Pre-packed Evolve®D columns 250-600 mm

Pre-packed Evolve®D columns 250-600 mm

Th e Evolve ® D columns are a range of disposable , pre - packed columns , specifically designed for use in b iopharmaceutical applications.

The columns are supplied pre-packed and ready to use. The columns are designed to be an open platform to support Astrea Bioseparations’ resin products, as well as a wide range of other chromatography resins. The columns are qualified in terms of performance and pressure flow characteristics.

This quick start guide relates to five diameters (250 mm-600 mm) within the Evolve®D range and packed bed heights up to 40 cm.

The columns maintain an entire flow path which is non-metallic; this has the following advantages:

• Eliminates the corrosion risk and contamination of the process

• Allows the use of high concentration sodium chloride and guanidine hydrochloride

• Prevents any product inactivation through metal contact

Columns of these diameters (250-600 mm) are fitted with hydrophilic polyethylene bed supports. These are manufactured from high density polyethylene and modified so that the internal and external surfaces are permanently hydrophilic.

• A lower water intrusion pressure helps reduce the pressure drop through these supports. Values do not limit typical chromatography applications

• A uniform surface facilitates consistent flow across the diameter of the column thus enabling an efficient separation process

• The material has good chemical compatibility and enables a non-metallic flow path to be maintained through the column

Product code

The product code is formatted as shown below. The alphanumeric code includes the product range identifier AD, the column internal diameter and bed height hardware configuration.

The packed bed height as Customer specified is given on Certificate of Analysis.

Evolve®D column

Wetted flow path column components

Column tube

Flow cells

Flow tubes

Column diameter (mm)

Column height configuration

SDH - bed heights up to 20 cm

LBH – bed height 20–40 cm

Product code

Acrylic

Polypropylene

Polypropylene

Tube seals EPDM

Sanitary clamp seals

Flow tube adapters GF Polypropylene

Bed supports Polypropylene

Bed support retention N/A

Santoprene®

Polypropylene

Hydrophilic polyethylene

Polypropylene

Adjuster seal Santoprene® EPDM

Bed support seals Santoprene® EPDM

Connections

Cleaning /sanitization

Recommended storage condition

Shelf life

Inlet/Outlet: 25 mm (3/4”) sanitary clamp fittings

For packed resin/adsorbent, see appropriate user guide

Column hardware, sodium hydroxide (0.5–1.0 M)

Sodium hydroxide (0.1 M) + ethanol (20%) Peracetic acid (300 ppm)

2–30 °C (dependent of packed resin/adsorbent). Packed column may be stored in any compatible solvent (refer to the Chemical Compatibility table) and dependent of resin/adsorbent

Up to 2 years (dependent of packed resin/adsorbent)

All materials in contact with the process stream have been selected for their suitability for use in equipment utilized in biopharmaceutical applications and so either conform to relevant sections of FDA code of Federal Regulations vol. 21 170-199 and/or passed USP class VI test for in vivo toxicity.

For further information and certificates of material compliance, please access technical guides on Astrea Bioseparations’ website.

Evolve®D columns are designed for use with a wide range of aqueous solutions commonly used in chromatography applications. A guide to the chemical resistance is provided in the appendix of this quick start guide. The information contained in this time has been compiled from a wide range of sources and from material supplier databases.

The non-metallic flow path permits the use of halogenated solutions, such as NaCl and guanidine hydrochloride.

