TOP CROP MANAGER

Trai T advanTage varies Economics of benefits questionable PG. 6

Managing rhizocTonia

Progress is slow but steady PG. 20

r ooT w or M resis Tance

To BT corn

A new call for a new challenge

PG. 10 be ready.

Trai T advanTage varies Economics of benefits questionable PG. 6

Managing rhizocTonia

Progress is slow but steady PG. 20

r ooT w or M resis Tance

To BT corn

A new call for a new challenge

PG. 10 be ready.

8 | Tillage erosion: it happens

Mitigating it is simple, but seek advice before taking action. by Treena Hein

14 | Minimum tillage a smart move

Many equipment options available to deal with heavy corn residue. by Treena Hein

Attempts to reduce glyphosate in Argentina a wake-up call by Treena Hein

Increasing glyphosate resistance in Ontario by Treena Hein

10 | Rootworm resistance to Bt corn

A new call for insect resistance management. by Carolyn King

20 | Towards better management of Rhizoctonia

The latest research points to slow but positive progress. by Carolyn King

Where do agronomists come from? by Melanie Epp

AccORDING TO AN AGRIculTuRAl EcONOMIST from Purdue University, growers will have to pay more to grow corn, soybeans and wheat in 2012. Land rent costs and volatility in the fertilizer markets are the two main drivers of increasing costs, which in the US could push up by 16 percent the price of growing corn, by 15 that of soybeans and by 12 percent that of wheat. www.topcropmanager.com

6 | Trait advantage varies: recent findings question the need

Are the economic benefits of hybrid traits over-hyped? by Heather Hager, PhD

Weed resistance a spreading issue by Ralph Pearce

AND NUTRIENTS

Ontario’s sulphur situation by Treena Hein

Ralph peaRce | editoR

Weed resistance is becoming more of an issue for farmers, retailers, advisors and the chemical industry. In the past two years, there have been seminars and large-scale plot tours to highlight and focus attention on the issue. now, in the past year, there has been a bevy of news articles detailing researchers’ confirmations of a growing number of cases of weed resistance. All of this is pointing to a future that, in spite of higher commodity prices (at least for the time being), will be defined more for its challenges to growers in the field of weed management.

US sources cite an increasing frequency of herbicide resistance in weeds, and although glyphosate is most commonly identified, the list of herbicide groups continues to grow. Most recently, University of nebraska researchers confirmed resistance to 2,4-D in waterhemp plants in a field of grasses in that state. Seeds from the weeds found in a few fields of warm-season grasses were gathered in 2009 and 2010, and tested extensively, finally yielding the positive result in October 2011. Still, that means there are now six different herbicide groups to which waterhemp has developed some level of resistance in the US Midwest. The same is true for palmer pigweed, an Amaranth species that has crippled growers in much of the Midsouth region, including Arkansas and Tennessee. Here at home, the problem can be seen in giant ragweed plants, which are also showing resistance to glyphosate.

One step forward. . .

In spite of the efforts of the universities, the ministries and the chemical and traits companies, this problem is only going to worsen before it ever gets better. In fact, from a perspective that is purely based in agribusiness, the focus now seems to be on traits and stewardship, as well as seed treatments and inoculants. Although all of those platforms are worthy and much needed, there may be a more pressing sense of urgency to help growers with management strategies to handle weed resistance. And it is not a matter of the chemical companies coming up with “another glyphosate.” That strategy was dismissed in summer 2010, during a field day in Arkansas. researchers and retailers alike called glyphosate a “once in a lifetime discovery,” noting they wanted it available for many years to come. Switching to some other so-called silver bullet solution, such as glufosinate, would only land farmers in trouble in another five years, when they would face similar resistance issues with that new active ingredient.

The key, said the researchers and retailers, is similar to profitability: people do more to manage their money than hope for the lottery to smile on them. And weed resistance has a similar outlook.

The only good news in this case is that US examples are our “canary in the coal mine” here in Ontario. It is not a matter of “if” but “when.”

One last note here: page 6 contains the swan song of Dr. Heather Hager, our field editor here in eastern Canada. For the past three years, Heather has provided crystal-clear writing, an uncanny ability to simplify even the toughest subjects, and a value to this magazine that is just too hard to measure. She is moving on to the University of guelph, where I am certain she will become as treasured and valued as she has been at Top Crop

You will be missed, Heather.

GROuP PuBlIsHER Diane Kleer dkleer@annexweb.com PREsIDENT Michael Fredericks mfredericks@annexweb.com

PUBLICATION MAIL AGREEMENT #40065710 RETuRN uNDElIVERABlE CANADIAN ADDREssEs TO CIRCulATION DEPT. P.O. Box 530, Simcoe, ON N3Y 4N5 e-mail: mweiler@annexweb.com

Printed in Canada ISSN 1717-452X

CIRCulATION e-mail: mweiler@annexweb.com Tel.: 866.790.6070 ext. 211 Fax: 877.624.1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

suBsCRIPTION RATEs

Top Crop Manager West - 8 issuesFebruary, March, Mid-March, April, June, October, November and December - 1 Year - $44.25 Cdn. plus tax

Top Crop Manager East - 7 issuesFebruary, March, April, August, October, November and December - 1 Year - $44.25 Cdn. plus tax

Specialty Edition - Potatoes in Canada - February1 Year - $8.57 Cdn. plus tax All of the above - $76.19 Cdn. plus tax

Are the economic benefits of hybrid traits over-hyped?

by Heather Hager, phD

Genetically modified traits for corn are becoming ubiquitous. roundup ready, Liberty Link, corn borer, corn rootworm, western bean cutworm, double stacks, triple stacks, super stacks – the options seem limitless. However, some growers are wondering if the extra costs to buy this seed are actually resulting in a yield advantage that gives more bang for the buck. As it turns out, that is a difficult question to answer.

A number of people have probed this topic; the latest investigation is a field project funded by an Ontario Soil and Crop Improvement Association regional partner grant involving essex, Kent and Lambton counties in southwestern Ontario. “It’s very much a grower-driven project,” says project lead Adam Hayes, soil management specialist for the Ontario Ministry of Agriculture, Food and rural Affairs (OMAFrA). He explains that some of the association’s growers say they have been planting conventional hybrids and getting great yields at low seed cost. However, seed companies are offering fewer conventional choices and moving to higher-priced seed with multiple traits. The growers wanted to evaluate if there is an economic advantage to switching from conventional hybrids to those with traits.

To do this, the project basically compares net income based on seed costs and yields (assuming $4.50-per-bushel corn) for several hybrid sets. A hybrid set has similar base genetics but different trait packages. For example, a hybrid set might comprise a hybrid with no traits (conventional), the same hybrid with one trait for herbicide tolerance (rr), the same hybrid with one trait for european corn borer (eCB) and the same hybrid with three traits for rr, eCB and corn rootworm (CrW). “When we started out, the idea was to have a hybrid without the traits and then the equivalent hybrid with one or more traits in it to compare. And that’s become more difficult each year with the project,” Hayes explains. He says this is because fewer conventional hybrids are being marketed and because some of them have different base genetics and do not fit into a set. “So the check has often been a roundup ready hybrid, rather than a hybrid that doesn’t have any traits in it.”

Country Farm Seeds, Dekalb/Monsanto Canada and Maizex donated seed for the project.

Based on yields and seed costs, Hayes found more of an economic disadvantage than an advantage of using traits in preliminary results from 2009 and 2010. For three hybrid sets each year averaged over multiple

Growers should ensure they have a particular issue to be addressed, such as corn rootworm, before adopting the technology.

sites, only one set showed an economic advantage, and that was for the rr trait and the rr-eCB-CrW triple stack over the conventional. Calculated net losses of planting hybrids with traits were in the range of $11 to $40 per acre; net gains were $11 to $12 per acre. However, Hayes points out that a hybrid set could show differences in economic performance at different sites. “In 2010, we did have a set of Country Farm hybrids where there were no traits, one eCB, one rr, and a triple stack as well. At one site there was no advantage to the rr,

and at the other site there was a pretty good yield advantage to the rr.”

He also notes differences between the two years for the same site. As an example, he says, “There was a site north of Thamesville where, the first year, there was some advantage to the traits, but then the second year, there wasn’t an advantage to some of the traits.”

