RANCONA

THE NEW CHAMP

LE NOUVEAU CHAMPION

Take out True Loose Smut.

Make seed and soil borne Fusarium bite the dust.

Fight for a better yield. Rancona is the seed treatment that will make it happen. New micro-dispersion formulation for better flowability and seed coverage with minimum dust-off. With outstanding performance in all cereal crops, Rancona is first in its class.

Éliminez le charbon nu véritable.

Vous verrez le Fusarium transmis par les semences et le sol mordre la poussière.

C’est le temps de combattre pour un meilleur rendement. Rancona est le traitement des semences qui vous permettra d’y arriver. Nouvelle formulation micro-dispersion pour une fluidité et une couverture améliorées avec émanation minimale de poussières.

Grâce à une performance exceptionnelle dans toutes les cultures céréalières, Rancona est le meilleur de sa catégorie.

Seed Focus

Changes in the seed trade have been the big news throughout most of 2009, yet some of the news, particularly relating to markets, carries a more serious tone.

Weed Management

Although most of the crop is harvested, weed control is a subject that needs to be reviewed even at this stage of the year.

Machinery Manager: Combines

For all the planting and production concerns, fall is the time for assessing on-farm performance, and that is where the Combine comes in.

www.topcropmanager.com

Reference information of this calibre is hard to find, so many growers choose to keep Top Crop Manager issues on file. If you have not kept issues for your library, you can find our stories, and more, on our interactive website. Cover:

One last look at the planting season, even this late in the year.

Photo by Ralph Pearce.

November 2009, vol. 35, No. 15

EDITOR

Ralph Pearce • 519.280.0086 rpearce@annexweb.com

FIELD EDITOR

Heather Hager • 888-599-2228 ext. 261 hhager@annexweb.com

CONTRIBUTORS

blair Andrews

bruce barker

Carolyn King

Treena Hein

EaSTERN SaLES MaNaGER

Steve McCabe • 519.400.0332 smccabe@annexweb.com

WESTERN SaLES MaNaGER

Kevin Yaworsky • 403.304.9822 kyaworsky@annexweb.com

SaLES aSSISTaNT

Mary Burnie • 519.429.5175 888-599-2228 ext. 234 mburnie@annexweb.com

PRODUCTION aRTIST

Gerry Wiebe

GROUP PUBLISHER

Diane Kleer dkleer@annexweb.com

PRESIDENT Michael Fredericks mfredericks@annexweb.com

PUbLICATION MAIL AGREEMENT #40065710

RETURN UNDELIvERAbLE CANADIAN ADDREssEs TO CIRCULATION DEPT.

P.O. bOx 530, sIMCOE, ON N3Y 4N5

e-mail: mweiler@annexweb.com

Printed in Canada

IssN 1717-452x

CIRCULaTION

e-mail: mweiler@annexweb.com

Tel.: 866.790.6070 ext. 211

Fax: 877.624.1940

Mail: P.O. box 530, simcoe, ON N3Y 4N5

SUBSCRIPTION RaTES

Top Crop Manager West - 8 issuesFebruary, March, Early-April, Mid-April, June, October, November and December1 Year - $50.00 Cdn.

Top Crop Manager East - 7 issues - January, February, March, April, August, October and November - 1 Year - $50.00 Cdn.

specialty Edition - Potatoes in CanadaFebruary - 1 Year - $9.00 Cdn.

All of the above - 15 issues - $80.00 Cdn.

From time to time, we at Top Crop Manager make our subscription list available to reputable companies and organizations whose products and services we believe may be of interest to you. If you do not want your name to be made available, contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2009 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication. www.topcropmanager.com

No time like November

November is a much maligned month in the calendar of the year. Typically it is viewed with dread as it provides a glimpse of the winter months to come. Or it represents 30 days wedged between the colour and splendour of October and the bright lights and festivities of December. Yet there are many positives that come with the month of November. There is the rugged, earthy beauty of the landscape. Sure, the leaves are gone from the trees and the sun sets earlier each day. But along the country roads, beside one field of discarded corn stalks and leaves or frostburnt alfalfa is a field of winter wheat, stretching like a carpet of green velour between fence lines. And whether you are out for a walk or heading home at the end of the day, there is the chance encounter with a ribbon of wood smoke or the tang of manure from a nearby field.

It provides assurance, familiarity and a unique sense of belonging.

As I come to the end of my 15th year involved in agriculture, I am thankful for these gifts, these moments that tell me there is something wonderful to be found, even in a month with a dark and dull reputation like November. There is always something beautiful to be seen or some intangible element to bring comfort.

We just need to be open to the opportunity, and that in and of itself, is

what I consider to be one of the key defining notions of agriculture today. There are opportunities coming, there are opportunities that are here already; we just need to be aware and willing to see them for what they are.

Do not despair November’s arrival; find a reason to celebrate it.

November is also the month we provide a glimpse into the seed industry, with our Seed Focus issue. The seed world is in a rapid state of change, far greater than we anticipated, or than we have seen in any period in this industry.

As a sort of bookending of the growing season, we are also breaking new ground with our latest Machinery Manager feature, which looks at combines, including our streamlined specs and accompanying links to our website for the complete listings from our eight featured manufacturers.

As a final note, we are revising our Traits and Stewardship Guide on our website to include Horizon Seeds on the corn traits listing. From time to time, details can slip through the cracks. This revision corrects an oversight and provides a more comprehensive resource for our readers.

And that is always our primary focus.

Ralph Pearce Editor Top Crop Manager

Pests and dIseases

Investigating pest management for low-linolenic soybeans

by Heather Hager, PhD

Low-linolenic soybean makes “heart-healthy” oil, but is it good for pests too?

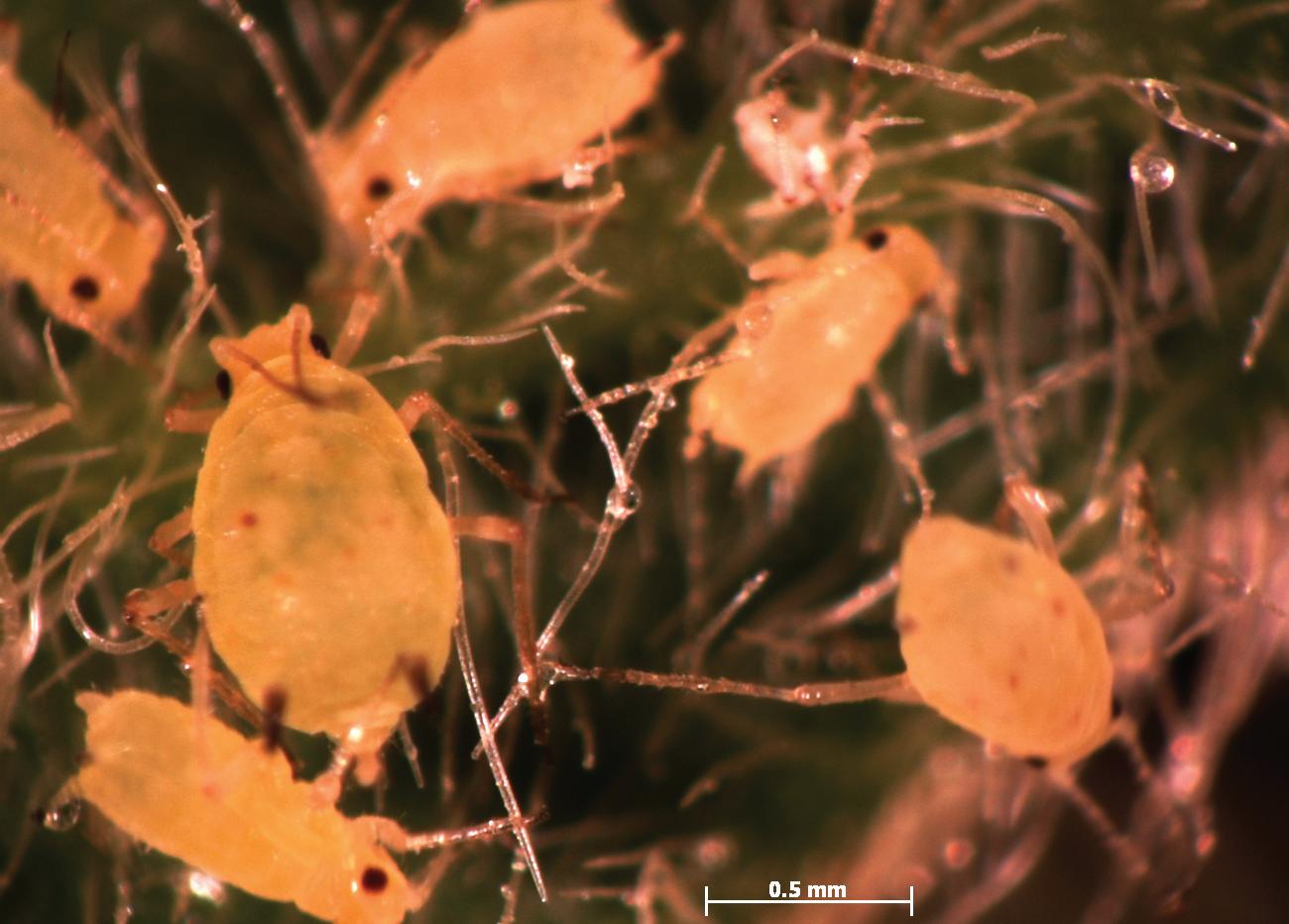

It all started in the lab. Dr. Gustavo MacIntosh, a molecular biologist at Iowa State University, was investigating how soybean aphid feeding affects soybean plant gene expression and metabolism. One particular change he noted was an increase in the concentration of linolenic acid in soybean leaves in response to the aphid. “We know that linolenic acid is an important part of the plant defence response,” says MacIntosh. So he wondered whether soybean varieties that are bred to produce seeds with low levels of linolenic acid might be more susceptible to soybean aphids than conventional varieties.