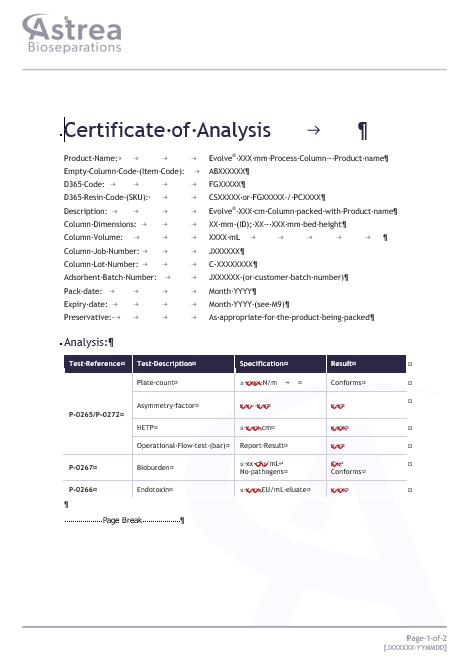

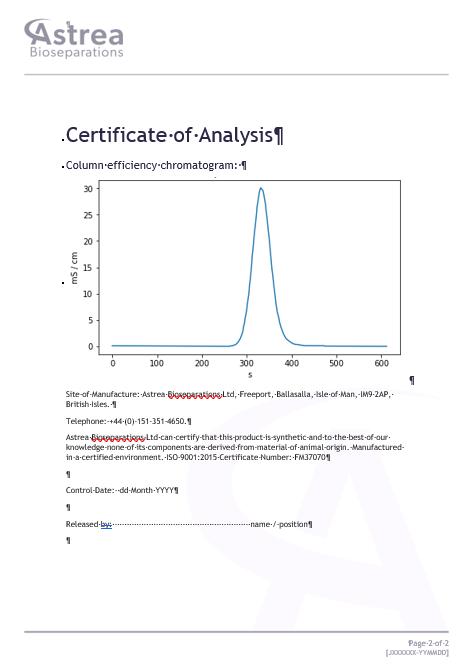

Two documents are provided with the column:

• A Certificate of Quality which gives the manufacturing date of the column hardware and the serial number of the column

• A Certificate of Analysis which provides the test information and performance of this prepacked unit. It also provides information of the resin and date the column was packed

An example of the C ertificate of Analysis is shown below.

Example of a Certificate of Analysis

The following safety guidelines are presented:

The safety rules in this document are intended as a guide for the safe operation of the column.

All operation and service personnel working with the equipment should be familiar with this information prior to system start up.

• Please review the Regulatory Support File for additional information regarding the product

• The Evolve®D pre-packed column may be shipped in an ethanol-based preservative. This solution is required to be flushed from the product during equilibration and preparation for use and disposed of appropriately

• Please follow all local laws and regulations for safe disposal of the column

Evolve®D columns are designed and manufactured with consideration to accepted safety standards. We advise the following:

1. Ensure the maximum rated operating pressure cannot be exceeded by installing overpressure safety device(s).

2. Include over or under temperature protection devices if it is possible that temperature deviations could mean that the column operated outside the temperature range of the equipment, or where temperature deviation could present a hazard (for example, freezing of process or storage solutions).

3. Ensure that no air is introduced into the column during any column operation (for example, by using a bubble trap). Air inclusion is often detrimental to chromatography processes, but the column is categorized under Pressure Equipment Directive (EU)/The Pressure Equipment (Safety) Regulations 2016 (UK) on the basis that no gas is present.

Pre-packed columns are heavy, and care should be taken when moving or handling the columns.

Across the range the columns are provided with wheels, two of which have brakes. This enables the columns to be moved without the need for any lifting equipment.

When moving the columns, attention should be paid to pathway the column is to be moved along All obstacles and potential hazards should be removed, and the column should only be moved when it is safe to do so. All columns should be moved slowly; larger columns have a large momentum, and consideration should be given to having a safe stop.

When stationary, the column brakes or column feet should be deployed so the unit cannot be accidentally moved which may strain connections.

In addition, the columns are fitted with points are provided and, if used, the following advice should be followed:

Mechanical handling equipment or manual handling aids should be utilized to safely lift or move or position the column or its subassemblies. This will avoid potential damage to the equipment and injury to personnel.

It is essential that good practice is adopted regarding the use of appropriate slings and associated equipment, and to ensure the safety of personnel and prevent damage to equipment.

It is assumed that the user has available a hoist with hook and slings.

1. Ensure the rated capacity of the lifting equipment is sufficient to lift the column.

2. Ensure the lifting eyes are orientated in line with the slings. If they are not, there is a possibility of bending the eyes.

3. Ensure the shoulder of each lifting eye is in contact with the surface of the load (top plate) and the eye is securely fastened.

4. Use only one sling leg to each lifting eye.

5. Do not fit the sling hook directly to the lifting eye: use a shackle.

6. Ensure the slings are sufficiently long. The included angle should not be more than 60º. Slings which are too short suffer excessive tensile load, which may lead to damage to the lifting eye or the sling. As a rule, ensure the slings are longer than the horizontal distance between the lifting eyes.

These instructions are intended to supplement users’ existing lifting practices rather than replace them and should not take precedence over Company or national standards.

1. Only qualified personnel should operate this column.

2. Do not operate column beyond its maximum rated pressure or outside rated temperature limits.

3. Do not dismantle the column while it remains under pressure.

4. Do not stand on any part of the column.

5. Take care when handling heavy assemblies and column components. Use lifting eyes and appropriate lifting equipment.

6. Do not operate faulty or damaged equipment. Ensure proper maintenance and service procedures have been performed.

This manual lists those substances for which the columns are compatible. If substances not listed are to be used, the user must consider their effect as the integrity and safety of the column could be compromised.

Users of these chromatography columns must ensure that the maximum operating pressure is not exceeded. It is recommended that an over-pressurization protection device such as a Pressure Relief Valve or equivalent is utilized.

