Refresh Kit: Guide to Replacing the Wetted Flow Path

Evolve® 600 mm Process Column

Refresh Kit: Guide to Replacing the Wetted Flow Path

Evolve® 600 mm Process Column

This manual describes the procedures necessary to replace the wetted flow path components in the Evolve® 600 Process Column using the Column Refresh Kit.

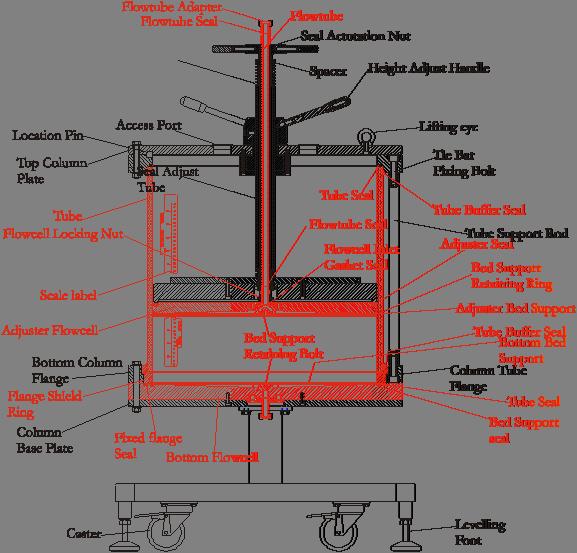

Figure 1: List of Refresh Kit components and Column schematic. Parts shown in red are the wetted flow path components

There are four stages to refreshing the column by replacing the wetted flow path. The first three stages are based on the disassembly and reassembling each column sub assembly with new components, before the final stage of rebuilding and testing the complete column.

STAGE 1 – Refresh the Adjuster Assembly of the Evolve® 600 mm Process Column

STAGE 2 – Refresh the Tube Assembly of the Evolve® 600 mm Process Column

STAGE 3 – Refresh the Fixed Assembly of the Evolve® 600 mm Process Column

STAGE 4 – Rebuild and Test the Evolve® 600 mm Process Column

To disassemble and assemble the columns follow the instructions below. After reassembling the column, ensure that the column does not leak by performing a hydrostatic leakage test.

THESE PROCEDURES MUST BE PERFORMED USING AN OVERHEAD HOIST

ALL PROCEDURES MUST BE PERFORMED BY TWO PERSONS

NOTE: When assembling/dissembling attention should be paid to: -

1. Always use the correct size tools. A comprehensive tool kit is provided with the original column. See Table below.

2. Ideally components should be at approximately room temperature (approximately 20°C). If not, take particular care as thermal expansion or contraction may make components fit more tightly and thus more difficult to disassemble.

3. Dismantled assemblies should be rested on a clean, dry surface.

4. Pay particular care not to damage the edge of the flow cells.

5. When unpacking columns be careful not to scratch the inside of the column tubes

6. Be careful not to damage stainless steel surfaces by bumping, knocking or scratching.

7. Do not over-tighten components and use correct torque settings as given in this guide.

8. Good engineering practices should always be followed and operations carried out in an approved and safe manner.

9. The components of the Evolve® 600 mm Process Column are heavy and large. Mechanical handling equipment or manual handling aids should be utilised to safely lift or move the column or its subassemblies. Provision is made for the use of a hoist as eye nuts are fitted or supplied. It is essential that ‘good practice’ is adopted regarding the use of appropriate slings and associated equipment. See original column manual for guidance

10. All these operations should be performed by two people.

The following tool kit is provided with the original column.

