Today’s Asphalt Plant

• Knock Out Plant Odors

• Transition to Propane for EPDs

• Builders Asphalt Loads Efficiently

• Knock Out Plant Odors

• Transition to Propane for EPDs

• Builders Asphalt Loads Efficiently

Astec paves the way for sustainable, innovative asphalt plants. The new IntelliPac Moisture System is a revolutionary solution that integrates seamlessly with Astec control systems. This provides unparalleled, real-time visibility into virgin aggregate moisture content. IntelliPac empowers operators to optimize mix design, minimize energy consumption, and reduce environmental impact. With Astec, you get superior asphalt production – better for the environment, better for your business.

The reverse air baghouse engineered to lead your plant to peak performance.

The Dust Pilot reverse air baghouse is built for high-capacity operations with precision airflow control and fewer moving parts, minimizing maintenance. Its robust, customizable design ensures cleaner air, enhanced plant performance, and compliance with environmental standards. Available in multiple sizes, the Dust Pilot delivers reliable and effective dust control tailored to your plant's needs.

6 – Smart Unplanned Downtime By Sandy Lender

8 – Prevent Heat-Related Tragedies with Coolwear By Sandy Lender

12 – Neutralize Odors at the Stack and Baghouse Improve community relations and stay in operation when you knock out odorous emissions at the HMA plant By Glenn B. Crisler II

16 – The 6 Steps to Take Before Starting Your Next Estimate By Bill Stanley

– Sustainable Roads with WMA By Dan Swiertz, PE

– Co-Hosted Industry

– International

By Claudia Wyrzykowski

Lender

28 – Assess the Dryer at Your Batch Plant Here’s how to inspect the dryer at your asphalt batch plant By Rick Rees

30 – Focus on Performance Proper Lubrication Strategies Save Money at the Plant By Clay Calk

32 – Understanding EPDs: How Propane Can Help Asphalt Producers Meet Targets By Reena Mistry

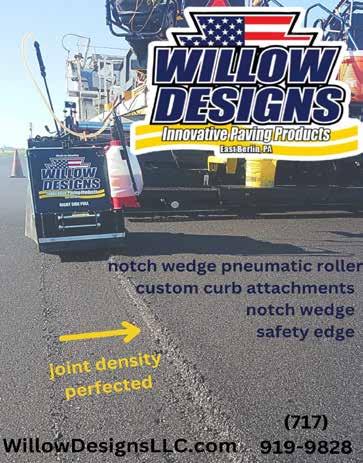

34 – Focus on Performance Builders Asphalt Uses P-Tier Loaders to Achieve Success on Major Projects From John Deere

Welcome to the new readers joining us this month. If you need a copy of AsphaltPro delivered to one of your team members, it’s easy to subscribe at https://theasphaltpro.com/subscribe/. Among our how-to project stories, you’ll find discussions of new tech, iron and best practices, to enhance your bottom line at the asphalt plant, lab and work zone. Amid our talk of “new tech,” we keep the essential worker in mind.

Even with intelligent systems—like Astec’s IntelliPac™ Moisture System, which computes necessary drying adjustments based on real-time aggregate moisture changes—we still need workers on the team who understand the basics.

A few years ago, industry was looking at the feasibility of putting a lone worker at a loadout site where automated controls handled logistics. While it’s within the realm of possibility, it’s not a safe solution to workforce gaps.

To oversimplify it—someone with a working knowledge of asphalt paving systems must monitor these advanced operations. We cannot think the new hire will hop onto the automation-filled roller and produce a bonus-worthy mat because he (or she) is proficient with a video game console.

Just because we can let AI systems compute impact spacing, yield, potential for vehicle incursion, and other vital aspects of asphalt operations, we still need sentient workers on the team. We need operators who understand mix design, production, and paving basics to program, use, and monitor not only the technology but its mistakes, too. If the AI on the breakdown roller senses an obstruction and shuts down vibration (good) and stops on the 300° mat, someone needs to know how to resolve the issue, so the 14-ton machine isn’t sinking two 84-inch-wide canals in the pavement.

My most recent “caution” comes courtesy of travel during World of Asphalt 2025. At the end of the show, I was fortunate to spend some time with my parents, who live in the St. Louis area. We met outside the city; Dad drove about an hour in his 2024 Honda hybrid before the car detected an error,

which it couldn’t identify, and shut down. He had no choice but to pull over to the side of I-44, and call Honda Roadside Assistance. I’ll not bore you with that part of the story. The point is the car decided to stop, so stop it did. It wouldn’t allow the driver to reach the next available exit or restart.

One might argue this was a safety feature.

As a person stranded on the highway for an hour, I’d suggest “safety” wasn’t the first thing that came to mind. What did come to mind was the inconvenience such a thing would cause to a contractor’s project.

Imagine being on a multi-million-dollar state job and your MTV flashes a message, “Error detected. Shutting down until you fix that.”

In the March/April edition, I wrote about the positive use of compaction technology allowing a less experienced worker to operate a roller to complete the day’s paving successfully. (See “NDDOT Trials New Technologies on Hwy 14.”) While at WOA, the AsphaltPro staff took notes on smart tech that would shut down to protect workers from struckbys and when detecting errors. The former— Sakai’s Guardman™—looks like a fantastic use of technology to prevent fatalities; the latter could be a fiduciary nightmare if you don’t have alternate equipment staged nearby.

Like my dad, you probably don’t anticipate a 1-year-old machine will experience a small rock piercing the radiator and sending its computer into panic mode. You probably don’t anticipate needing a backup breakdown roller at the side of the multi-million-dollar paving project. Are we in the infancy of the “smart” technology where backup machines are necessary? I’d like to hear your opinion.

When you set up your paving train, do you make concessions for smart equipment to shut down? That’s some unplanned downtime I hadn’t considered prior to WOA travel. Have you considered it?

Stay Safe,

Sandy Lender

602 W. Morrison, Box 6a Fayette, MO 65248 (660) 728-5007 • www.theasphaltpro.com

GROUP PUBLISHER

Chris Harrison chris@ theasphaltpro.com

EDITOR

Sandy Lender sandy@theasphaltpro.com (239) 272-8613

DIGITAL EDITOR

Sarah Redohl sarah@theasphaltpro.com (573) 355-9775

MEDIA SALES

Cara Owings cara@theasphaltpro.com (660) 537-0778

ART DIRECTOR

Kristin Branscom

BUSINESS MANAGER

Susan Campbell (660) 728-5007

AsphaltPro is published 11 times per year. Writers expressing views in AsphaltPro Magazine or on the AsphaltPro website are professionals with sound, professional advice. Views expressed herein are not necessarily the same as the views of AsphaltPro, thus producers/contractors are still encouraged to use best practices when implementing new advice.

SUBSCRIPTION POLICY: Individual subscriptions are available without charge in the United Sates, Canada and Mexico to qualified individuals.

One year subscription to non-qualifying Individuals: United States $90, Canada and Mexico $125.00. For the international digital edition, visit theasphaltpro.com/subscribe/

BY SANDY LENDER

hile asphalt professionals implement safety measures to protect workers from extreme heat and the effects thereof, heatstroke is still a danger to watch out for. If you see the signs of heatstroke in a co-worker while in the field—or at the plant, etc.—don’t hesitate to act. Call for help and get the affected worker to a shaded or sheltered area.

The Korey Stringer Institute provided, “Heatstroke is a multi-system illness caused when heat accumulation outpaces heat dissipation.” Researchers at the institute, specifically CEO Dr. Douglas Casa, spoke of an emergency device to assist workers who are overcome by heat.

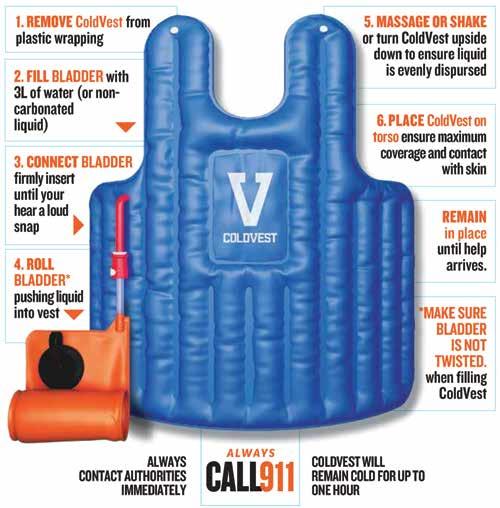

“ColdVest is a viable treatment option for rapid cooling during transport or in remote work situations when cold water and ice are not available,” Casa said.

