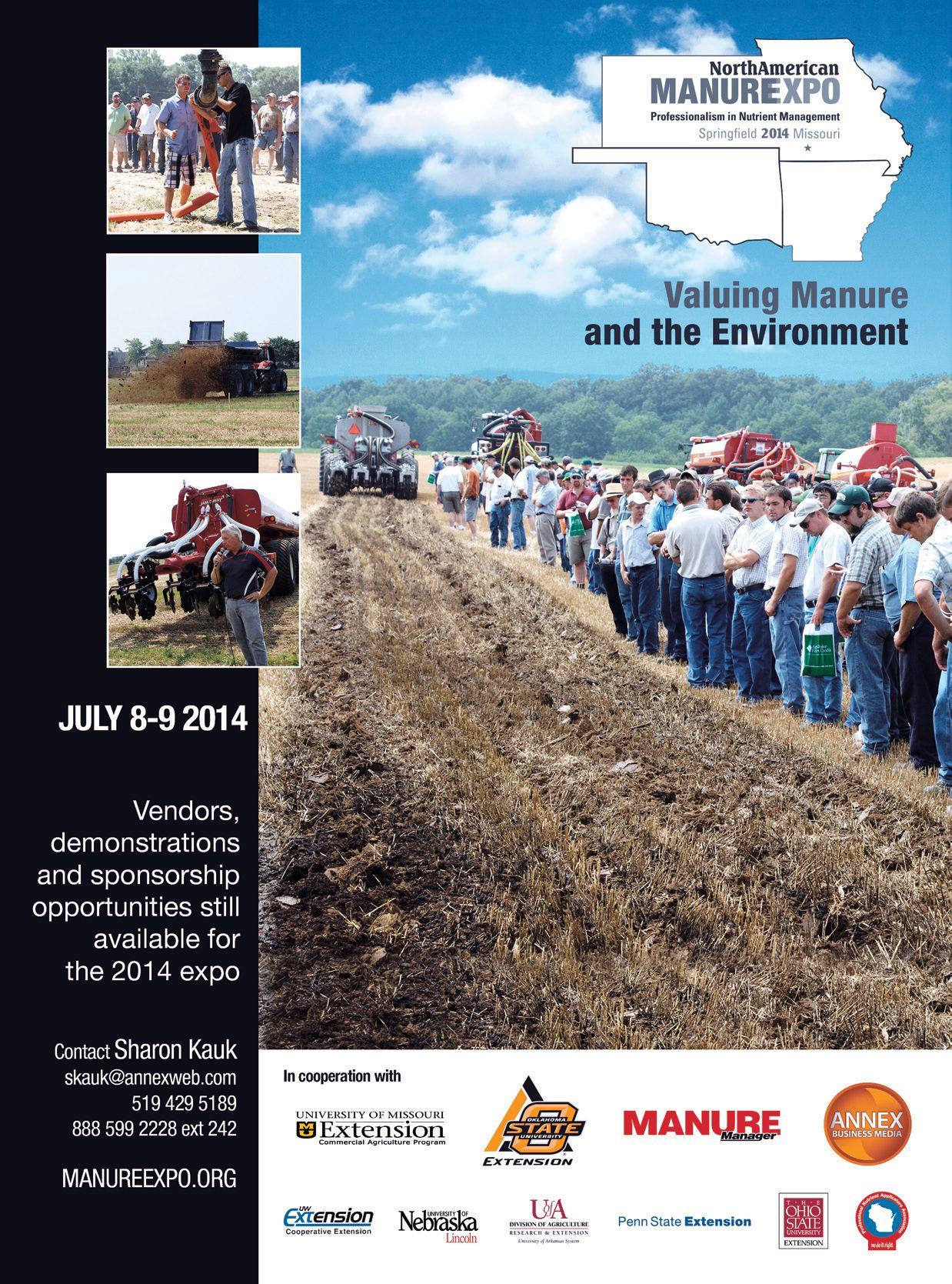

TOP CROP MANAGER

Early warning systEm for disEasE

New tools to monitor airborne pathogens

PG. 5

Compromising bordErs

Invasive weeds on the rise

Pg.18 grain bin gamE plan

Safe tips for proper grain bin storage

Pg. 30

New tools to monitor airborne pathogens

PG. 5

Compromising bordErs

Invasive weeds on the rise

Pg.18 grain bin gamE plan

Safe tips for proper grain bin storage

Pg. 30

MANA Canada HerbicidesSame active as Phantom™ (Imazethapyr)

Arrow® (Clethodim)

Bison® (Tralkoxydim)

Badge®II (Bromoxynil & mCPA Ester)

Thrasher®II (Bromoxynil & 2,4-D Ester)

m

Bromotril®II (Bromoxynil) Pardner®

Bengal® WB (Fenoxaprop-p-ethyl) Puma® Super

Diurex® (Diuron) Karmex®

MANA Canada Insecticides Same active as Silencer® (Lambda-cyhalothrin) matador®

Pyrinex® (Chlorpyrifos)

Alias® (Imidacloprid) Admire® and Stress Shield® Apollo® (Clofentezine)

MANA Canada FungicidesSame active as Bumper® (Propiconazole) Tilt®

Blanket AP™ (Azoxystrobin & Propiconazole)

Mission® (Propiconazole)

Folpan® (Folpet)

(Iprodione)

At MANA Canada we believe that growers and retailers deserve choice in crop protection products. Our growing portfolio of strategic active ingredients is used in over 20 MANA Canada branded herbicides, fungicides and insecticides manufactured to the highest standards.

For the best return on investment, choose the MANA Canada advantage.

Amy Petherick

Stefanie Croley | aSSoCiate eDitor

“Most sunflower growers know during harvest it’s not if they will have a combine fire, but when.” This is the first sentence of an article I recently came across about a team of agricultural engineers from South Dakota State University (SDSU) who are developing a system to prevent combine fires – a widespread problem amongst sunflower producers.

That first line was enough to capture my attention. Dan Humburg, a professor at SDSU who led the agricultural engineering research team, noted in the article that harvesting sunflowers requires continuous attention and some producers won’t grow sunflowers at all because of the risks involved. It was discovered during the study that sunflower debris ignites at temperatures that are from 20 C to 30 C (68 F to 86 F) lower than corn or soybean residue, so the odds of a combine bursting into flames while harvesting sunflowers are high – too high, in my opinion.

The article goes on to describe the prototype system that Humburg and his team are developing. The system uses a fan to pull clean outside air (containing no dust) through a filter. It was tested in the 2012 and 2013 harvest seasons, and producers have seen great results, according to the article. The national Sunflower association became involved in 2013, and prototypes have now been tested in three operations. Currently, the research team is looking at testing the device on other crops – including soybeans – that create a heightened fire hazard for producers.

We’ll keep an eye out to see if this system crosses the border anytime soon. In the meantime, it’s another step in the right direction toward decreasing the rates of agricultural accidents and deaths. according to the Canadian agricultural Safety association (CaSa)’s most recent stats, 70 per cent of agricultural fatalities from 1990 through 2008 were machinerelated. But overall, Canada’s rate of agricultural fatalities declined by 38 per cent from 1990 through 2008 – an encouraging statistic.

March is a good month to be reminded of farm safety issues: besides celebrating Canadian agricultural Safety Week from March 9 to 15, it tends to be a slower time of year before planting season begins. When our schedules fill up, it’s easy to put things like safety on the backburner and focus on what’s happening in the present. But one week in March dedicated to talking about safety is not sufficient. accidents can happen year-round, and farm safety and accident prevention need to be top of mind no matter how busy you are.

We’ve highlighted a few safety issues and best practices in this edition. on-farm grain bin storage is on the rise, and with that comes the need for a reminder on proper grain bin storage and monitoring. Check out Grain bin game plan on page 30 for tips from the experts. and although we hope you don’t ever have to use it, a business safety plan is a great way to ensure you, your employees and your business are covered in case of an accident. paul Vaillancourt has more details on forming a plan fit for your operation on page 38 (and you can visit CaSa’s website at www.casa-acsa.ca for more information and ways to get your employees and family involved in farm safety).

