5 minute read

Plants extracts in aquafeeds: Standardization as a key parameter

Plant extracts in aquafeeds: Standardization as a key parameter

Mathilde Buffiere, Nor-Feed, Rôger Oliveira e Silva, Federal University of Vale do São Francisco

Betting on each batch of a plant-based product

“Plant extract” is a generic name of a very diverse group of compounds. From a semantic point of view, a plant extract is nothing but the product obtained after contact between a plant and a solvent. This process leads to the solubilization of some molecules from the plant into the solvent.

The final product depends on many parameters, such as the part of the plant used (leaves, bark, roots, fruits, seeds, etc.), the kind of solvent (polar/apolar), the process (duration, temperature, pressure), etc. Even in controlled conditions, plant extracts obtained from two different batches can be very different. This is linked to the plant’s growing conditions or the so-called “terroir”, well known by wine lovers.

Secondary metabolites produced by the plants depends on their growing conditions, such as weather conditions, substrate composition and pathogen pressure. In the aquafeed industry, this “terroir” effect is not desired, as we are looking for standardized products. Standardization is then a prerequisite as it enables regular performance.

The compounds to standardize

Quality Control Plan (QCP) is commonly applied to raw materials. Hence, feed formulators understand that nutrients such as protein, fat and ash are different from batch to batch and must be consequently and regularly analyzed to formulate an efficient feed. It is exactly the same for plant extracts composition. Let’s take the citrus extracts example. Citrus are well

Figure 1. Lemon extract thin layer chromatography clearly shows the difference between primary metabolites (osidic compounds) and secondary metabolites (active compounds).

that they have prebiotic activity. They stimulate the growth of beneficial bacteria and inhibit the adhesion of pathogenic bacteria. They also stimulate SCFA production. For those reasons, Nor-Feed standardizes the POS content in every batch of Nor-Spice AB® that comes out of its production lines.