A previous study by two Agriculture and Agri-Food Canada researchers compared conventional hybrids and similar hybrids with the eCB trait under natural eCB pressure. The research took place in the Ottawa area during the 2000 to 2002 growing seasons. Their published results say that on average, they found “…no yield advantage of Bt hybrids in comparison with their conventional counterparts when stalk lodging and breakage of the non-Bt counterpart by eCB was low to moderate.”

Another study by four researchers at Cornell University in new York during the 2007 and 2008 growing seasons compared sets of a conventional hybrid, an rr-eCB double stack, and a rr-eCB-CrW triple stack. Comparing yield income at $4.67-per-bushel corn along with seed, grain drying and herbicide costs, they found the economics were highly site dependent. They concluded that stacking the Bt traits with rr “may not always be justified,” as three of their eight comparisons showed a profit, three broke even and two showed a loss. They suggested, “…growers in new York should carefully match each hybrid trait to their specific fields and not buy Bt stacked hybrid traits indiscriminately because of their availability…”

What does it mean?

There is value to traits that cannot always be measured in this type of experiment, says greg Stewart, OMAFrA corn specialist. He has compared conventional and rr corn in past Ontario Corn Committee hybrid trials. As an example, he says, “In the broader, real-world situation, there probably is some value to having glyphosate-tolerant corn. In the context of a farmer using it, there’s simplicity, there’s a wider window of application and there’s better control of a broader spectrum of weeds. But if you tried to examine that in carefully done trials like we’ve done, you end up finding that the conventional chemistry applied on time, on target, et cetera, does just as well.

“I think out of the three possible technologies that we’re talking about – herbicide tolerance, rootworm control and european corn borer protection – I think it would be easiest to argue that the eCB

actually has value (for Ontario growers),” he states. Stewart says that is because there really was not a good way to control eCB economically before the Bt trait was introduced, so growers were taking a six- to eightbushel yield loss. In contrast, insecticides applied through the planter were used to control CrW for the few corn-on-corn acres in Ontario.

These studies suggest some good news for producers using the Bt traits, who are required to plant refuge acres. Taken together, the results of these studies indicate that, unless growers are in an area that is prone to heavy eCB infestation, the net economic result from the refuge acres should not be much different than that from the rest of the acres. “There are lots of refuge hybrids that are pretty competitive,” says Stewart, “as long as it didn’t happen to coincide with an onslaught of eCB or if perhaps you didn’t get harvested on time and you had stalk breakage.”

eCB feeding can contribute to stalk breakage. “If you can get it harvested relatively early, the loss is pretty small. You could take that same area of the province with the same relatively high eCB pressure, put in a different hybrid that maybe has poor stalk strength, and make it the last field you harvest instead of the first field you harvest, and now the losses are going to look much worse.”

And indications are that eCB numbers have gone down since the Bt trait was introduced, say both Stewart and Hayes. “There aren’t the same numbers of corn borer around as there were say, 10, 15 years ago,” says Hayes, “so the refuge shouldn’t be suffering as much as it would have 10 or 15 years ago.”

John Waters, a certified crop advisor with Lakeside grain and Feed in Lambton County, says that growers should be using traits “all the time. Our biggest trait users would not be using it if they didn’t think there was a payback.”

He notes that many growers in that area believe that they would not be able to grow corn if the traits were not available.

Hayes has different ideas. He emphasizes viewing the traits as tools and paying close attention to site characteristics. “If you have a field with a particular issue, pick the traits that fit for the various situations,” he recommends. “What we’ve shown for the most part hasn’t shown much economic value to some of these traits, in trying to average it out. But it’s more the individual situations. There are field or farm situations where it makes sense to use those traits, either from an insurance perspective or just from the management system that fits better for a particular operation.”

Mitigating it is simple, but seek advice before taking action.

by Treena Hein

In the summer of 2009, brothers Ivan and Brian DeJong decided to move about three inches of topsoil up an eroded sidehill on an experimental basis. Using a reynolds scraper/ earth mover, these owners of Youngfield Farms Ltd. (a cash crop and poultry farm north of Bowmanville, Ontario, east of Toronto) were able to boost the crop yield on an affected oneacre area in 2010 to 95 percent of the field average. “The yield increase was dramatic, as the area had historically averaged 50 percent of the field average,” says Ivan. “We also maintained the historical average on the flat area of the field where the topsoil was removed. We realized that by bringing the topsoil up the slope, we can grow a better crop, with more root mass and crop material to hold the soil.”

This is exactly the type of activity, known as mitigation or remediation of tillage erosion that Dr. David Lobb has been studying for more than 20 years. “Our analysis has shown there’s a three- to six-year payback period for all of the costs associated with putting the soil back on a hilltop,” says Lobb, a University of Manitoba soil scientist based in Winnipeg, who coined the term “tillage erosion.”

What matters most when cost-return is achieved is crop value. “even if your yield on the slopes that you’ve worked on goes up, which it will, if you’re not getting a profit for your crops, then it is difficult to pay for any form of land improvement,” Lobb notes.

“Obviously, the market value of crops is very important.” economic return also has much to do with what happens on the slope after the soil is moved back. “If you follow with conventional tillage, you’ll have to repeat the process after a while and that’s not economically wise,” Lobb notes. “To turn this practice into profit, you need to sustain the yield increases beyond the three to six years for payback. To keep the soil and the yields up on the hilltops for a few decades rather than a few years, you need to use no-till or reduced till.”

In their crop rotation, the DeJongs plant no-till soybeans into corn stalks, no-till winter wheat into soybean residue, and use spring tillage to plant corn. “We use vertical tillage with a coulter implement,” says DeJong. “Instead of moving the dirt from one place to another, it lifts dirt and puts it back on the same place.” He notes that the farm’s subsoil is more prone to erosion than its topsoil. “If we mix topsoil and subsoil together, which is what we do when we till eroded areas, it’s not as erosion-resistant as just having top soil and it’s also not as good to grow your crop,” he says.

In Lobb’s view, smooth and ripple coulters are preferable to wavy coulters. “Use a moderate, constant speed,” he advises, “and

ABOVE: On rolling ground, the primary form of erosion is from tillage, with bigger equipment and higher speeds worsening the situation.

also avoid terrace-type efforts because every break in the field slope increases tillage erosion.”

That is, if a grower puts three breaks into a long slope, there may be a decrease in water erosion by as much as 50 percent, but now there is four times the tillage erosion.

One-pass seeding and fall harrowing is not a guaranteed method of eliminating tillage erosion. “Some zero-till is low disturbance, and some zero-till is high disturbance,” Lobb says. “We’ve compared and concluded that high disturbance seeders cause as much tillage erosion as a moldboard plow through moving a little soil a long way away and with a lot of variability.”

In other words, with high disturbance seeding, a grower can remove so much topsoil that he may never recover the productivity on an eroded hilltop, even when using zero-till for 20 years

In January 2011, DeJong attended Lobb’s presentation at the Southwest Agricultural Conference in ridgetown, Ontario. “Lobb confirmed our view that in rolling ground, the primary form of erosion is tillage,” DeJong says. “It moves the most dirt. It’s obviously been happening over a long time period, but big equipment and higher speeds are making it worse. Also, there’s more row cropping now, whereas long ago, there used to be mixed fields where sod would be left.”

Lobb says that on the prairies, loss of topsoil is almost completely due to tillage erosion. “Here, the soil is readily available to put it back on top of hills,” he observes. “In Ontario, at least in some areas, gullies are more prevalent, and in these cases, the soil

that’s been moved to the bottom of a hill can be flushed away with water so there’s less available to put back on top.”

The good news for farmers is that while wind and water erosion actually degrade the soil structure, tillage erosion simply moves soil downhill like a conveyor belt. “You really don’t lose much in terms of quality,” Lobb says. The bad news is that tillage erosion is not confined to hills. “Many farms have flat or wet areas that need surface drains, and tillage erosion can fill in these small areas quickly,” he says. “While tillage erosion happens on every piece of farmland, farmers must strike a balance between how much to remove from the base and how much to add to the top.”

This is work for the fall, Lobb asserts, after all other field operations, are finished and could take many years to complete on a large farm.

“It’s great that farmers are realizing they can repair damage from tillage erosion, but I’d advise them to talk to a specialist about how much soil to place on knolls and where to take it from,” says Adam Hayes, the Ontario Ministry of Agriculture, Food and rural Affairs (OMAFrA) field crops soil management specialist. “We’ve included it in OMAFrA publications for about 10 years, and it’s also part of the soil management section of the environmental Farm plan, he says. “David’s research is helping us to raise awareness of the issue and how to address it.”