MacIntosh approached Iowa State University entomologist Dr. Matt O’Neal, nematologist Dr. Greg Tylka, and agronomist Dr. Palle Pedersen with his idea, and, with financial support from the Iowa Soybean Association, the group is now collaborating on a field experiment. “The hypothesis,” explains O’Neal, “is that producing low concentrations of linolenic acid in the seed may affect the levels in the plants, which in turn, may make the plants more at risk for pests.”

O’Neal is concerned about potential implications for soybean production. He says if the hypothesis is supported, it may mean that recommendations for the production of lowlinolenic soybeans need to be altered. Growers may need to use different management tactics against pests when they produce low-linolenic varieties than when they produce conventional varieties. Therefore, one goal of the project is to determine management recommendations for low-linolenic soybeans.

Field experiment

The group has established a massive field experiment near the university, co-ordinated by graduate student Mike McCarville. It involves six soybean varieties and six pest treatments, all replicated five times, for a total of 180 individually caged plots. The six soybean varieties comprise three varieties with different levels of linolenic acid in the seed, each with and without soybean cyst nematode resistance. “The experiment has a conventional variety that is seven percent linolenic acid in the seed; and then we’ve got a low level, which is defined as three percent of the seed; and then an ultralow, which was developed by Walter Fehr, a breeder here at Iowa State, and it’s at one percent,” explains O’Neal. The six pest treatments are an untreated control, soybean cyst nematode alone, brown stem rot alone, soybean aphids at 250 per plant, unlimited soybean aphids, and a treatment with all three pests together. “We have microplots of about 10 plants in a 0.5-m2 plot, and we can control the amount and timing of the exposure of the plants to the different pests.”

The experiment began in 2008 and will encompass three growing seasons. “In Iowa in 2008, we had a very wet spring and early summer, so our first year was challenged by

1: In the plant, linolenic acid is synthesized from oleic acid and may be used to synthesize compounds involved in plant defence against insect attack.

having to replant some of the plots because the experiment was drowned,” says O’Neal. In fact, according to the 2008 Annual Climate Review: US Summary, prepared by the US National Climatic Data Center, Iowa had its 11th coolest year, and eighth and seventh wettest spring and summer, respectively, since the start of the 20th century, and was plagued by flooding. Unfortunately, this meant that the researchers were not able to get soybean cyst nematode and brown stem rot to establish that first year.

However, they did manage to collect data from the aphid treatments. “What we’ve seen in the preliminary data from 2008 is that low-linolenic varieties were no more susceptible to aphids than the conventional varieties, which is good news,” says O’Neal. “We didn’t see differences in aphid populations or yield among the low-linolenic and conventional varieties.” He cautions that more data from additional years are needed to look for clear trends.

The experiment is progressing well in 2009, says O’Neal. “We had a great spring. We got in early, everything’s planted, and we didn’t have to replant. The beans are growing, and the cages are all set up. We’re really looking forward to seeing what we gather from this year.”

A complicated puzzle

MacIntosh’s task is to analyze the composition of leaf and seed tissue from the field experiment. “I am just analyzing the first year of data, so I don’t have a lot of information on the composition yet,” he says. He notes that the expression of the linolenic acid trait is complex because a number of factors can affect the concentration of linolenic acid in the plant. These include insects, temperature and moisture, all of

Figure

Pests and dIseases

to various pests.

Iowa state unIvers ty RIGHT: Linolenic acid, a precursor of compounds involved in plant defence, increases in soybean leaves in response to aphid feeding.

which could interact.

which step of the biochemical pathway is altered to get the low levels of linolenic acid, says MacIntosh. For example, if low-linolenic acid is achieved by a mutation in the plant that increases the conversion of linolenic acid to one of the plant defence compounds, then the insect resistance could be unchanged or increased compared to a conventional variety. However, if low linolenic acid is achieved by a mutation that blocks one or both of the conversion steps from oleic acid to linolenic acid, which is the case in at least two documented mutants, the resistance could be reduced.

Another factor to consider is that different pests may activate different plant defence pathways. “Linolenic acid is involved in jasmonic acid defence, which is mostly for insects,” says MacIntosh. “Fungus seems to induce a defence that involves salicylic acid. Nematodes are more complicated, it is a mix.”

Understanding the biochemistry and molecular biology of the low-linolenic trait can help in predicting its effect on plant defence. To synthesize linolenic acid, enzymes in the plant convert oleic acid to linoleic acid and then to linolenic acid (Figure 1). Under insect attack, specific plant defence systems are activated, converting linolenic acid to green leaf volatile compounds and/or jasmonic acid via a number of steps. Green leaf volatiles attract predators of the insect herbivore, whereas jasmonic acid signals the plant to produce compounds that are toxic to the insect.

The effects of the low-linolenic trait on plant defence could differ among low-linolenic soybean varieties, depending on

So, if there is an effect of the lowlinolenic trait, it may only manifest in response to certain pests. “We do have some reports from farmers that the aphids sometimes seem to prefer the low-linolenic varieties,” notes MacIntosh. These observations have not yet been validated. Further experiments are required to test whether aphids really do choose low-linolenic varieties over conventional varieties when both are available.

However, based on the field experiment’s first year of results, “it’s not clear that the breeders have reduced the linolenic acid concentration enough to have an effect on the insect,” says O’Neal. “But our concern is that going forward, growers are being asked to produce more and more of this, and we want to make sure they have the best recommendations to protect these plants.”

Indeed, ensuring the suitability of management recommendations may become even more critical as additional specialty traits such as high oleic acid and high omega-3 fatty acid are rolled out for soybeans. n

Genuity™ SmartStax™ Corn is the most advanced, all-in-one corn trait technology ever. i t combines the broadest spectrum control of above and below ground insects, together with unsurpassed weed control and the industry’s first and only reduced refuge system – to just 5% of planted acres. i t all adds up to more whole-farm yield potential. i t’s just one of the ways that the g enuity™ brand is helping farmers do what they do best, even better.

ABOVE: Scientists ask whether altered fatty acid levels in the seed affect a soybean plant’s response

Photos courtesy of Gustavo MacIntosh

Markets

A look at changing IP soybean premiums

by Carolyn King

Various emerging conditions will affect the size and availability of premiums.

During the fall of 2008 and spring of 2009, premiums for the 2009 crop of identity preserved (IP) soybeans reached a high of $2 to $3 per bushel. This was up about $1 per bushel from the year before. The peak was brought about by a convergence of several factors, including some frantic short-term action in the commodities markets and some long-term efforts and trends.

The identity preserved process ensures the identity or purity of soybeans with certain characteristics that the buyer requires, like high protein or high sugar. The IP process provides documentation tracing the soybeans each step of the way from the seed grower through the soybean grower, the elevator and the shipping system. The key characteristic required by many IP buyers is that the beans be non-genetically modified (nonGMO). Producers who grow IP soybeans look for the premium because of the extra work and extra costs involved: keeping detailed records; using certified seed; thorough cleaning of planting, harvesting and storage equipment before use; and maintaining separate bins. As well, production of non-GMO soybeans usually incurs higher herbicide costs.

Market madness and changing soybean sources

Market forces strongly influence IP premiums, and the premiums for the 2009 crop are no exception. Martin Harry, eastern marketing manager for SeCan, says world food demand and speculation drove the IP premiums up in late 2008 and early 2009. “The 2007 crop wasn’t good for IP, so there was a shortage of beans, and that pushed up the demand. Then commodity prices went through the roof and there was big scare. Why were beans $16 a bushel or $14 a bushel? Because of speculation. That caused panic that there was a shortage of beans and food around the world, and every-

body went nuts.”

John Johnston, a long-time soybean grower and a member of the Ontario Soybean Growers board, says, “2008 was an exciting time in commodity agriculture. We had record prices on corn and beans, and the IP premiums rose up with them.”

