Egg Farmers of Canada is proud to support the next generation of agricultural leaders through our national young farmer program and women in the egg industry program These programs provide continuing education, leadership, and skill-building opportunities. Contact your egg board to learn more.

Learn more at eggfarmers.ca

Facebook.com/eggsoeufs

This spring, Canadian Poultry launched our third annual Top 4 Under 40 program, an initiative designed to recognize young poultry leaders. We were truly blown away by the incredible submissions we received.

Please join us in congratulating the following four young poultry professionals selected as part of this year’s program: Cheryl Norleen, 4GPoultry, Raymore, Sask.; Jeff Kamlah, Kamlah Farms Ltd., Didsbury, Alta.; Kieran McKeown, Daybreak Farms, Terrace, B.C.; and

Ryan Snyder, Research Scientist/Director, Redyn’s Research, Hagersville, Ont.

McKeown runs the only egg operation in her remote community and led a multimillion-dollar effort to modernize her family’s egg operation.

Norleen is a first-generation producer who founded an organic egg business, for which she producers her own feed.

Kamlah owns the full broiler gamut, from broiler breeders to hatcheries to chicken production and has also served on industry boards for years.

And Snyder works on Ceva Animal Health’s vaccination program while also running his own research barn.

Our full podcast interviews with each of these young poultry leaders are available at canadianpoultrymag.com. Now, in the pages ahead you can read highlights from each discussion.

4

Kieran McKeown Remote responsibility

Daybreak Farms’ general manager leads a large egg operation in an isolated community.

6

With broiler breeder barns, hatcheries and chicken barns, this producer oversees the whole broiler gamut.

8

Dr. Ryan Snyder Animal health excellence

Scientist works on Ceva Animal Health’s vaccination program and runs his own research barn.

10 Presented by

Cheryl Norleen Organic entrepreneur

First-generation organic egg producer Cheryl Norleen is committed to personal development.

Q&A with Kieran McKeown

To hear our full interview with Kieran, visit canadianpoultrymag.com

Daybreak Farms’ Kieran McKeown leads a large egg operation in an isolated community.

By Brett Ruffell

Kieran McKeown was just 29 when she took over as general manager of the family layer farm, Daybreak Farms. Since then, she’s been overseeing egg production, a grading station, a feed mill and about a dozen staff. She’s also led a multi-million-dollar modernization project to convert her older barns to enriched housing. We spoke with McKeown about balance responsibilities, leading a massive redevelopment project and going the extra mile for her industry and community.

Can you describe where your farm is situated?

Terrace is in northwest B.C. I think we’re about 1,600 km north of Vancouver, and roughly about the same from Edmonton. So, all the way west from Edmonton on highway 16.

The closest big city would be Prince George, and that’s about six hours away, east of us. We’re close to the coast. So, we’re quite isolated in a very stunningly spectacular, beautiful area tucked away in in northwest B.C.

Are you the only large commercial producer there in that area?

Yeah, the only egg farmer and commercial farmer. Because we have the grading station, we actually sell our product directly to customers. The closest grading station is Fort St. John, which is probably like 10 hours away. So yeah, we’re very isolated.

What sorts of challenges does being so isolated present?

Well, you have to be prepared, for sure. When I moved up here, I hadn’t fixed anything.

My dad fixed everything. So, I had to learn a lot. I found it a lot of fun learning and actually fixing something – it was really satisfying.

But yeah, to farm up north you have to have a lot of supplies, whether that be extra motors or extra parts. Because things will break down and we are the ones that are fixing them, so we better figure it out.

And we need a month’s worth of extra feed because we have a feed mill. There’s one highway that goes in and out of the northwest.

the only commercial egg farm and we’re the only grading station. The people don’t know any other farming other than Daybreak and small hobby farming.

So, this is a was a big deal for the town. And they were a bit divided. Some people really appreciated having us here and having a local farm here, because things like floods down south happen and there is nothing on the shelves except for Daybreak eggs because we are already up here.

