You don’t back down from a challenge, and neither do we. Bobcat equipment is engineered with the power, durability and versatility you need to dominate any task. When failure isn’t an option, Bobcat steps up. Ready when you are.

MAKE YOUR MOVE

Push

... more material with the new Hyundai HD100 crawler dozer's best-in-class power-to-weight ratio.

See ...more than ever with the unobstructed view to the blade.

Engage ...more accurately and more productively with standard 2D or optional 3D machine guidance.

Doze

No wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, or na.hd-hyundaice.com.

...with confidence, knowing your new 115 hp Hyundai crawler dozer delivers the quality and value you expect from Hyundai, with the peace of mind that comes with our industry-leading warranty.

TEAM PLAYERS THAT WORK TOGETHER INTELLIGENTLY AND STRENGTHEN EACH OTHER. In linked plant combinations, the MOBICAT MC 110 EVO2 jaw crusher and the MOBICONE MCO 90 EVO2 cone crusher really flex their muscles. SPECTIVE makes both plants easy and intuitive to operate. Also, an advanced drive concept ensures greater efficiency with lower consumption. Maximum throughput is achieved thanks to the material flow concept coordinated via line coupling across both crushing stages. Go for the perfect team!

Keep everything running exactly as it should with the right parts, consumables and preventative maintenance programs backed by our team of skilled technicians and equipment experts.

18

FEATURE STORY EQUIPMENT & TECHNOLOGY ADVANCES THAT BOOST YOUR PRODUCTIVITY, MAXIMIZE YOUR ROI, AND BENEFIT THE PLANET

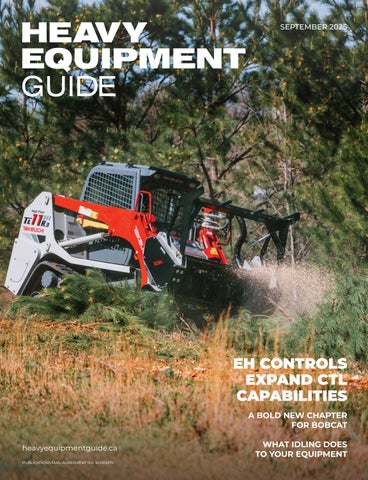

24 34 A BOLD NEW CHAPTER FOR BOBCAT

EH CONTROLS FOR CTLS

WHAT IDLING DOES TO YOUR EQUIPMENT

COMPACT TRACK LOADER.

EDITOR IN CHIEF Kaitlyn Till ktill@baumpub.com 604-291-9900 ext. 330

SENIOR WRITER

Meghan Barton mbarton@baumpub.com 604-291-9900 ext. 305

ASSOCIATE PUBLISHER

Sam Esmaili sam@baumpub.com 604-291-9900 ext. 110

ADVERTISING

PRODUCTION MANAGER

Tina Anderson tanderson@baumpub.com 604-291-9900 ext. 222

DESIGN & PRODUCTION

Morena Zanotto morena@baumpub.com 604-291-9900 ext. 325

PRESIDENT/PUBLISHER

Ken Singer ksinger@baumpub.com 604-291-9900 ext. 226

VICE PRESIDENT/CONTROLLER

Melvin Date Chong mdatechong@baumpub.com

FOUNDER

Engelbert J. Baum

Published by: Baum Publications Ltd.

124 - 2323 Boundary Road Vancouver, BC, Canada V5M 4V8

Tel: 604-291-9900

Toll-free: 1-888-286-3630 Fax: 604-291-1906 www.baumpub.com www.heavyequipmentguide.ca @HeavyEquipGuide

FOR ALL CIRCULATION INQUIRIES

Toll-free: 1-866-764-0227 email: heg@mysubscription.ca

WE’D LIKE TO HEAR FROM YOU

Do you have a job site story, innovation, or industry concern that our readers should know about? We’d like to hear from you.

Contact: Editor in Chief Kaitlyn Till at ktill@baumpub.com or 604-291-9900 ext. 330

How EH controls and high-flow hydraulics expand CTL capabilities Turn to page 34 . SEPTEMBER 2025 | VOLUME 40 • NUMBER 6

Subscription: To subscribe, renew your subscription, or change your address or other information, go to: http://mysubscription.ca/heg/

Heavy Equipment Guide serves the Canadian engineered construction industry including: roadbuilding and maintenance; highways, bridges, tunnels; grading and excavating; earthmoving; crushing; trucking and hauling; underground utilities; trenching; concrete paving; asphalt paving; demolition; aggregates production; fleet maintenance; and asset security and management. The magazine is distributed to key industry personnel involved in these sectors.

Subscription Price: In Canada, CDN $91.00; Outside Canada, US$149. Heavy Equipment Guide is published eight times a year in January/ February, March, April, May/June, July/August, September, October, and November/December.

Heavy Equipment Guide accepts no responsibility or liability for reported claims made by manufacturers and/or distributors for products or services; the views and opinions expressed are those of the authors and not necessarily those of Baum Publications Ltd.

Copyright 2025, Baum Publications Ltd. No portion of this publication may be reproduced without permission of the publishers.

We acknowledge the financial support of the Government of Canada.

Printed on paper made of FSC®-certified and other controlled material. ISSN 1715-7013.

PUBLICATIONS MAIL AGREEMENT NO. 40069270

Return undeliverable Canadian addresses to: Circulation Dept., 8799 Highway 89, Alliston, ON L9R 1V1 email: heg@mysubscription.ca Toll-free: 1-866-764-0227

These are tense times, I think we would all agree, as ongoing trade and tariff negotiations continue to pressure the construction industry.

Construction is a global business. Equipment is complex, expertise is often regional, and raw materials, components, and finished machines must cross international borders. There is no choice for any OEM that wants to be a global player.

Take Caterpillar, for example. Cat is the most recognized construction equipment brand in the world, and the company utilizes a global workforce to manufacture equipment for multiple sectors, including earthmoving, roadbuilding, power generation, and more. In Peoria, the deeply skilled people who manufacture dozers can’t just transition to manufacturing cold planers — that expertise can be found in Italy, where Cat also has a factory.

But now spreading the fruits of that expertise around the world, in the form of importing and exporting machines, is a whole lot more expensive for almost everybody, and it is going to restrain the spread of innovation and quality equipment.

Jumping into a new global market is hard. Take an example from this issue: Sanha Machinery Tech (SWT) is a Chinese attachment manufacturer just entering the North American market. As you’ll learn, entering a new market isn’t as simple as setting up shop. The customers won’t just appear, and they won’t trust the product at face value.

Entering a new market is a strategic, long-term investment, just as any new business venture should be. It involves getting to know the market, getting to know the conditions on the ground, understanding the local culture, and appreciating the expectations of customers by meeting them where they are at.

Uncertainty in global markets makes a difficult and potentially risky venture more difficult and could dissuade the global spread of construction equipment expertise.

Consider the tiltrotator. The tiltrotator is a Scandinavian innovation that took off in Europe before slowly spreading to North America where the technology had to prove itself over many years before receiving the much wider adoption that it has today. Would the tiltrotator have stood a chance in the

Equipment is complex, expertise is often regional, and raw materials, components, and finished machines must cross international borders.

North American market if it had been introduced under today’s economic circumstances? Would it have been introduced here at all?

Today, tiltrotator manufacturers have subsidiaries in North America and they manufacture on this continent. Reasonable trade conditions made that possible, and the end result is that operators and contractors get to realize the benefits of this incredible technology that started as a unique, localized innovation.

The movement of materials and machines across borders is vital for the global construction equipment industry. The reality is that no country can innovate alone, and if this tariff situation continues to escalate, it leads me to wonder: what innovations won’t make it across the ocean?

Kaitlyn Till Editor In Chief

ktill@baumpub.com heavyequipmentguide.ca

Komatsu’s WA475-11 and WA485-11 deliver

• Lower fuel consumption

•

• Increased climbing speed

LiuGong is entering the North American motor grader market and marked the occasion by welcoming over 100 government officials, contractors, and industry leaders from Oklahoma and the surrounding region to Apex Equipment.

