Paving Makes A Family Legacy

• Ways to augment your paver

• New lab collab potential

• Support fallen workers

• MoDOT trials TMAs

• HAPI changes

• Ways to augment your paver

• New lab collab potential

• Support fallen workers

• MoDOT trials TMAs

• HAPI changes

Astec paves the way for sustainable, innovative asphalt plants. The new IntelliPac Moisture System is a revolutionary solution that integrates seamlessly with Astec control systems. This provides unparalleled, real-time visibility into virgin aggregate moisture content. IntelliPac empowers operators to optimize mix design, minimize energy consumption, and reduce environmental impact. With Astec, you get superior asphalt production – better for the environment, better for your business.

6 – Screed Setting: Attitude of Gratitude

8 – AutoTMA: Bringing AI-Driven Alerts to the Frontline of Work Zone Safety From AsphaltPro Staff

12 – New Testing Lab Handles Asphalt and Concrete Fibers

Kristin Crawford

14 – How to Dial in Efficiency for Maximum Production

– Reconstruct Airfield Runway Pavement

– Arizona Paving Company Puts Legacy in Every Layer

22 – Pennsylvania Officially Joins Women of Asphalt Ranks By Sandy Lender

– International Rehabilitation From Wirtgen Group

– Augment Your Paver to Make the Crew’s Job Easier

– National Golf Tournament to Support Fallen Construction Workers’ Families

In recent paving best practices articles, we’ve discussed setting the angle of attack to get the screed’s attitude positioned for optimum success. This concept applies to more than the iron with which we work. Look at the way we set ourselves and our colleagues up for optimum success. And look at the way we can use the holiday season we’re entering to increase that success.

We’re going into the winter down season in many parts of North America where we see some workers laid off from construction work until spring, some put on call for snow removal, some shifted to equipment or site maintenance, and so on. It’s not easy to handle a three- or fourmonth furlough from employment. It’s not easy to be the one to show up at midnight when the temperature is 5°F to man the sand/salt truck for a handful of parking lots ahead of a winter storm.

In last month’s column, I suggested we can adjust our own outlook, as well as that of a colleague, by reaching out with kindness to those who may be distracted or hurting. I think I suggested we all remember to touch grass. That may sound flippant at first, but it’s a reminder to take responsibility for our thoughts. Track with me here.

During the month of November, our thoughts turn to thankfulness. Made-forTV specials show us families reconnecting and adorable cartoon characters gathering for clumsily assembled feasts. It’s a time to slow down in our personal lives and consider gratitude.

What are we thankful for?

At the end of the day, what do we list among our blessings? I’ve been through the times when those blessings were nothing more than surviving whatever the nurses at an oncology center were doing to me. I’ve enjoyed the times when those blessings filled pages of lists of positivity like petals of poetry. And I’ve seen myself look for blessings in between.

It may sound trite or New Age-like to suggest, but setting our attitudes for gratitude and looking for the blessings in each day goes a long way toward derailing the negative reactions I mentioned last month. Rather than letting outside forces “trigger” a body into staying home to drink a 12-pack, a healthy mindset processes the nightly news appropriately and gets back to daily life.

This month, we have an article from Cal Beyer of SAFE Project sharing some of the resources and tips for employers to address alcohol use as it affects the workforce. I’d like to hear how employers and workers alike are planning to minimize alcohol consumption this holiday season for whole-body health and to assist in clearing minds for positive thoughts. It’s that time of year when such conversations may be easier to dive into—why not take advantage of that and help a colleague see that the downward trend in alcohol use among his or her age group is something to celebrate and emulate?

As I mentioned at the beginning, we set our equipment at the start of a paving shift to get the right result. That involves getting the screed’s angle of attack just right. Why then wouldn’t we set our minds and spirits at the start of a day to get the right result? This involves so much more than dialing numbers, but one I’d like to remind readers to have on hand is 988—the national suicide and crisis lifeline. You can also text “hello” to 741741. Skilled, trained counselors are available 24/7 to help you or a colleague. Personally, I want to set my attitude to gratitude, even on days when it may be tough to do, and I’m thankful for the reminder this November. From the AsphaltPro staff, we hope you have a Happy Thanksgiving with your loved ones and friends.

Stay Safe,

Sandy Lender

602 W. Morrison, Box 6a Fayette, MO 65248 (660) 728-5007 • www.theasphaltpro.com

GROUP PUBLISHER

Chris Harrison chris@ theasphaltpro.com

EDITOR

Sandy Lender sandy@theasphaltpro.com (239) 272-8613

DIGITAL EDITOR

Sarah Redohl sarah@theasphaltpro.com (573) 355-9775

MEDIA SALES

Cara Owings cara@theasphaltpro.com (660) 537-0778

ART DIRECTOR

Kristin Branscom

BUSINESS MANAGER

Susan Campbell (660) 728-5007

AsphaltPro is published 11 times per year. Writers expressing views in AsphaltPro Magazine or on the AsphaltPro website are professionals with sound, professional advice. Views expressed herein are not necessarily the same as the views of AsphaltPro, thus producers/contractors are still encouraged to use best practices when implementing new advice.

SUBSCRIPTION POLICY: Individual subscriptions are available without charge in the United Sates, Canada and Mexico to qualified individuals.

One year subscription to non-qualifying Individuals: United States $90, Canada and Mexico $125.00. For the international digital edition, visit theasphaltpro.com/subscribe/

Highway work zones have always been hazardous places. Crews operate inches away from high-speed traffic, relying on signage, cones, arrow boards and the heavy shield of truck-mounted attenuators (TMAs) to keep them safe. The job of the TMA is to absorb impact energy when a driver fails to stop in time. But for all their effectiveness, TMAs are reactive devices. By the time a TMA absorbs a hit, the danger has already arrived.

A recent study led by the University of Missouri–Columbia in partnership with the Missouri Department of Transportation (MoDOT) proposes a shift in approach: that of using the TMA to prevent a crash by warning drivers of an obstruction or work zone danger in real time. The project, documented in MoDOT Research Report cmr 25-007, introduces the Automated Audible Alert System (AutoTMA), which is an AI-enabled solution designed to detect errant vehicles and trigger audible and visual warnings automatically.

The findings point to an advancement in how work zones can be secured, with direct implications for the professionals who set cones, operate TMAs and maintain roads under live traffic every day. Let’s explore the report’s information now.

Work zone crashes have been climbing nationwide. According to the authors’ findings, in 2021, over 105,000 crashes occurred in U.S. work zones, resulting in nearly 1,000 fatalities and Missouri had seen its own troubling rise in TMA strikes, with incidents increasing by more than 20% between 2020 and 2023.

For crews, every TMA collision represents more than just damaged equipment. It means direct risk to the TMA driver, the workers ahead of the truck and the motorists themselves. Many of these incidents trace back to distracted driving, speeding or late lane changes, all factors that static signage and even high-visibility attenuators cannot fully counteract.

Traditionally, audible alerts in TMAs have been manually activated by the driver or a spotter. This method relies on human vigilance, fast reactions and constant monitoring of approaching traffic.

AutoTMA is built to take human reaction time out of the equation. Using a sensor fusion package that combines cameras, radar and LiDAR, the system continuously monitors traffic approaching the TMA.

At the heart of the system are two deep learning models: YOLOv5.0, which identifies and classifies vehicles in real time; and DeepSORT v2.2, which tracks those vehicles across frames, maintaining continuous awareness of their position and movement. The system then applies a time-to-collision (TTC) model to determine whether an approaching vehicle is a risk. Based on this analysis, AutoTMA categorizes threats into escalating levels: normal, elevated, severe and danger.

At the severe and danger levels, the system automatically activates audible alarms (sirens or air horns) and visual strobes. Alerts are graduated. Quieter and shorter alarms are for less urgent threats. Louder and sustained alarms are for imminent impacts. All of this happens within 100-150 milliseconds, which is a response speed that no human operator can consistently match.

The research team subjected AutoTMA to a multi-phase evaluation program, starting with simulations and ending with deployment.

1. Simulation Testing: Using Unity 3D models and controlled driving scenarios, the system’s detection algorithms and alert logic were validated against varied traffic and environmental conditions.

2. Laboratory Calibration: Sensors were tuned for precision in speed, distance and trajectory estimation. False positives and negatives were measured and minimized.

3. Controlled Field Trials: At MoDOT’s test facilities, TMAs equipped with AutoTMA were exposed to staged vehicle approaches under varying speeds and lighting.

4. Operational Deployment: The system was mounted on MoDOT TMAs in real work zones to capture live performance data.

Researchers noted some key outcomes. First, detection accuracy was greater than 98%, with near-zero missed detections during structured field trials. Response times were under 0.15 seconds, ensuring virtually immediate hazard recognition. False alarms stayed low thanks to multi-sensor fusion, improving crew confidence and reducing unnecessary disruptions.

Driver behavior was impacted as well. In more than 80% of highrisk cases, the audible alerts prompted drivers to slow down or change lanes in time to avoid collisions.