Martin Vanderloo with Huron Commodities takes a closer look at the effect of those market fluctuations on premiums. “In 2007 we had a rather poor soybean crop; we had lower yields, almost 50 percent of what we were expecting, and poor quality. That was for most of Canada and a good part of the United States. So non-GMO and particularly IP soybean varieties were in very short supply.” As a result, trading companies, distributors and manufacturers all wanted to buy more soybeans than usual to avoid shortfalls in 2008 and 2009.

Then market speculation drove up soybean prices, and the high prices drove up the premiums. Vanderloo explains, “With soybeans at $15 and $16 a bushel, growers were saying, ‘Why would I bother with IP beans, going through all the work and the headaches, for a mere

$1.50 or $2 per bushel premium? I can grow Roundup Ready beans and it’s simple and the yields are good, and I get $16.’ So we said to the buyers, ‘When soybeans are $8 a bushel and we pay the grower a $1 premium, percentage-wise that’s a good deal. But when soybeans are $16 a bushel, and you pay him a $1 premium, the grower’s going to say it’s not worth it.’ So that’s part of the reason why the premiums got higher.”

Johnston notes, “I think a second factor in the higher premiums was that the Asian buyers, in particular the Japanese, after visiting here many times, were starting to understand that it was going to take that kind of a premium to secure some acres. They could see the cost differential between growing genetically modified beans and food-grade nonGMO beans, the dollars and cents difference that growers had to have to justify that extra work and management.”

Another factor influencing premiums was the Canadian dollar. Vanderloo explains, “The strength of the Canadian dollar has a very dramatic effect, not only on soybean basis, as we all know, but also on premiums. When we’re dealing

Premiums for identity preserved soybeans reached a high last spring in part due to frenzied market activity.

Since 1977, Case IH has been building its Axial-Flow ® combines the same way: with a single rotor and fewer moving parts. Over 4 billion acres later, that simple, innovative design is still the standard by which all others are judged. Case IH also offers the industry’s most comprehensive line of combines, with models ranging from Class V to Class IX, including two new Class VII machines. To learn how you can count on Axial-Flow combines to simplify your harvest, visit www.caseih.com.

Markets

with an 85-cent dollar, it’s much easier to pay the grower a reasonable premium than when we are bumping up against a 94-cent dollar.” For instance, at end of December 2008, the Canadian dollar was down around 80 to 82 cents.

An additional consideration for IP buyers is Chinese soybean production. “China has become less of a soybean exporter and more of an importer. In addition to that, Chinese consumables don’t have a good image in the rest of the world. The Chinese at one time had something like 35 to 40 percent of the Japanese food-grade market. That’s fallen to a very small percentage,” says Vanderloo. “And guess what? Canada has picked up the slack for the most part.”

Vanderloo says the hard work of Canadian soybean breeders, growers, processors and exporters toward high quality food-grade non-GMO soybeans has helped to create a strong international reputation. He notes the IP market is crucial for Canadian soybeans: “We need to be more than a commodity soybean producer because frankly we’re not competitive in the world market on crusher soybeans. So we have to do something different. And I think we do a good job of that.”

Johnston comments that market awareness by the Canadian Soybean Council and exporters, along with some government funding for trade missions, have also helped attract international buyers to Canadian IP soybeans.

He adds, “I was on a mission in February of 2009, and in Japan it was made very clear to us that Japan did not want to buy as much food-grade beans from China as it had in the past because of a couple of food scare issues. That made the Japanese look elsewhere for a supply of beans. I think some of the other suppliers just weren’t able to find the acres. For instance, the Americans couldn’t find the acres because everyone there was going to genetically modified soybeans.”

Where are IP premiums headed?

As of September 2009, IP premiums are looking softer. “A lot of the 2009 crop was secured at very good premiums. But if a grower hasn’t signed a contract with a processor, I think they’ll be very shocked at how little the premium will be this fall. I think the buyers have already got a lot of beans booked, so nobody needs any beans right now,”

explains Johnston.

Harry notes, “I just did a survey of all the brokers, and the premiums for 2010 will probably come back down. There are lots of acres of IP beans out there. There’s lots of inventory from last year still. Japan has full inventories right now. So premiums will probably soften back to that $2 range; we’ll lose that $1 we gained. That’s the feeling right now, but it’s not harvested yet.”

Vanderloo says, “In our case and in most others I believe, we’ve sold a larger percentage of the 2009 crop by December of last year than we ever had before in the past. I think it comes back to that shortfall in 2007, and the paranoia that came from that. So here we are about to go into soybean harvest, and the Japanese warehouses and the inventory are at record levels of 2008 beans.”

However, Johnston, Harry and Vanderloo all agree that premiums could quickly change if an early frost or other problem affects soybean yields or quality this fall.

Vanderloo sees another possible con-

sideration on the IP premium horizon. “Roundup Ready 2 soybean varieties are being pushed by industry players. If these varieties in fact turn out the way they are hoping, with substantially higher yields than the traditional varieties, that’s going to mean that we must continue to pay reasonable premiums, I won’t say they’ll be the same as they were a year ago, but reasonable premiums, for a grower to grow IP soybeans and non-GMO varieties.”

He concludes, “Whether it’s a premium or basis levels or the futures market itself, and whether it’s soybean or corn or wheat or hogs or cattle or gasoline, if it’s a commodity, we will always have peaks and valleys in a market. It’s dictated by supply and demand, and of course Mother Nature plays a very big role in what we do. I think, long-term, we’ve got a good product, so people shouldn’t be discouraged by what we see today. I’m confident that things will turn around and that once the buyers use up these inventories that they are kind of choking on today, they’ll be back.” n

Reasonable premiums for IP soybeans will be the answer to competition from increasing yields expected from advances in genetically modified soybeans.

Hyland Seeds is building better beans with GenuityTM Roundup Ready 2 YieldTM technology

• SCN tolerant

• Outstanding yield potential

• Excellent spring emergence

• Tall plant height 3025 CHU

• SCN tolerant

• Outstanding yield potential

• Excellent seedling vigour

• Medium-Tall plant height

You’ll be harvesting higher yields when you include GenuityTM Roundup Ready 2 YieldTM soybeans from Hyland Seeds in your 2010 plans. These new high-yielding varieties consistently deliver more yield* than Roundup Ready® soybeans. Choose from these two varieties from Hyland Seeds: HS 24RYS01 – exclusive to Hyland Seeds, 3175 heat unit, soybean cyst nematode (SCN) tolerant variety; and 5201RR2Y – 3025 heat unit, SCN tolerant variety.

3175 CHU

Pests and dIseases

Attack fusarium head blight head on

Potential for serious infection is always one or two conditions away.

Finding a way to better manage fusarium head blight would be like finding a cure for the common cold, except it would do more than prevent nuisance aches and sneezes. It would save millions of dollars in lost yield and quality annually.

Like a seasonal illness, wheat growers have come to accept fusarium head blight as an unfortunate and risky fact of life. Unlike head colds, however, there has been recent progress in stemming the spread of the disease. Since the cereal disease first made its appearance more than two decades ago, new practices and new wheat varieties have helped curb the spread of fusarium head blight. And, a new fungicide in the fight against fusarium is now on the radar.

“Today we have more options and more tools to manage the disease, although we still cannot achieve 100 percent control when conditions are favourable for infection and disease development,” says Dr. Dave Hooker, field crop agronomist at the University of Guelph’s Ridgetown Campus. “Every year, there are at least some growers, somewhere who suffer tremendous losses due to fusarium head blight.”

Those losses start with yield: a 20 percent infection rate can reduce yield by up to 20 percent, says Hooker. And other problems follow from there. Infected seed commands lower prices, has lower feed and processing value, and if reseeded, typically results in a thinner, less vigorous crop.

Weathering the weather

The real challenge of managing fusarium head blight is that so much of its spread is dependent on the weather.

Head blight in wheat, which is caused by the fungus Fusarium graminearum, overwinters as mycelia or spores in crop residue. It can also affect seedlings upon emergence through the residue. Wind and rain-splash can further spread the spores to aboveground portions of the

By reducing the incidence of fusarium head blight in wheat, growers will benefit from increased yields, better quality seed and peace of mind.

plant and across fields.

Humid, warm conditions, between 10 and 30 degrees C, five to 10 days before wheat head emergence favour the development of the spores, which can infect the heads at flowering if warm and moist conditions persist.

Advances in fusarium head blight management

But if there is no cure, there is still room for optimism. “Wheat breeders have made tremendous progress in developing some resistance or tolerance to the disease,” says Hooker. “In winter wheat today, we have a handful of varieties that are moderately resistant to the disease. A decade ago, nearly all varieties ranged from susceptible to highly susceptible. However, even for varieties with resistance, fungicide options and other agronomic tools are still recommended to minimize risk.”

Good production practices are also fundamental to stemming the spread of disease. According to the Ontario Ministry of Agriculture, Food and Rural

Affairs (OMAFRA), the best way to manage all diseases, including fusarium head blight, is a sensible rotation.

Outbreaks occur because three things are present in a field: the pest (in this case, fungal spores), the host crop and the right environmental conditions. The grower cannot control the weather, so the two top management practices for reducing the risk of infection are to choose a wheat variety with some resistance to the disease, and to avoid planting wheat after corn.