For more information: read about tillage erosion in the Manitoba Agriculture, Food and rural Initiatives Soil Management Guide at www.gov.mb.ca/agriculture/soilwater/soilmgmt/ fsm01s00.html.

A new call for insect resistance management.

by Carolyn King

In July 2011, Iowa State University researchers reported finding field-evolved resistance to Bt corn by the Western corn rootworm (WCr) in some Iowa fields. For Ontario corn growers, the Iowa situation underlines how crucial it is to take steps to slow development of insect resistance to their Bt products.

The study, led by Dr. Aaron gassmann, was initiated in 2009 after some Iowa farmers reported that certain fields with Bt corn targeting corn rootworm had suffered severe injury from that insect. The researchers collected rootworm samples from four problem fields and from control fields. In the lab, the researchers found that rootworms from the problem fields had significantly higher survival on corn with the Bt protein Cry3Bb1 than rootworms from the control fields, indicating some resistance to Cry3Bb1 in the problem fields. However, survival of rootworms from the problem fields was lower on the Cry3Bb1 corn than on non-Bt corn, suggesting the problem fields contained a mixture of resistant and susceptible

rootworms and/or that resistance was incomplete.

In both Canada and the US, corn with insecticidal proteins from the bacterium Bacillus thuringiensus (Bt) is widely grown to manage a number of important insect pests. Cry3Bb1, introduced by Monsanto in 2003, is a major Bt toxin for rootworm control and is in products such as Yieldgard VT Triple.

Dr. Mark Lawton, Monsanto’s technology development lead in eastern Canada, considers the Iowa case to be “an alleged fieldevolved resistance.” He says, “We’re working with Dr. gassmann to understand exactly what is happening in that area where he made those observations. We have some additional studies going on in collaboration with him. We do know the area where he made the observations is a part of Iowa with intense corn-on-corn

TOP: Severe injury by corn rootworm can cause lodging. INSET: Adult corn rootworm beetles lay their eggs in cornfields in the fall.

production. As well, there are pretty high populations of corn rootworm in the area, testing the corn year after year. From our end, the jury is still out on whether it’s resistance or just the plant being overwhelmed by the high rootworm population. That’s what the additional studies are going to help clarify.”

Whatever the outcome of these additional studies, Lawton says, “Whether it’s weeds or insects, in a biological system things can evolve and adapt. The Iowa situation is a good reminder about the importance of insect resistance management.”

“I think the Iowa State study should be an important wake-up call for Ontario,” says Jocelyn Smith, program lead in Insect r esistance Management (I r M) at the University of g uelph’s r idgetown Campus. “We may have taken for granted how well Bt corn products have worked for us to date. We do not expect widespread rootworm resistance in Ontario in the near future, but there are lessons to be learned from these reports.”

All of the problem fields in the Iowa study were planted to corn for at least three years in a row, which encourages high rootworm populations. “Adult corn rootworm beetles lay their eggs in corn fields in the fall, the eggs overwinter there, and the larvae hatch in the spring. The larvae need corn roots to feed on to survive, so planting a crop other than corn following corn will ensure the death of most larvae,” explains Smith.

Secondly the problem fields were planted to the same Bt protein for at least three years in a row. “One of the major factors affecting the speed at which resistance develops is how much pressure you put on the target population. p lanting the same toxin year after year in the same field is maximum pressure,” says Dr. Christian Krupke, an entomologist from p urdue University in Indiana.

The most commonly used Bt proteins for rootworm control are Cry3Bb1 and Dow AgroSciences’ Cry34/35 . In the Iowa study, the rootworms from the problem fields did not have enhanced survival on Cry34/35 corn. Krupke says, “ neither of those toxins are high-dose, but Cry3Bb1 has been around longer and planted on more acres than Cry34/35 . Therefore the overall selection pressure may have been higher for a longer period of time for Cry3Bb1 .”

The fact that the Bt toxins for rootworm are not high-dose increases the risk of resistance. “The low- to moderate-dose rootworm toxins may kill about 95 percent of the insects, but

five percent of a population of rootworm beetles is actually a large number of insects and some of those could be carrying genes for resistance,” says Smith.

“If whatever is helping the rootworm survivors to survive is heritable, then they have a chance to mate and produce offspring that are also survivors, and so on. This is how resistance develops. For this reason, the refuge is critically important for these particular toxins,” explains Krupke. “We need to have susceptible, unexposed individuals to dilute any resistance gene or genes.”

As most growers are aware, a refuge is a portion of a Bt field planted to a similar corn hybrid that does not have the insecticidal protein.

Although the farmers in the Iowa study were not asked about their refuge practices, the researchers note that only 50 percent of Bt corn planted in the US Midwest complies with refuge requirements, so it may be that insufficient refuge plantings contributed to the Iowa situation.

Smith identifies a further concern: “From some of the initial research on rootworm resistance to Bt corn, it appears as though the genes for resistance may not be recessive.”

If the resistance genes are dominant instead of recessive, then inheritance of those genes is more likely to occur.

Another factor pointing to the likelihood of rootworm resistance eventually occurring in corn fields is that researchers have already created resistance in the lab. “After just three rootworm generations, a group of researchers in Missouri was able to develop resistance to the Cry3Bb1 toxin in the lab/greenhouse environment,” says Krupke.

Furthermore, the corn rootworm seems to have a talent for developing resistance. Smith says, “Historically rootworms have been very good at becoming resistant to different control measures used against them. For instance, there are multiple insecticide groups that they became resistant to in the US where, year after year, growers used either soil or foliar insecticides to control the larvae or adults.”

There is also a rotation-resistant rootworm variant in some areas of the US Corn Belt. “In some of the states where they have a two-year rotation of corn and soybean, rootworm beetles will lay their eggs in soybean, resulting in problems in first-year corn,” explains Smith. “Dr. Art Schaafsma (from the University of g uelph) and I have been monitoring for that variant in Ontario for quite a few years. We think it may be here, but it is not yet at levels that would create an economic problem in Ontario.”

One of the main advantages for rootworm control in Ontario and many Corn Belt states is that corn-on-corn cropping is not as common as it is in Iowa. Smith emphasizes, “Crop rotation is still our best method to control corn rootworm in Ontario.”

Another key practice to slow development of resistance is to follow the Bt refuge requirements. Krupke says, “The Iowa situation underscores how important the refuge is. Something is going on in Iowa and we have anecdotal reports from other areas in the Midwest. There’s no reason why Bt resistance could not happen in other areas. Iowa is not so different in terms of growing practices and pest pressure, that the rest of the Corn Belt can just say, ‘It could only happen there.’”

Monsanto’s Lawton describes some recent developments that are making it easier for growers to comply with refuge requirements.

“For the first-generation Bt technologies that have been available for a number of years, farmers are required to plant a 20 percent structured refuge - where the refuge is planted separately from the traited product. We now have next-generation Bt proteins for both above-ground insects and below-ground insects. When you combine the two in the same product, you have dual modes of action: two different proteins that work on the same bug in two different ways. That reduces the probability of resistance developing, allowing farmers to reduce their refuge from 20 percent to just five percent of their planted acres.”

Both the genuity SmartStax and genuity VT Double prO products have dual modes of action for rootworm control. The company also hopes to have approval for genuity VT Double prO rIB Complete in time for the 2012 planting season.

growers can also slow the development of resistance by varying their control methods. “That could include alternating the different Bt traits for rootworm, using stacked traits, or soil insecticides, and seed treatments may be effective when you have smaller populations of rootworm,” says Smith.

For Krupke, another other key message from the Iowa study for growers is “vigilance.” He explains, “The only reason we are even discussing the situation in Iowa is because corn growers were alert

“I think the Iowa State study should be an important wake-up call for Ontario,” says Jocelyn Smith.

and they contacted members of industry and extension educators and eventually the word made its way to a scientist at Iowa State. With all the corn fields out there, we need producers to be watching their own fields. And when something is going on, they should not be afraid to follow up and ask questions and see if in fact they do have an issue.”

