TOP CROP

MANAGER

Moldboard

Plow deMo

Hook up your plow and start your engines

PG. 8

New Soybea N

Viru S

Industry looking for info and answers

PG. 17

w e S ter N b ea N

Cutwor M

Farmers, OMAFRA and the U of G working together

PG. 22

Hook up your plow and start your engines

PG. 8

Viru S

Industry looking for info and answers

PG. 17

Farmers, OMAFRA and the U of G working together

PG. 22

Jeanine Moyer

By Amy Petherick

Daynard

Sara avoledo | editor

Soybeans are hardly new to the Canadian farmer. They arrived in Canada in the mid1800s, and growing trials have been recorded from 1893 at the ontario agricultural College in guelph. Soybeans didn’t become a commercial oilseed crop until a crushing plant was built in southern ontario in the 1920s, but since then their share of growing acreage has continued to climb.

Today, soybeans are ontario’s largest field crop in terms of dollar value. Through breeding advances the versatile soybean is in demand by the food, livestock and industrial sectors.

In this issue of Top Crop Manager, we will cover much of the technology and manyh of the research innovations you’d expect, but we will also focus on the soybean and examples of new innovations and research into its issues, pests and diseases.

For example, a new local business offering an oilseed extruder to process feed on farms is featured on page 15. The press can process one tonne of your own soybean seed every day, which produces enough feed for more than 300 cows and 80 litres of filtered oil you can use to fuel your machinery. So not only could you save money by producing your own feed, but also you could save fuel costs associated with the running of tractors and implements alike on your operation.

When it comes to your yields, and concerns therein, the soybean vein necrosis virus (SVnV) has been confirmed in southwestern ontario as of late September 2012. If you haven’t heard, SVnV is a relatively new disease in both Canada and the United States, and very little information is known about it yet. Top Crop readers can learn more from albert Tenuta on page 17.

The soybean cyst nematode (SCn) is one of the most – if not the most – important yield-reducing pathogens that threatens soybean yields throughout Canada and the United States. Yet growers are still not managing their fields to prevent and control this important pathogen. Learn more on page 20.

a new research project studying the western bean cutworm is featured on page 22. as part of the WBC Trapping program, which has been set up in all regions of ontario and Quebec, farmers have used “milk jug traps” on their operations to collect data. pheromones in the top of the trap attract the moths to the jugs, where they drown in a mixture of antifreeze and water. This setup has allowed accurate data to be collected to teach us more about the moth and its larvae.

Finally, we have recently featured several stories related to soybeans. one explores a new asphalt sealant made from soybean oil that is being tested in ontario. another discusses a new soybean oil-based lubricant coming to a retailer near you. all of these innovations create new opportunities for you, our soybean, grain and oilseed farmers in eastern Canada.

perhaps the day is not far away when the versatile soybean will come to mind along with wheat, corn and hay when people think of Canadian agriculture.

Make sure you are checking back frequently at www.agannex.com for more information and news stories relevant to your operation and your farming business. our weekly e-newsletter broadcast can keep you up to date and is delivered directly to you via e-mail. I look forward to hearing more about your thoughts and opinions on this issue in our conversations online . . .

DECEMBER 2012, vol. 38, no. 16

EDIToR Sara Avoledo • 226.979.9094 savoledo@annexweb.com

EASTERn SAlES MAnAGER Steve McCabe • 519.400.0332 smccabe@annexweb.com

WESTERn SAlES MAnAGER Kevin Yaworsky • 250-317-1992 kyaworsky@annexweb.com

ACCounT CooRDInAToR Alice Chen • 905-713-4369 achen@annexweb.com

MEDIA DESIGnER Katerina Maevska

GRouP PuBlISHER Diane Kleer dkleer@annexweb.com

PRESIDEnT Michael Fredericks mfredericks@annexweb.com

PUBLICATION MAIL AGREEMENT #40065710 RETuRn unDElIvERABlE CAnADIAn ADDRESSES To CIRCulATIon DEPT. P.O. Box 530, Simcoe, ON N3Y 4N5 e-mail: mweiler@annexweb.com

Printed in Canada ISSN 1717-452X

CIRCulATIon e-mail: mweiler@annexweb.com Tel.: 866.790.6070 ext. 211 Fax: 877.624.1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

SuBSCRIPTIon RATES

Top Crop Manager West - 8 issuesFebruary, March, Mid-March, April, June, October, November and December - 1 Year - $44.25 Cdn. plus tax

