5 minute read

Tales From the Waterside

“annus horribilis” for our nation on many fronts. But we must look ahead with whoever is in the White House and work to solve the problems cited above and others that might arise.

To all the readers of this column, I say “stay safe, stay sane, and may the holidays offer you a relaxing respite.”

Janet Kopenhaver is president of Eye on Washington and serves as the AWT Washington representative. She can be reached at (703) 528-6674 or janetk@eyeonwashington.com.

Save the Date

Education

Advocacy

Networking CaSO4 + H2X –> CaX + H2SO4

2021 Annual Convention & Exposition

SEPTEMBER 22-25, 2021 Rhode Island Convention Center | Providence, Rhode Island

How PTSA and Remote Monitoring Protected a Cooling Tower System From Gross Chemical Overfeed

By Gene Tonetti, CWT, Water Systems Management (Editor’s note: “Tales From the Waterside” is a new column in the Analyst that will feature real-life experiences as shared by water treatment experts and how they approached problems or important lessons they learned.)

PTSA (1,3,6,8 pyrenetetrasulfonic acid, sodium salt) is a fluorescent molecule that was marketed as TRASAR™ and patented by Nalco Chemical Company in 1988 as a chemical treatment monitor. In 1991, Nalco received a second patent for the use of PTSA for continuous on-stream monitoring of cooling tower water. PTSA has since gained wide acceptance by water treatment chemical suppliers because of the ease of testing and the ability to continuously monitor treatment levels from remote locations.

A few years ago, I made a sales call on an old customer who was recently promoted to plant manager at a CO2 plant that was adjacent to a large ethanol plant. The customer had a very expensive custom-built, modular cooling tower controller that monitored conductivity, pH, and oxygen reduction potential (ORP). The controller was about 17 years old, and all of the sensor probes had been replaced several times. The new plant manager at this CO2 plant wanted to replace the old controller system with a new, more reliable, state-ofthe-art controller system; however, when he received quotes from his current chemical supplier, he realized he did not have money in the budget to cover the price.

In addition, the corrosion inhibitor chemical control was poor because the inhibitor was added during tower blowdown (bleed and feed), and the plant operators were lax in testing the treatment level on a routine basis. If the plant manager could get a more reliable controller with remote monitoring capabilities for pH, conductivity, ORP, and corrosion inhibitor without purchasing it from his capital budget, he was willing to change water treatment suppliers. The owner of the company I worked for at the time agreed to provide the new controller, the inhibitor chemical (with PTSA added), and the new chemical storage tanks. This offer was accepted by the plant manager, and preparations were made to get the new program underway.