The week-long demonstration event showcased the all-new LiuGong 4215D motor grader, the first of its kind for the brand in North America, and gave attendees the opportunity to test its capabilities in real-world operating conditions.

According to LiuGong, this motor grader is built for productivity and affordability. The 4215D is engineered with a Tier 5 Cummins engine and a smooth-shifting 6-forward, 3-reverse ZF powershift transmission. This combination delivers high torque with low fuel consumption, making it ideal for long work days in variable terrain.

Its limited-slip differential enhances traction in demanding conditions, while the comfortable operator station, equipped with air conditioning and optional ROPS and FOPS protection, ensures safety during extended operations.

The LiuGong brand has been increasing its presence in North America, offering construction and earthmoving equipment that blends durability, modern design, and advanced engineering, said the company. Backed by a growing network of dealers like Apex Equipment, LiuGong said it is focused on delivering high-impact machines with unmatched long-term value.

With the successful launch of the 4215D and the enthusiastic reception in Oklahoma, LiuGong intends to position itself as a serious contender in the North American motor grader segment.

In response to Saskatchewan joining the Memorandum of Understanding with Ontario and Alberta to advance new natural resource infrastructure projects, AEM Senior Vice President of Government and Industry Relations Kip Eideberg released the following statement:

“The Association of Equipment Manufacturers (AEM) welcomes the Government of Saskatchewan joining with Ontario and Alberta in signing an agreement to explore the potential of new pipeline and railway projects that will increase the flow of critical minerals and energy to new markets and strengthen Canada’s long-term economic security.

“Canada’s equipment manufacturers are committed to meeting the opportunity to build up the country’s economy head-on, using Canadian-made equipment powered by Canadian labour. New pipelines that connect western Canadian oil and gas to new and existing refineries in Ontario and a new deep-sea port in James Bay will help meet increasing demand for Canadian energy abroad, further cementing Canada’s status as a critical player in the global clean technology supply chain.

“We look forward to working with all levels of government to ensure these vital projects move from feasibility studies to reality, creating lasting benefits for Canadian workers, communities, and the Canadian national economy.”

Manitou Group and Hangcha Group have signed an agreement creating a joint venture manufacturing and distributing lithium-ion batteries with operations located in France. The establishment of this joint venture will be effective after review and approval by the European competition authorities. The objective of the partnership is to upgrade lead–acid battery-powered vehicles with safer lithium-ion batteries to expand the operational lifespan of vehicles.

New product ranges from Manitou will benefit from the lithium-ion battery venture, in particular, the Manitou ME LIFT forklifts, first launched at the end of 2024. This initiative will directly support Manitou Group’s “LIFT” strategic road map to expand its electric offerings and reach 28 percent of units sold by 2030.

Through a collaborative effort with local authorities in Le Mans, France, the partnership will recruit employees, including engineers, operators, sales representatives, and aftersales service technicians. Le Mans Metropole will support the recruitment and local integration of these future employees.

Innovations in equipment and technology contribute to a greener construction job site.

Turn to page 18.

J.M. Wood Auction Co. has been operating in the heavy equipment auction industry for over 50 years and has now officially joined Richie Bros. following the completion of a previously announced acquisition.

Backed by the global reach, technology, and resources of Ritchie Bros., J.M. Wood will maintain regular operations at its Montgomery headquarters, in-person auction format, and leadership team. The company’s values and approach to business

will now benefit from increased scale and service for buyers.

Founded in 1973 by Malcolm and Brenda Wood, J.M. Wood has made a name for itself in the Southeast, with deep roots in the construction, transportation, and municipal sectors.

Buyers of J.M. Wood will gain access to Ritchie Bros. global sales base, digital tools, and value-added services, while continuing to work with the same team. For Ritchie Bros., the move adds regional expertise, sectoral strength, and a proven live-auction operation. J.M. Wood’s upcoming auctions will continue as scheduled, with added support and reach through the Ritchie Bros. network.

Motion Industries, Inc., a distributor of maintenance, repair, and operation replacement parts and a provider of industrial technology solutions, has entered into a partnership with Tagodi Development Corporation. This resource contracting firm invests in the local Tahltan Nation in Northern British Columbia. The agreement focuses on delivering economic and operational benefits to the community. The largest focus will be work and training in the mining sector, a major part of the region’s industrial landscape.

MEC Aerial Work Platforms opened its Engineering Center of Excellence located at the company’s headquarters and factory in Kerman, California. The centre features advanced CAD design technology, modern communication and meeting spaces, specialized testing equipment, and a clean-room R&D lab.

The two-story, 8,000-square-foot centre is designed to foster creativity and collaboration among MEC’s engineers, tech-

nical support teams, new product development personnel, manufacturing personnel, and industry experts. With a focus on developing next-generation products, the new centre will enable MEC to attract top design and engineering resources, accelerate innovation through new and enhanced products, rapidly resolve technical challenges, and explore emerging technologies that drive future growth.

The facility will also serve as a training centre, providing opportunities for continuous professional development for MEC team members and customers. In addition, it will host collaborative projects with industry partners, furthering MEC’s mission of driving advancements in safety, performance, and technology.

The loader trailer mover from Ignite Attachments is a compact, lightweight solution for moving trailers with skid steers and compact track loaders. Weighing just 26.5 pounds and built from Grade 50 steel, it supports Class 2 hitch loads up to 3,500 pounds. The attachment uses a universal quick-attach interface and features dual 2-inch receiver slots, allowing operators to mount it to either side of the loader plate for better sightlines. Its compact size (18 inches wide, 11.5 inches deep, 6.5 inches tall) allows for easy storage in a truck or toolbox. Designed for standard 2-inch ball or pintle hitches, it improves job site safety and manoeuvrability in confined areas without the need for a spotter or second machine.

John Deere has introduced the 3012 DH and 3812 DH, two new direct-hitch scrapers engineered for high-capacity, self-loading earthmoving projects. The 3012 DH features a 30-cubic-yard single pan and is compatible with John Deere 9R, 9RT, and 9RX tractors. It enables self-loading, transporting, and spreading with a single operator, making it well-suited for smaller jobs where multiple pans are not practical. The 3812 DH is the largest tractor-pulled single pan in the John Deere lineup, with a 38-cubic-yard capacity and 12-foot cut width, designed for use with 9RX 710 and 770 tractors. The 3812 DH also features enhanced flotation and simplified service access for demanding conditions.

The Mini Brush Cutter Pro X from Diamond Mowers delivers commercial-grade performance for stand-on skid steers. With a 42-inch cut width and the ability to clear brush and trees up to 5 inches in diameter, this compact attachment is built for property reclamation, perimeter maintenance, and light land clearing. It features a spindle-driven, double-blade system that reduces mechanical complexity and grinds stumps flush to the ground. Weighing between 660 and 725 pounds, the cutter operates within a hydraulic flow range of 11–25 GPM. Heavy-duty steel construction and a one-year product warranty ensure durability in demanding conditions. An offset, bolt-on mounting plate improves manoeuvrability in tight areas and helps minimize track wear on the host machine.

POWR2 has become the first mobile battery energy storage system (BESS) manufacturer in its size class to achieve UL and CSA certification for use in the U.S. and Canada. The POWRBANK XPRO Plus 60Hz model meets UL 9540, UL 9540A, UL 1741, NFPA 855, NFPA 70, and CSA standards, confirming its compliance with North American energy storage safety and performance requirements. This 100 kVA system offers 108 kWh of energy capacity and is designed for high-demand, temporary power applications. With certification in place, the system is now approved for use in high-compliance environments, including cities, airports, and essential infrastructure, as well as in sectors like construction, healthcare, emergency response, and live events.

The SCREENPRO S16 is EDGE Innovate’s latest tracked scalping screen, offering a compact alternative to the S18. Designed for feed capacities up to 600 tph, it features a 4.9- x 1.5-metre (16- x 5-foot) two-deck screen and 14 square metres of screening area. Adjustable angles (14 to 20 degrees) and a variety of screen media options (woven mesh, punch plate, finger screens, and bofor decks) allow operators to tailor the machine to diverse applications. Optional over-band magnets and magnetic head drums support metal recovery for recycling jobs. With remote control capability, hydraulic folding conveyors, and intelligent load management, the S16 combines high throughput with ease of operation and fast servicing. Additional features include a low-level feed hopper, hydraulic lift-up screenbox with dual walkways for fast mesh changeovers, and a remote-control system with up to 100 metres range. The machine is available in diesel, dual power, or hybrid configurations.

