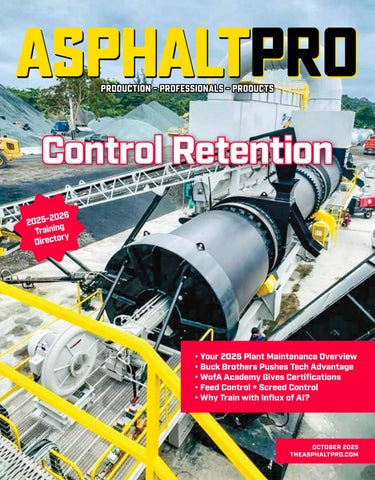

Control Retention

• Your 2026 Plant Maintenance Overview

• Buck Brothers Pushes Tech Advantage

• WofA Academy Gives Certifications

• Feed Control = Screed Control

• Why Train with Influx of AI?

• Your 2026 Plant Maintenance Overview

• Buck Brothers Pushes Tech Advantage

• WofA Academy Gives Certifications

• Feed Control = Screed Control

• Why Train with Influx of AI?

Astec paves the way for sustainable, innovative asphalt plants. The new IntelliPac Moisture System is a revolutionary solution that integrates seamlessly with Astec control systems. This provides unparalleled, real-time visibility into virgin aggregate moisture content. IntelliPac empowers operators to optimize mix design, minimize energy consumption, and reduce environmental impact. With Astec, you get superior asphalt production – better for the environment, better for your business.

The reverse air baghouse engineered to lead your plant to peak performance.

The Dust Pilot reverse air baghouse is built for high-capacity operations with precision airflow control and fewer moving parts, minimizing maintenance. Its robust, customizable design ensures cleaner air, enhanced plant performance, and compliance with environmental standards. Available in multiple sizes, the Dust Pilot delivers reliable and effective dust control tailored to your plant's needs.

6

8

10

12

You Listen To?

You can’t let a sense of overwhelm or existential dread paralyze you when there’s a multi-million-dollar project looming. Maybe it’s my Type A personality talking, or the memory of my high school marching band director shouting, “No pain, no gain,” but adults like myself know we must power through the days when we feel a sense of emotional turmoil and complete the job in front of us. Especially when you’re in a small company, you don’t have the luxury of calling the foreman and saying, “Hey, I feel triggered by the evening news and need to eat a tub of ice cream in my sweats instead of coming in to run the paver tomorrow.”

Don’t get me wrong. We don’t want distracted or hurting workers trying to operate heavy equipment. It is better to reach out and offer kindness to those colleagues.

But we also want to toughen up. The mental health wellness of our co-workers and ourselves doesn’t have to be predicated on stock market performance or some other construct the mainstream media tells us is worth obsessing over today. Our mental health wellness could instead be influenced by touching grass for a few minutes more today than yesterday.

Our mental health wellness can also exist within a system where we give one another grace because we have cross-trained employees to handle tasks when someone needs to take a break from the stress of construction season. As Laura Ingalls Wilder taught us in her Little House books, you make hay while the sun shines. That means we have high expectations of workers to show up and contribute for long hours in demanding conditions for a set number of months per year.

When that grueling schedule bumps against a worker’s financial, family or other strains, forcing him to operate the milling machine could spell disaster in mistakes, accidents or both. Wouldn’t it be a boon to your company if you had multiple crew members trained to operate the mill skillfully?

When you cross-train members of the rolling train, it’s a relief to know the breakdown operator can take a day to help an ailing family member rather than sit atop this important and heavy piece of equipment while distracted with worry. In fact, the team at Hamm launched its Smart Compact technology, discussed in the “NDDOT Trials New Technologies on Hwy 14” article in our March/April edition, to take some of the

onus off the operator, and this makes it easier to bring a new person to the machine.

Someone still has to program it, of course. It’s in everyone’s best interest that all operators know their “asphalt fundamentals” and are prepared to react to changes in their surroundings. That concept is discussed in the plant maintenance wrap-up, on page 50, included in our annual training directory.

Also mentioned in the training directory, many original equipment manufacturers (OEMs) offer training schools, online webinars and in-person help to teach workers how to use and maintain their equipment. You’ll have seen on social media how asphalt contractors and laborers are quick to offer guidance and opinions—sometimes in a constructive manner—for best practices. It may feel overwhelming to pick through and find the right person to lean on for information when there are so many experts to select from.

I want to suggest it’s always a good idea to reach out to your OEM or dealer for information that’s specific to your machine. Depending on the OEM/dealer, you may also find general best practices training with them.

But don’t forget to seek sources, like AsphaltPro magazine, that offer a sampling of voices with a range of experiences to help you educate your workers. The team at AsphaltPro is made up of individuals who joined the industry in 1992, 1998 and the early 2010s. This means we know where to gather the consultants and experts to speak to you in our annual training directory, regular training department, weekly Toolbox Tips and more. We do the legwork for you and present it here.

602 W. Morrison, Box 6a Fayette, MO 65248 (660) 728-5007 • www.theasphaltpro.com

GROUP PUBLISHER

Chris Harrison chris@ theasphaltpro.com

EDITOR

Sandy Lender sandy@theasphaltpro.com (239) 272-8613

DIGITAL EDITOR

Sarah Redohl sarah@theasphaltpro.com (573) 355-9775

MEDIA SALES

Cara Owings cara@theasphaltpro.com (660) 537-0778

ART DIRECTOR

Kristin Branscom

BUSINESS MANAGER

Susan Campbell (660) 728-5007

AsphaltPro is published 11 times per year.

Stay Safe, Sandy

Lender

Correction: In the August issue of AsphaltPro Magazine, we accidentally misspelled the name of the business for the producer profile department, featured on page 22. The company’s correct name is Myrl & Roy’s. We deeply regret this error.

Writers expressing views in AsphaltPro Magazine or on the AsphaltPro website are professionals with sound, professional advice. Views expressed herein are not necessarily the same as the views of AsphaltPro, thus producers/contractors are still encouraged to use best practices when implementing new advice.

SUBSCRIPTION POLICY: Individual subscriptions are available without charge in the United Sates, Canada and Mexico to qualified individuals.

One year subscription to non-qualifying Individuals: United States $90, Canada and Mexico $125.00. For the international digital edition, visit theasphaltpro.com/subscribe/

BY SANDY LENDER

The Construction Industry Alliance for Suicide Prevention (CIASP) has published a guidebook to help members of the construction industry when initiating conversations about mental health wellness and suicide prevention. The 11page booklet, titled “Talking About Suicide In The Construction Industry,” is designed to offer safe messaging guidelines for presenters, trainers, members of the media and anyone trying to help members of the construction industry.

The booklet is segmented into four main parts.

• Safe Messaging Around Suicide in the Media

• Safe Messaging Around Suicide in Group Trainings & Discussions

• Safely Talking About Suicide with an Individual Who May Be at Risk, and

• Post-conversation Self-care.

The whole booklet starts off with key tips to keep in mind in any setting, including excellent information two presenters shared during a webinar Aug. 13 introducing the guidebook’s points to an audience of over 200 attendees.

Sonya Bohmann, the executive director of CIASP, and Jessica Bunting, the research to practice (r2p) director for the Center for Construction Research and Training (CPWR), both spoke of the importance of bringing your authentic self to conversations with persons who might be struggling with mental health wellness or suicidal ideation. This message is stated clearly in the guidebook: “Bring your authentic, human self to the conversation and approach it with empathy and sincerity. Each person may need a different approach when they are struggling, so the most important thing is to be real and listen to express support.”

Bohmann shared during the first part of the presentation that “being compassionate, being yourself, showing up with empathy”

is more important than getting every vocabulary word correct. The fact that you’re showing care and compassion for a colleague, friend, employee or other person is what’s important.

Having said that, the CIASP education committee prepared the guidebook for a reason. By offering a guidebook that supports other materials, the committee offers a baseline for kind and compassionate language, reporting, training and help.