Tool

Allen Key Set

Allen key 14 mm Adaptor & Torque

Wrench 3/8" Drive

Spanner 22 mm/24 mm

Spanner 19 mm/24 mm

Adjustable Spanner

Spirit Level

S/Driver with Wide Blade

O ring remover tool

Maintenance blocks

Lifting Eyes and Fixings

Where used

Various locations

Tie Bar fixing Bolts

Flow tube adaptor, Adjuster Flow tube, Column Feet

Flanges bolts Adjuster, Fixed and locking flow cell nut

Locking nut and seal setting tube

Used to level the column

Removal of bed support retaining ring

Assists O-ring removal

General

Additional eye nuts to fit to tube unit during maintenance procedures

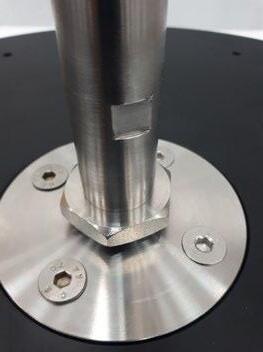

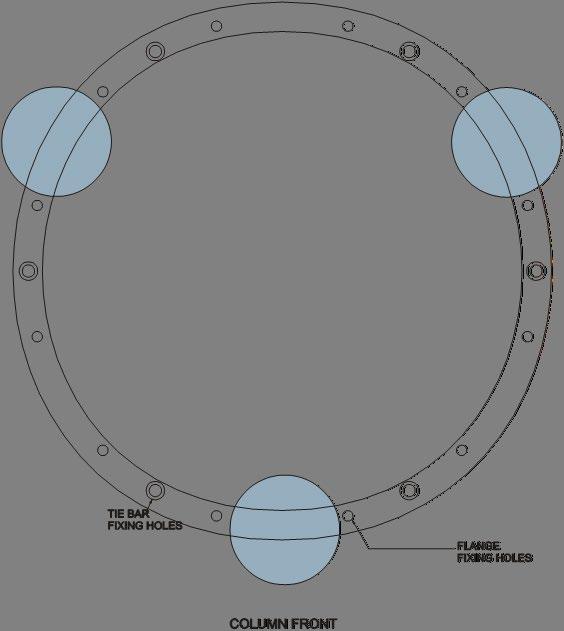

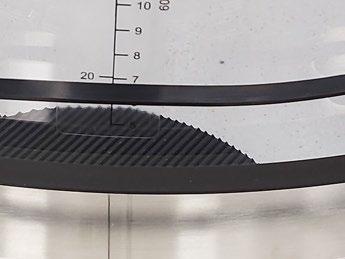

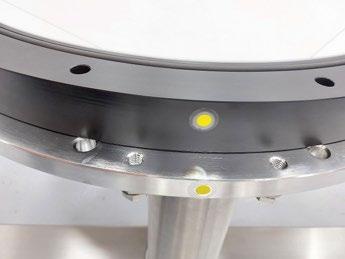

Alignment indicators are attached to the top flange, tube flanges, bottom flange and base plate. These should be used to assist the alignment and orientation of components.

Alignment indicators

1. Detach any pipework from the top sanitary clamp adapter.

2. Remove flange fixing bolts from the top column tube flange. Retain bolts, nuts and washers.

3. Check that adjuster seal is released by turning the seal actuation nut counterclockwise.

4. If necessary, remove the blue handles from the seal actuation nut if they interfere with the hoist slings. Keep the seal adjust nut in place.

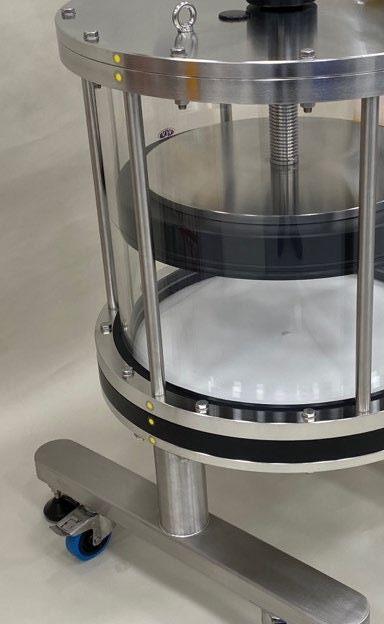

5. Using a hoist lift adjuster unit out of tube unit

3: Photograph of Evolve® 600 mm Process Column adjuster unit removal from column tube

6. Move the adjuster along the hoist rail or move the remaining column unit so access to the lifted adjuster unit is possible.