For those working in or around work zones, AutoTMA offers advantages such as reduced reliance on manual monitoring; consistent protection because automated alerts fire every time conditions warrant; improved warning effectiveness because audible cues reach errant drivers at the critical moment, increasing their chances of corrective action; and safer operating procedures. Crews can focus more on their tasks when they know an intelligent system is continuously scanning for threats.

The system is designed to integrate with MoDOT’s existing TMA fleet with minimal modifications, ensuring a smoother adoption curve for crews already familiar with current setups. From a policy perspective, AutoTMA is breaking new ground. Current Manual on Uniform Traffic Control Devices (MUTCD) guidance does not specifically address automated TMA warning systems, so this places

2 0 2 6

For over a half a decade Blaw-Knox has earned its reputation as the go to source of training and instruction on hot mix paving.

The Blaw-Knox University, is dedicated to training paver operators and foreman on proper Paver Operation and Maintenance and applied Best Paving Practices through classroom-style and handson application courses.

Blaw-Knox provides improved technical and problem-solving skills on a variety of paver operations and maintenance topics. Course instructors share decades of field and teaching experience with attendees, including training on the latest DOT requirements.

• January 12 - January 15

• January 19 - January 22

• January 26 - January 29

• February 2 - February 5 2026 DATES

All details can be found at www.blawknox.com/training or contact at (407) 290-6000 ext. 342 or training@blawknox.com

AutoTMA (Automated Audible Alert System) is a next-generation safety system designed for truck-mounted attenuators (TMAs). Unlike traditional TMAs that passively absorb crashes, AutoTMA actively scans traffic, predicts collision risks, and issues audible and visual alerts in real time. Its modular architecture combines AI-driven perception with rugged hardware to reduce TMA strikes and protect work crews.

During development, researchers evaluated multiple system configurations to balance performance, cost and reliability under real-world work zone conditions. They found that automated detection was consistently faster and more reliable than human observation and multi-sensor systems (camera + LiDAR or radar) significantly reduced false alarms while extending detection range up to 150 meters. They also found that radar-based configurations offered the best all-weather reliability, making them practical for year-round deployment. While cameraonly systems provided a cost-effective entry point, researchers recommended multi-sensor setups for broader adoption. Let’s look at what they tested, specifically:

Camera-Only (Vision-Based Prototype)

• Uses rear-mounted cameras with AI detection (YOLOv5) to identify approaching vehicles.

• Strengths: Cost-effective, straightforward setup.

• Weaknesses: Struggles in low light and adverse weather; higher false alarms from shadows or lane-adjacent vehicles. Vision + LiDAR Integration

• Adds LiDAR to improve depth accuracy and object detection precision.

• Strengths: Maximum accuracy and detailed object profiles; strong performance in clear weather.

• Weaknesses: Expensive; reduced effectiveness in rain or fog. Vision + Radar Integration

• Combines cameras with radar for speed and distance verification.

• Strengths: Reliable all-weather performance; reduces false alarms by confirming vehicle trajectory and speed.

• Weaknesses: Less object detail than LiDAR but balances cost and resilience.

• V1: Early camera-only prototype, validated viability of automated detection.

• V2: Multi-sensor system with refined fusion algorithms, reduced false positives, and improved robustness in field conditions. The bottom line is AutoTMA is adaptable. Agencies can choose a cost-efficient camera-only version or invest in multi-sensor configurations for maximum accuracy and reliability. Both options shift TMAs from reactive barriers to proactive safety systems.

Missouri at the forefront of shaping how such technologies will be regulated and standardized.

In chapter six, the report recommends a phased deployment strategy:

• 2024–2025: Final testing and optimization of AutoTMA.

• 2025–2026: Secure regulatory approvals and integrate SOPs for operators.

• 2026: Begin rollout in high-risk operations such as bridge repair and striping.

• 2027–2028: Expand to statewide use across MoDOT districts.

• Beyond 2028: Integrate with smart work zones and pursue national expansion.

In parallel with the deployment strategy, the team recommends developing training protocols for TMA operators and supervisors; aligning AutoTMA with federal policy through collaboration with FHWA and AASHTO; and exploring technical refinements, such as adaptive warning tones for different vehicle types and integration with vehicle-to-infrastructure (V2I) systems.

AutoTMA represents a transition from reactive to proactive safety in work zones. By merging AI, sensor technology and automated alerts, the system directly addresses the risks posed by distracted or high-speed drivers approaching work zones. For road-building professionals, the benefits go beyond reduced crash risk. Fewer TMA strikes mean lower equipment repair costs, fewer work delays and greater worker confidence in their safety on the job.

As Missouri prepares for phased deployment, the system holds promise not just as a local solution but as a potential national model. The combination of technical performance, operational feasibility and policy alignment positions AutoTMA as a leading candidate to set new standards in work zone safety.

For crews and contractors, TMAs have long been the last line of defense against errant drivers. With AutoTMA, they may soon also become the first line of warning. By detecting threats faster than humans can react and issuing unmistakable alerts, AutoTMA has the potential to reduce both the frequency and severity of work zone crashes. For professionals working daily in Missouri’s work zones, this technology offers more than innovation. It offers peace of mind.

The authors of “Audible Alert and TMA Lighting,” prepared for Missouri Department of Transportation, Construction and Materials Division, Research Section are:

• Yaw Adu-Gyamfi

• Carlos Sun, Ph.D., P.E., J.D.

• Mark Amo-Boateng, Ph.D.

• Gahan Gandi

• Neema Jakisa Owor

At the Department of Civil and Environmental Engineering, University of Missouri-Columbia

Review the full MoDOT Research Report cmr 25-007 here: https://www.modot.org/research-publications.

BY KRISTIN CRAWFORD

FORTA LLC, Grand Rapids, Michigan, held the grand opening of its Grand Rapids Testing Lab on Sept. 11, 2025.

Speaking at the ribbon-cutting ceremony, Peter Ferris, CEO of FORTA, highlighted the significance of the new lab: “Today marks a historic moment, not just for our company, but for the entire industry. This facility is the world’s first asphalt and concrete fiber lab, and it stands as proof of FORTA’s role as the world’s leading innovator in fiber reinforcement. From the very beginning, we’ve led the way in strengthening asphalt and concrete, and this lab allows us to continue setting new standards for the future.”

The Grand Rapids Testing Lab is ISO 17025 certified, ensuring the highest levels of quality, accuracy and reliability. The facility can run over a dozen separate ASTM, AASHTO and EN tests, providing a range of testing and validation capabilities. More than a testing center, the lab represents a promise that every result and every innovation is backed by rigorous science and integrity.

This investment underscores FORTA’s long-standing commitment to Reinforcement That Lasts™. With infrastructure playing such a

Sign up for the free quick-tip email from AsphaltPro Magazine in time for your next tailgate talk!

critical role in communities across the globe, the lab’s work will focus on ensuring that roads, bridges and other critical facilities are safer, stronger and built to endure for decades.

Companies that conduct daily, 15-to30-minute toolbox talks reduce TRIR rates by 78% and DART rates by 79% compared to companies that hold them monthly.”

—Source: Associated Builders and Contractor

Looking forward, the lab will serve as a hub for research and development, driving innovation in fiber reinforcement technology and bringing next-generation solutions to market. A spokesperson explained this emphasizes the company’s ability to test a wide range of products within its own portfolio. But engineers at FORTA aim to test new products and innovations within the industry as a whole. This means that while the company will perform testing on its own products, researchers are also open to testing new and innovative fiber technologies from various sources, including from other vendors.

“The Grand Rapids Lab is a testament to our commitment to excellence, to innovation, and to building a stronger, more resilient future—with FORTA leading the way,” Ferris added.

For more information, visit https://fortacorp.com/.

Bill Stanley of American Pavement Specialists shares how he squeezes maximum efficiency out of fall paving with smart scheduling, plant choices, and eliminating dead time.

BY BILL STANLEY

Ican accomplish more in one day in September than I can in a week in April. In spring, the new crew is still learning, you’ve got equipment bugs to shake out, and customers are juggling other deliveries that bump your schedule.

By fall, it’s the opposite. The crew and machines are running smoothly and customers are motivated to get their projects finished before winter. That combination makes September through November the most productive stretch of the year.

But, to really capitalize on the fourth quarter, you’ve got to go beyond those natural gains and manage the details that squeeze every bit of production out of each day. Here are three ways I gain more time for every fall day, when every minute matters.

In the spring, I’ll bend to a customer’s schedule. If they say Tuesday, I’ll make Tuesday work—even if it means hauling machines across the county. We’re moving slower anyway, fighting weather, and the customers who are ready that early usually have stronger preferences on timing.

By the fourth quarter, everything’s running hot. Every wasted hour on the road is an hour we’re not putting asphalt down. Last week I had a client who wanted Tuesday, but we were working in another part of town that day. If I gave him Tuesday, we’d lose three hours moving iron around. The customer grumbled when I told him we’d have to come to him on Wednesday, but I don’t regret it. Come fall, those three hours could allow us to complete one more job that week!