The design of pressure containing vessels has previously been governed by the European Pressure Directive 2014/68/EU. Following the EU withdrawal Act 2018 preserves the regulations; however, the governance has passed to UK government and are covered under The Pressure Equipment (Safety) Regulations 2016. These regulations are mandatory and govern a wide range of pressure containing vessels. The design and manufacture of chromatography columns including the Evolve®D column are affected by these regulations.

The regulations are divided into categories and the Evolve®D column range assessed; see table below.

The foundation of the assessment is based on the following:

• The Evolve®D columns are liquid chromatography columns and, when used in accordance with their operating instructions, there should be no gas, e.g., air present in the columns

• The substances that will be used in the column will remain in liquid form during the entire operation at the maximum stated operating temperature

In addition:

• The maximum operating pressure is greater than 0.5 bar and less than 10 bar

• The product pressure x volume is equal to or greater than 200 bar liters

Evolve®D 70-450 columns fall within the Sound Engineering Practice (SEP) category, and the Evolve®D 600 column falls within SEP with bed height of 20 cm and below, and Category 1 where bed height are 20–40 cm. Where Category 1 is required, conformity assessment module A is adopted This relies on internal production controls, and no notified body involvement is required.

In addition, when a column falls into Category 1, it will have a CE and UKCA mark and a technical file exists, which includes a Risk Assessment against the Essential Health and Safety Requirements of these regulations.

On receipt, the packing crate will have the following attached:

• Instructions on how to uncrate the column

• A Certificate of Quality and serial number label. Remove and retain the Certificate of Quality

Follow the instructions as shown on the external of the crate, removing the panels in the correct order.

The column is transported with its feet lowered. Ensure the column feet are raised to allow movement of the column to its location.

Before use, it is essential that the column is levelled. This ensures even flow and effective air removal. To facilitate this, columns are fitted with height adjustable feet, adjustment of the feet also increases ground clearance.

1. Identify the inlet port of the column. This is central port at the top of column.

2. Removing the sanitary caps on the inlet by unclipping the sanitary clamp. The sanitary clamps are reusable and are removed by pushing one of the rachet end perpendicular from the other ratchet end (please note the rachet ends are one directional).

3. Connect the inlet of the column to a chromatography system that has been cleaned and primed and set at a slow rate to minimize any risk of air entering the column with 25 mm tri-clamp (TC) sanitary fitting. A 4-port, 2-way valves can also be used to create this connection. Suitable TC or sanitary gaskets can be used to from a seal the 25 mm TC sanitary connection from the chromatography system. Fit a tri-clamp or sanitary clamp around the two sanitary fitting flanges and secure firmly (if re-using the click clamps, press the two rachet ends together firmly).

The column is transported containing a storage/preservative solution (ethanol-based solution or other) please consult the relevant user guide of the packed resin/adsorbent. This will need to be flushed out prior to use. The recommended flow rate is 50% of operational flow rate (e.g., if the operation flow rate is 120 cm/hr set the initial flush flow rate at 60 cm/hr using an appropriate equilibration buffer solution. Allow at least 3 column volumes of the buffer to flow through until the eluent matches the pH and conductivity of the buffer/solution entering the column.

The following are not prescriptive; please refer to the specific resin/adsorbent user guide with respect to flow rates, pressure recommendations and other process conditions. Thorough investigation of these parameters at a small scale is recommended to identify optimal conditions and level of flexibility that can be tolerated with respect to the chromatography resin/adsorbent, buffer choice, and process conditions.

• Filter all buffers and feed stream through an appropriate filter 0.22 µm is recommended

• Do not exceed the maximum operating pressure limit for the size of Evolve® process column regardless of whether the resin/adsorbent can withstand higher values. See table below for maximum operating pressure limits

• The inlet of the column is located at the top and central of the column, outlet is at the bottom and central of the column with a pipe spool attached so the connection for the outlet is on the top of the column

• The column is normally operated with a flow direction of top to bottom, however for certain operations, e.g., cleaning in place (CIP), the column may be operated in a reverse flow

The flow rate table provides a quick reference guide to determine linear (cm/hr) to volumetric flow rates (L/min) in the respective Evolve®D columns.

Please refer to the appropriate resin manufacture’s user guides for the recommended flow rates.

NOTE: Do not use abrasive cleaning materials or pads, as these may score plastic components.