But the conversation shouldn’t stop here. Have you ever had a gut feeling that something was about to go wrong? In the case of sunflower producers dealing with combine fires, Humburg (the agricultural engineer) says a grower in South Dakota could tell when a fire was imminent because of the odour coming from the combine. That’s what I call sensing a problem before it arises. Keep safety in mind and trust your instincts so you’ll be able to do the same.

Fredericks mfredericks@annexweb.com

MAIL AGREEMENT #40065710 rETUrN UNDELIVEraBLE caNaDIaN aDDrESSES TO cIrcULaTION DEPT. P.O. Box 530, Simcoe, ON N3Y 4N5 e-mail: subscribe@topcropmanager.com Printed in canada ISSN 1717-452X cIrcULaTION e-mail: subscribe@topcropmanager.com Tel.: 866.790.6070 ext. 202 Fax: 877.624.1940 Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

SUBScrIPTION raTES

Top crop Manager West - 9 issuesFebruary, March, Mid-March, april, June, September, October, November and December1 Year - $45.00 Cdn. plus tax

Top Crop Manager East - 7 issuesFebruary, March, april, august, October, November and December - 1 Year - $45.00 Cdn. plus tax

Potatoes in canada - 4 issues - Spring, Summer, Fall and Winter 1 Year - $16 CDN plus tax

All of the above - $80.00 Cdn. plus tax

Occasionally, Top crop Manager will mail information on behalf of industryrelated groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2014 annex Publishing &

Advances in DNA tools are enabling monitoring of the full range of airborne crop pathogens.

by Carolyn King

Improving Fusarium head blight forecasting, providing early warning of the arrival of a virulent stem rust pathogen, identifying emerging disease issues to be added to crop breeding programs – those are just a few of the possible future uses of a Canada-wide system for monitoring airborne pathogens.

The system is called aerobiota Monitoring and Forecasting network, or aeronet. a pilot project completed in 2013 showed that aeronet is capable of broad-spectrum monitoring of airborne bacteria and fungal spores. now aeronet researchers are working on enhancing the system’s capabilities. and they’re starting on the next step in aeronet’s development – to build practical applications so that timely, relevant pathogen data may be used by crop growers, extension agents, researchers and others.

a start in soybean rust monitoring aeronet grew out of an innovative system for early detection of asian soybean rust, a destructive disease spreading into north america. about a decade ago, a large group of U.S. government agencies, along with the ontario Ministry of agriculture and Food (oMaF), came together with soybean industry groups and researchers to launch the north american Soybean rust Monitoring network. The network’s public website provides real-time monitoring and timely information on soybean rust outbreaks to help growers in making fungicide application decisions.

Dr. Sarah Hambleton with agriculture and agri-Food Canada (aaFC) and albert Tenuta with oMaF were instrumental

in getting the ontario network going in 2005. By 2008 alberta, Saskatchewan, Manitoba and Quebec also had monitoring sites.

The network uses automated rain and air sampling equipment to collect samples. The airborne organisms found in these samples are analyzed with Dna-based techniques to quickly identify the presence of soybean rust spores.

The network also involves field scouting, sampling and lab analysis to validate the automated sampling system and to watch for other soybean pests. This additional work has led to the identification of other pest issues, like the soybean vein necrosis virus. “In 2011, we noted that some locations in Kent County and elgin County had unusual browning-purpling-yellowing of the leaves associated with the veins in particular. We identified the problem as soybean vein necrosis virus. That was the first time it had been confirmed in ontario,” says Tenuta, a crop pathologist and co-ordinator of the ontario network.

The information gained from this additional work was one of the things that sparked the aeronet pilot project. The idea was that perhaps the rain and air sampling equipment and Dna testing could be used to look for much more than just asian soybean rust spores – perhaps the system could monitor the full range of airborne fungal spores and bacteria.

aeroNet pilot project

“Without the asian soybean rust monitoring program as a foundation, we would not have started this work. They had already made a significant investment in infrastructure, like setting up the sample collectors, and they had a few years of collecting samples and extracting the Dna to look for asian soybean rust,” notes Dr. andr Lévesque, the aaFC mycologist who is leading aeronet.

“at the same time, the cost of Dna sequencing had started to plummet. When the first human genome sequence was completed about 10 years ago, the cost of that was $3 billion. Today the cost to sequence a full human genome is getting close to $1,000. That change has been transformative; it’s revolutionary,” he says.

“So we thought here’s an opportunity to exploit new sequencing technology while making use of existing Dna samples already available through the asian soybean rust system.”

Lévesque’s research team for the pilot project included oMaF’s Tenuta, Hambleton and others from aaFC, as well as people from the national research Council of Canada and the Canadian Food Inspection agency. The project received funding and support from a wide variety of sources such as aaFC’s growing Forward 1, the Canadian Safety and Security program, the federal genomics r&D Initiative, and the Canadian Bar Code of Life network. The ontario component of the project received support from oMaF and grain Farmers of ontario.

The project involved a total of nine sampling sites from prince edward Island to British Columbia. It used the same three types of sampling equipment as the rust system: a passive rainfall collector, which is a big funnel that captures rainfall, dust and dirt; an active rain collector, which is a bucket with a lid and an automated system that opens the lid only when rain is falling, to catch clean rain water; and an air sampler, which sucks in air. Most sites have at least two types of sample collectors.

“In each sample, you’ll have hundreds or thousands of different kinds of organisms, so you have many, many genomes in the same sample. So instead of sequencing full genomes, we target one region of the genome – one ‘marker’ – and we sequence that marker across

all the different organisms,” explains Lévesque. “Some call this marker a ‘Dna bar code.’ It’s a region of the genome that allows you to separate species. It’s only about 0.001 per cent of the genome, but

it’s the same 0.001 per cent of all the organisms in the samples.”

There are about 25,000 to 100,000 Dna bar code sequences per sample. Those Dna bar codes are compared to

Meet the team that’s tough on weeds. Guardian® herbicide delivers maximum knockdown and residual activity on hard-to-kill weeds like dandelion and annual sow thistle. And if you’re looking for increased protection, Guardian® Plus contains an additional mode-of-action designed to control Eastern black nightshade, and herbicide-resistant pigweeds and lamb’s-quarters. Get the protection you need to give your IP and GT soybeans a clean, weed-free start. Questions? For more information, please contact your retailer, call your local DuPont rep or the DuPontTM FarmCare® Support Centre at 1-800 - 667-3925 or visit guardian.dupont.ca or guardianplus.dupont.ca

a Dna bar code reference database to determine the identities of the different species. The reference database already has the Dna bar codes for thousands of fungal and bacterial species, and it’s getting larger and larger as scientists expand our knowledge of microbial Dna

over the course of the pilot project, the aeronet team processed 350 air and rain samples from across the country and generated 55 million Dna bar code sequences.

“It is unprecedented to be able to do this kind of thing,” says Lévesque.

“The wonderful thing about being able to assess the risk of airborne diseases early is that it provides ample opportunities for management to be initiated.”

The pilot project showed that this approach works. aero net is a rapid, accurate system for detecting, identifying and counting a wide range of airborne organisms sampled directly from the environment.

The project also emphasized that ‘bioinformatics,’ the analysis of biological data, is a big challenge because of the enormous amounts of data generated by sequencing the D na bar codes for thousands of organisms in every sample. Lévesque notes, “You’re always running out of disk space, running out of computers to run the analysis, and running out of skilled people who can do the programming.”

a s a result, the researchers have temporarily paused their data collection efforts and are focusing on developing faster tools for analyzing the data.

