Motorsport Mix

• AP's lowdown on Maui mill-and-fill

• More tips for a smooth takeoff

• BMD reality limits on Hwy 14

• AP's lowdown on Maui mill-and-fill

• More tips for a smooth takeoff

• BMD reality limits on Hwy 14

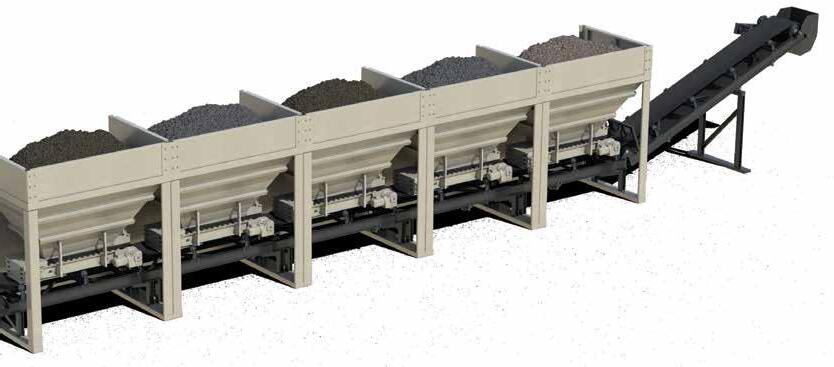

Astec paves the way for sustainable, innovative asphalt plants. The new IntelliPac Moisture System is a revolutionary solution that integrates seamlessly with Astec control systems. This provides unparalleled, real-time visibility into virgin aggregate moisture content. IntelliPac empowers operators to optimize mix design, minimize energy consumption, and reduce environmental impact. With Astec, you get superior asphalt production – better for the environment, better for your business.

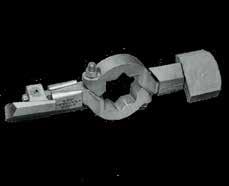

The reverse air baghouse engineered to lead your plant to peak performance.

The Dust Pilot reverse air baghouse is built for high-capacity operations with precision airflow control and fewer moving parts, minimizing maintenance. Its robust, customizable design ensures cleaner air, enhanced plant performance, and compliance with environmental standards. Available in multiple sizes, the Dust Pilot delivers reliable and effective dust control tailored to your plant's needs.

6 – The Extreme Resilience of the Asphalt Industry By Sandy Lender

8 –Make Your Jobsite 7 Times Safer By Sandy Lender

SMARTS

10 – Craft Estimates That Close the Deal By Bill Stanley

14 – Start Paving Off Right: Part 1 By Benjamin Everett

MAINTENANCE

20 – Maui Mill-and-Fill Wraps Early By Sandy Lender

OF ASPHALT

24 – Biscuits Help Build the WofA Workforce in South Carolina

The South Carolina Women of Asphalt branch uses a novel approach to lead and inspire women in the asphalt industry through its Building Community with Biscuits program By Sandy Lender

SNAPSHOT

44 – International President From Eurobitume

GALLERY

46 – Through Storms of Production By Sandy Lender

TECH

57 – Track Compliance with PAGA Reform By Andrew Fowler OFF THE MAT

58 – Suicide Prevention as a Construction Health and Safety Priority By Frank King

28 – Paving the Future for Speed Sunland’s pioneering precise work on APEX Motorsports track By Immanuel Martinez

34 – Increasing BMD Efficacy with Technology: Part 2

A look at balanced mix design and intelligent systems to minimize human error and increase pavement performance on a North Dakota test project By Sandy Lender

40 – Focus on Performance Daigle Improves Fleet Efficiency By Evan Trigg

ON THE COVER Will Morrison and Matt King of Solterra Materials were on the team supplying the high-performance PMA for Sunland Asphalt’s APEX Motorsports track in Arizona. See related story on page 28. Photo courtesy of Sunland Asphalt & Construction, LLC

Prior to our current website archives, AsphaltPro Magazine prepared an article with Stansteel Hotmix Parts & Service discussing the mechanics of building hot-mix asphalt (HMA) production infrastructure that could withstand violent lateral forces. While combining information about natural disaster impacts on production for this issue (see the intro to the product gallery on page 46), I was reminded of visiting Stansteel’s facility in Louisville a couple summers ago and seeing components ultimately destined for a site in California.

The iron that day took me back to the old conversation. The concept is taking me back again.

We don’t talk about our iron’s resilience as often as we talk about our end product’s resilience. It’s worth mentioning, now that we’re entering the second month of hurricane season, the asphalt industry has taken the responsibility of sustainability seriously for decades. We’ve taken our infrastructure and product resilience seriously before it was mandated that we do so, and I daresay we’ll continue to take it seriously as cooler heads offer sensible solutions to permitting and progressing projects to completion.

Check out this liquid tank article that includes adherence to earthquake-resilient regs: https://theasphaltpro.com/ articles/do-your-ac-tankinspection-procedures-passthe-test/

Indulge me while I share; I moved to Southwest Florida about a week before Hurricane Charley nailed the community. That was the year four hurricanes (five storms) hit the state in six weeks, offering me quite the “welcome.” Yes, 2004 was tumultuous weather-wise but each year since, as hurricane season has approached, I’ve heard forecasters share the doom and gloom of a planet on the verge of collapse because humans have the audacity to drive cars on highways before engineering a plug for Mount Etna (and others).

Maybe I’m tempting fate to suggest: the east coast of the USA is still here. As is the asphalt paving industry that works to safeguard the environment and the economy.

The goals of safeguarding the environment while building the economy can and do go hand in hand, even when non-elected staffers lose the ability to mandate egregious

rules around it all. As we were preparing this issue for press, the House of Representatives had passed HR1, which, if ratified, will reinstate the 100% bonus depreciation and the increase in Section 179 expensing levels.

Something I didn't see industry associations talking about at press time were Sections 42111 and 42112, regarding the rescission of greenhouse gas emission (GHG) corporate reporting and environmental product declaration (EPD) assistance. HR1 is set to repeal Section 60112 of Public Law 117-169. If ratified, it will rescind the unobligated funds that were allocated under Section 60112 of that law. It will terminate the program and remove remaining financial support.

Is this devastating? It doesn’t have to be.

There are members of the asphalt industry who have been participating in product category rule (PCR) development and EPD creation because it is for the good of the industry and environment to understand a product’s complete carbon footprint—thus impact— on the world. See my May note for more on this concept. But keep in mind, we can’t control what we haven’t measured.

By instituting EPDs, our industry has created a metric to measure and control. But we don’t need a non-elected bureaucratic agency mandating how we measure and control our product.

As evidenced by the baghouses at asphalt plants, fume extraction systems on pavers and the silica dust controls on milling machines, our industry has been taking care of business, workers and the environment for decades. I bet we continue working as good stewards of the air, land and water after a Big Beautiful Bill gives us permission to do so as responsible humans and not while under duress.

Whether you’re installing earthquake- and flood-resilient components at your HMA plant, designing a flexible asphalt pavement that won’t require new materials for 30+ years, or using intelligent compaction to seal up a perfect density for that long-lived pavement, you’re participating in an industry that has a lengthening track record for environmental excellence and sustainability. You’re engaged in an industry that cares for its communities and functions as a steward of the air, land and water around it. You’re among upstanding people who are resilient themselves.

Stay Safe,

Sandy Lender

July 2025 • Vol. 18 No. 9

602 W. Morrison, Box 6a Fayette, MO 65248 (660) 728-5007 • www.theasphaltpro.com

GROUP PUBLISHER

Chris Harrison chris@ theasphaltpro.com

EDITOR

Sandy Lender sandy@theasphaltpro.com (239) 272-8613

DIGITAL EDITOR

Sarah Redohl sarah@theasphaltpro.com (573) 355-9775

MEDIA SALES

Cara Owings cara@theasphaltpro.com (660) 537-0778

ART DIRECTOR

Kristin Branscom

BUSINESS MANAGER

Susan Campbell (660) 728-5007

AsphaltPro is published 11 times per year. Writers expressing views in AsphaltPro Magazine or on the AsphaltPro website are professionals with sound, professional advice. Views expressed herein are not necessarily the same as the views of AsphaltPro, thus producers/contractors are still encouraged to use best practices when implementing new advice.

SUBSCRIPTION POLICY: Individual subscriptions are available without charge in the United Sates, Canada and Mexico to qualified individuals.

One year subscription to non-qualifying Individuals: United States $90, Canada and Mexico $125.00. For the international digital edition, visit theasphaltpro.com/subscribe/

BY SANDY LENDER

The Associated Builders and Contractors (ABC) reported in May that construction professionals can safeguard workers with best practices in the health and safety arena. That might sound like common sense, but there’s proof now quantifying what safety directors have known for years. Let’s take a closer look at the report titled 2025 Health and Safety Performance Report.

