It’s criminal. Trespassing disease pressures can steal up to 30% of your yield, reduce grain quality and ultimately divest you of your hard earned money. Ensure the safety of your wheat and barley by using state of the art disease protection products from Bayer CropScience.

Trust ProlineTM fungicide for unparalleled control of fusarium head blight in your wheat and barley. It also significantly reduces the levels of mycotoxins – especially deoxynivalenol (DON) – ensuring the highest grade, quality and yield. With curative, protective and eradicative properties, Proline sets a new standard in disease protection.

Safeguard your wheat with Folicur® fungicide. Folicur provides protection from the broadest spectrum of leaf disease pressures, including rusts and tan spot.

Every year at this time, Top Crop Manager provides our annual Weed Control Guide, and this year’s edition provides the latest additions to the marketplace, including ratings from OMAFRA’s Publication 75.

As the value of inputs and the number of chemical agents continue to rise, so does the need to address issues such as weed resistance. Field editor Heather Hager was in Florida for a recent Pan-American conference, and offers an exclusive report.

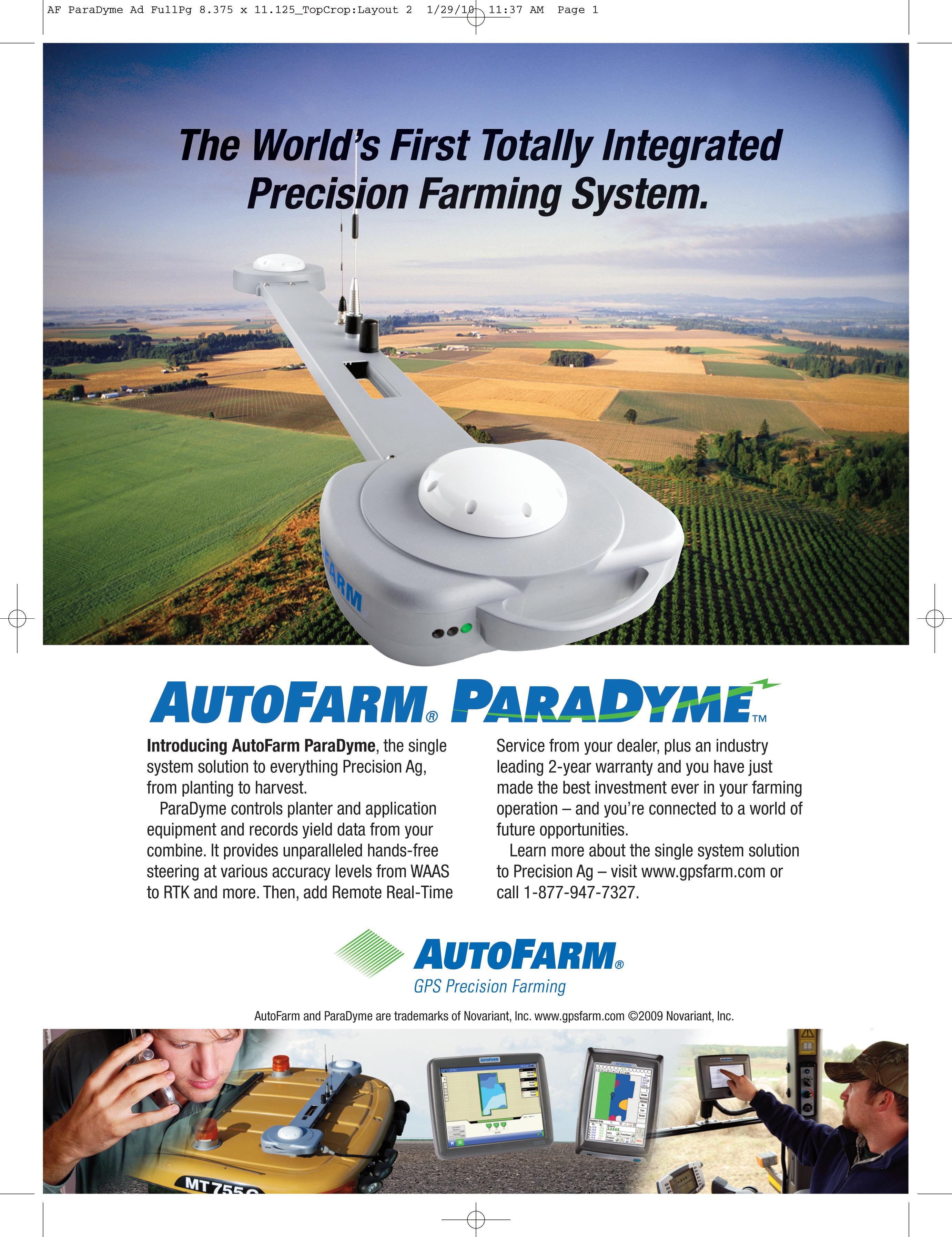

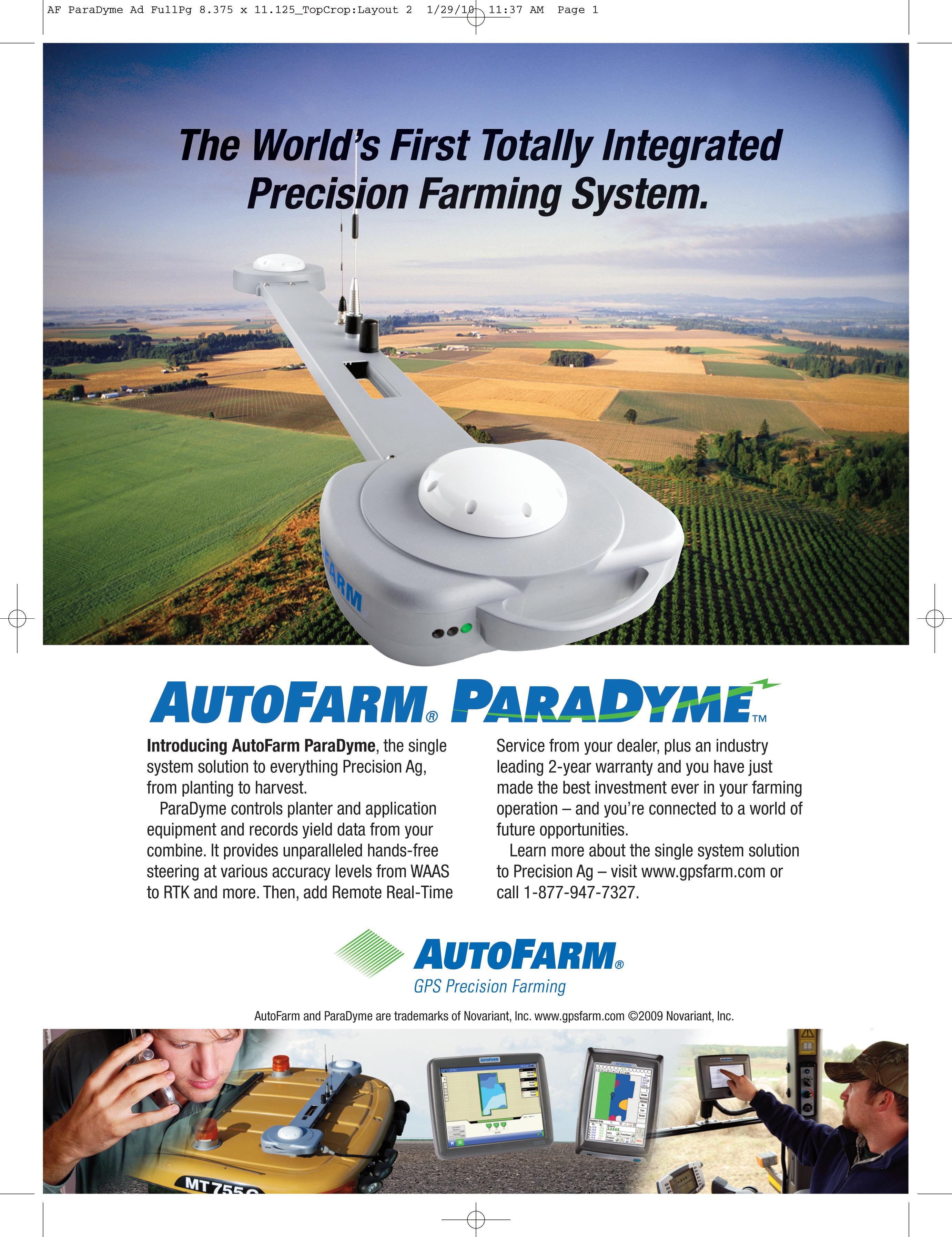

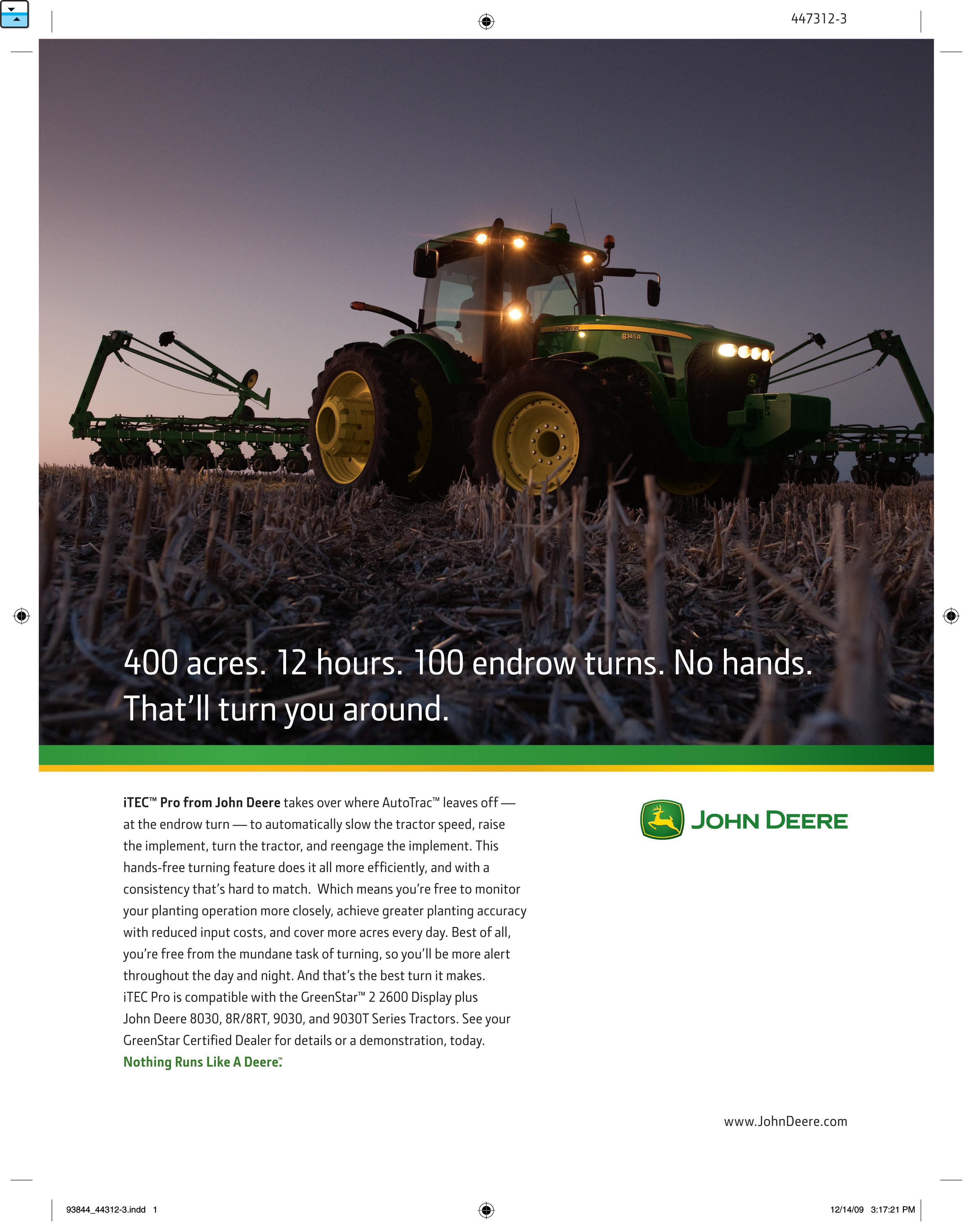

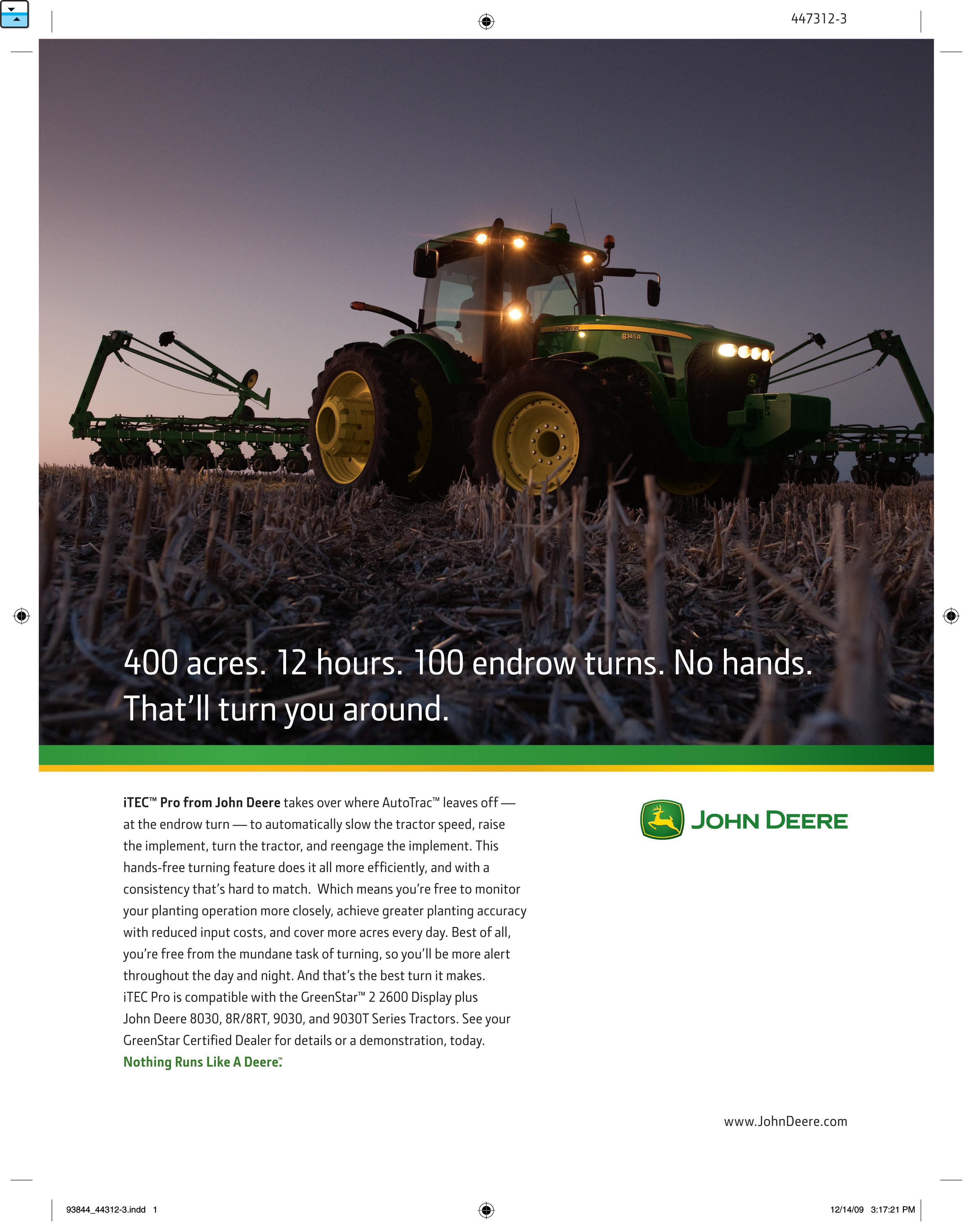

Machinery Manager: Precision Agriculture Systems

More growers are focusing on managing costs with greater efficiency, and this latest edition of our Machinery Manager provides information and helpful charts on the subject.

Reference information of this calibre is hard to find, so many growers choose to keep issues on file. If you have not kept issues for your library, you can find our stories, and more, on our interactive website.

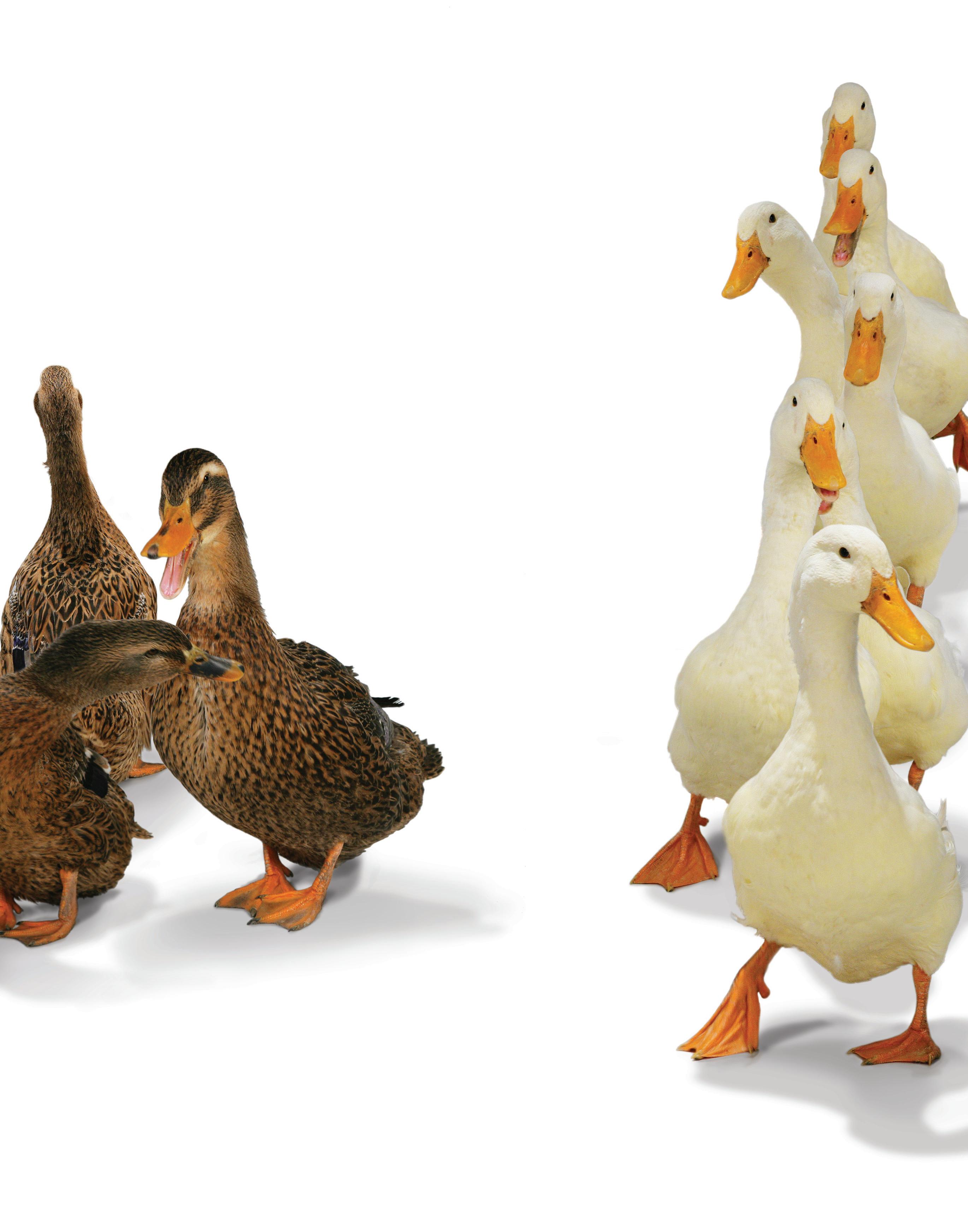

As winter turns to spring, images such as this

and

Cover:

as well. Photo by Ralph Pearce.