We’re busy this time of year, and so are the plants. Their production is dialed in just like ours, but the lines can get long because every contractor is trying to finish before winter. Nobody ever wants to wait on mix—but come fall, we’re moving too fast to waste production efficiency on truck delays.

For a job coming up tomorrow, I called three local plants to see which one would have the fastest cycle times. That’s the one we’re using. It doesn’t matter if it’s my preferred plant or not—what matters is keeping trucks turning.

By this time of year, our drivers know the prevailing traffic patterns of the area so we can optimize their routes. They know where to enter and

Hard-won know-how for the next generation

exit our sites and where to clean out their beds, so we avoid on-site traffic jams. Managing those details—plant choice, haul route, on-site traffic—is what keeps the whole train moving at playoff speed. (Read more about how Bill approaches ‘paving playoffs’ in the article “Prepare for Playoffs to Start Next Season Strong” on theasphaltpro.com.)

Downtime is one thing. Dead time is another. A tailgate talk that should take two minutes cannot turn into a long coffee and chat like it could earlier in the season. Equipment cannot show up late because it wasn’t staged wisely the night before. Our water and fuel cannot end up ¼ mile from the paving train as we move down the road because we didn’t plan ahead.

Cutting out that kind of wasted time can save us six to eight hours in a week. When you’re already working 60-hour weeks to beat winter, that might mean saving my crew a whole shift or knocking out another job or two that week.

The way I fight dead time is by paving the job in my head before we ever show up. I run it step by step. Where’s the water coming from when we start the job vs. when we finish the job? Where are employees parking? How can we best stage our equipment for a fast start-up?

If I can spot the friction ahead of time, I can fix it before the crew ever hits the ground. It’s like an athlete visualizing success before a big game— you see it enough times in your head, and it runs smoother in real life.

Keep Rollers Staggered | One place dead time shows up fast is at the rollers. If both machines run out of water at the same time, the paver has to stop. In hot weather you might get away with it, but in the cooler temps of fall the compaction has to stay close to the mat. So I tell operators to stagger their fills—if one’s at half a tank and the other’s at a quarter, the guy at a quarter goes now. Then when he’s full, the other one goes. That way, there’s always a roller on the mat and the paving train never breaks rhythm.

You might look at how efficiently we run in the fall and think, if only we moved at that pace all year… No slow winters, no spring start up—just steady production. There’s truth to that. But I’ve come to see the bright side of this slower time of year.

When the season ends, I finally get the chance to step back and work on the business instead of in it. We go over the equipment—what got beat up, what needs replacing, where we need to invest. We look at the numbers—which jobs made money, which didn’t, which customers pay too slow. And we evaluate the crew—who’s ready for more responsibility, where we need to add, where we can tighten.

That off-season planning is just as important to our fourth-quarter success as the daily details. It’s like a team watching film after the season’s over. You study what went right and what went wrong, and you make a better game plan for next year. By the time September comes again, we’re not just back in rhythm—we’re sharper than before.

Bill Stanley owns American Pavement Specialists, Danbury, Connecticut, with his wife, Colleen. Stanley has more than 50 years of experience in the asphalt industry

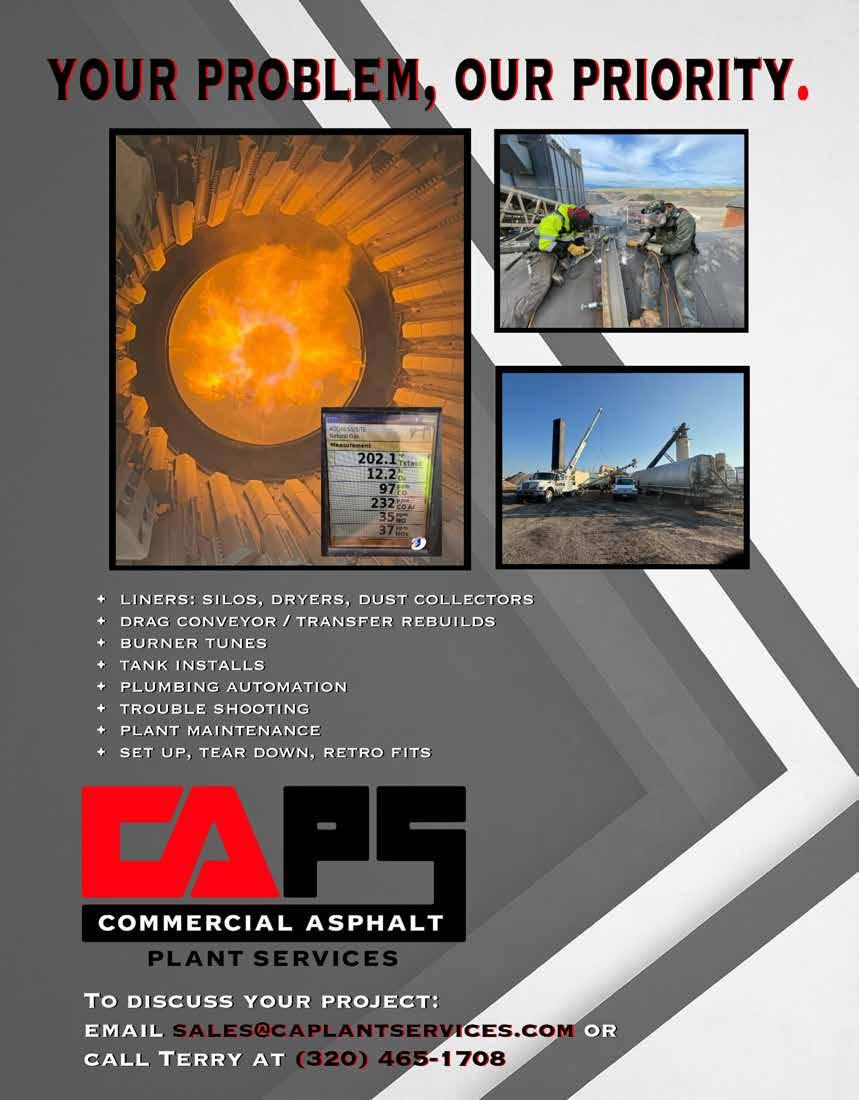

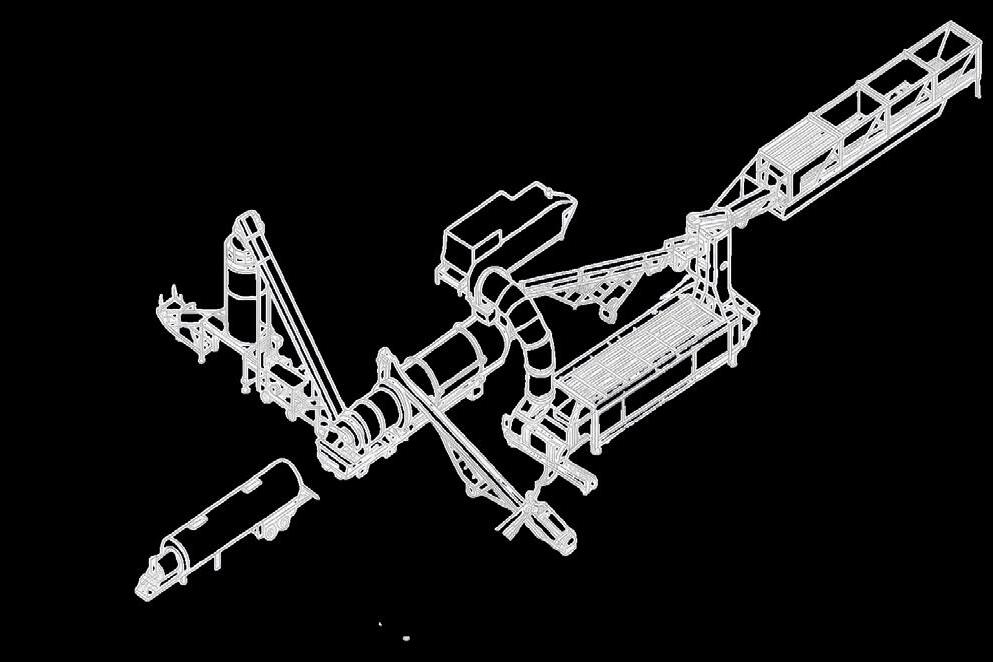

The only Full Ser vice Custom Integrator of ALL BR ANDS of asphalt plants.

INTEGRATION is achieved by combining existing plant components with new components, used equipment or re-engineering plant parts and pieces to yield a fully functioning hotmix asphalt plant facility.

Integration of a new drum, new frame, new ductwork, new knockout box, new blue smoke system and a new control house. All while utilizing components from the existing plant.

BY LEN HUNT

Situated alongside North Carolina’s Crystal Coast, Michael J. Smith Field serves as an important aviation hub for the communities of Beaufort and Morehead City. Supporting general aviation, emergency response and regional economic activity, the airport spans more than 400 acres and includes three asphalt runways.

As part of ongoing efforts to maintain and improve its infrastructure, the airport identified the need to reconstruct its Runway 3-21, an aging strip that had fallen out of regular use and required modernization to meet evolving standards. To carry out the $5.1 million rehabilitation, S.T. Wooten was selected to lead a comprehensive runway reconstruction project designed to meet modern specifications and support the airport’s long-term operational needs.