The project also highlighted some key gaps in the reference sequences, so the researchers now know where to target their resources for expanding the reference database.

a s well, the project showed that the type of sampling equipment can affect the types of organisms captured in the equipment. “ even though the collectors were side by side and the samples were collected on the same date at the same time, [for some groups of organisms] we would find a lot of one species in one type of collector and none of that species in another type of collector. For other groups, the type of collector didn’t matter; the same species would be in all three collectors,” says Lévesque. according to Lévesque, those differences likely have to do with the ecology of how the various species disseminate. “When the rain falls, it flushes the air out of all the spores and dirt and everything. So in the active rain collector, you are getting a snapshot of the spores in the column of air roughly above the collector, depending on the wind. Some spores fly higher up and will need the rain to bring them down. Some are probably flying lower all the time, so the air samplers, which are just a metre above the ground, can pick them up 24/7. and the passive rain collector continually collects dirt, dust and other particles in the air, along with any rain. In those passive collectors, we picked up things that I would have never thought were in the air – we even picked up nematodes [tiny worm-like organisms].”

“In the future, we want to deliver real-time information to producers – information for forecasting or disease modelling, but also looking at pathogen loads and what species are out there. We’re trying to put all the pieces together that could lead to development of a broad-spectrum airborne pathogen early warning system,” says Tenuta.

“Ideally the system could be established throughout Canada or north america as local networks or regional monitoring systems. This system allows you to not only detect what you have but to watch for new issues, so you can prepare for up-and-coming diseases of concern. You could use it to watch for threats like Ug99, the stem rust pathogen that is of great concern to the wheat industry and is starting to move into different parts of the world. really, you could use this for any airborne disease problem because it’s based on D na – as long as you can identify the D na , you can develop a system.”

right now, the aero net team is starting on the system’s next phase: development of some specific practical applications for use by crop growers.

Tenuta sees many exciting possibilities. “The wonderful thing about being able to assess the risk of airborne diseases early is that it provides ample opportunities for management to be initiated. For instance, it could be used to give growers a heads-up to scout their fields. o r if foliar fungicide applications were necessary, you could do them in a timely fashion, while the disease levels were still low or the disease was still in its early stages, so you could get the most from your fungicide and reduce the potential yield impact.”

The team is currently exploring how to use aero net data to improve Fusarium head blight forecasting. “Farmers are already using forecasting systems for diseases like Fusarium head blight and potato late blight. But these systems are strictly based on weather conditions; they just assume the inoculum is present but that is not always true. If farmers had additional data about whether the inoculum is present, then they could plug that information into these forecasting systems to improve the accuracy of the forecasts,” notes Lévesque.

He sees huge potential for aero net’s early warning service because it could be used for any crop. He hopes grower associations and other crop industry stakeholders might be interested in partnering with his team to target some priority pathogens, work out how to use the aero net data to help growers in managing those pathogens, and develop ways to deliver real-time information to growers.

“We would like to take this system to the next step, including exploring ways to enhance its diagnostic capacity so you could have samples processed within a few days and working out the logistics of rapidly delivering the information to growers,” notes Tenuta.

a s well, Tenuta and Lévesque see many other ways aero net information might be used. For instance, it could help crop pathologists monitor changing disease patterns, or inform crop breeders about emerging disease issues to address in their breeding programs, or be used as part of a public security system to watch for nasty organisms. In addition, researchers from other disciplines are already contacting Lévesque to find out if aero net has detected various species of interest and to ask for advice on how to do this kind of monitoring work for their own area of specialization.

aeroNet’s passive rain collectors continually collect dirt, dust and other particles in the air, along with any rain, so they capture many different organisms.

So aero net has already made substantial progress. and, although there is more work to be done, it looks like the system has the potential to offer some real benefits to crop growers and many others in the years ahead.

We aren’t surprised to hear words like impressive and dependable when people talk about NORAC’s award winning Hybrid Mode™.

Hybrid Mode™ reduces the need for the operator to take manual control of the boom while spraying lodged, thin or uneven crops.

What you may be surprised to hear is that our Hybrid Mode™ advanced crop spraying feature is exclusive to NORAC Spray Height Control Systems.

by Melanie epp

The importance of insect pollinators to both the agricultural industry and the environment cannot be understated. Their presence is vital, which is why a team of key individuals was organized to conduct research on neonicotinoids and their effects on pollinators last summer. The team included Tracey Baute, a field crop entomologist at the ontario Ministry of agriculture and Food (oMaF) and Ministry of rural affairs (Mraa), art Schaafsma, a professor of field crop entomology with the University of guelph ridgetown Campus, and Cynthia Scott-Dupree, a University of guelph researcher. Their research has resulted in new recommendations for the 2014 planting season, including a new requirement for seed lubricant products. It is their hope that the new recommendations will help to reduce the risk to bees and other insect pollinators in ontario.

The research

neonic studies have identified a few routes of exposure, Baute says, but the most significant one is still the contaminated dust coming off of vacuum planters. researchers wanted to know where the

contaminated dust was going and what it was affecting.

“There are significant levels that can escape those planters,” she says. “and not only do they escape the planter in the immediate vicinity, but they do get picked up and carried with the wind outside these fields, and in particular, onto flowering vegetation downwind including weeds and trees.”

Funding came from all fronts; the Corn Dust research Consortium (CDrC) provided some, but oMaF put up the majority. a partnership with grain Farmers of ontario and further funding through the Canadian agricultural adaptation program helped tie all of the research together.

The CDrC, a north american not-for-profit initiative supervised by the pollinator partnership organization out of San Francisco, asked Baute and her team to answer just two questions. First, they wanted to know what flowering resources bees were foraging on at the time of corn planting. They also wanted to know the

aBOVE: dust traps were placed both horizontally and vertically downwind from planters to collect settling dust.

Field envy. Included with every box of our glyphosate-tolerant soybean herbicide.

Fast, complete burndown that lasts.

Nothing gives growers a feeling of pride like a great looking eld. And it’s one that’ll last thanks to Optill® herbicide. Of course, neighbours may be equally envious of the new Swiss Army watch you can earn during “The Time is Now” Offer.* Just watch the online module, enter PIN OPT357 by March 30, 2014 and purchase 1 case of Optill to receive yours. The time is now to visit agsolutions.ca/optill, and see what Optill herbicide can do for you.

*Full offer terms and conditions at agsolutions.ca/optill

Always read and follow label directions. AgSolutions is a registered trade-mark of BASF Corporation; KIXOR, and OPTILL are registered trade-marks of BASF SE, all used with permission by BASF Canada Inc. All other trade-marks are properties of

efficacy of modified seed lubricant products, in particular, Fluency agent by Bayer CropScience.

To answer the first question, researchers scouted the perimeter of 18 field sites weekly over six weeks to determine what flowering trees, weeds and shrubs were there. They collected pollen from pollen traps to see where the bees were foraging most. The big “aha” moment, says Baute, was when they realized that the majority of the pollen brought back to the hive comes from flowering trees, including willow, maple, hawthorn, apple and dogwoods, and that this matched the types of trees that were present around the fields.

“This tells us that we need to take all the measures necessary to contain that dust, or at the very least keep it down closer to the ground and reduce the risk of it being blown onto those flowering resources,” he says.

To answer the second question, researchers set up vacuum bags on the vacuum planter’s exhaust manifolds and dust traps to collect dust particles downwind from the planter, adjacent to the first pass. The traps were placed horizontally to collect settling dust, and vertically to collect dust travelling by airflow. The Ministry of the environment

• 9 paired fields (18 total) within 2 to 3 km of bee yards

• 16 row or larger vacuum planters

• 1 field of the pair planted with old lubricant

• 1 field of the pair planted with efP lubricant

also set up air samplers both upwind and downwind from the planters.

results from the vacuum bag test indicate that the use of Fluency agent at the recommended application rate reduced the quantity of neonicotinoid active ingredient escaping from vacuum planter exhaust by 21 per cent. The Health Canada pest Management regulatory agency (pMra) released a statement in January stating that Fluency agent is now the only seed flow lubricant permitted for use with corn or soybean treated with insecticides clothianidin, thiamethoxam, or imidacloprid.

Using oMaF funding, further research was conducted. Baute says they wanted to collect as many samples as possible, while they had the chance. First, they tested soil residue. preliminary research revealed that the half-life of neonics in ontario cornfields is likely around 0.5 to 0.75 years. However, it appears that neonic residues accumulate in dry soil dust on the soil’s surface as it is drying. This, says Baute, is a minor contributor to exposure when compared to what is exhausted from the planter itself but is still a risk and requires further investigation. Dust drifting from the fields may be another route of exposure.

