All Roads’ Upgrade During Production Keeps Company Green

• CRH promotes industry circularity

• More ways to augment your paver

• Solve laboratory materials bans

• Asphalt = resilient Hawaiian airfield

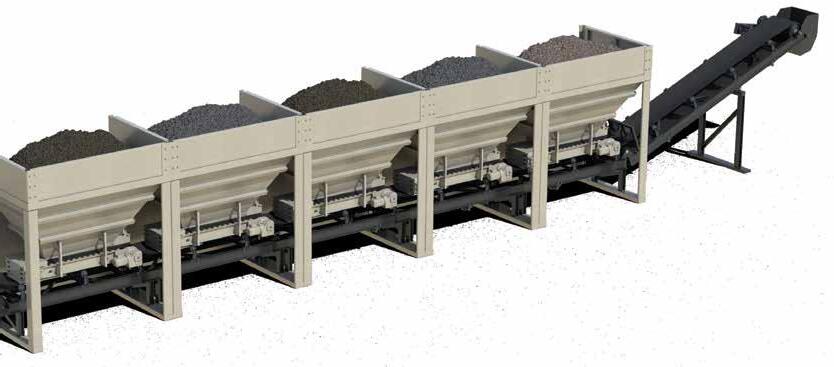

• Hall shares efficient, safe loadout option

• CRH promotes industry circularity

• More ways to augment your paver

• Solve laboratory materials bans

• Asphalt = resilient Hawaiian airfield

• Hall shares efficient, safe loadout option

Astec paves the way for sustainable, innovative asphalt plants. The new IntelliPac Moisture System is a revolutionary solution that integrates seamlessly with Astec control systems. This provides unparalleled, real-time visibility into virgin aggregate moisture content. IntelliPac empowers operators to optimize mix design, minimize energy consumption, and reduce environmental impact. With Astec, you get superior asphalt production – better for the environment, better for your business.

6 – Season's Greenings By Sandy Lender

SPOTLIGHT

8 – 5 Trends Shaping Workforce Mental Health and Substance Use Prevention By Cal Beyer

IT UP

12 – Navigating the Transition from TCE in Asphalt Testing By Jason Wielinski, P.E. and Wes Cooper

14 – We Still Need a Good Rotary Depth Crank By Benjamin Everett

16 – Surface Upgrade for Hawaii Military Airfield By Jayanth Kumar Rayapeddi Kumar, P.E., and Jonathan DeHart, PMP, CHST PRODUCER PROFILE

20 – SPT Recycles Asphalt to Reduce CO2 By Jordan Fontaine

OF ASPHALT

24 – Maryland WofA Networks with Paving & Pastries Events By Sandy Lender

72 – ABC Tech Alliance From ABC

74 – Clarifying NCAT’s Role and Findings Reported in the Article “Reverse the Effects of Asphalt Aging After Dark” By Raquel Moraes, Ph.D.

30 – 70% More Storage—No Shutdown Necessary By Sarah Redohl

36 – Augment Your Equipment Achieve precise paving when everyone has what they need, safely at their fingertips By Sandy Lender

40 – CRH’s Sustainable Practices Give Preferred Results By Sandy Lender

48 - Loadout Control Offers Peace of Mind for Hall Contracting By Sandy Lender

50 – Focus on Performance Comparative Analysis of Hot Oil and Electric Heating By Iván Fernández Hevia

55 – AsphaltPro’s 15 Top Products of 2025 By Sandy Lender

As we do each December, we offer a look at sustainable practices throughout the asphalt industry in this issue. I’d like to take the opportunity to discuss consumerism this season, too. Let’s face it, there’s money to be made when greening up the environment, whether with monitoring devices or electrified equipment.

Polaris Market Research reports that the air quality monitoring system market is projected to be worth USD 11.62 billion by 2034; up from USD 5.73 billion in 2024. The research firm states: “An air quality monitoring system is an instrument or collection of instruments...that helps identify impurities such as carbon monoxide, nitrogen dioxide, ozone, particulate matter (PM2.5 and PM10), and volatile organic compounds (VOCs).”

The systems are designed to provide real-time data, which guides environmental management of pollution control measures and so on. Asphalt professionals may be familiar with these devices as a recurring element that citizen environmentalists “quote” at town hall meetings. One of the problems with average citizens erecting such stations to gather ammunition against the local asphalt plant is the average citizen’s lack of science methodology practice. Not every soccer mom understands the impact of Canadian wildfires, the dust plume from the Saharan Air Layer, or twice-daily traffic jams less than a mile from the station on readings. Not every soccer dad is ethical enough to care.

I don’t want to paint a negative picture of our neighbors. I’m sure there are people who want to shut down an established asphalt plant who would not dream of idling a rusted out 1994 Dodge Ram 2500 next to an air quality monitoring station to influence its readings.

Of course, a person would have to look hard to find such a truck. In July and August 2009, the U.S. government distributed about $3 billion in funds for the Car Allowance Rebate System (CARS). This program involved a straightforward voucher given to an individual trading in a not-so-fuel-efficient vehicle to buy a new, efficient one.

Folks in the construction industry can apply that concept to their fleets today with this decade’s incentive programs. Many of the current programs are directed at fleets, operators or businesses, rather than individual consumers. These incentive programs often focus on zero-emission technology rather than just purchasing a more fuel-efficient machine.

For example, the California Air Resources Board launched a voucher program for offroad heavy equipment called the Clean Off-Road Equipment Voucher Incentive Project. This initiative encourages the purchase or lease of zero-emission off-road equipment like loaders, excavators, mobile power units, etc. In New York State, the Truck Voucher Incentive Program, which has expanded to include non-road equipment such as construction, agricultural, etc., of-

fers incentives up to 45% of the base cost when you replace and scrap the gas/diesel equipment.

On the federal level, we have the Clean Heavy-Duty Vehicles Grant Program, overseen by the Environmental Protection Agency (EPA). This isn’t a trade-in voucher program for off-road heavy construction machines like CARS was for consumer vehicles, but a grant program to which businesses can apply, to accelerate replacing internal-combustion heavy-duty vehicles (Classes 6-7) with zero-emission vehicles and their associated infrastructure.

Personally, I drive a 2006 Chevy Cobalt with manual door locks and crank windows. Does it have some rust spots? Sure. I broke the turn signal handle earlier this year because plastic gets brittle over time. I pay a mechanic to keep it running because you’ll have to pry that vehicle out of my cold, dead hands.

Call me all the generational names, but the last thing I want is a car that "conveniently” unlocks the doors for me when I put it in park...in downtown Detroit. Or that shuts off while traveling 55 mph on a remote highway because it detects a pinhole leak in the radiator. I have enough anxiety without adding “range” to it, thank you.

The problem is that the car is old and will need to be replaced, but, thanks to CARS of 2009, simple cars are few, far between, and priced like something out of a science fiction movie.

Is this the direction our construction industry is headed? Will we look back at the mid-2020s when we were trading in tried-and-true machines for 45% off a newfangled electric or hybrid model and wish we hadn’t?

It looks like Michigan DOT has their answer. MDOT conducted research for Fleet Electrification Strategies and recently released Research Report Number SPR-1739 wherein they state: “MDOT was provided with a number of considerations for transitioning its fleet [of 5,000 units] to low- or no-emissions alternatives. These include conducting pilot projects to test electric or hybrid models of a specific unit and evaluate how well they actually perform compared to MDOT’s current gas- or diesel-powered model....Electric-powered versions of these units are available and have been determined to meet MDOT’s operational requirements.” Read the full report online.

No matter how many units from your fleet you feel comfortable replacing to effect cleaner air, this is the edition where we share the sustainability initiatives your peers are also considering and implementing. As we dive into December and the festive green season, the staff at AsphaltPro wishes you and yours a blessed, peaceful, Merry Christmas!

Stay Safe,

Sandy Lender

602 W. Morrison, Box 6a Fayette, MO 65248 (660) 728-5007 • www.theasphaltpro.com

GROUP PUBLISHER

Chris Harrison chris@ theasphaltpro.com

EDITOR

Sandy Lender sandy@theasphaltpro.com (239) 272-8613

DIGITAL EDITOR

Sarah Redohl sarah@theasphaltpro.com (573) 355-9775

MEDIA SALES

Cara Owings cara@theasphaltpro.com (660) 537-0778

ART DIRECTOR

Kristin Branscom

BUSINESS MANAGER

Susan Campbell (660) 728-5007

AsphaltPro is published 11 times per year.