ABC published the annual guide to construction jobsite health and safety best practices ahead of Construction Safety Week 2025 to support an industrywide call to action for safer jobsites and a stronger safety culture. Within the report, ABC member companies that participate in ABC’s STEP® Health and Safety Management System, provide data and tools for improving safety practices across the industry.

STEP was established in 1989. It’s a program that provides contractors and suppliers with a no-cost framework for measuring health and safety data and benchmarking with peers in the industry. According to ABC, the 2025 report discussed herein showed top-performing ABC members participating in STEP achieved incident rates 658% safer than the U.S. Bureau of Labor Statistics construction industry average, reducing total recordable incident rates by 85%.

The 2025 report detailed research from more than 1 billion work hours completed by participants in the construction, heavy construction, civil engineering and specialty trades in 2024. Here are the five foundational best practices these safety leaders have in common:

• They offer new-hire safety orientation: Companies that conduct an in-depth indoctrination of new employees into health and safety culture, systems and processes experience Total Recordable Incident Rates, or TRIR, 52% lower than companies that limit their orientations to basic health and safety compliance topics. Additionally, Days Away, Restricted or Transferred, or DART, rates are reduced by 56%.

Sign up for the free quick-tip email from AsphaltPro Magazine in time for your next tailgate talk!

• They offer substance-abuse prevention programs: Robust substance abuse prevention programs and policies with provisions for drug and alcohol testing where permitted lead to a 52% reduction in TRIR and a 55% reduction in DART rates.

• They offer more frequent toolbox talks: Companies that conduct daily, 15-to-30-minute toolbox talks reduce TRIR rates by 78% and DART rates by 79% compared to companies that hold them monthly. If you don’t already subscribe to the free Toolbox Tips newsletter from AsphaltPro, sign up for that weekly email at TheAsphaltPro.com. And check out the library of Toolbox Tips for those topics most relevant to your team at TheAsphaltPro.com.

• Their top management is engaged: Employer involvement at the highest level of company management in safety best practices produces a 49% reduction in TRIR and a 52% reduction in DART rates.

• They assess leading indicators: Tracking and reviewing activities carried out to prevent and control injuries, such as safety training, new hire safety orientation and substance abuse prevention, leads to a 59% reduction in TRIR and a 60% reduction in DART rates.

—Source: Associated Builders and Contractor

“Transforming the status quo to set the expectation that all incidents are preventable creates a culture where health and safety are elevated to core values, a moral obligation for employers and employees,” said Greg Sizemore, ABC vice president of health, safety, environment and workforce development. “Priorities change frequently, but values remain consistent. The tools in ABC’s safety report draw the blueprint for industry leaders and workers to create a culture of health and safety, win and deliver work to communities without incident and protect the construction industry’s most valuable resource: its workforce.”

ABC’s 2025 Health and Safety Performance Report is made possible by DEWALT, a Stanley Black & Decker brand. Any company can participate in STEP. To get started, visit abc.org/step.

With over a century of innovation to its credit, Blaw-Knox® pavers have earned a reputation for quality, durability, and performance unmatched in the industry. Our continued focus on innovation is what drives our product engineering with designs that improve performance while maintaining user-friendly, ergonomic comfort and reliability for the operator.

BLAW-KNOX, THE LEGACY LIVES ON.

For more information contact your Blaw-Knox dealer or visit www.blawknox.com

Hard-won know-how for the next generation

You don’t need to drive 100,000 miles a year to win good work. In Part Two of Bill Stanley’s series on estimating, he shares how winning work doesn’t start with his truck keys—it starts with a smarter estimate.

BY BILL STANLEY

Iused to put 50,000 to 60,000 miles a year on my truck just driving to look at jobs. Walkthrough after walkthrough, shaking hands with people who may or may not even be serious. These days? I still rack up plenty of miles, but I’ve cut that number almost in half—and I’m doing better business because of it.

That’s what this second part is all about: working smarter, not harder. If Part 1 (steps one through six) was about figuring out which jobs are worth your time, this one’s about what to do after you’ve found one that is. I’ll walk you through how we draft quotes without leaving the office, how we protect ourselves with the right paperwork,

and how we make sure we’re the ones the customer calls next time—without all the back-and-forth. Because a good estimate doesn’t just land you the job. It sets the tone for everything that comes after.

Use online tools to draft a preliminary quote.

These days, before I ever get in the truck, I’m pulling up the site online. Tools like Google Maps or Go iPave let me take a good look from the sky and start sizing up the job without burning a drop of fuel. Not only do we collect more information for the estimate, but it’s an opportunity to illustrate our expertise and build rapport with the customer.

Once we look at the project from the sky, we often determine it might not be as good a fit as we thought. Then, we can recommend another company to perform the work without having wasted time and gas on a walkthrough.

If this virtual walkthrough goes well, we’ll send a preliminary quote. If the customer likes our preliminary quote, we’ll schedule a walkthrough. This way, I’m only traveling for estimates that are halfway sold already.

Prepare your estimate.

By now you should know the importance I place on doing my homework before I ever put pen to paper (or input project details into an estimating software).

Once I’ve done that legwork, I know I’m spending my time preparing competitive estimates. Believe me, once I’ve determined a project is in our wheelhouse, I turn around that estimate lighting fast. And my numbers are going to be aggressive because that’s the exact type of job I want on my job board.

A lot of companies feel okay putting together an estimate based on the basic job details, but I need to know more than that the project is a 10,000-square-yard 2-inch mill and fill. For me, it’s all about the logistics. This starts with establishing my mobilization charge. I need to know where the job is, my route to get there, and whether or not my crew can park on-site, but I also need to know how I’ll deliver my equipment and whether or not I can store my equipment on-site overnight (or for a few days). The ability to store my equipment on-site alone will have a huge impact on my bid, not only because of transport costs but also the cost of paying my crew to wait around for equipment to arrive because the lowboy’s stuck in commuter traffic.

All else equal, my mobilization cost may be the one and only reason a perfect project might not be so perfect. If the project’s smaller and far away, a local contractor will probably give that customer a more competitive bid—and I’m not afraid to tell the customer that!

I also estimate the cost of prep work and related manhours. Next, I look at my material costs. Then, hauling costs. I need to know the miles, route and travel time from the plant I’m sourcing material to the project site. If I can, I want to know how fast or slow that plant is loading trucks. Then, I factor my paving crew and equipment (including both laydown and breakdown time/activities).

Another overlooked line item on commercial work is traffic control. Just because it’s private property doesn’t mean you don’t need traffic control. And it isn’t only a matter of safety. Inadequate traffic control can really slow down the paving process. Maybe we need a pre-site visit to set up signage and cones, maybe we need to factor in adjusting traffic patterns throughout the day, maybe the project requires a couple of crew members dedicated to traffic control. If those things aren’t in the bid, that’s coming out of your profits.

All else equal, my bid for a parking lot with two entrances will be cheaper than a lot with only one entrance. With two entrances, we can leave half the lot open while we work on the other half. With one entrance, we’ll either need the customer to close shop for the day or else pay us more because the job’s going to take a lot longer.

Close the deal.

Once the customer has accepted our estimate, we get our proposals signed. This is an especially important step with new customers. We also confirm both parties are on the same page in terms of project timing and payment terms.

Although I’ve taken on many projects with different payment terms, what I prefer to put in the contract is 50% due upon signing and 50% due upon completion. Most of our larger projects don’t meet those terms, but I still put terms in there that give me an advantage to walk away if necessary.

Before we close on the deal, I make sure to talk customers through what could go wrong on a project, such as weather delays or mechanical failures outside our control. I also make sure the customer understands how their choices will impact the pavement in the long term. For example, if we’re working in a large lot with a 1% grade and one drain in the corner, I let the customer know they’re risking bird baths on their lot in a few years. There may be no money in their budget to improve drainage, but I don’t want my customer to face any nasty surprises down the road.

We just did a large project with a 60day payment term and a 10% retainage, which means on a $1 million job, $100,000 stays with the client until everything is signed off. That can take a very long time! If the company goes bankrupt while they’re holding that money, we won’t be getting it. That’s why I factor in the total retainage in my bids at the outset.

The estimating process doesn’t stop when the contract is signed.

Years ago, a semi-retired paving guy who was estimating for me part time brought in a new customer. He’d promised this customer we’d show up on a specific day. When that day came and we weren’t ready to do the job, he asked me to “just send a couple guys over to drop off a piece of equipment.” I said no way. What if I need that piece of equipment between now and then? What if the customer has a question the guys can’t answer?