Standing water was also tested for residue, and in some cases it contained problematic levels of neonics, particularly after replanting or heavy rains. The pollinator survey also showed some interesting results. The researchers looked to see what types of non-apis pollinators were foraging in the area and found plenty; Diptera, for one, were present, and in particular, Syrphids, as well as other bee species, including small carpenter bees, mining bees and sweat bees. Bee pollen samples revealed that honeybees will forage on corn and soybeans if nothing better is available to them, but field crops are certainly not their first choice. Finally, during corn pollination, concentrations of neonics were found in the pollen collected by bees, which shows that pollinating corn is sometimes a foraging resource.

The work involved in collecting this data was immense, especially given the time constraints. proposals were put in at the end of February; by mid-March, the researchers were collecting co-operators (growers and beekeepers), and Baute says the researchers were in the fields by the end of april.

The biggest hurdle was finding the cooperators needed for the project – both growers who met the CDrC’s criteria,

The mostpowerful farm implement in

The Connected Farm™ dashboard. Remote hands-on farming for the smartphone or tablet you already use. Covers thousands of acres in a single swipe. Reports the weather. Reads the market. Moves equipment. Monitors crops. Connects operators in the field to operations in the office. Makes real-time decisions real—in a snap. Only from Trimble Agriculture. See it at ConnectedFarm.com. Fleet management irrigation monitoring | weather and rain data | Field operations maps real—in a snap. Only from Trimble Agriculture. See it at |

and willing beekeepers located in close enough proximity to them. The farms they chose had to use large vacuum planters – at least 16-row planters or wider –and had to be fairly sizeable (80-acre or larger fields). Making the project even more challenging is the fact that all 18 fields were planted within a very short period of time. In fact, 13 of the 18 were planted in a four-day window, making for a very hectic few days.

“We were very aware of how thorough we needed to be, how we needed to ensure that we were taking samples correctly and properly storing everything,” says Baute. “The crew really knew the importance of ensuring cross-contamination of samples wouldn’t happen, and proper storage and labelling was critical.”

The study revealed that there isn’t one single solution to the problem, and the responsibility for reducing risk to pollinators is in the hands of all stakeholders.

“and that includes growers, beekeepers, industry, seed trade associations, CropLife and even extension to get the information out and try and make our best effort at reducing the risks for 2014,” she says. “To show that we can reach a balance and hopefully still be able to use the neonic seed treatments, where needed, and protect the bees.”

Recommendations for the 2014 planting season

after putting together their findings, oMaF and Health Canada have come up with a new list of recommendations for the 2014 planting season. The list of Best Management practices is as follows:

Read and adhere to the pesticide label and seed tag directions

In order to minimize risk to human health and the environment, follow the directions for use as outlined on the product label.

Use an integrated pest management system

Having a solid integrated pest management system in place is an integral part of insect control. evaluate fields to see whether or not there’s a high pest risk that warrants using treated seeds. also, before acting, be sure that if pests are present, they’re at threshold levels. only use insecticide if absolutely necessary. If it is necessary, choose a product with the lowest

effective seed treatment rate. Finally, talk to your seed dealer about non-insecticide treated seed. There are other options available.

Communicate with beekeepers good communication is key. growers should let beekeepers know the timing of their planting, so that beekeepers can take action to protect hives and ensure that they have clean water sources available.

Reduce dust exposure, particularly near pollinator habitat as previously mentioned, bees and other pollinator insects collect pollen from nearby trees and shrubs, as well as flowering crops and weeds. growers need to be aware that dust emitted from planter exhaust will land on foraging resources under all types of conditions. growers should avoid planting treated seed under very dry and/or windy conditions, as pollinator exposure can be increased.

Handle product with care growers should avoid generating dust when handling product. For obvious reasons, do not clean equipment near bee colonies or in areas where they may be foraging.

Decrease dust drift by managing plant equipment according to research, the use of vacuum planters creates insecticide-containing dust, which is released into the air via the planter’s exhaust system. exposure to this dust poses a risk to pollinators. growers should try to both reduce and control the dust that is exhausted from planters. Using deflector equipment, for instance, will redirect that dust towards the ground and reduce drift. Clean the fan housing and hoppers regularly between plantings.

Ensure proper cleanup and disposal although it might seem obvious, spilled seeds and dust should be incorporated into the soil or cleaned up off of the soil’s surface. Keep treated seed and its dust away from water sources, and do not leave empty bags in the field. Whenever possible, participate in seed bag collection programs.

Finally, always report suspected pollinator pesticide poisonings by contacting the appropriate federal or provincial authority.

It’s not just for bugs and diseases anymore.

by amy petherick

Insect invaders and windborne diseases are common foes of the average farmer but invasive weeds usually don’t take centre stage. expect that to change.

organisms with roots are less inclined to get up and travel, but the sneaky things are slipping into eastern Canada all the same and ambushing the unsuspecting. Just ask Sophia Boivin, who works for Quebec’s provincial ministry of agriculture, the Ministère de l’agriculture, des pécheries et de l’alimentation (MapaQ). She’s been working closely with the Canadian Food Inspection agency (CFIa) and le Centre de recherche sur les grains in Quebec to monitor and contain woolly cupgrass, the very first plant to be regulated by the CFIa.

Woolly cupgrass came to the United States from asia around the 1950s and was discovered in Quebec just over 10 years ago. “We tried to eradicate the weed, but it was not a perfect success,” Boivin recalls. “We have been able to manage the weed and we try to keep it restricted in a small part of the province.” Despite targeted herbicide applications in the fields, pastures and disturbed

areas along fences, ditches and roadsides where it’s found, the plant has proven more challenging to control than other annual grasses. growing between 30 and 200 centimetres high, with dark green, hairy leaves and a typically crinkled edge of the leaf blade, woolly cupgrass lives up to its name thanks to a velvety feel.

“Unlike other invasive species, we have more time with woolly cupgrass because it can only move with soil or grain, not with wind,” says Boivin. She adds she can’t stress to farmers enough the importance of ensuring any seed or farm equipment that they want to move between regions is as clean and as free of dirt as possible. according to the CFIa, about 58 per cent of all invasive alien plant species are intentionally introduced to Canada, most commonly for ornamental reasons. However, of all the alien plants

TOP: Invasive weeds like wild parsnip are sneaking into Eastern Canada and becoming more of a threat to producers, according to Kristina Pauk, an officer with the CFIa’s Invasive alien Species and domestic Program.

Weeds can be a detriment to your soybean crop. Fortunately, DuPontTM CanopyTM PRO contains two modes-ofaction to both manage troublesome weeds and help prevent resistance. Plus, if you tank-mix with glyphosate, you’ll be able to take advantage of three weed-busting modes-of-action. In addition, CanopyTM PRO delivers broad-spectrum residual activity on tough weeds like velvetleaf, dandelion and annual sow thistle. Give your crops the protection they need with CanopyTM PRO

Questions? For more information, please contact your retailer, call your local DuPont rep or the DuPontTM FarmCare® Support Centre at 1- 800 - 667-3925 or visit canopypro.dupont.ca

How soybean growers are using innovative agronomic tools to control weeds now and keep their options open for the future.

Back in the day, weed control was strictly a function of the present time. Growers needed to know which product would control which weeds in this year’s crop. Simple.

Over the past several years, though, growers have been coming to grips with weed control decision-making that’s far more complex. e question now is, what’s the best balance between today’s weed control and tomorrow’s agronomic challenges? at’s not so simple.

e reason, of course, is weed resistance. While resistance to various herbicide groups is well documented, the looming concern continues to be glyphosate resistance.

In Ontario, for example, glyphosate resistance has been associated with three weed species: giant ragweed, Canada eabane and common ragweed. It’s an inconvenience in corn, where growers have multiple modes-of-action available to control resistant weeds. In soybeans, with fewer alternate mode-of-action products, weed resistance is now a pressing agronomic issue. And although there appear to be some new technologies to mitigate the problem, the solutions will not be a simple x with a single new mode-of-action.

