42

Plant extracts in aquafeeds: Standardization as a key parameter Mathilde Buffiere, Nor-Feed, Rôger Oliveira e Silva, Federal University of Vale do São Francisco

Betting on each batch of a plant-based product “Plant extract” is a generic name of a very diverse group of compounds. From a semantic point of view, a plant extract is nothing but the product obtained after contact between a plant and a solvent. This process leads to the solubilization of some molecules from the plant into the solvent. The final product depends on many parameters, such as the part of the plant used (leaves, bark, roots, fruits, seeds, etc.), the kind of solvent (polar/apolar), the process (duration, temperature, pressure), etc. Even in controlled conditions, plant extracts obtained from two different batches can be very different. This is linked to the plant’s growing conditions or the so-called “terroir”, well known by wine lovers.

Secondary metabolites produced by the plants depends on their growing conditions, such as weather conditions, substrate composition and pathogen pressure. In the aquafeed industry, this “terroir” effect is not desired, as we are looking for standardized products. Standardization is then a prerequisite as it enables regular performance.

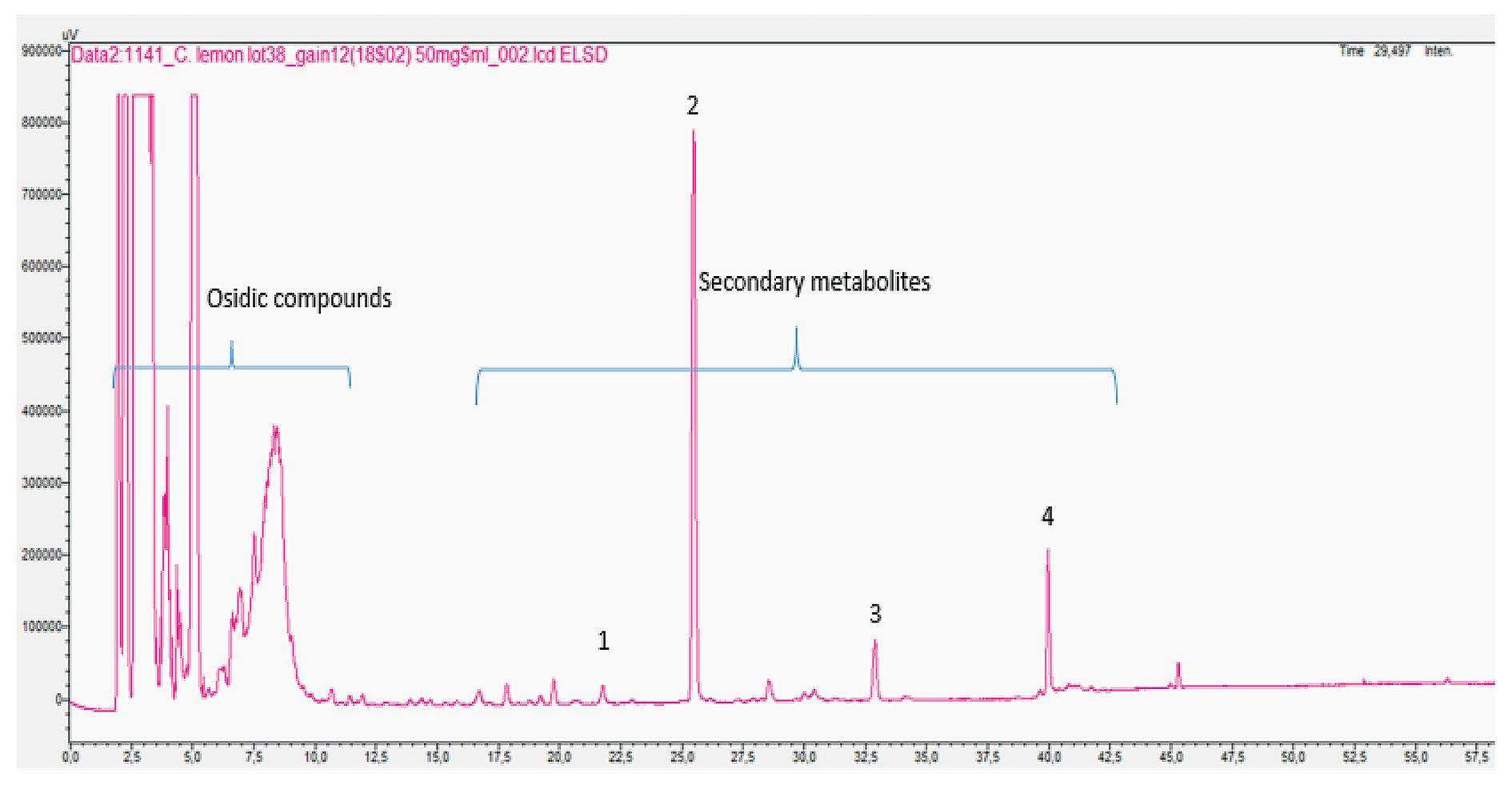

The compounds to standardize Quality Control Plan (QCP) is commonly applied to raw materials. Hence, feed formulators understand that nutrients such as protein, fat and ash are different from batch to batch and must be consequently and regularly analyzed to formulate an efficient feed. It is exactly the same for plant extracts composition. Let’s take the citrus extracts example. Citrus are well

Figure 1. Lemon extract thin layer chromatography clearly shows the difference between primary metabolites (osidic compounds) and secondary metabolites (active compounds).

Aquafeed: Advances in Processing & Formulation Vol 13 Issue 2 2021