Writers expressing views in AsphaltPro Magazine or on the AsphaltPro website are professionals with sound, professional advice. Views expressed herein are not necessarily the same as the views of AsphaltPro, thus producers/contractors are still encouraged to use best practices when implementing new advice.

SUBSCRIPTION POLICY: Individual subscriptions are available without charge in the United Sates, Canada and Mexico to qualified individuals.

One year subscription to non-qualifying Individuals: United States $90, Canada and Mexico $125.00. For the international digital edition, visit theasphaltpro.com/subscribe/

BY CAL BEYER

The AsphaltPro Magazine was one of the earliest publications in the construction industry to share information on mental health and suicide prevention. I met Editor Sandy Lender when I worked for a hot-mix asphalt (HMA) producer and specialty paving contractor in the Pacific Northwest. In 2017, AsphaltPro published a series of articles authored by me and Dr. Sally Spencer-Thomas on mental health and suicide prevention.

Lender periodically invites me to share updates on industry trends on these topics. Her most recent request was a deep dive to share insights on a “top five current and future trends” positively affecting the mental health and wellbeing of employees in the aggregates and asphalt industries.

The five trends identified in this article reflect the growing expansion of workplace mental health initiatives being increasingly adopted throughout the construction industry. These trends show the increasing need to address the intersection of mental health and substance use to decrease the prevalence of both suicide and overdoses in the industry.

In the 2019 book, The Fearless Organization, Amy C. Edmonson defined psychological safety as “the belief that one will not be punished or humiliated for speaking up with ideas, questions, concerns or mistakes.” Edmonson further described team psychological safety “as a shared belief that the team is safe for interpersonal risk taking.”

Frequently, psychological safety is closely associated with high-risk environments where trust and open communication is essential—from the executive suite to the crew on the ground. This fits the aggregates and HMA industries.

Psychological safety is an essential condition for improving communication, teamwork and problem solving. It grows from intentional team learning of respect and trust, that empowers employees to speak up, share ideas, and take risks, without fear of judgment, criticism, or repercussions.

Psychological safety increases when first line supervisors cultivate open communication and feedback where team members feel comfortable taking risks to give feedback and share ideas without criticism and repercussions. As psychological safety increases so too does hazard reporting and correction, including near miss reporting and a willingness of crews and supervisors to exercise stop work authority.

Psychological safety helps organizations unlock higher performance at the crew, project and organizational level. Companies that intentionally created cultures with shared values for psychological safety evolve into learning systems that reduced friction and conflict, increased collaboration, spurred innovation and problem solving, and decreased incidents and injuries.

Where workers feel greater trust, they are more inclined to seek help for mental health or substance use issues. In short, when crews feel psychologically safe, they’re more willing to speak up—not only about job hazards, but also about personal struggles. Psychological safety is a pre-

cursor for promoting workplace well-being, the intersection between physical health and emotional wellness.

An important way to boost psychological safety is to educate the workforce about how common substance use challenges are—and the services and supports available for prevention and recovery. This serves to decrease stigma and promotes help-seeking leading to recovery. The Recovery Research Institute (RRI) defines recovery from a substance use disorder as “a process of improved physical, psychological, and social well-being and health after having suffered from a substance-related condition.”

Traditional approaches to substance use prevention in the workplace do not result in employees or family members receiving services. Historically, companies took a “hands-off” approach to substance use in asserting it is not the business of businesses to care what people do in their time away from work unless it becomes an issue at work. Unfortunately, this passive approach did not acknowledge how common substance use challenges were, and did not recognize how important it is for employers to support employees seeking support and services for substance use treatment and recovery.

In industries under the jurisdiction of Federal Highway Administration (FHWA) Department of Transportation (DOT) regulations for safety sensitive positions, companies have historically relied on Drug Free Workplace policies and drug and alcohol testing protocols. Often these programs are punitive in nature, and result in disciplinary actions, including loss of employment. This reinforces stigma about mental health and substance use and keeps people from being comfortable seeking or asking for help.

It is important to teach all employees about substance use and misuse. It is important to focus on prevention and early intervention with family members to minimize crises relating to worsening substance use disorder. By offering training on Recovery First-Aid and Recovery Allyship, workplaces can provide a necessary safety net to help employees and family members needing vital support. (See the SAFE Project website for information on Everyday Etiquette for Recovery Allies).

In 2018, the state of New Hampshire became the first to adopt a Recovery Friendly Workplace (RFW) program. As of 2025, over 25 states have adopted various versions of RFW programs or initiatives. There is even a national certification program sponsored by the National Recovery Friendly Workplace Institute.

A primary purpose of RFWs is to expand labor rate participation by increasing the recruitment and retention of persons in recovery. There remain significant levels of stigma around substance use and addiction. This creates bias and judgment resulting in potential discrimination for persons in recovery in the hiring process. This can include being passed over for promotions and other career advancement opportunities.

2 0 2 6

For over a half a decade Blaw-Knox has earned its reputation as the go to source of training and instruction on hot mix paving.

The Blaw-Knox University, is dedicated to training paver operators and foreman on proper Paver Operation and Maintenance and applied Best Paving Practices through classroom-style and handson application courses.

Blaw-Knox provides improved technical and problem-solving skills on a variety of paver operations and maintenance topics. Course instructors share decades of field and teaching experience with attendees, including training on the latest DOT requirements.

• January 12 - January 15

• January 19 - January 22

• January 26 - January 29

• February 2 - February 5 2026 DATES

All details can be found at www.blawknox.com/training or contact at (407) 290-6000 ext. 342 or training@blawknox.com

When employers commit to being an RFW, they create a safe space for employees and their families to seek care—without fear of judgment or career consequences. The organization is encouraging employees to seek help and support and ensuring access to necessary services.

There are many emerging pockets of success that point to the benefits of this innovative program. Successful RFW programs highlight decreased absenteeism, lower turnover, improved workplace trust and engagement, and higher productivity by hiring persons in recovery.

Despite the growth of the RFW movement, awareness remains a challenge. A survey in September 2024 by consulting firms ForsMarsh and the Human Resources Certification Institute highlighted “60% of human resources professionals had never heard of recovery-friendly workplaces before this survey.” One source of confusion can be that RFW is called Recovery-Ready Workplaces by the federal government and as Workplace Supported Recovery by the National Institute of Occupational Health in its Total Worker Health initiative. Fundamentally, all three names refer to the same approach.

RFWs are an opportunity for the construction industry to close the shortage of skilled and unskilled labor by providing fair chance employment opportunities. The RFW movement offers the industry a positive way to reduce stigma and provide meaningful improvement to help employees and their family receive support and services to address problematic substance use.

According to data from the Centers for Disease Control and Prevention (CDC), the construction industry has the highest rate of overdose deaths among major occupations. Long hours, physical strain injuries and access to prescription opioids can create a dangerous mix for workers, many of whom are trying to manage chronic pain while showing up for the job.

Preventing the first exposure to opioids starts with strong injury prevention programs—especially for soft tissue injuries from material handling, falls, vehicle incidents and struck-by hazards. It is especially important for companies to focus on the prevention and management of soft tissue injuries frequently occurring in material handling tasks, slips/ trips/falls, motor vehicle incidents, or being struck by or caught between moving objects.

Naloxone, also known by the brand name Narcan, is a life-saving medication that reverses opioid overdoses, and is just as essential for a first-aid kit as an automated external defibrillator (AED). SAFE Project encourages all employers to provide another layer of protection for workforces by breaking the stigma that surrounds overdose response and equipping job sites and field teams with naloxone.

Naloxone works by blocking the effects of opioids in the brain, restoring normal breathing in minutes. It does not affect someone who hasn’t taken opioids and is safe to administer in emergencies. Yet overdoses rarely happen the way Hollywood portrays them. Most occur in homes, bathrooms or parked vehicles. Some happen at work; in fact, 10% of job site fatalities are overdoses. They often involve fentanyl—a synthetic opioid up to 50 times stronger than heroin—hidden in pills or powders without the user’s knowledge.