OMAFRA recommends growers consider planting more-tolerant varieties of wheat. Clean plowing of infected trash has very little effect, say the Ministry guidelines, but the risk of infection from nearby fields remains high if weather conditions are favourable.

Another area of progress is fungicides. Caramba, a new systemic triazole from BASF, has performed well in Hooker’s replicated field trials. “In our trials, Caramba was one of the top fungicides for reducing the visual symptoms of fusarium head blight and for reducing

Photo courtesy of Basf

Pests and dIseases

deoxynivalenol (DON) mycotoxin concentrations in winter wheat,” Hooker says. “No fungicide achieves 100 percent control, but Caramba consistently achieved between 50 and 70 percent control” when applied properly. Caramba also delivered some of the strongest control of leaf rust and stagonospora glume blotch.

Dave Eadie, who farms near Lucknow, Ontario, was part of a grower-applied research trial in 2008. He compared Caramba with Proline on side-by-side, 20-acre plots. For his farm, he wanted to see which product delivered the best fusarium control and which improved yield. With Caramba, he says,

“We got both.”

Both stands looked similar, Eadie says, but the real difference came at harvest. “The yield on the Caramba test strip was 124 bushels, and on the Proline, it was 119 bushels. Yield wise, it was exceptional; that’s the best yield I have ever seen out of my winter wheat.”

Application timing and techniques are also as important as the fungicide itself. If not applied properly, results may not be satisfactory if weather conditions are favourable for the disease. Pioneering work from Hooker and OMAFRA suggests that the best approach is to use nozzles that spray the wheat heads nearly horizontally, from the front and from

the back, using a high water volume. This ensures the most uniform coverage of the wheat head. Conversely, application trials show that the effectiveness of the fungicide can be reduced with the use of conventional nozzles that spray downward.

Clearly there is no magic bullet for the control of fusarium head blight, but the various tools available to manage the disease have improved significantly. A sound rotation that includes the use of the right wheat varieties, and proper treatment with an effective fungicide if conditions warrant its application, is the best way for growers to protect their wheat production. n The PRIDE FX2 System featuring New GenuityTM Roundup Ready

“Are my farm management practices the best they can be?”

This question came in to us from a grower in Essex County and we promised him an answer he could hang his hat on. Equipped with a portfolio of knowledge based products and the collective insights of hundreds of Cargill farm management experts around the world, our team set out to analyze everything from planning to performance.

Using this whole-farm approach, we discovered a grower with great farming ability but untapped farm potential. Our remedy? To provide the farm management solutions, measurements and support he needed to realize greater farming success.

As a result of Cargill’s expertise, there’s now a grower in Essex County with superior management practices and greater farming confidence.

Nanotechnology in agriculture

by Heather Hager, PhD

Tiny leaps for humankind.

Fabric sensors in a field change colour, indicating the arrival of pathogens. Tiny wireless electronic sensors in grain bins detect incipient spoilage, alert the farmer via mobile phone, and begin specific remediation. Specially formulated fertilizers and pesticides act with greater efficacy, allowing less product to be applied. These are just some of the potential applications of nanotechnology in agriculture that are being explored. “Nanotechnology is the concept of working with materials at a very small scale,” explains Dr. Nils Petersen, director general of the National Institute for Nanotechnology in Edmonton, Alberta. To get an idea of just how small this scale is, one nanometre is one-millionth of a millimetre, or half the width of a strand of DNA. A strand of hair is roughly 100,000 nanometres wide. “At this scale, the properties of materials change tremendously because of the large surface-to-volume ratio and changes in the quantum mechanical behaviour of materials,” says Petersen.

The enormous surface area of nanomaterials facilitates their interaction with other substances, giving the nanomaterials unique properties such as exceptional strength or greater chemical activity. Researchers are exploring new applications for these unique properties, and the field of nanotechnology is expanding rapidly, with applications in areas of medicine, electronics, engineering, computers, energy, environment, plastics, and food science, to name a few. Although discoveries in these areas may be of relevance for agriculture, there is also some direct interest in nanotechnology to aid agricultural production.

Sensing grain spoilage

At the University of Manitoba in Winnipeg, microelectronics and nanotechnology have been combined to create a tiny sensor that can help farmers in the early detection of grain spoilage during storage. The sensor was developed by Suresh Neethirajan, research and development engineer in the Department of Biosystems and Engineering, along with

colleagues from electrical engineering, entomology and chemistry. The standalone sensor is the size of a dime and can detect parts per billion levels of carbon dioxide and odour-causing chemicals to determine the level and cause of spoilage. “There are two or three major insects in grain,” says Neethirajan. “Each insect produces a specific chemical inside the grain bin. Similarly, if the grain is being infested with fungus, it produces different chemicals. Our particular sensor has seven chips in it and will identify which insect or fungus is causing the spoilage.”

The sensor also measures changes in carbon dioxide to detect incipient and ongoing deterioration of stored grains. Once the cause of spoilage is identified, a specific treatment can be used to correct the problem. “We are also looking at building the sensor to be wireless,” says Neethirajan. He envisions that multiple sensors would be distributed throughout the grain to pinpoint problem areas and would communicate with a central hub. The central hub would automatically update a household computer, website, or personal mobile

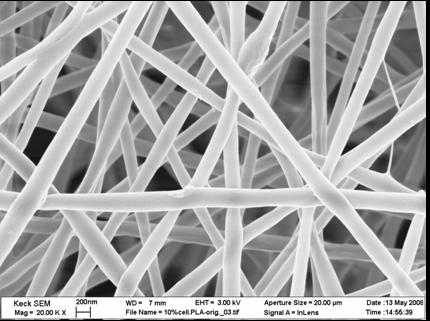

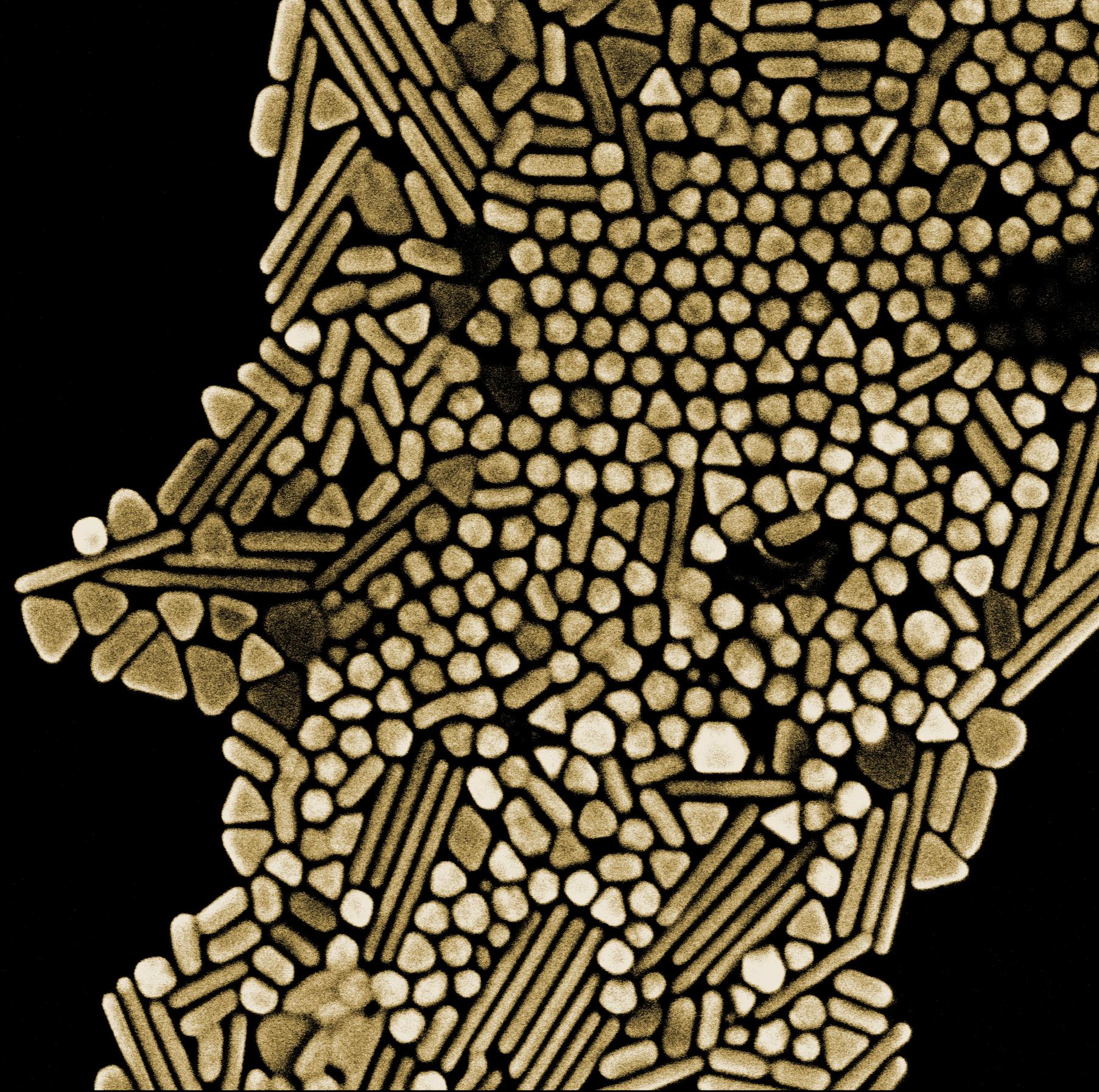

Fabric made of cellulose and polylactic acid nanofibres slowly degrades, releasing agricultural pesticides held within the pores. Scanning electron microscope images courtesy of Dr. Chunhui Xiang, Fiber Science and Apparel Design, Cornell University.

device such as a cellphone so that a farmer could monitor the grain on a daily basis without having to visit the grain bin. By catching and treating spoilage before it becomes severe, additional benefits might include reduced chemical usage and better grain quality.