His team studied the ColdVest emergency product from the company ColdVest. It’s designed to support compliance with the Occupational Safety and Health Administration’s (OSHA) National Emphasis Program (NEP) on Heat Standards.

Another way to stay in compliance with the NEP is to prevent overheating. Sylvia Allen, founder and CEO of StaCool Industries Inc., Lecanto, Florida, designed and manufactures the StaCool Vest™ Body Core Cooling System, which is designed to be worn while working for prevention of emergencies. Her invention incorporates the use of frozen gel packs inserted into vest panels to help maintain safe body temperature while working.

She shared, “The StaCool Vest is worn while working to help prevent the need of the ColdVest. The StaCool Vest can be worn so that the body temperature is kept at a comfortable level, not reaching the point of heat exhaustion. Wearing the StaCool Vest while working also helps with symptoms prior to heat exposure such as weakness, fainting, etc., which then could result in the possibility of more extensive

injuries, not only to the person affected but to others as well.”

Allen’s vest is designed to be worn over and over again, with removable gel packs to freeze overnight and re-insert at the beginning of a new workday. As a preventive measure, it helps keep the worker from going into an emergency situation.

“The ColdVest is a great concept for those that reach that stage of heat exhaustion or other heat-related issues,” Allen said. “Wearing a StaCool Vest while working will help to prevent the need for use of the ColdVest; however, with that said, there is always that possibility, even while wearing the StaCool Vest, if not changing out

ThermoPaks in a timely manner or if any other health issues or emergencies arise, having the ColdVest on hand and available while waiting for additional help to arrive would be a great addition to the safety equipment. Our summers are getting hotter and that is the new normal now, so any additional cooling equipment that can help prevent serious injury is always welcome.”

A colleague in distress isn’t always noticeable. “Commercial contractors have numerous people working on a project at a time,” Allen reminded readers, “so to be able to watch each and every person working and be able to notice the signs of heat exposure and exhaustion is almost impossible unless

With over a century of innovation to its credit, Blaw-Knox® pavers have earned a reputation for quality, durability, and performance unmatched in the industry. Our continued focus on innovation is what drives our product engineering with designs that improve performance while maintaining user-friendly, ergonomic comfort and reliability for the operator.

BLAW-KNOX, THE LEGACY LIVES ON.

For more information contact your Blaw-Knox dealer or visit www.blawknox.com

—Source: Associated Builders and Contractor

the person is able to bring it to someone else’s attention. Unfortunately, with heat stress, that rarely happens because the person affected does not notice the signs themselves until it’s too late. Individuals working with heavy equipment such as what’s used in the asphalt industry are also susceptible to heat exposure beyond just the physical work; this I would consider extremely dangerous to those around them.”

If you see the signs of heatstroke in a colleague—which the Mayo Clinic lists as a core body temperature of 104°F or higher, confusion, agitation, slurred speech, delirium, nausea and vomiting, flushed skin, rapid breathing, racing heart rate, and headache—immediately call 9-1-1 and help the affected worker get to a shaded area. If you have a ColdVest on hand, the steps for its use are outlined in the sidebar. If you don’t have a ColdVest on hand, Mayo Clinic recommends removing the victim’s excess clothing and spraying them with cold water. Place ice packs or cold, wet towels on their head, neck, armpits and groin. Check out the more in-depth article "Comply with NEP” for additional guidance.

Step 1. Remove ColdVest from its plastic wrapping.

Step 2. Fill the bladder with 3 liters of non-carbonated liquid.

Step 3. Connect the bladder by inserting the tube to the vest’s red receptacle until you hear a loud snap.

Step 4. Roll the bladder like a toothpaste tube, pushing water into the vest. (Note: Make sure the bladder isn’t twisted when filling the vest.)

Step 5. Massage, shake or turn the vest upside down to ensure water is evenly dispersed.

Step 6. Place the ColdVest on the victim’s torso; ensure maximum coverage and contact with skin. Remain in place while waiting for emergency personnel to arrive. ColdVest is designed to stay cold up to one hour.

Improve community relations and stay in operation when you knock out odorous emissions at the HMA plant

BY GLENN B. CRISLER II

Asphalt production and paving are essential foundations for modern infrastructure. Despite its indispensable nature, when the production of asphalt generates pungent odors, it negatively impacts surrounding communities and potentially creates operational disruptions. This problem is widespread due to asphalt’s global demand, as well as increasing urban development in areas surrounding production facilities.

The volatile organic compounds (VOCs) in asphalt binders create emissions, which can cause concerns from neighbors and passersby smelling the offgas. If left unaddressed, these concerns can become complaints, which can lead to regulatory restrictions.

This article explains the intricacies of odor control in asphalt production, particularly at the stack and baghouse. It also examines modern and effective solutions using plant-based formulations and delivery systems, mitigating emissions and fostering positive neighborly relations.

In asphalt production facilities, both the stack and baghouse play a distinct role in managing emissions. Understanding their functions and how they influence odor release, while rudimentary to most readers, is necessary for implementing effective odor control strategies.

Readers will recognize, the stack vents exhaust gases generated during various stages of production, including:

• Aggregate drying,

• Asphalt binder heating, and

• Aggregates and binder mixing.

The stack’s primary function is to vent these hot gases and direct them away from the facility and surrounding areas. Stack height and design play a key role in dispersion, reducing the concentration of odors at ground level.

In many cases, plant neutralizers are blended directly into the asphalt mix, but for odor control at stack and baghouse outlets, vapor phase systems provide a simple and precise methodology for delivery. These systems disperse product as a vapor, maximizing contact with airborne VOC key emission points. Ecosorb vapor phase dispersion systems are designed to distribute plant-based odor neutralizer as a vapor at VOC key emission points, maximizing contact with odorous air without the need for water dilution.

Readers will also recognize, the baghouse is an air pollution control device that removes particulate matter, such as dust, from the exhaust streams before they are released through the stack. It functions as a large filtration system, trapping particles in fabric bags, while cleaner air passes through.

While effective for removing particulates, the baghouse does not inherently remove VOCs, which are the primary odorous offenders. These malodors pass through baghouse filters in the clean air streams and are typically released into the atmosphere. While optimizing baghouse operation and maintenance improves overall air quality and indirectly contributes to odor reduction by minimizing dust emissions, absolving the issue adequately requires addressing VOCs more comprehensively with additional processing.

The variable chemical composition of asphalt fumes is a leading challenge in asphalt production odor control, as it creates a dynamic mix of VOCs that fluctuates based on several factors.

Crude oil variability—Asphalt, a byproduct of crude oil refining, inherits the variability of its feedstock. Different crude oils have distinct chemical compositions, influencing the types and concentrations of VOCs produced during asphalt production. The use of “opportunity crudes,” which are lower quality and higher in sulfur content, further complicates odor management.

We’ve been designing and manufacturing custom mixing solutions in Tennessee for nearly 40

LEFT: An Ecosorb field scientist collects air samples around a facility to ascertain an odor profile. RIGHT: Markes thermal desorption tubes contain sorbent material designed to efficiently capture airborne odor molecules during sampling, and to preserve them at representative concentrations for lab analysis up to several weeks after collection.

Asphalt binder grades—Different asphalt binder grades have varying viscosities and chemical makeups, causing variations in VOC emissions during heating and mixing. In particular, asphalts with higher viscosities require higher temperatures for processing, which increases volatilization of odorous compounds.

Recycled asphalt pavement (RAP)—The incorporation of RAP, while a sustainable practice, introduces additional complexity. RAP contains residual binders from previous asphalt mixes of varying age and source, which release their own unique malodors not found in the base asphalt.

Additives and polymer modification—Additives and polymer-modified asphalt binders are designed to enhance pavement performance. However, in addition to releasing their own VOCs when heated, the additives and binder can react with each other, further diversifying the odor profile.

Regional and seasonal variations—Crude oil sources and refining processes vary geographically, leading to regional differences in asphalt binder composition and odor profiles. Seasonal weather changes also influence VOC volatilization rates, affecting odor intensity.

