JOIN US ONLINE

REGISTER FOR THE SIXTH ANNUAL INFLUENTIAL WOMEN IN CANADIAN AGRICULTURE SUMMIT.

Join us live online, from anywhere, to hear from today’s most influential leaders and changemakers in Canadian agriculture. Hear from the 2025 IWCA honourees and other agricultural trailblazers as they share their experiences, triumphs and lessons learned during the virtual IWCA Summit.

Join us for an afternoon of panels, interactive conversation and audience Q&A as our honourees pass down their knowledge, wisdom and advice to other women in agriculture.

LEARN LEAD CONNECT

5 What’s new in cereals and forages?

The latest in cereal and forage varieties for Eastern Canada.

6 Cover crop lessons from the field

Type and timing can give spring crops a head start or hold them back.

8 Managing nutrient stratification

A quick summary for how it happens and what to do.

10 Outgrowing weeds with in-season cover crops

Testing systems for corn and soybean production in the Maritimes.

14 Reducing oat lodging and disease

Digging into some intriguing findings to develop improved management practices.

ON THE COVER: Cover crop-corn trial at the Harrington Research Farm on Prince Edward Island. Photo courtesy of Andrew McKenzie-Gopsill, AAFC. September/October

FULL OF BEANS

Since taking over the Agriculture and Agri-Food Canada (AAFC) dry bean breeding program in Harrow, Ont., Jason Larsen continues to work on building upon the program’s strengths, improve efficiencies and tackle emerging issues like western bean cutworm resistance.

Readers will find numerous references to pesticide and fertility applications, methods, timing and rates in the pages of TopCropManager. We encourage growers to check product registration status and consult with provincial recommendations and product labels for complete instructions.

FROM THE EDITOR

by Jillian Filmer

Stepping into new territory

After an incredibly hot and dry summer, I’m sure we’re all looking forward to bringing out the cozy fall clothes in anticipation for the cooler fall weather. As I write this in late August with the AC still running – I know I’m ready for some fall.

In case you couldn’t tell, I’m a new face here. I joined Annex Business Media as the editor of Top Crop Manager East, along with Fruit & Vegetable, back in April, and to say it’s been a whirlwind would be an understatement. I come from an ag and B2B marketing background – but the editorial world is a whole new can of worms.

Farmers often step outside their comfort zone and adapt to the challenges each year brings to remain resilient.

I was introduced to the field of agricultural research during a co-op work term placement at the Indian Head Research Farm in Indian Head, Sask. After spending 8 months walking through plots of wheat, counting emerging weeds, rating disease in canary seed and numerous other data collection activities for a variety of field crop trials – there was no looking back. I knew agriculture was where I needed to be. Personally, making the transition from ‘writer’ to ‘editor’ was a big one. But I truly think growth comes from stepping outside of your comfort zone. And in today’s current economic climate, and literal climate, that’s what a lot of farmers need to do when it comes to making decisions for their operations – on and off the field.

Whether it’s adjusting to the changing climate, extreme weather events, the shifting range of insect pests, the emergence of herbicide resistance or international trade wars, farmers often step outside their comfort zone and adapt to the challenges each year brings to remain resilient. This is where research can help play a major part in continuing to innovate and improve on management solutions.

I recently attended the Southwest Crop Diagnostic Days at the University of Guelph’s Ridgetown campus where I had the opportunity to chat with a few farmers and crop consultants. In these conversations, my biggest takeaway, when I mentioned that Top Crop Manager covers agricultural research, is farmers want to know what kind of research activity is happening out there.

Getting research findings into the hands of farmers is of the essence. And this is what Top Crop Manager aims for with each issue – including this one. And I’ll strive to uphold this directive as I continue to ease into this role.

Here’s wishing for a smooth, successful harvest!

What’s new in cereals and forages?

The latest in cereal and forage varieties for Eastern Canada.

BY JILL FILMER

For growers considering a cereal or forage in their rotation for 2026, Top Crop Manager has compiled a list of new varieties for Eastern Canada. All information has been provided by each of the respective seed companies.

EASTERN GRAINS INC

AAC Excellence is an oat with exceptional performance, high density and plump kernel. It’s an excellent straw yielder.

AAC Madawaska is a barley. As an excellent performer, it provides a high test weight and overall excellent characteristics.

MAIZEX

Sibia is a hard red spring wheat with very high yield potential, good drought and disease tolerance, and stable yield in every zone.

Shaka is an oat with very high yield and test weight, along with very good standability.

KWS Aviator is a forage hybrid winter rye with excellent spring vigour, higher plants and very good winter survival.

Source H20 is an alfalfa variety, featuring branched roots and a high leaf-to-stem ratio. It’s good in variable fields and is very high yielding.

Revive is a birdsfoot trefoil variety that provides very good spring vigour with fast establishment and excellent persistence.

Greendale is a tall fescue featuring fine and soft leaves, with late maturity and tolerance to stress and disease.

KWS SEEDS CANADA LTD

KWS Inspirator is a rye that features short, strong straw, ensuring excellent standability and smooth, efficient harvestability. This combination of high

performance and durability makes it a top choice for farmers looking to maximize productivity and ease of harvest.

QUALITY SEEDS

Shield II is an alfalfa variety that is branch rooted, has medium maturity, and is excellent for hay and haylage production.

ABOVE Winter wheat trial in Ridgetown, Ont.

Melina is an Italian ryegrass. It’s a tetraploid that is high yielding with excellent forage quality.

SECAN

AAC Captain is a white hulled spring oat with very strong performance in Ontario Cereal Crops Committee (OCCC) performance trials. It has excellent lodging resistance, and it is a great option to push yield boundaries.