Top Crop Manager East - 7 issuesFebruary, March, April, August, October, November and December - 1 Year - $44.25 Cdn.

by amy petherick

There’s a spirit of unity converting farmers across the nation, thanks to a group of industry representatives challenging farmers to change their ways and start speaking out for agriculture in harmony.

agriculture More Than ever is a movement that was first started by Farm Credit Canada (FCC) in May and has grown to include more than 40 industry partners committed to promoting the cause. Frustrated bymainstream media’s portrayal of farmers as either hillbillies or fat-cats, the campaign’s creators agreed the public needed to see farmers as they really are. greg Stewart, FCC’s president and chief executive officer, says there’s been a growing feeling that agriculture’s public image needs for a facelift for quite some time and FCC’s message has been received with enthusiasm.

Stewart says it’s no secret that the industry hasn’t done the greatest job of sticking up for itself in the past. although that may have been acceptable in the past, we simply can’t afford to keep staffing the industry “in house” in light of the growing global demand for food and the declining numbers of primary Canadian producers. overcoming the negative portrayal of farming in the media, sometimes even by farmers themselves, is now more important than ever to ensuring the continued success of the industry, says Stewart.

“We need the best and the brightest in agriculture, and the more people are uninformed about agriculture, the less chance we’re going to attract talent,” says Stewart. “given what you would have heard, you may not think [agriculture] is a great place to start a career and we know that’s not true.”

Stewart says the future for agriculture has never looked brighter but that message isn’t getting out there and the best people to deliver that message are farmers themselves. Jim Snyder is the national director of agricultural practice development for campaign supporter BDo Canada, and he believes farmers are equally frustrated by the public image. He thinks farmers are reluctant to really speak out for two reasons: it goes against the current culture of humility in the industry, and some farmers may have only limited experience in public speaking.

“We come from a culture that says we would rather be judged by our actions than our words,” says Snyder. “When we all get a little bit more confident and competent in having these conversations, hopefully we can do something to change the perception of the other 98 percent.”

Snyder also suspects some farmers don’t consider themselves to be specialists or experts in their field. But focusing less on exper-

tise and speaking solely about their passion for the industry and their vision of the future as eternal optimists can still do a lot of good. Stewart says he rarely comes across a producer who honestly regrets choosing a career in agriculture, and it isn’t too difficult to press most into admitting that these days. He thinks it’s a really good time to showcase the level of talent and the technology that’s needed to run a modern farm, as well as how much farmers care about animal welfare and the environment. But he says it’s a realization all farmers have to come to.

■ Seed-placed liquid orthophosphate

Immediately available in cold soils

Faster emergence; Larger root mass

Higher yields

■ NPK analysis with micronutrients A complete starter fertilizer

■ Convenient low rate liquid Easy set-up on large planters

Hook up your plow and start your engines.

by Melanie epp

There’s nothing like lining up a bunch of plows to spur the competitive spirit in. a lthough the moldboard plow demonstration at Canada’s o utdoor Farm Show was not set up to be a contest, judging from the oohs and aahs in the crowd, there were a few clear winners. Below is a description each plow, as provided by the manufacturer.

Kuhn Farm Machinery

Model: Kuhn Vari-Manager Semi-Mount

Rollover Plow

Kuhn n orth a merica is said to be one of the world leaders when it comes to tillage technology. It provides a full line of mounted and semi-mounted rollover and conventional plows. The plow that was featured at C o FS was an in-furrow, semi-mount rollover plow with a two-wheel undercarriage. The plow features excellent manoeuvrability and stability, and its built-in suspension system allows for safe transportation.

Kuhn plows can accommodate all soil types. Bottom models 7 to 12 offer an on-land hitch option as well. Like most Kuhn plows, the Vari-Manager Semi-mount r ollover plow has spring-

protected coulters and hydraulic Vari-width, available with a choice of moldboards, trash boards and skimmers.

In g ermany, Lemken has been making moldboard plows since 1780. It is known simply as the “plow shop.” The company’s latest addition, the Diamant, is available from five to nine furrows in a number of different versions. It features a number of options, including hydraulic stone security, variable working width, multiple skimmers, plain or serrated disc coulters, and plain or slatted moldboards. Choose the on-land version and plow with the tractor wheels in or out of the furrows.

o f specific interest to o ntario corn producers is that the plow has huge frame clearance of 120 centimetres in length.