EQUIPMENT & TECHNOLOGY ADVANCES THAT BOOST YOUR PRODUCTIVITY, MAXIMIZE YOUR ROI, AND BENEFIT THE PLANET

BY KAITLYN TILL, EDITOR IN CHIEF

Sustainability is a net benefit of the advances in equipment and technology that make today’s job site more efficient, more cost-effective, and safer. From the quarry to the construction site, the latest machines and processes are designed to reduce the amount of fuel burned to do a job, to reduce rework and improve build quality, and to extend the longevity of equipment.

Remanufacturing; power modes optimized to the task; job site connectivity, telematics, and machine control; and alternative fuels and powertrains all contribute to construction sites that are cleaner, safer, and more productive. Let’s explore each of these sustainability solutions and see how they can benefit both your bottom line and the planet.

Remanufacturing involves the restoration of genuine parts to like-new condition that matches the performance specifications of the original product but may also incorporate engineering updates.

The remanufacturing process keeps used parts within the supply chain and out of landfills, preventing still-viable elements of equipment components from going to waste. Cast steel that doesn’t take wear, or only takes minor wear, can be recovered while the consumable portion of the component is replaced.

Many OEMs offer remanufacturing programs. For example, customers who purchase a Cat Reman component can send a core (a used Cat component) back to their dealer to go to a Caterpillar remanufacturing facility and receive a core deposit refund, allowing them to save money versus the cost of a new part. The purchase price of a Cat Reman part is typically between 45 and 85 percent of the cost of a new component, and Cat Reman is an option for many engine, drivetrain, undercarriage, electronic, and hydraulic components for construction, mining, energy, and transportation equipment.

The remanufacturing process keeps used parts within the supply chain and out of landfills, preventing still-viable elements of equipment components from going to waste.

Remanufacturing contributes to a circular economy, keeping as many components as possible within the equipment ecosystem while assuring equipment owners that they will receive a component with like-new quality and warranty coverage from the manufacturer.

Work modes give operators the flexibility to tailor their machine directly to their task — whether they need to lift heavy materials or just require raw power.

Operating modes will vary depending on the machine and the OEM, but across the board work modes are designed to optimize the power that the operator needs to complete the job correctly and efficiently without burning unnecessary fuel or causing unnecessary wear on the machine.

Eco Mode is available on machines across sectors including on earthmoving, crushing, lifting, and roadbuilding equipment. Broadly, Eco Mode reduces engine RPM when full power

isn’t needed. This balance of performance and efficiency in turn reduces fuel consumption and can lower noise levels and reduce wear on parts.

Access to data on the job site, including real-time as-built data and telematics, gives operators and project managers feedback, insight, and assistance to confidently meet their targets using the fewest resources necessary.

Machine control technology can give operators of all skill levels a leg up on the job site and helps operators reduce the amount of time needed to complete a task, the amount of fuel burned, wear on the equipment, and the number of hours against the warranty of the machine.

When as-built data from equipment with machine control is transmitted from the machine to the office, or even to the site manager’s personal device on the ground, all stakeholders can see if the work is done to the correct specifications in real-time, rather than learning days or weeks after the fact that something went wrong. This eliminates the need to return to a job site for re-work. Equipment can be freed up to move on to another project with the assurance that it won’t have to be trailered back to address a problem.

Telematics data provides actionable insight into equipment use and maintenance that can help owners guide their operators toward sustainable operating practices that reduce wear on the machine and unnecessary fuel burn. Adhering to maintenance alerts will also keep that machine operating at peak efficiency, extending its life and reducing emissions.

There are many OEM platforms that gather all of this data from the job site and present it to project managers in an easy-to-understand format with actionable insights that can help them meet their sustainability goals. For example, the

John Deere Operations Center gives users comprehensive insight into job site progress, machine health, and fuel consumption, as well as analysis on the use of technology and its impact on job site productivity — just for a start.

One new piece of technology that will be incorporated into the John Deere Operations Center is Hamm’s Smart Compact Pro. This precision asphalt density scanning tool gives the operator and site manager an instant compaction quality assessment. Real-time insight into the quality of the surface helps the operator make decisions to help them precisely hit compaction targets which ultimately maximizes the longevity of the road. With this new technology, Hamm hopes to eventually eliminate the need to do coring for quality control, and the real-time density scan will help contractors avoid financial deductions for imperfections and avoid the need for early road refurbishment.

There is no one-size-fits-all solution to transitioning the construction job site to clean power, but different solutions can work in tandem to lower job site emissions and improve job site air quality for workers and the community.

The more straightforward switch for operations is to use biodiesel instead of petroleum diesel. Biodiesel is made from vegetable oil, tallow, or used cooking oil. According to the U.S. Department of Energy, emissions released from biodiesel combustion can be offset by the carbon absorbed from growing the feedstock, such as soybeans, to produce the fuel. Biodiesel also does less damage than petroleum diesel if spilled in the environment; it is far less combustible and thus safer to handle, store, and transport. OEMs can provide guidance on the right biodiesel mix for a given engine working in a given environment.

Engine OEMs are also extending their expertise into other propulsion solutions that reduce emissions.

Cummins, for example, is advancing a broad portfolio of power solutions that also includes electric, hybrid, natural gas, and fuel cell technology to serve a range of industries, and its X15 HELM engine platform will give customers the ability to select the best combustion option to suit their needs, whether that’s diesel, natural gas, or hydrogen.

JCB has been developing a hydrogen combustion engine for its construction machines for several years, and in early 2025 the company was approved to sell its hydrogen combustion engines across Europe. JCB has tested the hydrogen engine extensively with customers, most notably in backhoe loaders and telehandlers.

Hybrid technology also significantly reduces fuel consumption and CO2 emissions, and hybrid excavators are well-proven. Komatsu has been a notable leader in this area since it introduced its first hybrid excavator in 2008. Komatsu’s hybrid excavators feature an electric swing motor/generator that captures and regenerates energy as the upper structure slows down. The stored energy is then used by the generator/motor to assist the engine. These machines excel at providing fuel-efficient, responsive truck loading.

Volvo CE takes a different approach with its hydraulic hybrid excavators. Its machines capture up-and-down boom motion. The energy generated by the boom down motion is captured by a hydraulic accumulator to assist with the boom up motion, which is where the most pressure and power is needed.

Battery-electric power is now well-proven for compact machines, including excavators, wheel loaders, and compaction equipment, in certain applications. It is here that Volvo has also excelled at delivering a range of solutions. The company started small with compact electric machines, which it demonstrated in real-world applications where the investment in the new technology makes sense and charging power can be readily available: in indoor environments, around animals, in ecologically sensitive areas, and in urban settings. Most major

Access to data on the job site, including real-time as-built data and telematics, gives operators and project managers feedback, insight, and assistance to confidently meet their targets using the fewest resources necessary.

OEMs that manufacture compact equipment now offer electric machines, and larger equipment is now starting to get the electric treatment.

Drivetrain flexibility is also particularly notable and widely available for crushing equipment. Many of today’s crushers can be spec’d in hybrid or fully electric configurations. Hybrid crushers give equipment owners the most flexibility. When power is available, the machine can be plugged into the mains to run as a fully electric machine. But, should power not be available, the equipment can still run off of a diesel engine if needed.

Job site sustainability is not a finish line, but an ongoing practice that can be improved by using any combination of the technologies and equipment solutions that we’ve discussed here. Most importantly, these solutions do not have to be adopted for sustainability’s sake — they can have very real and significant lasting benefits to your job site’s productivity and to the quality of your work. HEG

BY MEGHAN BARTON, SENIOR WRITER

Bobcat may be synonymous with compact equipment, but the company’s latest product introductions are a strategic shift into larger territory. Bobcat’s new wheel loaders range from 142 to 189 horsepower, with operating weights be tween 27,274 and 34,487 pounds and bucket capacities ranging from 2.5 to 3.5 cubic yards. With the rollout of the L205, L235, L255, and L285, Bobcat is entering the mid-size wheel loader market, offering customers high-performance machines with out the bells and whistles that can inflate price tags.