7. Place the adjuster assembly so that the flow cell face is on the floor with the hoist still attached.

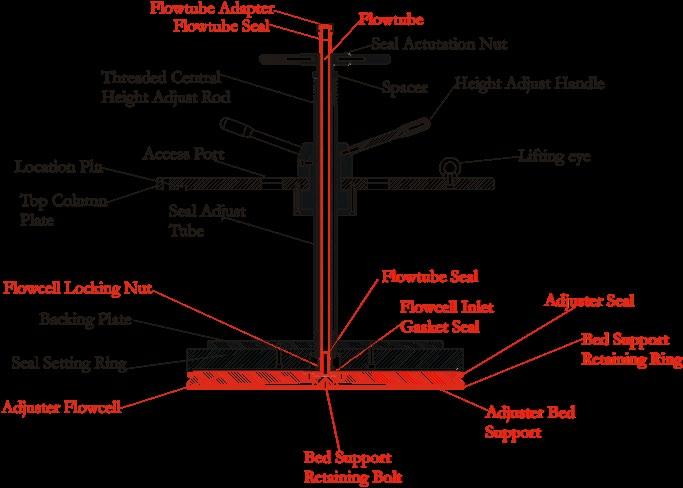

8. Identify the parts as shown in the schematic and photograph below.

Figure 5 (a-c): Disassembly stages of the Adjuster Assembly

9. Remove the seal actuation nut and spacer (Figure 5a)

10. Slowly, using the hoist, lift the adjuster flange. Pause the lift when the adjuster is approx. 2 cm from the surface and wait for the flow tube, seal setting tube and flow cell to drop onto the surface.

11. Continue to lift to assembly (Figure 5b) until the flow tube is completely exposed from the threaded rod (Figure 5c)

12. Move the remaining adjuster assembly away from the flow cell so that clear safe access is possible. Lower the remaining components of adjuster assembly onto a flat surface.

13. Ensure the flow cell is on a flat surface.

14. Undo the locking nut on the flow cell inlet (Figure 6a) and move it towards the flow cell (Figure 6b).

15. Using “flats” and adjustable spanner, undo the seal setting tube and slide it upwards and retain (Figure 6c)

16. Remove the flow tube using the 22 mm spanner (Figure 7a) and discard.

17. Discard the adjuster bed support, flow cell, bed support retaining ring and bed support retaining bolt.

18. Refer to the table below and ensure the correct components are retained and discarded.

Adjuster Assembly Wetted Flow Path components

Sanitary Clamp Adaptor

Flow tube seals x2

Flow tube

Adjuster bed support

Adjuster Flow cell assembly, inc flow cell inlet, flow cell locking nut and gasket seal

Adjuster seal

Bed support retaining ring

Bed support retaining bolt

Seal Actuation Nut

Spacer

Stainless steel Seal Adjust tube

Threaded central height adjust rod

Height adjust handle assembly

Adjuster Flange

Seal setting ring

Backing Plate

At the start of the procedure, the adjuster assembly is partly assembled and consists of adjuster flange, seal actuation handles, threaded central seal height adjust tube and seal setting ring.

The adjuster flow cell is supplied as an assembled unit which simplifies adjuster assembly protocols. Refer to photographs below to provide visual guidance through the procedure.

1. Place the adjuster flow cell on a flat surface (Figure 8a) and check the flow cell locking nut is located against the flow cell (Figure 8b).

2. Carefully invert the adjuster flow cell.

All handling of bed supports should be performed by a user wearing gloves.

3. Locate the bed support into the bed support retaining ring. The smooth side (glossy side) of the bed support should be uppermost with the coarse side (dull in comparison to other side) in contact with the flow cell. (N.B bed support retaining ring shown as blue to highlight assembly – actual component black).

4. Fit the bed support retaining ring and bed support to the adjuster flow cell. Working around the retaining ring click it into position by locating the outer edge into the groove on the outside of the flow cell.

