and ergonomic access to the controls.

MAINTENANCE AND SUPPORT

CASE’s advanced telematics allow dealers to run diagnostics and update software remotely without an on-site service technician. CASE’s ProCare heavy machine support program comes standard with a 3-year/3,000-hour full machine factory warranty plus 3-year/2,000-hour planned maintenance support and a 5-year advanced telematics subscription.

CASE’S NEW CX380E EXCAVATOR.

10% LESS ON PARTS. $20/HR LESS ON SERVICE.

New Lower Prices. Same Powerful Value.

As a family-owned Canadian company, we believe in showing up for Canadians when it counts. That’s why we’ve dropped our everyday parts prices and service rates to help you face uncertainty, tariffs, and rising costs head-on.

10% Lower Parts Pricing

Prices cut across key parts categories by 10% on average.

$20/hr Lower Shop Rates

The same expert service, now for an average of $20/hr less.

New Compact Construction Rate

FAMILY-OWNED

A new rate built just for compact equipment owners. Price Match Guarantee

Got a better quote? Bring it. We’ll match it.

To learn more about our lower prices, visit brandt.ca/delivering-value or call 1-866-4-BRANDT (1-866-427-2638).

CATERPILLAR HYDRAULIC EXCAVATOR TECHNOLOGY UPDATES

aterpillar has updated the technology options for its hydraulic excavators built in 2025. These technology updates include Cat Grade 2D and 3D, a new User Interface (UI), and an Advanced Payload option for Cat tracked excavators. Updates apply to Cat small, medium, and large excavators, plus material handlers, wheeled excavators, and forestry and specialty machines.

CAT GRADE 2D AND 3D

With 2025 model builds, Cat Grade with Advanced 2D features and functions are now integrated into standard Cat Grade with 2D. Compared to traditional grading methods, Cat 2D technology empowers operators to work more efficiently in a range of applications by delivering real-time guidance for accurate vertical and horizontal control. It helps to ensure that cuts and fills are made to exact spec-

ifications, without undercutting or overcutting, and it can eliminate the need for ground stakes in most applications.

It’s easy to adjust the target depth and slope using joystick commands, the touchscreen interface, or a jog dial. The interface displays the target grade with visual guidance plus height and depth. Cat 2D technology is compatible with multiple bucket types and applications, including buckets for digging, cleaning, grading, and tilting.

For more complex designs, Grade with 3D technology is now a factory-installed option that can be ordered for tracked and wheeled excavators. This new option includes all of the hardware required for the 3D system installed and tested from the factory. Caterpillar says that it is an easier upgrade path for customers who want to add Cat Grade with 3D after their initial machine purchase.

NEW FACTORY INSTALLATION OPTION FOR CAT GRADE 3D.

NEW USER INTERFACE FOR CAT PAYLOAD

Cat Payload for excavators and material handlers delivers precise bucket load information with on-the-go weighing to help prevent overloading or underloading. From reordering work tool lists to creating new work tool combinations, the display’s new UI starts quickly and enables operators to easily set up the machine and access information. Opera-

tors keep track of the amount of material moved and can split tasks between truck loading in Weigh Mode and moving material around the site in Stockpile Mode. The ability to input couplers and attachments into the system makes setting up work tool combinations highly efficient by significantly reducing calibration time.

ADVANCED PAYLOAD FOR CAT TRACKED EXCAVATORS

crease efficiency by helping new operators get up to speed faster and experienced operators work more accurately; and monitor safety by helping to prevent truck overloading, which results in heavier and more unstable loads.

Customers with tracked excavators can now upgrade the Cat Payload system to Advanced Payload to take advantage of expanded capabilities, such as custom tags, daily totals, and electronic ticketing. When combined with VisionLink, Advanced Payload enables customers to analyze job sites and individual assets for remote management of production targets and key metrics.

Cat Advanced Payload helps operations lower costs by saving time, labour, and fuel consumption; improve accuracy with precise payload targets that help eliminate over- and underloading; in-

SMOOTH OPERATOR

Skilled, resourceful and adept at navigating any situation with ease and finesse: sounds like the perfect compact track loader. With new features like auto-shift, track response, and a heated air ride seat, you can feel the difference every time you step in to the pressurized, quiet cab. If you’re looking for a specialist in operator comfort, elite performance and boundless versatility, you need a smooth operator like the SVL97-3.