If Ontario corn growers see severe insect damage when scouting in a Bt field, Smith suggests they contact their seed company representative to confirm that the plants are expressing the desired trait, and let extension personnel from the Ontario Ministry of Agriculture, Food and rural Affairs (OMAF rA) and the Canadian Corn pest Coalition (www.cornpest.ca) know about the situation.

by Treena Hein

More soybean farmers are using no-till, and this practice, added to the stronger, denser corn stalks that are the standard now, means growers are facing excessive residue issues. Leaving some corn residue on the fields provides important soil conservation benefits, but heavy amounts can bring disease risk and other stresses down on newly planted soybeans. Using no-till in more than one crop in the rotation can also stress seedlings through the creation of “tight” soil.

Luckily, there is a way to help protect soybean yields. “Using minimum-till provides the benefits of tillage but avoids the negative aspects of no-till,” says Horst Bohner, soybean specialist with the Ontario Ministry of Agriculture, Food and rural Affairs (OMAFrA).

no-till is believed to add organic matter to the soil and build soil structure, whereas plowing reduces it over time. On the other hand, a small amount of tillage can lower slug populations and warm the soil for planting, leading to higher yields.

Within the last decade, new “vertical tillage” and minimum tillage implements have been introduced to help manage heavy corn residue. Among the many options available in the Canadian marketplace are the Salford rTS, Landoll VT plus, the Amazone Catros, International Turbo 330, gregoire Besson Disc 0 Mix and the Case IH 330. Sunflower released its 6630 VT in fall 2010 and has sold 30 units in Ontario so far. “We can’t get them in fast enough,” says product specialist Steve Hosking. “Our niche is the saber blade and an aggressive configuration, which allows us to perform better at slower speeds equalling less maintenance, horsepower and fuel consumption.”

In 2003, Salford Farm Machinery in Salford, Ontario, released its rTS vertical tillage unit, with individual, spring-loaded shanks that carry coulters. “The standard rTS is equipped with fluted coulters, which enter the ground 1.5 to 3 inches deep at 90 degrees,” says Salford’s national sales manager Jim Boak. “This prevents the creation of ‘secondary density layers’ that using a cultivator can cause, and also avoids ‘side-wall smear’ like the angled blades of a disc.”

The rTS operates most effectively at high speeds (8 to 12 mph). Salford also offers more aggressive vertical tillage models such as the rTS extreme, which features two rows of shallow concave blades mounted at the front of the unit.

Since 2005, Bohner has studied whether minimal tillage can

help to increase yields for no-till soybeans, or whether more aggressive tillage is necessary to maximize yields. The studies were supported by the Agricultural Adaptation Council (AAC), the g rain Farmers of Ontario and the Ontario Soil and Crop Improvement Association. The first part of the study from 2005 to 2008 used an rTS unit followed by seeding with a John Deere no-till drill. “The average yield gain over the three years of the study was only 1.8 bu/ac,” notes Bohner. “This is not enough of an increase to warrant the use of minimum tillage in every case when the costs of time, diesel and equipment maintenance are factored in. But in cases where the yield response was higher (heavy soil types, poor crop rotation, and extremely heavy residue), it starts to make sense.”

In 2010, Bohner ran tillage trials near Lucan and Bornholm that showed minimum tillage does impact yield positively in heavy corn residues, but says the results have to be examined in light of conditions seen during the 2010 growing season. “It was not a particularly good year to show the advantages of using some tillage versus none,” he says. “The spring was not overly wet or cold so the soybeans got off to a good start. Overall, the growing season was exceptional, with great weather, no significant insect or disease pressure and very high yields.”

He adds, “One of the reasons that tillage proved to have a positive impact on soybean yields at these locations may be that these trials were planted relatively early.”

Bohner found the rTS e xtreme prototype to have a greater impact than the rTS. He says these results show that there is promise for using minimal tillage units to increase yields, but that “it may take more tillage than one-pass vertical tillage to significantly change yields.”

At the Lucan location, Bohner also ran a treatment in which corn stalks were removed with a hay rake before no-till soybean planting. “The results were very significant – a yield gain of over 7 bu/ac,” he notes.

This huge response to residue removal led to Bohner setting up more trials in 2011. They involved testing 10 different tillage types and three rates of corn stalk removal for a total of 30 different treatments. These trials also focus on the timing of the tillage (fall, spring, and a combination of both) on varying soil types. “Although no definitive conclusions can be made at this point from these trials, it seems that some sort of corn residue management in a heavy residue situation is a wise move to protect soybean yields,” Bohner says.

BioStacked® means greater plant vigour, root biomass and more nitrogen-fixing nodules on every plant. Only HiStick® N/T and HiCoat® N/T S225 are BioStacked® –which in turn means increased performance, superior Return-on-Investment and most importantly, added yield potential.

In the planter or in the bag – ask your retailer about BioStacked® HiStick® N/T inoculant and HiCoat® N/T S225 pre-inoculant system – Canada’s #1 soybean inoculants.

Some fields may have small deficiencies, but not most across southwestern regions.

by Treena Hein

Interested in starting a debate within agricultural circles? Just mention sulphur. “There are lots of opinions on whether it needs to be added to soil now or in the future, where, how much and in what form,” says Keith reid, soil fertility specialist with Agriculture and Agri-Food Canada (AAFC).

One thing, however, is for certain: plants need significant amounts of the nutrient to grow properly and fend off disease. Canola is the most responsive crop to sulphur, notes reid, followed by corn, hard winter wheats and alfalfa, with soybeans unlikely to respond to added sulphur in most Ontario soils.

ever since heavy industry started to boom in southern Ontario and the neighbouring US states, sulphur has been deposited on soils through acid rain. In fact, the practice of adding supplemental sulphur to fields was stopped during the 1850s. Farms in northwestern Ontario which are upwind of the province’s main industrial regions, have never seen as much sulphur from acid rain as their southern counterparts.

However, reid says that due to manufacturers using new air quality technologies, the passage of legislation restricting how much sulphur can be emitted into the atmosphere from factories, and the recent slowdown in industrial output due to the recession in 2008-2009, the amount of sulphur coming down from the skies has declined considerably. “I would argue that the recession had more impact than anything,” observes reid.

Adding to lower sulphur soil levels is the fact that fertilizers, insecticides and fungicides are “cleaner” nowadays, and contain less

incidental sulphur. There have also been some long-term decreases in cattle, sheep and pig livestock farming in Ontario, which means fewer fields are receiving sulphur through manure applications. Lastly, ever-increasing crop yields mean more sulphur is being removed from the soil than in previous decades.

Whether sulphur needs to be added to soils is dependent on a few factors. Farmers should first be reminded that soil tests, critical for other major nutrients like n, p and K, are not terribly helpful when it comes to sulphur. “Soil testing for sulphur can result in more confusion than enlightenment,” says reid. “Sulphur is difficult to get a handle on because it becomes ‘tied up.’ It cycles from soil organic matter into the soil solution and back again.”

In soils with a lot of calcium, it combines with the calcium atoms, goes back into solution and back to binding with calcium again, depending on how much calcium is present, the type of soil, and whether the sulphur is exposed to open air. However, Steve redmond, a certified crop advisor and new environmental specialist with the Ontario Ministry of Agriculture, Food and rural Affairs (OMAFrA), sees value for cash crop farmers who do not have

continued on page 22

ABOVE: Canola is one crop that reflects the benefit of sulphur applications, as will corn and hard winter wheats, but soybeans show little response.

The latest research points to slow but positive progress.

by Carolyn King

Rhizoctonia is a serious disease issue for many different crops across Canada and around the world. In Ontario soybean fields, it is an increasing problem, with yield impacts ranging from less than five percent to 50 percent. A recently completed survey of Rhizoctonia in crop fields across Canada is providing up-to-date information needed for improving control of this major disease.

The disease is caused by Rhizoctonia solani , a fungus that lives in the soil and on decaying plant matter. “Although there have been some studies of Rhizoctonia solani in Canada in the past, most of them were regional or looked at a single crop, and there wasn’t a lot of current information. So we wanted to get the current picture of the prevalence and distribution of Rhizoctonia solani in field crops in Canada,” says Melody Melzer of the University of g uelph, who led the survey.

“We’ve know for a long time that Rhizoctonia is a very important disease in Canada in many crops, but there has never

been a survey such as this that actually documents the incidence of Rhizoctonia across the country in various crops,” adds Harold Wright, biological assessment manager for Syngenta in e astern Canada. “The information from the survey is really important in helping us better understand the potential impact of the disease and in developing a full management plan for Rhizoctonia across the crops that may be grown in a region.”