March 2010, Vol. 36, No. 6

EDITOR

rpearce@annexweb.com

FIELD EDITOR hhager@annexweb.com

CONTRIBUTORS

Blair Andrews

Bruce Barker

Treena Hein

Carolyn King

Rosalie I. Tennison

WESTERN SALES MANAGER

kyaworsky@annexweb.com

EASTERN SALES MANAGER smccabe@annexweb.com

SALES ASSISTANT

888-599-2228 ext. 234 mburnie@annexweb.com

PRODUCTION ARTIST

Gerry Wiebe

GROUP PUBLISHER

Diane Kleer

dkleer@annexweb.com

PRESIDENT Michael Fredericks mfredericks@annexweb.com

PUBLICATION MAIL AGREEMENT #40065710

RETURN UNDELIVERABLE CANADIAN

ADDRESSES TO CIRCULATION DEPT.

P.O. BOX 530, SIMCOE, ON N3Y 4N5

e-mail: mweiler@annexweb.com

Printed in Canada

ISSN 1717-452X

CIRCULATION

e-mail: mweiler@annexweb.com

Tel.: 866.790.6070 ext. 211

Fax: 877.624.1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

SUBSCRIPTION RATES

Top Crop Manager West - 8 issuesFebruary, March, Early-April, Mid-April, June, October, November and December1 Year - $50.00 Cdn.

Top Crop Manager East - 7 issuesFebruary, March, April, August, October, November and December - 1 Year - $50.00 Cdn.

Specialty Edition - Potatoes in CanadaFebruary - 1 Year - $9.00 Cdn.

All of the above - 16 issues - $80.00 Cdn.

From time to time, we at Top Crop Manager make our subscription list available to reputable companies and organizations whose products and services we believe may be of interest to you. If you do not want your name to be made available, contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2010 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication. www.topcropmanager.com

There is a surprising theme that people outside of agriculture seem to be following these days, and it is easy to find in the pages of a newspaper, on television, radio or the Internet.

To say agriculture is misunderstood by many Canadians is a bit of an understatement, like Torontonians tend to be a little…self-centred.

The disconnect that exists between Rural and Urban defies any and all attempts to “re-bridge” the gap. Some of it comes from the “hat in hand” approach of our national farm press; workshops and conferences are organized every year to attract some editor or news director to unveil the secrets of getting favourable farm stories (“our stories”) into the pages of a big city daily or on television. At the same time, we read about the ongoing need for urban gardens (to lessen our carbon footprints) or that the damnable ethanol industry in the US (and Canada) is stealing the food right out of the mouths of the starving masses of the world. What is often lost on the vast majority of these people, however, is that increasing the scale of urban gardens to meet consumer demand would push prices too high to make the whole process feasible. As for the starving masses, few, if any, of them would eat grain corn (as opposed to food-grade or sweet corn). Most do not want to hear contrary opinions and bristle at the notion that they may be ill-informed.

One of my college instructors referred to this as “forced stupidity.”

Through it all, there remains a need, not to get “our stories” published or aired, but for a shift in thought and consideration. Sorry to say, but the federal government may be on to something. For years, the agriculture

ministry has been known as “Agriculture and Agri-Food Canada,” a designation which has always seemed to be a tad confusing. But now, its subtle differentiation is completely logical, in much the same manner as, “All poodles are dogs but not all dogs are poodles.” In our world, “all food results from agriculture but not all agriculture results in food.”

That is an important and rapidly emerging truth in this industry. Farmers are not solely responsible for food production; you are feeding people, yes, but also livestock and industry, science and health care, plus energy, education and equipment. The demand is expanding as is the opportunity to supply it.

What also needs to expand is the understanding of what agriculture entails.

And maybe that small distinction would help create understanding and awareness – for everyone.

Maybe that is the thought to remember for all of us as we “march” into spring.

And, as we march into spring, Top Crop Manager offers our standard fare of features, just in time for the vernal equinox. There is the Weed Control Guide, our latest Machinery Manager section and a solid array of stories dealing with everything from weed management to plant breeding to fertility and nutrients. It is a timely and information-packed issue, at a time when making informed decisions is really what it’s all about.

Fight tough soybean weeds with Valtera™ Herbicide. Valtera provides excellent residual control against tough weeds such as Eastern black nightshade and even weeds resistant to Group 2 and Group 5 herbicides. And with great rotational flexibility, there are no rotational restrictions or carryover into next year’s crop.

by Heather Hager, PhD

More than five years after consumer and industry concerns prompted Monsanto to shelve its introduction of genetically modified (GM), glyphosate-tolerant wheat to the Canadian marketplace, nine grain organizations in the United States, Australia and Canada have officially agreed to support the introduction of GM wheat. Their Wheat Biotechnology Commercialization statement, released in May 2009, notes that wheat is losing ground as a major commodity crop, in part because of superior competition from other GM crops like corn, soybeans and canola. Thus, the aim of these groups is to “… work toward the goal of synchronized commercialization of biotech traits in our wheat crops. …to minimize market disruptions and shorten the period of adjustment.” This has reopened the debate about the potential merits and market acceptance of GM wheat.

Those involved in the wheat supply chain are considering the ramifications of introducing GM wheat. “I think the tides are changing a bit compared to what it was a couple of years ago,” notes Archie Wilson, general manager of C&M Seeds, based near Palmerston, Ontario. “Whether people think it’s right or wrong, I do think the momentum for GM wheat to come now is much greater than it ever was.”

Wilson cites two reasons for this. First, he says, the debate is not just about herbicide-tolerant wheat anymore. “To me, it’s much bigger than that. If we said we have something that’s going to give us Fusarium tolerance or drought resistance in a much stronger way than we currently have, I think the perception might be different. And take it a step further. What if someone comes up with some type of attribute that has a proven health benefit? Would people look at it the same?”

Second, larger seed and chemical companies that have ignored wheat in the past seem to have developed a new interest in the crop. “They likely haven’t

Wheat is starting to lose ground due to biotech advances in other crops such as corn, soybeans and canola, creating a sense of urgency in discussions on the potential merits and market acceptance of GM wheat.

been in wheat up until now because of the poorer return on investment because of bin run wheat and the inability to protect their intellectual property rights,” suggests Wilson. However, he notes that both Dow Agrosciences and Monsanto have established partnerships recently with companies that focus on

C&M Seeds is currently evaluating the opportunities that GM wheat will bring to its customers, says Wilson. Rather than having its own breeding program, the company obtains genetics from multiple programs and focuses on developing new markets for its customers. Its

The issue of segregating GM wheat from non-GM varieties is confounded by a system that is currently suited to large-volume handling, storage and shipping, with considerable blending and pooling.

response, and the varieties it offers, will be geared towards meeting its customers’ needs. Wilson says he has not had many comments from customers yet about the issue of introducing GM wheat.

Other seed companies are eager to push the potential new market opportunities that they anticipate appearing with the introduction of GM wheat. For example, John Cowan, general manager of Hyland Seeds at Blenheim, Ontario, sees it as an opportunity to segregate the market into GM and non-GM wheat and multiply the market opportunities, particularly in Ontario. “Any time you can segregate, you’ve got an opportunity to add value to everybody who’s in the value circle,” he says. “I think we’ve proven we can keep genetically modified crops separate and traditional breeding separate already. Soybeans are a great example of that.” He says that Hyland Seeds has definite interest in offering GM wheat options.

One concern with introducing GM wheat has always been the potential loss of markets that want non-GM wheat. Cowan says that segregation and identity preservation should take care of these markets. “Europe has some problems with genetic modification in terms of market acceptance, so if you’re growing for that market, you

would take that into account and not grow GM wheat.”

More complex than simple segregation Further down the supply chain are the processors, transporters, exporters and market users, who must closely consider market acceptance and the logistics of segregation. Here, the issue is more complicated than simply offering both GM and non-GM options. Many factors need to be accounted for, including the costs of identity preservation and who will bear them, the capacity to segregate all classes of Canadian wheat into non-GM and various specialty GM traits, the setting of acceptable tolerance levels and tests for commingling of GM and non-GM wheat, and the availability of GM and non-GM markets, to name a few.

Despite this, the North American Millers’ Association, composed primarily of US member companies, is a signatory to the Wheat Biotechnology Commercialization statement. In contrast, the Canadian National Millers Association (CNMA) does not yet have a formal position on GM wheat. According to the association’s president, Gordon Harrison, the CNMA met with others in the supply chain in the fall of 2009 to assist the milling industry in understanding the potential implications of declining

producer returns from wheat production relative to alternative crops.

Harrison believes that the CNMA will be supportive of the concept of synchronized market introduction and sees it as a responsible approach. “I’m trying to foster a discussion among other stakeholders with our members and some customer industry organizations so that they have an appreciation for what the farmers who are the advocates for GM wheat are saying. If producers on two continents and in three major wheat producing countries have said this is really isarmportant to them, I think it’s deserving of careful consideration.”