Beyond commonly recognized hydrogen sulfide (H2S) offgas, other VOCs play a significant role in the overall odor profile. Mercaptans, for example, are potent sulfur-containing compounds with a garlic-like odor, and they are frequently present alongside H2S. A wide range of hydrocarbons—including aldehydes, ketones and aromatics—also contribute petroleum-like notes to the mix.

Operational factors further influence odor emissions. Processing temperatures impact VOC volatilization, with higher temperatures intensifying odors. Additionally, wind speed and direction affect odor dispersion, influencing the perceived intensity and impact on surrounding areas. Even plant layout and surrounding topography affect airflow and odor dispersion patterns.

Effectively controlling odors in asphalt production requires a holistic understanding of operational factors and all odorous components’ chemical composition. Addressing only H2S, for instance, is insufficient, because it overlooks the contributions of other VOCs and the dynamic nature of asphalt odors. Successful mitigation strategies must target and neutralize the specific odor-causing compounds in each mix, considering multiple contributing factors.

To address these and other challenges, modern and eco-friendly plant-based formulations leverage scientific advancements to neutralize odor-causing compounds at their source. These blends utilize natural plant oils and other biodegradable ingredients to effectively neutralize a broad spectrum of VOCs, including H2S, mercaptans and other hydrocarbons.

These products do not merely mask odors, but instead chemically react with and break down odor-causing molecules, significantly reducing the smell. This targeted approach provides both greater efficacy and environmental responsibility compared to traditional methods that rely on harsh chemicals and masking agents.

Recognizing the inherent variability in asphalt odor profiles, specialized suppliers offer both standard and custom solutions. Standard blends provide convenient and cost-effective odor control, covering a variety of compounds common in asphalt mixes. This approach increases implementation speed and simplifies startup.

For more complex or unique odor profiles, custom formulations offer a tailored tactic. In these cases, a specialized supplier employs advanced analytical techniques, including gas chromatography-mass spectrometry (GC-MS), to pinpoint the specific VOCs responsible for the odor at a particular plant. This type of detailed analysis guides the development of a customized blend of plant-based ingredients, optimized to react with the facility’s specific odor profile.

Effective application of these plant-based solutions is as important as the formulations themselves. In many cases, plant neutralizers are blended directly into the asphalt mix, but for odor control at stack and baghouse outlets, vapor phase systems provide a simple and precise methodology for delivery. These systems disperse product as a vapor, maximizing contact with airborne VOC key emission points. Their low-maintenance design is comprised of nozzles that are designed not to clog.

Vapor phase systems provide flexibility, adapting to multiple airflow rates. Leading suppliers use computational fluid dynamics modeling to optimize dosing, a sophisticated technique that simulates airflow patterns within the stack and baghouse. This enables precise placement of injectors to ensure thorough mixing, maximizing the interaction between neutralizer and targeted VOCs.

At one hot-mix asphalt (HMA) manufacturing facility situated near a residential area, frequent community complaints about strong and persistent odors posed shutdown risk. The plant served numerous contractors and construction firms, producing over 1,500 tons of asphalt daily.

The facility previously relied on a standard odor-mitigating additive, but changes in asphalt mix composition—including increased use of RAP—and the introduction of a new polymer-modified asphalt, rendered the existing solution ineffective. Recognizing the urgency of addressing the odor issue to avoid regulatory action and improve community relations, the plant approached Ecosorb, a leading supplier of plant-based odor control solutions, to assess the situation and develop a targeted solution.

The first step entailed comprehensive air sampling at various locations around the facility, including the stack, baghouse outlet and storage areas.

Using Markes thermal desorption tubes, the supplier collected samples over multiple production runs, providing a comprehensive understanding of the plant's odor profile with different operating conditions and asphalt mixes. The samples were then analyzed using GC-MS at the supplier’s lab to identify and quantify the odor-causing compounds present in each sample, providing a detailed breakdown of the facility’s odor profile. The GC-MS data revealed not only the presence of H2S and mercaptans, but also a host of other contributing VOCs.

The team then formulated a customized blend of plant oils to neutralize the identified odor-causing compounds at a molecular level. The blend was dispersed at the sampling locations as a vapor, maximizing contact with the odorous air without the need for water dilution.

In the subsequent months after the solution was installed, the plant noticed a significant reduction in odor complaints from the surrounding community, enabling it to preserve operations and improve community relations. This outcome highlights the power of a targeted, data-driven approach to odor control, utilizing plant-based solutions to effectively and sustainably address complex odor challenges.

Odor control is an integral component of responsible asphalt production. While conventional masking agents are inadequate in addressing this issue, leading suppliers with application expertise offer standardized and customized solutions for manufacturers, providing optimal odor control with formulations that fit each specific application.

By applying plant-based odor neutralizers at the stack and baghouse, producers can effectively mitigate foul odors using safe, environmentally friendly and cost-efficient methods. These formulations do not mask smells but instead neutralize them by breaking down and nullifying odor-causing VOCs present in the offgas. These solutions empower asphalt manufacturers to proactively manage odor challenges, ensuring compliance, fostering positive community relationships and facilitating focus on core business operations.

Glenn B. Crisler II, Ph. D., is the senior research and development scientist for Ecosorb, where he manages the research & development laboratory.

Hard-won know-how for the next generation

You don’t get paid what you’re worth—you get paid what you estimate. Industry leader Bill Stanley shares how he protects his profits by sizing up clients, projects, and timing before he ever puts pen to paper.

BY BILL STANLEY

”Ideserve to profit from my hard work.” Reread that. Commit it to memory. Make it your mantra. I’ve made it mine. Let me explain with a story.

A long time ago, I arrived to estimate a small commercial project. The business owner eyed my shiny new truck and said, “I’m not paying for that fancy truck of yours.” This isn’t the first time someone implied that an asphalt professional shouldn’t be able to afford nice things.

I wanted to tell the guy his small project wouldn’t pay for one truck tire, but instead I said this: “You have two options: hire an unsuccessful contractor who won’t answer your call when your lot falls apart in a few years because he’s out of business, or hire a successful contractor like me.” He hired me.

Getting paid what you’re worth is so important that it was the first topic I ever wrote about for AsphaltPro (July 2024, “Know Your Worth to Get Paid Your Worth”), so it should come as no surprise that an article about estimating would start with knowing your worth.

Once you’ve understood that much, here is my approach to the estimating process that I use to ensure my business is as profitable as possible. There’s a whole lot that happens before I ever put pen to paper—we’ll cover that in this issue and the rest of my estimating process in the July issue.

Consider economic conditions. Profitable estimating starts well before a prospective customer calls you for a quote. First, by considering the economic conditions you’re working in. In the May issue of AsphaltPro, I predicted that we’re entering a ‘Golden Age of Paving’ with my advice on how to level up your asphalt business.

If I’m right, this means we at American Pavement Specialists are going to get even pickier with our projects. That means focus-

Choosing the right project starts with identifying work that fits your business model, Stanley said—like this well-funded, clearly scoped residential development.

ing on work that is most profitable for us and choosing our customers wisely.

During this time, we want to focus on established customers who have solid funding. It’s a bit counter-intuitive, but it makes sense if you read the example I shared in the May 2025 issue about how APS had our best year ever in 2008 during the Great Recession—because the only people who had hired us were well-established companies.

On the flip side, when the economic outlook is positive, companies may bite off more than they can chew. This can be particularly dangerous for the asphalt contractor because we’re the last one in and the last one to be paid. Will that speculative client building a new strip mall have enough money left to pay you by the time the project is finished—after he’s paid every contractor who came before you? You can bet I’m going to do extra due diligence on the

project owner or general contractor for a project like that, especially if there’s plenty of other, less-risky work to be had.

Consider the time of year.

For any paving contractor, January through March is a nail-biting time. Until there’s work on the books, you want to be sure you can guarantee 40 hours a week for the crew coming back at season start-up. For this reason, many contractors bid more cautiously in the pre-season. As the books fill up, our confidence grows and we become more selective with the work we fill the remainder of our books with.

For example, we started the 2025 season with 20 miles of municipal road work scheduled in small towns in our area. This staple work isn’t hugely profitable, but it keeps

things stable. Having this work in the books allows us to go after only the projects that are perfect for us.

Even the estimating process can be lengthy—and that costs me money, too. People love to ask for a “free estimate,” and sure, the estimate might be free on paper, but my time isn’t. I hate when someone expects me to spend hours reviewing plans, making calls, or driving to a site, like that time doesn’t have value. When you’re running a business, time is one of your most expensive resources, and giving it away for free adds up fast.