The University of g uelph and Syngenta worked together to carry out the three-year survey, and Syngenta helped to fund it. The Ontario Ministry of Agriculture, Food and rural Affairs (OMAF rA) provided some funding for surveying Ontario fields.

The survey focused on Rhizoctonia in seedlings, which is usually when the disease is most damaging. “ Rhizoctonia impact on a plant depends on when the disease strikes. It can

ABOVE: Symptoms of the fungal disease Rhizoctonia on soybean INSET: Damping-off and crown rot in soybean seedlings.

cause seed rot, so the seed doesn’t even germinate. It can cause pre-emergence damping-off, when the seed germinates but the shoot is killed before it emerges out of the soil, and postemergence damping-off, when the shoot dies quickly after it emerges. These impacts are very serious because you’re completely losing the plant,” explains Melzer.

“In older plants, Rhizoctonia can cause crown rot and root rot. I heard one pathologist say that Rhizoctonia solani can be a bit of a nibbler – it nibbles away at the roots, causing a general stunting or decline of the plants that you may not notice in the field,” she says.

For the survey, Syngenta collected seedlings from more than 150 fields in Alberta, Saskatchewan, Manitoba, Ontario and Quebec. Most of the samples were from canola, soybean and wheat, although some were from other crops. In Ontario, they sampled more than 80 fields and most of those were soybeans.

The sample analysis was done in Dr. g reg Boland’s lab in the School of e nvironmental Sciences at the University of g uelph. Melzer says, “We isolated Rhizoctonia from the seedlings and then characterized the isolates that we recovered. For each isolate, we determined the anastomosis group (Ag ) and tested its virulence (its ability to infect a plant) and its host range in the growth room.”

In a fungus, “anastomosis” is the term used to describe the fusion of fungal filaments, called hyphae. If the hyphae from two different isolates are able to fuse together, then those two isolates are considered to be in the same “anastomosis group” (Ag ). Rhizoctonia solani has at least 13 Ag s. r esearchers use Ag s as a way to subdivide Rhizoctonia solani because it is quite a broad species. In a sense, Ag s are sort of like strains or races of this pathogen. “For any disease organism, we need an understanding of the distribution of the different subsets of that pathogen,” explains Albert Tenuta, field crop pathologist with OMAF r A. “For instance, when we’re doing our testing of seed treatments or other control methods, we

need to be testing with the disease strain or race or anastomosis group that is actually out there. And in crop variety development, you want to challenge the new upcoming varieties with that particular strain or race or anastomosis group, so you can get a true indication of how well the varieties could perform in the field. And it’s helpful to know which strains or races or anastomosis groups are in other areas too, because then we can learn from those other areas as well. More information provides us with the best ability to manage or lower grower risks.”

Identifying an isolate’s Ag can give an indication of its host range. Melzer says, “For example, Ag 2-1 is known to be a problem on canola seedlings, but it will often cause little or no disease on other crops. Ag 3 is a problem in potato. Ag 2-2 and Ag 4 are a problem with sugar beets but can cause significant disease in other crops, too. Often there is some level of host specificity.”

The researchers hope to publish the survey’s detailed scientific results soon. One of the major results is identification of the very broad distribution of this pathogen in major crops across Canada. Melzer says, “In the overall survey of over 150 fields across Canada, we recovered Rhizoctonia solani in about 30 percent of the fields.”

In the Ontario portion of the survey, a key finding relates to host range. The researchers tested the Ontario isolates on five crops: canola, corn, wheat, soybean and pea. “We found that many of the Ontario isolates had a wide host range, and some of the isolates were highly virulent on all the hosts we tested,” says Melzer.

Having corn and small grains in a rotation with soybeans is considered to be a way to help manage Rhizoctonia in soybean, so the finding that some isolates were very virulent on all five crops is valuable information.

Wright notes, “Although crop rotation is very important for good crop management, this survey result reinforces the need for other practices when managing Rhizoctonia .”

He adds, “I’m positive the survey results will be very important in the development of complete management programs for Rhizoctonia . I think it shows the need to look at crop production and disease management at the whole farm level and look at the cropping systems approach as we develop new tools for the farmer.”

“In soybean production, Rhizoctonia is an ongoing challenge. It’s an issue across the whole province, not just in southern Ontario, and it’s a problem in the northern US soybean production area as well,” says Tenuta.

“ e very year in basically every soybean field, we can find some degree of Rhizoctonia , but in some fields the disease becomes more problematic than in others. Factors that contribute to Rhizoctonia are more soybeans in the rotation; the pathogen’s ability to survive for years in the soil (rotation on its own has minimal impact on decreasing Rhizoctonia populations); early planting; and more crop residue and more notilling. These factors can all influence why we’re seeing more Rhizoctonia .”

Rhizoctonia has distinctive symptoms that help identify it. He explains, “You’ll see a sunken, brick red canker right on the stem at the soil line; the canker might go an inch or so above

the soil line but rarely much higher than that. However, it can work its way down and prune off a lot of the roots.

“It will be a much darker red colour than Fusarium root rot. With Fusarium , you’ll often see more of browning discoloration of the roots. If you cut into the roots you’ll often see more discoloration inside with Fusarium than with Rhizoctonia . Both diseases cause a leathery texture to the roots. In comparison, Phytophthora or Pythium causes the roots to become more

“For any disease organism, we need an understanding of the distribution of the different subsets of that pathogen.”

water-soaked or softer and they’ll disintegrate. So if the roots are leathery, then it’s Rhizoctonia or Fusarium , and if the stem has that brick red canker at the soil line, it’s more than likely Rhizoctonia .”

Tenuta notes, “There’s some promise for developing soybean varieties with tolerance to Rhizoctonia , but we’re not there yet. So seed treatment is the main method for managing Rhizoctonia in soybeans.”

He adds, “One of the more promising aspects of some of our work is we’re starting to see more newer active ingredients that are targeting specific disease problems, such as Rhizoctonia and Fusarium . Over the next few years, growers will be seeing additional seed treatment active ingredients targeting some of

continued from page 18

these increasingly problematic diseases. These new options can be added to our traditional seed treatments and achieve broader spectrum control and also targeted pathogen control.”

One of those new active ingredients is sedaxane, a fungicide being developed by Syngenta for seed treatment only. Syngenta’s research shows sedaxane has strong activity against all the anastomosis groups of Rhizoctonia . Wright says, “Sedaxane belongs to a class of chemistry called SDHI (succinate dehydrogenase inhibitors) fungicides; it’s not an entirely new family, but sedaxane is the newest in this family, and it is the only seed treatment fungicide in that family. Sedaxane offers incredible Rhizoctonia protection in a wide range of crops, as well as control of other smut and bunt diseases in cereal crops. Sedaxane is under regulatory review at the moment and we hope to have it available for Canadian growers in the near future.”

Other Rhizoctonia management measures include practices that reduce stress on the plants – such as good drainage, good fertility and seeding into good growing conditions – because stressful conditions tend to make Rhizoctonia worse.

Tenuta notes, “growers are planting earlier in the season to maximize yields, and in some cases they are not planting into the best conditions or the weather after planting turns cool and wet. Those conditions can slow germination and early growth, allowing these early-season disease organisms to get a foothold. It is best to plant into good, warm soil and good growing conditions so the beans get a good start. In many cases good, rapid growth can minimize the amount of disease development. The plants can still be infected but they may not be injured as much.”

livestock, and thus have not been applying manure, in testing the soil for sulphur at the same time every year to get a sense of any long-term trend.

Soil pH is not a factor that affects sulphur availability to crops, but soil type can seem to matter in many instances. In trials carried out while reid was still with OMAF rA, he observed that adding sulphate resulted in a crop response in the “occasional” field, generally those with sandy soils and low organic matter content, but not always. “The results have been inconsistent,” reid concludes. “We use sulphate because that’s the form which plants can absorb. e lemental sulphur is not available until bacteria in the soil convert it to sulphate, which can take a year or more.”

redmond, who has worked extensively in the area north of London as a certified crop advisor, has seen cash crop clients get improved yield from using sulphur in corn starter mix on a regular basis. “g enerally, this is not the case south of palmerston, but north of that, especially the canola and corn growers, are using a lot of sulphur and it’s making a difference.”

r edmond took soil samples in the fall of 2010 from five fields in the Lucan area, with four of the five having a history of manure application and all five containing a similar average organic matter level. “Soil test results showed that these four contained 18 pounds of sulphur per acre (with somewhat less available in the spring due to some loss over the winter), but

the one that hadn’t had manure in the top six inches had half that,” says r edmond.