SAFE Project commends Vulcan Materials Company for its bold action in 2025 to stock naloxone at all company workplace locations. While stocking naloxone is still relatively new in the industry, early adopters are setting the tone for a culture that treats overdose prevention like any other workplace safety measure. Vice President of Safety, Health and Envi-

ronmental Chad McDougal advised that Vulcan Materials deployed naloxone at over 550 locations. (See article featuring Vulcan Materials posted on the SAFE Project website).

Increasingly, more contractors are training their workforces in suicide prevention as part of their safety and wellness programs. VitalCog is a brief, evidence-informed suicide prevention training tailored for the construction industry. VitalCog in Construction was co-developed by the University of Colorado’s Helen and Arthur E. Johnson Depression Center, United Suicide Survivors International and LendLease.

VitalCog in Construction is becoming a training of choice that equips first-line supervisors and crew members with the skills to recognize common warning signs, how to hold direct conversations and connect peers to support. VitalCog in Construction is available in both English and Spanish.

VitalCog can be completed in a period of one to two hours and captures valuable data in post-training surveys. Research reported in the Journal of Workplace Behavioral Health showed attendees experienced increased confidence identifying suicide warning signs and a significant rise in comfort talking about suicide and offering resources. An increasing number of trainers throughout the construction industry are offering VitalCog in Construction. Learn more at: https://vitalcog.com/suicide-prevention-in-construction/

Cal Beyer, CWP, NAC is the senior director of SAFE Workplaces for national nonprofit SAFE Project (SAFE stands for Stop the Addiction Fatality Epidemic). He has 35 years’ experience as a safety, wellness and risk management professional and is an advocate for workplace mental health, suicide and overdose prevention, and recovery. He helped launch the Construction Industry Alliance for Suicide Prevention (CIASP) in 2016. He is a 2025 inductee of the National Academy of Construction. For more information, visit www.safeproject.us or contact him at cal@ safeproject.us or (651) 307-7883.

If you are interested in learning more about these trends in workplace mental health, consider attending the 5th annual Construction Mental Health and Wellbeing Conference in Portland, Feb. 23-26, 2026. The main conference is held on the final two days.

• Monday, Feb. 23: Optional Pre-Conference Storytelling Retreat & VitalCog Instructors Convening

• Tuesday, Feb. 24: Optional(?) Pre-Conference Workshop Sessions

• Wednesday, Feb. 25: Mental Health & Suicide Prevention

• Thursday, Feb. 26: Addiction Treatment, Recovery & Overdose Prevention

For more information: https://www.unitesurvivors.com/ construction-mental-health-wellbeing-conference/#2026

Your first stop in the FAYAT GROUP road lifecycle, ADM makes the plants that make the hot mix. When it comes to North American roadbuilding, FAYAT Group brands including ADM, BOMAG, Dynapac, LeeBoy, and Mecalac have you covered.

See a totally new EX Series asphalt plant at ConExpo/ConAGG March 3-March 7.

BY JASON WIELINSKI, P.E. AND WES COOPER

Editor’s Note: Reporting around the industry in late summer 2025 may have added some confusion to the discussion of when trichloroethylene (TCE) was banned. As early as Dec. 21, 2023, AASHTO petitioned EPA to grant the industry a 20-year phase-out period to allow state DOTs time “to investigate alternative methods for asphalt testing with the goal of eliminating TCE from their testing protocols.” By Dec. 17, 2024, our industry was included in the final ruling’s 10-year phase-out period. See paragraph two below for more detailed information.

The Environmental Protection Agency (EPA) proposed a rule in 2023 to prohibit the production and use of trichloroethylene (TCE) in many industrial applications, including asphalt testing. After a period of comment review and discussion, the EPA published its final ruling in December 2024 in favor of a TCE ban.

To alleviate issues with immediately banning TCE from asphalt labs, a phase-out period has been identified: five years for open systems (this would include centrifuges and reflux systems used in binder extraction from asphalt mixtures) and 10 years for closed systems (this would include auto-extractors). However, those organizations continuing to use TCE during this phase-out period will be required to monitor and document procedures on training employees and establishing a Workplace Chemical Protection Program (WCPP).

The transition away from TCE will affect asphalt laboratories in several ways, including binder solubility testing and solvent-based extraction and recovery. Fortunately, options are available to asphalt labs to make the necessary adjustments in light of these rulemaking directives and concerns. To that end, the following insights are offered from the Asphalt Institute as a means of assisting asphalt test labs during the transition away from the use of TCE.

TCE is still the primary solvent used for ensuring that an asphalt binder is relatively free of non-organic mineral matter. The two most common test methods for this type of determination (often referred to as the “Solubility Test”) are AASHTO T 44 (Solubility of Bituminous Materials) and ASTM D2042 (Standard Test Method for Solubility of Asphalt Materials in Trichloroethylene or Toluene). AASHTO T 44 lists TCE or trichloroethane (TCA) as the allowable solvents, while ASTM D2042 permits both TCE and toluene. Of the two test methods, AASHTO T 44 is the most widely used in the United States but is the most restrictive in that it only allows for the use of chlorinated solvents.

In 2016, AASHTO T111 (Standard Method of Test for Mineral Matter or Ash in Asphalt Materials), commonly referred to as the “Ash Test,” began to replace solubility testing in AASHTO specifications for anionic, cationic and polymer-modified asphalt emulsions. ASTM emulsified asphalt specifications followed suit in 2020, allowing for the use of either D2042 or D8078 (Standard Test Method for Ash Content of Asphalt Binder and Emulsified Asphalt Residues). A primary reason for this change was to eliminate testing difficulties related to polymer-modified

If your organization relies on trichloroethylene (TCE) for asphalt tests, the immediate priorities are these:

• Implement the required workplace chemical protection program (WCPP) and exposure controls now, keeping in mind the TCE rule’s Workplace Chemical Protection Limit (WCPL) states airborne exposure cannot exceed 0.005 ppm (over 8 hours).

• Begin validating alternatives or engineering controls (especially to avoid manual centrifuge uses before December 2029).

• Track state DOT or state environmental guidance (states may add additional requirements or timelines).

At this time. Start by confirming that your lab’s use of TCE falls under “laboratory chemical for asphalt testing and recovery,” then assess your equipment. Identify all equipment and methods using TCE, such as centrifuges, vacuum recovery, asphalt binder extraction, etc.

Also assign a responsible official or Chemical Hygiene Officer to oversee your TCE phase-out and worker-protection compliance. When implementing your WCPP, develop and maintain written records that cover:

• Engineering controls (fume hoods, closed-loop extraction systems, solvent recovery enclosures);

• Administrative controls (restricted access, time limits, cleaning schedules);

• PPE program (respirators with organic vapor cartridges, gloves, chemical-resistant lab coats);

• Exposure monitoring and medical surveillance; and

• Recordkeeping (SDSs, exposure logs, training records).

By December 2029. Discontinue TCE use in manual centrifuges for asphalt recovery. Replace it with closed-loop or automated extraction systems using alternate solvents (like those approved in ASTM D8159). Make sure you document your conversion or discontinuation.

By December 2034. All TCE use for asphalt testing and recovery must end. Identify and validate alternative solvents or solventfree recovery methods. Validate new methods through ASTM or AASHTO standards and your client/state DOT specs. And make sure you document it all. Maintain records of solvent substitution testing and approvals, notifications to clients or DOTs about method changes, and all equipment modification and/or decommissioning. As every good lab should do, follow your ongoing best practices, too.

• Keep up with your emergency procedures: Maintain spill kits, eyewash stations, and first-aid plans specific to chlorinated solvents.

• Double-check your ventilation systems: Inspect and certify hoods or local exhaust every six months.

• Manage waste: Dispose of TCE waste as RCRA hazardous waste (F002 listing).

• Communicate: Ensure vendors are aware of the EPA ban timelines.

residues. For example, latex-modified residues are known to “gel” on the crucible during solubility testing, plugging the filter pad and making the test procedure difficult or even impossible to perform. Like solubility testing, the Ash Test is meant to ensure that paving binders and emulsified asphalt residues are relatively free of mineral matter. Whereas the Solubility Test involves dissolving organic matter with a solvent, the Ash Test uses a muffle furnace to incinerate all organic material, leaving behind a percentage of inorganic mineral matter. The Ash Test procedure accommodates more complex binders while removing the risks associated with the use of chlorinated solvents.