I’d rather deliver the bad news to the customer that we’ll be there in two days. Of course I want to make good on my promises—and that’s why I never make a promise I can’t keep. This is also why APS self-performs all the work we do. I don’t even subcontract my trucking. If a project requires a service we don’t offer, I don’t sub out that work. I provide the customer with a recommendation for a reputable company that performs that service.

If I tell the customer the lot’s going to be paved by Wednesday, I want to make sure my portion of the work is done by Wednesday. That’s going to be much harder to do if I’m hiring subs who might reschedule on me. If ever expectations aren’t met—whether we did something wrong or if it’s a matter of mismatched expectations—you can bet I’m not going to let that complaint linger.

By the time we leave that project, I want our customer not only to have a beautiful new pavement, but also to feel like APS delivered on our promises without disrupting their business. That’s the key to the repeat and referral business that fills our books without requiring so much estimating effort.

The estimating process also doesn’t stop when we finish the project and leave the lot. I make sure my customers have my cell number and encourage them to call me if they have any problems in the future. A new parking lot is a large expense and I want them to know I stand by my work.

I didn’t cut 25,000 miles off my year just by luck. I did it by treating estimating like the foundation for everything that follows—protecting my time, my crew, and the promises we make. It’s not just about winning the job; it’s about making sure the job we win is the right one, done right, for the right customer. That’s how you build trust, repeat work, and a business that runs smoother every season.

BY BENJAMIN EVERETT

Do you ever get frustrated after setting up the paver and pulling off a start joint only to realize you are too low or too high after just the first 13 to 16 feet (4 to 5 meters) or so? We all take pride in delivering the best outcomes we can and need to do so repeatedly for our good reputation and good pay. Let me share a few “go to” tips for achieving consistently great results that avoid re-work, stopping the paver, or having to fix low spots because the screed took a dive immediately after coming off the starting reference. Low or high spots created by an improper takeoff cause handwork that affects the quality of your lift. Typically, it takes the crew at least 10 to 15 minutes to correct a poor start-off defect. And no matter how

good your guys are (and I’m blessed to have several incredibly talented team members who possess excellent handwork skills), handwork always shows up as a different mat texture. It usually doesn’t look as nice or as “ironed” as a well compacted, homogenous lift placed by a paver that’s been set up properly and operated correctly.

Let’s talk about how to start off correctly.

First, I would like to reference some excellent steps from Caterpillar with their “Paving by the Numbers” step-by-step process. This is an effective and good method to follow. Most paver manufacturers such as BlawKnox, Bomag, Vogele and Roadtec/Astec have their own similar but unique guidelines that are well worth carefully studying and adopting.

In addition, John Ball of Top Quality Paving & Training, Manchester, New Hampshire, has excellent best practices and on-site training. I have attended many of his classes at industry events and can recommend them.

Just so you know, even after 39 years in the asphalt industry, I still attend at least three refresher or new education sessions at events like World of Asphalt (WOA) and CONEXPO-CON/AGG and attend Todd Mansell and Caterpillar’s excellent courses annually. It’s important to stay sharp, up to date and on point with new industry lessons, new techniques and new material types. Plus, one can never have enough good old-fashioned refresher courses. Let’s face it, we don’t always remember every single thing, especially if you don’t do much of a particular technique.

We want to apply the new practices to our quality paving while remembering the important basics to start off every job right. My go-to startup steps that I use every single time, no matter what type of job I'm doing, include those discussed here.

Ensure the screed plates are not warped or out of shape from being overheated or being hung up coming off a lowboy that didn’t have long enough ramps for a paver. This is surprisingly common.

You cannot expect to deliver quality outcomes with a damaged screed or paver that isn’t within tolerance. A screed is a precision tool that must be treated as such. It needs to be operated professionally by competent people and maintained and repaired as required.

Think of it this way: a professional musician wouldn’t mistreat or neglect their prized guitar or piano, nor would a sportsperson wreck or damage their tennis racket or golf clubs. I’ve never seen a first-class fitter turner or skilled tradesman treat their lathe or other essential tools of trade in a bad manner. We are professional craftsmen; a screed needs to be treated the same way. Respect it and operate it like a pro.

Get underneath it every morning and have a look at it. Don’t just assume it’s okay; verify it! Don’t allow it to be slammed into obstructions trying to avoid the tiniest bit of handwork. Professionals don’t do that.

*Remember: safety first. Be sure to engage the screed locks, apply the parking brake, chock the wheels/tracks etc. before inspecting the equipment.

Assuming your screed and paver are in acceptable condition to place a great mat, if it’s the first time you’re using this machine (maybe it came from another crew), you need to physically check the screed for the following:

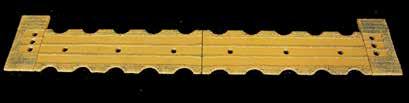

• Check for correct flatness front and rear of the main and extender plates. Use either an aluminum straightedge or a stringline and 3 X equal size nuts to verify the leading edge and trailing edge are essentially flat transversely and if required, a slight positive lead crown. (Check with manufacturers recommendations regarding lead crown; don’t automatically assume it is required.)

• Examine the strike-off plate condition. These often get bent or damaged on ironwork on mill-and-fill jobs, or caught on a lowboy when loading/unloading.

Irregular areas must be filled by hand prior to paving. You want to precompact these areas with a plate compactor or tamper, so you get the entire patch compacted. If you attempt to roll these areas with a steel drum roller, you may bridge the internal area and fail to achieve proper compaction.

• Check the strike-off plate vertical height. You’ll refer to your screed manufacturer’s recommendations; often it’s ½- to 1-inch (12.5- to 25mm) above the bottom of the screed plate, but this depends on your material thickness, nominal maximum aggregate size (NMAS) and viscosity of the binder, etc., as these all affect the screed’s ability to float on the mat and one size doesn’t fit all. You have to experiment on different jobs to find the sweet spot for that screed, on that material and thickness that allows the screed to float properly at the right angle of attack.

• Check the extender slope stops are correct, and the scales or gauges for crown, slope and match height are calibrated correctly. Most manufacturers have a step-by-step screed adjustment and set-up process that guides you through these critical checks. You wouldn’t believe the number of times I’ve come across pavers and screeds with bent or missing delta plates, warped or bent screed plates, and screed frames in a poor state of repair.

You cannot achieve precision asphalt paving with a screed that isn’t fit for purpose or in a proper condition for the intended use. Get these basics right first, before even thinking about placing a mat. It’s best to perform this screed check the day before in a workshop with a clean, flat concrete floor and with the assistance of a competent mechanic or fitter. Follow the OEM steps methodically.

After you have ensured the tractor and screed are both calibrated and in proper, serviceable condition, you may think you’re ready to go lay some mix. But wait! Have you checked the grade?

A number one mistake we often fall victim to is assuming that the surface we are going to place mix on is flat, smooth and free from high areas and low spots. That’s the exception in my experience; it’s hardly ever within spec. If it’s a commercial car park with grader placed or skid

LEFT: High areas that won’t allow proper depth of paving need to be leveled with the mill. You might think it’s acceptable to leave these “high” areas alone and let the screed scrape across the top of them, saving yourself the cost of material, but these will be areas of low quality in the mat where the compaction train will encounter problems. RIGHT: Mark low spots, outlining the area with a color that indicates the repair to be made. On large enough projects, you may wish to write out the tonnage required for repairs.

If you put down a starting tarp, you can avoid having excess material to clean off the existing surface, and you can provide a clean, welldefined starting transverse joint. This allows the breakdown roller to get onto the mat quickly and efficiently. Place your take-off boards (which need to be about 40 inches long) in the correct position on top of the tarp. One of the single most important determiners of nailing a professional take-off joint is sizing the thickness of the take-off boards correctly.

steer placed granular base like stone or base coarse, invariably that will require careful inspection. You may have to check with a straightedge and correct by hand to fill low areas.

Remember: asphalt generally compacts approximately 22 to 25% after the full compaction process. Therefore, if you are placing a 2-inch (50-mm) compacted mat, this means you need to pave it about 2.5 inches (62 mm) loose from the paver to allow enough compaction. When you find those random low spots that are about 1/2- to 1-inch (12.5to 25-mm) or more, which I guarantee most jobs have, mark them out with spray paint, fill them by hand and compact them before you even think about using the paver.

As an example, on a recent FAA resurfacing project my team and I were on, the pre-leveling generally took between 20 and 60 minutes to complete before paving began. This was on an area of around 3,109 square yards (2,600 square meters) per day. We had to comply with less than a 1/4-inch (6.4-mm) finished level tolerance, and as we were only placing a single layer of asphalt, it was essential to ensure the grade we placed it on was level.

You want to plan for a similar 20- to 60-minutes depending on the extent of the areas to be filled. High areas need to be cut off with a milling machine on milled surfaces and cut down by the motor grader on granular base and reprepared and recompacted.