According to Luke Hill, senior product specialist at Bobcat, the move is rooted in evolving customer needs.

“Our customers are growing. Their job site needs are grow ing. Their businesses are growing,” says Hill. “Their equipment needs are also increasing. So our goal here is just to grow with our customers.”

Bobcat has already spent years establishing itself in the com pact wheel loader segment, which helped ease the transition to heavier machines. According to Hill, snow removal emerged as an important driver behind the shift.

“Our compact wheel loaders met many demands, but we recognized an opportunity to better serve our customers, par ticularly in northern states, by offering machines with higher capacity and speeds for demanding winter snow work,” he says.

The new lineup positions Bobcat dealers to serve customers who previously had to go elsewhere for their larger equipment needs. For longtime Bobcat users, this means the ability to stay with the same brand and dealer, even as their job sizes and project scopes scale up.

“We’re committed, and our dealers are committed, to offering that same exceptional service to compact equipment owners with our new heavy wheel loaders,” says Hill.

While the size class is new for Bobcat, Hill sees it as a natural opportunity for the brand to compete with full-line brands and to offer something slightly different.

“We’re focusing on those core productivity enhancements without having some of the expensive frills you see on other established wheel loaders,” he says. “We want to be high perfor mance, high productivity, at a very attractive price point.”

Hill believes this approach will also appeal to users of com petitive equipment.

“It gives our dealers and Bobcat the opportunity to play in a backyard typically dominated by companies that have a full line of equipment,” he adds.

Each of the four models shares the same core productivity-enhancing features designed to support efficient operation across a range of jobs. These features include:

Return-to-dig: Helps operators consistently achieve the correct bucket angle for grading or snow removal, reducing cutting-edge wear and improving material pickup.

Ride control: Stabilizes the machine when travelling with a full bucket, minimizing material loss and improving roading comfort.

Inching mode: Disconnects the transmission to deliver full power to the loader arms while stationary, allowing for faster loading and dumping.

“These are features that increase productivity, especially for newer operators,” says Hill. “They’re intuitive and effective.”

All four machines also offer selectable power modes for job-specific fuel efficiency and quieter operation. Visibility from the cab is another standout.

“We have windows that stretch from floor to ceiling,” says Hill. “So the visibility in these wheel loaders is just tremendous. We have a glass door with a frame where you can open

the window or see through the door almost entirely, just driving excellent visibility and awareness on the job site.”

While the core features remain consistent, each model in the lineup is tailored for specific job site needs:

L205: The most unique of the group, featuring a hydrostatic transmission for smooth, intuitive operation. It’s ideal for snow removal in residential areas and small-scale construction projects. “It’s kind of your do-it-all machine at a cost-effective price point,” says Hill.

L235: A versatile option with an automatic transmission and a three-cubic-yard bucket. Well-suited for construction or snow removal, it offers more capacity and power than the L205 without a major size jump.

L255: Slightly larger than the L235 with a 3.5-cubic-yard bucket and increased lift capacity. Hill notes that it’s optimized for loading material into taller trucks or stockpiles.

L285: Bobcat’s largest wheel loader to date, with nearly 27,000 pounds of straight tipping load and maximum material-moving capability. “You’re getting solid performance and the ability to move a massive amount of material,” Hill says.

All four machines are available with Bobcat’s dealer-installed payload scale system and are compatible with third-party machine guidance solutions like Topcon for grading and material placement.

“We can offer those high-end guidance features either through Bobcat or close collaboration with a third party,” Hill notes.

The shift into heavier equipment also means making sure Bobcat’s dealer network is ready, and, according to Hill, they are.

“Many of our dealers already do a very good job at on-site and/or remote service. This is going to be nothing new for those dealers,” Hill says. “We do have many dealers that are taking our heavy equipment lineup for the first time with this [expansion into larger wheel loaders], and they’re getting creative in how they’ll fit those into their shops.”

Rental customers have long associated Bobcat with compact machines, but Hill sees strong potential for the new loaders in fleet applications.

“It allows our dealers to go for that full line of heavy compact equipment,” says Hill. “We can go after those rental companies or those rental customers that come in and need a [larger] wheel loader to move material quickly across the job site, and also need compact [machines] to clean up or get into smaller areas. Now our dealers can target both with a full range.”

For contractors who haven’t previously considered Bobcat, Hill has a clear message: now is the time.

Our compact wheel loaders met many demands, but we recognized an opportunity to better serve our customers, particularly in northern states, by offering machines with higher capacity and speeds for demanding winter snow work.

Luke Hill Senior Product Specialist, Bobcat

“For those compact customers who also own heavy equipment, Bobcat is ready to play,” he says. “Our dealers have exceptional service, and we have the performance to match.”

While initial shipments are just reaching dealers, early feedback from demos has been strong.

“They’re absolutely blown away at the power and performance,” says Hill. “The excitement is real.” HEG

2.9 M square feet of exhibits / 139,000 attendees / 2,000 exhibitors / 150 education sessions

2.9 M square feet of exhibits / 139,000 attendees / 2,000 exhibitors / 150 education sessions

BY MEGHAN BARTON, SENIOR WRITER

The Caterpillar D6 XE may be the world’s first high-drive electric-drive dozer, but for operators stepping into the cab, it doesn’t feel radically different — just better. That’s by design.

Introduced in 2018, the D6 XE combines Caterpillar’s highdrive undercarriage with a diesel-electric powertrain that de livers smooth, uninterrupted torque and up to 35 percent bet ter fuel efficiency than its predecessor, the D6T. But it’s not just about saving fuel. The machine’s aggressive pushing power, intuitive assist technology, and lower long-term maintenance costs are redefining expectations for medium-class dozers.

“We were able to take customers that are very familiar with the old tractor and put them in this new one, and they’re like, ‘Yeah, it’s not different, it’s just more powerful,’” says Sam Meeker, marketing professional at Caterpillar. “It feels like a really aggressive version of the regular D6.”

That familiarity is part of what’s made the D6 XE a seam less progression between convention and innovation. “One of our secrets to success with this tractor has been making it different but not so different that people are afraid of it,” says Meeker. The form factor is recognizable, but the experience is next generation.

The D6 XE is designed to deliver exceptional fuel efficiency. The Cat C9.3B diesel engine feeds an electric generator, which powers the drive motor through the steering case and on to the final drives. This eliminates the need for a conventional trans mission or torque converter.

The result is constant power to the ground with no gear shifting, reduced mechanical wear, and the ability to ramp into a load instead of bogging down.

“We like to run this machine at a lower RPM, not only for fuel efficiency, but then it allows us to lug up into a load,” explains Meeker. “So when we pull the load on, instead of the tractor lugging down, it actually increases the RPM and the power output, maintaining that consistent torque.”

The D6 XE features a switched reluctance electric motor and generator, an update from the older permanent magnet

CAT’S D6 XE IS DESIGNED TO DELIVER EXCEPTIONAL FUEL EFFICIENCY.

system used in Caterpillar’s first electric-drive dozer, the D7E. The newer architecture is more power-dense and efficient. Unlike its predecessor, the generator doesn’t require cooling.

“We only make as much power as we’re going to use,” Meeker says. “And we generate less heat than previous designs.”

Caterpillar identifies three pillars that define the D6 XE’s value: fuel efficiency, lower total cost of ownership, and aggressive performance. The combination of performance, resource optimization, and serviceability supports Caterpillar’s mission to lower life cycle costs.

Depending on the work cycle and the machine being replaced, contractors may see anywhere from 10 to 35 percent improved fuel economy. Fuel and productivity gains are most apparent during tasks like finish grading and truck-dump spreading, where second-gear torque plays a larger role.

