Tales From the Waterside continued

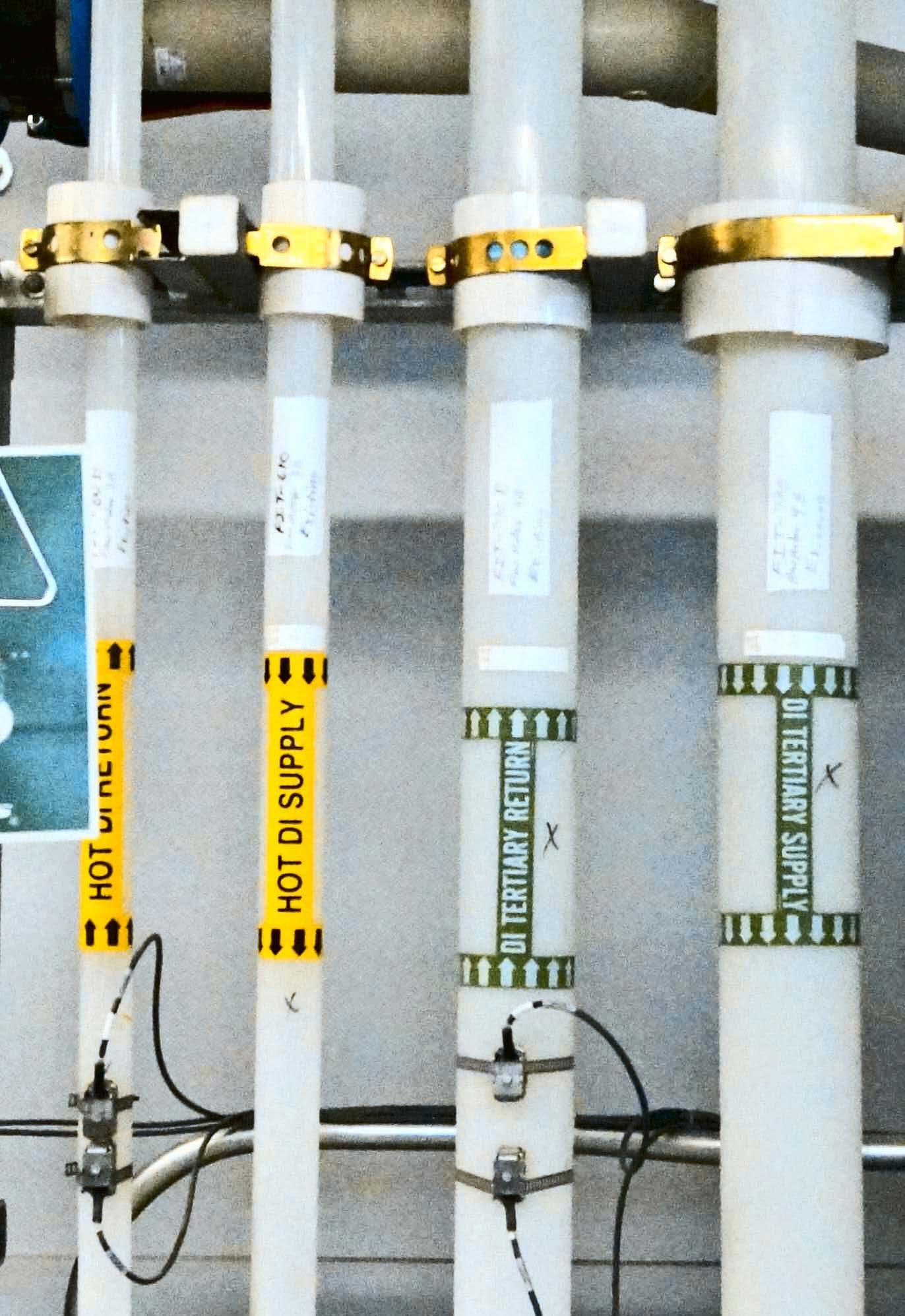

the discharge tubing. An anti-syphon valve is basically a one-way valve that prevents liquid from syphoning through a pump after it shuts off. Anti-syphon valves are required if the point of chemical injection is below the chemical pump discharge. The evening after the new inhibitor chemical feed was initiated, the service representative arrived home and used his laptop to access the controller. He noticed an alarm for high PTSA. He checked the controller inhibitor pump relay to determine if it was energized and discovered that it had been off for several hours. He then looked at the controller PTSA trend graph and noticed it was continuing to increase! At that point, he realized the inhibitor was syphoning through the pump since there was no anti-syphon valve on the inhibitor pump discharge tubing. A call was placed to the plant operator to remove the inhibitor feed line from the tower basin location and to temporarily place it in the minibulk tank. When the hose was removed from the tower basin, this “broke” the syphon, and the feed of corrosion inhibitor stopped. The service rep visited the plant the next day with the correct fittings and injection nozzle in order to feed the inhibitor chemical into the CPVC controller bypass line downstream of the controller sensors. No further incidents involving inhibitor chemical overfeed have occurred. If it was not for the PTSA alarm callout features and remote monitoring capability of the controller, the entire 110 gallons of inhibitor could have been added to the system in less than 24 hours. Not a good way to start a new program with a new customer!

84

Closing Thought

The use of PTSA and remote monitoring are excellent applications for cooling tower water systems. This story illustrates the value of these technologies. As a word of caution, there is always a chance of controller sensor failure, sensor fouling, and damage to controller electronics caused by power surges and other unforeseen conditions. Controller sensor calibration should be checked on a routine basis, preferably at least monthly. In addition, chemical actives should be checked (in this case zinc) and compared to PTSA values. Table A: New Monitoring System Parameters Sensor

Purpose

Range

pH

Acid feed

7–7.4

Conductivity

Blowdown

1,800–2,000

PTSA

Inhibitor feed

60–80 ppb

ORP

Bleach feed

600–650 mV

Free chlorine*

Bacteria/algae control

0.15–0.30 ppm

*The controller does not directly monitor free-chlorine level.

Gene Tonetti, CWT, is the founder of Water Systems Management. He has worked in the water treatment field for more than 41 years and has expertise in wastewater and high-purity, boiler, and cooling tower water. His experience in treating water includes treatment chemicals, chlorine dioxide, reverse osmosis, and process controllers. Tonetti is a 1973 graduate of RoseHulman Institute of Technology with a B.S. in biological engineering.

the Analyst Volume 27 Number 4