Supercoiled pDNA processing for consistent highpurification performance with a single platform for all sequence lengths

Purifying plasmids for cell and gene therapy vectors requires chromatography systems where sequence size is not a limitation. This article describes a two step purification approach combining pDNAHERO® hydrophobic interaction chromatography and Q PuraBead® Edge anion exchange to deliver high-yield, high-purity plasmid DNA across a wide range of sequence lengths.

Multiple plasmids are necessary to manufacture raw materials used in cell and gene therapy, which can vary considerably in length. Lentiviral vectors are generated using a transfer plasmid, packaging plasmids, and an envelope plasmid; while AAV vectors require a helper plasmid, a RepCap plasmid, and a capsid plasmid. Size constraints inherent in poreor channel-based adsorbents mean purification of vector plasmids can be challenging. Often, separate chromatography media is required for longer sequences, particularly for those over 6 kilobases (kb).

A robust pDNA purification platform will enable consistent performance independent of sequence length, ultimately supporting more reliable manufacturing of gene-based therapies.

To provide consistent processing results where manufacturing demands are variable, Astrea Bioseparations has developed a two-step orthogonal purification process that enables efficient pDNA capture from large volumes of lysate and high resolution of supercoiled plasmid DNA (sc pDNA), with consistent performance for both short and long sequences. The capture step is performed with a hydrophobic interaction chromatography (HIC) adsorbent, pDNAHERO®, followed by polish with Q PuraBead® Edge anion exchange chromatography resin.

pDNA capture

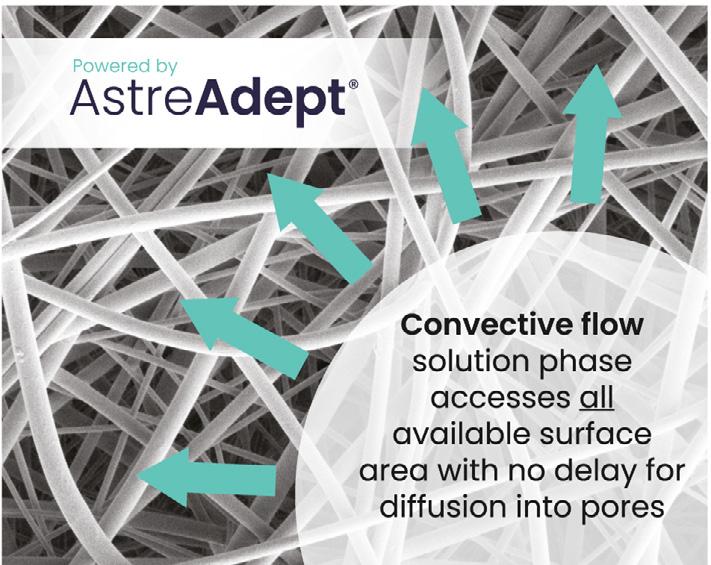

The pDNAHERO® addresses common bottlenecks in plasmid capture by replacing conventional pore- or channel-based chromatography media with an advanced electrospun nanofiber structure (Figure 1). Unlike packed resin beds, the interconnected flow paths of the nanofiber matrix eliminate dead zones where product can become trapped, and flow can be restricted. This novel architecture removes size and pressure limitations, enabling high-speed processing without sacrificing product recovery or purity.

Size-independent capture of pDNA

Convective flow

Screening through to process development Pilot-scale,

The unique flow path of the nanofiber matrix also facilitates the efficient processing of larger plasmids, with successful performance demonstrated for constructs over 30 kb. Capable of flow rates up to 10 membrane volumes per minute (MV/ min), the nanofiber matrix enables rapid processing of large lysate volumes, a major advantage when working with lowcopy plasmids that require greater biomass to achieve target yields.

The matrix features a highly open structure, with an average flow path diameter of approximately 860 nanometers. Importantly, this is not a traditional channel or pore, but rather a true path through the material, providing instant access to a very large available surface area. As a result, there is no diffusive limitation to binding, which allows extremely high flow rates without sacrificing binding performance. By dramatically accelerating the capture step, the nanofiber matrix helps compress overall process times and improves the flexibility and throughput of plasmid manufacturing workflows.

In addition to its nanofiber structure, the pDNAHERO® uses a radial flow format to enable straightforward scalability. Rather than increasing bed height, scale-up is achieved by expanding the surface area exposed to the flow path, allowing consistent performance without increasing pressure drop. In this design, fluid enters through the center and moves outward, ensuring uniform exposure to the entire adsorbent matrix while maintaining a minimal bed height of just a few millimeters. This architecture minimizes backpressure, supports very high flow rates, and allows predictable, scalable performance from small-scale runs to full manufacturing volumes.

Polish of product-related impurities

The Q PuraBead® Edge is specifically designed for highresolution separation, delivering excellent removal of nicked or otherwise degraded open circular (oc) plasmid species.