Understand the difference between bids and estimates—and prioritize accordingly.

Many years ago, a prospective new customer was hounding me for a bid on a driveway. He insisted I meet him at the project site on a Sunday morning. When I arrived, he’s standing in front of a densely wooded lot. He hadn’t even bought it yet and he was trying to get an estimate on the driveway!

There’s only so much time in a day, so many days in a week, so many weeks in a year. Given that reality, I’m going to prioritize estimating projects happening this paving season above those happening next year (or later). This is equally true of bids requested by general contractors who haven’t yet won the bid themselves.

The closer the project is to paving also simplifies the estimating process and increases the accuracy of my bid. How accurate could my driveway bid have been when all I see is a wooded lot? The same is true for an empty field that will one day, several years from now, contain a fulfillment center, strip mall or apartment complex.

The quicker the customer wants paving to begin will also speed up my estimating process. If a prospective customer calls and says they want the project done in three weeks, we’re going to get started on the estimate immediately. If the project’s slated for two years from now, I’m probably not going to spend an hour discussing the nitty gritty details of that project when they’re likely to change by the time the paver touches the ground.

We often get emails from multiple general contractors bidding on the same project. This gives us a chance to duplicate our bid and increase our chances of getting the job regardless of which GC wins the bid.

Never underestimate the value of referrals.

Referrals are the cornerstone of my business. Anytime I receive a phone call from a potential customer, I’m not just on the phone with that customer. I’m on the phone with everyone they know. If they choose to hire APS and we do a good job, you can bet they’re going to refer us to their friends and colleagues. Whether that customer manages 12 apartment complexes or owns 20 Taco Bell franchises, their friends and colleagues are probably in a similar financial situation. Once I’ve earned my customers’ trust, the whole process becomes much easier for them and for us. They won’t feel the need to collect 10 estimates; we don’t have to trade so many emails and paperwork. Once someone’s a returning customer, all they need to do is call my cell phone and we can work it out for them really quickly.

Earning trust is a two-way street. To protect ourselves, we structure our deposits and progress payments differently, put everything in writing, and charge a higher amount for customers with whom we don’t have a history.

Take your time to determine if the project’s a good fit. Whenever a new customer requests an estimate, we ask a standard set of questions to gauge how well their project fits into our wheelhouse. We want to know their project timeline and their budget. For example, if they’ve got a budget of $500,000 but the project seems like a $1 million job, that’s going to be a problem. I want to know if the work will be inspected by a third party and if the payment will come from a third party, as well as payment terms and if there will be a retainage involved—among other questions.

My questions probably won’t be the same as yours, because they’re customized to identify the types of work we want to perform, the type of work we’re set up to perform, and the type of work we can perform most profitably. The more of those questions the customer answers the way we’d like them to, the better of a fit the project is for us. If the customer doesn’t answer at least half of those questions the way we want, we’re probably going to refer them to another company that is more aligned with their project.

Don’t be afraid to walk away. The other day, I showed up to a local school system for a mandatory walk through. The project wasn’t even very big—a volleyball court, 600 feet of curb, some maintenance work—but there were 10 other contractors there! Given the project specifics and its location 40 miles from our shop, I realized the chances of being the low bidder on this project were probably slim to none. So, I scratched my name off the sign-in list and walked out. You know what’s worse than not winning a bid? Not winning a bid while earning yourself a reputation that you’re too expensive. I don’t want that reputation when that same school system requests bids to pave their parking lots, a service for which I know my bid will be very competitive.

It’s also a matter of time. The time I save estimating a project that isn’t a good fit can be spent on projects that are a perfect fit. If our job board isn’t full, I can always reconsider customers who might’ve only answered six (or five, or four) of our target questions right.

If you want to be more successful in your estimating, this starts with knowing what types of projects are most profitable for your company (if you haven’t read my article “What’s Your Why?” in the March/April 2025 issue of AsphaltPro, go read that now). The second key is to establish an estimating process that sets you up to do more of those profitable projects (and less of the other stuff), as I’ve outlined here. For the third, I’ll go back to where this all started. Remind yourself that you and your company deserve to be profitable for the good work you do.

Stay tuned for the July issue of AsphaltPro, where Bill Stanley will explain the rest of his estimating process, from drafting a preliminary quote (without leaving his office) to closing the deal and building a referral-based business with one new customer at a time.

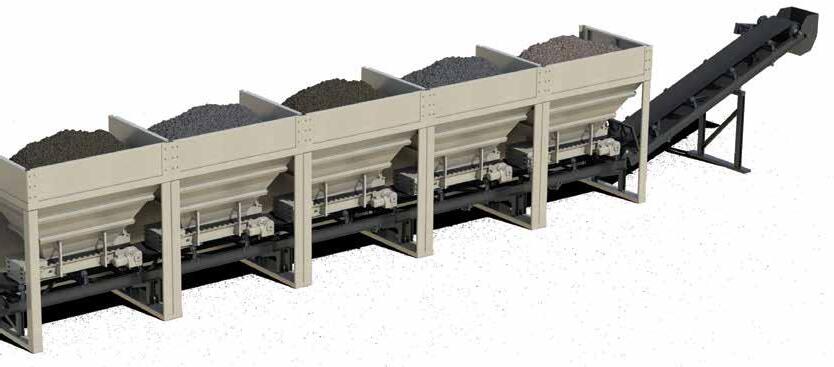

A snapshot of the millions of dollars of our asphalt plant par ts inventory to suppor t producers throughout Nor th America.

If the part you are looking for is not listed, please call. Chances are, we will have what you need.

We carry parts for every make and model of asphalt equipment.

Motors

Baghouse Parts

Silo Parts

Replacement Flighting

Sprockets for Slat Conveyors

Thrust Rollers to Retrofit

Rotary Airlocks

Baghouse Valves

Baghouse Valve Repair Kits

Burner Safety Switches

Trunnions

Hot Oil Heaters

Electronic Parts

Electronic Safety Switches

Thermocouples

Used Plant Components

RAP Gator Recycling Breakers

Air Cylinders

AC Metering Pumps

NiteOwl Plant Alert System

Dryer Seal Systems

Gear Reducers

AC Valves & Seals

Warm Mix Systems

Inline Liquid Blending Systems

Wear Plates

Custom Shafts

Bearings

Idler Wheels

Variable Frequency Drives

Actuators

Used Asphalt Plants

Hotmix Parts is located within minutes of the UPS world air hub. Many parts can be delivered within hours!

BY DAN SWIERTZ, PE

In the construction industry, the asphalt paving sector has consistently led the way in sustainability efforts. Warmmix asphalt (WMA), loosely defined as asphalt mixtures produced with a significant temperature reduction, is a suite of technologies that allows the asphalt paving industry to gain even more ground on sustainability goals. Decades of laboratory research and field performance validate the effectiveness of WMA, making it a winner for pavement performance as well. As agencies adopt more sustainability-weighted purchasing practices, WMA technology will serve as a valuable tool for producers to remain competitive.

For asphalt mix producers, incorporating WMA technologies into daily practice is straightforward, but does require some additional consideration during the mix design and mix production processes. This article details how several Wisconsin agency-producers are leveraging WMA technology to meet paving demands locally while fostering responsible stewardship of resources within the industry at large.

There is consensus within the asphalt industry that the objective of WMA is to produce and place asphalt mixtures at temperatures below those used in standard hot-mix asphalt (HMA) without sacrificing performance. The National Asphalt Paving Association (NAPA) uses a temperature reduction of 10°F as a temperature reduction threshold when surveying mix producers, but temperature reductions of 25-50°F are common and reductions up to 90°F have been reported, according to “Asphalt Paving Industry Survey on Recycled Materials and Warm-Mix Asphalt Usage, 2022,” Information Series 138 (IS 138) from NAPA. WMA technologies generally fall into two categories: additive technologies and

asphalt plant-based foaming technology. Use of plant-based foaming technologies has steadily declined since about 2010, with additive technologies increasing in prevalence during the same timeframe. In 2022, chemical additives represented about 64% of all WMA technologies used, according to IS 138.