Dr. Hugh e arl, an associate professor of oilseeds physiology in the department of plant agriculture at the University of g uelph, recently analyzed data from a fertility trial at e lora. “Of course, we already know that n and S interact in canola, but these data show that with no added sulphur, our nitrogen additions actually reduced yields, while we got a nice positive response to n fertilizer when we added enough ammonium sulphate to provide 20 kg of S per hectare (about 18 lbs per acre),” he says. “At the highest n rate, the S almost doubled the yield.

e arl says that like many growers, he is in the habit of applying ammonium sulphate to canola just as cheap insurance. “We won’t be changing that practice any time soon,” he concludes. reid says that overall, with all the sulphur that has been added to soil through acid rain, “the excess isn’t what it was, but we still have adequate sulphur. From everything I’ve learned, we still have more than enough at this point in time, with some occasional fields being the exception.”

He advises those farmers who are concerned to look into it. “especially if you have low organic matter, sandy soils, or you’re in northwestern Ontario,” reid says. “Switching from urea to ammonium sulphate, if the nitrogen price stays the same, won’t cost you anything. If you want to know for sure, alternate strips of urea and ammonium sulphate in the field to see if there is any yield difference.”

Sooner or later you’ll run into resistance.

Overuse of glyphosate is becoming a serious concern in Ontario, and it won’t just put a dent in your wallet this year.

But now there is an alternative. Rotate to the LibertyLink® Soybean system and get the complete package. Powerful non-selective weed control with no trait associated yield drag. And with Liberty®, the only group 10 in the marketplace, you also get effective resistance management. For more information visit: www.BayerCropScience.ca/LibertyLinkSoybeans

by Treena Hein

Argentina is currently the world’s third largest producer of soybeans, and much of this rise in position came as a result of the advent of roundup ready technology. However, governments at several levels in that country have taken steps to restrict the use of glyphosate. This is a development the global scientific community, political bodies such as the european Union and major agricultural companies are keeping an eye on. The farming community in Argentina is also concerned; however farmers around the globe, including those in Canada, should take notice, too.

In March 2010, one province in Argentina banned the use of glyphosate within 875 yards of homes. In 2011, a federal bill was introduced to ban the use of glyphosate herbicides within 109 yards of urban areas. This bill is still in play, and some politicians are pushing for a 10-year phase-out of all glyphosate-containing products.

These actions all stem directly from research done by Argentine government scientists, which found that glyphosate causes abnormalities in frog and chicken embryos. In 2009, the researchers had their findings published in newspapers – an unusual move that is always met with suspicion by the scientific community. In mid-2010, they managed to have it published in the Journal of Chemical research and Toxicology. However, their conclusions, and their methods used to reach them, have been highly criticized.

Before establishing why the research has been criticized, it is prudent to note the latest information on glyphosate research. “glyphosate and its potential effects have been reviewed and rereviewed for about 30 years, and it’s been found over and over again to be environmentally benign,” says Dr. Keith Solomon, professor emeritus in the School of environmental Sciences at the University of guelph. “There are very few pesticides that are safe, yet it’s the most widely used herbicide in the world.” glyphosate breaks down relatively quickly in soil after application (known as low “persistence”). Solomon notes that the only safety issue a person could have with the substance would be if he or she got the concentrated form in the eye. “But what’s coming out of a sprayer is of a low concentration,” he says, “and those mixing and loading a sprayer should be trained, as they are in Ontario, and using eye protection.”

Active ingredients such as glyphosate are put through extensive and ongoing tests, to ensure maximum safety for users.

The global scientific community has taken issue with many aspects of the Argentina experiments, but two stand out, in particular. “The concentration of glyphosate used was grossly excessive,” Solomon notes. “It is nine times higher than would be lethal to tadpoles and is about 3000 times greater than the highest value measured in frog habitats in agricultural areas of Ontario.”

Much of the disconnect regarding the use of pesticides on farms is related to the average person’s lack of familiarity with scientific principles and methodologies.

Secondly, the “mechanism of exposure” was completely unrealistic. That is, glyphosate was injected into the eggs with a syringe, rather than topically applied, and this does not in any way reflect what could happen in the real world. Furthermore, injecting any number of benign substances (such as caffeine) into eggs will result in embryonic abnormalities. Solomon also points out that for risk assessments the World Health Organization does not recognize toxicity studies on pesticides or herbicides where injection is used to treat the animal.

In late 2010, the european Union’s Standing Committee On The Food Chain And Animal Health reviewed the experiments and concluded that they “had been performed under highly artificial conditions, extremely different from what can be expected in agricultural circumstances, and that it is hardly possible to predict adverse effect on mammals on this basis. . . There is a comprehensive and reliable toxicological database for glyphosate and the effects observed have not been revealed in mammalian studies, nor evidenced epidemiologically in humans.”

After the study was published, the journal in question received and published a number of letters criticizing the research. In addition to the above points, the letter writers lambasted overall experimental design, description of the method and poor statistical analysis.

The question that remains is an important one: Why is this one study, containing research that was severely criticized by the global scientific community, still forming the basis for proposed federal legislation in Argentina? The answer is complex. It is partly because how science is properly conducted is not easily understood by those without a scientific background. It could also be that the

media in Argentina have downplayed or misreported the criticism of this study, or not reported on it at all, leaving politicians and the general public in the dark. There is also conjecture that the proposed legislation is a result of animosity between the president of Argentina (who is politically left-leaning) and the farmers in that country (who are mostly right-leaning).

However, what is happening in Argentina is not unique. In Ontario, cosmetic use of any synthetic pesticide was banned in April 2009. “This was very clearly driven by a coalition of non-profit organizations, some with a focus on the environment and others with a focus on health,” says pierre petelle, executive director of regulatory affairs at CropLife Canada, the trade association representing the manufacturers, developers and distributors of pest control products and plant biotechnology. “none of these groups is a credible scientific organization and none provided credible scientific references to back the concerns.”

petelle says more evidence that science was ignored is found in the singling out of synthetic pesticides. “The safety of a product has nothing to do with whether it was derived synthetically or naturally, which is further evidence of the political nature of the decision,” he says. “The fact that the Ontario government disregarded the thorough scientific assessments of Health Canada not only deprives Ontarians of access to safe and effective tools for protecting their valuable landscapes, it also jeopardizes the potential for Ontario farmers and other commercial users to keep pace with the tools their counterparts in other areas of the world will have access to because Ontario is now seen as a risky place to invest in registration.”

Bans on cosmetic use of pesticides have also been enacted in nova Scotia and on prince edward Island.

In May 2011, a nAFTA tribunal announced that Quebec had lost a challenge brought forth by Dow AgroSciences in 2008 over that province’s complete ban of 2,4-D. Dow’s legal team had referred to Health Canada’s findings that 2,4-D can be used safely when label directions are followed, and in the settlement, the Quebec government states that it agrees with these findings. Of the win, CBC reported on its website that Brenda Harris, Dow’s regulatory and government affairs manager, said, “We always believed that there was no basis for their decision: their decision had nothing to do with science.”

It is still illegal to employ 2,4-D for cosmetic use.

These are signs that the global agricultural community must pay attention to. All farmers must consider it important to seek opportunities to speak to friends, neighbours and strangers about modern agriculture. “The level of science literacy and awareness of modern-day agricultural practices is very low in the general population,” says Trish Jordan, public and industry affairs director with Monsanto Canada. “As a science and technology company, we stand behind our products and their safety and we are always available to share information. But it is even more important that farmers defend their access to these important tools.” Jordan adds that farmers have a high level of credibility with consumers, plus they have firsthand experience using these products and can help consumers understand why they are critical to producing a healthy, abundant and safe crop. “Farmers have a great story to share about environmental stewardship and sustainability,” she says. “When they share their stories, they help build understanding. With understanding comes acceptance.”

The Trimble® EZ-Pilot™ steering system features a sleek design integrated into the steering column, providing clear access to instrument panels and controls. It turns the steering wheel—your vehicle’s original wheel or an optional wheel—using GNSS guidance from the CFX-750™ or the FmX® display.