TOP: The Salford plow is said to be the only plow in the world that can accommodate both European and North American needs.

INSET: The plus XMS 1050 Vario offers a working width of up to 55 centimetres per body and a depth of up to 40 centimetres.

The ever-popular slatted moldboard has several advantages, including reduced friction areas, which can save power and reduce wear and tear. It can be used in most soil types and each of the slats can be individually replaced.

Kongskilde Industries Inc.

Model: Overum CVL698-6 Furrow Roll Over

This plow is a semi-mounted six-furrow roller with 22-inch, spring-loaded ripple coulters. Its features include hydraulic lead furrow width adjustment and non-stop hydraulic stone release and reset, which allow the plow leg to trip both up and side to side. a s well, the hydraulic pressure can be adjusted to accommodate different soil types. This plow features a single rear flotation tire with hydraulic steering. For narrow transport width, it can roll to a butterfly position. Kongskilde offers a variety of plows, including both conventional and semi-mount types.

Salford began manufacturing moldboard plows in 1978 in the village of Salford, o ntario. Since then, its line of products has

grown to a full line of semi-mount plows (up to an eight-furrow), as well as two articulating models from seven to 14 bottoms that operate on land. The Salford plow is said to be the only plow in the world that can accommodate both e uropean and n orth a merican needs since it offers a variety of style bottoms best suited to specific regions.

“The standards for residue clearance that are now recognized and replicated worldwide were set by Salford many years ago and this all-Canadian plow remains today the industry leader in managing residue in high-yielding, high-residue crops,” writes Jim Boak, national sales manager for Salford.

o ne of the major plow manufacturers in e urope, Vogel & n oot offers from two- up to 12-furrow semi-mounted plows for tractors up to 500 horsepower. The plow on demonstration was a four-furrow model with hydraulic non-stop stone release. The plow is extremely compact, making it suitable for a variety of soil and field conditions.

InVigor growers are just like other growers. Every day, they’re up before sunrise and work until everything gets done. Because when you love something this much, it’s not just a job. It’s everything.

InVigor growers might be just like every other grower, but the same can’t be said about their canola. InVigor consistently delivers early season vigor, high stress tolerance and superior yield. This year, grow with confidence.

This year, grow InVigor.

Learn more at BayerCropScience.ca/InVigor

“With its big clearance (105 cm length and 78 cm height), and in combination with the special body form (WXL430), it provides a perfect job, even in extremely hard soil conditions, as well as with lots of trash,” says the event writeup. This plow offers a working width of up to 55 centimetres per body and a depth of up to 40 centimetres. The “wearing parts” are specially heat treated to provide extreme resistance and a longer service life, as well as reduced traction power.

In order to help keep the plow straight before turning, it has been equipped with an automatic beam re-centring device. It has also been equipped with a hydraulic side shift for front furrow adjustment, making setup that much easier.

Based in g ermany, r abe has been manufacturing plows since 1889. Known for its superior quality and unsurpassed working results, r abe offers a variety of plows, from mounted, semimounted and on-land plows that vary in size. Mounted plows can have from three to six furrows. Semi-mounted plows can

“In this business, you deal with a lot of uncertainty –weather, soil, timing. You can plan all you want but you never really know how things will turn out.

“InVigor is the one thing on my farm I know I can trust. Year in and year out, it delivers early season vigor, incredible stress tolerance, and some of the highest yields I’ve ever seen.

“Why do I plant InVigor? Drop by at harvest and see for yourself.”

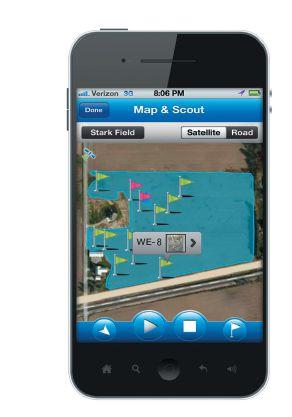

• Share guidance lines and coverage maps from vehicle to vehicle.

• Exchange prescription maps, guidance lines, coverage maps, drainage designs, soil sampling/scouting jobs, and yield data between the office and field.

• Access real-time movement of your vehicles, engine performance data, vehicle alerts, and vehicle breadcrumb trails.

• FREE! Use the Connected Farm™ app on your smartphone to map field boundaries, flag points of interest, and enter scouting information.

