24

Fish protein concentrate can partly replace water as plasticizer in the fish feed extrusion process Tor Andreas Samuelsen, Nofima

Consistent and high physical quality of feeds to aquatic species are crucial for efficient feed transportation, feeding logistics and reduced feed loss to the aqueous environment. Extrusion processing is a technology that enables the manufacturing of such quality and is the dominating technology used in commercial production. The extrusion process involves several processing steps to transform the dry recipe powder feed mix into expanded extrudates that can be dried to durable pellets and added oil in a vacuum coating operation. To obtain high physical pellet quality, the feed mix is moistened and heated by water and steam addition in the preconditioner and further heated by the use of mechanical mixing and viscous heat dissipation in the extruder barrel. During this processing, the powder is transformed into a plasticized and flowable material that can be shaped through the extruder dies. Normally a plasticizer in the form of water is added to reduce the temperature needed for this transformation and improve cooking efficiency in the extruder barrel. A plasticizer is a small molecule that penetrates the dry powdery feed mixture and weakens the intermolecular binding forces in the particles. The particle polymer chains then unfold and slide past each other creating a plasticized melt. The use of fishmeal in salmon feed formulations has been reduced from 65% to 15% in the last two decades and has partly been replaced by alternative plant-based ingredients, with soy protein concentrate (SPC) and vital wheat gluten as the dominating protein sources. Plant proteins, especially SPC, demand high water level and temperature in the extrusion process to obtain satisfactory plasticization and durable pellets. This gives

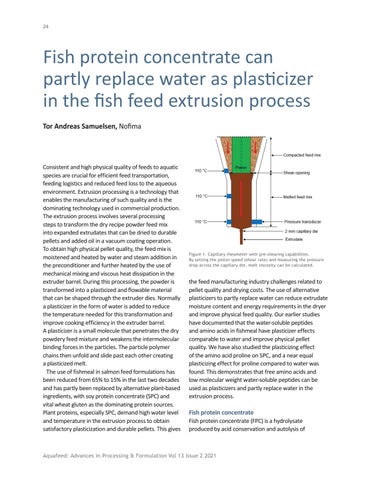

Figure 1. Capillary rheometer with pre-shearing capabilities. By setting the piston speed (shear rate) and measuring the pressure drop across the capillary die, melt viscosity can be calculated.

the feed manufacturing industry challenges related to pellet quality and drying costs. The use of alternative plasticizers to partly replace water can reduce extrudate moisture content and energy requirements in the dryer and improve physical feed quality. Our earlier studies have documented that the water-soluble peptides and amino acids in fishmeal have plasticizer effects comparable to water and improve physical pellet quality. We have also studied the plasticizing effect of the amino acid proline on SPC, and a near equal plasticizing effect for proline compared to water was found. This demonstrates that free amino acids and low molecular weight water-soluble peptides can be used as plasticizers and partly replace water in the extrusion process.

Fish protein concentrate Fish protein concentrate (FPC) is a hydrolysate produced by acid conservation and autolysis of

Aquafeed: Advances in Processing & Formulation Vol 13 Issue 2 2021