Caldwell is a soft red winter wheat variety with top performance across areas 1, 2 and 3 in OCCC performance trials. It’s a racehorse that rewards extensive management with exceptional yield response.

SEMICAN

Beloukha is a wheat variety with excellent yield and good standability.

Arvida is a wheat variety with excellent yield and high protein.

Cover crop lessons from the field

Type and timing can give spring crops a head start or hold them back.

BY STEPHANIE GORDON

The spring wheat wasn’t looking so healthy to start. Tarlok Singh Sahota, the director of Lakehead University’s Agricultural Research Station in Thunder Bay, Ont. had an inkling as to why.

“One year, one of the farmers here had grown a winter rye cover crop and his following spring crops, spring wheat, was not that healthy in the beginning,” Sahota starts, hinting that he suspected the cover crop had something to do with it. “But there was no check, no place where the cover crop was not seeded, so it cannot be said definitively that the cover crop was having that negative effect right? That’s why I did the experiment.”

CHALLENGING WHAT WE KNOW ABOUT COVER CROPS

For three years (2021,2023 and 2024), Sahota and his team tested the effect of a winter rye fall cover crop on the following spring crops of wheat, barley, flax, canola, soybean and lentils. The experiment had three main plot treatments: fallow, winter rye without fertilizer and winter rye with

fertilizer. Results demonstrated that winter rye cover crops lowered yields in the spring crops compared to the fallow plots.

Farmers plant cover crops for various benefits: prevent soil erosion, control weeds, prevent leftover nutrients from leaching into the environment, add organic matter, and enhance the biological, chemical and physical properties of the soil. But all this was challenged when the fallow plots “outperformed” the winter rye cover crop plots – at least in terms of spring crop yields.

In Northern Ontario, the growing season is short, and soils are silty clay or loam. Winter rye is usually grown for forage because it’s a low maintenance, hardy winter crop that matures quickly. Adding fertilizer is not a common practice for cover crops, and in Northern Ontario it’s more common for farmers to apply manure instead. However, in Sahota’s study, an average of three years of data showed fertilizers significantly increased the dry matter yield of the winter rye cover crop by approximately 40 per cent. The more important question was whether the winter rye with added ferti-

Photo courtesy of Tarlok Singh Sahota.

LEFT Tarlok Singh Sahota stands in a field of winter rye, a cover crop he suspected was responsible for lowering yields in the spring crops planted after.

lizer would benefit the following crop too.

COVER CROP IMPACT ON YIELD

According to Sahota’s research, both winter rye with and without fertilizer lowered the grain, straw and biomass yields of all crops, except for soybeans.

There are two potential explanations for why yields were lower in crops planted after winter rye: snow cover protection and nutrient availability.

The soil in the fallow fields was protected by a blanket of snow – a characteristic fitting for Northern Ontario. “In Southern Ontario, snow comes and then it melts, then comes again, then it melts. Here, once the snow comes in late November, it stays and doesn’t go until mid-April. So, the freezing and thawing that creates leaching of nutrients, that doesn’t really happen in our area,” Sahota explains.

Mineralization happens under the blanket of snow, and this increases plant-available nutrients. Once the snow melts, crops in the spring can access these nutrients. “You need quite a bit of nutrients before even the crop growth takes place,” Sahota starts.

In terms of nutrient availability, when compared to the fallow plots, the winter rye plots take and give nutrients. However, in the 10 to 20 days between the winter rye being killed off and seeding spring crops, there won’t be much mineralization. “Which means, from the winter rye plots, the nutrients will be less available when compared to the fallow plots,” Sahota says. There is an adjustment period where the soil is replenishing itself from the nutrients taken up by the winter rye, so spring crops are planted into soil that is temporarily low in nitrogen. Winter rye also produces benzoxazolinones, a type of allelochemical that suppresses the growth of other plants, which makes it great for weed control but not ideal for spring crops.

FALLOW OUTPERFORMED FERTILIZED

WINTER RYE PLOTS

by an application of solid manure, and then 40 acres of corn for the spring.

Soil tests in spring 2024 indicated that winter rye grown without fertilizer application lowered nitrate nitrogen, magnesium (Mg) and calcium, pH, organic matter, CEC and the potassium (K) to Mg ratio in the soil.

However, for the fallow plots, the snow blanket proved effective: “The fallow plot had higher, almost double nitrate nitrogen than winter rye grown without fertilizer,” Sahota says.

The study also revealed that the winter rye plot with fertilizer had more nitrate nitrogen than the fallow plot (17ppm > 13ppm), but this did not translate into higher yields. “Because the biomass had to be decomposed, some nitrogen will be utilized for that purpose. So

that’s why ultimately, it didn’t give higher yields than the fallow plots,” Sahota says. “So this is the main thing, nitrogen is not readily available from winter rye, even though it has nitrogen in it. This organic form has to get converted into nitrate form, which takes time before it becomes available to the plants,” Sahota concludes.

The main takeaway for Northern Ontario farmers is that they don’t have to seed winter rye as a cover crop if they want to get good spring yields. Sahota says mixing cover crops is a better balance, like an oats and radish mixture or an annual ryegrass and clover mixture. He adds that even a winter rye and oats mixture does not deplete the soil to the same extent. Ultimately, your cover crop selection depends on what you’re planting before and after.

MIXING IT UP

Jason Reid runs a mixed operation in the Thunder Bay area with 300 ewes, around 80 cow-calves, and a couple acres of vegetables and potatoes. He seeded a 17 multi-species cover crop mostly for pasture and their operation focuses on using as little inputs as possible.

“I would prefer to buy a truckload of hay than a truckload of fertilizer, because I can buy those nutrients on a truck of hay, put it through the cows, and make better quality nutrients,” Reid starts. “So, the idea behind this blend crop is to be able to grow on lower fertility soils and produce a crop while building the soil up instead of taking it out,” Reid says.