“‘Segregate the market.’ It sounds really simple, but it’s really quite complex,” notes Dr. Peter Phillips, a political scientist at the University of Saskatchewan, who studies the economic and regulatory impacts of new technologies. He has held both the NSERC-SSHRC (Natural Sciences and Engineering Research Council of Canada and Social Sciences and Humanities Research Council of Canada) Chair in Managing Knowledge-based Agri-food Development and the Van Vliet Chair in Agricultural Economics at the University of Saskatchewan, and has been studying the debate around GM wheat for close to 10 years. “One difficulty is, the pre-existing system is based on a fairly

With Converge® XT herbicide, you get an extended window of application with excellent crop safety and the same trusted, seasonlong grassy and broadleaf weed control of Converge PRO. The patented safener lets you confidently apply Converge XT from pre-plant surface right up to the three-leaf stage of corn. So you can keep on spraying and spraying and spraying.

Of course, a big question in this debate is: Who will pay to segregate GM varieties from non-GM varieties?

heavy reliance on bulk handling techniques, which means that we have very large granaries, and we do a lot of blending and pooling as we warehouse, ship and move it through the early stages of processing,” says Phillips.

This could make it difficult to segregate GM traits on a large scale. Although there are currently several identity-preserved programs for specific types of wheat, these involve additional costs. So, another part of the debate focuses on who is responsible for and pays the costs of segregating GM from non-GM wheat. “The reality is that the people who would buy and consume GM stuff are largely indifferent between GM and non-GM,” states Phillips. So those who want non-GM will likely have to pay a premium for it.

Rather than paying a premium, however, buyers could simply obtain the product from a different market source where GM is not grown. “In fact,” says Phillips, “that’s what we’ve found in products like soybean, canola, even some of the corn. As long as there’s somebody who’s not using the technology, you can buy from them. If Europe, for example, stayed GM-free at the production level, they might export at virtually no extra cost because they’re producing it anyway; they don’t have to spend on control costs.” Premiums are usually only viable if the product type or quality, for example, cannot be obtained elsewhere.

Then there are the regulatory difficulties involved in synchronizing the introduction of GM traits. “Trying to get a whole bunch of national regulators to

agree to respond at the same time with generally the same decisions is not as easy as you might think,” observes Phillips. Countries vary in terms of regulations, evaluation processes, language translation needs, and other requirements, all of which affect the timing of decisions.

Disagreements among member states within political jurisdictions also affect the introduction of GM biotechnology. Two examples noted by Phillips are Australia and Europe. In Australia, the member states enact their own laws for agriculture and other matters that are not controlled federally under the constitution; in the past, some states have prohibited the commercial release of GM crops, even though they have been approved nationally. In Europe, although the member states do not have the legal authority to contravene European Union decisions, they still have some practical capacity to defy those rulings by preventing the sale of GM seed.

Ultimately, whether GM traits in wheat are accepted will likely depend a lot on which traits are put into which classes of wheat: the bread, pasta, or feed wheats. “The fundamental question is, where do they put the GM trait?” poses Phillips. “If they introduce it into durum, that’s going to be a big impact because Italy buys a lot of our durum.” And Italy has generally opposed GM wheat. In contrast, says Phillips, much of the feed wheat stays in Canada and the United States, which are markets that already

accept GM corn and soybean for animal feed.

In terms of the first traits to be introduced, herbicide tolerance might not even be a consideration. Many producers are saying that their fields are fairly clean if they are already using other herbicide-tolerant crops in the rotation. And although producers might like to see traits such as Fusarium tolerance, lodging resistance or drought tolerance that will improve agronomic performance and yield, many proponents agree that traits that add value for the consumer might work better to improve the initial acceptance of GM wheat. These would include traits that enhance the milling properties or health and nutritional benefits of wheat. For example, the development of gluten-free wheat with suitable milling properties would be beneficial for the many people who suffer from gluten intolerance and/or celiac disease. Another trait that might gain easier acceptance could be one that tackles the difficult Ug99 strain of wheat stem rust (Puccinia graminis), which can cause very high yield losses and reportedly may eventually threaten a large proportion of global wheat crops, and thus possibly global wheat availability.

The Wheat Biotechnology Commercialization statement on synchronized biotechnology introduction in the United States, Canada and Australia is available from the US National Association of Wheat Growers website: www. wheatworld.org/wp-content/ uploads/biotech-trilateral-statement-20090514.pdf

Ontario Wheat Producers’ Marketing Board’s statement on biotechnology in wheat can be viewed at www.ontariowheatboard.com/ about_bpositions.php.

Editor’s Note: In early February 2010, the Western Organization of Resource Councils (WORC) released a report that stated that if genetically modified wheat varieties were introduced in the United States, the price for wheat could drop as much as 40 percent for hard red spring wheat and as much as 57 percent for durum wheat. The report cites Japan and European countries as those jurisdictions showing the greatest opposition towards genetically modified wheat, with the suggestion that European customers might shift to importing Russian wheat instead of US shipments.

Don’t miss the chance to pick up a Trimble® AgGPS® EZ-Guide® 500 display, Trimble EZ-Steer® system, or Trimble EZ-Boom® system and put some money back in your pocket!

Trimble has been increasing your productivity with EZ products since 1998, beginning with the AgGPS EZ-Guide SL lightbar up to the current, industry-leading AgGPS EZ-Guide 500 display. We’re committed to using our more than 30 years of industry-leading experience in the GPS business to develop innovative ways to strengthen your farming operations.

EZ-Steer system – US$500 cash back

EZ-Guide 500 system with DGPS – US$300 cash back

EZ-Boom system – US$150 cash back

The EZ Products Cash-Back Program runs from February 8 –May 15, 2010. The maximum cash back amount per customer is US$5000. See your local Trimble dealer for complete program details. Visit www.trimble.com/locator or call 1.800.865.7438.

Agriculture. The line everyone follows. See your local Trimble dealer for further program details.

by Treena Hein

Mapping the genome brings the fight against the pathogen to a whole new level.

Pythium has been lurking under the radar lately on the crop breeding scene, and that is not a good thing. “Companies nowadays are developing new soybean varieties very quickly,” says Ohio State University professor Dr. Anne Dorrance, “and how these varieties stand up to what are considered minor diseases like Pythium has been somewhat ignored. That may come back to haunt us in a significant way.”

Most species of Pythium inhabit the soil and cause a variety of diseases, including seed rots and damping-off; root, stem and fruit rots; foliar blights; and postharvest decay. This genus of plant fungal-like pathogens, closely related to other oomycete plant pathogens such as Phytophthora species, has a large geographic distribution and host range. There are approximately 120 recognized species. “Pythium has been a historically important issue in Ontario and is getting more important,” observes Ontario Ministry of Agriculture, Food and Rural Affairs field crop plant pathologist Albert Tenuta. “There are species that affect only corn or wheat or soybean, and others that can affect two or all three crops.”

Tenuta believes that identification and awareness of the disease are improving among farmers. “People are learning to distinguish it from Phytophthora and other early season root rot diseases,” he says. “Its foothold depends a lot on environmental conditions. It likes to establish in cool wet conditions, 15 degrees C or less, and then it decreases as it warms up, and Phytophthora takes over.”

Surveys in Ontario during the last few years have shown that there are about 14 species in eastern Ontario that affect soybean, corn and wheat, with some affecting only one or two of the three. The species affecting corn seem to be increasing more than others.

Perhaps Pythium’s most worrying aspect is that it is a major cause of seed rot prior to germination, especially in poorly drained soils. “Almost all germinating seeds and developing roots are exposed to infection by Pythium,” says

Tenuta. Hence the importance of fungicide seed treatments will be important until such time as effective resistance genes are identified.

Work is now underway

It is not easy to beat down a pathogen that has such a wide range of deleterious effects, even if it is well understood at the molecular, genetic or genomic level. However, the good news is that with the recent sequencing and annotation of the pathogen’s genome, researchers are now better prepared to do battle.

Dr. André Lévesque, a mycologist with Agriculture and Agri-food Canada, with project leader Dr. Robin Buell of Michigan State University and collaborator Dr. Ned Tisserat of Colorado State University, initiated the genetics project in 2006 after obtaining funding from the US Department of Agriculture. Almost 50 scientists from around the world are currently finalizing the genome annotation, which will be released in late 2010. “Having the genome completely sequenced and annotated is going to make a huge difference,” Lévesque says. “We know that cultivars with root rot resistance to Phytophthora are not re-

sistant to Pythium. We also know that the two pathogens have different ways of attacking the plant; Phytophthora has a sophisticated “signalling system” that helps it enter the root, and Pythium has more of an opportunity-based system. Now, with the genome mapped, we’ll be able to understand better how Pythium attacks, and pinpoint the genes that relate to its different life stages.”

He adds, “Knowing more about the genes that are responsible for the way the pathogen works at root surface will also help breed resistant plants.”

Dorrance is equally excited about the avenues that having the genome sequenced will open up. “Being able to compare the genome of different species, which attack different parts of the plant,” she notes, “will go a long way to also helping us develop effective seed coat treatments.”

Dorrance recently isolated a new species of Pythium that attacks in warmer temperatures and on older plants, as opposed to the usual infestation of younger plants during cool, wet springs. Despite the fact that this particular species is not very aggressive, it is causing growers to conduct costly replanting in Ohio. “We’ve discovered it in a few locations, but it’s hard at this point to say what its range is,” she says.

If the climate models are correct and warmer temperatures become more common in the future, Tenuta says that Pythium species that require colder temperatures might begin to suffer, but those that can tolerate warmer temperatures might increase. “Pythium is very flexible,” he says. “There are species that can function well in both types of scenarios.”

The fact that there is not yet much information about things like the virulence of various Pythium species or the degree of resistance to them that may exist in the new rapidly developed soybean varieties means that growers stand on dangerous ground, in Dorrance’s opinion. “The last three summers have been dry and so haven’t been conducive to proper screening for Pythium,” she says. “We need expedited screening methods to get the information we need.”

The performance you need, from the brand you trust.