• FREE! View and analyze your collected mapping and scouting data from the online viewer.

by Carolyn King

To get the most out of your post-emergent herbicide applications on soybeans, one of the things to consider is the time of day you spray. a recent ontario study has found that herbicide effectiveness tends to be greatest for applications during the warmer, brighter parts of the day, although the impact varies depending on the herbicide and the weed species. In some situations the time-of-day impact is big enough to affect soybean yields.

“a lot of growers apply their herbicides early in the morning or late at night, because that’s when the wind speeds are lowest and they want to reduce the impact of spray drift. But we were finding that sometimes we were getting poorer weed control from herbi-

cides that we knew should have been effective. as we investigated it more, we found that if we applied the same herbicide at midday we would get better control. So we set up a study to look at that further,” explains Dr. robert nurse, a weed scientist with agriculture and agri-Food Canada at Harrow.

nurse and Dr. peter Sikkema, a weed management researcher at the University of guelph’s ridgetown Campus, worked together on this three-year study, which was funded by the grain Farmers of ontario.

ABOVE: The time-of-day effect was greatest for annual broadleaf weeds.

The study’s aim was to find out the effect of time of day for some post-emergent herbicides commonly used in soybeans in ontario, so growers could use that information to help maximize herbicide effectiveness and reduce weed escapes.

The field trials took place at ridgetown and Harrow, and involved six post-emergent herbicides: Basagran, Classic, reflex, roundup, pursuit, and assure II. each herbicide was applied at 6 a.m., 9 a.m., 12 noon, 3 p.m., 6 p.m., 9 p.m. and midnight.

“all herbicides are different, so you can’t make a blanket statement in terms of what happened. However, generally speaking there was maximum herbicide performance when the herbicides were applied between 9 a.m. and 6 p.m. Herbicide activity tended to decrease with really early morning applications as well as applications made late in the evening,” explains Sikkema.

The importance of the time-of-day effect depended in part on the weed species. generally speaking, there was a greater effect on annual broadleaf weeds such as velvetleaf, com-

mon ragweed and redroot pigweed, while annual grasses including green foxtail and barnyard grass were least affected.

The time-of-day effect also varied with the herbicide. With assure II, the researchers found little time-of-day impact. For roundup, Classic and pursuit, the results showed a time-of-day influence to varying degrees; roundup showed only a slight effect. all three herbicides showed a general trend for improved control when applied between about 9 a.m. and 6 p.m., with the greatest impact for broadleaf weeds and less of an effect for grasses.

For example, roundup control of common ragweed at ridgetown was: 74 percent for the 6 a.m. application; between 90 and 94 percent for applications between 9 a.m. to 6 p.m., with the peak at noon; 79 percent for the 9 p.m. application; and 53 percent for the midnight application. In contrast, roundup provided complete control of barnyard grass no matter what time of day it was applied.

In some cases, the time-of-day effect influenced soybean yields. For roundup, there

was about a 3- to 4-bushel/acre difference between the midday applications and those in the late evening or early morning.

Sikkema notes, “You don’t always get a yield impact due to what time of day you spray. However in environments that are more stressed, where you have heavier weed pressure, where the weeds may be larger at the time of application, you get a greater time-of-day effect, and that can translate into a difference in yield as well.”

Why does time of day influence herbicide efficacy? Sikkema says several studies by researchers in the United States have tried to correlate the time-of-day effect with various factors. “The two factors with the best correlation are air temperature and leaf orientation.

“In terms of temperature, it’s known that almost all metabolic processes in a plant increase with increasing daytime temperature, and therefore herbicides become more biologically active. as well, it’s thought that it is easier for the herbicide to cross the cuticle [protective waxy covering on the leaf surface] since it becomes less viscous at warmer temperatures, and there’s increased membrane permeability, so it’s easier for the herbicide to penetrate into the living portion of the plant. You have greater rates of diffusion of the herbicide into the plant. Therefore, you get improved herbicide efficacy as temperatures go up. and temperatures can vary quite a bit over a 24-hour period, so that has a significant impact on herbicide efficacy.”

Changing leaf orientation over the course of a day is important because it influences herbicide interception. Sikkema says, “In some plants, the leaves tend to be almost horizontal during the brightest sunlit hours of the day. Then from midnight to 6 in the morning, in some plants the leaves drop so they are almost vertical, or in some other plants the leaves move up and almost clasp the stem. In either case, you have less interception of the spray by the leaves during the night period and therefore poorer weed control.” other factors, such as heavy dew, relative humidity and sunlight levels, may also influence herbicide penetration into the plant and/or translocation through the plant. overall, for roundup, pursuit and Classic, spraying between 9 a.m. and 6 p.m. helps maximize weed control in soybean. If you’re facing windy weather during those hours, nurse advises monitoring the size of the weeds in the field. even though you may get reduced control by spraying early in the day, it may reduce the chances of a drift event.