This should be evaluated and identified by the paving supervisor or other competent individual well prior to the crew, paver and gear arriving on site. Inspect each site one to two days prior and preferably rectify these problems before you turn up to pave it.

Get the client to attend the site walkover or pre-handover visit with you so there is no doubting what the situation on the ground is. Preferably get a surveyor to take levels to validate the low areas. Then ensure the client or client’s representative agrees with you on the additional makeup material and time and labor for the fix. You need to get this in writing, or it’s going to be on you after you have paved the project to try and recover the extra costs later. This is such a fundamentally important step in the process for a quality outcome and a happy client.

The only Full Ser vice Custom Integrator of ALL BR ANDS of asphalt plants.

INTEGRATION is achieved by combining existing plant components with new components, used equipment or re-engineering plant parts and pieces to yield a fully functioning hotmix asphalt plant facility.

Integration of a new drum, new frame, new ductwork, new knockout box, new blue smoke system and a new control house. All while utilizing components from the existing plant.

Here’s a quick tip! Be sure you lay the tarp down neat, square and straight just back from the edge of the take-off joint, leaving the joint exposed ¾ to 1 inch (19 to 25 mm). This is to allow just enough overlap of material onto the existing grade to form a proper, tight and dense transverse joint, but not so much you then have to go back and start bumping the joint or tempting well-meaning laborers to try to push the edge back. We need to avoid that.

You’ve ensured the paver and screed are in good condition and you’ve ensured the project area is ready for the paving crew to do its best work. Now let’s eliminate handwork at the takeoff joint. Place a tarpaulin at the start point.

It’s all about working smarter, not harder.

A procedure I like to use on any job, whether it be a commercial parking lot, city street or an airport, is to try to avoid having to touch the start joint by hand. I want to avoid having to “fix it up” after the paver’s pulled off the joint. No matter how good your best laborers are, the moment you touch material by hand, some degree of segregation is going to occur, and it will stand out.

Not only that, but handwork also compacts differently than paver placed material due to not having the weight of the screed imparting a degree of pre-compaction on the material. The paver placed mat always

Avoid having to touch the start joint by hand by using a length of truck tarpaulin—or similar tarp material—at the start-off point. You want to place it about 1 inch from the joint and have it extend about 1 to 2 feet wider on each side of the lane.

has a nice, ironed appearance to it and is always going to be more homogeneous in appearance than handwork if it’s being set up and operated properly and the feed system operating in a consistent, steady manner. Try to minimize the amount of handwork you need to do, by paying more attention to the set-up steps for the screed, which I’ll share next month.

The tip I’m sharing right now is to use a length of truck tarpaulin— or similar tarp material—at the start-off point. It needs to be at least 1 to 2 feet (305 to 610 mm) wider on each side than the width of the lane. It also should be at least 40 inches (1 m) deep (front to back) to allow enough coverage to avoid material having to be picked up by hand. Just before you are ready to set the paver down to place each pass, lay this tarpaulin down on the grade at the take-off joint.

Place your starting or take-off boards (which need to be about 40 inches or 1 m long) in the correct position on top of the tarpaulin. One of the single most important determiners of nailing a professional take-off joint is sizing the thickness of the take-off boards correctly. If the milling crew didn’t cut that transverse take-off joint quite deep enough, you need to reduce the thickness of your starting reference accordingly. Otherwise, you’re going to be too high and losing time rushing back to fix it by hand.

I would rather take an extra five to seven minutes at the set-up stage of each pass to be sure these small but critical details are right, than cutting corners and getting caught with a bad start. The bad start could take 10 to 15 minutes to sort out and will never look as nice as a joint that was completely placed by the paver.

With these basic start-off tips in mind, you’re set for a successful beginning to each pull. What’s next? See you next month for the sequel to “Start Paving Off Right.”

Benjamin Everett is the owner of About Asphalt Ltd., and has worked in the asphalt industry for nearly four decades. For more information, contact him at bjeverett@aboutasphalt.co.

BY SANDY LENDER

Maui Paving, a joint venture formed by Goodfellow Brothers and Grace Pacific, recently completed the reconstruction of Haleakalā Highway for the Hawaii Department of Transportation (HDOT) ahead of schedule. Tyrone Pullman, foreman and construction manager for Maui Paving, shared in a video interview this highway is one of the biggest on the island. It connects the densely populated valley with the surrounding rural areas.

The team from Maui Paving removed and replaced 4.2 miles of divided highway at a depth of 8 inches. They used two Wirtgen milling machines—a W 210 Fi and a W 200 Fi— as well as a SUPER 2000-3i paver from Vögele among other equipment on the project.

“It is the demolition of 4 inches of ultra-thin white top and 4 inches of asphalt treated base, and then placing back 6 inches of asphalt treated base and 2 inches of Mix IV,” said Zack Gonzales, general manager of Maui Paving.

Gonzales shared in a video interview that the plan was originally to cut up and remove those sections with an excavator, but Maui Paving had a better idea. It was more sustainable to mill the highway and recycle all that material. And with the Wirtgen cold planers, they were able to mill the full depth in one pass.

“It’s a hundred percent recyclable,” Gonzales shared. “We’re recycling the material that we’re demoing out and then also our asphalt that we’re placing also includes 20% RAP, which is a recycled asphalt pavement as well.”

Discover the next generation UltraMax® 1200-CC, Eagle Crusher’s most popular plant enhanced with new features to make setup, operation, and transport a breeze. The plant features a redesigned return conveyor, allowing quicker setup without having to attach parts after extension. The plant also features a new fully hydraulic side discharge conveyor, making setup and teardown easier as well as a self-lowering control panel, no longer requiring additional equipment to remove from the plant. The new 1200-CC is also available with an onboard cross-belt permanent magnet that stays on for transport. See how this next generation of Eagle Crusher’s 1200-CC plant can work for you.

TRUST THE STRENGTH OF EAGLE CRUSHER ®

The SUPER 2000-3i highway class paver from Vögele with an engine rated output of 186 kW (250 hp), in combination with the VF 600 paving screed, was used to place the PMA with 20% RAP in lifts of 6 and 2 inches.

Tyrone Pullman, foreman and construction manager for Maui Paving, shared details of the project’s progress and the crew’s experience with the new equipment. For more information about that, watch the YouTube video here: https://youtu.be/9NvlYMlb7DY?feature=shared

Members of the DOT provided the details, with Brandon H. Hee, the Geotechnical and Pavement Design and Shoreline Section Head for the DOT, explaining the 16-year-old pavement’s condition prior to project start. Hee shared that the 4 inches of ultra-thin white topping (UTW) placed in 2008 over the existing 3 to 5.5 inches of ACB placed in the 1970s was failing. “The failure appeared to extend into the underlying ACB, and this is why the cold-planing was done to 8 inches deep,” Hee explained.

Kyle Suzuki, P.E., of HDOT Highway Division, explained the department doesn’t use pavement condition indices (PCI) to assess structures. “We use internal indices to characterize pavement condition and performance. The closest index to the PCI is HDOT’s Pavement Quality Index (PQI), which this road had a score of 78 out of 100. 78 is rated at fair and would be in the range of warranting minor rehabilitation.” He also shared the pavement had an average IRI (MRI) of 163 in/mi as measured on Jan. 19, 2023.

THE HIGHWAY HAD A PAVEMENT QUALITY INDEX (PQI) OF 78. “78 IS RATED AT FAIR AND WOULD BE IN THE RANGE OF WARRANTING MINOR REHABILITATION.”—

KYLE SUZUKI,

P.E.

To replace the pavement, the Maui crew used the Vogele Super 2000-3i to pave a 2-inch polymer-modified asphalt (PMA) Mix IV over a 6-inch ACB with polymer, Hee explained. “We use the SBS polymer.”

Kristi Grilho, Bituminous Engineer for HDOT, discussed the mixes in more detail. “Mix IV is a ½-inch dense-graded mix. Both ACB (also called Hot Mix Asphalt Base Course (HMAB)) and Mix IV used PG64E-22 asphalt binder. From mix design submittals, both used 20% RAP. HDOT doesn’t require additives or other accommodations for RAP percentage allowed (up to 20% for surface, and 40% for HMAB (drum plant).”

Wirtgen Group reported: The deployment of this paver was a première on the Hawaiian island of Maui. To enable Maui Paving’s personnel to exploit the full potential of the machines, they all received appropriate training from Wirtgen America before the start of the project. The familiarization of the crew with the machines went off without a hitch for everyone, from the mechanic to the operating personnel on the site. All three machines deployed on the project [paver and two cold planers] impressed the construction crew with powerful performance, precision and low noise levels.