This time of year, you’ve got a lot on your mind. With Roundup Ultra2® herbicide you get legendary preplant weed control, industry leading warranties and guarantees, and the con dence that comes from using the brand you know and trust. One great herbicide, one easy decision. Smiling yet?

See your retailer for details.

Potash in starter fertilizer can give a boost to corn when soil test K is low.

Greg Stewart calls potassium “the Rodney Dangerfield of nutrients” that gets no respect, at least in comparison to phosphorus and nitrogen, in starter fertilizers for corn. But his current research is showing that it can pay to give attention to potash.

Stewart, corn specialist with the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA), is leading a three-year project to evaluate the yield and economic responses of corn to various starter fertilizer options. “We know that proper use of starter fertilizers can increase corn yields and net profits. But growers are faced with choosing among many options for products, placement and rates. And these choices affect yields and/or application costs,” he explains.

The project is funded by the Ontario Corn Producers’ Association (Grain Farmers of Ontario), Innovative Farmers Association of Ontario, Ontario Research and Development Program, University of Guelph, John Deere and OMAFRA.

When Stewart started the project in 2008, he was focusing on nitrogen (N) and phosphorus (P), which are the two usual nutrients for starter fertilizers (see box). He included potassium (K) in some of the treatments because the field sites with low P levels also often had low K levels.

The project’s sites are in Ontario, with four sites in 2008 and 10 in 2009. The sites have loam, silt-loam or silty clayloam soils with medium to medium-low soil test P and K levels.

The starter fertilizer treatments compare several products: ammonium polyphosphate (10-34-0); urea ammonium nitrate (UAN, 28 percent); mono-ammonium phosphate (MAP, 11-52-0); 6-24-6; and 5-20-20, at various rates (see chart). The treatments are also comparing infurrow placement versus a band two inches to the side and two inches below the seed row (2x2).

To meet the crop’s nitrogen needs, 150 lbs of N per acre of bulk N fertilizer was applied at all sites. To try to meet the crop’s K needs, 200 lbs per acre of pre-

by Carolyn King

plant broadcast potash (K2O, 0-0-60) was applied to all treatments at the Elora site in 2008 and 2009 and at the Ancaster site in 2008.

Unexpected yield boost

Not surprisingly, data from the project’s first two years showed that yields and returns varied widely, depending on the

starter fertilizer option. However, the results for the starters with K were a bit of a surprise.

“The results show that on fields with medium to medium-low soil P and K tests, profitable yield responses are more likely to occur when N-P-K-based starters are applied, as compared to starters that contain only N and P,” says Stewart.

“In some cases you could say the starter N and P investment was wasted if you didn’t address the low K levels.” For instance, at the Elora site in 2009, yields with the N-P starter treatments were not significantly different from the yields with no starter fertilizer at all, whereas the yields with the N-P-K starters were significantly better than with no starter (see graph).

The effect of starter K was apparent even at the sites where 200 lbs per acre of broadcast K was applied. “Two years ago, I would have expected that if I had broadcast 200 lbs of potash, then potash in the starter fertilizer would have been irrelevant. That doesn’t appear to be the case. Even with 200 lbs of potash, when soil test K is down into the 60 to 80 ppm range, the starter fertilizers that included potash still tended to out-perform the starters without K,” notes Stewart.

Generally, either in-furrow or 2x2 placement of the N-P-K starters provided profitable yield responses, although the 2x2 placement produced a larger response.

Starter fertilizer based on soil test levels Stewart says that falling soil potassium levels may not be all that uncommon in Ontario corn fields these days. Highyielding corn crops and frequent soybean crops both use a significant amount

High-yielding corn, frequent soybean crops and higher potash prices in recent years have resulted in lower soil potassium levels.

PHOTO BY RALPH PEARCE

“With a starter fertilizer you are trying to give a high concentration of nutrients to the plant early in its life when it’s got a small root system,” explains Keith Reid, OMAFRA soil fertility specialist. “We could do that by building up the soil fertility in the entire rooting zone but that would be awfully expensive. It’s much more efficient to band some fertilizer near the seed, to sort of spoon-feed it to the plant when it’s got a small root system.”

The plant’s response to the early high nutrient concentration is called the starter effect.

Starter fertilizers for corn are usually placed either in the furrow with the

seed or in a band two inches to the side and two inches below the seed row. Infurrow placement gives the seedling immediate access to the starter nutrients, but it increases the risk of crop injury if the rates of nitrogen and/or potash are too high. “In most production systems, the most important nutrient for the starter effect is phosphorus. Corn especially has a high demand for phosphorus as a seedling and so we get a pretty consistent response to either seed-placed or side-banded phosphorus close to the row,” says Reid.

The second most important starter nutrient is N. He says, “We put some nitrogen with that starter phosphorus because it increases the uptake

of phosphorus. In conventional till soils, one part nitrogen to four parts phosphorus optimizes the amount of phosphorus uptake. In no-till soils, we have found a response to more nitrogen in the starter, probably because the soil is cooler and it’s slower to release nitrogen from the soil organic matter. In no-till soils, we like to use a starter fertilizer that has a fair bit of nitrogen.

“The third nutrient that we have found to be important, and that’s just in the last couple of years with Greg Stewart’s field trials, is, if the potash level in the soil is low, there’s a pretty significant response to having some potash in the starter.”

of K. As well, producers may have been limiting their K applications because of high prices for potash fertilizer in recent years.

For K applications for a corn crop, he recommends: “If your field has over 121 ppm of soil test K, you don’t need to include K in your starter. If your field has soil test K in the 80 to 120 ppm range, the OMAFRA recommendation is to apply 50 to 30 kg of K2O per hectare (44.6 to 26.8 lbs per acre), respectively. In terms of starter versus broadcast K, the best approach is to apply K in the most costeffective manner for your operation. If your soil test K levels are in the 60 to 80 ppm range, the OMAFRA recommendation is to apply 80 kg of K2O per hectare (71.4 lbs per acre). The project results suggest this K application may be critical to corn yield and, in some cases, starter K may increase yields even when broadcast K is applied.”

The only way for a grower to tell which nutrients the soil needs is by soil testing. OMAFRA soil fertility specialist Keith Reid says, “No farmer or agronomist can look at a handful of soil and tell

Both Greg Stewart and Keith Reid were surprised to see project results showing a yield response to K in the starter fertilizer.

PHOTO BY RALPH PEARCE

which nutrient concentration is there. A soil test is a fairly inexpensive way of getting a snapshot of what’s in the soil.”

Reid explains that a soil test will tell a grower about both starter fertilizer needs and bulk fertilizer needs. “A plant might respond to a little bit of potash near the seed, but if you’ve got a low soil test, the crop is going to need a lot more than that in total to meet its needs. So

you have to balance both; what do you need for that starter effect, and what do you need to meet the needs of the crop to get optimum yields? The soil test gives you both of those pieces.”

Like Stewart, Reid was initially surprised to see the project results showing a yield response to K in the starter fertilizer. Reid says, “Two years ago I would have said you don’t need much K in the seedling because the seedling is not very big. When you track potassium uptake, it pretty much matches the plant’s growth pattern. So when you have a small plant, it doesn’t take up a lot of potassium. As it gets bigger during periods of rapid growth, it’s taking up a lot of potassium. And as it matures, the plant is actually losing potassium back to the soil.”

Reid says the response to starter K at the project sites is likely because soil K was in such short supply. “The seedling’s root system is small enough that even the relatively modest K requirements of the seedling can’t be met quickly enough from the soil in low K fields unless there’s a little bit extra potash.”

When you live agriculture, you see things differently Canadian producers know they’re part of something special. In fact, they’re feeding the world. These entrepreneurs rely on people who understand that agriculture is unique. FCC financing is designed for them. Agriculture is life www.fcc.ca/advancing

Weed management is one of the top priorities for corn and soybean growers. Each year, the choices available for products and timing of use become more complex. To simplify the decision-making process and to provide a handy reference tool, offers this annual Weed Control Guide

As mentioned in past weed guides, an important feature of these tables is the chemical group column. Using this, growers can quickly check the group their product or tank-mix options belong to, making it an important first step in managing the development of herbicide resistance in weeds, with the potential for rotating products with different modes of action.

We are grateful to Mike Cowbrough, OMAFRA’s weed management specialist, for reviewing the Top Crop Manager Weed Control Guide and making numerous helpful suggestions. Product suppliers also have been of assistance in keeping the guide up-to-date. We have made the tables as user friendly and as concise as possible. Remember though, it is a

guide adapted from OMAFRA’s Publication 75, and is not a definitive text.

Growers should always doublecheck provincial guides and product labels to avoid errors

The Top Crop Manager Weed Control Guide is laid out with products listed for each crop by trade name and in alphabetical order with major grassy weed products listed first, then major broadleaf products, then the tank-mix partners, and finally products that are solely for herbicide-tolerant crops. This format allows growers to compare their options of grassy weed and broadleaf weed products, and then, after making their choice, to take the second step of comparing the tank-mix choices and picking one that best tackles their grassy and broadleaf weed spectrum.

Product ratings for each weed are the same as in Publication 75, and tank-mix ratings are based on the better rating for each weed attributed to the products in the tank-mix. In some cases, the ratings of efficacy for a product may differ from one application timing to another. Note

that this guide includes only one rating. The ratings provided in the tables should be used as a guide when selecting herbicides. Growers should be aware that the actual control obtained can vary greatly depending on a variety of parameters, including soil type, moisture conditions, weed pressure, weed size and environmental conditions.

Again, we stress that the information contained in the tables is derived from OMAFRA’s Publication 75 and we strongly suggest that growers check the publication and use the product labels for details and cross-reference.

Each year, new products are introduced and some are withdrawn from the market. However, due to publication lead-time conflicting with confirmation of registration for new products, we may not have been able to include all of them. We suggest readers make a suitable note in their copy of the tables as new products are introduced.