But then there’s also some people that didn’t want to see a farm so close to the city. We’re within city limits, and the farm has been here since the 50s. And the town has just kind of grown around us. So, there were some people that thought we should relocate, for sure. Which we explored and

“To farm up north you have to have a lot of supplies.”

So, if anything happens along that highway, whether it be mudslides, fires, if something happens down south like floods, we have to be prepared and so we always keep a month’s worth of extra feed on hand.

You’ve led a multimillion-dollar modernization project. Can you give us an overview of that?

It all started when my dad passed away. I became general manager, and I inherited this farm. But the farm wasn’t zoned. It was zoned for hobby farming, not commercial farming. We were just kind of grandfathered in because it was already operational when they zoned it. This was an issue that that nobody wanted to deal with. So, we were really only able to do renovations – we weren’t able to build new with the zoning that we were in.

When I took it over, if I wanted to do anything, move this farm forward in any way, I would have to go and get the property rezoned. So, that’s what I did. It was a pretty long and hard process. Like we kind of talked about, we are the only egg farm. We’re

it just was not feasible to move to a different location.

So, that was a lot of consultation. A lot of just explaining what we want to do. We were putting sticky notes in all of our Daybreak cartons saying, Hey, this is our modernization plan. Use this QR code and go to our website and check out what we want to do. We had coasters that we put in the brewery and the local bar, again with QR codes.

That process really made me kind of visualize where I wanted to take the farm and forced me to put down on paper and in a in a package where I wanted to take the farm, so I could present it to city council. And really be very transparent about where I want to take the farm for the next 30 years. This is what I want to the farm to look like.

So, you took care of the zoning obstacles. You rallied public support. Have you been involved in designing the new facilities as well?

Yeah, that was a lot of fun. The first project was demolishing the barn and building a new barn. The industry was changing

to enriched production. And a lot of the market up here wants cheaper egg rather than ethically raised eggs. So, we went with a mega structure with six individual barns in this one structure. Doing a mega structure instead of, say, three individual barns was just more efficient. Each barn is an enriched – stackable, enriched housing. And they each have their own ventilation system. They all have their own climate control. Their own manure removal, egg collection, and feeding systems. So, they’re really their own barn.

You’ve worked to rebrand your farm and to become greener. What are some of the ways you’ve done that?

We had Styrofoam cartons, and we’ve just totally converted away from them. So you can compost or recycle your your egg cartons now, which we were pretty behind on. And then for the future know we’re focusing on being self sufficient and reducing our carbon footprint,

What are some of the ways in which you’ve gone the extra mile for your community and industry?

Because we have a grading station here, we can grade our own eggs and process them on site. And we’re so far removed that the town doesn’t don’t have anywhere else to get their eggs from. So, instead of shipping all of our surplus down south, we’ll donate to food banks, shelters, fundraisers… Any way that we can support the community. This is our community. These are the people that support us. So, why shouldn’t we support them and give back to them?

Also, we, we do a lot of advertising. We go to local fairs, trade shows, and promote the farm. But also, we’d have raffles where every hour we’d give a dozen eggs away.

How do you spend your downtime?

We live in such a beautiful area. It’s honestly like living in a national park. So, we have mountains, rivers, the ocean is so close. So wintertime I like to go snowmobiling in the mountains. Summertime, a lot of jet boating along the rivers and up into places that you would never see just in a car.

Q&A with Jeff Kamlah

To hear our full interview with Jeff, visit canadianpoultrymag.com

With broiler breeder barns, hatcheries and chicken barns, Jeff Kamlah oversees the whole broiler gamut.

By Brett Ruffell

Jeff Kamlah started in poultry as a turkey producer after growing up on a mixed farm. Now, he owns the full gamut of broiler operations, from broiler breeders to hatcheries to chicken farms. He’s also spent years serving various poultry industries in influential roles.

To start, tell us a little bit about your background growing up in agriculture.