“The transition to the Wirtgen milling machines has been so smooth and seamless, not only due to their efficiency, but also to the fast delivery of parts by Pape, (the local John Deere/Wirtgen Group dealer) and the training provided by the Wirtgen Group,” reported Zack Gonzales, general manager of Maui Paving.

• High production drum mix Plant with high RAP capacity

• World class customer service experience and project management

• Cutting-edge HMA technology

• Innovative Plant controls with roadbuilding digital solutions

• Environmentally friendly, robust, and sustainable Plants

• Customizable stationary and portable Plant solutions

The South Carolina Women of Asphalt branch uses a novel approach to lead and inspire women in the asphalt industry through its Building Community with Biscuits program

BY SANDY LENDER

As part of the South Carolina Women of Asphalt branch’s vision to lead and inspire women in the state’s asphalt industry, its steering committee launched an outreach program in March 2024 taking events to workers in the field. The Building Community with Biscuits (BCB) program fits the goal of “community” and Noelle Arena, chair of the committee and the BCB program, explained further.

“The idea was brought up by Kimberly Lyons, the South Carolina Branch Vice Chair,” Arena shared. “She had long contemplated a way to reach more women in the field and in the lab. Since they often work long hours and rarely have the opportunity to attend events, especially those that require travel or occur during working hours, she wanted to take the events to them. The committee members take responsibility for the program. We each contact those contractors/companies we know well and work with. As the Chair, I ensure the program continues and we remain focused on our message.”

The logistics Arena mentioned there started with dividing the state into manageable sections for the program. “We have split the state based on where asphalt plants are located to make the task of speaking with everyone more manageable,” Arena shared. “It also correlates with where the Steering Committee leaders live/work. We have divided the state by Upstate, Midlands, Coastal, and Pee Dee.”

Steering Committee members reach out to companies to coordinate a visit. “As many of the Steering Committee leaders as are available will go to the job, or lab, or office to meet with the women employees of the company we are partnering with on that day,” Are-

na shared. “We typically meet with the women in the early morning, before the workday begins, so we do not disturb their schedule. This is where the idea of bringing them biscuits came in. Food is a sure way to get people together!

“We meet each of the women, introduce ourselves, and then talk for a moment about Women of Asphalt, the resources available to them, and share stories. We want to hear from them; any stories they have of working in the industry, any suggestions for us, and any way we can help them with their career

goals. It’s a very friendly and casual environment. If we are in an office building, we sometimes hop around and say hi to everyone who didn’t gather with the group.”

Of course, the committee members visit with anyone who’s interested in the organization, men and women alike.

As of press time, the program had visited 12 companies to create supportive relationships and introduce more than 100 women in the state to the SC WofA branch.

“We have focused primarily on asphalt producers, those who sit on the SCAPA board

Committed to Your Success, Every Step of the Way. Let’s build something great together.

Scan Here To Learn More!

and have supported us since day one,” Arena shared. “We are looking to extend our visits to engineering firms, safety companies, municipalities, DOT, etc., while also revisiting those companies we have already to ensure we speak with everyone.”

South Carolina isn’t the only branch participating in boots-on-the-ground outreach. “We have presented this program in a few meetings in which the various branches’ leadership have come together to share ideas,” Arena said. “Maryland has started a similar program focused on connecting with women in the field called Paving and Pastries, where they meet with female employees before heading to the field where they promote WofA, membership and their mission. They also have created potty packs which are dispersed to all female field employees which include several hygiene items, hand sanitizer and a cute pair of pink gloves!”

The South Carolina BCB program has proved itself inspiring not only to the women in the field, but also to the women coordinating it.

Lyons, who is not only the vice chair of the SC branch for WofA but also the asphalt materials engineer for South Carolina Department of Transportation (SCDOT), shared her experience: “At one of our recent Building Community with Biscuits with Coastal Asphalt,

there were so many women there with different backgrounds and levels of experience. It ranged from a high school senior who was working there part-time to an experienced woman who had spent most of her career in the asphalt industry. There was even a registered nurse and middle school teacher who had changed careers and were now working in the asphalt industry. In that moment, I realized just how vastly different the background of the women in this industry can be and how their past experiences could help other women succeed in this industry as long as the knowledge is shared. That was the purpose of our visit that day, to build a network of women in the industry that would encourage others by sharing their knowledge and experiences. I also recognized that it was never too late to change careers and join the asphalt industry. That we should always be promoting our industry because you never know who is looking for another career choice.”

Brigetta Laird, regional sales manager for Southeast Emulsions and events chair for the SC branch of WofA shared that she’s had “many magical moments in our BCB visits with the contractors.” One that stood out to her took place during the visit to Blythe Brothers Asphalt.

“One of the ladies, a truck driver, said she’d never felt seen as a woman in the industry,”

Laird said. “I remember her sharing that since she is around men all day every day, it’s just become normalized to be in a ‘man’s world’ in her day-to-day, and for an organization like WofA to come out and ask how we could support her felt like such a huge milestone for her as a female in the industry. She said she’d never been in a meeting before that was only women, and she was looking forward to more

events to come. Connections like these really bring me back to how powerful it can be just to show up and promote opportunities to support other women. She mentioned wanting to join the mentorship program in 2026, so that was also exciting.”

Laird is also reaching out to bring participants to the visits. Melissa Cole, business unit leader at Palmetto Corp., shared that she learned more about the SC WofA branch through one of the visits that Laird initiated. “I was somewhat familiar with SC Women of Asphalt but hadn’t had the chance to truly connect until Brigetta Laird reached out to schedule a Building Community with Biscuits visit with our team. I was incredibly impressed by their commitment to meet our team members out in the field and take the time to share more about the mission of Women of Asphalt.

“The visit wasn’t just beneficial for our female coworkers, who learned how to get more involved—it also gave our male employees a chance to hear, firsthand, the passion and purpose driving this organization,” Cole continued. “It created meaningful dialogue, and I believe sparked a deeper interest and appreciation for the role(s) women can play in shaping the future of our industry.”

Eric Faulk, the chief operating officer at Palmetto Corp., shared the importance of not only launching a program like BCB, but also the importance of supporting Women of Asphalt in our industry. “I believe an intentional commitment to initiatives such as the SC Women of Asphalt is important for organizations wanting to remove outdated perceptions within the asphalt construction industry where women have long been underrepresented. By engaging in such programs, we are exposed to different experiences, needs, ideas, etc., and thus provided a glimpse into how we can become better stewards of a diverse workforce. When actions back up these principles, companies promote the idea that women’s achievement and career growth matter. In my experience, a supportive environment with a clear path to development benefits all employees and supports an industry drastically in need of talent.

“Traditionally women represent a largely untapped resource for our industry. With that in mind, supporting women in asphalt construction is a winning proposition for Palmetto Corporation and the broader asphalt industry. We firmly believe the capacity to add value, innovate and lead is not bound by gender. This belief has not only opened new doors for our organization but has also

empowered the remarkable women who contribute to our success.”

With the successful visits the BCB program has already undertaken, its continuation promises to bring more women from the industry into a positive and nurturing group. With women reaching out to not only interact with one another, but also to support and encourage one another, the BCB program is of-

fering women in the field an opportunity to become aware of and involved in the Women of Asphalt. Communication is crucial—it can make or break your day. Time management, work ethic, prioritization, multi-tasking, attention to detail, adaptability, problem solving, being able to work as part of a team—they all matter.

Sunland’s pioneering precise work on APEX Motorsports track BY IMMANUEL MARTINEZ

Sunland Asphalt & Construction, LLC, Phoenix, Arizona, ran three Vogele Super 2000-3i pavers in echelon to pave phase two of the APEX Motor Club track at widths of 42 and 50 feet wide with no cold longitudinal joints. All photos courtesy of Sunland Asphalt

TThe high-speed world of motorsports demands world class precision, performance and durability. At Sunland Asphalt & Construction, LLC, Phoenix, we embraced these principles when we took on the development of the second circuit at the APEX Motor Club track in Maricopa. Spanning from August 2024 to February 2025, this project represents an incredible milestone in Arizona’s racing landscape.

The transformation of undeveloped farmland into a high-performance racetrack required extensive engineering and meticulous attention to detail in our planning. Grading was a critical component,

“AT THE TRANSVERSE JOINTS, WE USED A 12-FOOT STRAIGHTEDGE TO CHECK FOR FLATNESS AND MADE NECESSARY ADJUSTMENTS TO MAINTAIN LEVELNESS. ALONG THE OUTER EDGE TIE-INS, WE

ALIGNED THE SCREED TO MATCH THE ELEVATION OF THE EXISTING ASPHALT FOR A SEAMLESS TRANSITION.”—GREG

HUGHES

with 138,960 cubic yards of material cut and 121,163 cubic yards of fill placed to shape the building pads, retention basins, multiple track sections, runoff areas and paddocks.