Standardizing efficiency in plant extracts

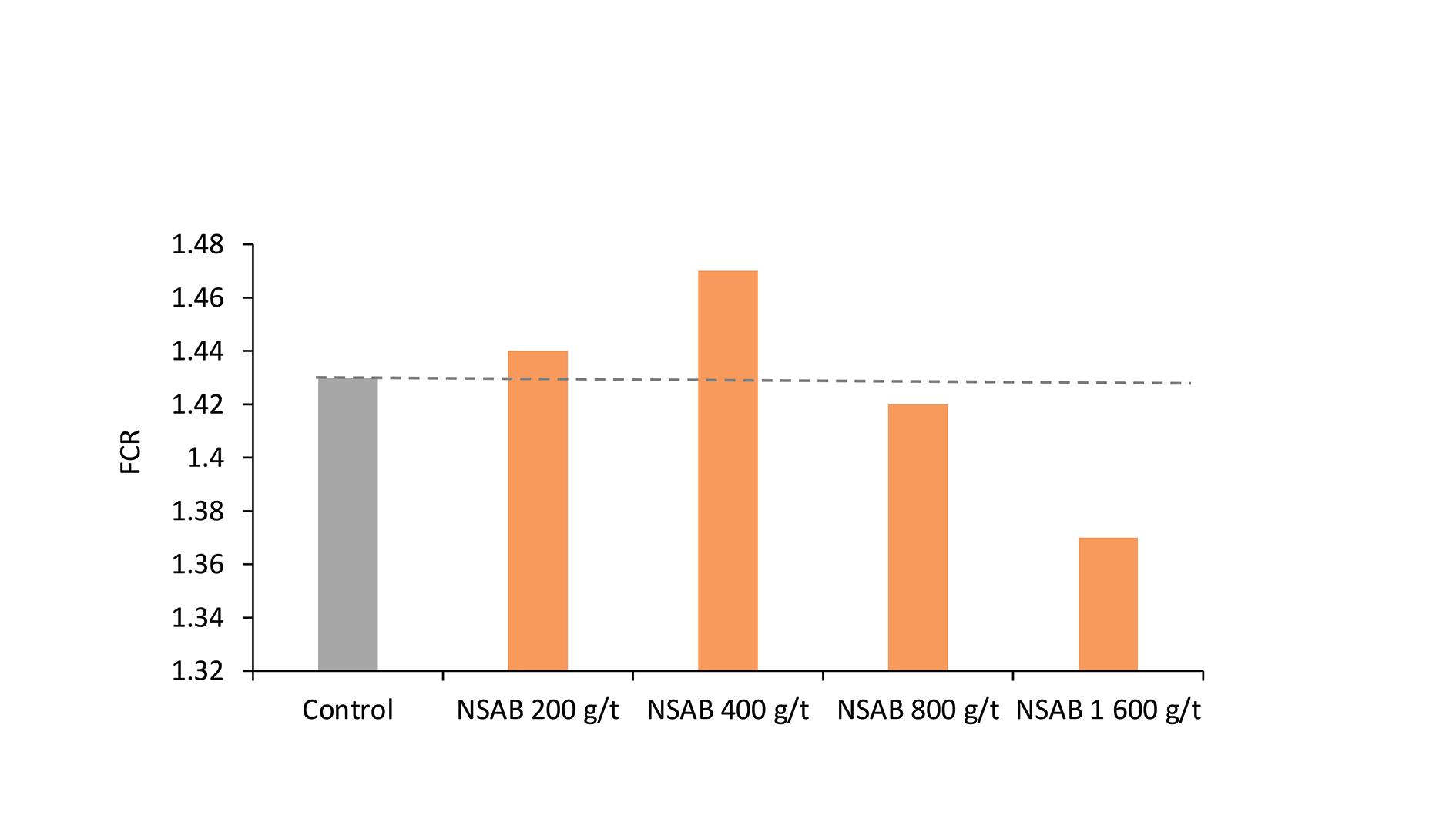

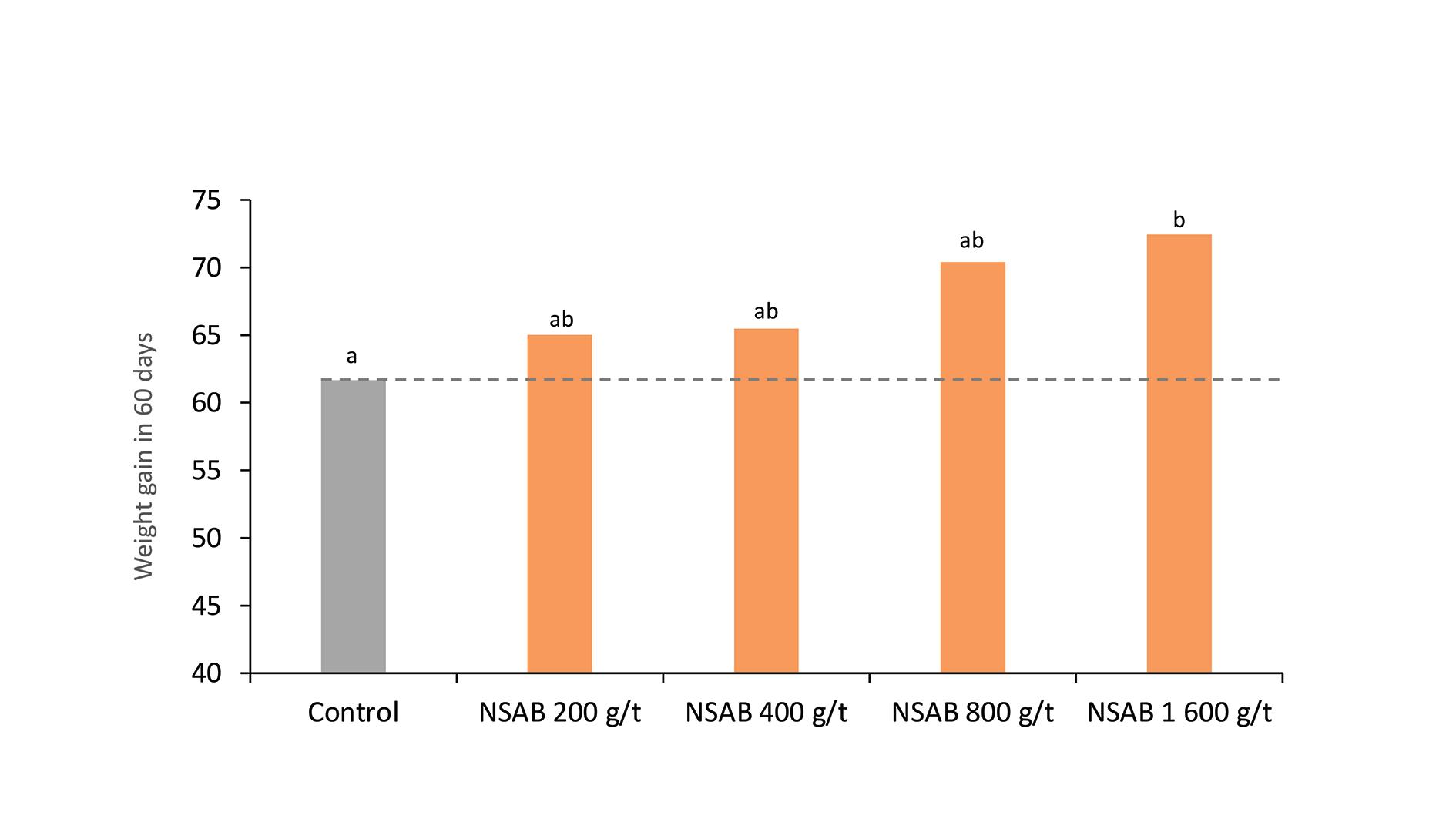

Apart from analytical compounds, plant extracts can also be standardized for their activity. It means it’s possible to analyze the in vitro activity of the product for a given property. Nor-Spice AB®’s ability to stimulate the growth of beneficial bacteria is one of its QCPs. Indeed, this activity is checked in vitro for each and every production batch. The product can only be sold if it increases lactic Figure 2. Weight gain in 60 days and FCR in a trial with NOR-SPICE AB® in tilapia. acid bacteria growth 7 fold or more compared to the same culture known for their positive effects on aquaculture species media without the product. The stability of the abovegrowth. Fine characterization of the commercial mentioned components allows customers to purchase product Nor-Spice AB® allowed the identification of a product whose effectiveness is constant, batch about 40 secondary metabolites, including after batch. 17 citroflavonoids such as eriocitrin, hesperidin and naringin. Some of these molecules are well Standardization, extrusion and plant protein described in scientific literature. Their types of The efforts made by the Nor-Feed R&D team in action encompass beneficial bacteria growth collaboration with FeedInTech Laboratory to develop stimulation, inhibitory effect on several bacterial precise, repeatable and efficient analytical methods species and short-chain fatty acids (SCFA) production are not only useful to characterize the additive itself stimulation. For these reasons, Nor-Feed chose but also to analyze product behavior during the feed to standardize citroflavonoids in the product. manufacturing process. As a plant extract is basically

Apart from flavonoids, citrus are among the made of plants, it is a particularly tricky task to isolate most pectin-rich fruits known to date. Pectins are and analyze it in even more animal protein devoid complex polysaccharides known for their important aquafeeds. High-fat levels contained in fish feed role in plant cell adhesion and maintenance, might also interact with the analytical process. allowing these cells to fuse with each other. Thanks to in-depth R&D efforts, Nor-Feed team was Pectin hydrolysis leads to the production of pectic able to develop a method to find and dose Nor-Spice oligosaccharides (POS). Their influence on microbiota AB® in complete feeds made of plant products, even is well documented in the scientific literature. when the product is used with a concentration as low Among other properties, it has been demonstrated as 150 ppm. This development was also used to test