The impact of the TCE ban may be felt more acutely for labs who perform solvent-based extraction and recovery of binder from asphalt mixtures. One alternative is to replace the use of TCE with toluene as outlined in ASTM D2172 (Standard Test Methods for Quantitative Extraction of Asphalt Binder from Asphalt Mixtures) and ASTM D7906 (Standard Practice for Recovery of Asphalt Binder from Solution Using Toluene and the Rotary Evaporator).

Toluene does not carry the same long-term exposure risks as TCE and is thought to be easier to remove from the binder during the recovery process. However, the flash point of toluene is notably lower than TCE (around 40°F); thus, labs must ensure that storage and handling procedures are updated, and engineering controls are put in place to mitigate any fire risk. For many agencies and organizations, the increased flammability risk makes toluene a non-starter. Additionally, the low flash point means that toluene is incompatible with the closed-loop systems used in auto-extractors.

Where does this leave labs who depend on auto-extraction systems? ASTM D8159 (Standard Test Method for Automated Extraction of Asphalt Binder from Asphalt Mixtures) currently allows for the use of tetrachlorethylene (PCE) and methylene chloride (DCM) as suitable alternatives. Like TCE, PCM and DCM are chlorinated solvents that carry their own risk to human health; if labs make the switch to either of these solvents, care should be taken, including proper personal protective equipment (PPE) such as appropriately rated chemical-resistant gloves, exposure monitors and solvent respirators. Engineering controls are also vital, including walk-in fume hoods to house extraction systems or snorkel vents that limit exposure to fumes.

Implementation of changes will be context-specific, and while innovation may lead to any number of viable alternatives, it will likely take time for these to emerge in the market. Undoubtedly, there will be more questions to arise and challenges that the asphalt industry will face over the course of the TCE transition period. Working together and sharing knowledge can help everyone who depends on these solvents for accurate binder characterization and quality control.

Jason Wielinski is an Asphalt Institute regional engineer based in Ohio. Wes Cooper is the laboratory manager and senior research scientist at the Asphalt Institute Laboratory in Lexington, Kentucky.

BY BENJAMIN EVERETT

here is an adage: “If we always do what we always did, we’ll always get what we always got.” Now this subject is all about the reason (as I see it) for the screed rotary depth cranks (or screws) and why they’re included on U.S. style screeds but not on European screeds. Why does one European paver and screed manufacturer not even install threaded adjusting screws on the screed at all? Let’s look at why these are important and when and why you should use them. There are a lot of fundamental misconceptions around the above, which I would like to use to stimulate conversation.

To clarify my thoughts, I am not suggesting that there shouldn’t be a manual, rotary depth crank on the screed. I absolutely believe there should be as it is essential for balancing the screed and keeping the nose in the ideal attitude.

I like to think of the depth cranks as being very similar in operation and theory to the rear horizontal stabilizer and elevator that you find on the tail of most modern jet airplanes. Basically, the elevator is adjustable (just like a rotary depth crank) and is the method that the pilot uses to maintain the optimum, slight nose-up attitude or horizontal pitch of the airplane during flight. It’s always slightly nose-up to give lift; just like a screed.

A motorboat is usually fitted with a similar device called trim tabs. These are right at the rear end of the hull and are also used to adjust the planing angle of the craft to also create a slight nose-up attitude. This is the same principle a screed requires to float.

We require a means to adjust and dial in the optimum angle of attack to provide a tight, dense mat texture. I believe though, once you have established this optimum angle of attack (1/8-inch to ¼-inch slight noseup typically), you shouldn’t start messing with that setting during normal paving operations. This procedure should be done at the start, then left alone.

Because if you use the depth crank instead of the tow point, invariably you will

upset and change that initial, ideal slight nose-up angle of attack. This can lead to the screed planing on a less than ideal angle of attack (either nose-up too high or low), which can result in a variable mat texture, transition lines and in extreme cases, excessive and uneven wear to the leading edge or rear tail of the screed with uneven compaction. This will often create issues like the screed being difficult to control and a poor mat texture.

I had this discussion with a well-known industry expert from a leading original equipment manufacturer (OEM) at World of Asphalt in 2024. He basically agreed with me and believed the reason so many operators use the depth cranks to adjust mat depth, rather than using the tow points,

comes down to tradition; or “we’ve always done it that way.”

I don’t advocate removing the depth cranks (as one OEM does on the European tamping screeds it makes) or taking the handle off and leaving an adjustable threaded rod (like most E.U. screeds have), as that creates other problems. I’ve seen people using the screed at an incorrect angle of attack for a certain mat depth it was not set up to achieve because adjusting the threaded rod was difficult or they didn’t have the wrenches on site to make adjustments. That’s just as bad as playing with the cranks and changing the pitch during paving.

Also, I absolutely agree with using the depth cranks to “buy back cylinder” in certain situations such as when following a variable grade or using slope on one side. I do that myself when required so it’s important to have depth cranks for this.

What I’m suggesting is once the operator has established and dialed in the correct angle of attack, after checking the screed is planing at an ideal angle and the screed pivot point is fairly parallel to the tow point pin, he or she will use the tow points to adjust mat depth after that (in both manual and automatic) and leave the cranks alone. After all, if you carefully think about the concept and practice of correctly setting the screed pitch or angle of attack, you want to maintain that ideal setting, not change it.

I appreciate that some folks will almost certainly have strong views either way about this, and that’s a good, healthy subject to discuss. I recall about 15 years ago, I first obtained a copy of the asphalt “Bible” I regularly consult. This is the same U.S. Army Corps of Engineers’ “Hot-Mix Asphalt Paving” handbook 2000 (AC 150/5370-14A Appendix 1) I referred to in my previous article “Control the Feed to Control the Screed.” At that time, I had been full time in the asphalt industry for around 25 years, and I had been taught in the mid ’80s how to compact asphalt in the “old school way.”

This procedure involved “nipping the joint” or basically rolling the longitudinal joint match first by about 1 to 2 inches to push the joint down so it looked nice. I thought that was the only way and the right way.

However, upon reading this handbook, I discovered in the compaction section that the old method was no longer a best practice. It was not a recommended procedure due to quality issues that methodology often created. Well, it caused me a great deal of personal angst, and I struggled with the concept that what I had done for 25 years was now “wrong.” And it took me about three years to accept the idea. It was kind of like I was thinking to myself, “You mean to tell me I’ve been doing it wrong for the past quarter century?!”

But sometimes you have to reconcile yourself to realizing that as time passes, often new knowledge, learning and understanding of evolving processes can come to light. Now, I’m a complete convert in the current U.S. best practice compaction methodology. I realized eventually that what I had been doing

for all that time wasn’t “wrong” for that time. Instead, knowledge evolves over time, and we all must be prepared to re-evaluate some things if new lessons come to the fore.

After all, it was George Bernard Shaw who so accurately stated: “Progress is impossible without change, and those who cannot change their minds cannot change anything.”

Let me know what you think about the use of rotary depth cranks and tow points

and other long-held paving practices. It’s a challenging vocation we share, and it’s not for everyone, but I wouldn’t trade it for anything.

Benjamin Everett is the owner of About Asphalt Ltd., and has worked in the asphalt industry for nearly four decades. For more information, contact him at bjeverett@ aboutasphalt.co.

BY JAYANTH KUMAR RAYAPEDDI KUMAR, P.E., AND JONATHAN DEHART, PMP, CHST

Nestled high on the saddle between Mauna Kea and Mauna Loa mountains on Hawaii’s Big Island is the Pohakuloa Training Area (PTA). Located over 6,000 feet above sea level, PTA is the largest U.S. military training ground in the Pacific. The base is also home to Bradshaw Army Airfield, which has an asphalt runway (designated 9-27) approximately 3,700 feet long and 108 feet wide. Originally constructed in the mid-1950s, the aging runway required upgrades to meet the evolving needs of the U.S. military. To address this, the U.S. Army undertook the effort to rehabilitate the runway and upgrade key airfield infrastructure. The project was awarded to Hawaii-based Elite Pacific Construction, Inc. (EPC), who served as the general contractor. EPC partnered with Jas. W. Glover, Ltd. (JWG)— also a Hawaii-based general contractor, construction materials supplier, and paving contractor—to perform the runway rehabilitation work. While the project addressed many aspects of the airfield’s infrastructure, this article will focus specifically on the runway’s condition prior to rehabilitation, as well as the challenges and successes encountered in the mix design, production, and placement.