For example, the first section reminds us, “The messaging used in media and news reporting has a significant influence on the way people talk about suicide and mental health. It is important for spokespeople and members of the media to discuss the issue responsibly.” The section offers a list of action steps and reminders for media and those who may be interviewed by the media or those who may be posting on forward-facing sites.

While each of the sections offers valuable and important guidance, reminders for leaders of group training stood out during the webinar. Bunting spoke of the role both discussion leaders and “helpers” placed within an audience play. “You will be looked at as a safe person if you’re leading the discussion. Or if you’re a helper in the room.” As a safe person, you can expect people to approach you with questions or concerns. By taking these roles seriously, performing research ahead of group training, and having resources ready for any struggling persons who may approach you during or after the session, you can be an effective leader (or helper) in group training.

The final section for self-care also offers a reminder of how important it is to take your own mental health wellness seriously when reaching out to help another.

Throughout the presentation and the perusal of the guidebook, it became clear that CIASP and CPWR have assembled a resource for individuals and companies within the construction industry to share a message of hope with one another. The guidebook is available now at the link in the sidebar.

The following links will be easier to click and view with the online version of this article at www.TheAsphaltPro.com upon publication of the October issue.

Talking About Suicide in the Construction Industry, a guidebook https://www.cpwr.com/wp-content/uploads/GB-Suicide_Prevention_Safe_Messaging_Guide.pdf

Video and Other Resources on the CIASP Website

https://www.preventconstructionsuicide.com/get-informed

How to Have a Tough Conversation

https://www.nami.org/relationships/how-to-talk-and-listen-to-someone-experiencing-suicidal-thoughts/

2 0 2 6

For over a half a decade Blaw-Knox has earned its reputation as the go to source of training and instruction on hot mix paving.

The Blaw-Knox University, is dedicated to training paver operators and foreman on proper Paver Operation and Maintenance and applied Best Paving Practices through classroom-style and handson application courses.

Blaw-Knox provides improved technical and problem-solving skills on a variety of paver operations and maintenance topics. Course instructors share decades of field and teaching experience with attendees, including training on the latest DOT requirements.

• January 12 - January 15

• January 19 - January 22

• January 26 - January 29

• February 2 - February 5 2026 DATES

All details can be found at www.blawknox.com/training or contact at (407) 290-6000 ext. 342 or training@blawknox.com

Hard-won know-how for the next generation

As automation transforms the paving industry, American Pavement is proving that smarter machines need smarter crews (not smaller crews)—and training has never mattered more.

BY BILL STANLEY

Training used to mean showing a guy how to use a rake, feed the hopper, or set up the screed. These days, it means learning GPS, understanding automation and keeping up with changing specs. Some folks in our industry worry that jobs are going to disappear as more and more of what we do gets automated. I don’t see it that way.

Look at the construction of the American railroad. It started with picks and shovels. Then came the bulldozer, and people thought, well, there go the jobs. But the guy who dropped his shovel, climbed into that dozer, and learned how to run it? He didn’t just stay employed. He made more money, worked safer and built a better future.

It’s no different today. Anyone who knows this business knows paving in 2025 looks nothing like it did 10 years ago. The real MVP on any crew is the one who knows both—the one who can run the old-school work by feel, but also knows how to make the most of what the new tech can do.

That’s what this article is about. How we train our MVPs at American Pavement—not just to know the fundamentals, but to embrace the fact that the learning never stops.

You can spend a million dollars on the best tech out there, but if your crew doesn’t understand what it’s doing, you won’t get a quality job.

At American Pavement, we don’t just train guys to push buttons. We train them to understand what the machine is doing and why. If you don’t know how slope control works—or what the slope is supposed to be—then all the tech in the world won’t save you the second something goes wrong.

That’s why we focus on fundamentals. How to read a plan. How to think about drainage. How to understand pattern and material flow. Because once you know that, then automation becomes a tool, not a crutch.

Automation can guide a machine, but it can’t read a job site. It doesn’t know if a truck is late, if the sun’s moving on your compaction window, or if the site plan doesn’t match what’s in front of you. That still takes a crew that knows how to think on their feet.

We teach our team to pay attention. Watch the mix. Watch the trucks. Watch each other. Because the model might say one thing, but if the conditions change, the crew has to know how to adapt.

Some jobs come with a full set of specs. Others don’t. And if your crew only knows how to follow directions, they’re going to struggle on the second kind.

At American Pavement, we break jobs into two buckets. There’s spec work—like state, county or municipal paving—where every-

thing’s written down: grades, depths, temperatures. That stuff’s actually easier to train. It’s like baking a cake from a recipe: follow it step by step and any cook who knows their way around a kitchen will get a quality result.

But for the second set of jobs you need a chef with enough experience to write their own recipes. That’s where you need a crew that knows how to think on their feet. This requires experience, instincts and attention to detail.

In this line of work, graduation day never comes. There’s no final exam, no diploma that says, “You know it all.” Because the second you think you’ve got it all figured out, the job changes.

We pave in towns, counties, and states—all with their own specs, their own inspectors, and their own way of doing things. You might train a guy for weeks on one type of job, but then you move on to the next site and they’ve got to start learning all over again.

Another reason why there’s no graduation day in this business is because the curriculum keeps changing. The spec books get updated. New technologies are invented. You can master what’s out there today, but tomorrow, there’ll be something new.

At American Pavement, we do our best to keep up. This is why I read AsphaltPro magazine, go to trade shows and continue to ask questions. We may not always be the first to implement new technology, but you can bet we won’t be the last!

Paving’s not a trade. It’s a skill that you refine over time. It takes time in the seat. Time on the ground. Time seeing different jobs and learning what works. And that kind of experience only comes if you can keep your crew around long enough to build it.

At American Pavement, we try to offer more than just a job. We give folks a chance to build a career. We keep as many people as we can working through the winter. We invest in the employees who are invested in us.

Skill doesn’t show up on day one. It’s built with time and pressure. That’s how you make diamonds.

At the end of the day, training isn’t something you check off a list—it’s something you build one day at a time. That’s what we’ve done at American Pavement. We train the new hire and the guy with 30 years on the paver. We train for the blueprint jobs and the curveballs. We train for the job today, and we train for the one coming tomorrow.

Because the best crews—the ones that are still standing 10 years from now—will be the ones who never stopped learning.

The sonic feed sensor, seen at the far right of the picture, must be aimed at 90 degrees to the pile of asphalt to ensure the sound wave remains perpendicular (or “square”) to the asphalt material in the auger box. You want the beam to bounce back and forth between the material and the sensor and not bounce off into outer space as it were, causing the signal to create erratic or “on-off” feeder system operation and mat texture issues. Photos courtesy of Benjamin Everett

BY BENJAMIN EVERETT

Constant, ongoing observation and evaluation, then timely intervention, is critical to maintain a consistent head of material. This is the bedrock of accurate, repeatable, consistent quality results when paving. To me, it seems a lot of operators aren’t sure when to intervene and make adjustments to the material feed sensors. This directly results in inconsistent outcomes, variable depths and noticeable mat texture differences. Here, we’ll get a proper understanding of what to do, when to do it and how to do it for confidence in the paving process.

Establishing and maintaining a suitable amount of material in front of the entire screed (including the extensions) is in my view the sin-

gle most important skill set required to build high quality, smooth asphalt mats consistently. The head of material directly impacts the screed’s behavior, your ability to control it, and everything that passes beneath the screed plate.

I routinely refer to the U.S. Army Corps of Engineers’ “Hot-Mix Asphalt Paving” handbook published in 2000, AC 150/5370-14A Appendix 1. It reinforces the importance of managing the head of material. This excellent reference states that approximately 90% of all mat defects can be traced back to both an unmanaged head of material and poor screed set up.

Frequently I observe people who either don’t appreciate the importance of this paving fundamental or don’t consider the downstream negative effects an uncontrolled head of material invariably leads to. Being that it is such an important procedure to both understand and master, I think it’s timely to have a bit of a refresher on it.

That’s why we bring more than just tools, we bring the fire.