Neethirajan thinks that this technology could be available to farmers within two to three years. “We have demonstrated that our sensor works, and we are now focusing on commercializing the technology,” he says. A patent is being obtained, and several companies have expressed interest in licensing the technology.

Controlled-release textiles

In another application, nonwoven fabrics made from nanofibres are being used as a platform for controlled-release technology. The nanofibres are made by electrospinning, which uses an electrical charge to pull a very fine, long fibre from a droplet of liquid polymer. The fibre twists upon itself, creating a fabric. “The high surface area, high porosity and small pore size of the fabric all contribute to its absorption and release

now has

New AutoTracTM RowSense TM Universal – the best guidance choice for more combine makes and models

Love the idea of harvesting corn with AutoTrac, but don’t run a newer combine with integrated AutoTrac? Then we have the ideal solution: New AutoTrac RowSense Universal. It pairs with the AutoTrac Universal Steering Kit to provide incredible accuracy and ef ciency, even if you’re harvesting in down corn, around terraces, or on pivots. RowSense Universal works by fusing GPS guidance and data gathered from a new dual row feeler on the corn head, for unbeatable harvest precision. And because this system also can be used on non-John Deere combines, you can enjoy its bene ts, no matter the color of your combine or corn head. See your dealer for details. www.JohnDeere.com Hands-free

researCh

performance,” says Dr. Margaret Frey, associate professor in the Department of Fiber Science and Apparel Design at Cornell University in Ithaca, New York.

Frey and colleagues are using cellulose and polylactic acid, a polymer made from cornstarch, to create a biodegradable fabric. The fibres can hold up to 50 percent of their weight in agricultural chemicals such as pesticides; the chemical is gradually released as the fabric biodegrades. In experiments, gradual release was obtained during a four-month period, and the timing of release depended on the fibre’s composition. In greenhouse tests, 4 x 4 mm squares of pesticide-containing fabric placed in the soil successfully controlled whiteflies on bean plants.

Similar nanofibre-based fabrics are being used as a detection technology platform to capture and isolate pathogens. Frey’s research is currently focused on medical and food applications such as detecting Salmonella or Escherichia coli, but in future, the technology may be extended to include other pathogens and diseases. The nanofibres in this fabric are embedded with antibodies against specific pathogens. The fabric can be wiped across a surface and tested to determine whether the pathogens are present, perhaps indicating their presence by a change in colour.

“Research is continuing on both of these projects, and invention disclosures and patent applications have been filed on both of these materials,” says Frey. “With an industrial partner, these inventions could be available for use in three to five years.”

These and other agricultural applications of nanotechnology may be the next step in increasing farming efficiency. n

The sharpest ideas in cutting systems!

Exceptional Performance for Combines, Hay Machines & Windrowers

Crary’s patented Gold Guard

Spring-loaded Hold Downs

4 styles of sections

Increases crop feeding capabilities

Longer wear life

Increased ground speeds

Less crop shatter

Complete systems can be shipped via UPS

Special techniques and equipment and ultra-clean facilities are required to create nanoparticles such as these. Scanning electron microscope images courtesy of Anastasia Elias, Anne Cooper, and Jillian Buriak, National Institute for Nanotechnology, Edmonton.

Locate a dealer near you: www.topcrop.crary.com 800-247-7335

Regulating nanotechnology

Concerns over the effects of nanoparticles in the environment and on human health have prompted Health Canada and Environment Canada to develop some ground rules for nanomaterials under the Canadian Environmental Protection Act. At the international level, the International Organization for Standardization (ISO) and the Organisation for Economic Co-operation and Development (OECD) are developing standards to facilitate an international regulatory framework for nanotechnology.

Nanomaterials have unique properties and behave differently from typical common materials, so it is unknown how their effects might depend on the mass, number, size and shape of particles. Thus, it is necessary to determine if current toxicological evaluations will apply to these materials or if modifications or new methods are required. As a first step, the Canadian government is collecting industry data on nanomaterials’ use, properties, health and ecological toxicity, and water solubility Canadian Environmental Protection Act.

“We recognize as a scientific community and as an industrial community that there are issues that we have to face and identify before we get a lot of technology into the marketplace. We don’t fully understand yet what parameters we need to measure when we look at the effects of nanomaterials,” says Dr. Nils Petersen, director general of the National Institute for Nanotechnology in Edmonton, Alberta.

This is an active area of investigation that is receiving attention globally.

Pioneer agronomists, along with provincial extension personnel, have been scouting a lot of fields across Ontario and finding damage caused by western bean cutworm.

This rapidly spreading pest can hurt your bottom line. Uncontrolled, it can ravage corn fields, decreasing the yield of your crop. It can also impact grain quality by making it easier for ear diseases and rots to gain a foothold.

That’s where YieldGard® lets its guard down: It does not protect against western bean cutworm.

Herculex® insect protection is the only Bt trait on the market that protects corn hybrids from western bean cutworm.

Pioneer offers the broadest, most complete lineup of hybrids with the Herculex trait on the market – more than any other seed company. We can deliver high-performing hybrids for all maturities in the trait combinations you want.

Make sure your corn fields are protected in 2010.

Plant Pioneer® brand corn hybrids with the Herculex insect protection trait.

Call your local Pioneer sales representative for a recommendation on the right hybrid for each of your fields.

www.pioneer.com/canada

Photos above show typical western bean cutworm damage. All photos taken in Ontario in 2009 of hybrids that DO NOT contain the Herculex trait.

Ridgetown enrolment up as interest in ag increases

by Blair Andrews

Second careers and more optimism are largest factors.

The Ridgetown Campus of the University of Guelph is boasting a bumper crop of new students for the fall of 2009. Enrolment has been particularly strong in the Agriculture and Environmental Management diploma programs. “We’re expecting about 155 juniors in the Agriculture program, almost double last year’s number of 83,” says Dr. Art Schaafsma, director of the Ridgetown Campus. The number in the Environmental program has more than doubled, from 40 to more than 80.

While the downturn in Southwestern Ontario’s beleaguered manufacturing sector is playing a significant role, there are several reasons behind the stronger enrolment.

The factors driving the interest in the Environmental program are easier to explain. Katie Savage, campus recruitment co-ordinator, says many of those students may have lost their jobs and are going back to school to train for a different career. “A large number of students have received Second Career funding through the government, so they’re getting sponsored to come to school for retraining in our Environmental program,” explains Savage.

“Second Career” is a relatively new Ontario government program that, among other things, offers financial support to help laid-off workers train for a new career.

As for the Agriculture diploma program, Schaafsma is of the opinion that recent high school graduates continue to be the main focus. “My guess is that there is more optimism in agriculture, not simply in the primary agriculture field but all of the ancillary industries,” says Schaafsma. “There are the service industries, grain handling and marketing, and I think folks are seeing there are some decent jobs out there.”

The number of potential jobs also may be an attraction. Lezlie Cunningham, career placement officer at the campus, says there have been more jobs than students

to fill them during the past few years. The job postings come from various agribusinesses throughout Ontario and from across the country. “The toughest part of my job is taking calls from employers who have posted jobs for five weeks, and I haven’t had any applicants,” says Cunningham. “Many graduating students are going home to farm.”

While going back to the family farm may not be the case for the majority of the students, Schaafsma says it is becoming a better option for some, noting that there is a slight change in attitudes. “With some of the farmers, five to 10 years ago, they’re telling their offspring not come back to the farm. But that is starting to change and we’re seeing more family succession.”

And Schaafsma says the next generation values the type of education and training that is required for today’s agricultural industry. As an example, he says a number of the students who are interested in the Agriculture program are coming from a dairy background. “We have a course where the students manage the herd during a semester. The

dairy barn is the classroom, and they have to make breeding decisions as well as other management decisions.”