The runway reconstruction project involved full pavement removal, subgrade stabilization and the construction of a new asphalt surface to meet the Federal Aviation Administration’s (FAA’s) P-401 specs. These guidelines are among the most rigorous in the paving industry, covering everything from material composition and tolerances for smoothness, to joint quality and durability.

Crews began work by milling and removing the existing 150-footwide surface. The new runway geometry called for a slight alignment shift, which prompted the reclassification of the runway to 4-22.

To ensure precision throughout the site, the S.T. Wooten team relied on GPS-guided equipment and total station controls to manage grading operations. Accurate subgrade preparation was critical to achieving the smoothness and drainage performance required for airfield pavements. Using a total station positioned alongside the runway, crews guided trimming equipment to meet tight FAA tolerances and create a uniform, on-grade surface before any asphalt was placed.

One of the project’s most noteworthy technical achievements was the crew’s approach to longitudinal joints, which are prone to performance issues in many pavement applications. While FAA specifications typically require saw cutting and particular compaction techniques to ensure joint durability, S.T. Wooten adopted a more innovative approach to eliminate the need for saw cuts.

For the paving work, crews used a propane-fueled joint heater mounted to the paver to preheat the cold edge of the previously placed asphalt to approximately 250°F. This closely matched the temperature of the fresh mix and enabled thermal bonding between the two mats, allowing crews to uniformly heat up to 18 inches wide and 3 inches deep. As a result, the joint performed like a continuously placed surface, eliminating the need for post-paving saw cuts.

Discover the MaxRap® 25 Portable specially designed for the asphalt industry. Featuring Eagle’s UltraMax® 25 impactor with its high reduction ratio and North America lifetime rotor warranty, the MaxRap 25 Portable provides the same precision crushing of the stationary MaxRap, allowing operators to crush RAP at multiple locations with ease.

Experience the benefits of multi-feature deck selection, blending, and bypass; sampling to verify the mix-design spec requirement is correct, and ability to use the system for screening, direct to stockpile. Discover even more RAP benefits. Plus, this versatile plant may be used as a secondary unit for recycled concrete and aggregate by removing the diverter chutework to become two plants in one.

To further improve joint density and reduce the risk of cracking or water infiltration, the team used a wedge-shaped compaction attachment to shape and compress the edge during placement. This method helped create a smooth, strong transition between lanes and contributed to the project’s superior ride quality results.

The S.T. Wooten team relied on a range of specialized equipment to help meet the FAA’s P-401 specs. Key machinery included a Cat AP1055 paver with Cat screed and compaction devices, and a Heat Design Equipment infrared asphalt joint heater for seamless joint construction. Compaction was achieved using Cat CB-13 and Combo CB-34 rollers, while a Roadtec SB-3000 Shuttle Buggy® material transfer vehicle ensured consistent asphalt delivery.

Crews placed approximately 8,500 tons of FAA-compliant hot-mix asphalt (HMA), formulated with an optimum asphalt cement content of 5.1%, a PG76-22 binder and 25% anti-strip additive to improve moisture resistance. The surface mix incorporated aggregate sourced from two regional quarries, with 100% passing a ¾-inch sieve, ensuring uniformity and durability.

Meticulous material handling and precise execution helped the project deliver exceptional smoothness results, achieving an average International Roughness Index (IRI) of just 1.86 inches per mile with zero areas requiring corrective grinding. This outcome stands as a testament to the team’s attention to detail and technical performance.

The HMA for this project was produced at an S.T. Wooten plant roughly 45 miles from the site. Maintaining optimal temperature throughout the haul was essential to achieving proper compaction and surface quality.

To ensure a steady, uninterrupted supply of material, insulated trucks were used to transport the mix and plant operations were closely coordinated with on-site paving progress. Each of the two, 2-inch asphalt lifts were placed and compacted using a defined rolling pattern. Joints between the lifts were staggered to help distribute structural loads more evenly and prevent reflective cracking.

Because of the haul distance and limited paving windows, project logistics played a central role in execution. Careful planning around plant schedules, trucking routes and job site staging helped keep operations on track.

Following its successful execution, S.T. Wooten’s Michael J. Smith Field project was honored with the 2024 Ray Brown Airport Pavement Award from the National Asphalt Pavement Association (NAPA). Named after pioneering asphalt researcher Dr. Ray Brown, the award recognizes projects that demonstrate excellence in workmanship, innovation and compliance with FAA standards. The award underscores the high level of quality delivered by S.T. Wooten’s team and its partners throughout the project. The recognition reinforces the team’s reputation as a trusted partner in complex infrastructure projects.

While S.T. Wooten was proud of the award, the greater win was the successful completion of the runway, marking a significant infra-

The HMA for the runway project was produced at an S.T. Wooten plant roughly 45 miles from the Michael J. Smith Field job site.

structure improvement for Michael J. Smith Field. The reconstruction of Runway 4-22 ensures the airport can continue to support general aviation needs across the Crystal Coast with enhanced safety and reliability.

For S.T. Wooten, the project adds to a growing portfolio of award-winning aviation and road construction work. Thanks to the coordinated efforts of all involved, the runway was brought back to life with a special focus on quality and long-term performance.

Len Hunt is the eastern commercial division manager for S.T. Wooten Corporation.

www.wirtgen-group.com/technologies

BY JUSTIN ZUPANC

From humble beginnings patching potholes to tackling major roadways, Primavera Grading and Paving has steadily grown its business by prioritizing quality, fostering a dedicated team and forging invaluable partnerships.

In the competitive world of asphalt paving, a company’s reputation is its most valuable asset. For Oscar Estrada, CEO of Primavera Grading and Paving, this truth resonates deeply, echoing a sentiment once shared by legendary investor Warren Buffett: “We can afford to lose money—even a lot of money. But we can’t afford to lose reputation—even a shred of reputation.”

It’s this unwavering commitment to quality and integrity that has propelled Primavera from a small family venture to a thriving business now laying asphalt across major cities in Arizona.

The company’s story is deeply intertwined with the Estrada family. Oscar Estrada, Sr., Oscar’s father, laid the groundwork decades ago with Estrada Grading and Paving, starting with Massey Ferguson equipment and gradually moving into asphalt. Oscar grew up learning the trade alongside his father, running equipment and discovering the nuances of paving.

In 2019, Oscar decided to branch out, establishing Primavera Grading and Paving with a clear vision to pursue larger contracts and expand the company’s capabilities.

“When we started, it was Oscar Senior and me,” he said. “From there, one of my sisters, Priscilla, wanted to be a part of it. She’s currently doing a great job as an estimator.”

The family involvement didn’t stop there. Oscar’s oldest daughter, Nicole, now manages the financial operations, while daughter Adrian recently joined the office to assist the estimators. Even his younger children, 10-year-old Daniella and 16-year-old Oscar Jr., are eagerly contributing.

One of Primavera Grading and Paving’s biggest customers, ViaSun, provided the initial contracts that allowed the contractor to tackle larger street and highway projects in cities like Peoria and Phoenix. The expansion to larger paving projects necessitated a shift to larger, more advanced equipment. Photos courtesy of Volvo

“It’s been interesting working with family,” Oscar said. “Sometimes it gets tough, but it’s great to see them help out today, and it’ll be nice to see them running it all down the road.”

This multi-generational commitment is a testament to Primavera’s enduring strength and future potential.

Primavera’s journey from small patching jobs to significant road projects required more than just ambition.

“We started with parking lots,” Oscar explained. “Then we got an opportunity to get on the roads with one of our biggest customers, ViaSun. They helped us get into that.”

ViaSun provided the initial contracts that allowed Primavera to tackle larger streets and highways in cities like Peoria and Phoenix. This expansion necessitated a shift to larger, more advanced machinery.

“Initially we ran small equipment, but as we grew, we needed bigger machines to match the jobs,” he said.

This is where the relationships with Arnold Machinery Company and Volvo Construction Equipment became crucial.

“With our dealer, one of the biggest things that makes it easier is having partners when we’re out here,” he said. “They have the brand of equipment I like—the equipment I need. One of them is on my rollers. I use Volvo, and I love them.”

On a recent patching job in a residential neighborhood in Peoria, Primavera deployed a fleet of Volvo compactors, including a DD128, a DD25 diesel-powered asphalt compactor and a new DD25 Electric asphalt compactor. The project provided the perfect opportunity to compare the electric model against its diesel counterpart.

Eulojio Barrientes, a seasoned operator for Primavera, noted the critical role these machines played in meeting project specifications.

“Our compactors have to be able to hit hard so I can get the numbers that I need. And so far, we’re hitting them,” he said.

Barrientes, who has operated a range of brands over the years, said his experience with the new DD25 Electric was positive.

“It’s a lot smoother. It’s not as loud and there’s no exhaust,” he said.

The absence of diesel fumes and noise makes for a safer, more comfortable working environment, especially in the residential areas where Primavera often operates.