Asphalt Materials Inc.’s AMIBIND™ Performance Graded paving asphalts with WMA technology are an example of WMA chemical additive technologies that offer producers the flexibility of incorporating WMA into their existing practice without plant modification. For producers wishing to use WMA intermittently or on a trial basis, as was the case with the Oconto County Highway Department project, AMIBIND WMA is delivered and handled at the plant the same as standard PG asphalt.

Aside from the obvious fuel and energy savings during production, use of WMA technology has positive mixture performance impacts. Reducing production temperature lowers the rate of volatilization and oxidation (“aging”) of the asphalt binder during production, improving pavement durability. Many WMA technologies also function as compaction aids and anti-stripping agents even when used at standard hot mix temperatures. Lab and field studies show that WMA mixtures exhibit equivalent or even superior cracking performance to their HMA counterparts.

Temperature reductions at the screed of 30°F or more are common with AMIBIND™ WMA with good paving conditions and monitoring quality control in the field. Oconto County Wisconsin Highway Department

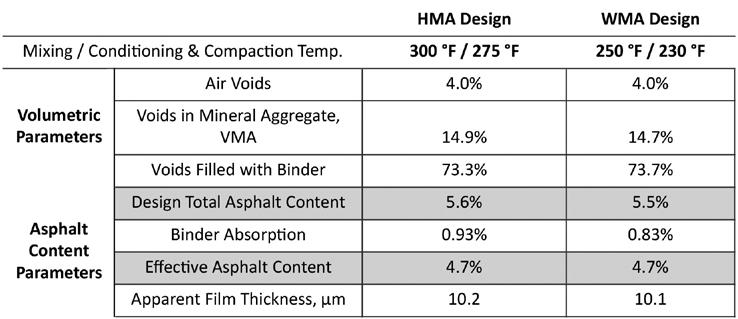

The mix design process and materials used for WMA projects are the same as those used for HMA, except care must be taken in the design lab to simulate the lower plant temperatures expected in the field.

The amount of asphalt binder absorbed by the virgin aggregate during the mixing and conditioning process may decrease when lowering mixing and conditioning temperature. The result is a potentially lower total design asphalt content, but similar effective asphalt content relative to HMA. Since effective asphalt content drives Voids in Mineral Aggregate (VMA) and durability, mixture performance is not sacrificed. The mix design theory and process remain unchanged in all other aspects relative to HMA. An example of the mix design process targeting a specific temperature reduction for the Barron County Highway Department is shown in Table 1; the total effective asphalt content remains unchanged, while the total asphalt

content is actually reduced slightly when using AMIBIND WMA. By reducing total asphalt content, this process ultimately yields additional cost reduction.

Agency specifications vary on how WMA additives are approved or allowed to be incorporated. Most agencies dictate that WMA additives may not substantially change the asphalt binder performance grade properties when used at the manufacturers’ recommended dosage levels. Some agencies allow the contractor to dose their asphalt binder with WMA additive at the mixture production facility, while others allow for asphalt binder terminal dosing only. Typically, the WMA additive and dosage used for a specific mix design is required to be listed on the mix design cover sheet.

Mix plant operations remain mostly unchanged relative to standard practice when using AMIBIND WMA. The aggregate must still be dried and thoroughly coated with asphalt prior to loadout. With modern asphalt plants the primary concern with lowering the mixing temperature is that the baghouse dew point will also decrease, which can create clogging and reduced efficiency. To safeguard against this, a best practice is to start production for the day using standard HMA temperatures (usually running 50-100 tons is sufficient) and slowly lower the temperature until the desired target is reached while monitoring baghouse temperature and aggregate coating, and watching for signs of residual moisture in the mix. The plant tem-

perature is again increased before shutdown to make sure the baghouse is completely dry for the next day.

Residual moisture in the mixture is a common but easily remedied problem when significantly lowering plant temperature that can create significant challenges achieving compaction in the field. A simple test to check for residual moisture is to sample mix into a clean steel pail with a tight-fitting lid. After approximately half an hour check the underside of the lid for condensation. It should be completely dry, signaling complete removal of moisture from the mix. Checking again at the paver using the same test can help troubleshoot whether residual moisture is causing compaction problems. If moisture is present, adjusting how stockpiles are worked and sampled, adjusting plant production rate and increasing plant temperature are all variables that can be used to remediate the problem.

The ambient climate conditions, time of year, aggregate moisture, haul distance, paving substrate and planned layer thickness all have a hand in determining the magnitude of temperature reduction that can be successfully achieved. Communication between the plant operators, paving crew and onsite density technicians is critical to fine tuning the temperature ranges that work best for a prevailing set of conditions. Lowering plant temperatures does not need to come at the detriment of paving quality. Taking detailed notes in the field will, over time, build a database of conditions that operators can replicate successfully on future projects.

WMA also works seamlessly with other paving technologies. The Sheboygan County, Wisconsin Transportation Department

Residual moisture in a mix sample will be present as condensation on the underside of the sample lid and may drip down the side of the pail. Adjusting how stockpiles are managed and worked, along with fine-tuning plant production rate and temperature, can remedy the problem.

had been utilizing J-Band®, a Void Reducing Asphalt Membrane (VRAM), to increase density at the longitudinal joint for several seasons before integrating AMIBIND WMA in 2024. Even with placement temperatures of 30°F or more below their standard practice, the WMA paving process incorporated VRAM at the centerline construction joint without issue and without changing mix placement or rolling practice significantly.

Agencies are finding creative ways to promote the use of WMA technology. The Minnesota Department of Transportation (MnDOT) is planning a WMA pilot program with seven projects in 2025 offering contractors up to 4% incentive for achieving various temperature reduction thresholds at the mixing plant. More widespread implementation of Environmental Product Declarations (EPDs) will also drive WMA usage as mix producers seek to lower their impacts and remain competitive in a new purchasing environment where using terminally blended WMA technologies allows producers to gain confidence with WMA in their system without investment in additional infrastructure.

Dan Swiertz is a specialty product technical manager for Asphalt Materials Inc., working out of the H.G. Meigs Portage Wisconsin location. For more information email dswiertz@ asphalt-materials.com.

BY SANDY LENDER

Even if you attended the 2025 co-hosted World of Asphalt Show & Conference (WOA) and AGG1 Aggregates Academy & Expo in St. Louis March 25-27, you probably missed a technology or two due to the overwhelming number of offerings on site. This recap of the show won’t be able to summarize every single thing available to the asphalt and aggregates professional that week, but AsphaltPro Magazine has multiple product galleries coming up over the next few months in which you can find new product news straight from the combined shows. Let’s kick off the coverage with a look at some important updates.

Asphalt professionals have sought solutions to the workforce challenge for years, with the introduction of proxy mechanics as far back as 2018 (see this discussion in the Training Directory 2018 on TheAsphaltPro.com) through the introduction of artificial intelligence (AI) assisting intelligent compaction (IC) in 2024 (see this discussion in the “NDDOT Trials New Technologies on Hwy. 14” also on TheAsphaltPro.com). Methods for training and assisting our evolving workforce dotted the WOA/AGG1 tradeshow floor.

For example, the growing portfolio from CM Labs, a vendor for simulation-based training solutions in the construction, utilities and ports industries, announced prior to WOA the launch of its Intellia Single Drum Roller Simulator Training Pack, which it states is the industry’s first-ever single drum roller simulation training. It’s designed to address the growing labor shortage by delivering a highly realistic training experience tailored to beginners who have no prior experience operating heavy equipment. This training module was on display at WOA and is described in this month’s product gallery. Training took place in the education sessions and around the show floor. AsphaltPro Magazine once again hosted its “Ask the Expert” with American Pavement Specialists’ Bill Stanley in the hot seat. Attendees could

The 2025 WOA/AGG1 event featured a record amount of square footage, including a new feature called the Community Zone. “This success is a direct result of the collaboration and hard work of all our partners, exhibitors and staff,” said World of Asphalt Show Director Brittany Schmidtke. “The momentum and growth in the asphalt and aggregates industry is evident by what we saw exhibited on the show floor and ultimately provided a richer experience for our attendees.” Photo courtesy of the Association of Equipment Manufacturers’ WOA website

stop by the AsphaltPro booth and fire their questions and quandaries at Stanley for the hour that he was available. That popular series returns to CONEXPO-CON/AGG 2026 with an impressive lineup already signing up over the five-day show to offer answers for paving, production, safety and QC/QA, so watch this space for details.