The D6 XE also offers lower operating and rebuild costs. With fewer moving parts (no transmission, no torque converter, and reduced fluid consumption), Caterpillar estimates customers can save roughly $1 per hour on powertrain rebuilds.

“It can be up to roughly 60 percent of new machine price,” says Meeker, referring to the cost of a full rebuild at the 10,000to 15,000-hour mark. “So you could be getting a half-price dozer for that second life.”

Even if customers don’t rebuild, resale value is strong. “The [ability to] rebuild and the strength of the Cat dealer network and the parts network [help] keep that value of that tractor higher,” says Meeker. “We can see anywhere between a $50,000 and $100,000 premium over our competitors at rebuild time based on used equipment sales data, including our own.”

The D6 XE is designed to perform across a wide range of dozing tasks, but its advantages become most apparent in medium-duty and finish grading applications where torque, speed, and fuel economy converge.

“In that truck-dump spreading application where you’re in second gear, that’s where we get that extra little bit of torque, and we’re able to be a bit more productive,” says Meeker. In heavier first-gear pushing, its drawbar pull is comparable to conventional D6 models. But as the work shifts from bulk material to spreading and finishing, the electric drive shows a clear edge.

“In finish grading, the advantage of the XE is going to be on fuel,” Meeker explains. “We’re able to use that lower RPM and that super-efficient powertrain to get the same work done while burning much, much less fuel.”

From owner-operators to large corporate fleets, the D6 XE has found traction with a broad customer base. According to Meeker, medium-sized contractors — those running fleets of 20 to 50 machines — make up a strong core of adopters. These companies often operate in site preparation, commercial development, and roadbuilding applications, where machines are expected to perform a range of tasks from heavy dozing to finish grading.

The D6 XE also appeals to owner-operators, particularly those who spend time in the cab themselves. “They can feel it, they can experience it,” says Meeker. “So the owner-operators say they really love this tractor.”

WITH FEWER MOVING PARTS, CATERPILLAR

ESTIMATES CUSTOMERS CAN SAVE ROUGHLY $1 PER HOUR ON POWERTRAIN REBUILDS OF THE D6 XE.

We like to run this machine at a lower RPM, not only for fuel efficiency, but then it allows us to lug up into a load.

Sam Meeker Marketing Professional, Caterpillar

Larger construction firms and even some quarries are also putting the D6 XE to work in tasks like stripping and stockpile maintenance. However, Meeker is quick to point out that the machine’s value is best realized when productivity gains translate directly to the bottom line. “If you’ve got somebody working solely by the hour . . . that’s probably not the customer for an XE,” he notes. In cases where billing is based on time rather than output — such as consultant work in oil field support — the fuel savings and performance gains may not fully offset the initial investment.

While the D6 XE incorporates advanced assist features and is grade- and autonomy-ready, Caterpillar designed the machine to accommodate all skill levels.

“We don’t force you to use the technology. It’s there. You can turn it on and use it if you want to, but we don’t force an operator to use it,” says Meeker. This approach appeals to both tech-savvy younger operators and more experienced users who value control. “I’ve got one particular operator that I deal with a lot,” Meeker recalls. “His motto is, ‘If it makes my life easier at the end of the day, why wouldn’t I want to do it?’”

• AutoCarry: Automatically adjusts blade height to maintain optimal load and traction.

• Slope Assist: Guides vertical blade control without GPS.

Stable Blade: Reduces unintended blade bounce or overcorrection when working at slow speeds.

• Steer Assist with 3D: Follows a design line horizontally to maintain alignment.

• Traction Control: Reduces slip in soft or uneven terrain.

• Blade Recall (coming in 2025): Speeds up return to saved blade positions.

Caterpillar recognizes that even on fast-paced job sites, operators need accessible ways to explore new technologies. That’s why the company has focused on integrating features that are easy to discover, intuitive to use, and available on demand. Meeker notes that idle time across typical dozing applications averages around 30 percent, providing short windows throughout the day for exploration and learning. “That’s 18 minutes an hour that you’re not working,” he explains. “That gives you quite a bit of time to look around and maybe experiment.”

To support operator adoption across all experience levels, Caterpillar offers on-demand learning resources through its online platform, catoperatortraining.com. Designed to be accessible any time and from any device, the platform is particu-

larly valuable for operators, whether they’re digital natives or seasoned professionals, navigating new technologies.

Meeker notes that he recently spoke with an operator in his mid-50s who was watching tutorial videos on his phone during a break. “He was looking up how to run a particular feature,” says Meeker. “We’re seeing more and more operators, regardless of age or tech background, making use of those tools to get more comfortable in the seat.” The ease of access and modular format allow operators to learn at their own pace, building confidence with new assist features without stepping away from the job site.

By combining the trusted high-drive undercarriage with a refined electric-drive powertrain and operator-focused technology, the Cat D6 XE stands out in the medium-class dozer segment. But Caterpillar also sees the D6 XE as a strategic stepping stone toward more integrated automation.

With more than 50 million hours of electric-drive experience across its product lines, and over two decades of implementing 3D grade control, the company has steadily introduced assistive technologies that could pave the way for future autonomy. As part of Caterpillar’s medium-dozer lineup, the D6 XE benefits from a modular platform that enables regular updates to machine control, assist features, and performance technologies.

“It’s just a great machine,” says Meeker. “We get a lot of customers, a lot of operators, that run it for even a few minutes or a week or a month, and they come back and say, ‘I never want another dozer.’”

With impressive fuel efficiency, lower cost of ownership, and aggressive performance built into its DNA, the D6 XE is engineered not just to work harder, but to work smarter for the long haul. HEG

BY LYNETTE VON MINDEN

Compact track loaders, or CTLs, are more popular than ever before, and that’s due in no small part to their incredible versatility. Available in a wide range of sizes and with a staggering number of productivity-boosting attachments, CTLs can come in handy on just about any job site, large or small. In fact, a skilled operator with a CTL and the right attachments can often do the work of multiple individuals — that’s especially important in today’s tight labour market.

Over the years, CTLs have advanced with more innovative features to meet changing operator and job site needs. Many now include around-view cameras with large monitors for better visibility when working in confined spaces and enhanced safety. These screens are also key for monitoring the machine’s health, and this is also where much of the customization takes place, such as adjusting auxiliary hydraulic flow to dial in the performance of a hydraulic attachment. That’s just the tip of the iceberg when it comes to advanced CTL features.

Speed-sensitive ride control reduces material spillage and creates a smoother ride for the operator. Auto two-speed shift allows the machine to automatically downshift when more traction is required for pushing into a pile, making sharp turns, or travelling uphill. Active power control optimizes engine speed and torque when under load.

CTLs that offer electric-over-hydraulic, or EH, controls, are even more customizable, seamlessly integrating with more advanced attachments for nearly effortless control and far greater productivity. While pilot controls were once standard on many CTLs, EH systems are now increasingly common as machines become more integrated with technology.

With hydraulic and electronic integration, these machines are no longer just dirt movers. They can do so much more, including clearing land with mulchers and rotary cutters or removing snow with advanced plows and snowblowers. These CTLs can prep sites for utility services by using cold planers to amend asphalt and concrete and trenchers to prepare for laying pipes and electrical or fibre-optic cables.

“Machines like our new Takeuchi TL11R3 reflect that shift,” says Dylan Freeman, CTL product manager at Takeuchi-US. “They’re not just built for moving dirt — they’re designed to take on demanding attachment work, with EH controls and highflow hydraulics that give operators more precision and power.”

So, how do EH controls differ from pilot controls? EH controls send an electrical signal to hydraulics to control travel and boom and bucket control. Traditional pilot controls consist of a mechanical process where the joystick moves valves to divert hydraulic flow for movement. EH has the advantage over pilot controls because many more functions can be easily added via electrical signals and controls can be customized to fit operators’ needs and preferences. The 14-pin connection to attachments on an EH-controlled machine can also often offer more versatility as it’s easier to integrate additional attachment functions into the EH controls.

From an operator standpoint, EH controls allow for easier customization right from the CTL’s monitor, such as specifying pattern and sensitivity level. This customization allows one machine to easily accommodate the preferences of multiple operators. Newer operators can set their EH controls to a slower response setting and switch to a faster setting as they become more accustomed to the machine.