Vehicle steering is immediately adjusted to compensate for rough terrain or slopes and hillsides with the new Trimble T3 ™ Enhanced Terrain Compensation Technology. And higher torque delivers better steering of vehicles with more rigid steering systems, such as floaters. Let the EZ-Pilot system keep you on line so you can focus on other important tasks. For more information, visit www.trimble.com/agriculture, or see your dealer.

Younger generation’s input vital.

by Melanie epp

Tail-end boomers across the country are watching as veteran agronomists begin to retire and they are wondering where new agronomists will come from. Certainly they will get their basic education through the University of guelph (or its ridgetown Campus), but where will they get their hands-on training?

Anne Verhallen, soil management specialist with the Ontario Ministry of Agriculture and rural Affairs (OMAFrA), is one of those tail-end boomers. “I’m watching as the retirement starts across the industry, not just within the government, but the consultants and the guys in the industry that I’ve known for years,” she says. “As you see that they’re getting closer and closer to retirement, or retiring, it’s nice to see that there are young people out there who are interested, engaged and getting the hands-on experience.”

Verhallen says students can get hands-on training through summer jobs or internships. There are two types of summer jobs that an agricultural student can seek: the more hands-on jobs, and the jobs that Verhallen calls the “pair-of-hands” jobs. While the pairof-hands jobs are mostly labour-intensive work, the hands-on jobs train students to do more practical work, which allows them to

apply some of what they have learned in the classroom. “The more the job offers them the opportunity to apply what they’ve been learning, to pursue a project, the better,” she says. “And have faceto-face dealings with growers; I think that’s really critical.”

The Undergraduate Student experiential Learning (USeL) project, a partnership project of OMAFrA and the University of guelph, provides five third-year students with the opportunity “to engage in work related to knowledge transfer and translation.” The project, which lasts for 16 weeks, allows students to work with a specialist, whether it is in livestock or crops. “I was kind of excited after seeing someone do this USeL program,” explains Verhallen. “I saw a young lady who had taken all of the courses, who had all the formal knowledge and got to watch her develop.”

Dr. Clarence Swanton, who teaches in the Department of plant Agriculture at the University of guelph, says OAC students have huge advantages when it comes to employment opportunities.

ABOVE: Summer students can expect to learn more about scouting weeds and identifying diseases.

“There is a large demand for students who are willing to work in the area of agronomy – in the area of crop protection – by a range of companies. They get good-paying jobs through the summer, and they get a lot of experience in working in the real world. And so they get jobs with consulting companies, scouting for insects and diseases, weed identification, nutrient recommendation, and they do so with the guidance of an experienced CCA.”

Swanton points to “a tremendous synergy” between studies within OAC and summer opportunities working within the industry.

Swanton is also the coach of the OAC Weeds Team, a group of students that volunteers to go to the United States for a weed science competition. In 2011, it was held at the University of Tennessee and one of the undergraduate teams won the entire competition. “They beat out 17 other US schools,” says Swanton. “And that’s the type of training opportunities, educational opportunities, and collaborative student employment opportunities that result from our training here at OAC.”

With only five positions available through the USeL program and one opportunity to join the OAC Weeds Team, the public sector’s jobs and volunteer experiences can be somewhat limited.

According to Mervyn erb, an independent certified crop advisor, many pursue summer jobs in the private sector. “Most of them got summer jobs with herbicide companies doing summer research work for the company, and there are some who got a summer job with the local fertilizer plant, doing fertilizer work,” he says, adding that equipment dealers also look for students with agronomy skills. “equipment companies, especially people who are selling tillage equipment; they really need people who are agronomy skilled, who know about soil, agronomy, plant growth and plants.”

While these companies offer more retail-oriented work, some companies offer fieldwork as well.

Craig Chapple manages Laresco, a division of Thompsons Limited, based in Blenheim, Ontario. Laresco hires summer students and interns to facilitate their summer work, including crop scouting, report writing, soil sampling and some larger projects involving mapping or scouting. Thompsons’ new hires receive hands-on training through special programs. “We spend a lot of time training them,” he says. “Obviously, they don’t come to us ready to go to the field.”

The modules of their training program run concurrently with the business cycle. “Basic fertility is something we’ll run in January-February because that’s when growers start coming in and asking questions,” says Chapple. “The students who come have a very strong background – we try to turn it into something more practical,” says Chapple. “You know, farmers don’t respond to Latin names for weeds, so we make sure they know all the common names.”

Asked about the difference between private- and public-sector job offerings, Chapple speaks positively about the latter. “At the OMAFrA level, it’s a different plane of work,” says Chapple. “It’s a different mindset. It’s very research oriented, and that isn’t a bad thing, especially if they go from there and come into the private sector. It often works really well. It’s good background to have.”

Chapple says that when students train with Laresco, they gain valuable experience that will help them become an agronomist, mostly from the crop-scouting side. He believes that a stint with Laresco makes students more hirable and desirable.

Chapple also hopes that students will consider staying with them. “We look at Laresco as being kind of their first taste of the private

sector and hope that they would consider us for future positions, and not necessarily just at Laresco, but at our parent company.”

But students are not always eager to stay with one company. Many times, private-sector companies act as stepping-stones to other positions, providing students with a variety of experiences. paul Sullivan of Sullivan Agro, for example, has seen four of his summer students go on to become certified crop advisors. As summer students, they scout fields as agronomy assistants, working hand in hand with the full-time crew, and learning about crops and the different aspects of production. “They get a chance to ask questions and get feedback on things that they see,” says Sullivan. “So it becomes a summer job, but also a learning experience for them.”

“There are certain aspects that you can learn at college and university,” says Sullivan. “probably the basic thing is just how to learn: have an open mind about things and interacting with people. Once you’re finished that, you get a chance to get out and work on those other aspects.”

To get varied experience, Sullivan encourages students to look to other positions, whether they are in sales or research, during the course of their three or four years at college or university. In the past four or five years, he has noticed a change in the industry. “The interest in agriculture is growing with younger people,” says Sullivan. “And there’s probably more opportunity with various companies, certainly from an experience standpoint.”

Verhallen agrees. She believes there are more developmental jobs out there, more so than is generally appreciated.

Monsanto Company is a member of Excellence Through StewardshipSM (ETS). Monsanto products are commercialized in accordance with ETS Product Launch Stewardship Guidance, and in compliance with Monsanto’s Policy for Commercialization of Biotechnology-Derived Plant Products in Commodity Crops. This product has been approved for import into key export markets with functioning regulatory systems. Any crop or material produced from this product can only be exported to, or used, processed or sold in countries where all necessary regulatory approvals have been granted. It is a violation of national and international law to move material containing biotech traits across boundaries into nations where import is not permitted. Growers should talk to their grain handler or product purchaser to confirm their buying position for this product. Excellence Through StewardshipSM is a service mark of Excellence Through Stewardship. ALWAYS READ AND FOLLOW PESTICIDE LABEL DIRECTIONS. Roundup Ready® crops contain genes that confer tolerance to glyphosate, the active ingredient in Roundup® agricultural herbicides. Roundup® agricultural herbicides will kill crops that are not tolerant to glyphosate. Acceleron™ seed treatment technology for corn is a combination of four separate individually-registered products, which together contain the active ingredients metalaxyl, trifloxystrobin, ipconazole, and clothianidin. Acceleron™, Acceleron and Design™, DEKALB®, DEKALB and Design®, Genuity®, Genuity and Design®, Genuity Icons, Roundup®, Roundup Ready®, Roundup Ready 2 Technology and Design®, Roundup Ready 2 Yield®, RIB Complete and Design™, RIB Complete™, SmartStax®, SmartStax and Design®, VT Double PRO™, VT Triple PRO™ and YieldGard VT Triple® are trademarks of Monsanto Technology LLC, Monsanto Canada, Inc. licensee. LibertyLink® and the Water Droplet Design are trademarks of Bayer. Used under license. Herculex® is a registered trademark of Dow AgroSciences LLC. Used under license. Respect the Refuge and Design is a trademark of the Canadian Seed Trade Association. Used under license. (TR2054-E-06/11)

3 3/8 x 4 7/8

Using integrated management of weeds is critically important.

by Treena Hein

Every year, the number of glyphosate-resistant weeds in Ontario gets larger, a lot larger. Dr. peter Sikkema, a professor of field crop weed management at the University of g uelph’s ridgetown Campus, is mapping these hot spots. “In 2008, we found one site in e ssex County confirmed to have glyphosate-resistant giant ragweed,” he says. “In 2009, we found an additional 18 sites (12 in e ssex County and six on pelee Island).”