For contractors seeking a way to augment a “green” workforce, exhibitors had offerings in the AI space, as well. GSSI and Hamm have collaborated on aspects of the Hamm Smart Compact system to assist roller operators in perfecting compaction no matter the operator’s skill level. And the engineers at Sakai have added echelon rolling to

its Guardman™ technology for safeguarding equipment and personnel. All of these teams were on hand to discuss the benefits of implementing these systems to help the new— and veteran—workers on the crew, and some of those benefits are outlined in this month’s product gallery.

Show management reported more than 11,500 industry professionals gathered in the America’s Center Convention Complex, stating in a March 27 press release that 59% of total attendees were under the age of 45, reflecting the positive future of the industry. Additionally, 10% of attendees were women, underscoring this growing segment of the industry. Visitors traveled from across the country and

American Pavement Specialists’ Bill Stanley showed details of the new CP-1000 center paver attachment to attendees during the product’s unveiling at the ShoulderMaster booth. Photo courtesy of AsphaltPro Staff

The next generation 1200-CC portable crushing and screening plant from Eagle Crusher features a self-lowering control panel. Photo courtesy of AsphaltPro Staff

abroad, some traveling as far as Australia, England, Argentina and Mexico to take part in the leading asphalt and aggregates trade show and conference, including a special delegation from Nigeria.

Attendees engaged in more than 120 educational sessions through the People, Plants, and Paving and AGG1 Academy. These conferences covered a wide range of topics essential to the asphalt and aggregates industries. AEM reported a few of the most popular sessions included “Lean Principles: It’s About People, Process & Change,” “Unleashing the Power of Intentional Leadership: Leading Yourself to Lead Others,” “Autonomous Quarry Trucks 101,”

“Extreme Ownership for Business and Life,” “Laydown Best Practices” and “Compaction 101: Doing the Right Things, the Right Way.”

In addition to education and equipment, the co-located shows offered a venue for networking and business meetings. For example, a new feature of the show this year was the Community Zone, which provided a dedicated space for attendees to relax, work and network. The Community Zone included presentations, such as one from Ashley Batson of the Women of Asphalt, and a book signing by Ajax Paving’s Vince Hafeli.

“The 2025 AGG1 and World of Asphalt show offered the increased ability for exhibitors and attendees to connect—from the Community Zone area, to the larger show floor space and media one-on-one opportunities,” said Michele Stanley, interim CEO of NSSGA. “Every year the event becomes better with new innovations and updates. We are proud to offer our NSSGA members this unique meeting environment so they can continue to reach their own business goals.”

And speaking of NSSGA, the association’s annual convention ran concurrently with AGG1. More than 600 aggregates industry leaders convened in St. Louis for the meeting, which featured the announcement of the 2025 NSSGA Leadership including Board Chair Ted Baker II of Blue Water Industries and the presentation of the Barry K. Wendt Memorial Commitment Award to Ward Nye of Martin Marietta. The annual membership meeting keynote was a moderated discussion by football legend Archie Manning. This year’s meeting comes as the association marks its 25th anniversary.

The first general session of the NSSGA Annual Convention March 23-26 featured Dr. Helena Boschi, an internationally recognized psychologist and neuroscientist specializing in the application of brain science to the workplace.

Women of Asphalt also hosted a conference-within-a-conference with the second annual Women of Asphalt Day. Women and allies from across the country participated in special programming and networking activities.

Show management shared 10% of show attendees were women, underscoring that growing demographic in our industry.

On March 26-27, the Women of Asphalt organization hosted its Women of Asphalt Day, during which industry professionals presented career and motivational information for the men and women who’d registered to attend this conference-within-a-conference. Also at the show, the AsphaltPro staff had the opportunity to meet with WofA leadership to make plans to support the group’s important work into the future. From left: Cara Owings, media sales representative of AP; Sarah Redohl, digital editor for AP; Brittyn Heisler, national executive director of WofA; Sandy Lender, editor of AP; Ashley Batson, chair of the board of directors for WofA. Photo courtesy of Rapport Storytelling

“We’ve talked to a lot of women,” said Silver Shark Construction’s Trish Morris, who’s opening an Oklahoma branch of Women of Asphalt. “A lot of men have come by and grabbed our cards so they can get their team members signed up. I think it’s great they’re willing to take that step and get their ladies involved as well, even if they’re not here.”

Aside from conferences, attendees could multi-task with receptions and networking. For the second year in a row, Raised on Blacktop and WOA collaborated to host a sold-out kick-off party. Also sponsored by Wirtgen and a handful of others, the event brought together nearly 400 asphalt professionals at Busch Stadium, the iconic home to the St. Louis Cardinals, to build relationships and excitement the night before the show’s opening.

On the first day of the show, a handful of guests visited Campbell’s Service Station, owned by a local contractor and celebrating

the historic Route 66. Check out the article “Contractor’s New Museum Offers Glimpse of Route 66 History” in the March issue for details and send your stories about preserving the iconic roadway to sandy@theasphaltpro.com.

Attendees enjoyed the Rock & Road Reception where a relaxed atmosphere allowed for networking on the show floor on Wednesday evening. It featured live music, mascots from the St. Louis Cardinals and St. Louis Blues, and treats from roaming characters. Another group of guests attended the EdgeVanta and Gearflow happy hour event at the nearby Buddy’s Wine Bar & Bistro. Everyone was welcome to attend the relaxed happy hour in the Stansteel Hotmix Parts & Service booth as well. Basically, attendees had ample opportunity to unwind with new and established friends amid the crush to gather information and business tips.

Save the Date for 2027!

Next year CONEXPO-CON/AGG takes place in Las Vegas, but WOA and AGG1 co-locate in New Orleans March 15-17, 2027.

Of course, the name of the game at a show like WOA/AGG1 is to see the iron and learn what new technology will help your bottom line. AEM reported the exhibitors unveiled new products, partnerships and advancements at a record 19 press events.

One of those unveilings took place at the ShoulderMaster booth on the first day of the show. This family-owned company introduced to the industry its center paving attachment for skid steers, the CP-1000, which is detailed in this month’s product gallery. Also check out the family’s story at the beginning of this month’s gallery on page 38.

Volvo Construction Equipment showcased during its press conference enhancements to its soil and asphalt compaction product lines with upgrades to multiple models and a forthcoming electric model. Show attendees also got the first look at a DD15 electric asphalt compactor.

IntelliShift unveiled its advanced asset-tracking technology. The system allows companies to monitor equipment location, track utilization and idle time, and mitigate theft and misuse.

Metso unveiled the Nordberg® HPe™ range expansion and aftermarket kits for the new HPe range. The company also celebrated a major milestone, the 40th anniversary of the Lokotrack® mobile crushers.

While the company didn’t host a press conference, Astec Industries had a few updates and official launches to share. Its SiteLine™ operator environmental awareness camera system for its cold planers was previewed at the 2024 WOA show and launched this year. Another stand-out item was the IntelliPac™ Moisture System, which is now compatible with RAP in addition to virgin aggregates.

Asphalt Drum Mixers (ADM), Huntertown, Indiana, displayed a brand-new EX 8845 asphalt plant in its booth. Because bigger plants can bring bigger profits, ADM EX Series asphalt plants are designed to produce up to 425 TPH and handle up to 50% RAP to meet producers’ high-capacity production needs. The EX 8845 features an 88-inch drum diameter and 45-foot drum length. Like all EX Series plants, it provides long aggregates drying and mixing times to offer consistent, quality asphalt.

Across the aisle from ADM, fellow FAYAT family member BOMAG premiered its new BD 2000 asphalt distributor and new CR 820 T-2 rubber track paver. The distributor offers an automatic burner and computer-controlled distribution. The paver features a 173-horsepower diesel engine and a new operating system for each console to pro-

The

kiosk at

showed the almost imperceptible differences between Cold Central Plant Recycling (CCPR) and traditionally produced asphalt. Photo courtesy of AsphaltPro Staff

vide easy viewing of critical operations. The BOMAG WOA display also included:

• BOMAG CR 1030 T-2 highway class paver with VERSA 20 front-mount screed

• BM 2200/65 cold planer 2-meter class mill

• BM1200/35-2 cold planer with maximum 13-in (330.2-mm) milling depth

• BW 28 RH pneumatic tire roller with large ballast compartment

• BW 120 AD e-5 Electric light tandem roller with electric drive

While WOA attendees could see the Honey Badger and Tremor Shaker from CWMF Corp., Waite Park, Minnesota, on display, they also had the chance to pick up information on CWMF’s newly branded Dust Pilot reverse-flow baghouse. This baghouse features precision airflow control, an advanced inertial separator and CWMF’s unique indexing wheel mechanism.