The extensive solvent and chemical resistance of the column components allows the use of a wide range of clean-in-place (CIP) solutions, including:

• Sodium hydroxide (0.5–1.0 M)

• Sodium hydroxide (0.1 M) + ethanol (20%)

• Peracetic acid (300 ppm)

Care must be taken when choosing a cleaning solution for the column; refer to the chemical compatibility guide. It should be noted that exposure to concentrations of above 20% alcohol solutions (ethanol, isopropanol, etc.) should be avoided due to an incompatibility with the acrylic tube

Storage

For in-process storage, the packed column may be stored in any compatible solvent (refer to the Chemical Compatibility table). Choice of a particular solvent will usually be dictated by the chromatographic media; refer to media manufacturer’s data. Common storage solutions include 0.1–0.5 M sodium hydroxide or 0.1 M sodium hydroxide + 20% ethanol, both of which are suitable for long term (several months) storage with Evolve®D columns.

Columns should be kept in a cool, dry, dust-free location and protected from light. Exposure of acrylic column tubes to direct sunlight for prolonged periods or sterilization with ultraviolet lights may reduce the mechanical strength of the tube.

As this column is provided as a pre-packed unit, if further advice or if performance is not as expected, it is recommended that you contact our Field Application Specialists:

fas@astrea-bio.com

This troubleshooting guide focuses solely on issues related to the column hardware, providing general advice on possible causes and suggested actions.

There are numerous factors that can cause excessive back pressure in chromatography, such as problems with the chromatography system (e.g., partial valve failure), issues with the media packed bed (e.g., over compression, consolidation, or bed fouling), the process fluid, or problems with the column.

Sudden decreases can result from bed collapse or cracking, flow instability or pumping issues. When troubleshooting sudden pressure increases or decreases, ensure that pressure readings are always taken at the same location so that accurate comparison can be made.

Restrictions to inlet/outlet pipework

Incorrect seal size used to connect pipework

Post column valve blockages

Bed support blockages

Loss of pressure

Ensure correct connections and diameter of pipework used

Ensure correct pipework seals used

Ensure valves fitted to column are correct functioning

Blockages can occur due to viscous or particulates containing feed streams. If situation is not remedied by running cleaning cycles, please contact technical support

Column leakage/seal failure Contact technical support

Leakage from inlet/outlet of the column

Damage to flow tube adaptor or pipe spool from using incorrect clamp or excessive clamp force

Replace any damaged components. Ensure plastic clamps are used as metal plastic can be over tightened and can cause damage

Care should be taken not to introduce air into the column by ensuring:

• Bubble traps are used upstream of the column

• Media and buffers are not vigorously stirred

• All connections are primed before made and all buffers are degassed

Possible cause

Suggested actions

Air inclusion after packed bed formed Flow in reverse direction until air is removed or any dry patches become wetted. Always requalify the packed bed after this procedure

For further enquiries, please contact:

sales@astrea-bio.com

Acrylic columns are ideally suited for aqueous-based applications. See the table below for detailed compatibility information.

Resistance Resistant; suitable for continuous use

Not resistant; not recommended Limited resistance

No information available

Notes General All solvents are at 100% concentration unless noted otherwise

Concentrations: % refer to w/w

All data is referenced to room temperature (15–25 ºC)

Chemical

1,2-dichloroethane

Acetic acid 25%

Acetone 5%

Acetonitrile

Ammonia aqueous <25%

Ammonium Sulphate 10-40%

Benzyl alcohol 1%

Benzyl alcohol 2%

Butanol

Calcium chloride 2

Calcium hydroxide 30%

Calcium hypochlorite

Chloroacetic acid 50%

Chloroform

Chromic acid 10%

Citric acid

Copper sulphate

Dichloromethane

Dimethyl formamide

Dimethyl sulfoxide 10%

Disodium phosphate

Ethanol 20%

Ethanol 70%

Ethylene glycol (1,2-ethanediol)

Formaldehyde 50%

Glycerol (Glycerine)

Chemical compatibility cont.

Chemical

Guanidine hydrochloride 6 M

Hydrochloric acid 10%

Hydrofluoric acid

Hydrogen peroxide

Industrial methylated spirit (IMS)

Methanol 20%

Methanol 50%

Methyl chloride (Chloromethane)

Methyl ethyl ketone (MEK)

Methylene chloride

Nitric acid 10%

Nitric acid 70%

Peracetic acid 300 ppm

Phosphoric acid

Potassium hydroxide 2 M

Iso-propanol 20%

Iso-propanol 40%

n-propanol 20%

Sodium acetate

Sodium bicarbonate 20%

Sodium carbonate

Sodium chlorate

Sodium chloride 2 M

Sodium chloride 6 M

Sodium hydroxide 0.5 M

Sodium hydroxide 2 M

Sodium hypochlorite 200 ppm

Sodium nitrate

Sodium sulphate

Trichloroethene (Trichloroethylene)

Triton® X-100 surfactant

Urea 6 M

Zinc chloride