Multiple modes-of-action are recommended.

What’s the best way to manage the threat of weed resistance? Years back, the most prevalent advice was to sequentially rotate herbicides with di erent modes-ofaction. More recent research indicates a better approach is to combine products with di erent modes-of-action in the same spray.

As Dave Kloppenburg explains, DuPont Crop Protection has been building up its arsenal of available modes-of-action in soybeans, making it easier for growers to follow the best resistance management advice.

“Our product Classic®, a group 2 herbicide, is the heart and soul of our expanding weed control platform for soybeans,” says Kloppenburg, the company’s Row Crop Segment Manager. “Classic® plus glyphosate you know as Guardian®. We added a group 14 to that to create Guardian® Plus.

ese products have been weed control mainstays for growers and, because they deploy multiple modes-of-action, they’ve been valuable tools for managing the threat of weed resistance as well.”

In 2013, soybean growers gained another powerful, exible agronomic tool. DuPont™ Canopy™ PRO herbicide combines Classic® with metribuzin, a group 5 herbicide for Identity Preserved (IP) or GT soybeans. It can be used pre-plant or pre-emergence in a variety of tillage situations including no-till, conservation tillage or conventional tillage. Canopy™ PRO delivers powerful action against many annual grass and broadleaf weeds.

Canopy™ PRO also addresses the growing concern felt by IP and GT soybean growers about weed resistance. By bringing together active ingredients from Groups 2 and 5, it delivers extra protection against resistance. To diversify beyond a glyphosate-only approach, growers can tank-mix Canopy™ PRO with the glyphosate of their choice for no-till burndown applications.

Growers like the exibility that Canopy™ PRO provides. For GT soybeans, it provides a solid base of early weed control to help keep the crop weed-free during the early, critical trifoliate stages. For a complete program, growers can follow up with an in-crop glyphosate application.

In IP soybeans, Canopy™ PRO should be tank-mixed with a broad-spectrum group 15 pre-emergence herbicide to ensure a complete approach to weed control and resistance management. To manage volunteer corn and annual grasses, follow up with an in-crop application of DuPont™ Assure® II herbicide.

e good news, in Kloppenburg’s view, is that grower awareness of resistance has increased dramatically. ey are informing themselves of the need to strike the right balance between weed control in the present and future-minded resistance management.

“Canopy™ PRO is an e ective weed control approach that’s as good tomorrow as it is today,” he says. “You’ll control a broadspectrum of annual weeds, including herbicide-resistant biotypes, and help mitigate the threat of weed resistance in future years.”

suspected to have been accidentally introduced to Canada, 72 per cent are believed to have travelled into the country as a seed contaminant, entered as a forage stowaway, or hidden among some other plant product. additionally, the most popular destination for these hitchhikers (as observed between 2001 and 2005) is ontario, with Quebec and British Columbia nearly tied for second place.

Kristina pauk, an officer in the Invasive alien Species and Domestic program at the CFIa, says that although these problems have developed relatively slowly, expanding the regulated pest list last year was due.

“Sometimes there’s more of a focus on insects, but invasive plants are definitely a threat and, as farmers know, increase the cost of crop production,” says pauk. “In 2011, there was a shift from insects and diseases to invasive plants in general because there was an obvious need, and since october 2013, we’ve added 15 additional invasive plants to our regulated pest list.”

one of the species that joined that list last fall is jointed goatgrass. pauk says this species has only been found in two small sites within ontario so far, originating from western asia and southeastern europe and well known in the United States as an 1880s invader. In the western states, jointed goatgrass has become

one of the most difficult weeds to control because it is so genetically similar to wheat that it can cross-pollinate. It even looks like wheat, standing 40–60 cm tall, except for narrow cylindrical spikes and evenly spaced hairs extending from the leaf blades. a series of spikelets, partially embedded in the stem, contain seeds that easily contaminate wheat seed. pauk says that the best way farmers can minimize the spread of jointed goatgrass, is to buy clean grain, hay, straw and certified seed, ensure any equipment they intend to move from one region to another is free of plant materials, and generally remain on the lookout for unusual species.

“Just to increase awareness of the species we’re focusing on I think is the biggest key to stopping the spread and avoiding them being introduced in the first place,” says pauk. “once they are here it’s very hard to get rid of them.”

Dave Bilyea is a professor and researcher at the University of guelph’s ridgetown Campus who spoke to farmers about being aware of noxious and invasive weeds at this year’s Southwest ag Conference. His focus was on the carrot family of weeds, which includes plants such as giant hogweed, spotted water hemlock and goutweed, but he says most invasive plants do not directly impact agriculture as much as they impact

rural properties in general. But knowledge is power, so monitoring is key, especially if weeds are being exposed to non-lethal amounts of herbicide spray drift.

“Waterhemp is an invasive species to ontario. It is not native, but at the present time, is not widespread. In the areas where it does exist, such as essex County and Lambton County, it does need to be monitored closely because of its reputation of being a significant weed problem in the midwest United States,” Bilyea shares. He adds that wild chervil, a very aggressive plant in the carrot family that’s not palatable to livestock, is thriving in pastures in the grey Bruce area and warns farmers that “if you cut it up, the hay will go moldy because wild chervil doesn’t dry well.” one invasive species that does directly affect agriculture is dog-strangling vine, which is widespread east of Toronto, in woodlots especially. “It will grow over small dwarf trees in orchards and they call it the tree killer,” says Bilyea. It seems as though the list of things to look out for could go on forever. But his point is that invasives start with a small toehold and then encroach on fields after they have already dominated surrounding ditches or woodlots.

“plants that are invasive tend to be more aggressive, so don’t ignore an unusual patch of plants growing nearby,” says Bilyea. “It’s worth checking out because you just never know, and usually it’s nothing, but just being diligent is an important part of farming, I think.”

Many invasive species go unreported because they are misidentified, inhabiting areas where they’re not really noticed, or they’re not creating a nuisance at this time, he explains. Unfortunately, the opportunity to gain control of these plants is often during these periods of insignificance. not that Bilyea believes every alien plant in the country must, or can, be eradicated. He recommends that farmers simply keep an eye on garden cleanings near field borders (goutweed, for example, is still sold in a lot of nurseries, and garden centres only stopped selling giant hogweed less than a decade ago) and ask neighbours to look for suspicious areas too. If there is an alien invader in the midst, consult with a certified crop advisor and contact the weed specialists at the local ministry of agriculture or the CFIa.

The best way to keep your field looking good –and performing great.

Maximize your yield by keeping your corn crop free of weeds and looking its best. Simply tank-mix Vios™ G3 with glyphosate or Liberty ®. Just one 1.78L jug of Vios G3 treats over 40 acres of corn, and provides the broadest spectrum residual weed control available from an in-crop application. It’s the easiest way to keep your field looking its best – and your crop performing its best.

Learn more at BayerCropScience.ca/ViosG3

MIX IT UP

Weed out herbicide resistance. Vios G3 uses 3 different modes of action to help you control resistant weeds. Visit MixItUp.ca to learn more.

Make a scouting program your priority this year.

by amy petherick

Chore is a word that gets thrown around often on the farm but few tasks are as unanimously unpalatable among farmers as field scouting. armed with the right tricks and tips, however, an improved scouting strategy offers many farms a significant opportunity to recapture value.

Maintaining intuitive knowledge of fields was easy when the family farm was no more than 100 acres, but on larger acreages gathering this knowledge is a daunting task few farmers do well. Yet independent agronomists like e d Hanson, based in Durham County, o nt., manage to service thousands of acres. Though most of the work he does for farmers relates to fertility, Hanson is becoming more recognized for his field scouting services. His strategy is to focus on scouting plants at critical stages of growth that he thinks are most likely to influence yield and quality. Difficult as it is to make scouting a priority at the time, Hanson believes that the most important time to be walking fields is immediately following emergence.

