WHY OUTSOURCE COLUMN PACKING?

Column chromatography is a well-established separation technique used throughout process development, clinical manufacturing, and commercial production of biopharmaceuticals. Fundamental to its success is the ability to effectively and consistently pack resin into column hardware.

As biopharmaceutical demand continues to grow, optimizing column packing processes remains critical to operational success and long-term sustainability in the competitive biomanufacturing landscape. Outsourcing this time-consuming and labor-intensive step can improve process efficiency and free up valuable resources.

Astrea Bioseparations supports this need with an extended Evolve®D range of pre-packed columns, with expert column packing service in conjunction with our proven Evolve® process range.

Successful chromatographic separations in the downstream processing workflow rely on effective column packing. By ensuring uniform flow distribution, minimizing pressure drops, and maintaining consistent packing conditions, biopharmaceutical manufacturers can improve process efficiency and safeguard the integrity of their therapeutic products.

Despite the challenges and substantial internal resources, many biopharmaceutical companies choose to pack their chromatography columns in-house. Selfpacking not only involves the column packing step itself, but also requires validation through efficiency testing and stringent bioburden checks to protect against contamination in downstream processes.

The consequences of improperly packed columns can be far-reaching. Among the most significant drawbacks is the potential need to repack or replace a column that has failed validation tests. Column failure requires unpacking, cleaning, repacking, and retesting, causing delays in production and potentially halting an entire bioprocess. Such delays are particularly costly in large-scale manufacturing, where other parts of the production process may be forced to wait for chromatography steps to be completed. Manufacturing consistency and reproducibility are key to ensuring regulatory standards are met.

An increasing number of companies are benefitting from outsource their column packing operations.

Astrea Bioseparations provides a unique offering to the market. Evolve®D columns are available pre-packed, and our packing service can also be used to pack new Evolve® process columns or repack existing ones. These enable biopharmaceutical companies to achieve timely delivery of prequalified, process-ready columns that are accompanied by all necessary documentation to integrate column quickly into downstream processing lines, saving valuable time and resources.

Benefits of outsourcing column packing

Time efficient

• Elimination of the packing process; increasing number of runs, leading to increased productivity

• Quick setup and changeover, critical for continuous or high-throughput processes

• Faster transitions in multi-product facilities or CDMOs

• Delivered to integrate into your production schedule

Resource savings

• Cost effective: Compared to in-house packing

• Labor saving: In-house column packing requires specialized personnel and significant labor hours

• Space saving: No need for dedicated packing suites or additional equipment

• Materials saving: No need for required for packing (buffers, solvents, etc.)

• Resource saving: Reduced water and energy costs

Quality assurance

• Columns packed in ISO 7 cleanrooms

• Consistent performance

• Prequalified and bioburden tested

• Documentation provided for seamless process integration

Enhanced consistency

• Prepared under controlled conditions, ensuring consistent packing density

• Outsourced packing reduces the risk of human error and inconsistencies

• Consistent performance and documentation associated with pre-packed columns can simplify regulatory compliance

Your pathway to a pre-packed column

While other column vendors offer pre-packed columns, Astrea Bioseparations provides a unique offering to the market. In addition to a pre-packed column range, Evolve®D, our packing service can be used to pack an Evolve® process column.

Pre-packed columns are designed as plug-and-play units that integrate into a well-defined and regulated manufacturing process. Often these units are supplied for a single campaign, disposed of, and reordered. Contract manufacture and large-scale processes can benefit from an integrated supply schedule.

For those already familiar with the Evolve® process range, our packing service offers all the benefits of a pre-packed column.