“The available automatic features EH controls make possible can help newer operators be more productive, as they’ll run the machine more efficiently,” Freeman adds. “On an older machine with pilot controls, operators would have to manually engage these functions, and it might take a more experienced operator to do that correctly.”

EH controls improve how operators interact with the machine, but to fully unlock a CTL’s potential — particularly with powerful attachments — high-flow hydraulics are essential. The combination of flow (measured in gallons per minute, or

An example of a job where the combination of EH controls and high-flow hydraulics come in handy could be when an offset cold planer or trencher is in use.

Dylan Freeman

CTL

Product Manager, Takeuchi-US

GPM) and hydraulic pressure (measured in pounds per square inch, or PSI) can be used to calculate a CTL’s auxiliary hydraulic horsepower. Typically, GPMs of more than 32–35 have been referred to as high flow. However, it’s becoming increasingly common for high-flow machines to have a GPM of 40-plus, with pressures of 3,400–4,000 PSI.

“Attachments that are required to spin at high speeds, such as mulching heads or snow blowers and attachments that require lots of power to cut or grind through material, such as cold planers or stump grinders, are becoming more and more popular,” Freeman says. “These types of attachments require lots of power to run and thus require a high-flow machine. Standard-flow machines fall short as their combination of flow and pressure doesn’t generate enough horsepower for these attachments to reach the rotation speed or power needed to complete their tasks.”

When a CTL has both EH controls and high-flow hydraulics, those systems can truly complement each other in the field. For example, attachments with the ability to move in multiple directions will often require more input controls than the machine offers. This fact also holds true for attachments requiring constant power for multiple components, such as pick-up brooms or cold planers where the broom or milling head is rotating and the water tank needs power to supply water. EH controls can be adjusted to accommodate all these functions and more.

“An example of a job where the combination of EH controls and high-flow hydraulics come in handy could be when an offset cold planer or trencher is in use,” Freeman says. “These attachments can pull the machine to one side. With the EH-enabled track compensation feature, the operator can adjust the flow to the drive motor on either side of the CTL and prevent that drift from happening. Meanwhile, high-flow hydraulics provide the horsepower needed to keep the attachment’s drum spinning in dense material.”

Other examples where the combination of EH controls and high-flow hydraulics are a must include the use of EH controls for smooth feathering through dense brush and precise boom movement around trees. In that situation, programmable flow rates and detents can reduce the risk of overloading the CTL. High-flow hydraulics are also a must for powerful snow throwing and effective operation in wet or deep snow. During snow removal, EH controls give precise chute rotation, deflection, and blade angling for a cleaner, more efficient result.

The combination of EH controls and high-flow hydraulics can also make it easier to fine-tune certain operator preferences or settings. According to Freeman, one time when this combination comes into play is when creep speed and high flow are used together for applications such as trenching.

“You can set the speed of the machine using creep mode,” Freeman explains. “This way the operator does not have to

worry about metering speed with the joystick while running the engine at max RPMs, which could result in uneven trenching or potentially stalling the machine if the operator travels too quickly.

Overall, features like EH controls and high-flow hydraulics are changing the way contractors think about CTL ownership and usage. Together, the customization now available with EH controls and the increased performance of high-flow hydraulics make it possible for manufacturers to develop new attachments and optimize those that are currently available. Operators will become increasingly efficient as the already-versatile compact track loader becomes even more functional. Freeman believes that contractors running older CTLs or bare-bones models might want to make the investment in a machine with EH controls and high-flow hydraulics to become more efficient and broaden their service menus.

“The efficiency of an older or less-equipped CTL truly depends on the operator’s proficiency,” Freeman says. “As newer, less-experienced operators enter the workforce, these advanced CTLs can help ensure there’s less of a drop-off in productivity. Newer machines like our TL11R3 model can simplify and optimize tasks that would have taken years of experience to master in the past.

“Time is money, and any time you can shave hours off a task, that’s more money in your pocket. With the combination of EH controls to enhance customization and precision, and high-flow hydraulics to send greater power to the attachments, you can complete even larger, more difficult tasks with a single CTL.”

LYNETTE VON MINDEN is a senior public relations specialist with Swanson Russell.

THE ALL-NEW

Designed for construction, demolition and quarry applications, including underwater jobs, our comprehensive breaker line includes 12 models. Blue Diamond Breakers are compatible with excavators, mini-skid, skid steer and compact track loaders.

Every one of our breakers features:

• Solid mono-block design; only 2 moving parts.

• Anti-blank firing to protect internal components.

• A unique poly case shell for vibration dampening.

• Interchangeable machine mounting brackets.

THERE’S SIMPLY NOTHING LIKE IT IN THE INDUSTRY.

Choose Blue Diamond –where all we do is elevate everything you do.

Ready to meet the most durable breaker in the industry? Visit us at www.bdabreakers.com!

ATTACHMENTS - IT’S ALL WE DO

Keestrack introduced two completely new machines at bauma: the R2 impact crusher and the C7 classifier. Keestrack equipment is available through Frontline Machinery in Canada.

The R2 compact track mobile impact crusher completes Keestrack’s impact crusher range and is available in two versions: a fully electric ZERO model and a conventional diesel/hydraulic drive model powered by a DEUTZ TCD 5.2 L4 engine that is compatible with biodiesel. The R2 is the smallest model in Keestrack’s impactor range.

Keestrack says that the R2 is easy to operate within city centres where high flexibility and mobility are essential. The new impactor has a capacity up to 150 tph.

The crusher design features are similar to Keestrack’s larger R3 impactor. The hopper (3 cubic metres) with integrated vibrating feeder (3,300 x 810 mm) and pre-screen (1,250 x 810 mm) also has an asymmetric design to feed the material easy into the inlet (860 x 730 mm), which is equipped with a replaceable entry beam.

The newly designed rotor, with a width of 840 mm and a diameter of 920 mm, is made of Hardox steel.

Rotor speed can be adjusted by a hydrostatic drive to fine-tune the desired grain size. The impact aprons can be easily serviced from the top.

The R2 impactor, fully equipped in closed circuit with a 1,200 x 3,040mm single-deck afterscreen, magnet separator, and windsifter has a total weight under 27 tonnes and a transport length of 13.05 metres, making it very agile for urban applications. The return conveyor of the closed circuit can also swivel outside to be used as a stockpile conveyor for oversize material.

Keestrack also introduced the brand-new high-capacity threedeck classifier to complete its product range for high-capacity precision screening. The C7, with a capacity up to 600 tph, is equipped with a triple-deck screen box of 5,450 x 1,800mm with interchangeable screen meshes that can be swapped quickly. The C7 is specifically designed for accurate and high-capacity precision screening for sand and aggregates. The walkways on each side of the screen box provide excellent service and maintenance access, and the C7 has no support legs, resulting in quick set-up times.

The C7 three-deck classifier is available in conventional diesel/ hydraulic drive, and Keestrack has plans to introduce a ZERO fully electric plug-in version. A two-deck version is also planned.

SBM’s track-mounted REMAX 600 mobile impact crusher was introduced at bauma 2023, and after a successful introduction into worldwide markets was on display again at bauma 2025. The 600-tph plant with a 1400 impact crusher for natural stones and recycling, with a feed size of 1,000 mm, is a fully hybrid plant with a diesel engine and a 520 kVa on-board generator that consumes 30 to 50 percent less fuel compared to conventional diesel-hydraulic plants, according to SBM. SBM demonstrated a new plug system for the plug-in option of this plant, including a second mains switch that is easy and safe to operate.

At bauma 2025, SBM also introduced an add-on single-deck screen in a 6-metre version for the REMAX 600. In a closed cycle, it provides a particularly high yield of defined fine grain sizes. Application examples include asphalt recycling with end products of 0/8 or 0/10 mm or corresponding aggregates in natural stones or concrete recycling. Two magnetic separators ensure purity and quality: a highly efficient electromagnetic separator with cross discharge above the main discharge conveyor and a permanent magnetic separator with longitudinal discharge at the screen transfer point.