From retrofits and relocations to maintenance, parts, and plant upgrades, Motion Engineering keeps your plant running hot and smooth. With over 30 years in the asphalt industry, we’ve seen it all and solved it all.

Let’s talk about how to make your next project faster, cleaner, and more efficient.

We want to train workers not to over-adjust with the depth crank. You’ll travel forward a full length of the paver before you see changes made here, so the screed operator needs to have patience and trust the settings.

YOU CAN FIT ALL THE AUTOMATION YOU WANT TO CONTROL THE THICKNESS, SLOPE OR GRADE, BUT IT WILL NOT BE CONSISTENT IF THE FEED ISN’T CONSISTENT.

There are several forces acting upon the screed which influence its behavior and the resulting mat quality and texture. Some of these things we may not have too much control over, such as weather, trucking delays, mix temperature and the existing grade, but the head of material is absolutely within our control, and it is the screed operator’s responsibility to manage this process.

If your head of material is both erratic and variable, this directly alters one of the primary forces acting on the screed. We need to manage that. Failure to do so will lead to inconsistent mat texture and thickness, and creates a lot of avoidable quality issues.

You can fit all the automation you want to control the thickness, slope or grade, but it will not be consistent if the feed isn’t consistent.

For some reason, I often observe people uncertain about what to do on this matter, and it appears on occasion they think because the paver has sonic auger feed sensors installed it should control the feed automatically by itself. But it doesn’t work like that.

Every time you extend or retract the extender(s), increase or decrease paving speed or alter the auger height, this fundamentally alters the view the sonic feed sensors have. In other words, if you have done a great job establishing a consistent head of material

(about halfway up the auger shafts along the full length of the screed) but then something changes, you must also make adjustments to the feed sensors to accommodate those new circumstances. You must readjust the sensor.

Remember, the sonic feed sensor needs to be pointed at a 90-degree angle to the pile of fresh asphalt being augered out. When the screed extenders are shifted in or out, it often results in a change to the sensor angle. You need to adjust it and refocus how it sees the head of material. If the original circumstances it was set up for change, its setting must change, too.

I find using something like an 18-inch-long object such as a straight edge or retractable tape measure can help to indicate that the sensor is angled correctly. Place it next to the auger sensor tube so you can see how it’s aimed.

Once you start pushing the extenders out more than about 50% of their travel (typically 19 inches with an 8-foot screed), it is important to mount both tunnel guards (or hydraulically extend them out if you have this feature) and install at least 16 inches of bolt-on auger extension to allow you to confine the head of material and to properly auger the material out to the endgates without overloading the center. You ideally want to aim for a distance of 16-18 inches from the ends of the auger shaft and tunnel guards to the endgate. Don’t have it too close to the endgate, though; it needs a bit of room to work properly and steadily. If it’s too close, it’ll be typically running on-off instead of a nice, consistent and steady speed like 20-40 revolutions per minute (rpm).

Trying to pave too wide without installing mainframe and auger extensions usually overloads the head of material in the center of the machine, and you will see it rocking the tractor side to side, behaving more like a boring machine than a paver. Don’t allow that to happen. Having

• High production drum mix Plant with high RAP capacity

• World class customer service experience and project management

• Cutting-edge HMA technology

• Innovative Plant controls with roadbuilding digital solutions

• Environmentally friendly, robust, and sustainable Plants

• Customizable stationary and portable Plant solutions

far more material in front of the screed creates multiple problems and typically results in:

• an excessively large pile of material that puts a lot of unwanted and undesirable forces on the screed. Often too much material will tend to make the screed rise because there is a lot more resistance acting on the screed than it both requires and should have. It also creates a steep-sided pile of excess material that will segregate because it’s not confined or contained in a tunnel.

• excess mix. If you are doing a lot of short pulls like 100-foot-long runs in a car park or commercial job, you are going to have a lot of excess mix to pick up at the end of each pass.

• material segregation. If you are paving longer runs, a lot of that excess head of material will basically stagnate in front of the extenders and not be consumed, nor will it pass under the screed. That’s a bad idea and it’s not going to do anything good for your mat, quality-wise.

• stress on the components. Consider the enormous and unnecessary stress and load a larger than required head of material also directly puts on the tractor, screed and material handling system; fuel burn goes way up, as does wear and tear on the augers and the extender bushes.

• loss of traction. If you are trying to drag a lot more material than the screed actually needs to float properly on a soft or marginal base, often this can cause the tractor to spin out or lose traction; particularly on a wheel paver or when paving up a steep grade or on wet tack.

The screed is a precision tool and feeding a consistent amount of material to it is paramount to success. When the surface to be paved has dips or poorly milled areas, the screed operator has to make adjustments to the material feed. In this picture, you can see how the paver is being used to pre-level or shape-correct an area that was too far out of spec to correct in one lift. In this instance, the lefthand side of the screed is dragging to zero on the existing grade. This will harm the screed and cause problems for precision paving in the future. Dragging the screed plates on the grade is not good.

If you are not confident or familiar with how to adjust the position of your auger feed sensors on the fly, the best idea is to practice. Say you have a wet day and you’re in the yard cleaning the paver. Request from your manager if you and the crew can use it as a training day and run fine crusher material through the paver and practice. You can also use this as an opportunity to hone the entire crew’s capabilities on running the screed so you have some additional members of your team who get to understand how the screed behaves and reacts. Cross training is very beneficial.

The material you use for “training day” should be fine crusher material such as <7mm or ¼-inch nominal maximum aggregate size (NMAS) dust to prevent extra wear and tear to the paver. You want to avoid running something like a 2-inch NMAS basecourse or gravel through the paver for this extra training as this leads to accelerated wear on the feeder components.

There is further excellent related training material and courses to complement and enhance this subject with AsphaltPro Magazine’s Asphalt Paving 101 resources with John Ball III, as well as Caterpillar’s Paving by the Numbers with Todd Mansell.

The reason why I consider it so important to discuss the issue of managing the head of material is because it’s arguably the primary factor in determining a consistent, quality outcome. And it’s completely within every screed operator’s ability to control.

Benjamin Everett is the owner of About Asphalt Ltd., and has worked in the asphalt industry for nearly four decades. For more information, contact him at bjeverett@aboutasphalt.co.

The Tank Manager TM allows you to monitor and regulate all of your A.C. tanks with the push of a button from the control room, tank farm or any smart phone.

The system recognizes a truck’s position, it links to the silo loadout system to con rm when a speci c truck is in the loading zone, approving the silo gates to open, eliminating the hood shot. U S Patent No. 12,378,087

We offer engineering, new and used components, parts and repairs for all brands, and excellent customer service.

That’s why the only call you need to make is to Stansteel/Hotmix Parts & Service.

The Accu-Track Advantage TM uses patented technology and techniques developed over several years from an accumulation of installations on all brands, types and manufactures of asphalt plants.

The Accu-Level TM makes it possible to never have to second-guess how much material is in your A.C. tanks or hotmix silos. The system monitors tank levels, aler ting when an over ll is approaching.

The Tank Tracker

allows you to monitor speci c operations of your plant. Completely mobile-friendly, the system can be operated on a computer, tablet or smart phone.

BY SARAH LARSON

Maplewood, Minnesota, is a suburb of St. Paul. With harsh winters and bustling changes among the seasons, street cleaning is a priority part of pavement maintenance to keep the town of about 40,000 residents looking idyllic and improve stormwater quality.

The municipality’s street cleaning program includes two rounds in the spring, cleaning after major storms in the summer, prepping for patching, cleaning up from milling prior to spot paving and cleaning through the fall beginning in mid-October and lasting as long as the weather permits.

Troy Brink is the streets and storm superintendent for Maplewood Public Works. He has been with the city for 24 years. Joe Sheeran is the communications manager for Maplewood.

The pair noted the necessity of street cleanings throughout the year with spring and fall being key timeframes.

“Sand and sediment build over the course of the winter,” Sheeran said. “Spring and early summer are key times to get that cleared before that material reaches storm sewers and goes to waterways. We’re proactive.”