Eagle Crusher, Galion, Ohio, also introduced something new at the show: its next generation 1200-CC portable crushing and screening plant. Its new features include a redesigned return conveyor, a new fully hydraulic side discharge conveyor, a self-lowering control panel, and an available onboard cross-belt permanent magnet that stays on for transport.

This quick overview of WOA/AGG1 offerings showcases the vast array of iron and technology that was on display. We’ll have opportunities to share more in future issues of AsphaltPro and we look forward to hearing back from you on your favorite innovations.

For more information visit WorldOfAsphalt. com and www.agg1.org.

Let's move the needle for Smokeless Asphalt and clear the air together.

The key to building longer-lasting roads while virtually eliminating smoke — just lower the temperature of your asphalt mix.

BY RICK REES

AAssessing components at the hot-mix asphalt (HMA) plant is only one step in the overall picture of plant health. This month, the plant maintenance series from Stansteel Hotmix Parts & Service, Louisville, Kentucky, focuses on the batch plant, showcasing the dryer specifically.

The first step with any plant maintenance, whether a continuous drum mix facility or a batch plant, is to make sure all inspections, markings or repairs happen while using proper OSHA Lockout/Tagout procedures. Ensure you have complete power disengagement before performing any inspections or repairs. For observations that require fans, motors or other components to be operating, listen or watch for vibration and noises from a safe distance or rely on your controls system to provide feedback on specific parameters. In this situation, you will observe and document, but do not touch the operating equipment.

For this series on assessing your asphalt plant for repairs and to avoid unplanned downtime, plant owners are reminded that only fully trained personnel should be allowed to conduct work on or around the equipment. For safety’s sake, the worker(s) should be fully trained on and act in accordance with all federal, state, county and local laws and regulations, and that includes OSHA and MSHA laws. You want your workers to be familiar with and act in accordance with the equipment specifications and manuals as well as your site-specific safety rules and regulations.

Workers have to take responsibility for their own actions, inactions, consequences and results, but you can ensure the best possible outcome for their safety and your operation’s success when you take the time to train and educate each worker who has access to the equipment and material at your facility.

Always utilize OSHA Confined Space procedures.

Observations from a safe distance while the dryer is running will give you some information at the beginning of your inspection. With the power off and proper lockout/tagout procedures in place, you can get closer to the motors, reducers, sprockets and guards for a full inspection. All photos courtesy of Stansteel Hotmix Parts & Service

While the dryer is still running, from a safe distance, observe the following:

❒ Are motors operating at normal temperatures? (Non-contacting infrared temperature guns work well and from a safe distance.)

❒ Is there excessive noise or vibration during motors’ operation?

❒ Do you smell any unusual odors during operation?

❒ Are bearings operating at normal temperatures?

❒ Is there excessive noise or vibration during operation of the bearings?

With proper lockout/tagout procedure in place, perform a visual inspection of the complete dryer system. You’re looking for noticeable issues—any areas that might be damaged or in need of immediate repair or replacement. Depending on what damage

you see, you may circle it with spray paint, paint or mark with a Sharpie to indicate exactly where the problem is, or place some other type of tape or marker where the mechanic or grounds crew can find and fix the damage efficiently. You will also record the damage or problem in your company’s log, whether that’s a paper worksheet or an app on the Tablet you carry into the field.

Also look at the dryer seals. You’re looking for cracked seals or missing sections. Make a note of these for repair or replacement.

While still outside the dryer, perform a shell thickness test in multiple areas. It’s helpful to “map” your drum with not only a thickness profile down the length of the drum, dryer or rotary mixer, but also to capture a temperature profile while in operation and note operational details such as tons per hour, percentages of reclaimed material being used, fuel used, etc. This can help to identify flighting problems or poorly tuned burners in the future.

This versatile and high-production, 12,000-pound batch plant features a dryer that is 36 feet long. The plant has two RAP bins and a RAP Gator. It can produce lower temperature mix through the process of dynamic foaming of the Accu-Shear™ system.

Following OSHA standards for Confined Space entry, it’s time to look inside the dryer.

❒ Are there any missing flights?

❒ Are there any broken flights?

❒ Are there any bent flights?

❒ Are there any heat-distorted flights?

❒ Are there any missing flight clips?

❒ Are there any missing or damaged materials dams?

❒ Inspect the inlet spiral flights and make notes for repairs.

❒ Inspect shell integrity, looking for excessive wear throughout.

❒ Check the combustion flight zone, where excessive heat from the burner flame exists; perform shell thickness tests in this area.

❒ Take photos of the interior, of the flights and of the burner area and date them.

You want to give special attention to the discharge paddles and check for the following:

❒ Are there any missing discharge paddles?

❒ Are there any bent discharge paddles?

❒ Are there any missing connection bolts?

❒ Inspect the discharge paddle ring and wear bars.

❒ Inspect the discharge chute for visible wear.

❒ Inspect the discharge chute for missing or worn liners.

The observations while the dryer was running gave you some information at the beginning of the inspection. Now with power off and proper lockout/tagout procedures,

it’s time to get closer to the motors, reducers, sprockets and guards.

❒ Are all motors properly ventilated? (Is heat dissipating; fins clean?)

❒ Are all motors connected to drive coupling with no signs of misalignment?

❒ Check and maintain proper oil levels in motors/reducers.

❒ Double-check that oil samples have been taken and that recommended oil changes have occurred.

❒ Are drive or driven sprockets showing signs of wear?

❒ Are there any visible cracks in shafts?

❒ If you have drive belts, are any cracking? Are they tensioned properly?

❒ Are sheaves showing signs of wear?

❒ Is the drive chain showing signs of wear?

❒ If you have a cradle chain drive, is there chain shoe wear?

❒ If you have a cradle chain drive, inspect the drive/driven sprocket.

❒ If you have a cradle chain drive, inspect the circumferential sprocket.

❒ If you have a ring gear drive, inspect the ring and pinion gear.

❒ If you have a trunnion drive, inspect the trunnion and tire faces as they can provide indications of poor wear patterns before excessive damage occurs.

❒ Are bearings properly lubricated?

❒ Is there visual abnormal coloration? (blackened grease)

❒ Is there excessive grease or oil escaping the bearings?

❒ Are bearing mounting bolts tight?

❒ Are there any cracks in bearing housings?

❒ Inspect tires for misaligned wear, as well as making sure all tire rigging is intact.

❒ If any rigging bars are missing, note for immediate repair and replacement.

❒ Check and measure the gap between the tire inner diameter and the surface of the support rigging. This is most important at the 12 o’clock position. Note if the drum is cool or hot.

The trunnion alignment and maintenance is so important that AsphaltPro Magazine has included several articles about this topic over the years. If you see excessive wear on trunnions and tires, this could be because of improper trunnion alignment. Stansteel Hotmix Parts offers the T-Trac Alignment System that is designed to establish a properly skewed trunnion roller setting to thrust the drum/dryer/rotary mixer in the uphill direction to its desired neutral thrust operating position. This can save thousands of dollars

in premature trunnion and tire wear. Make sure you inspect and note the trunnion for immediate repair and replacement, if needed. Also inspect the thrust rollers and bearings for excessive wear as well as spacing. If you have comments on any of the dryer elements you’ve inspected, make those notes for your grounds crew or mechanic and set a date by which you’ll check back on the progress of repairs. A well-maintained and properly functioning dryer is integral to the success of your batch plant. Keeping it in good working order keeps your operation safe as well as efficient.

A main component of the dryer is, obviously, the burner. Because burner design varies by manufacturer, you will want to consult the operations and maintenance instructions of the specific burner model prior to any maintenance or adjustments. Whether you’re working with a continuous plant’s rotary mixer or a batch plant’s dryer, there are some aspects of the burner that will remain constant when you perform your inspection.

• As always, begin with lockout/tagout and all safety procedures.

• Check the Y strainer, filters, water separators, pre-heater, valves and safety switches.

• Inspect all fuel lines for signs of wear or damage. Make sure you follow OSHA protocols for asphalt plant sites when dealing with potential fuel leaks, whether natural gas, propane or other. Note damaged lines for replacement.