the ability of the product to cope with the extrusion process applied in our partners’ plants.

From the Petri dish to the pond

The latest results obtained with Nor-Spice AB® in aquaculture species were gathered in Brazilian waters. The Aquaculture Laboratory team of the Federal University of Vale do São Francisco held a trial with Nile tilapia juveniles (mean initial weight = 12.8 ± 0.17 g). After a two-week acclimatization period, fish were divided into 5 groups containing 4 replicates each, where each group received a specific diet. The performance of the control group was compared with that of the animals whose diet was enriched with different doses of Nor-Spice AB®: 200 ppm, 400 ppm, 800 ppm, 1,600 ppm.

The fish were fed for 60 days. Daily feed intake was measured for all tanks and each fish was weighed individually at the end of the trial. The data were then subjected to an ANOVA.

Results demonstrate Nor-Spice AB®’s ability to positively influence the growth and feed conversion of juvenile tilapia. They are the most recent example underlining the link between the use of a standardized product in active compounds and its effects on aquatic animal growth.

References available on request.

More information: Mathilde Buffiere

Citrozest Range Product Manager Nor-Feed, France E: mathilde.buffiere@norfeed.net

Rôger Oliveira e Silva

Researcher Aquaculture Laboratory UNIVASF, Petrolina-PE, Brasil

CUSTOM AQUATIC FEED SOLUTIONS ARE WAITING

Surround Yourself with Unparalleled Resources for Extrusion and Drying Systems

Do you know what aquatic feed you need to produce – but unsure of the next steps? Wenger will put unsurpassed technology and process expertise to work, developing flexible solutions specific to your operation. We expertly evaluate and guide the development and processing applications for floating, sinking, shrimp and micro aquatic feeds. Every one of our systems is customized, serving you best by going beyond a standardized approach. Let us help you solve production challenges now. Email us at info@wenger.com today.

FLOATING

SINKING

SHRIMP

PHONE: 785.284.2133 | EMAIL: INFO@WENGER.COM | WENGER.COM USA | BELGIUM | TAIWAN | BRASIL | CHINA

SALMON MICRO