Yeah, so I grew up in a mixed farm. My mom and dad had cow-calf and a grain operation and through that it got me involved with 4-H. I did 12 years at 4-H and got my awards with that and some trips. Agriculture has always been a big part of my life right from the beginning.

Did you have exposure to poultry in the early years?

No, I did not. It was about my early 20s, I guess, through my in laws. They had a commercial turkey farm.

How did you end up entering the poultry business?

We worked with Lilydale (Sophina) in Alberta here and we rented a commercial turkey farm. Ended up getting some lease quota. And that’s how we entered. They had a large farm that was down with a disease outbreak and there was an opportunity to start up some barns that had been shut down. At the time, I was power engineering, and my wife was working in accounting and so we quit our jobs and moved to Didsbury, Alta., and rented some barns and had

Jeff Kamlah runs a mixed chicken operation and has held several influential industry roles.

some lease quota and originally started in the turkeys.

And then, how did you expand into a mixed poultry operation?

So, I’ve always believed in diversity. Even within supply management, there’s times

where one business is more profitable than the other. So once the turkey farm was established, we were able to lease some broiler quota. Through that we rented barns at Linden. And then about nine months later, we had the opportunity to purchase a broiler breeder farm out in Three Hills, Alta. So,

we then were involved in the three industries for about four years – turkey farming, broilers and broiler breeders.

What does your operation look like now?

Currently today we have a broiler breeder farm. We had sold the Three Hills farm and built new barns here at Didsbury. And we’re really excited to get those barns built and they’re a precast structure with Eagle Builders and modern technology, modern egg handling equipment. We also have a broiler farm shipping our broilers down to Lilydale.

And one of our biggest accomplishments as businesspeople is we currently have four hatcheries. So, we have we are the owners of Miller Hatchery, Rochester Hatchery in Westlock, Alta., and that’s currently where the majority of our hatching eggs are going. So, we’re able to see our eggs all the way through. And then Anstey Hatchery is in Saskatoon, and we service all of Saskatchewan. And most recently, we purchased Berg’s Hatchery out of Russell, Man.

So yeah, it’s really rewarding to see our eggs leave and then be able to hatch them at our own hatchery and then ship them back as broilers. And we’re also able now to hatch some of our own broilers as well for broiler farms. So that’s been rewarding to now build that complete circle.

We have a really good team of people. We’ve been really, really lucky. We have the same employee we had from day one in the broiler breeders. So, Nino has been with us for nine years now. And Mike’s in our broilers, he’s been eight years. We have a business manager at the hatchery, Sabrina. She’s managed the business for 16.

It really allows us to do the higher end management decisions versus necessarily at a lower level. We have a team right now, between the hatcheries and in the farm, about 38 employees that we’re able to employ year-round. So, we’re doing our own feed hauling our own egg hauling, chick deliveries, hatchery workers, our administration, customer service, and then on the farm

working side, egg pickers and everything that that entails as well. So yeah, we’ve been lucky in that sense.

What do you love most about poultry?

For us it’s seeing the success of the flocks that go out that you can look back and say, those ones were healthy and successful. It’s working with the people. Working with our customers at the hatchery. Everything from small order retail, all the way up to our big commercial customers, I hear from them all and I really enjoy people’s passion and being able to help them with their chicks and help them with their equipment and supplies.

I think one of the things that really hit home was seeing now our complete circle from their primary breeder stock from Aviagen arriving to the production of eggs to the hatch, to the broiler farm, to the processing plant back to the grocery store. It’s very uncommon.

What industry and community contributions have you made?

I grew up involved with a lot of different boards and different things. And through the years of 4-H, it definitely exposed me to running meetings and different things like that.

I was elected on to the Alberta Turkey Producers board the first year we were farming, just due to them not being able to fill their board.

So through that, then the chairman was looking to step down and I ended up chairing for four years and I in total, did six and a half or seven years, I guess, with Alberta Turkey Producers and then took a year off.