Ralph Pearce Editor

For the latest registrations, visit the News Section of www.Ontarioweeds.com

Problem weed control options in corn and soybean. Crop tolerance ratings for cereal herbicides.

Responsible glyphosate use guidelines for field crops. A table that calculates adjuvant rates to L/100 U.S. gallons.

$15 plus GST

New products and tank-mixes.

New crop staging diagrams.

More re-cropping information.

Herbicide-resistant weeds.

ORDER A COPY: 1-888-466-2372, press “1” and then “2” ONLINE ACCESS: www.omafra.gov.on.ca/english/crops/pub75/pub75toc.htm Queen’s Printer for Ontario, 2010. Reproduced with permission.

A Triazine-resistant biotypes exist.

B Imidazolinone-resistant biotypes exist.

CL Clearfield corn only. LL Liberty Link corn only. RR Roundup Ready corn only. * Early post-emergence/late post-emergence: each product has its own specific recommendation on stage of crop growth.

Check product label for details. ** Gramoxone: Topgrowth burndown for emerged weeds. Glyphosates: Season-long control may vary depending on weed species. Red type: Herbicide tolerant hybrids only.

5, 6, 7 = 50 to 80 percent control

8 = 80 to 90 percent control

9 = > 90 percent control

Control rating:

This table is presented as a guide only: It is strongly recommended that users refer to OMAFRA Publication 75 and product labels. Performance of some products on certain weeds may vary according to application timing. Some tank-mixes may have higher ratings on some weeds than shown, especially if various timings are recommended. Various formulations may be available and additional application rates may be recommended. Check Publication 75 or product labels for details.

? Insufficient data available to provide control rating. a Use high rate for optimum control.

b Use pre-plant incorporated timing for optimum control.

c Use pre timing for optimum control.

d Directed spray only. e Use post timing for optimum control.

DuPont™ Guardian® herbicide goes beyond glyphosate alone to deliver one-pass, broad-spectrum residual control including tough weeds like Dandelion, Yellow nutsedge and Annual sow-thistle. And, it guards against resistance and weed shifts.

For burn-down in all soybeans or for in-crop use in glyphosate tolerant (GT) soybeans, unleash the power of Guardian®

Now, take an even BIGGER BITE out of weeds with the New Guardian® MEGA™ 400 acre tote.

A Triazine-resistant biotypes exist.

B Imidazolinone-resistant biotypes exist.

CL Clearfield corn only. LL Liberty Link corn only. RR Roundup Ready corn only. * Early post-emergence/late post-emergence: each product has its own specific recommendation on stage of crop growth.

Check product label for details. ** Gramoxone: Topgrowth burndown for emerged weeds. Glyphosates: Season-long control may vary depending on weed species. Red type: Herbicide tolerant hybrids only.

5, 6, 7 = 50 to 80 percent control

8 = 80 to 90 percent control

9 = > 90 percent control

Control rating:

This table is presented as a guide only: It is strongly recommended that users refer to OMAFRA Publication 75 and product labels. Performance of some products on certain weeds may vary according to application timing. Some tank-mixes may have higher ratings on some weeds than shown, especially if various timings are recommended. Various formulations may be available and additional application rates may be recommended. Check Publication 75 or product labels for details.

? Insufficient data available to provide control rating. a Use high rate for optimum control.

b Use pre-plant incorporated timing for optimum control.

c Use pre timing for optimum control.

d Directed spray only. e Use post timing for optimum control.

HiStick® N/T soybean inoculants are BioStacked® for increased crop performance.

Our unique, patented microorganism, Bacillus subtilis, acts as a Nodulating Trigger,® and in combination with Bradyrhizobium japonicum results in more vigorous plants with greater root biomass, more nitrogen-fixing nodules, and what you really want – increased yield.

HiStick® N/T — value and performance that really stacks upTM

Triazine-resistant biotypes exist.

for details.

Gramoxone: Topgrowth burndown for emerged weeds. Glyphosates: Season-long control may vary depending on weed species. Red type: Herbicide tolerant hybrids only.

This table is presented as a guide only: It is strongly recommended that users refer to OMAFRA Publication 75 and product labels. Performance of some products on certain weeds may vary according to application timing. Some tank-mixes may have higher ratings on some weeds than shown, especially if various timings are recommended. Various formulations may be available and additional application rates may be recommended. Check Publication 75 or product labels for details.

? Insufficient data available to provide control rating. a Use high rate for optimum control.

b Use pre-plant incorporated timing for optimum control.

c Use pre timing for optimum control.

d Directed spray only.

e Use post timing for optimum control.

Finance day-to-day expenses with AdvancerPlus

Need funds to buy inputs and supplies? Want to take advantage of last-minute deals? AdvancerPlus is a short-term loan that’s always there to cover your day-to-day operating expenses. Pull out all the stops and get financing that keeps up with you.

To find out more about AdvancerPlus, call your nearest FCC office at 1-800-387-3232.

www.fcc.ca

The results are in. With Foundation Acre™ you get an average of 32 more kernels per ear. Foundation Acre is based on the discovery that corn can sense competition from weeds as it emerges. By applying Primextra® II Magnum® at the pre-emergent stage you’re ensuring your crop will develop a healthy root biomass and strong leaf development which ultimately leads to more consistent kernel output and yield. For further information, please contact our Customer Resource Centre at 1-87-SYNGENTA (1-877-964-3682) or visit SyngentaFarm.ca

Its exclusive 6-post application cab is made for visibility in sprayers, not tractors. And its 120-foot boom and 1,300-gallon product tank make quick work of the largest fields. The new line of RoGator ® sprayers is built for those who demand a professional job. They’re what you’d expect from the leader in sprayers. See more at applylikeapro.com

Please do not ingest product. Suitable for weeds only. Always read and follow label directions. Touchdown Total ® and the Syngenta word mark are trademarks of a Syngenta Group Company. © 2010 Syngenta Crop Protection Canada, Inc.

With less foam than ever before. Nobody likes to wait longer than they have to. Touchdown Total® has been formulated to create less foam, which means that you don’t have to wait as long for the foam to settle when spraying your weeds. Use to control weeds in all glyphosate tolerant corn and soybeans. Visit one of our bulk dealers to get your Touchdown Total in convenient packaging that fits your farm and remember, return your empties once finished. For further information, please contact our Customer Resource Centre at 1-87-SYNGENTA (1-877-964-3682) or visit SyngentaFarm.ca

c Use pre timing for optimum control. e Use post timing for optimum control. A Triazine-resistant biotypes exist. B Imidazolinone-resistant biotypes exist. RR Roundup Ready corn only. * Pre-plant incorporated rating: May differ from that shown. For most products, ratings for ‘pre-plant incorporated’ and ‘pre-plant surface applied’ are the same. For a few products ratings may change slightly between treatments. Check Publication 75 for details. ** Topgrowth burndown for emerged weeds: Gramoxone and glyphosates. *** Most annual weeds will be controlled if emerged. Red type: Herbicide tolerant varieties only.

Insufficient data available to provide control rating. a Optimum growth stages for best control of these weeds will not likely be attained prior to planting in early to mid-spring

timing. Some tank-mixes may have higher ratings on some weeds than shown, especially if various timings are recommended. Various formulations may be available and additional application rates may be recommended. Check Publication 75 or product labels for details.

of some products on certain weeds may vary according to application timing. Some tank-mixes may have higher ratings on some weeds than shown, especially if various timings are recommended. Various formulations may be available and additional application rates may be recommended. Check Publication 75 or product labels for details.

? Insufficient data available to provide control rating. A Triazine-resistant biotypes exist. B Imidazolinone-resistant biotypes exist. From OMAFRA Publication 75 Guide to Weed Control, copyright © Queen’s Printer for Ontario, 2010. Reproduced with permission.

to 90 percent

This table is presented as a guide only: It is strongly recommended that users refer to OMAFRA Publication 75 and product labels. Performance of some products on certain weeds may vary according to application timing. Some tank-mixes may have higher ratings on some weeds than shown, especially if various timings are recommended. Various formulations may be available and additional application rates may be recommended. Check Publication 75 or product labels for details.

Always read and follow label directions. Cruiser Maxx ® and the Syngenta word mark are trademarks of a

Watch your crops grow faster than ever before. Ongoing scientific research shows that the properties of Cruiser Maxx ® cause plants to emerge faster, resulting in stronger plants and a higher return on your investment. It also combines the best disease and insect protection. So, be sure to ask for Cruiser Maxx ® Beans when ordering your soybeans and edible beans. For further information, please contact our Customer Resource Centre at 1-87-SYNGENTA (1-877-964-3682) or visit SyngentaFarm.ca

® The Cargill logo is a registered trade-mark of Cargill, Incorporated, used under licence. © 2009, Cargill Limited. All Rights Reserved.

“What

This question came our way from a bean and corn grower in southern Ontario and we promised him an answer he could count on. Equipped with the collective knowledge of Cargill experts worldwide, we compiled a collection of the best products available.

Through our global network of agronomists and grain merchants, we determined the best products to meet the grower’s needs and secured a home for final production before the seed was in the ground.

As a result of Cargill’s expertise, there’s now a grower in southern Ontario with better crop protection knowledge, superior products and greater confidence.

by Heather Hager, PhD

Pan-American conference aims to tackle the issue of weed resistance development.

Agricultural producers are facing the serious issue of escalating weed resistance to herbicides. The numbers of resistant weed species, locations affected, and herbicide modes of action involved are all on the rise. Compounding the problem, some weeds have developed resistance to multiple modes of action, making their control that much more difficult, if not impossible.

Dr. Mike Owen, University of Iowa, works in the US Midwest corn/soybean belt, where the majority of acres are planted to glyphosate-tolerant crops and there is high pressure for the selection of glyphosateresistant weeds.