Before rehabilitation began, the runway was assessed for both smoothness and the extent and severity of cracking. Smoothness was measured using the Profile Ride Index (PRI) with a California-type Profilograph. Results showed that the center portion of the runway had a PRI of approximately 20 inches per mile. However, PRI values increased significantly toward the edges, reaching up to 70 inches per mile in some areas.

Due to site conditions, the contractor was unable to collect complete Profilograph data in certain sections. Heavy vegetation, potholes, and loose chunks of asphalt along the profile path prevented accurate measurements in those areas. Regarding cracking, there were numerous small (up to ¾ inch wide) to medium (up to 1½ inches wide) cracks running both longitudinally and transversely along the full length of the runway. Near the runway edges, extensive vegetation had grown through a dense network of cracks, extending roughly 20 to 25 feet toward the centerline. In some areas, the cracking was so severe that large sections had broken away, leaving gaps exceeding 5 inches wide. In total, over 15,000 linear feet of small cracks, 13,000 linear feet of medium cracks, nearly 1,500 square feet of large cracks, and more than 27,000 square feet of fulldepth pavement repair were identified within the main runway. There were also several sunken areas within the primary landing zone, likely caused by subbase issues due to the aged runway and shifting or compacting under the repeated load of large aircraft using the airfield.

The project scope included the full removal and reconstruction of the outer 24 feet on each side of the runway, while the center 60 feet in width was slated for an asphalt overlay. However, this central portion exhibited extensive surface cracking that required proper repair to en-

Paving of runway 9-27 at the Bradshaw Army Airfield was executed in 18-foot-wide passes at variable depths, mostly between 2 and 3 inches, at the site approximately 6,000 feet above sea level between two mountains. This situation presented the working crew with unique challenges— including scorching heat and persistent gusty winds. Photos courtesy of Elite Pacific Construction, Inc.

sure a stable and long-lasting finish. The repair process began with the removal of the existing crack sealant, followed by thoroughly cleaning the cracks to allow for proper bonding of the new sealant—a combination of asphaltic resin and polymer rubber.

The more severely damaged areas were milled down to the subgrade using a cold planer. A new base course layer was placed and compacted to 100% of the modified-proctor density and then paved with the approved asphalt mix. With the repairs completed, the runway was finally ready for the full overlay.

The Hot-mix asphalt (HMA) and paving operations were required to comply with the guidelines outlined in UFGS Section 32 12.15.13. This specification imposes rigorous standards for HMA design and during production to ensure long-term performance and durability.

Designing HMA with volcanic aggregates—commonly available in Hawaii—came with unique challenges. The aggregates used in the mix design were highly absorptive, leading to high asphalt binder absorption. Further, the project site was about an hour from the asphalt plant, so accurately accounting for asphalt absorption during the mix development phase was critical to ensuring the volumetrics of the mix met the project-specific requirements. Factoring all these concerns, the contractor’s quality control department submitted a proposed mix design for the asphalt plant in Waimea, located on the west side of the Island. The mix design was approved after a thorough review by the United States Army Corps of Engineers’ (USACE) Transportation Systems Center (TSC).

The paving contractor faced challenges managing the dust-tobinder ratio in the mix during production, mostly due to changes in the sand compared to what was used when the original mix design

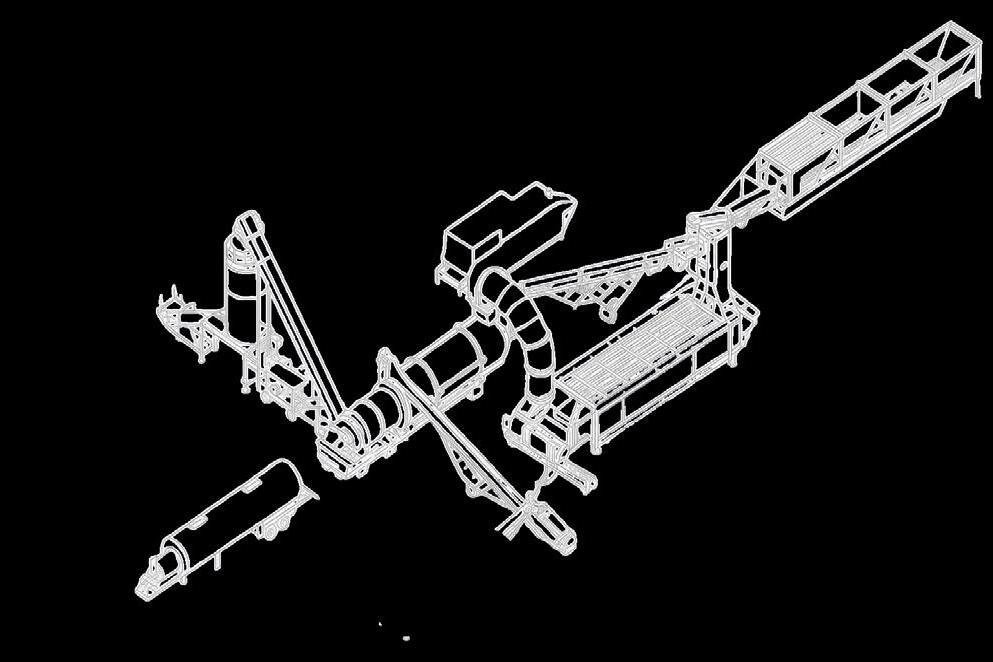

The only Full Service Custom Integrator of ALL BRANDS of asphalt plants. INTEGRATION is achieved by combining existing plant components with new components, used equipment or re-engineering plant parts and pieces to yield a fully functioning hot mix asphalt plant facility.

As an OEM, our parts are engineered and designed to make your plant run better. Our industry experts, from all backgrounds, specialize in retrofits and duplication of any type, brand or manufacturer of asphalt plants. We can provide you with anything for your asphalt plant.

We are here to assist in helping you sell your used asphalt plant equipment for the best price on the market. In addition, sometimes a used component can solve your issue as well as a new one for a much lower price. We will advise you on the best option for your particular situation.

The project site was about an hour from the asphalt plant, so accurately accounting for asphalt absorption during the mix development phase was critical to ensuring the volumetrics of the mix met the project-specific requirements.

The project scope included the full removal and reconstruction of the outer 24 feet on each side of the runway, while the center 60 feet in width was slated for an asphalt overlay. However, this central portion exhibited extensive surface cracking that required proper repair to ensure a stable and long-lasting finish.

Longitudinal joints were carefully constructed after cutting back the existing pavement edge to promote strong bonding, with joint surfaces thoroughly cleaned and tack coated before placing new asphalt. The completed project’s PRI showed a significant improvement of 57% to 90%, reflecting the collaborative efforts of the paving and quality control teams in overcoming tough conditions to deliver a high-quality runway.

was developed, leading to a few weeks of paving delays. Adding to the complexity, the asphalt plant in Waimea was scheduled to be relocated around the same time for another paving project. To maintain progress, a new mix design was developed using aggregates from a different source for the asphalt plant located in Hilo, located on the east side of the Island. After a careful review by USACE’s TSC, the new mix received the green light, and paving quickly resumed with minimal disruption.

Although not required by the project specifications, the proposed mix designs were also verified for optimum asphalt content using a simple analytical procedure published in the ASTM’s Journal of Testing and Evaluation, titled “Simple Analytical Procedure to Estimate Optimum Asphalt Content.” This additional verification produced results that closely matched the optimum asphalt content of the proposed mix designs, offering further validation and confidence in the final design asphalt content and the procedure.

The project site, situated at approximately 6,000 feet above sea level between two mountains, presented the working crew with unique challenges—including scorching heat and persistent gusty winds. These winds were intensified by the valley’s geography, which seems to act like a natural wind tunnel, accelerating airflow between the two mountain peaks. This not only complicated paving but also created mix cooling challenges. Despite the roughly one-hour hauling distance from the plant, the hauling of mix was well managed throughout. Mix temperatures stayed mostly within the target range, with only a few minor exceptions. Paving was done in 18-foot-wide passes at variable depths, mostly between 2 and 3 inches, using a standard rolling sequence of breakdown, intermediate, and finish rollers to ensure proper compaction. Longitudinal joints were carefully constructed after cutting back the existing pavement edge to promote strong bonding, with joint surfaces thoroughly cleaned and tack coated before placing new asphalt.