Oscar has also learned to appreciate the advanced technology available in today’s compactors, particularly Density Direct™ on the Volvo DD128, which displays mat temperatures, pass counts, density readings and more.

“I think having compactors with technology screens like these will take us to the next level. They help us understand the different mixes and how we can get the best results,” Oscar explained.

This real-time data allows operators to work more efficiently and to consistently meet stringent compaction requirements, which are essential for Primavera to maintain their reputation for high-quality results.

The relationship with Volvo dealer Arnold Machinery has been instrumental in Primavera’s success. Jake Zayas, the dealership’s Arizona branch manager, understands the unique demands of the paving business.

“There can be 10 trucks stacked up on an asphalt job, and if the paver or compactor goes down, it shuts the job site down,” he explained.

“That material has a lifespan, and it can cost the contractor a lot of money and reputation. So, with customers like these, if we get a call, it’s our number one priority.”

This commitment to uptime and responsive service has earned Arnold Machinery Oscar’s loyalty.

“Volvo compactors are great, and the service they bring me is what makes me stay with them,” he said. “I can call them any time, and they’ll have the equipment here for me. And if we need service or a part, they’re hands-down better than anything else out there.”

Oscar specifically credits Zayas for lifting Primavera to new heights.

“He really pushes us out here. He either makes me smile or gets me a little bit ticked off because he’s putting me somewhere uncomfortable, but I know it’s something better. It’s for me to grow and that’s what I’m going to keep pushing to, so I appreciate it.”

Primavera’s commitment to excellence extends beyond the equipment. Oscar takes immense pride in his team and his company’s appearance, which directly contributes to their strong reputation in the area.

“What makes us different is that we show up with great, good-looking, clean equipment that we’re proud of,” he said.

In residential areas, the stakes are even higher.

“The compaction has to be perfect on the asphalt. You can’t have bumps or things like that,” Oscar explained. “Especially in neighborhoods, we want to make sure the liability

goes down and make sure the families have smooth surfaces to walk and drive on.”

This dedication to safety and quality ensures a smooth, safe experience for the community.

Oscar has ambitious plans. In the next three to five years, he aims to transition from being a subcontractor to becoming a prime contractor on major projects, which will require more equipment and more crews.

“My goal is to have about seven crews working on that side of our business,” he said, up from their current four.

This vision relies heavily on the continued support of partners like Arnold Machinery and Volvo.

“Going back to Arnold Machinery, they’ll be able to help us out,” he said. “We know they can get us the equipment we need and can rely on.”

But it’s more than compactors he’ll be looking at. Oscar anticipates acquiring more Volvo compactors and even exploring other Volvo products like loaders and excavators for their dirt work down the road.

Primavera Grading and Paving has come a long way. Their journey is a testament to the power of strong partnerships, a commitment to quality and a deeply rooted family ethos. With powerful partners by their side, Oscar and his team are well-positioned to continue paving the way for a successful future.

Justin Zupanc is the compaction product manager for Volvo CE.

BY SANDY LENDER

With the event titled “Blueprints and Breakthroughs” on June 25, 2025, held in conjunction with the National Association of Women in Construction (NAWIC), the Pennsylvania branch of the Women of Asphalt (WofA PA) officially began its mentorship and encouragement of women in the state’s construction industry. Back in 2019, the executive director of the Pennsylvania Asphalt Pavement Association (PAPA), Charles Goodhart, held a panel discussion at the association’s annual conference to determine interest for a WofA branch in the state. The conversation lulled until 2022 when Mary Robbins, PhD, PE, joined PAPA as the director of technical services. She picked up the topic again and the women of Pennsylvania’s asphalt community took their future in hand.

Tammy Mysliwiec of Pine Test Equipment, Inc., Grove City, Pennsylvania, who

serves as the branch’s vice chair, shared that Robbins worked with Donna Sweeney, the PAPA office administrator, to organize a luncheon at the 2023 PAPA annual conference. She explained that Sheila Barkevich, who was at that time the WofA president, was gracious enough to come down and speak to the women.

“After that, Heather Warner of Allan Myers blew Mary’s inbox up about getting an official branch started,” Mysliwiec shared. “Mary then worked with Heather to find a group of women ready to lead the charge. Once the group was identified, a proposal was taken to the PAPA board of directors, and with their blessing, the forms were submitted to the WofA national organization. By December 2023 the PA branch was official!”

Mysliwiec explained that the group saw tremendous support from the PAPA network, which is not something that was prevalent in the early days of her career. “In a

male dominated industry like asphalt, it’s so nice to see women supporting women and mentoring younger members so they don’t have to ‘learn the hard way.’ I spent my first 18 career years in the metal industry and it was a very different story...PAPA brought in a panel of Women of Asphalt members to share at a session at the PAPA annual conference in January 2019 and hosted a lunch at the conference for the Women of Asphalt in January of 2023. The level of engagement and attendance at the luncheon really helped solidify the interest was there and the timing was right.”

The group’s charter was signed in December 2023 and its first meeting as an official branch was held in January 2024. Many events have been held in conjunction with PAPA, such as the annual conference each January, regional technical meetings and an environmental seminar in the spring.

The current leadership of the WofA PA branch has this structure:

• Heather Warner, Performance and Sustainability Manager at Allan Myers = Chair

• Tammy Mysliwiec, Sales & Marketing Manager at Pine Instruments = Vice Chair

• Sheri Eldredge, QC Central Lab and Systems Analyst Manager at Lindy Paving = Secretary

• Donna Sweeney, PAPA Office Administrator = Treasurer

• Kristin Crawford, Marketing Communications Manager at FORTA LLC = Communications Chair

• Mary Robbins, PhD, PE, Director of Technical Services at PAPA = PAPA Liaison

These women have clearly defined roles and goals, such as the chair serving as a branch liaison to the national organization and facilitating meetings with agendas and establishing annual goals for the branch. The vice chair prepares pre-event forms and submits those to the national WofA. She performs other duties as delegated by the chair.

One of the offices that’s unique to the WofA PA is that of a communications chair. In this role, Crawford is able to assist the branch with more than outreach. She handles the design of marketing materials and communicates branch initiatives through email and social media.

She also spoke of that outreach in terms of its value to the industry. “What really drew me to Women of Asphalt—both nationally and here in Pennsylvania—was their strong mission to lift up women’s voices in an industry that’s often male-dominated,” Crawford shared. “I’ve always believed that representation matters, and WofA doesn’t just talk about it. They do something about it with real programs that promote visibility, inclusion, and growth.”

Like Crawford, Eldredge, the branch secretary, looks to impact change by inspiring women and paving the way for women to be successful in the asphalt industry.

With the women of the Pennsylvania asphalt community leading the way, the women of that region have mentors to encourage and lift them in their careers going forward.

“After nearly three decades in the asphalt industry, I’ve seen a lot of change—but I’ve also lived through the challenges that come with being a woman in a space where we were once few and far between,” Warner shared. “Early in my career, I faced resistance—not just to my presence, but to my voice, my ideas and my potential. It was a

time when you had to work twice as hard to be seen and heard, and even then, acceptance wasn’t guaranteed. That’s why Women of Asphalt resonates so deeply with me. It’s more than an organization—it’s a movement that validates the experiences many of us have had and creates a space where women are not only welcomed but celebrated. It

brings visibility to our contributions, fosters mentorship, and builds a network of support that I wish had existed when I was starting out. It’s important because it challenges the status quo, encourages diversity of thought, and ensures that the next generation of women in this industry won’t have to fight the same battles alone.”

Steep inclines with hardly any room to maneuver and darkness made up the conditions for rehabilitating the surface course in front of Germany’s most famous castle. In order not to disrupt visitor operations, work could only be carried out at night. The contractor opted for the Vögele SUPER 1800-5 X paver and new Dash 5 technologies such as the integrated Light Package Plus.

Neuschwanstein Castle is a UNESCO World Heritage Site and arguably the most famous tourist attraction in Germany. A good portion of the approximately 1.4 million visitors each year make the climb to the castle by horse-drawn carriage. This is because, apart from emergency and maintenance vehicles, only they are allowed to drive on the steep, winding road. However, the horses’ iron-shod hooves put a unique strain on the asphalt. (See a similar situation with a mix design response in “Fuel-Resistant Asphalt Binder Resists Asphalt Breakdown in St. Augustine” from the June 2019 AsphaltPro issue.)

The Bavarian Palace Administration therefore commissioned Geiger Hoch- und Tiefbau GmbH & Co. KG to rehabilitate the sur-

face course along the entire length of 1.3 km, which features a winding, uphill road leading to the castle.

First, around 7,000 m² of asphalt surface was milled off using a W 100 CFi Wirtgen cold milling machine.

This was followed by paving with the SUPER 1800-5 X. In three nights, the paver laid approximately 800 tonnes of surface course material in a width varying from 5 to 6 m and a thickness of around 4 cm.