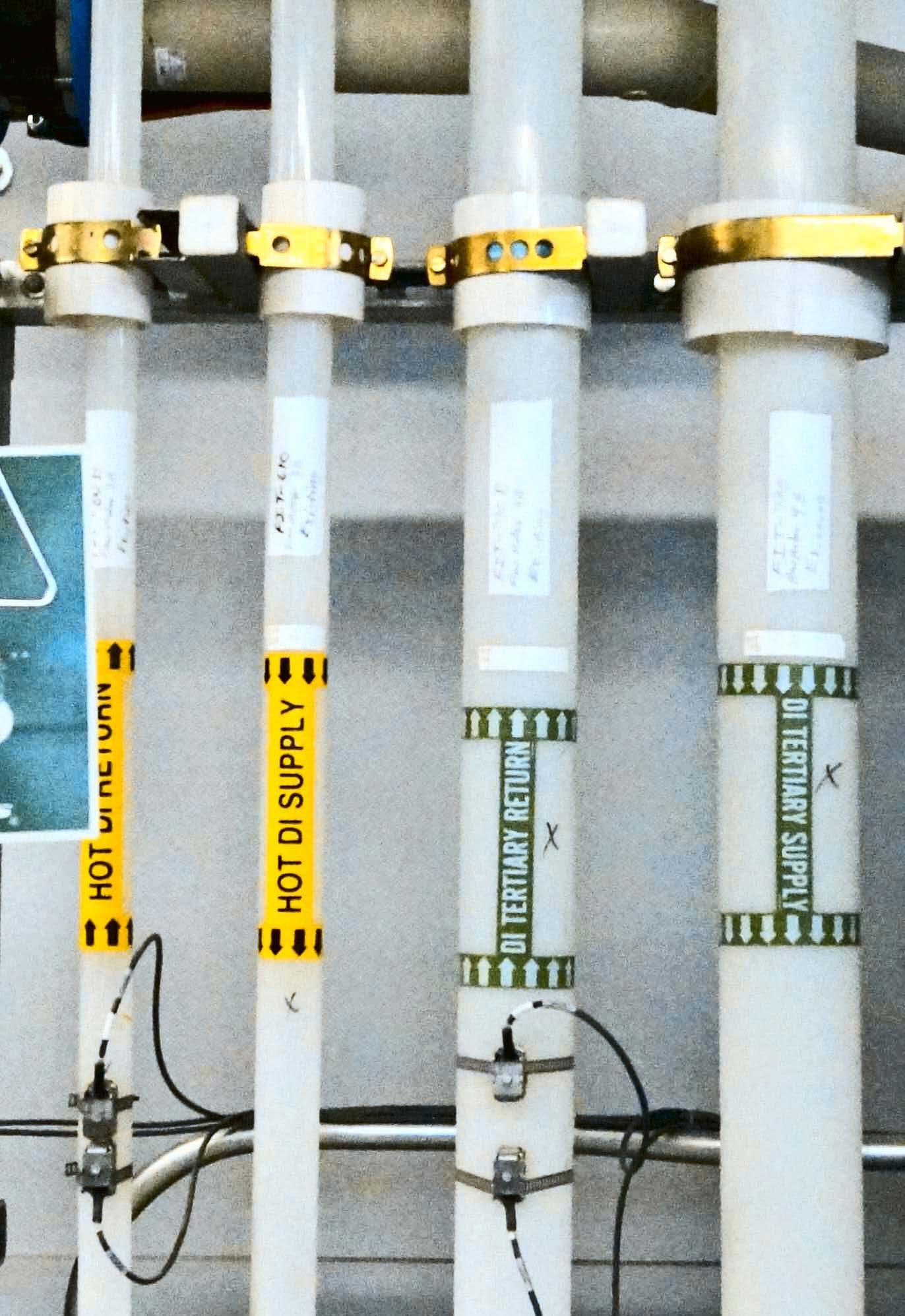

The new controller was manufactured by Walchem and was equipped with software provided by H2Tronics. The PTSA sensor was an in-line fluorometer. The controller could be accessed via a modem. A field rep or anyone who had password access could remotely monitor pH, conductivity, PTSA, and ORP (see Table A). Figure 1 shows the cooling tower control panel at the plant, and Figure 2 shows the facility’s cooling tower.

Figure 1: Monitoring panel for cooling tower.

Figure 2: Plant cooling tower.

A trend graph could be viewed and downloaded over a given period of time. In addition, the amount of on/off time that relays were functioning could also be trended. In other words, you could determine how many minutes a bleach pump, acid pump, inhibitor pump, or cooling tower blowdown valve was activated. You could also monitor makeup water and tower blowdown volumes if the system was equipped with the proper water meters. Any alarm set points could be adjusted to send a call-out signal to a mobile phone or laptop computer. In other words, you could basically observe how a cooling tower water treatment system was functioning from the comfort of your home. Remote monitoring is a great idea; however, it should not eliminate the need for periodic plant water testing. In this case study, the field rep should be testing for free chlorine and comparing the test result to the ORP value at the time of testing. Also, the PTSA values should be compared to the zinc corrosion inhibitor values—again when the test occurs.

The ethanol fermentation process produces a significant amount of carbon dioxide that the ethanol plant did not have the ability to recover, and it did not want the CO2-laden waste stream to go to the wastewater treatment plant. The waste stream from the ethanol plant was sent to the CO2 plant for processing before being returned to the ethanol wastewater treatment plant. The CO2 plant installed a rebuilt, single-cell Marley cooling tower to cool the plant ammonia condenser, the CO2 condenser, the compressor oil coolers, and the after cooler heat exchanger.

My company delivered 110 gallons of an all-organic scale inhibitor/zinc-based corrosion inhibitor product containing PTSA to a mini-bulk storage tank located near the cooling tower. Since there was a concern about discharge of phosphorus from the plant, we could not add any phosphonate scale inhibitor chemical to the inhibitor blend.

New chemical feed piping was installed prior to installation of the new controller and delivery of our blended inhibitor chemical. One of the old injection tees and the injection nozzles, as well as the old chlorinated polyvinyl chloride (CPVC) chemical feed piping where the injectors were located, were discarded by the plumbing contractor. The customer was anxious to get the program started, so our service rep decided to temporarily feed the inhibitor chemical directly to the concrete tower basin. The basin was below ground level and was also several feet below the chemical pump outlet. This turned out to be a big mistake, as there was no anti-syphon valve on