And then I was able to move over to Alberta Hatching Egg Producers for a three-year term. Helped with the finance committee. Helped with the Intensive Livestock Working Group. And helped with the pricing committee.

Q&A with Dr. Ryan Snyder

To hear our full interview with Ryan, visit canadianpoultrymag.com

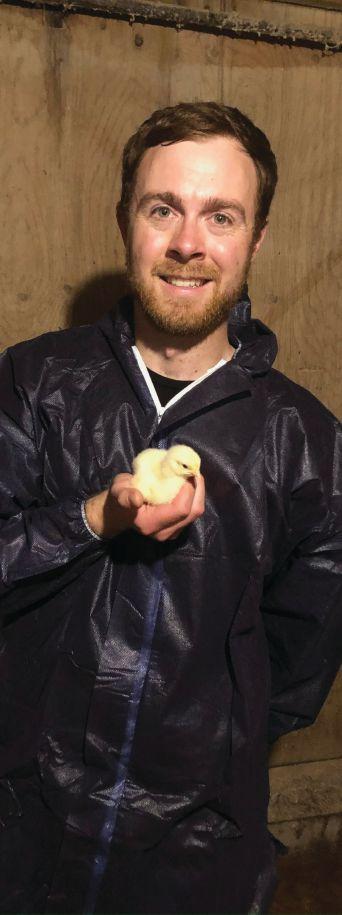

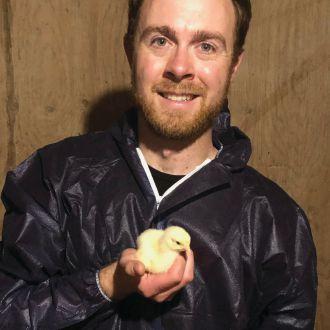

Dr. Ryan Snyder is a scientist who works on Ceva Animal Health’s vaccination program and runs his own research barn.

By Brett Ruffell

Dr. Ryan Snyder grew up surrounded by family in poultry. Thus, it’s no surprise that the young scientist is now making waves in the industry, albeit on the health research side. Snyder is a scientist with Ceva Animal Health, where he works on the company’s poultry vaccination program. He also owns and operates his own private researh barn.

Can we start by going over your background in agriculture?

Yeah, absolutely. I grew up on a poultry farm – broiler chickens – and we eventually had some turkeys as well at one point. But 100 acres of land – not too much, but enough to kind of keep ourselves busy from time to time as well. And yeah, dad was into chickens. His brother, my uncle Brian, was into chickens. My aunt Michelle was into chickens.

Grandpa was one of the first people to get quota back in the 60s. And he also had a hatchery. And from that experience, that also led to my dad and his siblings running Jarvis chicks for a time, probably from the late 80s until the early 2000s. So, my family is pretty extensive into the poultry industry. My brother grows turkeys now. I also have a cousin who’s working for a feed additive company for all sorts of livestock. So, I’ve been brought up with a lot of different people in the industry who are very well connected. I’ve been very fortunate to make other connections myself through them. And it’s been great.

Did you always feel like you wanted to continue in poultry?

No, actually in high school and early university I was more focused towards wildlife and ecology. My program kind of switched around a few times a university. So, I was thinking I was going to be working maybe more for the government, again on wildlife and ecology, but it wasn’t until after my undergrad that I started to switch. Now during my undergrad schooling, I did take a number of different agricultural courses. I went to the University of Guelph, so it was very easy for me to take both agriculture as well as ecology.

But it wasn’t until after my program – I wasn’t quite finding the jobs that I was looking for – that I started working for Trouw Nutrition research farm, which is just outside of Woodstock. They no longer are operating there. But that’s what got me back into poultry more or less. And then got kind of excited about research, which is kind of where my career led me. I spent a number of years working out of that farm outside of Woodstock, and there I started as a poultry barn technician.