Reid planted the multi-species cover crop, followed by an application of solid manure and then 40 acres of corn for the spring. Aside from the manure, there was no extra fertilizer added. The corn “so far looks really good” despite a dry planting season, but time will tell if the cover crop mix worked its magic. However, Reid acknowledges that growing corn for silage means it doesn’t need to reach crop standards that other farmers require.

“One thing we learned over the last 24 years we’ve been farming is the less time we spend in the field and the more time we spend in the barn, the more profitable we can be,” Reid says, highlighting that every farm used to have livestock before specializing. “You don’t necessarily need that entire cover crop that’s above ground going back into the soil, there’s a bit of profit to be had by harvesting that and selling it to your neighbour that’s got cattle or getting a few cattle to graze.” It all goes back to taking care of the soil, whether it’s cover crops or grazing. “I think long term we’re better off for the environment, we’re better off for the land, and I think that managed properly, we’re better off for the bottom line too,” Reid says.

Jason Reid planted the 17 multispecies cover crop, followed

Photo courtesy of Jason Reid.

Managing nutrient stratification

A quick summary for how it happens and what to do.

BY MATT MCINTOSH

Minimum and no-till management benefit soil biology. It can also lead to nutrient stratification, where phosphorus, potassium and other fertilizer elements concentrate on the soil surface.

Nutrient stratification is not always cause for concern. If acute enough, however, it can affect crop access to fertility resources – impacting yield. According to John Lauzon and Colin Elgie – associate professor in the University of Guelph’s School of Environmental Sciences, and soil fertility specialist with the Ontario Ministry of Agriculture, Food and Agribusiness, respectively –understanding how nutrients move, or don’t move, in soil helps inform how growers can remediate nutrient stratification.

PHOSPHORUS AND POTASSIUM IMMOBILITY

Stratification happens naturally as crops draw nutrients up from the soil. Approximately 80 per cent of absorbed phosphorus is stored in grain, which leaves the field, while the bulk of absorbed potassium –around 60 to 70 per cent – remains in the above ground plant matter.

“All the remaining nutrients [from crop residues] are dropped right on the surface,” says Lauzon.

This isn’t usually an issue for nitrogen and sulfur because they are held almost exclusively in water within the soil, moving “wherever the water goes.” Potassium, conversely, gets locked in place as its positively charged ions – also known as cations – are attracted to negatively charged soil particles.

“There’s exchange capacity. It acts kind of like a magnet which holds that cation out of solution… There’s always a little potassium in solution, which could move, but the lion’s share isn’t likely to move very much,” Lauzon adds.

Phosphorus moves even less. It reacts with other positively-charged elements, such as iron and aluminium, to form a precipitate – a solid substance that separates from a solution. The precipitate itself becomes part of the soil.

ABOVE Corn

planted in a no-till field.

“They’re all soluble. Phosphorus has by far the lowest mobility in water. Potassium is somewhere between,” says Lauzon.

Nutrients can also move within water, as well as with water, via diffusion. This is when nutrients shift from an area where its highly concentrated to an adjacent area where it has a low concentration.

“If you have high concentration near the surface, then eventually some of it will start to move down on its own through diffusion. The problem is there is different diffusion rates for different elements,” Lauzon says.

“Within in an entire year, phosphorus may move a

Photo courtesy of Bruce Barker.

sixteenth of an inch. Nitrogen moves about a thousand times faster in the water, along with the water…The concentration of phosphorus and potassium in crops hasn’t changed over time, but bigger plants mean there’s more uptake. The question is whether it’s a problem. That’s where the jury is still out.”

DOES STRATIFICATION REALLY MATTER?

Given the relative immobility of potassium and the very low mobility of phosphorus, Lauzon stresses the importance of fertilizer placement. Good placement of phosphorus is particularly important, he says, during early growth stages when the requirement for the nutrient is high.

Elgie says much the same, while heavier soils, like clay and clay loams, are at a greater risk of nutrient stratification due to higher cation binding potential. There is greater risk that moderate mobility nutrients like potassium move too quickly in sandy soils, which puts them below the reach of crop roots. In either case, good fertility placement is important.

“Tillage is one way to get that mix back in the soil profile. If you’re in a situation with extreme stratification, that might be the thing to do,” Elgie says.

“All the remaining nutrients [from crop residues] are dropped right on the surface.”

“Rather than destroy a no-till system, there’s options other than tillage to help place those nutrients better. Adjust the planter, maybe incorporate rather than broadcast. Try in-furrow or in a strip to mix up your placement a little bit.”

Some nutrient distribution will occur as earthworms move through the soil profile. While cover crops can also pull nutrients to the soil surface, they’re a useful tool for breaking up the soil and contribute to nutrient cycling. Although Elgie estimates the overall effect on nutrient stratification may be small because “you’re getting it both ways.”

For both Lauzon and Elgie, however, nutrient stratification is usually not something growers should lose sleep over.

“Most of the time we take a soil sample, we’re just getting that top six inches, so we don’t really see how that top inch or two differs from lower in the profile,” says Elgie. “The knee-jerk reaction to do something doesn’t really come until after you’ve identified there is an issue there.”

“We have to ask, ‘is this something we really need to fix?’ Maybe we already have a good supply of nutrients, so we’re really not going to see a difference.”

Outgrowing weeds with in-season cover crops

Testing systems for corn and soybean production in the Maritimes.

BY MATT MCINTOSH

At the Harrington Research Farm in Prince Edward Island, two projects are troubleshooting how to save money on inputs, improve soil health, and better manage weeds with cover crops and herbicide banding in maritime corn silage and soybean production.