The assignment presented the team with another challenge: To minimize disruption to visitors, work had to be carried out at night. The team used the Light Package Plus lighting. This package, offered by Vögele for all Dash 5 pavers, includes LED lighting integrated into the hardtop and crossbar of the control panel, which illuminates the driver’s workstation as well as all service points accessible from the platform. In addition, the tow point rams are equipped with LEDs. Three LED spotlights, which can be flexibly positioned thanks to magnetic mounts, illuminate any desired work area, such as the side plate of the screed or the hopper wall.

“With Light Package Plus, we were able to illuminate all relevant paver and work areas in a targeted manner, thereby ensuring maximum safety, even in the dark.”—Stefan Keller, senior site manager, Geiger Hoch- und Tiefbau Gmbh & Co. KG

LEFT: Given the steep incline and twists and turns, the high traction of the crawler track and the new SmartWheel steering system came in handy. The rotary control on the ErgoPlus 5 paver operator’s console enables particularly sensitive control. RIGHT: In combination with the latest generation of the AB 600 extending screed, the SUPER 1800-5 X was ready to give a relatively quiet paving performance.

THE LIGHT OUTPUT OF THE INTEGRATED LED SPOTLIGHTS IS COMPARABLE TO THAT OF LIGHT BALLOONS, BUT THEY DO NOT NEED TO BE TRANSPORTED OR ASSEMBLED SEPARATELY.

“THIS SAVED US A LOT OF SETUP TIME HERE ON THE JOB SITE,” SAID SENIOR SITE MANAGER STEFAN KELLER.

Light Package Plus, which was used during paving at Neuschwanstein Castle, features powerful LEDs integrated into a specially developed hardtop extension. They are designed to ensure optimum illumination across a paving width of up to 10 m and up to 4 m behind the screed. The light output of the integrated LED spotlights is comparable to that of light balloons, but they do not need to be transported or assembled separately.

“This saved us a lot of setup time here on the job site,” said Senior Site Manager Stefan Keller. “With Light Package Plus, we were able to illuminate all relevant paver and work areas in a targeted manner, thereby ensuring maximum safety even in the dark.”

In combination with the AB 600 Dash 5 extending screed and its compacting systems of tamper and vibrators, the paver also achieved high pre-compacting. All components that come into contact with the material are constantly heated, which ensured a homogeneous surface structure. Compared to the previous model, the new extending screed can be heated more efficiently and is quieter in operation thanks to structural optimizations. Together with the noise-optimized drive concept of the SUPER 1800-5 X, the paving team was able to ensure that nighttime operation was as quiet as possible.

• Project: Pavement rehabilitation of the access road to Neuschwanstein Castle

• Location: Füssen, Bavaria

• Paving width: 5–6 m

• Paving distance: 1.3 km

• Surface course layer thickness: 4–5 cm

• Paving speed: 3 m/min

You can achieve precision paving when everyone has what they need, safely at their fingertips

BY SANDY LENDER AND SARAH REDOHL

OOnce the crew gets the new paver to the job, each person has his or her preferred way to place the mat correctly behind it. Assuming everyone is trained on the best practices to achieve a smooth and well-compacted finish, let’s look at some ways to implement those practices in the most efficient and comfortable manner. Let’s look at ways to augment the paver delivered from the dealership or auction house.

We don’t want to imply original equipment manufacturer (OEM) factories don’t build something powerful and smart. Every paver out there has been designed to build specific pavement systems from golf cart paths to driveways to parking lots to city streets to airport pavements to highways. These machines are, after all, the original 3D printers.

The people working on and around these pieces of equipment have their preferences for how auxiliary equipment should be handled, stored and used. Those same people need a safe, uncluttered workspace where they can access an increasing number of tools and tablets during the shift.

We asked our social media followers how they augment the paver, and a variety of responses came in focusing on convenience. One respondent shared they place a cooler full of iced drinks on the paver deck. Blayze Oyster wrote, “We like to build custom racks for our pavers for shovels, lutes, brooms, depth sticks, etc. Makes it a lot more efficient to have all tools on board with us.”

That need to organize hand tools is a common theme and one contractor in the Northeast took it to the next level through collaboration and communication with the OEM directly.

One of the more notable collaborations that took place in the paving industry a few years ago involved Raised on Blacktop, Danbury, Connecticut, and LeeBoy, Lincolnton, North Carolina. The two entities worked together to trick out a special edition Raised on Blacktop paver, which was available as of February 2021.

Bill Stanley, the owner of American Pavement Specialists, Danbury, and partner in Raised on Blacktop, explained they’ve worked with LeeBoy, Mauldin, X-Broom, Wirtgen Group and others to modify and adjust what he defines as “creature comforts” of equipment for the contractor’s benefit.

“I think my son said it best when he said he spends more hours a day on the paving machine than he does in bed,” Stanley shared.

With this truism across the paving industry, it was important to the Stanleys to get the creature comforts right.

“We didn’t re-engineer anything,” he said. Instead, the family offered ideas that brought an existing machine up a notch, like adding a complete tool-carrying kit to the LeeBoy 8520B commercial paver. “When you’re paving, especially if you’re doing large commercial areas, a lot of tools get carried on the paving machine. We designed something where we have a secure spot for everything that we need, whether it’s our paint cans, our tape measures, our razors that we use to scrape our tools with, additional shovel holders and rake holders. So, everything has a secure location.”

This ensures hand tools are within the workers’ grasp at all times and don’t fall off the machine as it moves around the project. “We did a cell phone holder. We did a USB port because the operator can track the trucks. We did a cup holder.”

Another enhancement the Stanleys suggested for the Raised on Blacktop edition of the 8520B was a lighting package. “We also did a lighting package with safety lighting, putting LED lighting in areas that were probably not known to the manufacturer that needed it, like inside the tunnel to the paver. We needed lights along the back of the screed, we needed lighting in front of the paver.”

Stanley explained that the collaboration involved sitting down with the LeeBoy team to communicate what they were looking for openly and kindly. “When we sat down with the engineers with LeeBoy, the first thing I told them was, you know, we’re not here to redesign your paver. Actually, we’ve owned 20 of them. We love your paver. These are just things that the operator needs.”

LEFT: This left-hand screed operator pedestal includes modifications the T&K Asphalt Services Inc. crew in Whitman, Massachusetts, has made. They’ve added a basket to hold the work order and truck delivery slips. They’ve also attached a j-bracket where they keep the spool of string for lining out jobs. Photo courtesy of John Ball, Top Quality Paving & Training, Manchester, New Hampshire RIGHT: This is a convex mirror affixed to a light bracket. The team from APC, Golden, Colorado, has used a u-joint, which allows them to move the mirror forward and back, as needed. They’ve put one on either side of the hopper. The knob atop the u-joint allows them to loosen and tighten the grip on the mirror’s handle for ease of adjustment. The genius of this mirror placement is it gives the paver operator a better view of the entire material movement process from either operator platform. Photo courtesy of Ball

Pavers aren’t the only machines American Pavement Specialists and Raised on Blacktop work to improve in the industry. The Stanleys worked with Trout River Industries to turn two live bottom trailers into trucks that could auger asphalt mix into trenches. Check out the quick story at https://theasphaltpro.com/articles/partnering-on-the-perfect-truck/.

Photo courtesy of APS

Now that LeeBoy has offered these augmentations since 2021, Stanley has seen similar changes with other OEMs’ offerings. As he walks the floor at events like World of Asphalt, he notices other paving equipment OEMs have adopted cup holders, tool-carrying cages and other “creature comfort” elements on their equipment as well. It’s a positive development to see as OEMs have taken the operator’s work environment into consideration when designing and updating equipment.

Frank Foore, the proprietor of PaverLaser.com, formerly Asphalt Pokers, headquartered in Akron, Ohio, also came up with an aftermarket item to help the paving crew (seen on page 28). He developed the asphalt paver laser for his own use in paving a consistent, straight line a few seasons ago. It’s a device that attaches to the asphalt paver to “point” out a line for the operator to follow.

or

This PVC snorkel tube, with its cap tethered by a string, is about 4 feet long to house the smart levels. In these pictures, you can see how far it reaches beyond the

“I made this for the paver to follow or else you’re painting lines all day,” Foore said. “We’ve had them for a couple years now.”

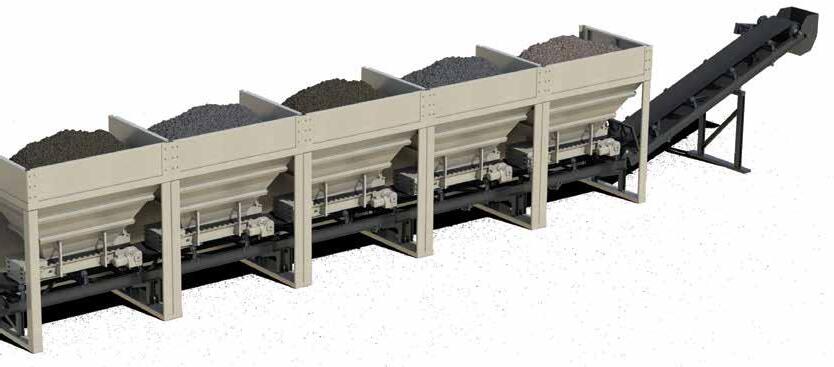

Silo cone opening is 36” wide for ef cient material ow.