Retaining Ring Adjuster Flow cell Bed Support

10: Location of bed support retaining ring onto the adjuster flow cell.

5. Locate the central bed support retaining bolt and secure, initially hand tight.

6. Carefully tighten the central bed support retaining bolt using the correct tool, keeping the tool perpendicular to the bed support. Incorrect use of the tool can cause damage to the bolt and ineffective tightening.

7. Check that the flow tube seal is located in the flow tube, and attach the flow tube to the flow cell inlet using the 22 mm spanner to tighten (Figure 12a)

CAUTION – Do not over tighten as this may lead to failure of the component.

8. Slide the stainless steel seal setting tube over the flow tube and connect to the flow cell inlet. Ensure that the tube is fully engaged, and no manual rotation can be achieved. Tighten using adjustable spanner (Figure 12b).

9. Move the flow cell locking nut upwards so it contacts the end of the seal setting tube (Figure 12c), and tighten the seal setting tube against the locking nut (Figure 12d)

10. Ensure eye bolts are fitted to the adjuster flange.

11. Using appropriate lifting slings attach the hoist to the adjuster assembly and lift the unit high enough to allow the flow cell assembly to be fitted.

12. Move the adjuster assembly over the flow cell (Figure 13a) and lower so the flow cell assembly slides over the threaded height adjust rod/seal setting ring assembly (Figure 13b).

13. Fit the spacer and seal adjuster handle - bit may be necessary to remove the slings to enable easy access. The seal adjust handle should be set so that the top of the handle is level with the top of the seal adjust tube; see Figure 14

14. Reattach lifting slings and slowly lift the assembly to about 5 cm from the flat surface. Fit the adjuster seal around the perimeter of the flow cell, ensuring it is seated correctly (see Figure 15), before lowering the assembly back to the surface.

15. The refresh of the adjuster assembly is now complete. Ensure the unit is firmly seated on a flat surface and detach the hoist.

Disassembly of the Tube unit.

Tube Unit Assembly

Wetted Flow Path components DISCARD

Tube (complete with scale label, Id labels)

Buffer seals

Flange Shield Ring & seals

Column tube seals

Non-wetted components RETAIN

Top column flange

Tie bars and bolts

Bottom flange bolts, washers and nuts

Bottom column flange

1. Attach the spare set of eye bolts, provided with the original column, to the top tube flange. The correct position for these is located 2nd hole to the location pin. The hole is also recessed on the underside of the flange unlike the flange fixing bolt holes.

Location pin

Lifting eye fixing hole, 2nd hole from location pin on tube flange

2. Identify the components on the schematic shown in Figure 17.

3. Using appropriate lifting slings or equipment attach the hoist to the eye bolts.

4. Using the correct spanners, remove and retain the column tube bottom flange bolts, washers and bolts.

5. Place the maintenance blocks on the floor. These should be spaced to support the bottom flange and equally spaced; see Figure 18

6. Lift the column tube unit away from the column base unit and move over the maintenance blocks. Slowly start to lower the unit, and when approximately 5 cm above the maintenance blocks, pause and check position of the blocks

7. When maintenance blocks are in the correct position, ensure that access can be gained to the tie bar fixing bolts.

8. Continue to lower the column unit until the unit rests on the blocks and hoist slings are slack.

9. Loosen the column top tie bar bolts using the socket adjuster. Remove and retain the tie bar fixing bolts from the top flange and remove the top flange (Figure 20a)

10. Loosen the column bottom tie bar bolts using the socket adjuster. Remove tie bars by manually twisting the bars (Figure 20b). Retain the tie bars and bottom fixing bolts.

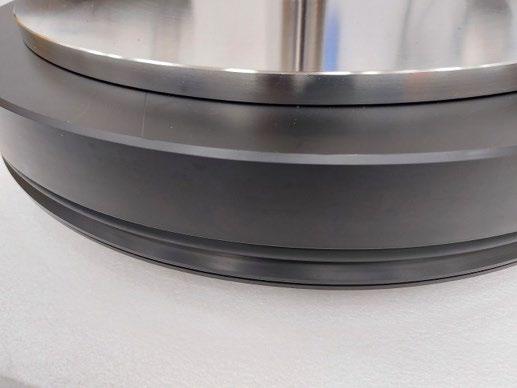

11. Remove the bottom buffer seal from its location (Figure 21a) and slide it up the tube so it is clear of the flange shield ring. It is now possible to remove the tube.