Andrew McKenzie-Gopsill, research scientist with Agriculture & Agri-Food Canada (AAFC), is behind both initiatives. With funding from the Atlantic Grains Council, by way of farmer checkoff contribution, and the AgriScience Program, under the Sustainable Canadian Agricultural Partnership, McKenzie-Gopsill is using cover cropping in corn and cover cropping with herbicide banding in soybeans to reduce input requirements for both production systems in the Maritimes.

CARRYOVER BENEFITS AND WEED SUPPRESSION IN CORN

The cover crop initiative for corn production is comprised of two projects. The first project measures the impacts of corn planted into standing cover crops, and the second measures the impact of cover crops planted in-season.

The purpose of planting corn into standing cover crops for the first project, McKenzie-Gopsill says, is to

determine if there is any carryover benefit from the cover crop to reduce input use.

Sorghum-sudangrass, crimson clover and a mixture of the two species, were planted in the spring for a full year of growth. Herbicide was subsequently applied the following spring, with corn direct seeded into the remaining biomass. Different nitrogen fertilizer rates

ABOVE Fall rye growing between 30-inch soybean rows in McKenzieGopsill’s trial.

All photos courtesy of Andrew McKenzie-Gopsill.

AMARANTH

Fri., Sept. 26th

Holmes Agro (Orangeville) 473088 County Rd. 11

AYLMER

Wed., Sept. 17th

Max Underhill Farm Supply

7887 Springfield Rd.

BRADFORD

Fri., Sept. 19th

Bradford Cooperative Storage

61 Bridge St.

were applied – from a control of zero to a 150 per cent rate of 167 pounds per acre. Now moving into the second year of corn planting, data from the first year indicates corn silage yields increased with nitrogen rate, when planted into sorghum-sudangrass, and the sorghum-sudangrass and clover blend. McKenzie-Gopsill says there doesn’t seem to be a plateau in this system.

In strictly crimson clover, however, silage yields dropped as nitrogen rates increased.

“We think what might be happening is some mismatch between nutrient demands and availability. Just too much nitrogen at the wrong time,” McKenzie-Gopsill says. And while crimson clover does benefit soil health, the significant biomass generated through a full season of growth tends to overwinter well, making it a challenge to manage without high rates of glyphosate the following spring he adds.

For the in-season cover crop project, McKenzie-Gopsill analyzed the weed suppression potential of annual ryegrass and yellow sweet clover planted at corn seeding, or at V6 growth stage. These two species were chosen from among several other species after previous trials indicated they performed the best – having the

least impact on silage yield – while providing ample grazing forage post-silage harvest.

“We’re doing our best to ensure it’s all tetraploid annual ryegrass,” he says, referencing herbicide resistance challenges, which have developed in some rye grasses in other parts of the world.

Weed control from annual ryegrass seeded at V6 was statistically equivalent to using an herbicide for control, as of V9 growth stage – and this includes no impact on yield. Yellow sweet clover seeded at V6 also brought no yield impact, but McKenzie-Godsill says weeds became “quite a bit of a mess” by V9. When cover crops were planted at corn seeding, silage yields decreased by 50 per cent or more.

Other data are being gathered from the two cover crop projects, including insect and pathogen measurements, as well as root analysis to determine possible nutrient transfer between cover crops and corn plants.

Adopting covers into corn silage production does bring challenges, though.

“Seeding at V6 requires the right equipment. A lot of the time, when broadcast seeding, a lot of that cover

Continued on page 18

BRODHAGEN

Mon., Sept. 15th

Hoegy’s Farm Supply Ltd. 6777 Perth Line 44

COLBORNE Mon., Sept. 15th

TCO Agromart Ltd. 12944 Telephone Rd.

DUNDALK

Thurs., Sept. 25th

Midwest Co-operative Services Inc. (Dundalk Agronomy Centre) 124 Proton St. N

DUNDAS Thurs., Sept. 25th

County AG Services Inc. 1377 Highway 5 W.

EMBRUN Thurs., Sept. 18th

La Co-opérative Agricole d’Embrun Limitée 926 Notre Dame St.

GLENCOE

Thurs., Sept. 18th

Agris Co-opertatives Ltd.

211 McKellar St., Unit 213

GUELPH

Fri., Sept. 26th

Woodrill Ltd. 7861 Hwy 7 E.

HARRISTON

Wed., Sept. 24th

Midwest Co-operative Services Inc. 56 Margaret St. S

HARROW

Wed., Sept. 24th

Hensall Co-op 5050 County Rd. 15 (Marsh Rd.)

HICKSON Fri., Sept. 19th

Oxford Agropro Ltd 596222 Hwy 59

LINDSAY

Mon., Sept. 22nd

Alliance Agri-Turf 2134 Little Britain Rd.

LUCKNOW Tues., Sept. 16th

Lucknow District Co-operative Inc. 86387 Lucknow Line

NIAGARA-ON-THELAKE

Mon., Sept. 22nd

Niagara Orchard & Vineyard Corp 1196 Irvine Rd.

PEMBROKE Wed., Sept. 17th

M & R Feeds 2768 Micksburg Rd.

PICTON

Fri., Sept. 19th

County Farm Centre

38 Cold Storage Rd.

SCOTLAND

Wed., Sept. 24th

Scotland Agromart Ltd.

218 Oakland Rd., RR 1

SIMCOE

Thurs., Sept. 18th

Central Ontario FS Delhi 1161 Fertilizer Rd., RR 7

TARA Thurs., Sept. 18th

Sprucedale Agromart Ltd. 291 Yonge St. S

THORNLOE

*2-week long collection period

Mon., Sept. 15th to Fri., Sept. 26th Temiskaming Ag Centre 964027 Development Rd.