• Inspect all piping, fuel lines or valves for any leaks. Note those for immediate repair or replacement.

• Check for proper fuel pressure, which will be listed in the manufacturer’s documentation.

• Check the burner tube and teepee for wear.

• Check flame eye cooling air for proper operation.

• Has the burner been re-certified under National Fire Prevention Association (NFPA) guidelines? Many insurance and other regulations require periodic, independent inspection.

If you have comments on any of the burner elements you’ve inspected, make those notes for your grounds crew, mechanic or certified burner technician, and set a date by which you’ll check back on the progress of repairs.

BY CLAY CALK

Editor’s Note: The Focus on Performance series from AsphaltPro Magazine allows OEMs and service providers to highlight professionals in the industry who have improved efficiencies and the bottom line through best practices and performance. This month’s installment, featuring Peak Oilfield Service Company, Prudhoe Bay, Alaska, focuses on predictive maintenance strategies.

IIndustrial facilities face many lubrication-related challenges, particularly with the demanding conditions found in industries such as mining or construction. The biggest challenges are contamination from dirt, infiltration of moisture and incorrect lubricant choice for the application. Failure to deal with these issues increases wear on mechanical equipment, resulting in greater rates of equipment downtime and higher maintenance expenses. Proper lubrication practices, with examples below, lead to better equipment performance and ultimately result in substantial cost savings.

About 75% of mechanical wear on industrial equipment is due to contamination from outside dirt. Internal friction and outside particles are destructive to metal. Circulating solid particulates in the lubricant risks damaging the base oil, stripping away additives and harming critical components. The best practice is to begin by filtering the lubricant—even when new—because newly delivered lubricants in pails, drums or totes tend to have elevated particle counts.

Before and after filtration, oil samples should be sent to the lab for two reasons.

• First, to verify that the product inside the container matches the label and product type ordered.

• Second, to confirm that filtration is effectively accomplishing the specific ISO Cleanliness Codes for the assets these new oils are going in.

The second biggest challenge is water or moisture. Ridding the oil of moisture is crit-

ical to provide the best overall performance. Moisture can lead to lubricant degradation and equipment damage, particularly in environments like surface mining and construction where equipment is frequently exposed to water and humidity.

The third challenge is making sure plant personnel are storing the lubricants properly and putting the right lubricant into the right application. Lubrication Engineers has conducted surveys that examine lubricants used in assets and cross references them with original equipment manufacturer (OEM) instructions and manuals. The studies have found that about 12-14% of lubricants being used are either the wrong type or the wrong viscosity, which may lead to more frequent oil changes or speed up the oil’s rate of oxidation. Once the lubricant film is ruptured, it cannot protect the critical component of the asset and may result in faster mean time between failure (MTBF).

Reviewing the health of the asset and the oil, and conducting an analysis that includes fluid properties, wear metals, particle count, contaminants (fuel, soot and moisture) and contaminant metals (silica and coolant) will ensure the asset’s integrity is not being jeopardized. Failing to do this will contribute to the need for more frequent oil changes or repairs.

To meet the challenges, facilities should consider the use of higher quality lubricants, which maintain the integrity of oil so it will last longer. Maintaining oil’s viscosity without breaking down is key; once you lose the integrity of lubricating oil, you are risking more wear on metal. With a higher quality lubricant, viscosity is maintained for a much longer period of time.

Using high-quality lubricants will result in fewer oil changes, repairs, reactive labor and unplanned downtime. Implementing best practices and protecting assets by using higher quality lubricants will result in greater savings across repairs, because they happen less frequently. Facilities achieve lower overall costs

with higher quality lubricants paired with preventive and predictive maintenance strategies.

Using the right lubricants and lubrication strategies will allow oil to maintain its health for the longest period. This maximizes return on that lubricated asset by reducing labor, parts in the storeroom, and the cost associated with asset availability and downtime.

In addition to the use of quality lubrication products, the use of predictive or preventive maintenance plays a key role in optimizing lubrication efficiency. Strategies should be developed to predict when a piece of equipment is expected to fail, then schedule and plan maintenance on the asset to avoid that failure. Many industries are trending toward scheduling oil changes with predictive condition-based methods versus older time-based methods.

These strategies can be helped by a thorough evaluation of a facility’s lubrication program. For example, Lubrication Engineers offers its Xpert Lubrication Benchmark Audit, a one-day walkthrough that looks at a facility’s lubrication program and ranks it compared to industry standards and best practices. Audit categories include lubrication best practices, asset and lubricant identification, storage and handling, oil analysis and sampling, contamination control, filtration, training, skill development and certifications, software, CMMS and EAM, and safety and accessibility.

Education and technical support are critical. Facilities should ensure their staff is properly trained in lubrication fundamentals, so they can understand and respond to OEM lubrication recommendations and specifications.

Often budget is brought up as the reason higher quality lubricants are not used. In fact, in many cases, switching lubricants may lead to a reduced need for electrical energy or reduced temperature, yielding electricity savings. Here are two examples that showcase the ROI achieved from investment in higher quality lubricants.

Example – Fleet maintenance program

Peak Oilfield Service Company, located on Prudhoe Bay, Alaska, partnered with Lubrication Engineers to evaluate the company’s fleet maintenance program with a goal of implementing a more proactive predictive maintenance program. The evaluation included benchmarking the current program to understand the overall cost per mile to operate the fleet.

Peak’s fleet is comprised of more than 2,000 pieces of equipment, including service trucks; wheel loaders; haul, vacuum and water trucks; snow blowers; diesel generators; and more. Prior to its new reliability program, Peak performed all service truck engine oil changes every 200 hours, and all heavy-duty, off-road equipment engine oil changes every 300 hours. Repeated trials and evaluation of LE’s Monolec® Engine Oils showed that the new product extended drains out to 1,500+ hours. Some equipment had extended oil drains as far out as 2,200 hours, and oil analysis demonstrated that the Monolec Engine oil still maintained its viscosity and TBN.

Following consistent trial successes, Peak switched all its engines to LE’s Monolec Engine Oils, establishing 1,200-hour drain intervals for all mobile equipment. Within 18 months, they had achieved 50% total savings in cost per run hour; 46% savings in engine oil usage costs; 67% savings in engine oil disposal costs; 76% savings in annual engine oil change labor costs; and 76% savings in annual oil change downtime costs.

Example – Drill rig transportation vehicles Peak Oil also used enhanced lubrication to solve a problem with frequent costly bearing failures in its custom-made John Deere Rolligons, responsible for transporting drill rigs to remote drill sites in Alaska. Due to the harsh environmental conditions, these roller bearings are subject to -60°F temperatures, extreme high loading, low RPMs (8-10), dirt, moisture and idle time.

The lubricant in use was a mineral grade lithium-thickened NLGI 2 EP grease that would wax up when exposed to freezing temperatures, allowing the oil to run out of the thickener and bearing, while at the same time allowing the ingress of dirt and moisture. The complete saturation of the bearing and housing caused excessive rust, lubricant degradation, bearing starvation, and frequent bearing failures.

Lubrication Engineers recommended its heavy-duty synthetic NLGI 2 EP grease containing proprietary additives. Almaplex Ultra-Syn Lubricant (1299) is designed for optimum performance under extreme operating conditions. In 2017, Peak had experienced a total of 114 roller bearing failures in its Rolli-

gon fleet with the previous commercial grease. After switching, that number was reduced to only 24 failures in 2018—a 73% reduction. At a cost of $1,450 per bearing and considering parts and labor, Peak saved approximately $196,200.

Proper lubrication practices are crucial for facilities to achieve cost savings and improve equipment performance. The challenges of contamination, moisture and incorrect lubricant usage can lead to downtime and main-

tenance expenses. However, by implementing best practices such as using higher quality lubricants, maintaining proper storage and handling, and integrating predictive maintenance strategies, facilities can significantly reduce these costs. This approach not only improves equipment reliability but also contributes to a more efficient and sustainable operation.

Clay Calk is the director of market development for Lubrication Engineers.

FFor asphalt producers, environmental product declarations (EPDs) are not merely a tool for evaluating and communicating one’s environmental footprint, but they are evolving into a component of business strategy, influencing project bids and stakeholder engagement. With this in mind, DCC Propane explored how transitioning from oil to propane in asphalt production can contribute to achieving essential EPD targets.