CAT’S ADVANCED PAYLOAD OPTION IS NOW AVAILABLE FOR TRACKED EXCAVATORS.

TILTROTATORS

MAXIMIZE YOUR EXCAVATOR’S CAPABILITY & VERSATILITY

STEELWRIST XTR20

1

ENGCON EC204 2

1

Steelwrist’s third-generation XTR tiltrotator lineup now includes four models for excavators from 0 up to 23 tonnes. These tiltrotators have steel cast components, including the upper coupler, gearbox, and quick coupler below the tiltrotator. The advanced tilt geometry, with optimized off-centre cylinder brackets, reduces cylinder spread and enables high-torque, fluid movement. The OptiLube on-board lubrication system ensures automatic and optimized greasing. LockSense is Steelwrist’s next-generation sensor system for indicating secure work tool locking. Operators receive both visual and auditory confirmations, guaranteeing safe work tool changes. The optional three-finger gripper, redesigned with a downward-angled position, extends the excavator’s reach and precision.

2

Engcon has updated its tiltrotator for 2- to 4-tonne excavators. The EC204 offers a 45-degree tilt angle, infinite rotation, and the ability to mount a detachable grapple or detachable sweeper for excellent versatility. The new EC204 is also prepared for EC-Oil both above and below the tiltrotator. It includes tilt angle and rotation sensors and centralized lubrication.

A variety of attachments, including a detachable grapple or detachable sweeper, are available. Engcon’s DC2 proportional control system, which offers stepless control and remote support via mobile network, is also available. Latest generation Engcon control compatibility (DC3) is coming soon.

3

3

Rototilt’s Rototilt Control concept combines tiltrotators, joysticks, an app, and a user-friendly control system with a focus on the operating experience, energy efficiency, and precision. The RC range now covers excavator models from 1.5 tonnes up to 43 tonnes. All tiltrotators in the RC range are outfitted with Rototilt’s SecureLock safety lock as standard, ensuring that all attachment connections are secure. The RC Connect app makes it possible to obtain remote support out in the field. RC joysticks are easily customizable and can comfortably accommodate operators with smaller hands.

WHY COMPACT MACHINES ARE ELECTRIC’S FIRST REAL WIN

BATTERY-ELECTRIC EQUIPMENT IS TAILORED TO MATCH THE NEEDS OF REAL-WORLD APPLICATIONS

BY LEE TICE

Battery-electric machines are showing up everywhere in construction headlines, but there’s one category that’s already proving its worth where it counts on the job site. While big machines chase future fuels like hydrogen and hybrid systems, compact equipment is quietly getting it done with battery power. This isn’t about what might work someday. This is about what’s already working today.

ELECTRIC’S FIRST BIG WIN IN CONSTRUCTION

Electric technology isn’t new, but finding the right fit for it in construction is. Compact machines like mini excavators, electric dumpers, and telehandlers have hit the sweet spot where battery tech meets real-world demands. These machines don’t need oversized battery packs or complicated charging solutions. They’re light, efficient, and built for jobs that match the strengths of electric power.

Why does this matter? Because construction is under increasing pressure to lower emissions, reduce noise, and work within tighter site regulations — especially in urban and residential areas. Compact electric machines meet these challenges without asking crews to change how they work.

PURPOSE-BUILT FOR HOW CREWS ACTUALLY WORK

Unlike heavy machines that stay put and grind through massive workloads, compact equipment moves with the rhythm of modern job sites — short bursts of activity, frequent transport,

and tight workspaces. These are not machines being used to dig mile-long trenches, they tackle specific tasks, get loaded back on the trailer, and head to the next job. Electric power fits that kind of routine perfectly.

Manufacturers have tapped into this reality using telematics and real-time usage data collected from connected fleets across North America and beyond. That data reveals how long machines are active, how often they're moved, and what types of work they’re actually doing.

Rather than building to theoretical extremes, manufacturers are designing for what’s typical. They’re engineering battery capacity to support a full day’s work based on duty cycles without overburdening machines with excess weight or complexity. Layouts are optimized for the electric drivetrain, not adapted from diesel platforms. That intentional design results in machines that are not only efficient but easier to operate and maintain.