“Sometimes there are in-season decisions to be made but for the most part, we just document what’s going on so that we can address them moving forward with a proactive strategy rather than a reactive strategy,” says Hanson. “g etting caught up in reactive actions sometimes means the damage is already done.”

By looking ahead of problems, Hanson has eliminated emergency spray applications completely for some clients. Field histories that indicate high risks for a particular pest receive preventive measures when conditions are right, and that’s how he earns his keep. Knowing how much money it can save, Hanson is bewildered that farmers who claim scouting is their least favourite job to do don’t just employ someone else to do it.

“g uys will spend a lot of money on iron but they don’t see the value in spending $5 per acre on scouting,” he says. “It’s a tremendous opportunity for improvement and it’s coming around but I really think it’s going to separate the good managers from the rest.”

In Huron County, Joanna Wallace dairy farms together with her husband. She’s been working in ag retail and agronomy since 1999, scouting a large number of acres for other farms every year and putting her skills to use on her own farm as well. If any of her fields are going to suffer from a lack of attention though, she admits they’re usually her own, which is why she would agree that hiring the problem out is likely the best way

Technology is changing the way scouting data is managed, replacing paper and simplifying the job.

to address scouting.

“I think if you’re doing it yourself, you just have to be prepared that things may slip by,” she says.

Wallace makes scouting a priority by including it as part of her overall crop strategy immediately at the beginning of every new calendar year. Through the winter, both she and Hanson spend a great deal of time reviewing the previous year’s records, not only to get the appropriate inputs ordered, but also to create watch lists for each field. “I’m planning the fertilizer and chemical for the year but I’m also looking at soil samples and weed history, jotting down notes on what symptoms of deficien -

cies or weed patches I need to be looking for when I’m scouting,” says Wallace. “Yes, there’re always last minute changes in the spring, but most of those weeds that are going to emerge aren’t going to change.”

In her experience, committing to a scouting program is the toughest in the early years but becomes easier as the eye becomes more trained and hot spot patterns emerge more quickly, not only in subsequent years, but even during the first season. at bare minimum, she recommends having a trowel in hand while scouting in the field and also suggests being prepared with a field history, a good weed identification book, and the o ntario Ministry of a griculture and Food ( oMa F)’s a gronomy g uide for Field Crops ( p ub 811) and g uide to Weed Control ( p ub 75). These guides outline a number of key scouting practices – including proper net sweep protocols, which path to take through the field in order to find certain pests – and offer thresholds to help determine next steps for the farm manager. But the most

• The AI3070 utilizes a unique, patent-pending design optimized specifically for fungicide application

• The 30° forward tilted spray penetrates dense crop canopies, while 70° backward tilted spray maximizes coverage of the seed head for excellent disease control

• Air induction technology produces larger droplets to reduce drift

“ The AI3070 increased overall deposit amounts and uniformity compared to the industry standard single and twin fan nozzles.”

TOM WOLF, RESEARCH SCIENTIST AT AGRICULTURE AND AGRI-FOOD CANADA standard

by Blair andrews

Encouraged by recent discoveries and increased interest, scientists are focusing more on the idea of developing crops that can get their own nitrogen fertilizer.

Dr. Krzysztof Szczyglowski, an agriculture and agri-Food Canada research scientist at the Southern Crop protection and Food research Centre in London, ont., is part of the global effort to optimize the growth of crops while reducing the use of synthetic fertilizers.

Szczyglowski’s lab is generating more knowledge about nitrogen-fixing symbioses of legume plants. While it still may be years away, he believes the research could lead to breeding varieties of cereal crops, like corn and wheat, that would have enhanced abilities to acquire nitrogen.

a first step is to gain a better understanding of the legumes.

“Legumes can take advantage of the atmospheric nitrogen as a source of natural fertilizer to support their growth and productivity while other plants can’t,” he says. “and the ability of those plants is due to their symbiotic or beneficial interaction with naturally occurring bacteria in the soil.”

Szczyglowski’s research focuses on understanding how this beneficial relationship develops. one of the main aspects is to learn why these specific soil bacteria can enter the root and why the plant then builds nodules. He likens the process to building an apartment complex.

“When a plant recognizes the presence of the beneficial soil bacteria, it induces the developmental program, which then builds that housing apartment, which we call root nodules, and that housing apartment will accommodate the bacteria,” he says. once colonized, the bacteria reside within the nodules and fix atmospheric nitrogen to ammonia.

“If we fully understand that process, then perhaps we are going to answer the question: Can we breed new varieties of crop plants, mainly cereals, which would be better prepared or provide their own food, so to speak?” says Szczyglowski.

While scientists have studied the relationship between nitrogen-fixing bacteria and plants for more than 100 years, Szczyglowski predicts there will be some exciting results in the next 10 to 20 years.

part of the optimism stems from a discovery about the genetic composition of the cereal crop plants. Szczyglowski says most re -

Pictured are nitrogen-fixing nodules in the model legume, Lotus japonicus. This plant is being used in many research laboratories, including the london lab of dr. Krzysztof Szczyglowski of agriculture and agri-Food Canada, to seek answers to questions concerning nitrogen-fixing plants and beneficial bacteria.

searchers thought legumes had gained something novel related to their nitrogen-fixing ability through evolution and that the non-legumes did not have this capability. But the modern tools of genetics and genome research have revealed that the “backbone” for nitrogen-fixing symbiosis already exists in most plants,

Under 40? Love agriculture? Take the next step with up to $500,000 to purchase farm-related assets. With variable rates at prime plus 0.5% and no processing fees, you can make your move. fcc.ca/YoungFarmerLoan

including cereal crops.

“That was probably one of the most important discoveries because that told us that something has been tweaked in legume plants in order to make that process viable,” he says.

one of the next steps is to learn how to tweak the machinery in other plants to activate the signalling for nitrogen-fixing symbiosis.

Szczyglowski’s lab contributed to the discoveries of many genes that are essential for this symbiosis in legumes. an exciting contribution was identifying a key gene in the plant genome that is related to the process of forming the root nodules.

“The gene, when stimulated, allows the legume plant to build the root nodule,” says Szczyglowski. “Why (non-legume) crop plants can’t build root nodules is the question.”

as all organisms are built to protect themselves from invaders, another important part of the research focuses on why legume plants allow the beneficial bacteria to enter their roots while keeping other bacteria outside. Szczyglowski says understanding that process will be critical when it comes to finding ways to breed new varieties that will be better prepared to acquire and use nutrients.

“In people’s minds, that only means we’re going to have to use genetic engineering to do this,” he says, adding he believes conventional breeding could accomplish the goal. “again, our research indicates the genetic composition in the crop plant is already there. and that perhaps the breeding with the proper variants of the genes may be sufficient.”

Should the research fail to produce new varieties of nitrogen-

fixing cereal crops, Szczyglowski says the process of learning about how plants interact with beneficial organisms can provide other benefits.

“It will allow us to adjust production schemes to take advantage of what already exists in the soil,” notes Szczyglowski. “I think the industrial fertilizer companies would be really interested in the formulation of a fertilizer that doesn’t leak into the water or atmosphere, stays longer in the soil and is better absorbed by the plants.”

In addition, the knowledge also could be used to answer questions related to fertilizer application methods and timing if the growth of the roots can be modified to scavenge nitrogen.

as global demand for food continues to increase, Szczyglowski says, finding these answers could have a significant impact on two areas.

“In the industrial countries, we have to reduce the nutrient enrichment in the environment by limiting or more targeted use of fertilizers, and in poorer countries we have to provide alternatives,” notes Szczyglowski, adding that productivity in the underdeveloped countries is poor, due in part to expensive fertilizer. “If you could provide them with varieties of plants which are better prepared to scavenge for limited nutrients, you could increase the productivity there by a large margin.”

For more on fertility and nutrients, visit www.topcropmanager.com.

CONTINuEd FROM PagE 25

important piece of advice Wallace can offer to farmers who want to scout their own land is to be sure to always check the back of every field. She four-wheels to the farthest parts of a field when she’s scouting, which she admits increases the risk of rushing over a field too fast if she’s not careful, but walking the whole field comes with a greater risk of seeing too little.