For the track’s foundation, an 8-inch layer of Aggregate Base Course (ABC) was placed and finish graded before receiving a 2.5-inch application of ½-inch asphalt—meaning ½-inch nominal maximum aggregate size (NMAS). The track itself was surfaced with 1.5 inches of a 3/8-inch Special Mix for the wearing course, ensuring superior grip and durability. Our use of echelon paving—simultaneously running three pavers— was key to achieving a seamless, high-quality racing surface.

“During echelon paving, we utilized three material transfer vehicles (MTVs): two Weilers and one Roadtec Shuttle Buggy,” said Greg Hughes, our project manager – Public Works. “Paving operations were carried out using three Vogele Super 2000-3i pavers. Paving this way almost eliminates any joint and acts as one continuous mat. The slope of the track was minimal, so additional support equipment was not required during rolling operations.”

APEX Motor Club, now owned by RJT Capital, is more than just a racetrack; it’s a haven for speed enthusiasts. Strategically located to serve Phoenix, Tucson, and even cities like Los Angeles and Albuquerque, this circuit caters to drivers who demand the best. Every detail, from the material selection to the construction techniques, was geared toward delivering a world-class racing experience.

The track’s continuity with Phase 1, which we paved in 2018, was another highlight of this project. Ensuring seamless integration required exceptional precision in tie-in joints and elevations. The result is Arizona’s longest motorsports track—a continuous circuit designed to push limits and set new standards in high-performance driving.

“The original track measured 2.27 miles, while Phase 2 added an additional 2.43 miles,” Hughes shared. “These two sections can be run independently or combined into a single 4.7-mile configuration.”

One of the most demanding aspects of this project was achieving the track’s stringent surface tolerance. That quality started at the base.

“To ensure grade tolerance, our blade utilized GPS technology to follow the project-specific model accurately,” Hughes explained. “At the transverse joints, we used a 12-foot straightedge to check for flatness and made necessary adjustments to maintain levelness. Along the outer edge tie-ins, we aligned the screed to match the elevation of the existing asphalt for a seamless transition.”

Echelon paving, which was crucial to ensuring consistent quality across the track’s 42- to 50-foot width, can have many complex

logistical challenges in coordinating multiple paving machines and maintaining uniform asphalt application.

“Since GPS technology was used to establish the desired grade during preparation, we paved using a 2D control system,” Hughes explained. “Each paver was equipped with 30-foot paving skis, which helped maintain consistent depth and alignment. The skis function as a leveling system by averaging the surface over their full length, effectively smoothing out minor grade variations. Additionally, the second lift served as a corrective layer, addressing any imperfections remaining in the base course.”

Additionally, Sunland installed 4,850 feet of concrete curbing designed specifically for APEX, improving both functionality and aesthetics. Our team also constructed a 100-foot by 85-foot box culvert and 1,020 feet of cut-off walls to manage water flow and en-

hance track stability, ensuring optimal performance under diverse conditions.

This project was a collaborative effort, made possible by our trusted subcontractors:

• Solterra Materials supplied the high-performance, polymer-modified asphalt, ensuring superior grip, durability, and smoothness. Led by Michael Thompson, Solterra’s expertise in asphalt production and logistics was instrumental in maintaining project timelines and quality.

• Vital Contracting, under the leadership of Stephen Boyd, executed all earthwork operations, delivering near-perfect tolerances essential for racetrack construction.

• CMT Technical Services, headed by DJ Peters, ensured compliance with rigorous material testing standards, performing geotechnical evaluations, density testing, and asphalt mix verification.

One of the key figures in bringing this project to life was Isidro Lopez, project foreman at Sunland Asphalt. With years of experience in the industry, Lopez played a vital role in delivering the precision required for a world-class track. He stated his favorite aspect of this job was, “Seeing the owner’s excitement when we finished—it was like kids opening Christmas gifts.”

The most memorable day for Lopez was, “Reaching the end of the track on that final day of paving—everyone was thrilled to achieve the end goal.”

Sunland Asphalt & Construction’s commitment to precision and innovation continues to drive our success. The completion of APEX Motor Club Phase 2 marks yet another milestone in our legacy of deliver-

ing top-tier asphalt solutions. From engineering complexities to flawless execution, this project exemplifies our expertise in high-performance paving—ensuring that APEX remains the premier destination for automotive enthusiasts across the Southwest.

For those who live life in the fast lane, APEX Motor Club is ready. And Sunland Asphalt & Construction is proud to have paved the way.

On this issue’s front cover, from left to right, Will Morrison is the asphalt plant operator for the Coolidge site and Matt King is an asphalt plant foreman for Solterra Materials, the company that supplied the high-performance, polymer-modified asphalt for Sunland’s APEX project.

Immanuel Martinez brings 20+ years of experience managing complex construction projects, pioneering 3D paving innovations, and leading high-performing teams across public and private sectors. To learn more about Sunland, visit sunlandasphalt.com and check out past articles on TheAsphaltPro.com.

WITH OVER 30 YEARS’ EXPERIENCE IN THE ASPHALT INDUSTRY, we have the knowledge and expertise to help you reach your goals without breaking the bank. Specializing in locating and retrofitting any equipment you need, we are all about upgrading your asphalt plant to maximize output and efficiency — with less lead time than others! Talk to us about your next project.

• PLANT RELOCATION / CONSTRUCTION

• PLANT MAINTENANCE

• CONSULTING

• NEW/USED PARTS

• NEW/USED EQUIPMENT

• INDUSTRIAL INSULATION SERVICES

• HOT OIL PIPING & AC PIPING

• SILO & TANK CLEANING

A look at balanced mix design and intelligent systems to minimize human error and increase pavement performance on a North Dakota test project

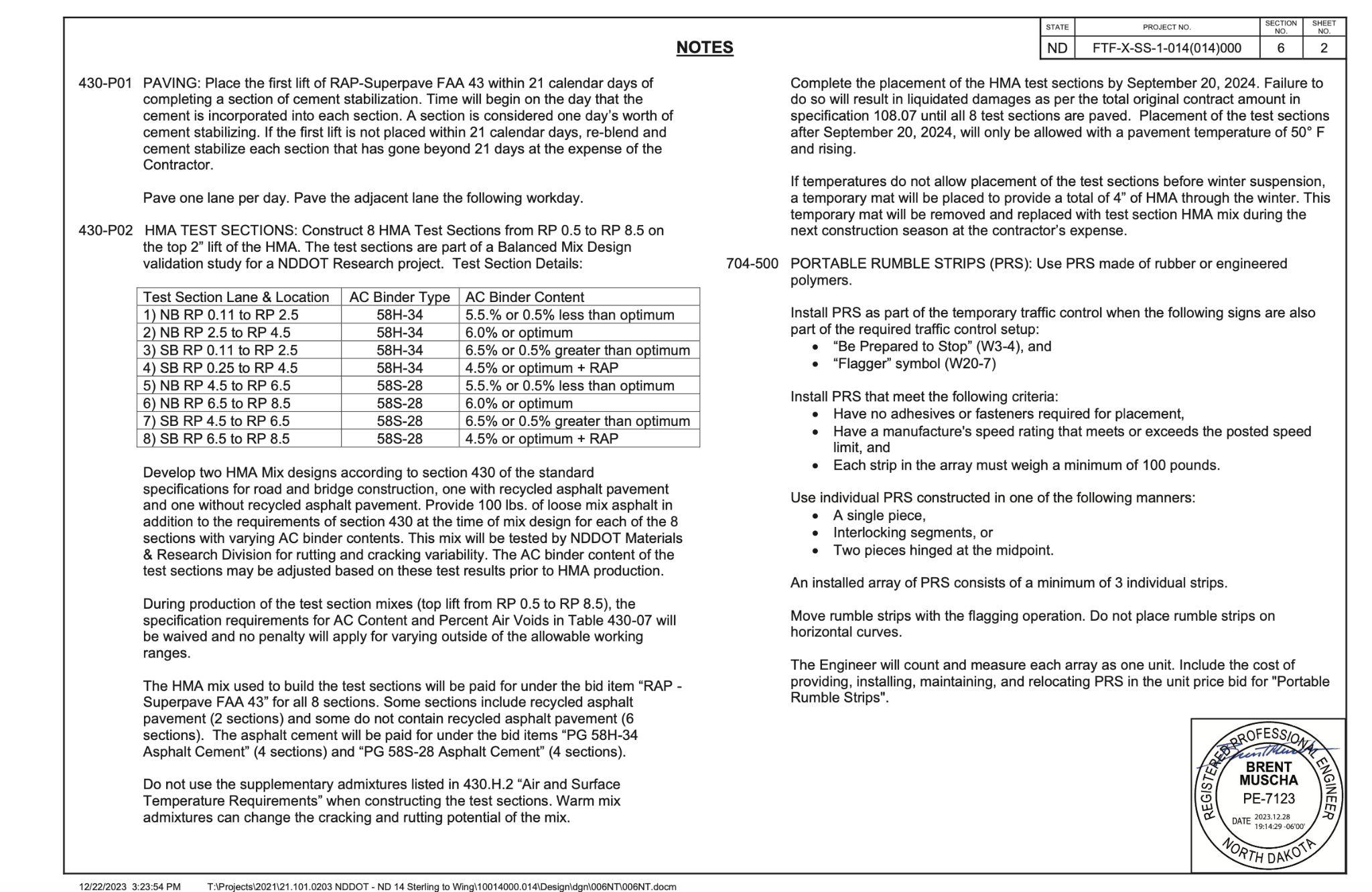

BY SANDY LENDER

As introduced in the March/April edition of AsphaltPro Magazine, Job 23273 along Highway 14 in Burleigh County, North Dakota, trialed not only an array of new technologies but also balanced mix design (BMD) in its eight test sections. The North Dakota Department of Transportation (NDDOT) let the job totaling 21.22 miles to test BMD and technologies and to repair the roadway. Jonathan D. Stork, P.E., is a research engineer for NDDOT Materials and Research and he outlined the roadway’s history.