The REMAX 600 features intelligent SBM Crush Control which supports the machine operator right from the set-up stage. It monitors the entire production process and uses a comprehensive sensor system to ensure trouble-free and smooth material flows.

Autonomous crushing development continues between SBM and its research partners at the University of Leoben, and following the successful integration of special sensors to

evaluate the final products, the company is currently working on optimizing the AI-supported visual real-time detection of the feed material. Autonomous crushers will be connected via the cloud to the SBM headquarters. A digital twin of the plant will in real time validate the settings made on site or optimize the crushing processes based on constantly growing reference data. SBM says that the new technology is expected to be ready for the market by 2026.

Whether you’re digging, loading, moving, placing – or all of the above – you need reliable, performance-driven equipment to get the job done right. Wacker Neuson o ers a powerful line of material handling models designed for jobsite e ciency and operator comfort. From excavators and dumpers to compact track loaders, and wheel loaders, Wacker Neuson has all it takes for the challenges you face.

The new heavy-duty Cat 980 GC wheel loader offers low fuel consumption with an on-demand fan, load-sensing hydraulics, intuitive controls, and Performance Series buckets. New to this model is the Engine Idle Management System (EIMS), which minimizes idle RPM and fuel consumption to help deliver low owning and operating costs.

The new 980 GC is powered by the Cat C13 engine. The engine’s Cat Clean Emissions Module works in the background without impacting production. The EIMS, Auto Engine Idle Shutdown, variable speed fan, and load sensing hydraulics combine to offer low fuel consumption and sound levels on the machine.

The wheel loader’s automatic planetary powershift transmission delivers high reliability and long service life, according to Caterpillar. Four forward/reverse speeds reach a maximum 39.8 km/h (24.7 mph) speed to quickly move about the site, and the Electronic Clutch Pressure Control (ECPC) shifting system provides smooth, efficient gear changes in all operating conditions. Available ride control improves operating smoothness over rough terrain, and the optional limited slip differential axle increases traction in poor ground conditions.

With a bucket capacity range of 4.3 to 5.8 cubic metres (5.75 to 7.5 cubic yards), easy-to-load Cat Performance Series buckets use a system-based approach to balance bucket shape with the

machine’s lift and tilt capacity, weight, and linkage. Cat says the bucket design improves material retention and reduces dig time with build options that include general purpose, flat floor, heavy duty rock, coal, and light material. The Cat Z-bar loader linkage with cast crossmember and tilt-lever provides strong digging efficiency and high breakout forces. Load-sensing hydraulics produce flow and pressure for the implement only when needed. The new 980 GC can be equipped with the Cat Fusion quick coupler and controls, and combined with optional third-function hydraulics, the coupler allows use of a wide variety of work tools.

Cat VisionLink is standard on the new 980 GC. Fleet managers can track critical loader operating parameters like machine location, hours, fuel usage, diagnostic codes, and idle time.

Cat Payload is an available option. It weighs material while moving to the truck and lifting for on-the-go weighing (not legal for trade). The Cat Payload for Trade option for Cat Advanced Payload allows you to integrate the scale data directly into your business processes. It is type approved by the International Organization of Legal Metrology and retains all the features of the standard version of Cat Advanced Payload.

The 980 GC’s spacious cab design gives operators excellent visibility. Pilot-operated hydraulic controls deliver low-effort, comfortable operation and include a remote transmission kickdown switch for operating comfort.

At Dimensions 2025, connection is magnetic.

Plug into a powerful network of industry experts, unlock hidden potential within your Trimble solutions, and master the latest techniques driving the future of your work. Discover innovative workflows and solutions, and solve your toughest challenges alongside peers, partners and Trimble professionals.

November 10–12, 2025 | The Venetian Resort Las Vegas

now to reserve your spot at

SAVE MONEY AND EXTEND THE LIFE OF YOUR EQUIPMENT WITH THESE SIMPLE OPERATIONAL CHANGES

BY JON GLENNON

You know that an idling machine isn’t making you money, but do you know how much it’s costing you? And once you know, do you know what to do about it? Here’s how this common job site practice can negatively affect your equipment and your business.

Many construction machines idle for more than half of their operating time. While it may seem like a harmless way to keep a machine ready to go, too much idling can compromise a diesel engine, which compromises your uptime and profits right along with it.

One of the most obvious downsides of idling is wasting fuel, which is a cost that everyone wants to keep in check.

Here are four other ways idling is bad for an internal combustion engine:

Carbon buildup: Prolonged idling can lead to incomplete combustion, which causes carbon to build up in the exhaust system, turbocharger, and cylinders.

Fluid contamination: Too much idle time prevents a diesel engine from reaching its optimal operating temperature. This can cause unburned fuel to dilute the engine oil, leading to increased wear and tear on engine components.

Low pressure: Idling can create conditions of low cylinder pressure and reduced lubrication, which also contributes to engine deterioration.

Emissions: Idling increases fumes and harmful emissions, such as nitrogen oxide (NOx) and particulate matter.

IT’S A FLEET MANAGER OR OWNER’S JOB TO MAKE SURE THEIR OPERATORS UNDERSTAND THE EFFECTS OF IDLING, BUT THERE ARE TECHNOLOGIES THAT CAN MAKE THAT JOB MUCH EASIER.

Use telematics reporting to compare similar machines and determine whether there’s a large variance in idling percentages.

Then you can determine if machines are running at higher percentages due to operator behaviours or whether variances point to something else, like using the wrong number or size of machines for the job.

So, how bad could it really be? Let’s do some math: Imagine two of the same machines doing the same type and amount of work on the same job site. Machine A runs with 50 percent idle time and Machine B idles at 25 percent. Over the course of a year, Machine A racks up about 2,000 hours, while Machine B only accumulates 1,500. At five years, Machine A will hit 10,000 hours and Machine B will only have 7,500.

This difference in hours can cost tens of thousands of dol lars in resale value, depending on the machine size and type.

Reasonable idle times also mean lower maintenance costs. In the situation above, assuming 500-hour service intervals, Machine A would require five more service appointments than Machine B. And if a warranty is involved, Machine A will reach the end of that period much sooner.

How can you address excess idle time to keep it from eating away at your bottom line? This question has two good answers: Lean on helpful technology, and follow through on operational adjustments.

It’s a fleet manager or owner’s job to make sure their opera tors understand the effects of idling, but there are technologies that can make that job much easier. Fleet utilization reporting is one of the biggest benefits of an advanced telematics system, and you should regularly review this data to identify issues and opportunities.

prioritization of trends and alerts.

Use telematics reporting to compare similar machines and determine whether there’s a large variance in idling percentages. Then you can determine if machines are running at higher percentages due to operator behaviours or whether variances point to something else, like using the wrong number or size of machines for the job.

Telematics usage is growing each year, and OEMs are continually improving their systems to incorporate customer feedback and make the technology work for you.

For example, Volvo CE is launching an updated version of its ActiveCare Direct system that will offer improved reports, more streamlined access to key features and functions, and clearer

A worthwhile telematics service will provide understandable alerts that give operators and fleet managers actionable insights, like high RPM shutdowns and speeding.

And speaking of taking action, there are several things your operators and technicians can do to reduce idle time:

Warm up under load: Instead of having a long idle period, allow your equipment to warm up by gradually increasing the load during the first few minutes of operation. This helps the engine reach its optimal operating temperature more efficiently.

Proper cooldown: Before shutting off the engine, allow it to idle for three to five minutes to cool the turbocharger (especially after heavy use).

Set time limits via automatic features: Take advantage of automatic systems where engine speed is reduced to idle — or even shut down — when the machine and controls are inactive for a preset amount of time.

Handle cabin temperature control differently: Instead of running the engine solely to control cab temperature, you can equip machines with auxiliary power units (APUs) or use battery-powered climate control systems. Keep filters clean: Regular maintenance, including the replacement of air and fuel filters, ensures that idling periods cause less damage.

Reduce warm-up idling in cold weather: Use block heaters to warm the engine coolant before getting to work. Use a low-temp diesel when needed: In cold environ-

ments, winter-grade diesel or fuel additives can prevent gelling and reduce the warm-up time needed.