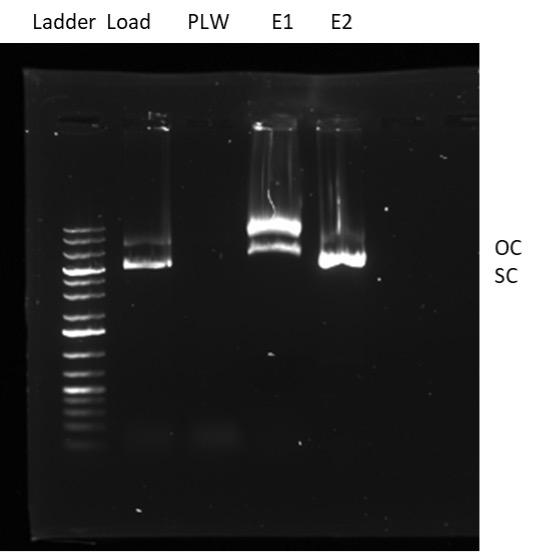

The Q PuraBead® Edge resin features a 65 µm particle size coupled with a highly monodisperse bead distribution, which enabling high chromatographic performance as demonstrated in Figure 2, while maintaining easy column packing and short residence times (as low as 2 minutes). Importantly, the adsorbent demonstrates equivalent binding capacity for plasmid DNA sequences ranging from 6 kb to 34 kb. Since plasmid targets of this size are too large to diffuse into the bead interior, binding capacity is determined by the available outer surface area, supporting consistent performance across a broad range of plasmid sizes.

2: PuraBead® resin has a highly monodisperse bead distribution, which enables high chromatographic performance.

CASE STUDY: Efficient and scalable processing of large plasmids

The following study describes the use of an orthogonal workflow combining HIC pDNAHERO® capture and Q PuraBead® Edge anion-exchange polish for the purification of supercoiled 8 kb plasmids.

pDNA capture with pDNAHERO®

The material was lysed from paste from pelleted E. coli expression. Alkaline lysis was followed by calcium chloride precipitation, diafiltration into TE, and conditioning to 2.85 M ammonium sulphate. The pool was loaded onto the pDNAHERO®1 column at 10 mL/min; the bound pDNA was washed with 3 M ammonium sulphate and eluted in 10%, 80%, and 100% steps of TE. The bulk of bound nucleic acids eluted in the 80% step (Figure 3).

10% breakthrough capacity of the pDNAHERO®1 mL column with pure pDNA was measured at approximately 4 mg of pDNA. However, it was not possible to accurately determine the concentration, resulting in the entire lysate batch being loaded onto the column.

Protein contaminations did not bind to the hydrophobic surface under these conditions and were removed in the flow-through. The 10% TE step removed weakly-bound contaminants.

The target pDNA eluted in the 80% TE step, whereas RNA and other small nucleic acid contaminants bound more strongly and were removed by the 100% strip in TE. The subsequent clean-in-place (CIP) with water and 1 M sodium hydroxide removed any remaining tightly bound contaminants.

The unit was flowed in reverse direction for the CIP to give the most effective cleaning. The unit was re-equilibrated in TE to restore pH and stored in 20% EtOH.

Polish using Q PuraBead® Edge

The elution pool from the pDNAHERO®1 was diluted with TE to a measured conductivity of approximately 52 mS/ cm, and loaded onto a 5 mm ID, 10.0 cm bed height (5 mL) Q PuraBead® Edge column. The column was equilibrated with a buffer of 600 mM NaCl in TE and eluted with 3 steps of 11%, 45%, and 100% of 1 M NaCl in TE blended with the equilibration buffer of 600 mM NaCl in TE.

After elution, the column was cleaned in place with 0.5 M NaOH, then re-equilibrated with 600 mM NaCl in TE, before being washed in water and stored in 20% EtOH.

The column was loaded with 0.64 mg oc/sc pDNA and recovery of sc was 0.553 mg (86%).

5: Agarose gel (0.8%) of fractions from Q PuraBead® Edge column (wells normalized to 0.3 μg/well).

Loosely bound, low-molecular weight nucleic acids eluted in the post-load wash. Note that the UV peak visible in chromatogram between 45–50 mL (Figure 4), however, there are no pDNA bands in the AGE gel corresponding to those fractions (Figure 5).

No oc band is visible in the AGE gel of the elution E2 (45% B). This material can then be desalted by diafiltration or precipitation to be used for transfection, or linearized to use as a template for in vitro transcription.

Figure 4: Chromatogram showing purification of pDNA on Q PuraBead® Edge.

Table 1: Reduction in process-related impurity clearance is shown across each process step. LOD = Below limit of detection; sc % is expressed as % of pDNA; RNA % is expressed % of total nucleic acids, measured by IEX HPLC (TSKgel DNA-NPR column); gDNA measured by qPCR (Thermo Fisher kit); HCP measure by E. coli ELISA (PROGEN kit); Endotoxin measured on Charles River Endosafe® system.

It is critical to remove impurities due to the potential of adverse immune reactions and reduction in therapeutic efficacy. The high enrichment of sc and removal of gDNA, HCP, and RNA to levels that meet regulatory standards are shown in Table 1.

Conclusion

The combination of the pDNAHERO® and Q PuraBead® Edge anion exchange resin provides a robust, high-performance platform for the purification of sc pDNA across a range of construct sizes and process conditions. The expansive flow path and radial flow of pDNAHERO® enable high-capacity, high-speed capture with minimal pressure drop, even for large plasmids and variable lysate quality, while the Q PuraBead® Edge resin delivers efficient polishing and excellent resolution of plasmid isoforms.

This orthogonal, scalable workflow addresses key bottlenecks in pDNA purification and supports reliable, high-yield production of high-purity sc plasmid DNA, essential for the manufacture of mRNA vaccines, viral vectors, and other advanced genetic medicines.

Astrea Bioseparations is a world class provider of chromatography adsorbent and resin services. With over 30 years of chromatography manufacturing expertise, we deliver a unique and trusted service in close partnership with our clients. For more information, please don’t hesitate to reach out at sales@astrea-bio.com or visit astreabioseparations.com.