In 2010, the numbers jumped again; 29 additional sites were confirmed, with the majority in e ssex, but for the first time one site was confirmed in both Kent and Lambton counties, giving a total of almost 48 sites for Ontario. That year, Sikkema also found eight sites with glyphosate-resistant Canada fleabane, all located in the southern half of e ssex.

g lyphosate resistance in the US is nothing new. In Indiana and Ohio, they have been battling glyphosate-resistant Canada fleabane for the past 10 years. The latest disturbing findings are of waterhemp. University of Illinois extension weed specialist Dr. Aaron Hager says that in Illinois waterhemp is showing resistance to five herbicide groups. “ resistance in a single plant to two groups is common and resistance to three will become more common,” he says. “We’ve come across one population of plants resistant to four of the groups.”

Based on recent surveys, 87 percent of plants were resistant to at least one herbicide; 66 percent of the samples were resistant to glyphosate, about 33 percent to pp O (protoporphyrinogen oxidase) inhibitors, and almost all waterhemp to ALS (acetolactate synthase) inhibitors. “There is the potential for waterhemp to become an unmanageable problem with currently available post-emergence herbicides in conventional or roundup ready soybeans,” Hager says. “With weeds like waterhemp, the male plants create pollen and female plants make seed and both seeds and pollen that contain resistant genes can move from field to field.”

Multi-pronged approach

experts such as Sikkema and Hager advise the use of an integrated approach in both managing resistance that may exist already, and preventing further resistance. These include:

1. Crop rotation – John Urquart, a cash crop farmer in the Kirkton, Ontario area, uses a three-year rotation of corn, roundup ready soybeans and wheat, and believes it is an important strategy in keeping herbicide resistance at bay.

Hager agrees. “We don’t see a lot of farmers in Illinois growing soybean-after-soybean, but two-year corn, oneyear soybean is used by many,” he says. What is worse, a substantial majority of corn hybrids planted in the US are roundup ready, which means some farmers are using roundup ready corn and soybean cultivars and therefore the same mode of herbicide action every year.

Sikkema notes, however, that some of the sites he is found with glyphosate-resistant Canada fleabane are on farms that “have had great rotation and the use of different modes of action. So for these farmers, it’s been an unlucky matter of windblown seed.”

So, while rotation is important, other actions must also be taken.

2. Tillage – Urquart plants his soybeans using no-till, but occasionally uses minimum-till. “We mostly do it because it warms up the soil for planting, but you do also get a small amount of weed control,” he says. “Spring tillage is very effective for the control of glyphosateresistant Canada fleabane,” adds Sikkema, “and will dramatically reduce the stand of glyphosate-resistant giant ragweed.”

3. Effective use of herbicides – g ood pre-plant weed control is imperative. In the spring, one to three weeks before planting, to control giant ragweed, Sikkema recommends roundup plus one of the following four herbicides: 2,4-D ( g roup 4), e ragon (14), Lorox (7) or First r ate (2). For Canada fleabane, Sikkema says growers can achieve excellent pre-plant burndown control with roundup plus one of six options: e ragon, Integrity (14 & 15), Amitrol (11), Sencor (5), Broadstrike (2) or First r ate.

4. Choosing different modes of action over time –“g rowers are advised to use non- roundup ready hybrids or cultivars in their rotation periodically to reduce the selection intensity for glyphosate- resistant weeds,” says Sikkema.

For a grower using LibertyLink soybeans, Sikkema says, “It’s still very important to start clean, so for giant ragweed, use roundup plus 2,4-D pre-plant, then apply Liberty in-crop before weeds are four inches in height, and again when the next weed flush is three to four inches in height. Apply it during the warmest, sunlit hours of the day with 15 to 20 gallons of water per acre.”

For Canada fleabane, he recommends roundup plus eragon preplant, with Liberty applications in-crop as for giant ragweed above.

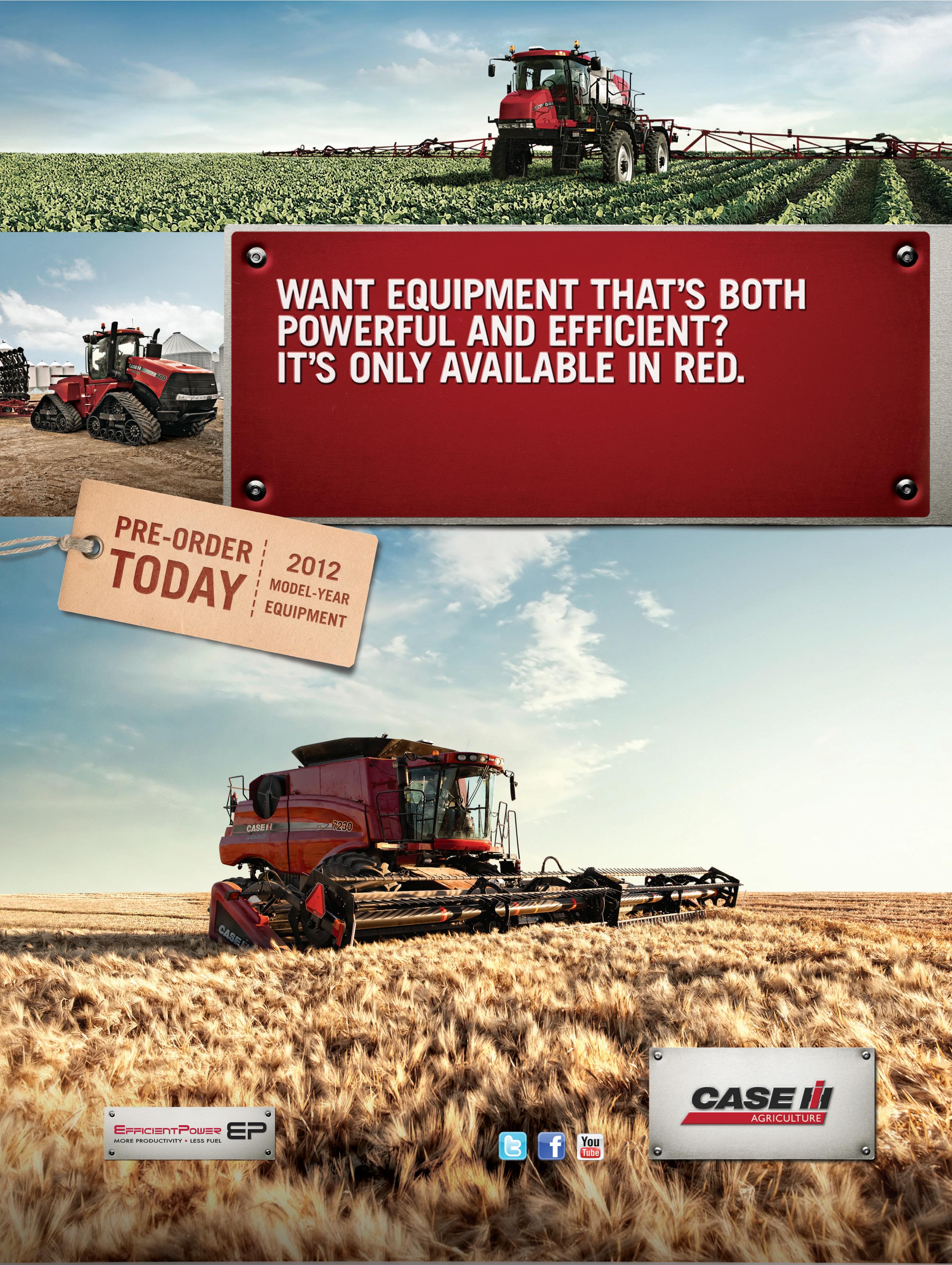

While other manufacturers scramble for long-term solutions, ours are already out there in the fields. And now, the same industry-leading Selective Catalytic Reduction (SCR) technology you’ll find in our high-horsepower tractors is available in our all new Axial-Flow ® combines and Patriot® sprayers. More power. More fuel efficiency. Lower emissions. Roll into your local Case IH dealer or visit caseih.com/efficientpower.

ready.