Higher demand for practical knowledge

Whether people are going home to farm or moving into a related agri-business, Elaine Graham, president and recruitment specialist of Bestard Agricultural Placements (BAP), says relying solely on a farming background is not enough. BAP has been connecting job candidates and employers for almost 20 years. “Farms are highly managed enterprises and we should be proud of our professionalism,” says Graham. “Saying that farming as a career is something you can ‘fall back on’ is absolutely not the case any more. You need more than practical experience; you need tangible skills.”

To illustrate her point, Graham cites the modern feed salesperson as an example. In relating the job description, she says the position requires many tasks in addition to receiving the actual order for feed. “It’s about a whole-farm program and being a trusted advisor,”

Greater opportunities across the width and breadth of the agri-food industry means higher enrolment for schools like University of Guelph’s Ridgetown campus.

• Two built-in GNSS receivers

• One to control your vehicle and one to control your implement

• Coverage from GPS+GLONASS satellite constellations which have more than 50 satellites combined to prevent operational downtime

• Large 12.1” color touch screen

• A single display that controls all your

• Assisted or automated steering

• Implement steering

• Nutrient management

• Mapping and variety tracking

• Variable rate application of seed, liquid and granular

• Field leveling and water drainage

• Automatic section control

• Seed monitoring

• Compatible with many 3rd party rate controllers

DEKALB® brand seed simply gives you the best chance for success, with advanced research, consistent performance and high yielding genetics to give you the most options to fit the way you farm In fact, this year alone we’re introducing 17 new corn hybrids and 9 new soybean varieties, plus two new trait technology platforms – Genuity™ Roundup Ready 2 Yield™ soybeans and Genuity™ SmartStax™ corn –that combine our genetics with next generation production technology That’s why, every year, more farmers put their confidence in DEKALB †

explains Graham. “It’s about having a broad background in a lot of highly technical areas, not just sales and marketing training. Whether its nutrition, genetics, biosecurity, information management technology or animal welfare and herd health, you are working in that individual farmer’s environment and it must be customized to him. The more you know, the more value you bring to the farm.”

Darryl Ayris, general manger of the Watford branch of Forest Agri-Services, personifies the increased interest in agricultural careers. Ayris, 37 years old, was born and raised on a farm in Kerwood, Ontario. Before entering Ridgetown as a mature student, Ayris drove a truck for several years, delivering feed to the United States. He was forced to look for another career after he injured his back in a work-related accident. Looking for what he says was “a decent career,” Ayris enrolled in the two-year Environmental Management program in 2006. After completing the environmental program, Ayris opted to go back to school for another year to obtain an Agriculture diploma from Ridgetown. “I was a

The value of programs at Ridgetown’s campus increases whether the jobs are in sales, in marketing or back on the farm.

mature student, and while in the mode of going to school, I figured I may as well take it,” says Ayris. It was a wise choice. Ayris landed a job at Forest Agri-Services, an independent agricultural supply company in Lambton County, shortly after graduation and he quickly moved into a management position.

Based on his experience, Ayris says the need for skills in agriculture is driven by technology. “There seems to be more call for crop scouts and more precision because input costs are high and a

missed application takes too much off the bottom line. Profits per acre are getting tighter,” says Ayris. “It has come to the point where farmers are passing off some of the decisions to agri-business, and that’s what you get paid for.”

Agri-business is not alone when it comes to being more innovative and entrepreneurial.

Schaafsma says the Ridgetown campus is moving in a similar direction. Becoming more than an “ag school,” it now offers a Bachelor of Bio-Resource Management degree, majoring in Environmental Management. Students in this program spend two years at the Ridgetown campus and then complete another two years at the Guelph campus. Meanwhile, Schaafsma says there are plans to add a new Renewable Energy course in 2010. “We’re being asked to be more self-sustaining, so we can’t rely on government funding and traditional revenues,” says Schaafsma. “We have to try to find ways to be creative. And that’s not a bad thing because that helps us engage in some of these new ventures, which will hopefully lead the economy.” n

DEKALB brand GenuityTM SmartStaxTM hybrids combine DEKALB genetics with new GenuityTM SmartStaxTM technology for the most advanced insect and weed control system available Together, they are the ultimate in confidence

See your DEKALB dealer about the m ost comprehensive lineup of GenuityTM SmartStaxTM hybrids

weed ManageMent

Learning more about weed control in IP soybeans

by Blair Andrews

New market demands push new strategies.

When it comes to meeting the challenge of controlling weeds in identity preserved (IP) soybeans, the key piece of advice is having the right plan to deal with the specific weeds in each field. With the resurgence of IP soybeans in Ontario and Quebec, farmers may face the additional challenge of making those plans early to ensure they get the herbicides they want.

In the wake of a June 2009 Statistics Canada estimate that calls for a record 2.4 million acres of soybean, reports surfaced about spot shortages of herbicide products.

Of the 2.4 million acres, 50 percent was not genetically modified (GM). By contrast, the 2008 acreage was 2.1 million acres, of which approximately 43 percent (900,000 acres) was non-GM. “For 2009, it was a very hectic market. It was a great year to launch a product because demand was strong,” says Regina Rieckenberg, sales and marketing manager for Valent Canada, referring to Valtera herbicide. “We sold out immediately and could have sold a lot more if we had it, and I think a lot of the other manufacturers were in the same position.”

Valtera, a new herbicide for Canada, can be used in both GM and IP soybean programs. For IP soybeans, Rieckenberg says it is used as an “add-on” in programs with other residual herbicides, providing control of small-seeded broadleaf weeds such as pigweed, lamb’s-quarters and eastern black nightshade.

“I don’t think it should be a concern, although I would say it is good for the grower to work with their retailer to help them understand what their product needs are going to be,” says Dave Kloppenburg, row crops project leader with DuPont Canada, commenting on the possibility of herbicide shortages.

The rise of the glyphosate-tolerant market, particularly in the United States, which dwarfs the Canadian IP market in comparison, has led to speculation that the supply of conventional soybean herbi-

cides will be short-changed. Kloppenburg, however, is noticing a different trend. “Our conventional soybean herbicides have had a real resurgence in both the United States and Canada, and the United States, is mostly a glyphosate-tolerant market. Conventional chemistry is being used in

conjunction with glyphosate on GM soybeans on a pretty wide scale,” says Kloppenburg, noting that conventional herbicides are being added to control weeds that are not addressed by glyphosate or to provide alternative modes of action to delay glyphosate resistance.

Although the IP sector is here to stay, the challenges of weed control continue to hamper growers, says Dr. Peter Sikkema.

weed ManageMent

Trevor Kraus, supervisor of research and commercial development in Eastern Canada for BASF, echoes Kloppenburg’s comments, saying his company responded to the surging Canadian IP market by acquiring more product than in previous years. “I think we were in pretty good shape for what transpired in the market. The whole industry has done a good job positioning itself in the global marketplace and global buyers really trust our IP system. I think we have a pretty vibrant market and I don’t see it disappearing,” says Kraus.

Same message, different fields

If the IP soybean market is here to stay, then it would appear as though the difficulties of weed control will also be around for a long time. “You can use the exact same herbicide program two years in a row: one year you get exceptionally good results and the following year it can be quite disappointing,” says Dr. Peter Sikkema, professor of field crop weed management, University of Guelph, Ridgetown Campus, commenting on the inconsistency of controlling weeds in IP soybeans. “When I started, I wanted to develop simple rules of thumb that everyone can use. What I have learned is I’ll never get there.” Sikkema stresses that weed management in an IP system will always be

The weeds that rob yield, may actually set seed in the growing season before IP soybeans are planted.

field specific, and producers should adjust their weed management program to each field. “I think it’s important that you start with a broad-spectrum soilapplied herbicide program and then be prepared to walk the field to address the weed escapes,” says Sikkema, noting that producers will also have to be wary of weeds resistant to Group 2 and Group 5 herbicides.

“Where people fall down on weed control is that they spray and they expect it to be perfect,” says Kloppenburg, echoing Sikkema’s recommendation. “If you have a plan, and you do have some weed escapes, then you’re ready, but it requires more management.”

Management strategies to consider Based on several years of field experiments, Sikkema found that this option is more consistent than relying on a postemergent program alone.

Trevor Kraus suggests growers can take the pressure off their soybean herbicide program by effectively controlling weeds in the previous crop. “Too many times I see a field that is in corn, maybe it’s a Roundup Ready corn, and they put on a timely glyphosate. But they have late-season weeds emerging that are setting seed, increasing the weed seed bank,” says Kraus. “Those same fields, if they are getting rotated into IP soybeans, are going to have much bigger weed control challenges.”

In addition to knowing the weed spectrum and matching the products to address those weeds, Sikkema says growers should also realize that soil texture and soil pH will affect herbicide performance. For example, a product like Sencor can result in more injury on sandy soils and high pH soils. Another important consideration when choosing an IP soybean herbicide is crop rotation. Certain herbicides should not be used in IP soybeans, if producers plan to grow vegetable or sugar beet crops the following year.