To keep Maplewood’s streets clean, the city employs 10 people including eight maintenance workers and two crew chiefs. They use the Elgin Pelican, which is a three-wheel mechanical sweeper designed to provide high maneuverability and visibility.

One of Maplewood’s sweeper operators has been sweeping for more than 40 years. Doug Edge swept the Minnesota State Fairgrounds, which consistently ranks among the top in attendance, when he was a kid, and now he works for Maplewood. Edge’s grandfather is believed to have received the very first Elgin sweeper in Minnesota. Since selecting Elgin, Maplewood hasn’t ventured away in sweeper choice.

“The sweepers have come a long way as far as comfort for operators,” Brink said. “The one button that drops all the brooms is nice. The guys like the greaseless pins and the remote hoses for grease points. It makes it easier to grease.”

Now Edge’s nephews, who work at Mike McPhillips Sweeping Inc., are also helping on Maplewood’s sweepers for upkeep. As a family business serving contractors and municipalities in Minnesota and Wisconsin, Mike McPhillips Sweeping Inc. has been in the sweeping industry for 80 years. Edge’s uncle runs the business.

Despite the history and operator family connections, Brink noted that the reliability of the Elgin is what keeps them coming back.

“I would say it’s reliable,” said Brink. “I don’t see us going away from the Pelican. I don’t think there is one that compares to cleaning leaves off streets.”

Brink noted that the fall season is the busiest.

“We try to keep up with the leaves. Late leaf drops are tough because we’re not able to get as many up,” said Brink. “We use two Elgin Pelicans and have them leapfrog one another. We do a curb line pass with each sweeper, and once one is full, the other is ready.”

With more than 150 miles of streets to clean, Sheeran and Brink pointed out that street cleaning is far more than looks.

“It helps us improve stormwater quality by getting the sediment and leaves cleaned up before it can reach lakes and streams,” said Brink. “We used to use sand in the winter time and now we use straight salt, so there is not as much sediment as when sand was used.”

M ANAGER

• ASPHALT MANAGER 2 cuts down on passes and avoids over compaction.

• Delivers professional level compaction results even when a novice is operating the roller.

• No manual drum adjustments required.

TanGO Takes the Risk out of Compacting near Buildings

• Tangential Oscillation (TanGO) is simple to operate and safe to run on bridges and near buildings.

• The TanGO technology creates a smooth mat finish even at higher working speeds.

Reduce Passes by up to 40% without losing Mat Quality

• Pair BOMAG BOMAP technology with ASPHALT MANAGER 2 and reduce your number of passes by up to 40% without compromising mat quality.

• Track and document compaction results in real time with the BOMAP App.

For Truly Intelligent Compaction look to BOMAG Heavy Tandem Rollers and BOMAG advanced compaction technologies like ASPHALT MANAGER 2, TanGO and BOMAP. BOMAG technologies not only improve finish quality but also reduce the number of passes needed and increase your compaction efficiency across the board. Even a novice operator can get professional level results with BOMAG! Contact your local BOMAG Dealer today to learn more. www.bomag.com

BY SANDY LENDER

When the Women of Asphalt Colorado (WofA CO) branch officers wished to lead and inspire through education, they not only developed a training program for women and men in the state, they found a way to make this training available free of charge and within the women’s unique schedules. The conversation started in 2021 and by 2022, the training committee had developed its training academy with four full-day sessions for students to attend. Now, the program includes five full-day sessions that culminate in one of two certifications for students.

Tammera Buck is an officer of the WofA CO branch and introduced the training academy as the brainchild of Nicola Upright. Upright is a founding member of the branch and a construction manager at RockSol Consulting Group, Inc., (RockSol) Loveland, Colorado. Both of these women participate in the training committee and spoke highly of the curriculum their instructor, Andrew Hieber, has assembled.

“The WofA CO Training Academy was the brainchild of Nicki,” Buck said. “Andy is our instructor and chairperson of the training committee. He has done a fantastic job of creating the curriculum for the sessions.”

“The training academy has been around for four years now, and we try to focus on knowledge that will help the ladies (and gentlemen) in their jobs or better their careers,” Upright said. “Andy is a wonderful instructor, and we are lucky to have him.”

Hieber wears a number of hats. During the paving season, he is the fulltime construction

manager II for RockSol, where he started in 2014. In this position, he oversees the Northern Colorado materials technicians, including training for certification, day-to-day activities, lab management and materials finals for Colorado Department of Transportation (CDOT). Since 2021, he has served as an adjunct professor at Colorado State University. “This past spring I started full time as an instructor for the College of Construction Management, so I am now primarily a professor at CSU,” he explained.

Those hats make him uniquely qualified to serve as the training academy chair and instructor.

“Nicki Upright came to me as I was finishing my masters (2020-2021) while on a project with her and asked how I would create a way to empower and strengthen women in our industry,” Hieber explained. “And through conversations we came up with the idea of a training academy. Then she asked me to create what those topics would look like. I sat down and reviewed the classes that I had taken in construction management both undergrad and graduate, looked at what field experience would benefit, and the best workers core values. Again, through conversations with Nicki and her experience we tweaked and played around with topics and ideas. Then at the very end, she said, ‘Great, now teach it for me.’”

Not only did the committee take all the training concepts into consideration, but they also thought about timing for the particular audience they’d be teaching. Hieber shared, “We started our first year in 2022, with just four sessions trying to strategically place them during times where families weren’t on vacation and kids were still in school to try and maximize our outreach of ladies in the industry or interested in the industry.”

Those first four topics in 2022 didn’t include certification but did include quality control/quality assurance (QC/QA) and quality control/owner acceptance (QC/OA) training and Colorado Asphalt Paving Association (CAPA) lab training. As future sets of sessions would do, that first year included a site visit with an asphalt plant and equipment tour. The sessions also offered information on career paths; the basics of project planning and preparing projects right down to drainage systems and structures and surface preparation; finance; project phasing and delivery; environmental management; and more.

In preparation for 2022, Hieber wanted to partner with CAPA to allow him to train and

sign off on the experience needed to certify a session in LabCAT Level A, which is laydown-specific.

“Why I chose Level A is because it is a great starting point in the asphalt world for Colorado.” It qualifies anyone with the certification for the following:

• Sampling of Aggregates

• Sampling of Asphalt

• Density of Asphalt

• Ability to get Level I or Asphalt Paving Materials Inspector Certification

The committee wanted to accomplish this with no cost to the attendees. “That year we had a golf tournament, so the majority of those proceeds go to the training academy

In preparation for 2025’s training season, Hieber proposed something new again. He suggested the training academy offer Level 1—the Asphalt Pavement Materials Inspector Certification—every other year. This would allow attendees who had achieved their Level A certification one year to achieve the next level of certification the next year, thus providing continuing value for returning trainees.

“This idea turned into why not do both?” he said. “Our golf tournament and wonderful sponsors had been doing so well that we had the funds to offer both certifications with no cost to the attendees. So, we kept the idea of being more specific with our training topics and now offering both certifications.”

They expanded to a five-session format in 2025. And here’s what that looked like this year.

Topics 2025:

• Session 1, held May 17, at the CAPA offices in Centennial: Binder Selection, Mix Design Review 2.0

• Session 2, held June 21, at the CAPA offices: Quantity Takeoff & Estimating, Emerging Technologies

• Session 3, held Aug. 23, at the CAPA offices: LabCAT Level A Training

• Session 4, held Sept. 20, at the CAPA offices: Level A Certification

• Session 5, Oct. 18, at the CAPA offices:

Asphalt Paving Materials Inspector Certification

“In the past few years, we have only offered the Level A or the Inspector certification,” Upright confirmed. “This year, we are offering both. All the certifications are paid for through the Women of Asphalt Colorado organization. We hold a golf tournament every year to help pay for all the training. We do offer lunch as well on the days of training to those in attendance.”

for lunches, and now the cost of the certification as well,” he said.