FTF-SS-X-1-014(014)000 was part of the Feb. 16, 2024, bid letting.

The roadway had originally been built in 1963 and saw an average daily traffic of 630 vehicles at the time of the most recent project design (2022).

“The existing pavement system had most recently received a 2-inch overlay in 2009, and a chip seal in 2013,” Stork shared. “The roadway was originally paved in 1963, with varying treatments throughout its lifetime. The overall IRI for the roadway before construction was near 90 inch/mile before improving to 40 inch/mile after project completion. The prior distress score for this roadway was categorized as fair (88), with main distresses being various cracking and patching.”

In 2022, it was time to address the underlying distress.

“Like many roadways constructed at its time, the original base course was somewhat lacking for today’s traffic counts. Because of the scope of work, the decision was made to build these test sections on a uniform, stabilized base to create a proper platform for many future years of service.”

The scope of work took a team to decide upon. As Pavewise’s Bryce Wuori commented, the job came together similarly to a design-build project. Stakeholders met and brainstormed the best way to use technologies to achieve the end goal.

“This is the first time I've participated in a process where a state highway in need of repairs was transformed into an 8-section test area without causing significant disruptions to the construction process,” Wuori shared. “The collaboration between the DOT, the contractor, and other stakeholders truly reminded me of a well-executed design-build project.”

Tyler Wollmuth, PE, assistant M&R engineer, NDDOT Materials & Research Division, explained, “The stakeholder group was instrumental in helping phase the work and set up the parameters of the test section construction. The remainder of the project was designed by the NDDOT and was mostly complete when the stakeholders started having meetings.”

“During the conceptual phase of the project planning, NDDOT formed a BMD working group comprised of various stakeholders including many of our local contractor partners and suppliers, Federal Highway representatives, university partners, and industry experts,” Stork explained. (See Sidebar) “From this working group, we were able to design and bid this project in a manner that was both reasonable and effective. This was important for all parties involved, as we wanted to balance agency and contractor risk while still obtaining the testing result spread that we needed to validate different performance levels.”

One example of modifying the parameters to facilitate the project’s execution was that of addressing certain volumetrics requirements in the field.

It’s a fact that fossil-fuel burners operate at only 85% efficiency when new, losing 15% of their heat in exhaust and emissions. What’s more, that efficiency quickly drops to 50% to 65% over time — especially without regular maintenance. PHCo Lo-Density® electric heat for asphalt tanks, hot oil circulating systems, fuel oil preheaters, and distributor truck heaters is clean, safe, consistent, and it offers 100% energy efficiency because all of its energy is used to heat. Find out more:

“We required our standard specifications for compaction incentive/disincentive, which can vary depending on substrate, mainline or joint placement,” Stork said. “We waived certain volumetrics (AC content, percent air voids) during the construction of the test sec-

wanted to protect. “Floating silt curtain was installed before work began in the Rice Lake Area, and was maintained throughout the duration of the construction,” Stork said.

From protecting the environment to executing a successful pavement

While the balanced mix design (BMD) component of the project was top of mind for the DOT, other aspects of the project made this one of national importance. Stork explained some of the overarching milestones the agency wished to achieve.

“The ultimate goal of selecting this project was to validate the performance thresholds for our future potential shift to balanced mix design,” Stork shared. “In doing this, we aim to link the test section performance to their various testing results and determine the path forward for setting requirements.

“When we have a project such as this, with multiple mix designs in a relatively small span of both time and quantity, we want to assess variability and ensure uniformity of both the materials and the operation,” he continued. “To achieve this, we relied on technology to help set up, monitor and assess the quality of the operations. In doing so, we feel we were able to limit the risk and ensure that the test results and conclusions are valid.”

The quantity to which Stork referred was just over 96,000 total tons of hot-mix asphalt (HMA). The time was roughly 180 days from start to finish, which involved milling, widening, pipe replacement and extensions, HMA and cement-treated base (CTB), and full depth reclamation (FDR) in all of the eight sections. Wollmuth confirmed work started on the project on April 15, 2024, and was completed on Oct. 19, 2024, with the BMD test sections completed during the second half of September.

According to a presentation from Zane Hartzog at the National Center for Asphalt Technology (NCAT), the four lab tests used to determine mix performance were the indirect tensile asphalt cracking test (IDE-

AL-CT), indirect tensile rutting test (IDEAL-RT), the disk-shaped compact tension (DCT) and Hamburg wheel track test (HWTT). Let’s break those down as they relate to the design phase of the Hwy. 14 project. All tests were performed by the NDDOT Bituminous lab, the NCAT mobile asphalt lab and the NCAT lab in Auburn, Alabama. Wollmuth stated NDDOT Bituminous lab did most of the testing referenced herein; NCAT lab results were very similar.

ASTM International defines the level of cracking resistance of a pavement as its cracking tolerance, or CTindex. The higher a mix’s CTindex, the better its resistance to cracking. This test is ASTM D8225. For the Hwy. 14 project design, lab techs prepared asphalt samples in the gyratory compactor and cured them for two hours at 77°F (25°C) before placing them in the IDEAL-CT device. Wollmuth shared: “IDEAL-CT results showed crack resistance results ranging from a CTindex of 49 to 220.”

ASTM International defines the level of rutting resistance at high temperatures as its rutting tolerance, or RTindex. The higher a mix’s RTindex, the better its resistance to rutting and the shallower ruts in the final pavement should be. The lower its number, the more resistant it is to cracking. This test is ASTM D8360. For the Hwy. 14 project design, lab techs prepared asphalt samples in the gyratory compactor and cured them for one hour at 115°F (46°C) before the peak load was applied. Wollmuth shared: “IDEAL-RT results showed rutting resistance results ranging from a RTindex of 70 to 145.”

The DCT (ASTM D7313) is a thermal cracking test. The higher a mix’s number, the better its resistance to cracking. For the Hwy. 14 project design, lab techs prepared asphalt samples in the gyratory compactor and cured them for two hours at –11°F (-24°C) before applying the energy to pull them apart until cracking occurred. Wollmuth shared: “DCT results showing thermal cracking resistance results ranging from an index of 331 to 492.”

The cyclic loading of the HWTT tests the rutting, stripping and aggregate breakdown of the sample. For the Hwy. 14 project design, lab techs prepared asphalt samples in the gyratory compactor and performed the test in water at 115°F (46°C). Wollmuth shared: “HWTT results showing rutting values that ranged from best 2.87 mm of rutting in 20,000 passes to the worst 12.5 mm of rutting in 9291 passes.”

With robust testing and planning on the front end and continuous monitoring and quality control throughout, the various members of the Hwy. 14 project team delivered a high-quality pavement to end users while providing a high-level trial project for DOT and industry to evaluate.

“This project had many unique features associated with it and came with additional complexity and effort,” Stork shared. “To employ so many technologies and new innovations takes lots of additional time and expertise, and we appreciate our involved partner’s willingness to further the research efforts. Overall, the contractor received performance bonus for both compaction and smoothness, and we consider this project as a success.”

The final installment of our Hwy. 14 series will dive into additional data points and final numbers and will take a look at how Border States earned bonuses with technology and technique.

The BMD stakeholder team for the Hwy. 14 project:

• Knife River Materials

• Mayo Construction

• Border States Paving

• Northern Improvement

• Sundre Sand & Gravel

• Terracon

• Aaron Swan Labs

• NDDOT

• NCAT

• FHWA

Sign up for our weekly Toolbox Tip emails to inspire your daily toolbox talks. Toolbox Tips: bit.ly/toolbox-tips AsphaltPro magazine is the leading “how-to” magazine for asphalt producers, highway pavers and public works specifiers, but we’re more than just a magazine! Get your AsphaltPro fix between issues by connecting with us online.