Timing is also key; Sikkema says that it is critical to apply post-emerge herbicides when the weeds are small. Producers are also reminded to rotate their herbicides to reduce the risk of resistant weeds. This ensures that the products available for IP soybean production remain effective and give growers one less challenge to contend with, in their weed control program. n

weed ManageMent

Manganese-glyphosate field trials seek to improve herbicide-nutrient reaction

by Blair Andrews

Newest product a benefit.

Glyphosate and manganese have helped soybean growers boost their yields, but chemicals have a poor reputation for working together. A new product on the Canadian market, however, could change the way soybean farmers view that maligned relationship. Ontario crop advisors are taking a close look at Max-In Manganese NF 2.00 as a potential tank-mix option. It is a foliar product from Winfield Solutions LLC, and is distributed in Canada by the Agromart retail group.

Farmers who believe their soybeans suffer from manganese deficiency have hesitated to add the micronutrient to the tank-mix, fearing it would antagonize the glyphosate. “You would start to lose weed control from the glyphosate because you don’t have as much glyphosate available and you’re going to tie up that manganese,” says Brandon Yott, product development and marketing manager for Agromart. “If you don’t use that tank-mix option right, you can lose both your glyphosate and nutrients.”

While the common recommendation is to spray manganese eight to 10 days after a glyphosate application, some growers think the extra pass is not worth the cost. Also, the weather conditions may prevent the manganese application even though farmers are willing to absorb the extra expense. “There are a lot of acres of beans out there that should be sprayed with manganese, but the guys just don’t want to make that second pass,” says John Waters, certified crop advisor with Lakeside Grain & Feed in Forest, Ontario.

In an effort to find a compromise, Waters and his Lakeside colleague Brian Hoven, have been running field tests on Max-In. It is a product developed with built-in adjuvants that uses a highly soluble micronutrient source, which helps ensure the movement of micronutrients into the plant from the leaf cuticle. The product’s literature says the Max-In nutrients mix easily with other crop nutrients and crop protection products, including glyphosate-based herbicides.

In the same field, an area that was missed with the ammonium sulphate application had a solid flush of dandelions the following spring.

“Adjuvants make the environment better for the chemistry to work and the more soluble something is, the less the plant has to work,” says Yott.

To determine if Max-In would reduce weed control under field conditions in Ontario, Waters and Hoven mixed it with Roundup WeatherMAX and sprayed the combination in strip trials in the fall of 2008. They targeted large, intensive dandelion infestations in separate fields in Forest and Oil Springs. “It is one of the harder weeds to kill in the fall. So if there’s going to be a problem, we figured it would show up,” says Waters, explaining the rationale for using dandelions to test the efficacy of the glyphosate with manganese.

Three combinations were tested and compared: glyphosate; the glyphosate-

manganese mix; and a mixture of glyphosate, manganese and Crimson (an ammonium sulphate product). Ammonium sulphate is used to tie up the cations in hard water, thereby increasing the availability of glyphosate for the plant.

When they went back to check their fields in the spring, Waters and Hoven had different results. Hoven saw little or no difference, saying he did not see any dandelions in his test strips. He also saw one area of solid dandelions in a small stretch that did not receive an application where he drove too wide between the manganese and the Crimson tests. “I know there was weed pressure there. So I know it definitely worked; the manganese didn’t tie up the Roundup,” he says.

In application tests done following soybean harvest, dandelion control was achieved in the test strips with the glyphosate, manganese and ammonium sulphate combination.

Although the Crimson did not seem to offer an extra benefit, Hoven says he would not remove it from the mix. He conducted his tests in early October following soybean harvest. Had he waited another three weeks, Hoven suspects the Crimson would have had a greater impact.

Yott concurs, saying research by Dr. Peter Sikkema of the University of Guelph, Ridgetown Campus, has shown that mixing an ammonium sulphate water conditioner at higher rates can help counteract the antagonism and the loss of weed control. “Crimson reduces the tie-up of glyphosate, manganese and other cations in the tank, ensuring the chemistry moves through the wax of the leaves on the dandelions, in this case, allowing them to take in the glyphosate better,’’ says Yott, who adds that the water conditioner is not a permanent solution to the problem. He says “it buys time” because the ammonium sulphate will eventually release the glyphosate, which will then bind with other cations. It appears as though the colder

conditions were a factor in the other test. Waters, who conducted his trial two weeks later and in colder temperatures, says there were discernible differences. “You could see every line,” notes Waters. He estimated that there was 75 percent weed control in the glyphosatemanganese strip; 85 to 90 per cent in the glyphosate-manganese-Crimson strip; and the strip sprayed with just glyphosate was clean.

Next steps

Testing the efficacy of WeatherMAX was just the first step of the assessment. Hoven and Waters would like to test more glyphosate products as well as analyze manganese performance during the growing season. “We’ve proven that the Roundup wasn’t tied up in a fall burn-down (in one trial). We’re now going to test it in-crop and see if we’re losing any manganese effectiveness,” says Hoven.

Hoven is planning to conduct more trials that will involve one strip with glyphosate, one with manganese and

one with glyphosate plus manganese. He adds that the results could reveal some key benefits for soybean growers if the glyphosate-manganese combination works well. “We have quite a few guys in our area that are finding a yield kick from manganese. If we can find something that works, then it will really improve yields.”

The other potential benefit is the convenience of one application. While Yott says the second pass of spraying manganese a few days after the glyphosate application is still preferable, growers may have another choice. “We’re looking at an option for a grower to eliminate a pass if that is what his desire is. The big thing is that the guys can put it (manganese) on when the plant needs it, and while they’re putting their glyphosate on already,” says Yott. “And if they can’t get that separate pass, for whatever reason, we have an option for them where they can still get some of the value of the manganese in their crop without compromising the performance of their glyphosate.” n

Customers worldwide trust Snobelen Farms to deliver Identity Preserved soybeans. A family business established in 1971 that purchases Identity Preserved soybeans province wide, processes and markets soybeans globally. Snobelen Farms continues to evolve with new technology and seed varieties to meet customer demand.

Snobelen Farms sources the best genetics from top soybean seed breeders and multiplies it to marketable quantities for sale under the SeCan, Hyland and Advantage brands.

Premium enhanced programs are offered for Identity Preserved varieties such as OAC Ginty (2850 HU), OAC Wallace (2750 HU), OAC Lakeview (2700 HU), or S03W4 (2650 HU).

Lucknow, Ontario CANADA

Tel.: 519-528-2092 www.snobelengroup.com

Plant BreedIng

Low-linolenic soybeans lose ground in Ontario

by Heather Hager, PhD

Multiple factors likely contributed to fewer acres planted.

Although low-linolenic soybean contracts have boomed in the United States, they have declined in Ontario. Fewer acres of Monsanto’s Vistive soybeans were planted in 2009 than in the first two years they were offered, despite the consistent 25-cent per bushel premium offered to grow them. “I think there were only 3000 or 4000 acres in the ground in 2009,” says Dan Wright, business development lead for Monsanto. “Originally, we had up to 10,000 acres.”

Low-linolenic soybean oil is targeted to the food industry as a heart-healthy oil. The decreased levels of linolenic acid increase the stability and slow the spoilage of the oil, preventing the need for hydrogenation, which can create unhealthy trans fats. Thus, the value of low-linolenic soybeans is in extracting the oil. And because soybeans are only about 20 percent oil in composition, it is much more cost effective to extract the oil locally and then ship it than it is to ship the whole soybeans. “When we launched the Vistive soybeans, we were trying to build the market and get some processors (crushing facilities) online. We guaranteed the growers a premium and viewed it as market development, to highlight the identity preservation capabilities of growers in Ontario and try to drive some of the market,” explains Wright. Unfortunately for Ontario growers, the local large crushing facilities have not yet provided segregated processing for these specialty soybeans. The soybeans must be shipped a long distance to facilities in the United States, and the added freight cost reduces the value of the premium.

Other options more profitable

Although the lack of a local crushing facility is a critical factor, it was likely not the only one that affected acres of low-linolenic soybeans in 2009, says Jim Campbell, general manager of Agris Co-operative, in Chatham, On-

tario. “We don’t have any Vistive contracts for the harvest this fall. We were offering one, but growers chose not to grow them.” He thinks two other factors contributed to the decision not to grow low-linolenic soybeans.

“First of all, the premiums were much higher for food-grade soybeans this year than in prior years. So, if they were an identity-preserved grower, they got a higher premium to grow food-grade soybeans. The other thing was the introduction of Genuity Roundup Ready 2 Yield soybeans. For growers that wanted a Roundup Ready soybean, the predicted yield improvement of a Roundup Ready 2 Yield, for some growers, made the economics of it surpass those of the Vistive for the 2009 harvest.” But, notes Campbell, these factors could differ from year to year.

Still, what does this mean for other specialty soybeans that are coming

down the pipeline?

High-oleic, omega-3, stearidonic acid, high beta-conglycinin: these are just some of the traits that are newly introduced or are in research and development. For those traits that are oils, a local crushing facility will be key for Ontario growers to extract their full value. “It’s one thing to grow them, but if we’ve got to truck them out of the country to get them crushed, it kind-of defeats the whole purpose of growing them here,” remarks Dale Petrie, Ontario Soybean Growers (OSG) general manager. “That’s why we’d like to see a specialty crush facility right here in Ontario.” Without a local, flexible crushing facility, he also fears that the larger seed companies might be less likely to put the new genetics into short-day soybeans suitable for northern growing conditions.