In 2023, the training academy held four sessions again. One session focused on topics geared toward making attendees better employees or better applicants in the industry. One session took attendees out in the field. Then two sessions were focused on the

Level A certification. “We certified seven ladies that year in Level A,” Hieber shared.

“In 2024, we wanted to be more specific with our training topic to provide a better understanding and decided to focus on asphalt binder selection and mix design,” he said. “We certified seven ladies again that year in Level A.”

Currently, the training academy is reaching women and men from all areas of the asphalt industry in Colorado.

“I would say on average we have anywhere from 10-15 attendees per session sign up,” Hieber said. “Maximum we have had is 20+ during a plant tour. We can have a maximum of 25-ish right now, but I am always more than happy to take more.”

Gina Fox, a resident engineer at CDOT is one of the attendees who has found the program beneficial. “The Women of Asphalt CO Training Academy offered me assistance in comprehending the construction documentation that I was required to review and approve as a newly appointed resident engineer with the state. Before attending these training sessions, I was engaging with reading materials and making inquiries; however, the trainings presented practical scenarios and facilitated direct interactions with experienced professionals. These training sessions have enhanced my confidence and expanded my knowledge in this area.”

“I have attended several training classes, not as a student but as a WofA CO officer to show support,” Buck said. “I can say that what I witnessed was great and impactful on the students. Andy is a phenomenal instructor and engages the students with his knowledge and humor. The students feel comfortable to ask questions and be interactive. I’ve had several past students tell me how valuable the training has been to them in their careers, and obtaining a certification at no cost to them or their employers is a huge bonus.”

The ability to ask questions in a comfortable environment has extended to guests. In an example that showcased the program’s flexibility for its target audience, Hieber shared one of the rewarding moments for him as an instructor. When one of the attendees for a session ran into a scheduling problem, it turned out to be a great opportunity for everyone in the room. “One attendee asked if they could bring their daughter to a session because they did not have a sitter and we said absolutely,” Hieber shared. “Some of the best questions from that session came from her daughter.”

Other rewarding moments of the training program for Hieber so far have included the outcomes and the opportunities. “Certifying these ladies, to watch them study and prepare for the written and practical aspects of it and to succeed and see the fire and passion in their eyes of ‘hey, I can do this,’” has been a bonus for Hieber. He also mentioned “the network we have created and continued to grow where it isn’t just women but men too. [Men] have a responsibility to make this a welcome and inviting industry and to see everyone come together is amazing to see throughout the year.”

“It has been amazing to see the progression of the training academy and all of the support from the industry here in Colorado for what we are doing,” Hieber said. While he doesn’t know yet what ideas will be stoked for future years, he said, “I just know it will be better than the year before!”

“Each year the training is a little different at the beginning of the year,” Upright said. “We are hoping to add in a day of training on the Western Slope this coming year for the ladies that can’t make it to Denver. I would also like to get some soft skills like leadership and managing into the academy as well. It is always a work in progress.”

Pe r fected f o r N o rt h A me r i c a

CLOSE TO OUR CUSTOMERS

A S THE GLOBAL LE ADER IN ROAD CONS TRUC TION TECHNOLOGY, the world is our proving ground, in ever y climate, condition, and ter rain From mining and milling, to paving, compac tion and rehabilit ation our machines are smar t, safe, and sus t ainable, consis tently delivering the highes t qualit y and lowes t tot al cos t of owner ship

BY MARY LEE SHALVOY

CM Labs, Montreal, Quebec, recently hosted AEM Day at its headquarters, welcoming industry professionals and representatives from the Association of Equipment Manufacturers (AEM) for an afternoon dedicated to engaging in insightful dialogue regarding innovation, strategic collaboration and future-focused initiatives.

“Bringing AEM members together at our Montreal headquarters allowed us to strengthen connections and exchange ideas that matter to our industry,” said Lisa Barbieri, CM Labs Vice President of Marketing & Strategic Partnerships. “It was a privilege to help create a space where meaningful conversations could take place around workforce development, policy and innovation.”

AEM’s Senior Advisor of Global Public Policy Alex Russ and Jean-Michel Laurin of Tactix Government Relations and Public Affairs provided a detailed look at AEM’s advocacy efforts. Their presentation addressed evolving government policy in Canada, emphasizing how trade relations and public infrastructure priorities affect member businesses.

Kody Blois, MP and Parliamentary Secretary to the Prime Minister, also joined virtually to discuss policy priorities of the current

Canadian federal government and engage directly with attendees during a live Q&A session.

Attendees then participated in a roundtable discussion focused on key challenges and opportunities facing the industry in 2025 and beyond, including workforce recruitment, sustainability, infrastructure development, and cross-border collaboration.

After the discussions, attendees had the opportunity to visit the state-of-the-art Sim Yard, CM Labs’ hands-on proving ground, where guests explored the full suite of training simulators and witnessed firsthand how innovation is shaping the future of heavy equipment operations.

“These events are a great opportunity for members to connect with each other and connect with the resources and insights they need to make the most out of their AEM membership,” said AEM Account Success Advisor Sara Stromski. “We appreciate CM Labs for hosting one of these valuable events, as we continue to build momentum in the Canadian manufacturing space.”

Mary Lee Shalvoy is the Director of Communications & Content for CM Labs Simulations, Inc.

Both

PBY SANDY LENDER

Properly heating asphalt and preparing food have more in common than you might think. Since I began reporting on the asphalt industry in 1998, I’ve embraced our penchant for using food analogies. Designing a mix is like baking a cake. Pneumatic-tire compaction action is like kneading dough. More recently, Travis Mick, vice president of CWMF Corp., Waite Park, Minnesota, used another cooking example for today’s heating discussion.

“If you cook a pizza in the oven per the instructions for 15 minutes at 425 degrees, it comes out properly cooked,” Mick said. “Alternately, if you cook the same pizza in the oven for 10 minutes at 525 degrees, the outside may get done or even burnt, but the center of the pizza could still be cold.”

This relates directly to our topic of dwell time. As Carlos O. Cardenas, the Midwest area sales manager for Ammann America Inc., Orlando, suggested, “Too much retention time can overheat your mix, increase fuel usage and age the binder unnecessarily. Too little, and the materials may exit the drum under-dried or uncoated. The real

value lies in the ability of the operator or control system to adjust and balance that time to fit each job’s demands.”

We see the analogy relates directly to the removal of internal and external moisture. Greg Renegar, the vice president of customer success for Astec Industries, Chattanooga, shared, “The primary reason to change the residence time of aggregate in a rotary dryer is to enhance heat transfer.”

Renegar included education about the entrained moisture concept in his “What An Aggregate Dryer Does” presentation, sharing that internal moisture trapped in the coated aggregate not only affects mix temperature, but also affects storability, or the absorption of binder while mix rests in the silo. Producers want to remove internal moisture before liquid binder is introduced to the process, and that may require taking a look at retention times.

“Another reason to make the aggregate spend more time in the dryer is moisture removal,” Renegar said. “External aggregate moisture is easy to remove, but internal moisture removal takes time. Time is

required for the heat to soak into the aggregate and drive the internal moisture out.”

Hervé Riche, the business development manager for ADM/FAYAT Group, Huntertown, Indiana, shared, “When it comes to asphalt production, increasing dwell time in the dryer drum mixer plays a crucial role in ensuring the mix is both high quality and road-ready.”

Riche listed thorough drying of aggregates, better heat transfer, improved coating efficiency, consistent mix quality and consumption control as benefits of lengthening dwell time. He explained, “Especially for high-spec pavements (like airport runways or highways), consistency is everything. Extra time allows for better homogenization of aggregates, additives and bitumen. Oddly enough, a well-optimized dwell time can actually reduce consumption, by giving the lowest exhaust gas temperature but keeping [gas temperatures] high enough to be above the dew point in the gas ductwork.”

“As the asphalt industry advances, the heat transfer and coating challenges of different mix designs and technologies make understanding the fundamentals of heat transfer and coating an important topic,” Renegar said.