TILBURY Mon., Sept. 22nd

Hensall Co-op 23404 Wheatley Rd., RR 3

TUPPERVILLE Tues., Sept. 23rd

AGRIS Co-operative Ltd. 17 Centre Side Rd.

VERNER Tues., Sept. 23rd Co-op Regionale de Nipissing-Sudbury 723 Gingras Ave.

WALKERTON Tues., Sept. 23rd

Midwest Co-operative Services Inc. 1291 Bruce Rd. 3

WELLANDPORT Tues., Sept. 23rd

Clark Agri Service 4891 Canborough Rd. WINCHESTER Tues., Sept. 16th Agri-Partners Crop Centre Ltd. 667 St. Lawrence St. WYOMING Fri., Sept. 19th Wanstead Farmers Co-op 5322 Wanstead Rd.

LEFT McKenzieGopsill’s cover crop-corn trial at the Harrington Research Farm.

ENHANCED EFFICIENCY

(3, 4-dimethylpyrazole

Active Stabilizer Plus Active AgriScience

(N-(n-butyl) thiophosphoric triamide) and DMPP (3, 4-dimethylpyrazole phosphate)

Anvol Koch Agronomic Services Duromide + N-(n-butyl)-thiophosphoric triamide (NBPT)

Arm U Active AgriScience N-(n-butyl) thiophosphoric triamide (NBPT)

Arm U Advanced Active AgriScience

BRIO P TIMAC AGRO

(N-(n-butyl) thiophosphoric triamide) and DMPP (3, 4-dimethylpyrazole phosphate)

Combination of liquid fertilizers with patented PHYSIO PRO Technology

Centuro Koch Agronomic Services Pronitridine

Duo Maxx TIMAC AGRO Nitrogen, soluble potash, NBPT, DCD, Tryptophane, Rhizovit Complex 15% nitrogen, 0.2% soluble potash, 0.8% NBPT, 0.2% DCD, 0.1% Tryptophane, Rhizovit Complex Dual

ESN Nutrien Dry granular urea with a polymer coating 44-0-0

Polymer coated urea granule releases N by diffusion through coating when in contact with water. Release rate controlled by coating thickness, type and soil temperature (controlled release). Dry fertilizer granule

Excellis Maxx TIMAC AGRO NBPT, DCD, Rhizovit Complex 12% NBPT, 3% DCD, Rhizovit Complex Dual mode

Humistart TIMAC AGRO Marine calcium carbonate with Calcimer with micronutrents

- 0.8%Mg - 4%S Soil ammendment Granular MicroEssentials SZ

Mosaic Company Monoammonium phosphate with ammonium sulfate, elemental sulfur and zinc 12-40-0 10S 1Zn

MicroEssentials S10 The Mosaic Company Monoammonium phosphate with ammonium sulfate and elemental sulfur 12-40-0 10S

MicroEssentials S15 The Mosaic Company Monoammonium phosphate with ammonium sulfate and elemental sulfur

fertilizer granule

fertilizer granule

fertilizer granule P2X Ostara Magnesium ammonium phosphate hexa-hydrate 7-33-0-9Mg 7% available total nitrogen (N), 33% available phosphate (P2O5), and 9% available magnesium (Mg) from magnesium ammonium phosphate hexa-hydrate

Premium Polysulphate ICL

Sul4R-Plus Sul4R-Plus calcium sulfate dihydrate (CaSO₄·2H₂O)

fertilizer granular

fertilizer

Gradual release to match crop uptake

Sulfur, 21% Calcium n/a Dry fertilizer granule SuperU Koch Agronomic Services Dicyandiamide + N-(n-butyl) thiophosphoric triamide (NBPT)

TAPP Three ICL Single superphosphate, triple superphosphate, polyhalite, potassium chloride, magnesium oxide

TAPP Three S ICL Single superphosphate, triple superphosphate, polyhalite, potassium chloride, magnesium oxide

3-22

NP

4-dimethylpyrazole phosphate)

Brought to you by:

Information compiled from fertilizer manufacturers. Follow the information on product labels and consult an expert if there are any discrepancies with the information in this table.

FERTILIZER PRODUCTS

RECOMMENDED USES

Liquid treatment to coat urea or additive to UAN

Liquid treatment to coat urea or additive to UAN

Recommended for surface, shallow-placed, shallow-banded or shallow-incorporated (less than two inches) application of urea and urea-containing fertilizers.

Liquid treatment to coat urea or additive to UAN

Liquid treatment to coat urea or additive to UAN

PRODUCT BENEFIT

By minimizing nitrogen loss, it maximizes nutrient availability within the root zone, promoting healthier plant growth.

Controls ammonia volatilization and loss of nitrogen through nitrification from urea and UAN fertilizers.

Featuring dual active ingredients, Duromide and NBPT, Anvol provides long-lasting protection against ammonia volatilization over a wider range of soil conditions.

Allows plants to absorb more nitrogen which otherwise disappears too quickly through conversion to ammonia gas.

Inhibits ammonia volatilization, nitrification and denitrification. Contains polymers that increase the activity of NBPT and DMPP, enabling a lower percentage of active ingredient and a lower use rate while maintaining efficacy.

All soil types, pH, replacing other liquid 2x2 and in-furrow starter fertilizer. Delivers phosphorus, other nutrients and amminopurines to stimulate early growth and promote strong root development. Provides a low salt index to reduce root burn and enhance uptake of phosphorus and calcium.

May be used with anhydrous ammonia, aqua ammonia, urea ammonium nitrate and other liquid ammoniacal or urea nitrogen fertilizers and liquid manure.

Treatment of granular or liquid fertilizers containing phosphorus and/or potassium.

Delays nitrification of ammoniacal and urea nitrogen fertilizer by inhibiting the oxidation of ammoniacal nitrogen to nitrate nitrogen. Noncorrosive to the metals used in anhydrous ammonia and UAN equipment. Easy to handle.