It’s clear that idle time has its place. But it’s also clear that too much of it has serious consequences. Your dealer and/or OEM should be more than happy to speak with you about technologies that can help you identify idle time issues. Then, armed with data and knowledge, you can help your team make the necessary adjustments to get your idling percentages in check.

JON GLENNON is the solutions sales manager at Volvo Construction Equipment.

BY DARIN GRONWOLD

Tires might not be the flashiest part of your compact equipment set-up, but they sure can steer your productivity in the right — or wrong — direction. Choosing between solid and pneumatic tires isn’t just about what you pay at checkout. It’s about how you work, where you work, and how often you want to deal with downtime. If you’ve ever been left flat on a demo site or burned a day waiting for a tire swap in the woods, you know: your choice in tires can make a real difference. Let’s get rolling into the pros, cons, and ROI of each option — and which one might be the best fit for your operation.

Choosing between solid and pneumatic tires starts with understanding your terrain. If you’re working around jagged rebar, demolition debris, stumps, or scrap, solid tires will keep your operation moving. Their puncture-proof design shrugs off job site hazards like a boss. Forestry, demo, and urban construction contractors love them because you can roll over a pile of nails and keep going without a second thought.

On the flip side, if your work leans more turf-friendly — think landscaping, snow removal, or light-duty utility tasks — pneumatic tires give you a smoother ride and reduce ground disturbance. They’re also easier on the operator, especially during long shifts on paved or hard-packed surfaces.

Still, most pros operate in the gray area moving from concrete to gravel to soft ground all in one week. That’s where tire choice can really steer your bottom line.

Pro Tip: One reason rental companies have been early adopters of solid tires? They eliminate customer complaints about downtime from flats and reduce the risk of unsafe blowouts caused by underinflation or overloading. With solids, you set it and forget it.

Let’s talk ride quality. Pneumatic tires win this round. Their air-filled cushion makes for a less jarring experience, especially over uneven ground. If you’re spending 8 to 10 hours in the cab every day, that smoother ride adds up.

Solid tires? Let’s just say they’re built for business, not pleasure. They’ll take a beating and keep going, but they transmit more vibration and bump. The payoff is in peace of mind. You’ll never have to worry about a flat in the middle of a haul or while loading logs at the far end of a muddy lot.

This is where the rubber really meets the road. Yes, solid tires come with a higher upfront cost. A standard pneumatic skid-steer tire might run you $250 to $500. A comparable solid could cost $800 to $1,200. But let’s zoom out.

Pneumatics often need to be replaced every 500 to 1,000 hours, depending on conditions. Solids? You’re looking at 3,000 to 4,000

hours of life in tough terrain. That’s 3 to 4 times the lifespan. Let’s do the math:

• 4 sets of pneumatics at $400/tire x 4 tires = $6,400

• 1 set of solids at $1,000/tire x 4 tires = $4,000

Solid tires are already ahead, and we haven’t factored in:

• Downtime waiting on repairs,

• Service call fees (often $200 to $400 per visit),

• Labour to swap out tires, and

• Lost productivity on the job.

Even just the daily task of checking air pressure adds up over time. And, let’s be honest, not everyone checks as often as they should.

Pro Tip: Consider a “lifetime cost calculator” that compares tire lifespan, maintenance, and replacement frequency. Some online tools or OEM support systems will even help match tires to your machine and application based on usage patterns and carrier specs.

Solid tires are heavier, and that matters. For example, a solid tire might be rated to carry 6,600 pounds compared to a similar pneumatic rated at 4,700 pounds. That extra load rating increases your safety margin and lets you haul more material, which is

great for productivity. But that added weight also subtracts from your equipment’s lifting capacity. Make sure to run the numbers, especially if you’re working near max load limits.

Tire sizing is another factor that can trip people up. A mismatch can throw off your machine’s balance, strain the drivetrain, or cause uneven wear. Fortunately, there are digital tools that take the guesswork out of tire selection by pulling from thousands of compact equipment specs. These make sure your wheels are matched to both your machine and the job at hand.

At the end of the day, choosing the right tire comes down to how you work and what kind of headaches you’re willing to deal with. Solid tires offer unmatched durability, fewer interruptions, and a higher long-term return. Pneumatic tires offer comfort and flexibility in more forgiving environments.

If your machine sees action in demanding, debris-heavy conditions, solids might just be your new best friend. If you’re cruising across landscaped lawns or clearing light snow, pneumatics could still be the right call.

Either way, taking the time to understand the differences and plan for the total cost of ownership can keep your operation rolling smoothly and your bottom line in better shape.

DARIN GRONWOLD is a product manager for Ignite Attachments.

BY MEGHAN BARTON, SENIOR WRITER

When Chinese manufacturer Sanha Machinery Tech (SWT) set out to expand into the Americas, the initial plan was to start selling high-quality excavator attachments immediately. But early resistance made it clear that success would require more than a good product. It would take market trust, built through performance, patience, and dealer buy-in.

“Our mentality was that we knew we had a great product, so we thought Canadians would know [that too],” says Jose Villalba, director of business development Americas for SWT.

“But . . . then we started hitting some walls.”

What followed was a deliberate, data-driven, multi-country process to validate SWT’s hydraulic power hammers and other attachments in three different markets, Canada, Mexico, and Uruguay, before attempting full-scale dealer expansion.

SWT initially approached the Americas with the assumption that product quality and competitive pricing alone would drive sales. But early pushback uncovered a disconnect between that belief and what buyers in the Americas actually needed: trust, service, and proof. Villalba advocated for shifting the company’s approach to be more focused on building this brand in a way that was tailored to meet local expectations.

“Before we looked for more dealers or tried to expand quickly, I said to the factory, ‘We need to know what [users] really need,’” says Villalba. “There’s a lot of competition in different price ranges. We need to manufacture based on customer use, not assumptions.”

Jose Villalba

Director

of Business Development, Americas, SWT

Villalba led a three-year testing phase, placing SWT hammers in the field across varying climates, applications, and operational intensities. In Canada, the attachments were left outdoors through winter and tested in the bedrock of Halifax. In Mexico, the hammers ran for 2,000 hours annually in high-use environments. Uruguay served as a smaller-scale test market representing conditions in Latin America.

“The product was tested across three different landscapes for three years,” he says. “In that time, we didn’t have a single warranty claim.”

The results confirmed what Villalba believed from the start: SWT’s hammers could stand up to the demands of the Americas, but proving it in the field was essential to earning buyer confidence. There’s a lot of competition in different price ranges. We need to manufacture based on customer use, not assumptions.

With technical validation complete, SWT focused on the business case for its target market segment: small and midsized contractors. The company introduced a two-year warranty and collected real-world performance data to support ROI estimates.

“In Canada, we determined you can get return on investment in seven months,” says Villalba. “And you have a warranty for two years.”

To reinforce that message, SWT is preparing to launch an online ROI calculator that lets contractors enter project data, such as machine make/model, attachment type, usage hours, and pricing, to get a payback estimate. The tool also helps match hammers to excavators and supports both purchase and rental scenarios.

“They can see the hammer, how much they’re going to make in revenue, the profit, and the payback,” Villalba explains. “It helps [our customers] feel confident.”

SWT’s go-to-market strategy now centres on selective dealer development, starting with Tidal Tractor in Atlantic Canada. Early lessons taught Villalba not to assume that dealer principals alone could drive momentum.

“You have to convince not only management, but the salespeople and the technicians as well,” says Villalba. “They need to know that what we are making is a really good product, and that’s what we promise.”

SWT has invested in training and service support, including

The insights from the three-year test didn’t just validate the product; they became the blueprint for its evolution. The real-world performance data was relayed directly to SWT’s engineers, who used it to fine-tune hammer configurations and create market-specific designs. This data-driven process was dubbed ‘Smart Work Technology,’ a name that also reflects the brand’s initials.

According to Villalba, this level of customization is SWT’s answer to an increasingly uniform market. “Today, the manufacturing of hammers and other excavator attachments has become commoditized,” he notes. “That’s why you see such similar product designs across different brands, even well-known ones.”