Multiple sources agreed increasing the time materials spend in the dryer drum can increase efficiency—but you must do it right. Most asphalt applications depend upon time and temperature, so let’s dive into the effects of time and temperature on mix quality.

“In asphalt production, retention time refers to how long aggregate and other materials such as recycled asphalt pavement (RAP) and filler spend inside the dryer drum,” Cardenas said. “And getting that timing right is critical. While it’s common to focus on increasing retention time to improve drying or coating, there are also times when decreasing it can benefit plant performance.”

He emphasized controlled flexibility and defined that as the ability to “tune” retention time up or down depending on the material, production rate and environmental conditions.

“In my opinion, dwell time has always been critical for mix quality,” said Mike Mauzy of Reliable Asphalt Products Inc., Shelbyville, Kentucky. “I believe, like so many other areas of improvement over the years, it has been a learning process. RAP, and specifically higher RAP percentages, have highlighted the issue of poorly performing pavements. ‘Stiff mix’ has been an issue with RAP mixes.”

Mick listed additional benefits of increasing dwell time for producers, showing that increasing the dwell time, thus efficiency, offers fewer British thermal units (BTUs) per ton. “It allows the opportunity for optimal heat transfer from the burner into the materials,” Mick said. “It allows more time for virgin and RAP materials to comingle, optimizing heat transfer and potentially reducing excessive fuel energy from the burner. You get better moisture removal in the RAP with longer dwell times. Additional dwell time allows aged RAP binder to activate and blend with the new binder. And you get reduced emissions with reduced BTUs.”

Steve Elam of Stansteel Hotmix Parts & Service, Louisville, Kentucky, shared: “An effective dwell time is not simply about how long material remains in the drum, but how efficiently that time is used to transfer heat, remove moisture and achieve uniform mixing. Optimal lifter flight design creates a consistent veiling pattern for maximum heat transfer, while in counterflow drums and dryers, maintaining adequate exhaust temperatures above dew point is critical to protect the baghouse.”

Elam continued, “Dwell time should be considered in two parts: material exposure in the drying/heating zone (which includes the com-

bustion zone), where efficient and consistent veiling is key; and the mixing zone, where longer duration improves coating, blending and allows for higher recycle content. Ultimately, dryer drum performance depends on balancing residence time with flight design, temperature and exit gas control, and mixing strategies to produce high-quality, homogenous output. When we maintain focus on the quality of the final hot-mix product, we may work backwards through the existing equipment of any individual asphalt plant and determine what is required to achieve this outcome, including critical dwell times.”

After considering the reasons for lengthening mix dwell time, producers may wonder how to effect this change at the plant. It’s not as simple as slowing down the drum’s rotation and expecting everything to magically blend more perfectly. Depending on your flight pattern, slowing the drum’s rotation may cause a failure of material to veil properly, resulting in uneven heat distribution.

Mick shared that changing the dwell time on an existing application will have an impact on load in the drum. “This could result in high amps on the drive motors, which could impact starting the drum up from a hot stop.” Mick recommended recording data before and after any changes.

“This can also affect your AC inject timing,” Mick shared. He suggested, if an additional load in the drum causes material to leak or backfill out of the inlet, you may need to make tweaks to the flighting.

“Flight design has played a large part in retaining aggregates in the drying portion of the drum,” Mauzy agreed. “Utilizing restrictor dams to hold material in longer has been a common practice. More recently, variable frequency drives have been installed on dryers as a means to control dryer rotation speed, thereby holding material in the dryer commensurate with the percentage of RAP in the mix.”

Elam elaborated on drum modifications—both inside and in alignment. “The flight configuration can be a myriad of different designs based on specific production and condition demands. Flight pattern, number and size of flights, and placement of flights inside the drum determines how aggregates are lifted and showered, which promotes even exposure to hot gases and effective energy transfer as well as impacting material throughput travel. Maintaining the correct aggregate bed depth (live load) in the drum at veiling zones is also critical; an insufficient material pool can disrupt veiling, elevate exit gas temperatures, and cause premature flight wear, especially at lower production rates.

• Do you have bottlenecks or hotspots? You may have slowed the drum without checking burner output or flight design.

• Do you have under-dried aggregate passing through to the mixing zone? You may have increased drum speed too much. Quick Tip: Monitor stack temperatures. Monitor discharge moisture content. Use these results to make small adjustments. Give the system time to respond to the adjustments before making more.

“Drum slopes and rotational speed matter,” Elam continued. “As an example, short drums with steep slopes operating at low RPM, or longer drums with shallow slopes at high RPM, may produce similar dwell times but differ in heat efficiency and wear implications.”

A spokesperson for an original equipment manufacturer (OEM) in the southeast, cautioned against making internal modifications to a drum without careful research and engineering, preferring a lengthened drum instead.

Mick also mentioned longer drums as an element some producers are putting into practice. “Traditional lengths are 50 feet long,” Mick said. “It is not uncommon to see 54- and 60-foot-long drums today. Changing the angle of the drum is another way to play with retention/dwell time. This is a bit easier to do on portable applications versus stationary.”

ADM/FAYAT Group’s Riche agreed the increased drum length offers more axial space for a longer material path, thus more time for drying and mixing. He shared this is best for new plant designs or major retrofits and cautions producers to watch out for the obvious cost and space constraints, but also to maintain proper heat gradients across the longer chamber.

Elam suggested, when reviewing drums for dwell times and efficiency, pay close attention to any drum shell deformations in the central combustion area. (These might be hidden by insulation.) Deformations could be mitigated by proper flame adjustment/shaping, proper combustion flight design and integrity, the use of proper materials capable of withstanding high temperatures from varying fuels, and so on. Avoid catastrophic failure in the drum by monitoring for drum shell deformation. With winter maintenance season coming on, you have the perfect opportunity to assess this vital plant component.

Ammann’s Cardenas also discussed the importance of monitoring flight patterns within the drum. “Flights control how material flows inside the drum,” he said. “Replacing or modifying worn or poorly performing flights can dramatically change retention time and heat transfer, whether you need more or less retention.”

For the discussion of aggregate retention time in an asphalt plant, Greg Renegar, the vice president of customer success for Astec, Chattanooga, shared how heat transfer is influenced by the particle’s size as well as its time in the production process.

“In general, most all heat transfer depends on surface area and time,” he shared. “In the asphalt industry the aggregate surface area can vary significantly from mix to mix. The percentage of aggregate minus the No. 8 sieve (fine material) is a good indicator of relative surface area. Fine particles have much more surface area per pound than larger particles.

“Inside the dryer, the finer particles come up to a high temperature quickly by convection and radiation, and convey their extra heat to the larger particles by conduction (touching). Remove the smaller particles from the mix design and there can be significant heat transfer challenges.”

Flight design in the drying zone, or front end, of the counterflow drum will directly impact veiling. Riche stated, “Optimized veiling equals faster, more uniform drying, which allows for gentler downstream temperatures.” This is an example of the ADM EX Series Model EX10254 counterflow asphalt plant.

“Changing flight arrangement can be one of the most cost-effective and impactful upgrades for increasing dwell time and improving efficiency,” Riche agreed. “From my vantage point, the drying zone is the most advantageous section to target.”

Riche reminded producers that the drying zone, or front end, of the counterflow drum is where aggregates enter with high moisture content. “Flight design here directly impacts veiling. Optimized veiling equals faster, more uniform drying, which allows for gentler downstream temperatures. Upgrading to ‘high-lift’ or ‘shower-type’ flights here can vastly improve heat exchange, reducing required peak temps and enabling more control over residence time.”

Veiling = the cascading curtain of material that maximizes surface area for heat transfer

“Every showering flight design requires some fill level of aggregate to ‘sprinkle’ or shower the aggregate through the hot burner gases,” Astec’s Renegar said. “If the aggregate is not showered uniformly across the cross-sectional area of the drum, some of the hot gases will escape the drum without giving up enough of their heat. This energy (heat) that bypasses the aggregate becomes wasted energy as it exits the fan stack into the atmosphere. It is also possible for some of the aggregate to retain moisture if this occurs.