EXPANDED OPERATIONS, GREATER OPPORTUNITIES

What really sets electric compact equipment apart is how it expands a contractor’s reach. These machines open up new job site possibilities by eliminating some of the biggest limitations tied to diesel: noise, fumes, and operating hour restrictions. With near-silent operation and zero emissions, crews can work in noise-sensitive zones like residential neighborhoods or around hospitals. Jobs can start earlier, run later, and be done indoors without the need for ventilation. That level of flexibility helps contractors secure more bids, meet stricter project specs, and reduce downtime waiting for access windows.

WHILE BIG MACHINES CHASE FUTURE FUELS LIKE HYDROGEN AND HYBRID SYSTEMS, COMPACT EQUIPMENT IS QUIETLY GETTING IT DONE WITH BATTERY POWER.

In practice, that could mean a crew pouring a foundation next to a school during class hours or finishing landscaping in a park over a weekend without disturbing the public. Electric compact machines make these types of jobs not just possible, but practical.

And it’s not limited to traditional construction. Sectors like food production, event venues, and equestrian facilities are embracing electric machines for their clean, quiet, and low-disruption operation. Whether it’s preparing a show arena, working inside a warehouse, or supporting maintenance at a processing plant, compact electric equipment extends its value well beyond the standard job site.

CHARGING THAT MAKES SENSE IN THE FIELD

Charging infrastructure has long been seen as a barrier to electric adoption, but that’s changing fast, especially in the compact space. Manufacturers are standardizing inputs and cable types across product lines, making it possible to run multiple machines on a single charger. No guesswork, no multiple systems — just plug and go.

These machines are designed to recharge overnight, keeping job site downtime to a minimum. And because they’re built from the ground up for electric, component placement and access are optimized for ease of maintenance and service. They are not crammed in wherever space was available.

THE PROOF POINT FOR THE FUTURE

There’s a lot of talk about the future of construction equipment, but compact electric machines are already proving

RATHER THAN BUILDING TO THEORETICAL EXTREMES, MANUFACTURERS ARE DESIGNING COMPACT BATTERY-ELECTRIC EQUIPMENT FOR WHAT’S TYPICAL IN ITS APPLICATION.

Unlike heavy machines that stay put and grind through massive workloads, compact equipment moves with the rhythm of modern job sites — short bursts of activity, frequent transport, and tight workspaces.

what’s possible. They’ve become a practical entry point into alternative energy without requiring a complete rethink of operations.

They’re not a compromise. They’re a solution backed by job-tested performance, operator familiarity, and growing demand in sectors that need clean, quiet, capable machines.

For anyone still on the fence about electric construction equipment, compact machines make the strongest case yet: it’s not about if, it’s about where to start — and this is it.

LEE

TICE is a product manager at JCB.

CRANES CRANES

THE LATEST INTRODUCTIONS & TECHNOLOGY

LIEBHERR'S LTM 1110-5.2 CRANE WITH DRIVER ASSISTANCE SYSTEMS.

THE FIRST LIEBHERR LTM 11105.2 WITH DRIVER ASSISTANCE SYSTEMS IS SHIPPED TO ULFERTS

Temmo Niekamp didn’t need to be asked twice to make a personal visit to the Liebherr plant in Ehingen, Germany, to collect his new LTM 1110-5.2 mobile crane. Together with Hermann Ulferts, he is head of the Ulferts Group which has purchased Liebherr’s 5-axle LTM 1110-5.2 mobile crane featuring new driver assistance systems. The driver assistance systems give the driver a much better view around the crane including visibility to cyclists, other motorists, and pedestrians that might be in blind spots.

“We are delighted to be able to try out and use the new systems in practice and therefore make a contribution toward greater safety on the roads,” says Niekamp.

“The new systems support and relieve crane operators significantly and make their everyday work easier. They allow the operators to monitor areas that were previously difficult or even impossible to see,” he explains.

The moving-off information system (MOIS) is used if there is a person in front of the crane. Due to their height, children in particular are impossible to see from the driver’s seat. Visibility is also hampered by the hook block. Two cameras scan the front area and provide the crane operator with a visual and audible warning which appears directly on the digital cockpit display.

The blind spot information system (BSIS) monitors the entire side area of the crane using a camera wing. Even with large mirrors, the crane operator is unable to reliably monitor the entire side of the crane. Digital cameras now scan this area and warn the operator with visual and audible alerts to dangerous situations.