Visit our website at theasphaltpro.com for exclusive content, including videos demonstrating equipment or showcasing various projects and blog posts covering the latest industry news. theasphaltpro.com Join us on Facebook, Instagram, X and LinkedIn for daily tips to improve performance, asphalt industry history and trivia, construction humor, and news and happenings. facebook.com/AsphaltPro instagram.com/theasphaltpro @AsphaltPro linkedin.com/company/asphalt-pro-magazine

BY EVAN TRIGG

Editor’s Note: The Focus on Performance series from AsphaltPro Magazine allows OEMs and service providers to highlight professionals in the industry who have improved efficiencies and the bottom line through best practices and performance. This month’s installment, featuring RJ Daigle, focuses on fleet management strategies.

AAs the third generation takes the reins at RJ Daigle and Sons in Baton Rouge, Louisiana, they are keenly aware of the company’s focus on integrity, dedication and quality. Those three pillars have helped the company grow from a single steel wheel roller to over 175 employees operating from two asphalt plants and a fleet of equipment worth millions of dollars. While traditions are great, they are also using technology to better manage their 10 crews. FleetWatcher by AlignOps helps them streamline production, enhance efficiency and control costs.

FleetWatcher aggregates data from the connected assets as well as other software programs to provide transparency into a company’s fleet operations. Users can see where rolling assets are, divert them around traffic problems, ensure that trucks are not waiting either at the asphalt plant or at the paver, and more. This allows users to make real-time decisions that have immediate results. If there are too many trucks on a job, one or more can be diverted to other tasks; if cycle times are too long, dispatch can re-route trucks or determine the cause of the slowdown, and more. The team at Daigle uses it for these functions and much more, including accurately paying third-party trucks and eliminating “truck burn.” That alone has saved countless hours and thousands of dollars.

Daigle operates 16 of their own trucks including 10 tri-axles, a pair of quad axles, and four dump trailers, all with Samsara installed. Since FleetWatcher integrates with Samsara, there is no need for an additional device in those vehicles. Depending on their workload they typically hire 35-40 additional trucks, most of which use the FleetWatcher app.

Logistics Manager Ryan Marciante starts each day with a look backward, paying those third-party trucks accurately for yesterday’s work. Rather than relying on estimates on when trucks showed up, or whatever the foreman said, he has accurate data from the virtual shift tickets, so he knows when trucks started, when they finished, what jobs they were on, and more.

“I go back to the LCAs and I create shift tickets for the jobs that ran the day before,” Marciante said. “Using the LCAs, I make sure they were at the plant on time, and where they ended the day. I’m able to put in exactly what jobs they were on, and the exact times.”

With the volume of projects going through Daigle daily, Marciante spends about three hours a day on this task, a far cry from what they used to go through. “Previously someone in account-

RJ Daigle’s team running its two asphalt plants can now use the FleetWatcher platform to adjust production based on real-time trucking information. All photos courtesy of FleetWatcher by AlignOps

ing would have to track down all the information, which was all scrambled—it might take a day and a half to do so,” and it was not always accurate. Now trucks are being paid fairly, and timelier, thanks to FleetWatcher.

There are still times when technology needs a human touch. “In the mornings, I check the shifts to see who’s supposed to be where,

and if I don’t see their GPS logged in, I’m on the phone calling them, ‘hey you need to turn your GPS on, you need to log in to the app.’ We let these guys know that this is how they’re being paid, so if you’re not logged on, I can’t pay you.”

“They enjoy it because all their scale tickets are there, so they can see all their tickets on their phone. They can see how much they’ve hauled that day, when they’re clocking in and out,” Marciante sad.

In addition to paying trucks accurately, FleetWatcher is helping to determine the optimum number of trucks for each project. Marciante recalled how the telematics platform helped them streamline trucking on a recent project in Gramercy, Louisiana. The project called for milling, patching and overlaying asphalt on 13 miles of LA-3152. Cycle time was about 30 minutes in each direction from the Geismer asphalt plant.

“The job itself is holding the trucks up because it is so long,” said Marciante. “We’re closing down lanes, and with some increased dwell time on site, a cycle is running about an hour and a half.”

In the days before FleetWatcher, they’d likely have budgeted 25 trucks for the project. Now they are consistently hitting their production goals with fewer trucks, by eliminating excessive waiting at both ends—no more waiting at the plant, nor waiting at the paver.

“If we cut, say five trucks from a job, we’re saving close to $5,000 a day just on trucking,” Marciante said.

If they have somewhere to send the trucks that are not needed on a particular project, they’ll pull them immediately. If not, they’ll finish the day and correct it tomorrow. The information is helpful for future projects as well.

“We have pre-construction meetings before every project,” Marciante said. “I’ll look through the completed shifts tab to see if we’ve done similar projects nearby and use those to better estimate the project at hand.”

As the day moves towards completion, Marciante looks ahead and begins to dispatch trucks for the next day’s projects. The process is simple and straightforward, saving him roughly an hour a day over the way it was done previously.

“Before using FleetWatcher dispatch, it was all done manually. I’d put the information in a notebook, writing truck names under the foreman, and then text each one individually, ‘hey I need you to go here tomorrow, here are the directions.’ It was an individual text to 30 or more people.”

With the FleetWatcher dispatch program, it is much simpler and faster. “If I need 12 trucks at our Geismer plant for 6:30, I can assign which trucks I want there, click one button and it notifies all 12 of

Ryan Marciante can assign trucks to projects in advance and notify drivers of their assignments with the FleetWatcher platform. “If I need 12 trucks at our Geismer plant for 6:30, I can assign which trucks I want there, click one button and it notifies all 12 of those trucks at the same time.”

those trucks at the same time. They all get the same message, with the pin drop so they know who they’re working for, and what the job is. It has sped the process tremendously.”

In addition to extensive use by Marciante, FleetWatcher is also used by the team running RJ Daigle’s two asphalt plants. They can see where the trucks are and when they are due back at the plant, so that they can adjust production accordingly.

Marciante, who had managed FleetWatcher for another company before joining Daigle, appreciates not only the value of the telematics platform, but the service he receives as well. When he first started, he and Rick Jennings, his customer success representative, would have weekly Teams meetings to go over the platform and have small training sessions.

“Rick is always just a phone call away,” Marciante said. “I can text him on the side and say, ‘I’ll send a formal request but here’s what I have going on, do you have a solution or something I can try?’ He’s been great to work with, as has the whole FleetWatcher team.”

RJ Daigle is a great example of a paving contractor that has continued to adhere to the three pillars that built the company. But adhering to tradition doesn’t mean they are stuck in the old ways. Technology, including the FleetWatcher telematics platform, is helping them to enhance efficiency and cut costs in many areas. Those savings allow the company to deliver on their core principles of integrity, dedication, and quality, as they build the company for the next generation.

Since its introduction, the Weiler P385 has set the standard for commercial pavers. The P385C raises that standard.

Increase to 120 hp with the Cat® C3.6 Tier 4F/Stage V engine.

Variable speed and reversible conveyors and augers and a 25% increase in tunnel height provide optimal material output.

Modular conveyor drive and sealed chain case increase feeder system reliability and life.

Enhanced heat system performance with direct-drive hydraulic generator and elimination of GFCI breakers.

Fabrice Blanc, the vice president of TotalEnergies’ Bitumen Business Worldwide, was elected the new president of Eurobitume at the association’s spring general meeting in Prague.

“It is an honour to have been elected Eurobitume president at such an interesting and exciting time for the industry,” Blanc said. “During my 12-month tenure as President, my focus will include communicating bitumen’s place in a sustainable, circular economy and continuing to ensure that Eurobitume meets the needs of its members.”

Since 2023, Blanc has been a member of Eurobitume’s board of directors and was Eurobitume vice president for a year, from April 2024 to April 2025.

The Eurobitume members also elected a new vice president—Sergio Bovo, the CEO of Alma Petroli, based in Italy—and treasurer—Jean-Nicolas Desprez, the bitumen technical & quality manager for Europe wihtin Shell Trading & Supply. The three will help drive Eurobitume forward in pursuit of its vision and mission.

The BOD for Eurobitume now includes two new representatives: Tim Metcalf from FM Conway and Mario Sandor from BASF. Established in 1969, Eurobitume is the voice of the bitumen industry in Europe and aims to be the first reference for bitumen in Europe. On behalf of its members, Eurobitume educates and promotes the efficient, economic, effective, safe and sustainable use of refined bitumen in road, industrial and building applications.