It enhances nutrient efficiency through a dual-action approach: protecting phosphorus and other nutrients from retrograde tie-up and reducing nitrogen losses via volatilization and leaching while stimulating microbial activity in the rhizosphere to improve nutrient cycling and root uptake.

eNtrench NXTGEN is designed for use with UAN, liquid manure and dry urea. Protects nitrogen by keeping it in the root zone in a positive ammonium form longer so it is available for plant use.

Any nitrogen fertilizer application.

Treatment of granular or liquid urea based fertilizers (Urea, UAN, etc.).

All soil types, pH, replacing other phosphate soils.

Any nitrogen, phosphorus, sulfur and/or zinc application.

Any nitrogen, phosphorus and/or sulfur application.

Any nitrogen, phosphorus and/or sulfur application.

Use in place of traditional phosphorus sources. Seed-safe and root-activated, allowing product to be placed directly in row with the seed.

The unique polymer coating protects and releases nitrogen at a rate controlled by soil temperature. ESN thereby supplies N to the crop at a controlled rate to reduce N loss, increase N-use efficiency and improve grower profit.

A nitrogen stabilizer containing the Rhizovit Complex, designed to enhance nutrient efficiency, improve nitrogen uptake, support root development, reduce nutrient loss and stimulate microbial activity for better overall plant growth.

Humistart-PhysioPro is a soil conditioner that improves nutrient uptake, promotes root development, enhances soil structure, increases microbial activity and supports plant growth through its high concentration of labile calcium.

The uniform nutrient distribution provided by MicroEssentials ensures product is delivered evenly across the field, providing crops an adequate chance of taking in key nutrients for season-long nutrition. By reducing the pH around the granule, the unique chemistry of MicroEssentials promotes interactions that improve nutrient uptake of P and S. In addition, MicroEssentials combines two forms of S, sulfate and elemental sulfur, in every granule to ensure S availability throughout the growing season. Sulfate sulfur satisfies seedlings’ needs for early-season growth, while elemental sulfur is available later in the growing season.

P2X is a single-source, root-activated phosphate that delivers phosphorus, nitrogen and magnesium in direct response to root demand. Unlike conventional fertilizers that release with moisture, P2X only releases nutrients when roots exude organic acids—ensuring a steady, efficient nutrient supply throughout the season. Backed by Crystal Green technology, P2X stays in the root zone, resists tie-up and maximizes uptake when it matters most.

Use in place of traditional potassium, sulfur or calcium/gypsum sources. Comprehensive four-in-one prill fertility supply, providing essential nutrients while enhancing efficiency.

Use in place of traditional potassium, sulfur or calcium/gypsum sources. Gradually releases four nutrients, providing essential nutrients while enhancing efficiency.

Recommended to use in place of traditional gypsum or in place of traditional sources of plant-available calcium and sulfur.

Any nitrogen fertilizer application.

Provides a slow-release nutrient profile to deliver nutrients to plants throughout the season and deliver exceptional blendability, uniform spreadability and low-dust handling.

Premium fertilizer featuring urease and nitrification inhibitors to guard against all three forms of nitrogen loss.

Seed-safe starter blend fertility option for in the seed row. Just add nitrogen. Five nutrients in one prill offering seed-safe, plant available nutrition that feeds the plant all season.

Seed-safe starter blend fertility option for in the seed row. Just add nitrogen. Five nutrients in one prill offering seed-safe, plant available nutrition that feeds the plant all season.

All soil types, pH, replacing other phosphate sources.

All soil types, pH, replacing other phosphate sources.

Protects liquid urea-based fertilizers from ammonia volatilization, leaching and denitrification. It can be used for any crop that requires nitrogen fertilization.

Any nitrogen fertilizer application.

Top-Phos is a proprietary phosphorus fertilizer designed for high solubility, efficient uptake and consistent performance across all soil pH levels. With a low salt index, sustained nutrient release and positive interactions with soil microbes, Top-Phos delivers smarter, longer-lasting phosphorus nutrition.

Proprietary nitrogen-phosphorus fertilizer combining N-Process and TOP-PHOS technologies, for effective performance across a range of soil pH levels, positive microbial interactions, etc.

Dual active ingredients NBPT, the most research-proven urease-inhibitor technology, and the patented active ingredient Pronitridine, safeguard nutrients from volatilization, leaching and denitrification.

Fertilizer treated with urease and nitrification inhibitors to help reduce volatilization, leaching and denitrification. With NBPT and DMPP working together, TSN improves nitrogen use efficiency and keeps more nitrogen available for your crop.

Reducing oat lodging & disease

Digging into some intriguing findings to develop improved management practices.

BY CAROLYN KING

Oat growers in the Maritimes are well aware that factors such as higher nitrogen rates, susceptible oat genetics and high winds with heavy rain can increase lodging, a serious threat to oat yields and quality. Now a project led by research scientist Adam Foster is investigating the role of disease in oat lodging and developing fungicide strategies to reduce lodging in maritime oat production.

“This project was inspired by on-farm agronomy trials conducted by the Atlantic Grains Council under the Canadian Agricultural Partnership from 2018 to 2022. In their project, they were trying to find a way to reduce oat lodging, and they were testing both growth regulators and fungicides,” notes Foster, who is with Agriculture and Agri-Food Canada (AAFC) in Charlottetown, P.E.I.

“One of the interesting results from those trials was that the fungicides actually had a much greater effect than the growth regulators on reducing lodging.”

Foster and his colleagues were really intrigued by this finding. “We had a lot of questions, and there wasn’t a lot of answers. So, my AAFC colleague Aaron Mills and I worked with the Grains Council to develop a new project to dig deeper into the role of disease management in oat lodging,” says Foster.