The paving crew, aware of the field conditions and the stringent specification requirements, approached and executed the paving operation to meet the project’s demanding standards. The quality control department provided critical support in continuously monitoring mat and joint densities. Cores drilled for thickness and density testing met specifications. Final profiling after paving revealed some areas needing grinding, and the quality control department worked closely with the grinding crew to address all must-grind bumps. The PRI showed a significant improvement of 57% to 90%, reflecting the collaborative efforts of the paving and quality control teams in overcoming tough conditions to deliver a high-quality runway.

Despite a few minor hurdles along the way—ranging from material adjustments to environmental and logistical challenges—the success of the runway rehabilitation at Bradshaw Army Airfield was a direct result of strong communication and coordination between EPC and JWG. While each team operated within its scope of responsibilities, it was our shared commitment to quality, problem-solving, and teamwork that ensured the project stayed on track.

The end result is a significantly improved runway that meets rigorous military standards and is ready to support the ongoing mission at the PTA for years to come. To mark the completion of this important effort, a ground blessing ceremony for the newly rehabilitated runway was held on Sept. 23, 2025, honoring local tradition and as a gesture of respect for the land.

Since its introduction, the Weiler P385 has set the standard for commercial pavers. The P385C raises that standard.

Increase to 120 hp with the Cat® C3.6 Tier 4F/Stage V engine.

Variable speed and reversible conveyors and augers and a 25% increase in tunnel height provide optimal material output.

Modular conveyor drive and sealed chain case increase feeder system reliability and life.

Enhanced heat system performance with direct-drive hydraulic generator and elimination of GFCI breakers.

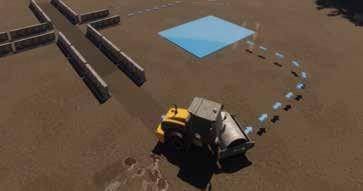

BY JORDAN FONTAINE

Founded in 2008 and spearheaded by President John Collins, Sustainable Pavement Technologies (SPT) has grown to become a leader in providing sustainable solutions for the heavy highway industry. The company focuses on asphalt pavement, roofing shingle material and concrete demolition recycling while operating out of five key sites in Texas, in major cities like Dallas, Fort Worth, Austin, San Antonio, and Houston as well as two additional sites in California. With a dedicated team and a mobile fleet of crushing, grinding and screening equipment, SPT consistently delivers for its clients.

The reclaimed material that SPT receives is processed and repurposed to create high-quality aggregates for use in hot-mix asphalt (HMA), ready-mix concrete and road base. As a recycled product, this material boasts a lower CO2 output than virgin material, as much of the environmental impact is incurred on its initial creation. This is further enhanced by SPT’s choice of diesel-electric driven crushing and screening equipment—the Gladiator range from Powerscreen Texas.

“The Gladiator is a great addition to our fleet for many reasons, including its versatility,” Collins said. “Having the ability to move our Powerscreen Gladiator 320SR to any one of our sites and be up and running within 24 hours has been a game-changer for us.”

SPT’s mobile production capabilities allow the company to handle various commercial projects and State Department of Transportation contracts, ensuring that materials are sized according to strict specifications. Whether it’s handling demolition debris from a construction site or reprocessing broken road surface material, SPT’s

Powerscreen equipment can transform waste into high-quality aggregates that contribute to new infrastructure projects across Texas.

The success of SPT has been supported by its long-standing partnership with Powerscreen Texas since 2016. The relationship between SPT and Powerscreen Texas began when Collins purchased a Terex Ecotec Phoenix 2100 trommel at an auction. Soon after putting the trommel to use, the machine ran into an engine failure. However, Powerscreen Texas quickly stepped in to help.

“I called Powerscreen Texas, and within a few days, they brought out a new engine and installed it for us,” Collins recalled. “Within the next year after using our newly fixed Phoenix 2100, we expanded our fleet of machines from Powerscreen Texas and have purchased a machine from them each year since.”

Today, SPT operates several pieces of Powerscreen equipment, including the Powerscreen Gladiator 320SR, Trakpactor 320, Chieftain 1700, Chieftain 2100 and the Terex Ecotec Phoenix 2100 trommel. This robust lineup of machinery allows SPT to handle large volumes of recycled material with efficiency and ease.

According to Collins, the Powerscreen Gladiator 320SR has been a valuable asset to the company. This diesel-electric hybrid unit is capable of processing 2,000 tons of material per day, consistently meeting SPT’s production targets while maintaining fuel efficiency.

“We achieve a considerable uptime with the Gladiator...” Collins said. “It’s a diesel over electric unit, so it gives a really steady and low fuel burn along with a very consistent output.”

The reclaimed material that SPT receives is processed and repurposed to create high-quality aggregates for use in hot-mix asphalt (HMA), readymix concrete and road base. As a recycled product, this material boasts a lower CO2 output than virgin material.

At SPT’s Fort Worth site alone, the company produces between 350,000 and 500,000 tons of recycled asphalt and concrete annually. These materials are processed into various gradations, depending on the specific requirements of each project. The recycled aggregates are then sold to commercial material producers or used in State DOT projects that demand precise material sizing for stringent specifications.

In addition to their work at fixed sites, SPT also takes on a wide range of contract work across Texas. With mobile crushing, grinding and screening spreads, the company can deploy its fleet of Powerscreen machines to any site, providing on-demand solutions for contractors and subcontractors in need of reclaimed aggregate materials.

Collins is proud of the company’s ability to adapt to different project requirements and environments. “We’ve worked in various quarries, recycling shot rock and other materials. No matter what kind of project comes our way, we can provide a solution thanks to Powerscreen.”

As the demand for sustainable construction materials continues to grow, SPT remains at the forefront of asphalt recycling innovation. Their commitment to quality, sustainability and customer service has made them one of the most trusted names in the Texas recycling industry.

“Our relationship with Powerscreen Texas has been a crucial part of our success,” Collins said. “We’ve had great support from their team, and we’re continuing to grow that relationship as we identify what our customers demand and what machines will better elevate our business to better serve the State of Texas.”

Looking ahead, SPT plans to expand its operations even further, ensuring that they continue to provide high-quality recycled materials for the construction industry. With more than 15 years of experience, the company is well-positioned to remain a leader in sustainable pavement solutions, helping to build a greener future for Texas and beyond.

BY SANDY LENDER

During the spring 2025 paving conference of the Maryland Asphalt Association (MAA) in March and again during an April 2025 lunch and learn event, the Maryland Women of Asphalt (MD WofA) branch introduced a new program called Paving & Pastries (P&P). The program officially kicked off with its first event, hosted at the Allan Myers Inc., Fallston office on May 13, with a second event in July at M Luis Construction Co., headquartered in Curtis Bay, Maryland.

The branch doesn’t yet have an outreach committee, so efforts like the P&P initiative help connect women across MAA’s member companies, offering more women, who might not otherwise have the chance, to learn of the MD WofA mission.

“While we do have numerous events throughout the year, we are not able to touch everyone with these events,” Chairwoman Amy Eckert explained. When it comes to connecting with the ladies when they’re in the field, timing can be difficult. Instead, the branch can set up a P&P visit at the member company’s site when it’s most convenient for workers. “When we are coordinating these events, we do them at whatever time is most beneficial to accommodate everyone’s schedule. We hold them at whatever location works best for that company. Some of our members have different facilities from their corporate office to their asphalt plants so we let them determine what space works best for them and we hold it there.”

After the MAA paving conference and lunch and learn event in the spring, women from Allan Myers and M Luis reached out to participate in the new initiative. Eckert coordinated the dates and times that worked for the companies and members of the MD WofA council who could join in. “It is a team effort,” Eckert explained. “But I generally am the main point person, coordinator with the company,

Amy Eckert gave a presentation during the first Paving & Pastries visit. She shared that having a warm welcome from the ladies at Allan Myers and getting to meet so many of their female team members made the event a memorable success for her. “We had a great turn out. I was nervous since it was the first one that we had done. I had gone over everything that I wanted say in my head but it’s a lot different when you are now in a room full of people but the team was so nice and engaging that it made my nerves simmer down and allowed a lot of connections to be made and great conversations.”

and do the majority of the presentation during the event.”

The events include more than a presentation from the WofA branch—they offer networking and community.