“Getting the right level of aggregate in the drum showering flights sometimes requires increasing or decreasing the residence time (or level) of the material in the drum,” Renegar continued. “This can be

done by adding or removing showering flights, advancing or slowing down the aggregate by other mechanical means (easy), changing the slope of the dryer (difficult), increasing the length of the drum (rarely an option), or using variable frequency drive (VFD) technology to change the rotational speed of the dryer (best).”

“Using a VFD to control drum speed gives you real-time flexibility,” Cardenas agreed. “Slow it down to increase retention time for wet materials or RAP-heavy mixes. Speed it up for drier aggregates or when running warm mix...But if you’re over-drying, you may benefit from smoother, faster-release flight designs. Combined with a variable speed drum, the right flight design can provide for the best control of material retention.”

Over-drying = adding unnecessary heat to the aggregate that does not add value to the mix

Another area where a producer might consider altering flighting is the combustion zone, and Riche offered some cautions about this. “This zone is where the burner flame directly interacts with incoming aggregates (in a counterflow setup), and it’s critical for initial moisture removal and heat transfer,” Riche said. “But it’s also where things can go very wrong if not managed properly, especially when playing with dwell time. It’s risky to tinker too much here because lots of times, the combustion zone length is minimized, but it is a critical choice. This area with a high density of energy and highest temperature spot needs to be properly designed to give enough space for a proper combustion on the whole range of burner capacity.”

The team at Ammann shared, “Controlling the rotational speed of the drum in a drum mix asphalt plant is a critical feature that offers significant value in terms of mix quality, efficiency, fuel economy and operational flexibility.” Because a slower drum speed increases the residence time of materials inside the drum, it allows better coating of aggregates. Conversely, a faster drum speed reduces the residence time of materials inside the drum, offering higher production rates and production of lighter mixes. The result, according to Ammann’s Carlos A. Cardenas, is precise speed control ensuring optimum mixing. This helps the producer get a more uniform and consistent asphalt mix.

When the mix design calls for a variable, the producer must also vary the rotational speed of the drum. Cardenas shared:

• When Using RAP: A longer retention time is typically needed to allow proper heating of RAP without direct flame contact. But too much retention can lead to blue smoke and binder oxidation.

• For Warm Mix: Reduced retention time often works better, especially when chemical or foamed additives reduce binder viscosity and required coating temperatures.

• Fine Aggregates: These heat faster than coarse material. Consider reducing retention time when running mixes with a higher fines content.

He suggested if the combustion chamber design is too small for the burner size, equipment could be damaged, emissions could be heightened or other problems with efficiency could arise quickly. But he offered some smart ways to optimize the combustion zone without overexposure:

• Tune burner settings, adjusting flame shape, length and position to avoid direct flame impingement on aggregates while delivering high radiant heat;

• Refine flight design in the combustion zone; and

• Segregate mixing from combustion and if you’re increasing dwell time elsewhere, ensure the liquid AC is introduced far downstream from the combustion zone.

“While the combustion zone isn’t the primary level for extending dwell time, optimizing it ensures that any downstream gains aren’t undone by scorching material too soon,” Riche said.

Stack temperatures and emissions are early indicators of combustion zone misbehavior. A sudden rise in either could indicate over-drying or incomplete combustion.

An area where a producer can often slow the forward progress slightly, giving binder more time to coat without increasing exposure to flame or oxidation, is the coating/mixing zone downstream. “While not the best target for increasing dwell time per se, the coating zone is still worth attention,” Riche said. “Installing paddle-style or scoop-type flights helps with thorough mixing of bitumen and additives, preventing segregation.”

Riche suggested the plant operator is engaged in the fine art of mix craftsmanship. While dwell time is important, the temperature is vital to monitor.

“Longer dwell time only benefits the mix if temperature is properly controlled,” Riche shared. “Avoid the overheating conditions trap: overheat will cause binder oxidation.”

Renegar spoke to this craftsmanship in detail. “Every asphalt plant has a section or external device that coats the hot, dry aggregate with liquid asphalt. If the time of passage is too short, insufficient coating of the aggregate can occur. On the other hand, excessive time can theoretically oxidize the mix. The optimum situation is to make adjustments that provide sufficient coating in the minimal amount of time.

“A little-known fact is that the ‘quality’ of mix improves with time in a storage silo,” Renegar continued. “While in the silo in contact with each other, the aggregate particles, large and small, come to the same internal and external temperature, and the film of asphalt equalizes on all particles. Yes, some oxidation occurs with the air in the voids, but that will happen regardless. The most important thing to remember when storing mix is to make the mix at as low a temperature as possible.

“Oxidation of HMA is linear with time, but exponential with temperature, so if one is concerned about oxidation, managing the mix temperature will have a much greater effect than changing the mixing time by a few seconds. That is one reason warm mix is so advantageous; the oxidation reaction slows down significantly. This is good whether the WMA goes from the plant straight to the road, or if it is stored in a silo.”

Oxidation = hardening of the binder in HMA

As discussed in the August issue’s “Avoid Explosions and Oxidation when Preheating RAP,” adding RAP adds complexity. Cardenas said: “Imagine you’re running a high-RAP mix. You might need more residence time to ensure proper blending and to bring the RAP up to temperature. Reducing the drum speed helps accomplish this without needing to oversize the burner or intensely overheat the virgin materials.

“The optimal drum speed is a balance that ensures enough time to dry and mix materials thoroughly, efficient use of fuel and burner energy, allows for proper handling of recycled materials (like RAP), and has minimal wear and environmental impact,” Cardenas continued. “Having too little or too much drum speed can have different effects on production. Finding the right speed is crucial for the best performance.”

Cardenas reminded producers, “The most common mistake is making drum speed changes without adjusting the rest of the system. For example, slowing the drum without considering burner output or flight action can create bottlenecks or hotspots. Speeding it up too much can allow under-dried aggregate to pass through to the mixing zone.” You guard against this by monitoring stack temperatures and the discharge moisture content. “Make small adjustments and give the system time to respond.”

Reliable Asphalt Products’ Mauzy said, “Even more recently, I believe the industry is understanding the benefit of longer dwell time for mixing the RAP and virgin aggregates prior to injecting liquid asphalt. In most conventional counterflow drum mixers, there is very little time between the RAP inlet to liquid injection. Two issues regularly surface. One, the RAP is not completely dry prior to coating the mix with liquid AC, which traps moisture in the mix. Two, the RAP AC and virgin liquid AC are less likely to mix at the differing viscosity. Several producers have figured out that increasing aggregate dwell time by utilizing flight modification, aggregate dams and dryer VFDs has resulted in better quality.”

One of the challenges Mauzy has seen and wanted to warn against is neglecting to achieve proper mix quality with dry enough or hot enough RAP when favoring a higher production rate.

CWMF’s Mick reminded producers that location affects the timing and temperature, too. “Efficiency equals profitability,” Mick said. “Your baghouse exhaust stack temperature is the measuring stick of efficiency. The closer you can keep this temperature to 212 degrees, the better. Given the multitude of mix designs, specifically at stationary plants, a VFD is a fantastic way to adjust dwell times and temperatures to achieve optimal efficiency. Plant results vary from one geographical location to the next. Achieving optimal efficiency takes some trial and error.” He recommended producers take the time to experiment to bring all the elements together.

“In the real hot-mix world, no asphalt plant operates at a single production rate (TPH), fixed moisture content, constant recycle usage percentage and single mix design,” Elam said. “Production demands fluctuate, materials vary and production requirements change daily. That’s why designing for flexibility and performance is not just preferred—it’s essential.”

Ultimately, you’re mixing a specific measure of time, heat, motion and material inputs. The best plant operators treat that process like a MICHELIN-star restaurant recipe with each ingredient (flights, valves, burner, controls, slope and speed of the drum) blending in harmony.