12. Using correct lifting techniques, lift the column tube out of the flange shield ring (Figure 21b). This is a two-person operation. Discard the tube and buffer seals.

13. When tube is removed, and moved clear of the maintenance area, lift out flange shield ring complete with tube seal and discard. Retain the stainless steel flange (Figure 21c).

In the column refresh kit, the tube is supplied ready for assembly with scale label, Evolve® label and rating plate and buffer seals on the tube wall. The flange shield ring and tube seal are required to complete this reassembly.

1. Ensure the column bottom flange is located on the maintenance blocks and the blocks are evenly spaced but do not obscure the tie bar fixings Insert the flange shield ring into the stainless steel column flange (Figure 22a).

2. Identify the location of the alignment indicator, as this will assist in orientating the tube correctly.

3. Identify the replacement bottom flange shield ring and locate into the bottom flange (Figure 22b)

4. Fit the column bottom tube seal into the seal groove in the column flange shield ring. Ensure this seal is located completely within the groove; see Figures 22c and 22d

5. The buffer seals should be in place on the outside surface of the tube at a distance of approximately 2 cm from each end of the tube.

6. Before lifting the tube into place ensure the tube is orientated correctly. The correct orientation is that the scale label should be at the front of the column perpendicular (90O) from the alignment indicators on the side of flange.

7. Lift and locate the acrylic tube. Ensure it is located centrally and evenly within the shield ring (Figure 24a). This is a two-person operation.

8. Locate and secure tie bars on the bottom flange using the bottom fixing bolts. Initially hand tighten the bolts, working diametrically opposite. When complete, use the torque wrench (set to 50 Nm) to tighten the tie bar bolts, again working diametrically opposite.

9. Using the hoist, lift the top column flange (Figure 24b). A top column tube seal is provided and although this seal is not process wetted it can be replaced. To do so place the flange on a flat surface, remove lifting eyes and invert. Remove seal and replace. When complete turn over the top flange and reattach lifting eyes. Reattach hoist and move over tube unit.

10. Place the flange over the tube unit so that the top fixing bolts can be engaged. Ensure alignment indicators are positioned correctly.

11. Lower the top flange (Figure 24c) and secure the bolts by hand but do not tighten the bolts.

12. Locate the upper and lower buffer seals into the bottom flange and underside of the top column flange.

13. Using the torque wrench set to 50 Nm, tighten the tube support rod bolts located in the top column flange.

14. Recheck the bottom fixing bolts and tighten if necessary.

Disassembly of the Fixed End Assembly.

1. To assist it is recommended that column feet are lowered to provide a stable base.

2. Identify the components on the schematic shown in Figure 25.

3. Undo, remove and retain bottom flow cell bolts.

4. Slide the bottom flow cell to one side (Figure 26) This makes it easier to lift the flow cell.

Figure 26: Displaced bottom flow cell during disassembly

5. Removing the flow cell is a two-person operation. Remove the bottom flow cell from the backing plate and discard. Fixed Assembly

Flow tube Adaptor and gasket

Bottom Bed Support & bed support seal

Column Flange Seal

Bottom Cell fixing bolts

Backing Plate

Column Levelling feet

Bottom Flow cell Casters

Santoprene Ladish Seal & click clamp

The bottom flow cell is supplied complete with the flow tube adaptor and gasket in place.

1. Move the column base (Figure 27a) under the overhead hoist and lower column feet to provide a stable base. Place the bottom flow cell on the backing plate using the alignment indicators to ensure flow cell is in the correct orientation.