An OSG and Ontario government

Trucking low-linolenic soybeans to crush facilities outside Canada reduces the profitability of any premiums.

Plant BreedIng

The lack of a dedicated crush facility cannot overcome the wealth of heart-healthy benefits provided by low-linolenic soybeans.

co-funded study supported the feasibility of a crushing facility that would process 1000 to 1200 tonnes per day of seed and could switch among various crops and oils. The study was on behalf of Agris Co-operative and Suncor Energy, which markets gasoline under Sunoco and Petro-Canada brands. The two companies are looking at the synergies of establishing a facility at Suncor’s corn-ethanol plant in Sarnia, but the project has been on hold since January 2009 because of the economic downturn. Campbell estimates that even if the project were at full steam today, a functioning facility would still be about 24 months away. “We’ll be back more seriously looking at it later this fall or early in 2010,” says Campbell. “Our observations today are that the recession has affected many things, including consumer willingness to pay for some of these more premium oils that can be produced. We do believe that as the markets recover, we will go back to a segregation of heart-healthy oils and specialty segregated oils.”

Only when all the factors align successfully will this new market really be poised to get off the ground. “We’re talking about a plant that would cost in excess of $100 million to construct, so one has to be certain that the market demand and economics are good enough to manage the risk,” says Campbell. “We still believe the opportunity’s there. It’s just a matter of timing.” n

MachineryManager COMBI ne S

For all of the precision and planning that goes into seeding and scouting, fertilizing and spraying, the ultimate measure of success in farming is measured by the combine. Today, it not only cuts and gathers, it can also provide information on a variety of production parameters, all of which can lead to betterinformed decision-making, and better production totals in future seasons.

Thanks to the efforts of our Western Canada field editor, Bruce Barker, Top Crop Manager can offer you this worthwhile and valuable resource tool for quick and easy reference, as well as the latest perspective on managing combines from a farm business-management point of view. In all, seven

manufacturers have contributed specifications for eight different series or classes of combines.

Once again, we have streamlined the tables and specifications, providing basic charts and write-ups on each manufacturer, while offering the complete specs from our website. Just go to www.topcropmanager.com for more information.

We also advocate that you consult with your local representatives, from equipment manufacturers to dealers to other trusted agronomy professionals. They work hard to keep up with the latest developments, and their expertise is a valuable resource for you and your farm.

Ralph Pearce, Editor, Top Crop Manager

Combines – MACHINERY MANAGER

Case IH Axial-Flow Combines

For more than 30 years, farmers have trusted Case IH, the inventor of single rotor technology, to keep harvesting simple. Available in every combine class, Axial-Flow technology continues to meet the demands of every operation. Case IH Axial-Flow models include the new 7088 and the redesigned 7120, as well as the new Axial-Flow 9120 harvesting behemoth.

The 20 Series combines are designed for larger operators looking for high-end features like CVT drives and rotor-reversing. The 88 Series models are redesigned with more horsepower and grain tank capacity. Both series have a similar, modern family look, with interchangeable headers.

Regardless of series, size or class, six core principles drive every Axial-Flow combine:

Simplicity – fewer moving parts for better reliability and easy service

Grain Quality – gentle grain-on-grain threshing minimizes grain damage

Grain Savings – through thorough threshing and efficient separation

Crop Adaptability – harvests more than 80 types of grains

Matched Capacity – optimizes crop flow and productivity

Resale Value – impressive resale value maximizes investment

Go to www.machinerymanager ca for further specifications and links to Case IH Axial-Flow combines.

AGCO’s Massey Ferguson 9005 Series, Gleaner A6 Series, and Challenger 600B Series Axial Rotor Combines

All from AGCO Corporation, the Massey Ferguson 9005, Gleaner A6 and Challenger 600B Series Axial combines share the same platform and many of the same features across brands and models.

The Class VI machines feature a 44-inch feederhouse, while the Class VII and VIII machines have a 55-inch feederhouse. The exclusive helical vane feed conveyor receives the crop from the feederhouse and centrally feeds the crop from the bottom while eliminating any stones into the rock trap. The Class VI and VII machines feature a 140 inch x 27.5 inch (3,556 x 700 mm) rotor while the class VIII machines have a 140 inch x 31.5 inch rotor. The long rotor is gentler during threshing and reduces grain damage.

The inline cleaning system eliminates any need of auger beds or discharge beaters. The cleaning system incorporates grain pan technology with opposing shoe motion creating a simple and reliable system, which provides a nice clean grain sample. Optional electric chaffer and sieve adjustment can be made on the ground from the rear left side of the combine or using the C2000 terminal while seated in the cab.

A 300-bushel grain tank is standard on the Class VI and VII machines. Class VII machines can be equipped with an optional 350 bushel grain tank while that option is standard equipment on the Class VIII machine. The “Direct High Volume” unloading system provides an industry leading 4.5 bushels per second at peak unloading rate and averages 4.0 bushels per second through the entire unloading cycle. The clean grain elevator system features a 12 inch diameter bin fill auger providing more capacity for high yielding conditions.

Combines – MACHINERY MANAGER

Gleaner A6 Axial Rotor Combines

Ferguson 9005 Series Axial Combines

Massey

Combines – MACHINERY MANAGER

John Deere 70 Series STS and T Series Combines

John Deere combines come in two harvesting separator configurations: T670 (tangential-tine separator) and STS (single-tine separator) combines.

The 70 Series STS Combines provide unprecedented rotary threshing and separating performance and capacity in all crops and conditions. The unique single-tine separator and exclusive TriStream crop-flow design provide superior material-handling performance in all conditions and higher levels of crop-harvesting capacity, as well as excellent grain quality. Four models ranging from Class V- through Class VIII-capacity size are available to match customers’ individual harvesting needs.

The T670 provides customers with unprecedented high-quality straw residue while delivering the highest productivity capable of a walker combine. The T670 is sized to deliver Class VII-size combine capacity specifically geared to small-grain harvesting.

All 70 Series Combines have built-in performance, safety, service and reliability features to make harvesting easier and more profitable for the customer.

For model year 2010, John Deere 70 Series Combines deliver performance that endures through advanced integrated technology, distinctive quality and reliability, and definitive performance.

From a larger header that maximizes harvesting operations to combine enhancements that increase performance, customers will appreciate the 70 Series STS Combines’ ability to get more done—in less time with less effort.

Go to www.machinerymanager ca for further specifications and links to John Deere 70 Series STS and T Series combines.

Gleaner R6 Series Transverse Combines

The Gleaner R6 series transverse combines take the proven Natural Flow rotary design to a new level of grain handling.

The R6 series feature a 39 inch feederhouse with a four-strand feed chain. A second feed chain conveys the crop mat into the processor in a smooth, natural flow, never changing direction. The unique rotor cage provides 360 degrees of quick separation for grain, and some small material other than grain.

The exclusive two-stage cleaning system on the R6 series with distribution auger and accelerator roll technology provides the industry with the cleanest bin sample and minimum slope sensitivity. Distribution augers uniformly distributed the crop to the accelerator rolls. The accelerator rolls propel grain four times faster than free fall through a high velocity air blast on to the grain pan. The unique two stage cleaning system provides a stream of air to blow lighter chaff out the rear of the machine without reaching the grain pan while the second stream of air provides finish cleaning on the shoe.

The swivel unloading system uses an efficient twoauger design that provides an impressive unloading rate and superior grain quality with reduced horsepower requirements. The 12 inch grain tank cross auger conveys crop over to the 14 inch unloading auger resulting in an unloading rate of 4 bushels per second. The added unloading auger length accommodates larger grain carts and trucks as well as greater header widths.

Combines – MACHINERY MANAGER

New Holland CX8000 and CR9000 Combines

New Holland’s CX8000 Super Conventional combines feature the industry’s fastest unloading rate and a cab that provides superior comfort and control. The CX8000 harvesting system’s massive capacity includes unique threshing and separating systems. Nearly all the grain is separated by a patented rotary separator before it is delivered to the straw walkers. The rotary separator removes 50 to 70 percent of the grain passing over the cylinder/concave before it moves to the straw walkers. Two speeds and two clearance settings allow the grower to adjust to changing conditions and crops.

The state-of-the-art Harvest Suite cab features an industry-leading 110 cubic feet of interior room for unrivaled control and comfort and view to the headers and stubble.

New Holland CR9000 Twin Rotor combines deliver the industry’s largest harvesting capacity along with impressive grain quality. The CR9080 model is the industry’s largest combine, delivering the most horsepower and capacity in North America. New Holland’s exclusive Twin Rotor design generates more centrifugal force than any other rotary combine for faster separation, higher grain quality, larger capacity and more even grain distribution on the cleaning system.