I’d be, you know, helping with the feeding, the weighing of the animals, collecting data as needed. And eventually I was asked to do more of an administrative role, more of a research assistant role. And that was ordering chicks, ordering feed, entering data, and coordinating staff to kind of bring the trials to life and bring them together. So, in between the scientists who had come up with the trial idea, and then the staff who

are kind of running the day to day of it. I spent a number of years there and decided I love research. I love poultry. So, I wanted to do more.

I went back to the University of Guelph for grad school. And that was in 2015. And I did both grad school and worked at the research farm for a couple of years at the same time. And I switched from the master’s program to a PhD program. And this isn’t so much my background in agriculture anymore, but it’s kind of more my career path. I started doing this this grad school in in parasitology, coccidiosis, for broiler chicken.

I was kind of taking all the industry experience that I had from the research farm, as well as I found a passion on my own. And that happened to be coccidiosis. I saw that there was a big need for more work in that area. And so, I started there in 2015. And I graduated at the end of 2020. And yeah, my focus was on broiler chickens and coccidiosis and how we control for that, using the different major methods, major strategies.

I’d call the two strategies that we use are either vaccination or medication. And I looked at how do those work today and in the field. So, I did a lot of field work as part of the start of my thesis. And then I looked at how can we prove each of those. So, I had a study where I looked at vaccination, and what’s the best way to vaccinate. Then I also looked at drug resistance, and then how can we improve drug resistance in order to keep those products viable for as long as we can, . And then finally, I also wanted to kind of

branch out and learn a little bit more about something that’s not quite well known yet. And it’s how can we tell the different cocci apart from one another? So, that was using DNA methods and different technologies that work with DNA to identify and quantify the different species.

As I finished my graduate studies, I joined Grande Valley Fortifiers as a poultry improvement specialist, and I worked with them for about a year and a half until I switched over to where I am currently with Ceva Animal Health.

What does a typical day look like?

My role is scientist in the R&D or research and development team. So, we have a coc-

cidiosis production facility right here in Ontario, and it produces vaccine for the world. So as an R&D scientist, I’m kind of looking more down the road at the products and product development and how can we make our vaccine better not on-farm but also how can we manufacture it better.

But day to day, I’m usually working on developing protocols or writing reports on some of the trials that we do. And this might involve animal trials.

A lot of times, it’s in the lab working with the microscope, a centrifuge, and the cocci itself. And there’s times when we work with other organizations.

We work with the University of Guelph from time to time.

“I’ve been brought up with a lot of different people in the industry who are very well connected.”

Can you tell me a bit about your private research facility?

A number of years ago, I thought it’d be kind of fun to have a research facility of my own. Like I mentioned, the old research farm that was out of Woodstock is no longer running. And the universities in Canada can only run so many trials at a time. And they have their own mandates. They have their own faculty running trials as well. So, my goal was to develop a private research facility that could help meet some of the more industry-related needs.

So just this year, I’ve got my first trial and basically, I have these battery cages that are best for small-scale research and I’m starting to welcome any customers who are looking for research. If it’s for product registration, proof of concept, getting good, specific numbers down to the gram, this is the type of facility that I think would be useful for many different people. It’s being run at my parents’ facility back home at a barn that’s currently empty and not in production.

Ryan Snyder

Congratulations to our colleague on being named one of the Canadian Poultry Industry's Top 4 Under 40.

Your passion and commitment to innovation are assets to the Canadian poultry industry and to Ceva customers world-wide.

Q&A with Cheryl Norleen

To hear our full interview with Cheryl, visit canadianpoultrymag.com

First-generation organic egg producer Cheryl Norleen is committed to personal development.

By Brett Ruffell

Cheryl Norleen co-owns and operates 4G Land & Livestock, a mixed farm that includes organic egg production. The mother of five has worked hard to develop not only her poultry acumen but her business and leadership skills as well. We spoke with her about starting an egg production business from scratch and her commitment to personal development.

Can you start by telling me a little bit about your background in agriculture?

I was raised in agriculture. My parents were professional horse trainers. And then when they divorced my mom remarried into mostly cattle. So, I was raised on a beef farm. And always had a backyard flock of chickens. So, I was raised with the familiarity of having free-range birds and homeraised eggs and meat birds.