Last century, getting retention time dialed in was prescriptive. The team at Stansteel Hotmix Parts & Service, Louisville, Kentucky shared this lesson.

“Looking at a throwback on batch plants, which were 100% of the plant population in the United States for a while, it was much easier. Either the contractor or the specifying agency said that the batch cycle time would be split into mixing the dry batch in the pugmill and then mixing the wet batch. They might have a short few seconds of dry mix time and then maybe a total batch mix in the pugmill of 60 seconds...That principle was that it took time and rotations of the pugmill mixer to thoroughly coat all of the different aggregate particle sizes, sand, mineral filler, etc., in order to have a good mix before being dumped in the truck going to the job site.”

Fast forward to today. With the variety of continuous drum mix plants available in 2025, it’s difficult to put a rubber stamp on what optimum retention or mix time should be.

“Also, there’s been a movement in many states to go to end result specifications and, in that, [the producer] can basically do anything with the aggregate, solid materials and liquid asphalt as long as it is mixed properly and has in-place compaction density on the road.

“When it comes to continuous mixers, since the designs vary so widely, there’s no question that there is more dwell time required to get all the materials heated, dried, coated and mixed thoroughly.”

The original equipment manufacturers (OEMs) who responded to questions for this article took time to share their expertise with the readers of AsphaltPro and provided excellent information. To address additional questions you might have, reach out to them, or your specific OEM, directly.

ADM/FAYAT

Hervé Riche • h.riche@mixingplants.fayat.com

Ammann Americas

Carlos O. Cardenas • Carlos.Cardenas@ammann.com

Astec Industries

Greg Renegar • Grenegar@astecindustries.com

CWMF Corp.

Travis Mick • Travis@cwmfcorp.com

Reliable Asphalt Products

Mike Mauzy • M.Mauzy@ReliableAsphalt.com

Stansteel Hotmix Parts & Service

Steve Elam • SElam@hotmixparts.com

Since its introduction, the Weiler P385 has set the standard for commercial pavers. The P385C raises that standard.

Increase to 120 hp with the Cat® C3.6 Tier 4F/Stage V engine.

Variable speed and reversible conveyors and augers and a 25% increase in tunnel height provide optimal material output.

Modular conveyor drive and sealed chain case increase feeder system reliability and life.

Enhanced heat system performance with direct-drive hydraulic generator and elimination of GFCI breakers.

BY MICHAEL PETRIE

Editor’s Note: The Focus on Performance series from AsphaltPro Magazine allows OEMs and service providers to highlight professionals in the industry who have improved efficiencies and the bottom line through best practices and performance. This month’s installment from Motion Engineering, Inc., focuses on plant maintenance strategies during the off season.

WWhen the last ton of mix goes out the gate for the paving season, it’s tempting to close shop and call it a season well done. But for the forward-thinking asphalt producer, winter isn’t downtime. It’s go-time for planning, inspecting and maintaining the critical equipment that keeps production rolling the other nine months of the year. Asphalt plants are complex systems of mechanical, electrical and combustion equipment—each with their own wear patterns, failure points and maintenance needs.

Many of the failures we see in peak season—burner malfunctions, seized valves, worn-out drag slats, failed sensors—are entirely preventable. The culprit is often deferred maintenance and a lack of thorough winter inspections.

When you fail to inspect and maintain during the off-season, you’re rolling the dice on everything from your drum bearings and flighting to your silo gates and burner systems. In most cases, early detection means a simple repair; ignored, it becomes a catastrophic failure.

Winter is the perfect storm for hidden damage as moisture intrusion causes rust and electrical issues. Also, thermal cycling can cause stress cracks and reduce the strength of welds. As with all mechanical equipment, periods of inactivity can result in seizing, corrosion or undetected mechanical failure.

At Motion Engineering, Inc., we’ve been in the guts of hundreds of plants, and we’ve seen what works, what breaks and what costs producers serious money. If you’re wondering what you should inspect this winter, here’s your prioritized guide, system by system, with insider tips on what to look for and how to address potential issues before they turn into operational nightmares.

I have personally seen entire drum sections separate from excessive wear and lack of proper inspection. With a new drum costing upwards of $1 million, it is critical to extend the life of your current drum by properly inspecting it and completing the necessary repairs. Here are the key areas that you should be evaluating once production stops for the season.

• Drum shell and tire wear: Look for excessive scarring, pitting or ovality. Uneven wear on tires or trunnion surfaces often indicates misalignment. It’s also important to inspect the thickness of the drum shell looking for cracks and separation.

• Flighting: Check for broken or severely worn flights that affect aggregate veil and drying efficiency. Check for worn out hardware.

• Trunnion rollers and bearings: Look for flat spots, vibration, excessive noise and leaking seals.

• Gearboxes: Check all gearboxes for oil leaks or unusual noises that may indicate failure.

• Thrust rollers: Inspect for proper positioning and contact pressure.

What to Do:

• Realign the drum if there’s abnormal wear.

• Install replacement liners if thickness testing comes back at a level reaching anything less than ¾ of the manufacturer’s original thickness.

• Replace broken or worn flighting to maintain proper drying.

• Grease and test roller bearings. If they’re noisy or have play, replace them before failure occurs.

As a distributor for multiple combustion manufacturers, I have witnessed the catastrophic failures and the impact they have on producers when these systems fail at the most crucial of times. Particularly when spring hits and the first batch of mix is on the schedule, the last thing you need is a burner malfunction.

Just this past spring, I had a customer that waited until their first job to fire up their burner only to realize the control system was having intermittent failure that would not allow them to run. This cost them unprecedented downtime and hundreds of thousands of dollars to try to diagnose and correct the problem. A simple test run earlier in the season could have prevented this from occurring.

Here are things to inspect on your test run.

• Combustion zone and flame shape: Look for evidence of soot, poor combustion or flame impingement.

• Blower motors and controls: Check the amperage draw, noise and contactor condition.

• Fuel lines and filters: Inspect for leaks, clogs or degradation.

• Ignition systems: Check spark plug condition, transformer performance and timing controls.

What to Do:

• Clean and calibrate the burner. A proper tune-up can significantly improve fuel efficiency and reduce emissions.

• Replace any aging or cracked fuel hoses.

• Make sure all safety components are working properly: Pressure switches, safety shut-off valves, flame supervision and limit switches.

• Schedule an inspection for the fuel filtration system.

• Make sure your burner management system is functioning properly. It’s not enough just to turn it on. You need to make a test batch and ensure your burner ramps up and down properly.

“WHAT I CONTINUE TO SEE OUT IN THE FIELD IS THAT WE ARE NEARING A TIME WHEN A SIGNIFICANT NUMBER OF PLANT OPERATORS WHO HAVE EXTENSIVE EXPERIENCE ARE RETIRING.”—

MICHAEL PETRIE

Any electrical or control failure at your plant is a sure guarantee of downtime at your facility. It is critical to ensure the functionality of all the equipment prior to your first scheduled job for the season. I have witnessed countless occurrences where producers have encountered electrical issues due to corrosion or water intrusion and simple weather proofing during the downtime could have prevented those issues.

Here is what I recommend inspecting and preparing for in the off season.

• Wiring and junction boxes: Look for water intrusion, corrosion and loose connections.

• Sensors and thermocouples: Test signal consistency and placement accuracy.

• Control panels and PLCs: Update software, test relays and backup settings.

What to Do:

• Replace compromised wiring and weatherproof enclosures.

• Calibrate all critical sensors.

• Perform a full system simulation before startup season.

• Have a backup CPU with your burner control program loaded.

Lack of proper maintenance on dust collection systems can lead to decreased efficiency, increased operating costs as well as safety hazards for your employees. The last thing you need is for a fire to start because of lack of inspecting your baghouse bags. Clogged or damaged filters are a primary cause of environmental issues and higher energy costs.

Here is what I recommend inspecting once your team winds down production for the season.

• Filter bags: Check for holes, abrasion or oil contamination.

• Dampers and ductwork: Ensure smooth operation and check for buildup or corrosion.