“Our project’s main goal is to find the most effective way to manage oat disease in a way that will reduce lodging at the same time. We are particularly focused on fungicide strategies, evaluating different products, modes of action and spray timings to see what works best… We are also investigating which pathogens are contributing to lodging and whether better disease control can also improve yields.”

This project, which is funded through the Sustainable Canadian Agricultural Partnership, is a collaboration between the Atlantic Grains Council, AAFC and

Dalhousie University. Along with Foster and Mills, the other key researchers are Nancy McLean with Dalhousie and PhD student Dustin MacLean, who is co-supervised by Foster and McLean.

ABOVE Researchers are investigating the role of oat disease in lodging and developing fungicide strategies to reduce lodging in the Maritimes.

FIELD TRIALS IN 2023 AND 2024

The project team collected preliminary data in 2023, and then the project officially started in 2024. It includes small-plot field trials and greenhouse experiments.

The field work in 2023 and 2024 involved two main trials, taking place at the project’s two field sites. One site, led by Foster and Mills, is at AAFC’s Harrington Research Farm near Charlottetown. The other site, led by McLean and MacLean, is at Dalhousie’s campus in Truro, N.S.

Oat lodging increased as the nitrogen fertilizer rate increased, as

and 150 kg/ha (top row).

One of the field trials examined the interactions between fungicide spray timing, fungicide mode of action, oat variety and nitrogen (N) fertilizer rate. The spray timing treatments compared a stem elongation application versus a flag leaf emergence application. The mode of action treatments compared a Group 3 product and a Group 11 product. The oat varieties were AAC Excellence and CDC Orrin.

The N fertilizer in this trial was applied preplant at rates of 50, 100 and 150 kilograms of N per hectare (kg/ ha). Foster notes that the 50 kg/ha rate is high, slightly above the recommended rate for oat production in the Maritimes, while the 100 kg/ha rate is very high and the 150 kg/ha rate is very, very high. He explains that they chose these high N rates to increase the risk of lodging. “We wanted to create conditions that would induce lodging because we’re looking specifically for lodging.”

The other field trial compared nine different fungicides and a control treatment. The fungicides included Group 3, Group 7 and Group 11 active ingredients, with products having either one or two modes of action, and also a Group BM02 biocontrol product. The fungicides were applied at stem elongation. Preplant N fertilizer was applied to the plots at 100 kg/ha to

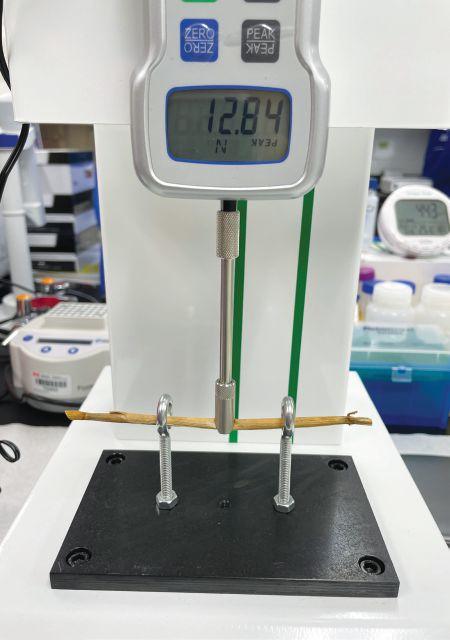

RIGHT The project is using this meter to test oat stem strength; it presses on an oat stem, recording the force needed to buckle the stem and reveal its lodging resistance.

ABOVE

shown in this trial at Harrington, P.E.I., comparing 50 kg/ha (middle row), 100 kg/ha (bottom row)

encourage lodging.

In the two trials, the team assessed various characteristics such as lodging, disease severity, stem strength and grain yield. In addition, when the stems first bent over in a lodging event, the team collected the buckle points so they could use the fungi infecting those buckle points in their greenhouse experiments.

Lodging problems can include stem lodging, when the stem buckles, and root lodging, when the root system fails to anchor the plant. “So far in this project, almost all of the lodging is stem lodging. It typically occurs in the lower part of the stem, in the first three internodes,” says Foster. And so far, the first instances of stem lodging each year have occurred right after full head emergence.

He adds, “We did see root lodging, but it tended to happen after stem-lodged plants lodged into other plants – lodging does tend to be a bit of a domino effect.”

As expected, the amount of lodging increased as the N rate increased. “We found that, as you put on more nitrogen, the plants get taller, the root systems get a bit smaller, and the stems get a little narrower and they are more likely to buckle,” he notes.

“We also found that the fungicide did reduce lodging but only at the 50 kg/ha nitrogen rate.” At the higher N rates, the plant’s architecture is so prone to lodging that disease management tends not to make much

difference to the overall lodging risk.

Some of the fungicides were more effective than others; the ones that were better at reducing lodging included Miravis Ace (Groups 3 and 7) and Group 11 products Headline, Quadris and Acapela.

There was not a significant difference between the two spray timing treatments.

SURPRISES FROM GREENHOUSE TRIALS

For the greenhouse experiments in 2023 and 2024, the team isolated the fungi from the buckle points and identified the different species. They found Parastagonospora avenae (which causes Septoria leaf spot), various Fusarium species, Drechslera species, Phoma species and several other fungal pathogens.

Stems of actively growing oat plants were inoculated with the different fungi. A pin was used to create a wound on the stem and then some of the hyphae (fungal filaments) was placed on the wound. After inoculation, they tracked the infection, measuring the length of the lesion and determined the stem strength.