There is an urgent need to develop and use tools and methods that will make the herbicides that are currently available more sustainable over the long term. For this reason, close to 300 participants from 18 countries met for a three-day conference in Miami in lateJanuary 2010 to discuss weed resistance issues. The meeting was hosted by Bayer CropScience and attended by representatives from industry, universities, governments, and the media.

Presentations of weed resistance cases from Canada, the US, Mexico, Brazil, Argentina and other areas drove home the fact that weed resistance is an increasing problem. Resistant weeds are present in all major crops, e.g., corn, soybeans,

rice, cotton, cereals, orchards and vines, and for virtually all classes of herbicide. Despite this, “the growers’ perception is that the resistance threat is low,” said Dr. Mike Owen, agronomist and weed extension specialist at Iowa State University. “It is not the herbicides, but the way they are used that cause problems,” stated Owen, a statement that was echoed by other industry experts during the conference.

As an extension specialist, he is trying to get growers to recognize that proactive management would effectively eliminate the resistance problem. He thinks that growers have been misled by the convenience and simplicity of some herbicide systems and have disregarded the risks of neglecting herbicide and crop diversity. “Growers want to take steps, but many are unwilling to initiate programs because they don’t want to spend time planning and spend money for different, more costly herbicides,” he said.

“Growers need to start using mixtures and diversity measures before their current technology fails on a large scale, not after,” stated another presenter.

The longer growers wait to address the weed resistance issue, the worse the problem becomes. The chemical

industry will not be able to develop new herbicides and modes of action to keep up with resistant weeds. “We need to recognize herbicides as precious chemical resources,” said Dr. Stephen Powles, plant and crop scientist at the University of Western Australia and director of the Western Australia Herbicide Resistance Initiative. “Glyphosate was a one in 100 year discovery,” he said, likening it to the discovery of penicillin. “We should do everything in our power to keep it working.”

“Weed resistance is a global problem, but it is controlled locally on each farmer’s field,” emphasized Dr. Harry Strek, head of integrated weed management and resistance biology for Bayer CropScience. He noted that herbicide companies could help growers by providing better herbicide information and tailored management recommendations.

The consensus is that the main way to lessen and manage weed resistance development is to use diversity in both herbicide application and crop rotation. This was stressed by various presenters. It will take more planning and more work by growers, and will likely have higher

Dr. Stephen Powles, University of Western Australia, demonstrates target-site resistance vs. non-target-site resistance due to enhanced metabolism or reduced translocation of herbicide.

costs. It will also require the registration of additional useful tank mixes by herbicide companies.

One way to facilitate herbicide rotation might be through mandatory labelling of herbicides with a clear indication of the herbicide group or mode of action, said Dr. Hugh Beckie, Agriculture and AgriFood Canada weed scientist and adjunct professor at the University of Saskatoon, Saskatchewan. He noted that such labelling is being tried voluntarily in Canada. He also suggested that close management of resistant patches within a field to prevent new seeds from entering the seed bank could help in containing resistant populations.

Speakers also stressed the importance of using the correct strength of herbicide products. For example, participants learned that much of the early glyphosate resistance that developed in Brazil arose before glyphosate-tolerant crop technology was made legal. During that time, growers were using the technology without supervision or company technology support, said Dr. Pedro Cristoffoleti, weed scientist at the Luiz de Queiroz College of Agriculture, University of São Paulo, Brazil. He suggested that application rates that were too low likely caused the rapid development of glyphosate resistance. Fewer glyphosate-resistant weeds have been found since the technology was legalized, he added. Insufficient application rates are problematic because they leave weeds behind and facilitate the selection of resistant individuals.

Herbicide must also be applied at the right time in the weed life cycle. If

applied too late, weeds are too big to be killed completely and can grow back, facilitating the selection of resistant individuals. For some weeds, the correct timing of application can be a matter of a few days’ window, so growers must keep on top of scouting weed development.

“The era of total post weed control is over, and I don’t think it’s coming back,” said Dr. Larry Steckel, University of Tennessee extension weed specialist for

row crops. He noted that glufosinate, a broad-spectrum, non-selective herbicide, is working with glufosinate-tolerant crops (e.g., LibertyLink) in some areas of Tennessee where glyphosate resistance is a serious problem. However, he cautioned that growers should be sure not to make the same mistakes they made with glyphosate by neglecting herbicide and crop diversity or else they will end up with no way of controlling some of the major, problematic weeds.

Use of residual herbicides exploded in 2009 as weed shifts and spray demands pushed producers to find solutions.

Adding a pre-emergence herbicide application with residual control to a glyphosate-tolerant or IP soybean crop buys a grower some time and quite possibly boosts yield by keeping the crop clean early on.

Mike Cowbrough, weed specialist with the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA), says that nailing the timing of a second, in-crop application of glyphosate in glyphosate-tolerant soybeans can be hard. It is like a grower putting all his eggs in one basket: miss the window for the second spray, and he will more than likely miss out on yield, too. “Maybe it’s windy for a week or there’s horrible weather and you get delayed by 10 days,” says Cowbrough. “In our trials in 2009, where we delayed the in-crop glyphosate application to the third or fourth trifoliate, which equated to 10 days, we were able to protect yield where we had a residual herbicide and lost yield where we didn’t have one. A custom applicator looks at that and thinks that for the price of DuPont Guardian as compared to a single application of Roundup, I’m buying a little insurance if I’m not going to get there on time.”

That may be the thought that is going through the minds of a lot of growers lately. Sales of residual herbicides for early-season weed control in soybeans grew substantially in 2009. The strategy worked well in 2009, when it was cool and wet across much of Ontario and Quebec. The crop was slow growing and slow to fill the rows, says Kerry Teskey, senior sales territory manager with DuPont. “We rely a lot on crop competition in soybeans, and if the sunlight reaches the ground, it puts pressure on nature to grow something on it. Soybeans that weren’t sprayed with a residual herbicide had multiple flushes of weeds.”

Untreated plots (left) contained 451 tubers after overwintering, whereas the plots treated with Guardian (right) had only 35 tubers in the same volume of soil.

Teskey says many glyphosate-tolerant soybean fields had to have a second or even third application of glyphosate. “Growers who used Guardian as a burndown or used it in-crop would have eliminated another trip across the field and kept their soybeans cleaner,” he says. “For those who used Guardian as a first in-crop application in conventional till, it may have been all they needed.”

It is a similar story in identity preserved (IP) soybeans. “In IP soybeans, there’s no question that the most effective way to get good weed control is to get some sort of residual herbicide down pre-emerge,” says Cowbrough.

There are several programs that work well. Cowbrough explains that in some situations, a tank-mix of Guardian and Boundary is best or Guardian plus Valtera. Both can be one-pass treatments.

Different challenges amoung regions

In some specific situations, e.g., controlling dandelions in the spring, a residual herbicide can boost the effectiveness of glyphosate substantially. Cowbrough says that researchers applied soybean herbicides on a yellow nutsedge patch with no crop competition at the Elora Research Station. They harvested the nutsedge tubers, which are the only part of the plant that overwinters to produce new plants in the spring. “Where we applied Guardian, we had an over 95 percent reduction in nutsedge tubers,” he says. “We had more than 451 tubers in a softball-sized amount of soil. In the soil treated with Guardian, there were only 35 tubers.”

Last year was a big year for IP soybeans in Essex County in Ontario. One retail outlet that does custom application, Agris Co-operative at Stoney Point, used a herbicide with residual

THEY SAY SUCCESS IS BEING IN THE RIGHT PLACE AT THE RIGHT TIME. WE COULDN’T AGREE MORE.

Early, even emergence starts with precision. Case IH Early Riser® planters help ensure accurate seed populations, precise in-row placement and consistent depth control. As well as ideal seed-to-soil contact. And they do it all while operating at high field speeds. So you can make the most of your seed and your planting window. To learn more, see your dealer or visit caseih.com.

to keep ahead of spraying. “It’s a necessity for us to start out with clean fields in this area,” says Chuck Belanger,

He says tank-mixing a herbicide with residual with glyphosate is key for good weed control. But it is also good prac-

Welcome to a new era in crop protection. MPOWER is the new brand name for our growing family of generic crop protection products.

Changing the industry and building member market power in crop protection since 2005, FNA looks forward to a wide open future, empowering our members with the ability to improve their farm pro tability by choosing high quality MPOWER products.

We are excited about the launch of several new crop protection products including wild oat control products for cereals, pulses and oilseeds, as well as broad leaf products, insecticides and fungicides. Our crop protection partners currently have over ten submissions for registration with the PMRA.

Call us today to nd out more.

Despite delays that equated to 10 days, field trials conducted by OMAFRA’s Mike Cowbrough showed that yield could be protected using a residual herbicide.

PHOTO BY RALPH PEARCE

Ontario, finished spraying a field for dandelions in spring 2009. But he had a few passes worth of herbicide in his spray tank so he polished it off in a second field. “When I fold up the boom, my GPS marks the spot where I stop spraying,” says Hoven. “When I was combining in the fall, I could see the line where the Guardian ran out and I had finished the field with glyphosate. There was velvetleaf from that point on that had germinated after I sprayed. They always said Guardian would do that but until I saw it with my own eyes I didn’t believe it.”

There are some hot spots of wild carrot and nutsedge across the province. But Cowbrough and others focus on the timing benefits of a residual herbicide. “The main thing to keep in mind is that a residual herbicide can help you spread out the workload,” says Roger Bourassa, DuPont senior sales representative. “You can do your burndown and buy yourself some time to make other in-crop applications.”

Argentina eyes Canada’s traditional food-grade soybean customers.

Soybeans are a staple export for many countries. When it comes to exports of soybeans for oilseeds, Argentina ranks roughly third in the world after the United States and Brazil. However, in recent years, Argentina has been making moves to enter the food-grade soybean market, with a stepped-up presence at international marketing conferences. At the World Soybean Research Conference in Bejing, China, in August 2009, Argentine businesses were represented by multiple exhibitors; Canada had only one.