What was that process like in terms of getting everything taken care of to become a first-generation egg producer?

Looking back, it was hard. It was interesting because I didn’t know anybody in the egg industry in Saskatchewan. So, I actually phoned the Saskatchewan Egg Producers quite often, and asked a lot of questions; researched at night.

And then we did hire somebody to put the business plan together to make it look professional. It was about a three-month process. And we never told any of our family. So, nobody knew what we were doing. I

While she and her husband originally planned on building an enriched barn, they instead went the organic route.

“I am completely a different person because I’ve invested in personal development.”

always just told everybody I was doing books that night when I was actually researching to enter the egg industry.

And then we went to the bank, and we sold ourselves on financing. I had been advised by the board that if you had all your financing in place and a viable business plan and did all the prework prior to being entered into the draw that was way more beneficial.

It was great. I was like nine months pregnant with another baby. So, it was a very stressful time, for sure. And then that same year, we were able to grow our farm as well. We doubled in size all at once. But now being five years into it, it has paid off for our operation and it’s given our kids the opportunity to hopefully stay on the farm.

What came next after being accepted into the new entrant program?

We got word in December that we were the new entrants for that year. We had pretty well everything planned out. We were able to start building right away in April. We took those next few months to decide the type of barn we were building. We had originally planned on doing an enriched cage barn and our grader asked if there was any chance that we could do an organic aviary barn instead.

At the beginning, we thought no because we were not organic farmers, so we didn’t really have land. And then we did some research and found out the regulations around the organic land and we do have pastureland because of being in cattle.

So, we ended up putting the barn on that land and going with an aviary system. And we were able to build that summer. They installed the equipment in October, and we placed our birds in November. So, the first year we were the first flock was not organic. And then we got our certification for the second flock.

So, the grader said there was demand for organic eggs and you had to adjust your business plan on the fly.

Kind of, yeah. They had just gotten one other producer in the province certified at a smaller barn, like certified organic, and so yeah, there was a demand if we can go that

route. And when we have the land and the opportunity we did, and it was by far the best decision we’ve made.

It was attractive to me because I wanted the brown hen because they’re quieter. And our kids are obviously very involved in the business and in the barns often and I wanted them to not be scared of the birds as they were growing up. And so that was another reason why I was like, we need to have brown, we need to be organic so that we can have brown hens Yeah, so that’s what we did.

Where do things stand today in terms of your farm?

Today, we have downsized our cattle a little bit. So, we have about 65 cow-calf pairs. We grain farm just over 3,000 conventional acres. We have since converted almost 500 acres into organic production just for chicken feed. And then we have 6,500 birds in the barn.

I know you’ve taken a few steps to develop your leadership skills such as participating in Egg Farmers of Canada’s young farmers program and agricultural business programs. Can you talk a little bit about this? They’re great. I am completely a different person because I’ve invested in personal de -

velopment. Personal development wasn’t a big thing when I started working or wasn’t really even encouraged, right? I see that Egg Farmers of Canada is investing in the next generation with the young farmer program. It was an eye opener for us.

It was a huge learning experience for my husband and I – an opportunity just to get to know a little bit about the industry. I mean, I was raised where you don’t talk about politics or religion. And I just felt like that’s exactly what we walked into was politics. But they really just guided us and showed us the ins and outs about it.

We actually went on and took the CTEAM course, through Agri-Food Training, which gives us a whole five year like we do it, we do the research on our own farm and gives us our numbers on our farm and like, what our cost of production is, where the downfall is, right? Like where we’re overequipped or under-equipped, or what’s paying and what isn’t paying.

And those things have been like astronomical for us in making all of our decisions. When you get into a room with successful people willing to grow, it just changes all of it. And I really think that’s what all of these programs have done for us is like, let us know there’s more to farming or there’s more to agriculture than seeding and harvesting every year.