“We got some surprising results. Most of the fungal species that we collected were able to cause lesions on the oat stems, but pretty much only the Fusarium species, particularly Fusarium graminearum , Fusarium sporotrichioides and Fusarium avenaceum, stood out as being substantially more virulent,” says Foster.

Furthermore, while most of the other fungi had little

BELOW Greenhouse fungal stem infections on AAC Excellence after three weeks: untreated control with pin wounding site (left); infected with Fusarium graminearum (centre); and infected with a Drechsleraspecies (right).

effect on stem strength, these three very virulent Fusarium species drastically decreased stem strength by up to 90 per cent, causing the infected plants to buckle and fall over in the greenhouse trials.

Although the infection levels in the greenhouse experiments are not necessarily what would be occurring in the field, Foster found it interesting to see this direct link between lodging and the Fusarium pathogens collected from the lodged stems in the field.

“One of the interesting results from those trials was that the fungicides actually had a much greater effect than the growth regulators on reducing lodging.”

The possibility that Fusarium pathogens could be contributing so strongly to lodging was unexpected given that people don’t generally think about oat stem infections being caused by Fusarium

“Fusarium species are really well known for causing Fusarium head blight of small grains, particularly the impacts on yields and the losses due to mycotoxin contamination. However, Fusarium also commonly causes disease in some other parts of cereal plants such as the roots and crowns and is well documented for causing stem disease in other plants particularly corn,” explains Foster.

“The Maritimes tends to have very favourable conditions for Fusarium, and it may not be overly surprising to see other tissues getting infected particularly when weather conditions are conducive. But if what we see in the greenhouse does relate to what’s in the field, it could help explain why the fungicides are helping to reduce lodging,” he says.

“Of course, in the greenhouse we are creating a forced infection in the oat plants. It is unclear how Fusarium infection of an oat stem would occur naturally. We don’t know whether the pathogen is spreading up from the root and crown or whether it is starting from stem wounding sites, perhaps wounds from insect damage. That is something we are going to explore more in the future.”

DIGGING EVEN DEEPER

The project team is starting some new trials in 2025, which build on their findings so far.

In the new main field trial at both field sites, they are comparing three fungicide timing options – at stem elongation, flag leaf emergence and anthesis (flowering) – to try to pin down which timing is most effective. They are assessing the interactions of these timing options with each of the nine fungicides. They are growing one oat variety, CS Camden, which was selected because it showed some lodging resistance in the multi-fungicide trial in 2024. And they are applying N fertilizer only at 75 kg/ha. This N rate was chosen as a midpoint between 50 and 100 kg/ha and because it matches the rates that growers in Mills’ Yield Enhancement Network (YEN) project are using to achieve good yields.

In the new greenhouse trials, the team is delving deeper into the role of Fusarium in oat lodging. “We are taking a look at

pretty much every oat cultivar that has been registered in the Maritimes that we can get our hands on. We want to see if any of them have different resistance responses to Fusarium stem infections,” says Foster.

“Then we’re hoping to potentially explore some molecular interactions to try to find out exactly what Fusarium is doing that is causing the stems to lose their structural integrity.”

By the end of the project in 2028, Foster and his team hope “to provide Maritime oat growers with new management practices to reduce lodging and help make oats grown here more resilient to extreme weather, which definitely seems to be happening much more often with our changing climate.”

WEED MANAGEMENT

Continued from page 11

seed is going to get stuck in the whorls,” says McKenzie-Gopsill. He adds there are also few weed control options with the clover-corn combination, versus corn plus annual ryegrass.

SAVINGS FROM HERBICIDE BANDING

Four years of data in McKenzie-Gopsill’s soybean project show significant cost savings can be found by incorporating cover crops and herbicide banding into soybeans.

Six-inch row spacing in soybeans is typical in the Maritimes. For this project, McKenzie-Gopsill and his colleagues expanded to the 30-inch rows commonly employed in parts of the United States, between which either fall rye or tillage radish were established. Controls featuring standard six-inch rows, and 30inch rows without cover crops were

also established. All plots had the same seed population. Four different herbicide programs were being tested as well, including banding herbicide over soybean rows rather than standard broadcast application.

“We’re finding regardless of herbicide program, if we seed in fall rye in spring it has no impact on yield. We’re getting the same yield as our control plots of three tons per hectare,” says McKenzie-Gopsill. Radish, on the other hand, overgrows the soybeans and reduces yield by a third or more.

The benefits of banding herbicide are consistently clear.

25_007033_Top_Crop_Eastern_Edition_SEP_OCT_CN

“The environmental benefit is a 73 per cent herbicide use reduction with banding. It’s a pretty dramatic reduction in savings…Most soybean producers in the Maritimes really aren’t using any pre-emerge

products. 90-plus per cent would just be doing a single glyphosate application at V3, or whenever they can get to the field. If people are going to use those pre-emergence products that are more expensive, banding really reduces the cost. All you have to do is modify your nozzle spacing and type.”

ABOVE Annual ryegrass growing between corn rows in McKenzieGopsill’s trial.

Meet the next generation of Canadian agri-food leaders

These exceptional students are the winners of the 2025 CABEF Scholarships. We are proud to support each of them with $2,500 for their ag-related post-secondary education.

Help us empower more students to pursue diverse careers in agri-food. Strengthen the future of Canadian agriculture and food by investing in the cream of the crop.

Become a Champion of CABEF and directly support a scholarship for a Canadian student.

Congratulations to this year’s CABEF scholarship recipients.

Leah Newcombe Cambridge, NS Allison Morse Hatley, QC

Abbigail Mettler Wallenstein, ON

Messina Schrof Starbuck,

MB

Morgan Debenham Kennedy, SK

Contact CABEF today to learn how you can become a “Champion of CABEF” at info@cabef.org

Colby Scott Hanna, AB

Zeyus Spenta North Vancouver, BC