Tricks of the trade

“Smartphones and i pads have been great tools for collecting data, and honestly, without the technology that we have today, we wouldn’t be able to do what we do,” Hanson admits. “It immensely simplifies our job and allows us to communicate a lot more effectively.”

Technology is changing the scouting business, especially when it comes to managing data. Though Wallace is still looking for the right program, Hanson is happily working with John Deere’s apex program. Ian McDonald, oMa F’s field crops applied research co-ordinator, also likes Scout Doc from agnition, and, though he’s not really familiar with it yet, he likes the look of iCropTrak by Cogent3D. But he reminds farmers that these programs aren’t compatible with every mobile device out there and that poses challenges when it comes to keeping up-to-date records.

“Some of these work only on smartphones, some only on

tablets, some do both,” he says. “The tools you are using have to be user-friendly and I think that is going to be critical in the future that you don’t have the data islanded on a device.”

McDonald envisions a future where cloud-based apps sync smartphones, tablets, and desktop computers with gpS mapping from precision ag equipment or even Unmanned aerial Vehicles (UaVs). UaV technology, as it could apply to agriculture, is still in its infancy so the equipment remains overly complicated to operate for most farmers; however, McDonald is confident this will improve. Sensory equipment will also need fine-tuning, if only to determine which of the many camera technologies that are available may be best suited to monitor field crops at first. McDonald notes that near-infrared cameras have proven effective at identifying areas of stress in a field but he’s even more excited about the potential of thermal cameras to identify plant stress even before visual symptoms appear.

“The ability of those things to find hot spots, so you don’t have to scout the whole field, is phenomenal,” says McDonald, but he soberly adds that applying this technology is still very much a work in progress. even at the advanced level, he says, the technology still can’t entirely replace the value in going out to check fields. “apps don’t overcome the fact that you physically have to be out there, walking the fields, stooping over, turning the leaves over, and doing counts.”

Tips for safely and properly storing your own grain.

by Melanie epp

There’s no question that on-farm grain bin storage is on the rise, and with it comes concerns about potential grain spoilage. The increase can be attributed primarily to the yield increases ontario growers have been experiencing, says Lisa Devolder, business manager at Devolder Farms Inc., near Chatham, ont.

“There definitely has been an increase in on-farm storage for the past five to seven years,” she says. “I believe that this trend will continue, especially as the use of precision agriculture continues to grow yield potential for farmers in ontario.”

growers are expanding their operations, and with that growth, Devolder says, growers have decided they need to upgrade their facilities in order to be as efficient and as productive as possible. This includes adding more storage tanks, installing larger and faster receiving pits, and installing larger and faster dryers.

“growers also use on-farm grain storage as a marketing tool,” she adds. “Taking advantage of market opportunities that are available because they have stored grain into the winter months can give them opportunities that simply would not be available to them without their own storage. This is always subject to change as the basis and market pricing changes throughout the year.”

“Stored grain is an investment and it must be monitored,” says Devolder. “Like any equipment – a tractor, truck, or a combine, for example – it has to be maintained. There is no way around that.”

First, lowering the moisture level of your grain will increase its marketability. Typically, corn is harvested at about 20 to 30 per cent moisture. It’s then dried down and sold to buyers who prefer that moisture content at about 15.5 per cent. To prevent spoilage, it’s important to store grain at moisture levels in and around that 15.5 per cent mark. When moisture levels are too high, you risk spoilage. Corn, says oMaF energy and crop engineer Steve Clarke, can be stored at moisture levels higher than 15.5 per cent, if it’s being used for feed over the winter months.

“The storage life of grain is based on temperature and moisture of the grain,” Clarke says. “Moisture and temperature and how long the grain will last are spelled out in charts called Allowable Storage Time for Grain. Let’s say your grain is at 50 F and

lisa devolder advises lowering the moisture level of your grain, which will increase its marketability.

30 per cent moisture content – you’ve got about 10 days.” grain can spoil alarmingly quickly, says Clarke. If and when grain starts getting too hot, that’s when it needs to be aerated. grain should be cooled to 0 to -5 C. “If it starts going up over 10 C or 15 C, you’d want to start aerating it to start bringing it down in temperature.” He advises checking the bin’s temperature weekly – top, bottom and middle. after grain is cooled down, another approach is to keep the

Two storage bins are shown here: a 27-foot-diameter by fiverings-tall grain storage bin (with a maximum bushel capacity of 10,039 bushels) and a 21-foot-diameter by five-rings-tall grain storage bin (with a maximum bushel capacity of 5,919 bushels).

grain mass within five degrees of the average monthly temperature. “So if the average monthly temperature is -10 C, then grain mass could be -5 C to -15 C.”

growers can run into trouble when too many fine particles are in their bins. Fine particles can fill holes and stop air from flowing through as much as is necessary. To eliminate this problem, Clarke advises running your grain through a cleaning drum before storing it.

“They’re basic principles,” says Clarke. “Cool your grain. If it gets too hot, aerate it. If you aerate it, you should follow aeration times.”

Today’s bins are being built with tie-off points for those who may be entering. Bins are also decaled with safety stickers to alert operators to the dangers or hazards associated with grain bins, including moving augers and pinch points.

“It is recommended that an operator never enter a grain bin alone,” says Devolder. “and that proper safety precautions are practised daily, like turning power off before anyone enters the bin, wearing proper harness/lanyard, two-way communication with someone outside of the bin, etc.”

Devolder says there are also many

Each of these 36-foot-diameter by six-rings-tall grain storage bins has a maximum capacity of 21,675 bushels per bin.

required per aeration

This table outlines the amount of time needed for the aeration front to move through the grain.

products available that comply with safety regulations and make working around the bin more safe. She suggests that growers, particularly those with older equipment, install extra handrails and cages for the stairs to prevent accidents from happening.

Last august, gerry ritz, federal minister of agriculture, announced the government’s plan to invest nearly $300,000 in imaging technology that could help reduce grain bin waste and, therefore, improve profitability. Winnipeg-based company 151 research Inc. and its co-founder, Dr. Colin gilmore, will spearhead the project.

“The current technology is basically a temperature sensor on a wire inside the grain bin,” says gilmore. “When the grain gets too moist, it sprouts and the temperature goes up. [our] technology will actually sense the moisture content. So, hopefully before the grain sprouts, you can get in there and fix it.”

Currently, the technology is expensive, but that’s because up until now it was being designed for potential medical applications. gilmore will use the same concept and apply it to his grain bin monitoring system.

“We’re fairly confident we can bring that cost down to be competitive with the temperature sensing wires,” he says.

1. Turn on the aeration fan.

2. Carefully look inside the bin for signs of moisture.

3. If signs are present, aerate the bin.

4. If snow has settled on the top of the storage bin, run the aeration fan.

5. Check the grain’s surface to make sure it is not off colour.

6. Check for odours.

7. Check for changes in the static pressure of the fan. An increase could indicate blockage.

8. Look for signs of insect activity.

9. Take notes for monthly comparison.

Together, we’ll create the financing plan that works for you. We get to know you, your farm and how you want to grow. If you’re ready to get down to business, talk to one of our farm business experts.

Wind tunnels may offer a new option for nitrogen management.

by Blair andrews

Anew research study in o ntario is taking an innovative approach that could help farmers maximize their nitrogen fertilizer application.

researchers at a griculture and a gri-Food Canada’s g reenhouse and processing Centre at Harrow are using wind tunnels to better understand and prevent nitrogen loss and boost the amount available for crops such as corn and wheat. The study has important implications because nitrogen is an essential but expensive component in the production system for both crops.

Dr. Craig Drury is leading the study and evaluating urease and nitrification inhibitors with the two most common sources of applied nitrogen – urea granules and urea-ammonium nitrate (Uan) in combination with different application methods. according to Drury, nitrogen fertilizers account for 72 per cent of all fertilizer sales in Canada. Meanwhile, he notes that a further breakdown reveals that one-third of fertilizer sales are

urea and Uan accounts for 16 per cent.