“We bring doughnuts, coffee and water for the ladies to enjoy,” Eckert shared. “We start out introducing ourselves, who we are with MD WofA as well as what our actual job is, how long we have been in the industry and a little bit of our journey. We then go around the room and have all of the ladies that are in attendance introduce themselves. I then tell them all about WofA as a whole, how we got started nationally, what our mission is, the current standings regarding all of the branches we have now and when our branch got started. From there it’s explaining all of the events that we do, what is in the works for our branch, and I open it up to any questions or comments that anyone has. We are still growing as a branch and it’s important to be beneficial to our mem-

bers so we value the opportunity to hear the thoughts and ideas that the ladies have to see if we can adapt and continue to grow.”

As part of the morning event, there are, of course, pastries.

“The first one that we did with Allan Myers was at 6 a.m. so that we could meet with the ladies before they had to get their day started. Which is also where the pastries come in. It’s always good to have some breakfast before they get their days started.”

Eckert also spoke of the inclusivity of the visits.

“It’s important to be able to connect with every woman that we can no matter their position or their length of time in the industry so they know that we exist, we welcome anyone to join us and are a valuable resource to help empowering women in the asphalt industry by mentorship, education and networking.”

The MD WofA come bearing gifts as well as encouragement.

and

“Another thing that we do for these events is give all of the ladies Potty Packs. We had zipper pouches made with our logo on it, and we filled them with necessities that women need when using the restroom. For the ladies in the field a lot of them rely on using a porta potty, which can be very hit or miss with the conditions of it. So in these bags we put packs of tissues (not enough room to fit rolls of toilet paper so this was the next best option), hand sanitizer, tampons and individually wrapped on the go flushable wipes so that they can carry these packs with them at all times and when they need to use the bathroom they can just grab them and take them with them so they have all that they need and not have to worry about going into a porta potty that might be out of toilet paper or hand sanitizer.”

Some of this may sound similar to the South Carolina WofA’s Building Community with Biscuits program outlined in the July issue, and there’s a reason for that. The WofA share ideas to help branches grow.

“Our past chairwoman, Stefani Martella, is a board officer for the WofA National and she had heard what South Carolina did and brought the idea to us so we could adapt our version of it in Maryland. I am the current chairwoman, so I have become more of the leader when it comes to speaking engagements and it’s something that I am passionate about, so it’s been easy to help lead this initiative when your heart is behind it.”

Others have seen the value and passion behind the project as well. Andrea Imhoff with M Luis is the woman who reached out to host a visit at the company.

Their daughters,

and Natalia Luis, now own and run the company. Natalia picked up her parents, so they were able to join everyone for the P&P event. “As a female owned company, they are very supportive of our mission,” Eckert shared.

“I was passionate about organizing the Paving & Pastries event for the ladies of M Luis to introduce them to the valuable resources available through the Maryland Women of Asphalt. It’s important to me that our female employees feel supported, empowered and equipped with opportunities for both personal and professional growth within our industry.

“In a traditionally male-dominated industry, having an organization like Maryland Women of Asphalt is truly invaluable,” Imhoff continued. “It offers a safe space for women to connect, ask questions, share experiences, learn and give back to the community—something that is essential for building confidence and long-term success!”

And that success is open to anyone who wants to attend. Eckert explained that any female that is employed by the company is welcome to attend a P&P event. “Executives, office personnel, drivers, ladies that work in the field or at the asphalt plant, it does not matter to us what their position is, our mission is to be able to connect with as many ladies as possible.”

So far, that mission of connection is off to a great start with the MD WofA P&P initiative. Any companies in Maryland that wish to participate can reach out to Eckert and other WofA branches who are interested in a similar program have two shining examples to follow.

Silo cone opening is 36” wide for ef cient material ow.

Safety gates on all silos, including long-term and standard options.

Recessed tub liners prevent silo wall wear, avoiding bulging issues.

Silo bin top batchers feature secure long-term seals.

Recessed wireways on silo tops eliminate trip hazards.

Meeker drag conveyors are larger, allowing slower chain speed and reduced wear.

Hydraulic chain adjustment on slats maintains asphalt entry point, minimizing wear.

Visual chain tension indicators on Meeker slat conveyors aid operators.

All silos prewired with top and bottom junction boxes.

All Roads Construction expands its Vancouver asphalt plant capacity without missing a shift— balancing growth, environmental performance, and nonstop customer service.

BY SARAH REDOHL

WWhen All Roads Construction opened its asphalt plant in Vancouver, British Columbia, in 2020, it set a new local standard for efficiency and environmental performance. Now, after a major upgrade completed in spring 2025, the company has increased its storage capacity by almost 70% while maintaining full production and the same cleanair results that defined the original facility.

All Roads President and CEO Rod Stephens said the decision to expand was about staying ahead of demand while protecting what made the plant successful from the start. “We wanted to grow our capacity without losing the reliability and environmental integrity we built this operation on,” he said.

The project reflects both market growth and All Roads’ long-term strategy: to meet higher material demands, adapt to new mix specifications, and keep the doors open to third-party customers 24/7. From planning through installation, the expansion showcases how careful coordination, in-house expertise, and a focus on service can turn a logistical challenge into another example of continuous improvement.

When All Roads Construction decided to expand its Vancouver asphalt plant, the move was driven by production realities, not speculation. “We have about 400,000 tons of Highway 1 Trans-

Canada paving to do,” Stephens said. “And over the last five years, our third-party sales have skyrocketed.”

The dual demand of major infrastructure work combined with strong third-party growth put pressure on the plant’s capacity and flexibility. “Not only were we coming up short on volume, but we also needed capacity for a broader variety of mix designs,” said All Roads Plant Manager Dennis Eby.

That last point became even more important when government specifications changed to require polymer-modified asphalt in toplift paving. The new spec meant the plant needed additional binder storage and more room to handle multiple AC products without disruption. As Stephens later explained, those evolving requirements were a key driver behind adding both new silos and a larger binder tank—ensuring All Roads could meet every mix design its customers demanded.

With more work ahead and more contractors relying on them, All Roads needed a way to produce multiple mixes at once while maintaining the customer service that helped drive that growth. “We run three plant crews so that we can run 24 hours a day and seven days a week,” Stephens said, adding that the company’s round-the-clock availability and commitment to customer service have been key to building customer loyalty.

Despite All Roads’ need to expand, they didn’t want the customer service so responsible for their growth to suffer. They needed to figure out how to expand production capacity while keeping the plant fully operational—and just as clean and efficient as the day it opened.

Expanding a continuously running asphalt plant required both precision and restraint. All Roads’ goal was clear: stay open, stay safe and finish on schedule.

“We started the planning process in November when we met with Gencor,” Eby said, adding that they began the upgrades the following

January. “Our goal from the beginning was to keep the plant open full time and accessible while these improvements happened.”

The project added two 200-ton silos and a 45,000-gallon AC binder tank, supported by 20 piles to make the new structures earthquake-resistant. “There was a lot of groundwork involved initially,” Eby said. “And that all happened simultaneously while we produced asphalt.”

Every bit of work from excavation to setup was handled by All Roads’ own crews, without a single injury or incident.

“During construction, we made minor tweaks in the yard to ensure that our customers could be loaded in conjunction with our crews,” said All Roads COO Mike Darby, who led the on-site construction work. “This included having internal and third-party sales truck lines and yard coordinators during busy times. We determined in advance that we wanted our customers to be impacted the least and typically sacrificed our own crew productions to accommodate this service orientated goal.”

Construction wrapped up just in time for the 2025 paving season. “This is the year of fives for our asphalt plant. It’s now five years in the making, with a recent upgrade to five storage silos, in the year of 2025,” Darby said. Eby added, “The tank came online first in the middle of May, and then the silos were up just in time for our busy season.”

A key decision early in the project ensured the plant would be ready for that surge. “I was originally just going to order one silo, not two,” Stephens recalled. “But Dennis just phoned me one day and challenged me, ‘Why are you wasting time? Let’s just get both going right now.’ And I accepted that challenge.” The choice to complete the full expansion at once proved essential to meeting production targets.

Unpredictable tariffs briefly complicated equipment delivery. “We ended up by getting two of our silos through with no tariff,” Stephens said. “And then when our AC tank came through a week later, they hit us with a $75,000 tariff.”

Even with that setback, the team refused to cut corners. “We wouldn’t have sacrificed the sustainability performance of our tank for the sake of the $75,000,” Stephens said. “We wanted the product to be consistent with everything else we have.”