Safety gates on all silos, including long-term and standard options.

Recessed tub liners prevent silo wall wear, avoiding bulging issues.

Silo bin top batchers feature secure long-term seals.

Recessed wireways on silo tops eliminate trip hazards.

Meeker drag conveyors are larger, allowing slower chain speed and reduced wear.

Hydraulic chain adjustment on slats maintains asphalt entry point, minimizing wear.

Visual chain tension indicators on Meeker slat conveyors aid operators.

All silos prewired with top and bottom junction boxes.

A plastic water tank holds 250 gallons of water with a small amount of dishwashing soap as a surfactant and nestles between the engine hood and safety railing. Husky nylon cables secure it in place on this Volvo 7170, rubber-tired paver. Typically, the steering tires would pick up tack and bring up mix. Laying a 7/8-inch mat means any pickup would be a problem. Using the spray system from a roller, the water is delivered via brass pipe, which is attached to 60-pound magnets on the underside of the hopper. The magnets saved the mechanic from drilling into the hopper or welding this setup together. Clamps hold the tubes. Notice the 30-degree angle of the nozzles direct the water onto the drive wheels only. For this job, you can see the Ajax Paving crew is using a shut-off valve on the hose coming out of the tank to ensure proper water control. The setup includes a pump. Photos courtesy of Ball

To keep the putty knife, stringline and other light-weight items within easy reach, this crew uses 60-pound magnets on the side of the paver and tow arm. This magnet holds the putty knife, which the laborers can grab to clean the lute in a hurry, then get back to business. There’s no looking around, fumbling with pockets while wearing protective gloves or trying to borrow a tool off a crewmate. This is organized and clean. Photo courtesy of Ball

Each paver laser includes a 12-volt plug and a DC plug, so the crew can select how best to power it. The device also comes with either a magnetic mounting bracket or clamp-style mount, depending on which you need for your model of paver. It also helps to reduce trip hazards, contributing to a safer job site. It’s even equipped with a builtin cooling fan so it can handle the intense heat of paving operations.

In these pages, we showcase some tried-and-true and new-to-you ideas for augmenting the paver on your job site. You probably have some ideas of your own to share with the industry. Maybe you have a photo of the brackets you’ve built to hold smart levels in place behind the tractor. Maybe you have a better way to cook lunch on the screed. Let’s see what kind of “better mousetrap” you’ve built to get a precise paving job.

That’s why we bring more than just tools, we bring the fire.

From retrofits and relocations to maintenance, parts, and plant upgrades, Motion Engineering keeps your plant running hot and smooth. With over 30 years in the asphalt industry, we’ve seen it all and solved it all.

Let’s talk about how to make your next project faster, cleaner, and more efficient.

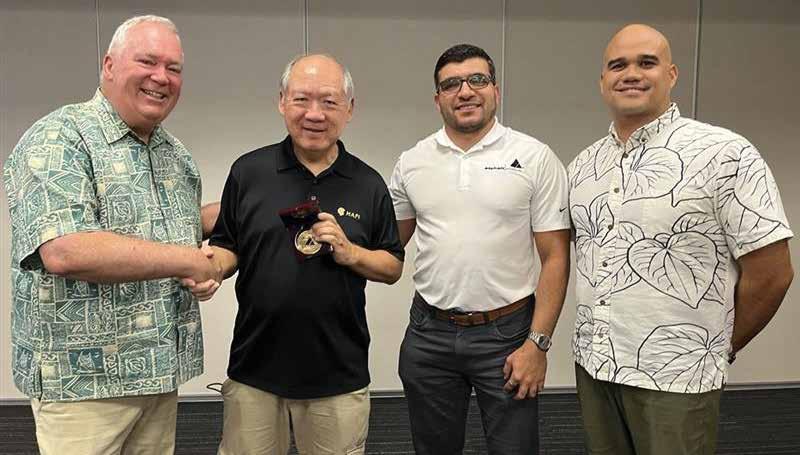

Director of Engineering and Training Danny Geirhart (at left) and Western U.S. Regional Engineer Jhony Habbouche presented outgoing HAPI Executive Director Jon Young (between them) with the rare and prestigious Asphalt Institute Medallion, honoring his quiet yet significant contributions to the asphalt industry. Also photographed is incoming HAPI Executive Director Brandon Lima (at right). Photo courtesy of Asphalt Institute

Changes in Hawaii leadership highlight industry’s cooperative nature

BY SANDY LENDER

WWhen Jon Young joined the asphalt industry, he brought with him a civil engineering background. He had served as a senior project manager at Belt Collins Hawaii (an engineering design consulting firm) and as a site design and construction manager at Gentry Homes. His responsibilities in those positions, as well as others, paved the way for communication among the different stakeholders in the Hawaii Asphalt Paving Industry (HAPI) as he took on the role of the group’s executive director in 2011.

“My diverse background in both the private and public sectors has been integral to my current role as executive director,” Young shared. “Over the years, I’ve had the opportunity to work in various settings—from being a sole proprietor and working at a small, three-person engineering design office to managing projects at large corporations and family-owned businesses. I’ve worked as a consultant, a client, a construction manager and a senior project manager.

“All these roles taught me the importance of collaboration, flexibility and how to view situations from multiple angles. Whether I’m dealing with an engineer, contractor or client, I can empathize with

their priorities and find common ground. This holistic approach has been invaluable in navigating the complexities of the Hawaii asphalt industry, where the key to success is understanding the unique challenges faced by each group and creating solutions that benefit everyone involved.”

Collaboration turned out to be a core element in Young’s leadership at HAPI. One of the exemplary programs he instituted for the HAPI membership is the HAPI Shorts lunch time lessons. Todd Mansell, a product application specialist for Caterpillar Global Paving is one of the recurring instructors for HAPI Shorts.

“I’ve had the greatest pleasure of working with Jon over most of his time at HAPI,” Mansell shared. “After first meeting at a NAPA meeting over 10 years ago, our working relationship also became a personal friendship as we soon found that we could start talking about planning for a HAPI Shorts learning session, then talk for hours and end up on another topic completely.”

Young described the HAPI Shorts in detail. “HAPI Shorts lunch time lessons launched in July 2020 to satisfy people’s appetite for asphalt knowledge,” Young shared. “Topics range from general subjects such as open-graded mixes, stone matrix asphalt, and specifying asphalt mixtures—which I present myself—to specialty topics covered by industry leaders, such as modified binder, VRAM, and mat defects. We also include non-industry topics like public speaking tips and career insights for effective leadership. Two or three new topics are added each year; this year, determining in-place density was added.

“We’ve conducted about 170 sessions attended by over 1,450 participants—not just from Hawaii, but from states like California, Florida and New York, and countries including Serbia, Canada, Japan, India and Saudi Arabia.”

Young shared that Milan Marinković, a professor at the Faculty of Technical Sciences Novi Sad in Serbia, has attended nearly every HAPI Shorts session since mid-June 2022, “Use of Recycled Materials in Pavement.” As of the end of August 2025, he had attended 83 sessions.

A note from Marinković: “There are several reasons why I have attended so many HAPI Shorts. I found out about HAPI Shorts through LinkedIn post because the topic for 18.06.2022 was related to my Ph.D. Thesis...from week to week I liked the themes and concept of HAPI shorts. Other reasons are related to Executive Director of HAPI Jon Young. Jon possesses such energy that it is unbelievable... for someone his age. He is very dedicated to convey his knowledge and experience in an interesting way. I learned so much from him not only about professional things but about the way of life. I can safely say that he has become a good friend of mine for life.”

“The biggest challenge has been keeping the sessions engaging for everyone—from industry newcomers to seasoned professionals,” Young contiued. “The most rewarding part is seeing participants respond with enthusiasm and appreciation, whether it’s a technical takeaway or a new skill for professional growth.”

Mansell spoke of other education Young augmented. “Jon is very open-minded and always willing to listen and learn, even though he is very experienced and knowledgeable himself. I believe he really advanced the HAPI Newsletter into the informative publication that it is today, along with really promoting education and learning opportunities for HAPI members in Hawaii and beyond.”

When Young accepted the role at HAPI, he hadn’t fallen in love with the industry yet, but he explained how that gradually happened.

“When I first considered taking the job 14 years ago, I asked myself, ‘Could I learn to love asphalt?’ I told myself I could— and I was right. A big part of that love came from the people I met along the way. I was inspired by engineers at the Asphalt Institute, whose passion and professionalism were contagious. My first NAPA annual meeting in 2012 left a lasting impression. Members were welcoming, excited and inclusive. One of my favorite experiences was the first-time attendees’ event, where

California Asphalt Pavement Association Executive Director Russell Snyder shared a moment with Young during the winter state asphalt pavement association meeting in Hawaii, presenting him with an award for his “quiet contributions” that have helped elevate the industry. Photo courtesy of Colorado Asphalt Pavement Association

icebreaker games and introductions instantly made me feel part of the community.”