Still, does the South American country have what it takes to unseat Canada when it comes to meeting the needs of the finicky Japanese market?

For the new chair of Agri-Food Innovation and Regulation at the Richard Ivey School of Business in London, Ontario, Argentina’s reliance on genetically modified (GM) varieties will keep them out of the markets where GM soybeans are not welcome. “The Argentine soybeans are largely GM, so this concerns the Japanese,” says Dr. David Sparling. “Canada is segregating GM from nonGM soybeans that go to Japan. The Japanese buyers carefully check our production, but we spend time and effort tailoring our production to meet that market.”

So far, there is little indication that the Argentines are a threat to Canada in the food-grade market because their system of segregation and tracking is not as sophisticated as Canada’s, yet. “At this point, Argentina is not a major competitor in the food-grade market because they aren’t producing specialty beans,” comments Crosby Devitt, manager of Research and Innovation with the Grain Farmers of Ontario. “However, Canada’s challenge going forward is to continue our focus on meeting the needs of our buyers and keeping our breeding programs focused on specialty varieties.”

Canada has a solid reputation of meeting the needs of customers and anticipating what will be expected in the

by Rosalie I. Tennison

PHOTO BY RALPH PEARCE

market. Both public and private breeding programs work diligently to keep ahead of trends so there are varieties ready to plant when buyers come calling. “Our breeders keep up with the latest nutrition information, and there is communication with customers on what their needs are,” Sparling explains. “It helps to have good partners to work with to help us know where the market is going.”

Growers knowing who their competitors are is a major aspect of market development, according to Devitt. Therefore, it would be wrong for Canada to rest on its laurels and not be aware of what is happening in Argentina. “Soybeans are a huge sector of the Argentinian agricultural economy,” he continues, “but it is built on large volumes for the crushing industry. Canada has to continue to work at keeping our customers happy, finding new ones and developing varieties with the quality traits they want.”

It is possible, adds Sparling, that Canada’s niche is its ability and commitment to giving high priority to what is wanted in the market and to determine how to meet those needs. “Without a doubt, Canada’s infrastructure is better in producing and tracking

food-grade soybeans,” he continues. “We back up our position with good genetic material and we have top breeders who do a great job. Argentina may want to be more active as a player in the food-grade market and may have this as a long-term goal, but that economy is facing major challenges right now.”

That is not to say that Canada should not be concerned about Argentina pushing its way into this country’s markets, with Brazil not far behind. So far, Canada’s edge lies in its ability to meet the needs of its customers, particularly Japan, with high-quality, nonGM soybeans for specific uses. Sparling says that is what it means to be a global player in the marketplace; there will always be a producer trying to take another producer’s place, and that individual will always have to work at being better.

For now, it appears that Argentina is a distant cloud hovering on the edge of the global food-grade soybean marketplace. However, that cloud could get closer. When it does, Canada’s industry, from breeders to growers to marketers, will have to be prepared to develop better varieties, improve production practices and deliver a product that buyers continue to demand.

by Treena Hein CROP MANAGEMENT

How to ensure that planting practices maximize the benefits offered by new genetics.

New crop breeding developments bring growers higher yields, better disease resistance, and much more. However, how we manage these crops must keep pace with genetic changes. Using outdated planting recommendations and incorrect advice about other best practices can prevent growers from getting the full benefits that crop advances offer.

Corn densities can be tweaked

Corn planting densities have steadily increased for several years because of the increased light-use efficiency of each new generation of hybrids. “Evidence continues to mount that corn growers can increase seeding rates to approach 35,000 seeds per acre,” says Jonathan Klapwyk, product and agronomy manager at Pride Seeds. “Many growers are now planting at 32,000 or 33,000 seeds per acre.”

New hybrids have featured better canopy architectures from a light utilization standpoint, with the upper leaves becoming more erect over time, says Dr. Elizabeth Lee, professor of plant agriculture at the University of Guelph. “The modern hybrid captures 95-97 percent of the light,” she observes, “so bumping plant densities much higher does not make much sense from the standpoint of light capture and utilization, but there could be some room for tweaking, perhaps in the range of plus or minus 10 percent, with specific hybrids.

Klapwyk agrees. Increasing corn plant populations is an avenue to capture additional yield from genetic gains in stalk strength and stress tolerance, he notes, as well as from additional management tools such as foliar fungicides.

“The growers that will have the most success with adjusting planting rates are those that understand the relation between individual hybrids and the soils that they are planting them on,” Klapwyk says. “It’s an issue that growers should have an in-depth look at with their agronomist or seed company representative.”

Soybean seeding rates decrease

The newest recommendations on soybean seeding rates released in 2008 by the Ontario Ministry of Agriculture, Food and Rural Affairs, are substantially lower than those previously provided. This is because of recent studies headed by provincial soybean specialist Horst Bohner and University of Guelph plant agriculture professor Dr. Hugh Earl.

The current 7.5-inch-row seeding rate recommendation has dropped from 225,000 to 194,000 seeds per acre. For 15-inch rows, it is now 177,000, down from 188,000 seeds per acre. The savings provided by following these new guidelines depend on the cost of seed, says Bohner, but it is reasonable to expect about $8 per acre (7.5-inch rows) and more than $3 per acre (15-inch rows) in savings.

Seeding rates have dropped, observes Dr. Istvan Rajcan, professor of plant agriculture at the University of Guelph,

“probably both because of improved genetics and the use of different agronomic practices.” In terms of the latter, some growers are using a lower seeding rate with treated seeds, which have a better survival rate. However, because treated seed is more expensive, any savings gained in using a reduced rate may be nullified.

In a large study conducted by Bohner and Dr. Dave Hooker of the University of Guelph, fungicide-treated seeds resulted in 5000 more plants per acre than untreated seeds using the same seeding rate. With fungicide- and insecticidetreated seed versus untreated seed, the results show that 10,000 more plants per acre emerged. In theory, Bohner says that should mean a grower can plant 5000 fewer fungicide-treated seeds or 10,000 fewer fungicide- and insecticidetreated seeds per acre than untreated seeds. But, he says,“Not all plants are going to make it to harvest, so cutting back too much on the recommended

rates when using treated seeds may not be wise. We currently recommend the same seeding rate for both no-till and conventional systems.”

Growers might also choose to use a lower seeding rate if they are seeding earlier in the season because it gives the plants more room to branch over a longer period. However, Bohner stresses, “Seeding earlier also means the plants are facing more stressful cold and wet conditions, so again, cutting back may not be wise. The mortality rate of soybean seeds is high. A seed treatment can help protect the seed when conditions are poor.”

Bohner has seen success in shaving down the seeding rate with the use of a precision planter instead of a drill. “We found this to be the case in 2008 for studies on two sites,” he says, “even though the stand differences were too small that year to make a statistically significant difference on yield. There was a 13 percent plant stand increase when using a planter compared to a drill in 15-inch rows. More studies are underway.”

One of the most common seeding

Ontario soybean fields, OMAFRA’s Horst Bohner says that seeding rates are going lower but not to the same extent as in parts of the US where the growing season is longer and the soils are more productive.

questions Bohner receives is why the seeding rates for US growers are lower. “I can assure growers that we have large amounts of repeated data that US rates are too low for Ontario,” he says. “It’s our growing conditions in this geographic location and our soil. You can

get away with a lower rate in the highly productive soils of Iowa. They also have a longer growing season.”

However, some differences in soil conditions among farms in Ontario may affect growers’ choice of row width, which in turn affects the seeding rate. “On heavier soil types such as clay, wider row widths increase the number of seeds per foot of row,” Bohner says, “which can aid in emergence.” The choice of row width should also depend on tillage system, equipment suitability, weed problems, white mould pressure and planting date. However, 30-inch rows are too wide for maximum yield potential in Ontario.

“There seems to be some advantage to using 15-inch rows if the soil conditions are good,” says Rajcan. “The plants will produce side branches with additional pods. However, if conditions are poor, 7.5-inch rows are better because they allow the plants to utilize sunlight more effectively. If 7.5-inch rows are used in good conditions, there’s too much interplant competition, and that will have a negative effect on yield and may represent a waste of seed.”

Trash Reduction

CALMER Trash Reduction

!!!CALMER’s!6+Tooth! Drive!Sprocket™!along! with!the!CALMER’s!9+ Tooth!Idler!Sprocket™

slow!down!just!the! gathering!chain!!!!!!! enabling!the!stalk!roll! to!make!additional!!!!!!!

CALMER’s!Beveled! Stripper!Plates™ are! longer!to!scoop!up!low! hanging!ears.!!Straight!in !revolutions,!while! ground!speeds!can!stay! the!same!or!increase. the!front!to!reduce!ear! wedging,!then!beveled!to! reduce!butt!shelling.!This! allows!the!stalk!rolls!to! engage!more!ear!shanks,! husks,!and!leaves. knives!that!accelerate! decomposition.

No)Till

CALMER’s!!BT!CRUSHER! Knife!Rolls™ 2!open! windows!which!receive! stalk!in!an!upright!position! (no!bulldozing!effect)!then!! crimping!!and!crushing!

If you’re going to quack about soybean yields, we think it best you first

Because when you line up all the facts, it’s time to ask Pioneer’s competitors just how their numbers stack up. In over 1,700 on-farm comparisons, Pioneer® brand soybean varieties with the original Roundup Ready® trait are outyielding varieties with the Genuity™ Roundup Ready 2 Yield® technology by 2.7 bushels per acre*. So don’t duck the question. If Pioneer soybean growers get more bushels in their bin, just what have you got to quack about?

*Pioneer® brand leader soybean varieties with the original Roundup Ready® trait are outyielding competitor varieties with the Genuity™ Roundup Ready 2 Yield® (RR2Y) technology by 2.7 bu/acre in 1,700 on-farm comparisons as of 11/16/09.