When the final pieces came online, All Roads had gained almost 70% more storage capacity without interrupting production—a rare feat for any continuous-run facility.

With the new infrastructure in place, the focus turned to performance: how the upgraded systems improved efficiency, environmental control, and the plant’s already-strong emissions record.

When the upgraded systems came online, the impact was immediate. All Roads produced more than 400,000 tons of mix in 2025—about 15% more than the previous year—without increasing emissions or energy use.

The new silos and binder tank have streamlined production and reduced downtime between mix changes, allowing operators to keep materials hot, organized, and ready for dispatch around the clock.

“The additional silos also allowed us to fill orders for the day shift immediately after the night shift projects were complete,” Darby said. “This gave us more room to better service our day shift projects and our smaller third-party customers.”

All Roads Construction’s Vancouver asphalt plant stands complete after its 2025 expansion, featuring five 200-ton storage silos and a new 45,000-gallon AC binder tank.

Stephens said the improvements also prepared the company for the province’s evolving binder requirements. “Now, nothing can stop us,” Stephens said. “There’s no mix we can’t make.”

Just as importantly, the expansion preserved the plant’s environmental performance—a cornerstone of All Roads’ identity. The company, which describes its facility as the greenest asphalt plant in Canada, continues to post its emissions data publicly. “Our particulate is not even a tenth of what we’re allowed to be able to produce,” Stephens said. “We blow the specs right out of the water and we’re proud of that, so proud we post those results online.”

That strong environmental record also made the permitting required for the expansion easier. “The [city] could do quick calculations to determine that with this upgrade we’re still way below permitted levels,” Stephens said.

Performance gains have come not only from technology, but also from experience. “It’s almost like our plant is getting greener and cleaner,” Stephens said. “Part of that is because our guys are actually learning the plant better… and it makes it burn more efficiently, which means we emit less.”

Five years after commissioning, the Vancouver plant continues to perform cleaner and more efficiently than when it was first built—a testament to both its design and the team operating it.

That same team—the operators, maintenance staff, and managers who keep the facility running 24/7—remains central to All Roads’ success and to sustaining those performance gains.

Behind All Roads Construction’s around-the-clock operation is a team that keeps the plant running smoothly, safely, and continuously improving.

“We don’t wait until the winter months to perform all our maintenance,” Eby said. “We’re constantly repairing and upgrading, and improving on the fly.”

All Roads Plant Superintendent Jordan Shepell skillfully lays out all maintenance projects in advance. “If we get a rain day or a couple hours, they know how long that maintenance task is going to take and they hammer it out fast.”

That responsiveness proved essential during the expansion and remains part of daily life at the Vancouver plant. Tight coordination between loadout crews and truck drivers ensures the site runs like clockwork even at peak capacity. Stephens credited the on-theground teamwork that allows materials and traffic to flow safely through a compact site without delay.

Investing in training has also strengthened the operation. Each year, All Roads sends plant personnel to Gencor’s training facility in Florida to sharpen their technical skills and deepen their understanding of the system. “They actually light a burner and show the guys there what a perfect flame is,” Stephens said. “The guys get so much out of that training. They get to understand the drum’s internal flighting system and all the plant’s major operating components.”

That emphasis on development has given All Roads more bench strength than most single-plant operations. “We have five plant operators,” Stephens said, “whereas most competitors can hardly find one.”

Stephens said a culture where learning, teamwork, and respect are daily values makes the company a sought-after workplace. “When you have people reaching out to you to want to come to work for you, instead of you trying to find these people, that’s a huge advantage.”

That sense of pride and camaraderie runs deep. As Stephens put it, “We’re here to have a lot of fun and hopefully make a little bit of money.”

Five years after opening what the company calls the greenest asphalt plant in Canada, All Roads Construction continues to prove that clean operation and high production can go hand in hand.

Looking ahead, All Roads plans to document its environmental performance even more formally. “We don’t have [an Environmental Product Declaration] yet, but it’s on my hit list to be able to achieve in 2026.”

For Stephens, that next step is part of the same philosophy that guided the expansion—continuous improvement, backed by investment in people and technology.

“Asphalt plants are necessary to service the industry and the roads we travel on,” he said. “At All Roads, we’re going to continue to do that in the greenest way possible.”

Achieve precise paving when everyone has what they need, safely at their fingertips

BY SANDY LENDER

IIn the November issue, we looked at a variety of ways to augment the paver delivered from the dealership or auction house, so it might offer its most efficient environment for the paving crew when handling, storing and using auxiliary equipment. Crew members need a safe, uncluttered workspace where they can access an increasing number of tools and tablets during the shift. Let’s take the discussion a step further this month with a deeper dive into safety and trucking, starting with a patent-pending design from N.B. West Contracting Co., Pacific, Missouri.

The National Asphalt Pavement Association (NAPA), Greenbelt, Maryland, awarded N.B. West the 2024 Asphalt Operations Safety Innovations Award during a ceremony at the association’s 70th annual meeting, for its protective guards for paver operators. While original equipment manufacturer (OEM) standard guards protect operators in fixed positions, N.B. West’s custom-fabricated guards, welded to the operator’s seat frame, provide protection regardless of seat position. Since the first installation in May 2024, the company had reported zero incidents or near-misses and, as of press time, had received approval to move forward in the patenting process.

NAPA stated in a press release, this worker safety initiative fills a void in commercially available paving equipment protection and offers a replicable solution for other paving companies. N.B. West Safety Director Tim Swaringam confirmed this concept, stating all seven of the company’s pavers, which include various makes and models, had the safety cages installed as of November 2024.

Logistics Manager Noah DeRousse and Shop Manager Nick Brewer worked with Swaringam on the company’s safety committee and helped design and build the protective guards.

Before he took on the role of logistics manager, DeRousse spent six months working directly with Swaringam in the safety department as the field safety coordinator. “During that six-month period, we really worked on these cages and tried to improve the safety of our operators here at N.B. West,” DeRousse said. “Prior to the six months in the safety department, I ran one of these machines...for 21 years. I’ve seen a lot of incidents happen over the years, a lot of operators injured, a lot of really close calls.”

Brewer explained that his team in the shop helped design and install the safety cages. He shared that whenever the paver operator’s seat is positioned right along the inside of the confines of the paving machine, there’s protection for the operator with the OEM’s platform structure. This position is typically used when transporting the machine.

“This is more for transportation of the machine out on the highways to and from the job sites,” DeRousse shared. “If I’m sitting here and my asphalt hopper is lifted up...I can see just fine.” If the hopper wings are down for paving, “you can’t see your line. You can’t see

For N.B. West Contracting Co., Pacific, Missouri, it was a team effort to design and build the safety cages to protect paver operators from struck-bys. The final result garnered them the 2024 Asphalt Operations Safety Innovations Award from the National Asphalt Pavement Association. Photo courtesy of N.B. West

To help the paving crew when doing handwork, Dwight Michael of Michael Trucking, Ft. Collins, Colorado, installed a covered switch at the back of the haul truck. Now, from outside the cab, he can toggle the switches to hydraulically raise and lower the truck bed. The round button above the two switches turns the hydraulics on. Photos courtesy of John Ball, Top Quality Paving & Training, Manchester, New Hampshire

where you’re trying to pave. So, you end up kicking this seat out the second or third click. Once you kick it out where you can see down the hopper, then you’re exposed out here if you don’t have a safety cage. Over all my years of running an asphalt paver, I was hit several times—one time causing some nerve damage in my elbow that never has gone away. And every operator that I’ve known that’s been a paver operator for any substantial amount of time has been hit or had a really close call. I would say over my 20-year career, probably 15 times I had trucks hit the back of my seat. Not all of them have hit me, but it would only take one to be a really big injury for someone.”

The safety cage design includes signage to alert drivers that the seat has been kicked out from the confines of the operator platform. Swaringam and Brewer spoke of adding the slow-moving vehicle triangle to the back of the operator’s seat.

When the operator moves the seat “out” to get a better view for paving, his upper torso is exposed. “The only thing protecting him is the back of that seat, which doesn’t really provide any protection at all,” Swaringam said. “Anything that hits that seat could possibly harm the operator. At nighttime whenever there’s low visibility, you can see there’s nothing on the back of that seat to visually see the operator sitting out there. The only thing is [the operator’s] Class 3 vest, but that’s really all that a passing motorist would see is his sleeve sitting there.”