The state asphalt pavement association (SAPA) group also played a key role for Young. “My first summer meeting in Texas won me over. Everyone was supportive and observing how seasoned executives helped newcomers feel at ease taught me a lot about the collaborative spirit of this industry. It wasn’t a single moment but a gradual realization. About two or three years in, I understood that I truly love this industry. Working alongside dedicated, passionate professionals—and seeing the tangible impact of our work on communities—made me fall in love with asphalt: its challenges, its people and its purpose.”

Young shared that the people were what he truly appreciated about the industry.

“Colleagues, engineers, contractors, agency staff, and volunteers alike bring professionalism, generosity, and a willingness to help others succeed. Even when challenges arise, there’s a shared commitment to getting things right. The mentorship, collaboration and camaraderie I’ve experienced have been as meaningful as the work itself—and that’s what makes this industry so rewarding.”

That feeling of camaraderie is shared among his colleagues. Reed Ryan, the president of Asphalt Institute, Lexington, Kentucky, has served in SAPA alongside Young and spoke highly of his mentor and friend. Ryan formed the Utah Asphalt Pavement Association (UAPA) in 2012 and served as its executive director for 12 years.

“Where the mentorship comes in is, Jon helped me when I was asked to start UAPA. Jon was the first to welcome me with a handshake and offer guidance. His demeanor is very welcoming and open. From there, our professional relationship and friendship blossomed.”

Ryan also spoke of Young’s collaborative spirit. “He brought some Hawaii DOT members to UDOT.” The DOT personnel were able to share best practices and participate in an information exchange that proved beneficial for both parties.

When it came to the SAPA group, Young again shared his collaborative spirit and passion for the industry by stepping up to handle tasks that his previous experience made him more than qualified to take on. “Jon carried the organizational torch to keep SAPA working and keep us all feeling like a cohesive unit,” Ryan said. “He was good at keeping the books in place and keeping up with the Facebook page. He was the best person for all of that because of his nature.”

Young may not have realized it until it was time to retire, but his calm and persistent work behind the scenes was noticed by his peers. He spoke of a moment from the SAPA meeting in Hawaii.

“Towards the end of the SAPA winter meeting this past January [2025], our president, Russell Snyder, called me up to be recognized,” Young said. “I received an award for my ‘quiet contributions’ that have helped elevate the industry. They noted the work I’ve done behind the scenes on initiatives that strengthened SAPA as a whole and benefited each state association individually. Honestly, it was a humbling experience that left me nearly speechless. Being acknowledged by peers I deeply respect, for work done quietly and without seeking the spotlight, was a moment I’ll never forget.”

The SAPA organization wasn’t the only one seeing Young’s quiet, persistent work.

During an airfield asphalt certificate program (AACP) inspector training session for HAPI, members of the Asphalt Institute had to wrangle him away from a business call and back to the meeting room to present him with another award. “The next thing I knew, I was being called to the front of the room. Danny [Geirhart], Jhony [Habbouche] and Brandon [Lima] began saying incredibly kind words about me, and then they presented me with a medallion. I was in such shock that I can’t recall everything they said—but I clearly remember feeling the heart behind their words.”

“Jon brought more than expertise to his role,” said Jayanth Kumar Rayapeddi Kumar, P.E., quality control manager for Jas. W. Glover, Ltd. “He brought genuine care for people and the future of the asphalt industry. His steady leadership, thoughtful approach, willingness to listen to diverse voices and deep commitment to helping others benefited everyone. His impact will be felt for years to come.”

Ryan used the word “persistence” to talk about Young. “Jon’s kind of persistence was stern, yet it was empathetic at the same time. He never stopped trying to work toward something better. Year after year, meeting after meeting, he kept working at it.”

Lima’s admiration for Young hinted at that persistence as well. “Jon has always been someone who has provided new perspectives during my time in the industry. He is not one to shy away from providing feedback and that has been tremendous in helping me develop my leadership skills over the years. That feedback coupled with encouragement has gotten me to where I am today. He is a relentless supporter whether it’s project related or just industry related information you may be interested in. The guy just doesn’t stop.”

“I will really miss working with Jon and I would like to congratulate him on a very successful tenure with HAPI, and for leaving the organization better off,” Mansell said. “I’m fully confident that Brandon Lima will continue Jon’s work in advancing the asphalt industry in Hawaii.”

With Young’s foundation and Lima’s skills coming in to build upon it, HAPI has a bright future.

“Brandon’s technical knowledge in materials and quality assurance is a big asset for HAPI,” Young shared. “His expertise helps ensure that our members have the right guidance and information to maintain high standards in their work. Where his focus is on testing and quality assurance, my background has been more in design, project management and construction management—planning, coordination and seeing projects through from start to finish.”

Lima’s background in the asphalt community began in 2011 with Grace Pacific LLC as a QC technician; he finished his time there as HMA plant/quarry QC supervisor (2020-2023). He took on the role of bituminous laboratory supervising technician with HDOT in October of 2023. Lima shared his philosophy of bringing that QC/QA experience to the executive director role.

“Quality is often the intersection where agencies and contractors meet,” Lima shared. “Sometimes traffic flows smoothly, and other times it leads to gridlock. My time at HDOT reinforced how essential consis-

tency, transparency and data-driven decision-making are to keeping that intersection clear and functional. Ultimately, when both sides commit to partnering, it leads to stronger trust and better quality outcomes for the traveling public.”

Lima’s approach is already welcomed. “Brandon brings a warm, approachable presence to the role and has quickly earned the respect of those in the industry,” Kumar said. “With big shoes to fill, his enthusiasm and thoughtful leadership is exactly what the industry needs for the road ahead.”

“Together, our experiences complement each other,” Young said. “Brandon brings a detailed, technical perspective on quality and testing, while my experience provides a broader view of design, specifications and project execution. This combination allows HAPI to be a comprehensive resource for our members and the industry, supporting both the technical and practical sides of asphalt construction.”

They’ve already partnered on a successful project. “During my time at HDOT, I had the privilege of assisting Jon with the kickoff event for the WoA Hawaii branch, which included a tour of the HDOT Central Lab’s facilities for asphalt mixtures, aggregates and binder/emulsion,” Lima said. “We not only reached full capacity for the event, but also had to create a waiting list. It was inspiring to see so many women eager to learn more about asphalt materials.”

At this time, Young has volunteered to remain with the HAPI organization in a part-time role as senior advisor to the executive director while assisting Lima in getting up to speed with the many tasks and responsibilities of the executive directorship. “He’s in charge,” Young said. “I’m just in the background. I’m still here and they [HAPI members] can call me until they have full confidence in Brandon and until he’s comfortable answering all their questions and talking the language of consultants.”

Lima’s already talking the language of contractors when it comes to Hawaii’s workforce. “HAPI Shorts has become synonymous with Jon Young,” Lima shared. “Given Hawaii's unique geographical position, this program has significantly facilitated connections between our local industry and asphalt professionals nationwide. Our industry, like many others, is experiencing a significant transition. With the wave of retirements, much generational knowledge is being lost, while fresh faces are joining the field. This influx creates a critical need for fundamental training, which I aim to address through HAPI shorts in the coming year.”

As the duo brings Lima into the fold, Young is looking forward to more time for himself and his wife.

“Most people know me for my career, but there’s more to life than work,” Young said. “In retirement, I’m diving back into piano—online lessons, new arrangements and maybe even composing songs like I did in high school and college. I’m also capturing memories from my 60-plus years in three books: Fond Memories, Quiet Skills, and Philosophies. Mostly for myself, though maybe one day they’ll be published—or turned into workshops and webinars.

“But what I’m most excited about is having more time to plan surprises for my wife. Some are small, just to make her smile. Some are grand, like the music video for our 37th wedding anniversary based on a song I wrote for her when we first met. Retirement, for me, is about creativity, reflection and the little—and sometimes big—moments that make life joyful. It’s a chance to slow down, explore passions I haven’t had time for, and focus on the people and experiences that truly matter.”

We’ve been designing and manufacturing custom mixing solutions in Tennessee for nearly 40

CConstruction Angels, Inc., headquartered in Palm Beach Gardens, Florida, is a 501(c)3 non-profit organization that provides immediate financial assistance and grief counseling to the children (19 years and younger) and spouse left behind when a construction worker is involved in an accidental work-related fatality. We offer construction scholarship opportunities to qualified applicants and additional scholarships to surviving children of a fallen worker. The charity began in Lighthouse Point, Florida, in 2011 and as of press time supports families in 33 states.

As we continue to grow in helping families across the USA, companies and their employees are showing more and more interest in supporting our fundraisers. Every dollar raised helps to get one step closer to ensuring no construction family has to face loss alone. Many of our fundraisers sell out, with many new and growing events coming online. Just by attending one of our events, supporting us on social media, communicating with others about our charity, or sponsoring an event at the state lev-

BY KRISTI RONYAK

el, you are a part of helping our charity help construction families in the industry.

We are enthusiastic about sharing our upcoming national golf fundraiser, to be held Monday, March 2, 2026, the day before CONEXPO-CON/AGG opens in Las Vegas.