The study also takes into account some critical changes that have occurred in farming. “Farm sizes have generally increased and farmers are under more and more time constraints, not only in order to plant in a timely manner but to get the fertilizers in the soil in a timely manner,” he says.

at the same time, the number of sources of nitrogen have decreased, namely the use of anhydrous ammonia application and ammonium nitrate. a s a result, granular urea and Uan applications have been rising.

In addition, the study is looking at three methods of applying the nitrogen sources: broadcasting, streaming and injection.

“We wanted to look at these different options and determine

TOP: an air sample is being collected before it enters the wind tunnel to determine the background ammonia concentration in the air.

if there is a better way of applying the fertilizers or a better combination of application methods and fertilizer sources,” says Drury. “How effective are these strategies at keeping the nitrogen in the soil and, ultimately, making it more efficient and thereby enhancing crop yields.”

The researchers are also studying different products that contain nitrogen stabilizers or inhibitors. an example is the urease inhibitor in a grotain. Urease is a natural enzyme in the soil that allows the urea to convert to ammonium. The inhibitor gives the urea time to move into the soil to reduce the amount of volatilization loss.

There are fertilizer products that contain both a urease and a nitrification inhibitor to decrease ammonia volatilization and slow down the process of converting ammonium to nitrate in the soil (i.e., nitrification).

“We’re looking at different inhibitors and different application methods to try to reduce the losses of nitrogen from the soil system to ensure that more of it goes into crop production and ultimately into corn or wheat grain,” he says.

The wind tunnels are used as a research tool to measure the amount of

ammonia that may leave the soil following the different treatments and application methods. air samples are captured before they go into the tunnel and after they leave it by using pumps and acid traps. By analyzing those samples and knowing the flow rates of the gas samples and wind speed of the tunnels, the researchers can calculate the amount of ammonia that has been lost.

Wind tunnels have been used for measuring ammonium losses from manure application; however, the study in ontario marks the first time they’re being used for looking at nitrogen sources and application methods.

“Wind tunnels are a diagnostic tool that provides us with a more accurate estimate of the ammonia volatilization losses rather than just measuring the inorganic n in the soils or back calculating losses using final grain yields,” says Drury.

noting that they only have results from one year, he is cautious when it comes to explaining the data from 2013. In a scenario faced by many farmers in southwestern o ntario, heavy rains forced the researchers to side-dress the nitrogen fertilizers three weeks later

than planned.

“So we, and many of the producers in e ssex and Kent counties, were applying nitrogen in hot, humid weather, which is a problem as ammonia losses increase with increasing temperatures,” says Drury. a s a result, the ammonia losses were extremely high in some of the treatments.

Broadcast urea application, not surprisingly, suffered the greatest losses. When a urease inhibitor was used with broadcast urea, ammonia volatilization decreased by 64 per cent. Similar results were experienced when streaming Uan and comparing to Uan with a urease inhibitor. The latter reduced volatilization losses by 26 per cent. also of note, injection reduced the losses by 38 per cent, compared to broadcasting urea.

“We’re looking at very dramatic reductions in loss when we either injected or streamed the nitrogen into the soil or when we added the urease inhibitors with urea or Uan fertilizers,” says Drury.

The study will compare the different treatment combinations over three years. Drury expects the next phase may focus on timing and rates to help farmers fine-tune their fertilizer applications.

In addition to helping farmers save money and improve their efficiency, the outcome of the study has the potential to change nitrogen management practices.

“We would like to reduce any of the environmental losses because we’re wasting very expensive fertilizer, and if we can reduce losses, then we might also be able to recommend the application rates that are also more cost effective,” says Drury. “ e mbedded into the current application rates are the losses that occur. Therefore, if we’re able to reduce losses, then we can better match the nitrogen fertilizer application rate to the crop demands.”

To reach its full potential, agriculture needs everyone in the industry to speak up and speak positively.

Agriculture More Than Ever is an industry-driven cause to improve perceptions and create positive dialogue about Canadian ag. Together we can share the facts and stories about this vibrant and modern industry, and tell the world why we love what we do.

It’s up to all of us to be agvocates and it’s easier than you think –visit AgMoreThanEver.ca and find out how you can get involved.

Senior exeCutive finanCial ConSultant inveStorS Group finanCial ServiCeS inC. | paul r. vaillanCourt, Cfp, Clu, CHS and CpCa

An accident can only take a second, yet it can have a huge financial impact. What would happen to your business if you or one of your key employees was momentarily distracted around the farm equipment or slipped and was injured? What would happen if you, as the owner, couldn’t work for an indefinite period due to illness, such as a stroke? With the Canadian agricultural Safety Week taking place in March, it is a good time to consider your insurance needs while you are implementing or updating your safety plan.

During your working life before age 65, it is estimated one-third of Canadians will become disabled for 90 days or longer and that a serious, life-threatening illness will affect one in three Canadians in their lifetime. Cancer, heart attack and stroke account for 85 per cent of critical illness claims paid out in 2009.

Let’s consider the following situation that you could be facing and review the options available to ensure you receive an income, your business can continue to operate and assets can remain in place, and to help your employees.

When a disability strikes, your potential needs as a business owner are twofold: you need an income and your business has an obligation to pay its bills. personally owned disability insurance coverage could help you replace your lost income with a tax-free benefit in the event of a long-term injury or illness. Business-owned overhead expense disability insurance can help you continue to pay your employees, business loans and other operating expenses while you recover. Key person disability insurance will help you hire a replacement if your key employee becomes sick or injured or even dies.

Many Canadians will consider registered retirement savings plan (rrSp) as both their key to retirement and an emergency fund to

deal with unexpected events such as a critical illness. How much of your rrSp are you prepared to cash out if you become critically ill? How much later are you prepared to retire than planned? Years of retirement savings could easily disappear in one year if a critical illness occurs. In addition to the loss of income, the average out-of-pocket costs for cancer are $287.41 per month and additional travel costs of $426.31. With advancements in medicine, more individuals are making a full recovery from cancer, stroke and heart attack or other critical illnesses, but it may not mean a full recovery of wealth. For example, if you need an additional $10,000 to cover these expenses, at a 35 per cent marginal tax rate, you would need to withdraw $15,385 from your rrSp. The amount would be $18,182 at a 45 per cent marginal tax rate.

Critical illness insurance covers you for expenses incurred for a covered illness, providing you with financial stability and allowing you to focus on your health and recovery. You receive a tax-free lump sum payment based on the plan coverage that you purchase (i.e., $100,000 as a result of stroke). You can use the benefits in any way you wish. So instead of depleting your retirement fund, you can use the benefits to help hire a replacement, to compensate your business for the loss of productivity or

to reduce business debt. You could also use the benefits for treatment not covered by provincial health insurance.

The cost for insurance varies by plan, which is tailored to suit your personal circumstances. Below are premium examples assuming Canada Life protection for a nonsmoker male, farm owner (2a occupation) and standard risk. This table is for illustration purposes only.

It is best to purchase this coverage before a health issue arises that may cause your insurance application to be declined or rated. The cost of not having adequate coverage could be potentially devastating to your family and your business.

put a business safety plan in place today that can help protect your financial goals. Speak with your financial advisor to learn more about disability and critical illness insurance, their features and their benefits.

This is a general source of information only. It is not intended to provide personalized tax, legal or investment advice, and is not intended as a solicitation to purchase securities. Paul Vaillancourt is solely responsible for its content. For more information on this topic or any other financial matter, please contact an Investors Group Consultant.

Using legendary Quadrac® technology, the Case IH Steiger ® Rowtrac™ series tractors are agronomically designed to deliver maximum yield. Featuring four, independent oscillating tracks on an articulated frame, these tractors increase flotation while reducing compaction and ground pressure. The result is an optimized seedbed for ideal growing conditions and the ability to cover more ground in row crop applications.

Learn more about the power and productivity of Steiger Rowtrac tractors by visiting your dealer, or go to caseih.com/rowtrac