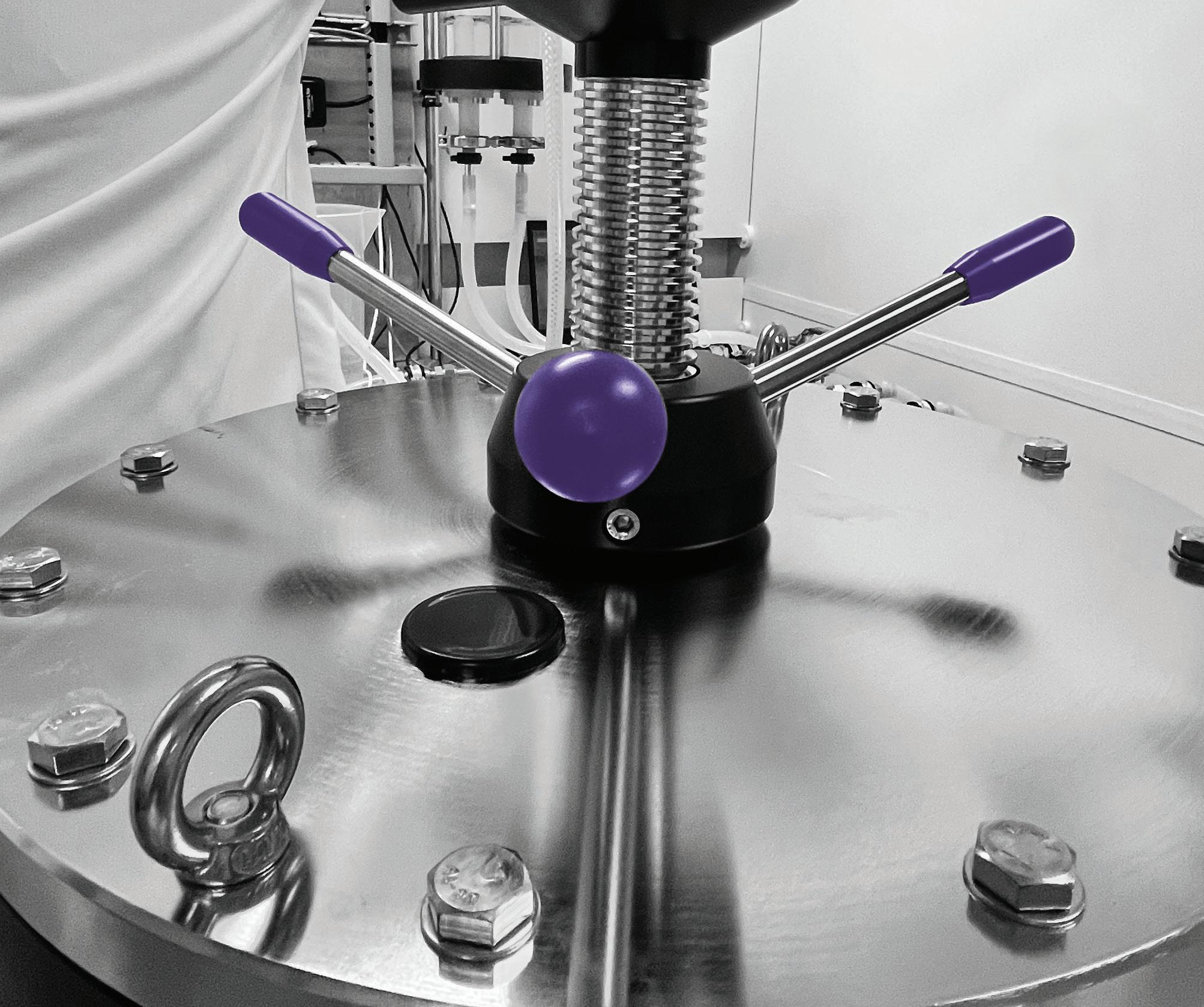

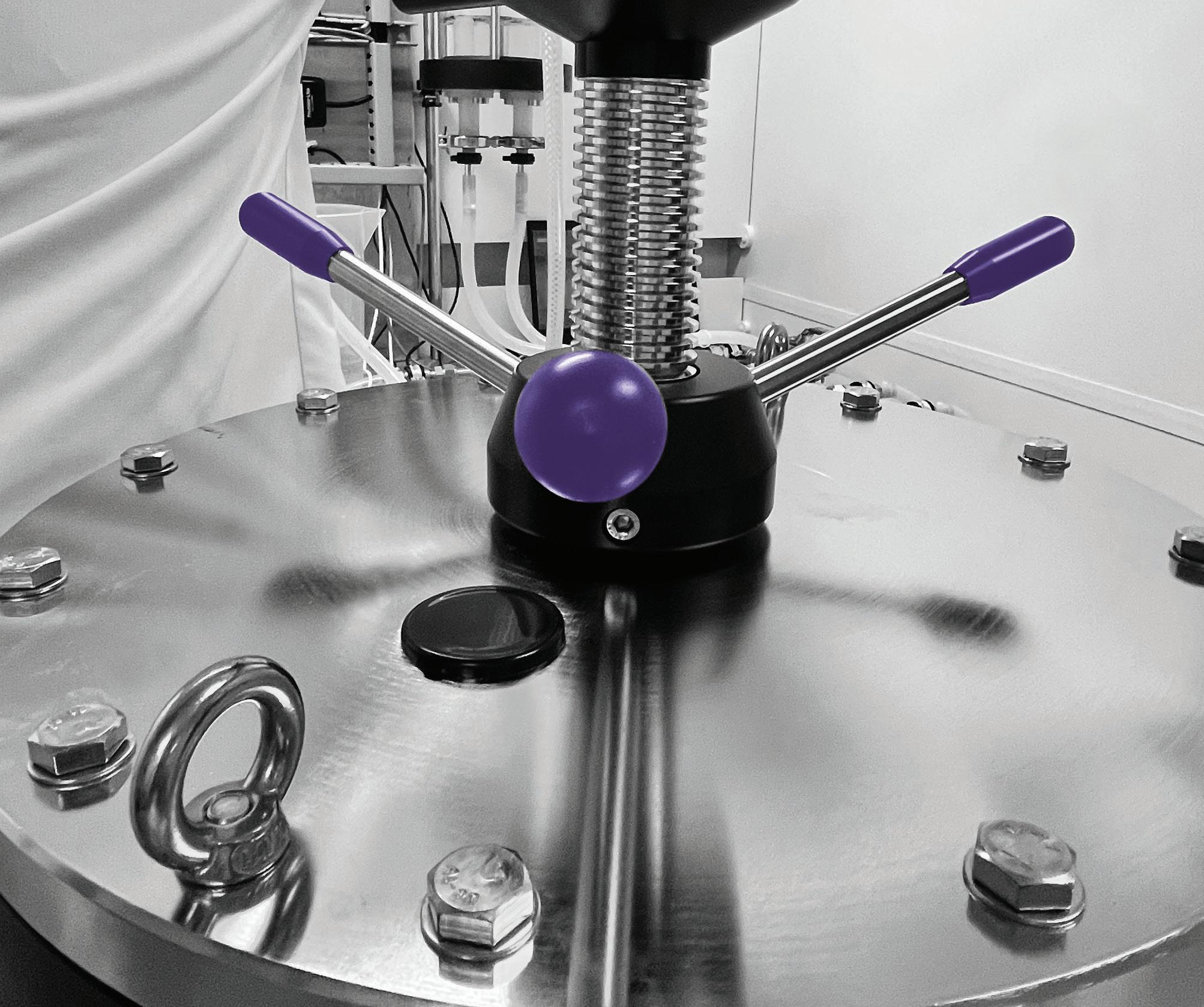

EVOLVE®D COLUMNS

Evolve®D columns are a purpose-designed range of pre-packed columns, providing a convenient plug-and-play solution for process chromatography. Built on the proven, scalable design and reliability of the Evolve® process range. Additional design features combine practicality with cleanability, making them a valuable addition to any process suite.

Evolve®D columns: Designed for commercial production

Astrea Bioseparations’ Evolve®D pre-packed columns offer scalable, high-quality solutions for diverse bioprocessing needs.

This range of pre-packed columns are designed to be a plug-and-play unit, suited for use in a single production campaigns, thus eliminating the need for cleaning, validation, and mitigating the risk of carryover contamination.

A wide range of resins, produced both by Astrea Bioseparations and by third-party suppliers, can be packed using customer-specified methods and over a range of bed heights. On smaller diameter columns, commonly used bed heights are available as standard, whereas on columns 250–600 mm customers can specify bed heights up to 40 cm.