2. Locate the bed support seal into the inner most groove on the flow cell.

3. Locate the bed support with the smooth side uppermost and secure using the bed support retaining bolt. Do not overtighten this bolt.

Note: Always use clean dry gloves when handling bed supports

4. Locate the column flange seal into the outer most groove on the flow cell.

5. Lift and place the flow cell onto the base plate, using the alignment indicators to achieve correct orientation. It is recommended to place the flow cell off centre (Figure 27b) to enable operator hands to be clear.

6. Slide the flow cell into position. Secure the flow cell to the column base plate using the bottom flow cell bolts (Figure 27c).

Reassembly of the column is the reverse of disassembly and starts from column bottom upwards. Each sub assembly is reassembled before attached to the column.

Assemble Tube Unit onto the Column Base and Bottom Flow Cell

1. Attach appropriate lifting slings to the eye bolts located on the tube unit flange. Lift the tube unit.

2. Move the tube unit over the fixed end assembly (Figure 28a)

Figure 28 (a-c): Reassembly of Column

3. Align the tube unit using the alignment indicators (Figure 28b)

4. Replace the bottom column flange bolts/washers in the tube unit.

5. Slowly lower the tube unit and use the column bottom flange bolts to align the tube unit onto the bottom flange.

6. When tube unit is in place on column base, locate the column bottom flange nuts. Hand tighten, working diametrically opposite to ensure equal loading on the seal, then using the correct spanner work diametrically opposite to tighten fully.

7. Remove the eye bolts from the top flange and store with other column tools.

8. Attach appropriate lifting slings to the eye bolts located on the adjuster assembly. Lift the adjuster assembly.

9. Move the assembly over the column unit, using alignment indicators to line up the adjuster. Slowly position the adjuster unit into the column tube (See Figure 28c). Alignment pins located in the top flange are provided to assist positioning (See Figure 29a).

10. Locate the top flange fixing bolts/washers. Hand tighten, working diametrically opposite to ensure equal loading (Figure 26b), then using the correct spanner work diametrically opposite to tighten fully.

11. Remove lifting slings (Figure 29c). Column has been successfully refreshed and ready for hydrostatic leak test and return to operation.

The purpose of this test is to check that there are no leaks from the column and the column is ready to use.

Due to the materials of fabrication, when the column is initially exposed to pressure the column components will flex. It is important that the hydrostatic leak test is performed as outlined below following a multiple step operation.

1. Fill the column with WFI (water for injection) or high-quality water and position the adjuster at the operating bed height.

2. Ensure the adjuster seal is wetted with buffer or other suitable liquid prior to assembly. This helps ‘lubricate’ the seal to ensure correct seating.

3. Activate the adjuster seal.

4. Ensure all air is removed from the column and any connections.

5. Attach a calibrated pressure gauge to the top inlet of the column.

6. Open the valve and increase the pressure until 1 bar (15 psi) and close bottom inlet valve. Wait 15 minutes for the pressure to stabilize.

7. Release the pressure in the column.

8. Open the valve and increase the pressure until 3 bar (43.5 psi) and close bottom inlet valve. Wait 15 minutes for the pressure to stabilize.

9. Check the pressure and ensure pressure is 3 bar (43.5 psi).

Due the nature of materials it is possible there will be a small pressure drop, however, this should not exceed 0.2 bar.

The Evolve® 600 mm Process Columns are fitted with height adjustable feet and a spirit level is provided. This enables the column to be levelled and/or to increase ground clearance.

1. Ensure the column is in the final process position and the column has been disconnected from any overhead hoist.

2. Place the spirit level on the top surface on the column.

3. Locate the flat portion on the column feet bolt and, using the correct spanner, adjust so that the bubble is located centrally on the spirit level.

4. Turn the spirit level by 90 degrees and repeat.

To view our Evolve® Column User guides please visit: https://www.astreabioseparations.com/resources/hardware- user-guides

For further enquires please contact: sales@astrea-bio.com

Revision

Comments

Date

A Released Jan 2022

B Further Disassembly/assembly Guidance provide May 2023

C Rebranding Apr 2024