Our team of Field Application Specialists are on-hand to discuss and assist in defining your packing requirements. Each pre-packed column is supplied with the necessary certification to allow columns to seamlessly fit into the process workflow. Chromatographic performance, pressure characteristics, and bioburden information are provided as well as material compliance information.

Performance scales seamlessly across the Evolve®D and Evolve® process column ranges, allowing transition from process development studies using this column format.

Columns are packed in an ISO 7 cleanroom environment at globally convenient locations. Supply schedules and contracts can be set up to ensure continuity and consistent availability.

Columns are designed to be maintenance-free and require no additional lifting apparatus to remove the column from shipment crates. Columns of diameters 70–200 mm are designed to sit on work bench whereas columns of diameters 250 mm and above can be wheeled into the process suite.

Flexible resin choices

• Pre-packed columns available for all Astrea Bioseparations resins

• Also supports third-party resin suppliers

• Wide range of packable resin types

• Evaluation of used resin available

Column hardware options

• Range of column diameters available 70–600 mm

• Standard bed height on smaller diameter columns

• Customer-specified bed height up to 40 cm on larger process columns

• Manufactured using bioprocess-ready materials

• Includes a non-metallic flow path compatible with high halide solutions and guanidine HCL

• Optimized inlet and outlet sizes to accommodate range of process flow rates and minimize pressure drop

Column performance

• Packed bed qualified using standard techniques (HETP, Asym, ΔP)

• Bioburden study performed and result provided

• Performance scalable and comparable to Evolve® process columns

Global experts & support

• Expert column packing operatives based in Europe (Isle of Man) and US (Canton, MA)

• Global team of Field Application Specialists (FAS)

• Documentation provided for seamless process integration (RSF, CofA)

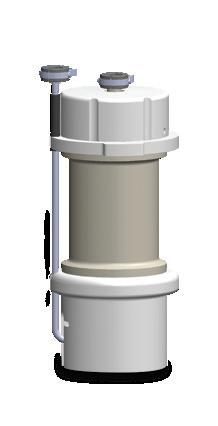

EVOLVE® PROCESS COLUMNS

Evolve® process columns offer scalable, high-quality solutions for diverse bioprocessing needs, from pilot- to large-scale manufacturing. Traditionally available in a self-pack format, they are now also available pre-packed. A ready-to-use column is well suited to a Design of Experiments (DoE) approach, making it ideal for resin screening, process development, or small manufacturing batches for initial clinical trials.

Designed for purpose

Evolve® process columns are available in various sizes and formats, offering flexibility for different applications and scales of operation. Performance is scalable across both the Evolve® and Evolve®D ranges, allowing easy interchange between them.

The columns are manufactured using bioprocess-ready materials and are supported by a comprehensive regulatory support file. Columns include a non-metallic flow path to give improved compatibility with highhalide solutions and guanidine HCl.

The inlet and outlet diameters have been optimized to accommodate a range of process flow rates and to minimize pressure drop.

Designed for extended use, they enable efficient resin removal, maximizing cycle usage, and support longterm studies while reducing costs. Using our column packing service eliminates the need for specialized expertise in column packing and dedicated packing areas and equipment.

Flexible resin choices

• Packing service available for all Astrea Bioseparations resins

• Also supports third-party resin suppliers

• Wide range of packable resin types

• Evaluation of used resin available

Column hardware options

• Range of column diameters available 70–600 mm

• Customer-specified bed height up to 30 cm

• Offering packing flexibility for different applications and scales of operation

• Manufactured using bioprocess-ready materials

• Includes a non-metallic flow path increased compatiblility with high halide solutions and guanidine HCL

Column performance

• Proven performance across the column range

• Packed bed qualified using standard techniques (HETP, Asym, ΔP)

• Bioburden study available for smooth process intergration

Global experts & support

• Documentation provided for seamless process integration (RSF, CofA)

• Expert column packing operatives based in Europe (Isle of Man) and US (Canton, MA)

• Global team of field application specialists (FAS)

OUR RANGE

Order information

Evolve®D 70–200 mm

250–600 mm (standard bed height 5–20 cm) cont.

250–600 mm (longer bed height 20–40 cm)

Evolve® process