To keep more value on the farm, put the squeeze on soys.

by amy petherick

No one wants to buy soybeans at a roadside stand, so there are fewer opportunities for grain farmers who want to capture more value at the farm gate. But a cleverly designed processing unit is helping some growers earn direct sales and become more self-sufficient with little extra effort or investment.

one increasingly popular company is helping farmers investigate the full potential of small-scale, on-farm feed processing. Jasmin Hofer of energrow, a newton, ontario-based company that designed and produces a european-style, cold screw oilseed press, says she has another busy fall ahead of her attending shows and trying to keep up with information requests. While many of her customers are dairy farmers who produce directly for themselves, Hofer says she is also receiving interest from cash crop farmers.

“The big interest for them is that this is a system that can be left running and it’s not something that they have to babysit,” says Hofer.

Dr. rex newkirk, with the Canadian International g rains

Institute, agrees that the machine’s ability to operate largely unsupervised is a convenient feature for farmers in this country. newkirk became familiar with the company a few years ago and featured its system last year during an educational day that explored biodiesel opportunities on the farm. newkirk says the system is unique because most competitive products have been imported, not designed specifically for the rigours of agriculture in Canada.

“ e nergrow has designed a system to deal with the fact that [Canadian farmers] don’t have a lot of staff to watch equipment, so they’ve put in safety systems to shut down if it runs out of seed and these kinds of things,” says newkirk. “They’ve been very realistic in using the product as fuel and have taken a much more reasonable, sustained approach to that opportunity.”

newkirk feels e nergrow customers are among the most

TOP: An Energrow press.

INSET: Energrow’s soybean meal.

well informed operators of biodiesel and vegetable oil powered equipment and he directly attributes that to the company. e nergrow ensures that any customer intending to use extruded oils as fuel or lubricants understands the importance of allowing the phospholipids to separate out over a two-week period and provide a filtration system that produces a fuel grade oil that meets e uropean DI n 51605 standards. newkirk says he sees more success for these customers in converting their equipment to run on biofuels and feels this diligence will help to reduce petroleum dependency on the farm.

Familiar with the use of extruders to process feed on farms in e urope, g eorge Heinzle has been looking for ways to cut his energy costs for years and he looked hard to include a press in his operation. Together with his wife and son, he milks 140 cows and runs a 600-acre cash crop operation where nearly everything is fed either by the bio-digestor and solar systems they maintain, or by the extruder. a s leaders in on-farm energy efficiency, the Heinzles are exactly the type of candidates newkirk describes as being ideally suited for an on-farm press, especially in volatile years like this.

“For the producers of the grain, it’s always good to see [price] spikes, but for the end user buying the product it’s a challenge to find ways to survive these ups and downs,” says newkirk. “o n farm, if you can produce some of your own meal, that can be pretty attractive.”

Heinzle says his press can process one tonne of seed every day, which produces enough feed for more than 300 cows and 80 litres of filtered oil. He preferred this press over the first model they tried on the farm because it does a better job of separating the oil out from the protein meal. even though dairy cattle are more forgiving when it comes to higher fat rations than other livestock, Heinzle takes care not to waste the oil through excesses in the feed since he started fuelling a tractor with it.

“We call it The Vegetarian,” laughs Heinzle. “When the fuel prices are up like this, we get good value for our oil and since spring, it’s been running excellent.”

Converting his Ford 9280 articulate tractor wasn’t too difficult, says Heinzle, but it does require two tanks. This is so the engine can be started on 100 percent diesel until it’s warm, then switched to pure vegetable oil once it’s running and later switched back to diesel while it cools down for shut-off. This prevents the oil from jelling in the fuel lines. Though it’s a little inconvenient, Heinzle says, he gets more power out of the oil than he did out of the diesel alone, and 1000 litres will last for three or four days of manure spreading. Hofer says that, although she’s pleased farmers like g eorge Heinzle are happy with their fuelling results, she believes there is still greater potential for selling the oil.

In Chesterville, o ntario, Dave Chambers has had three good years with his extruder. a s a cash crop farmer, Chambers started off much more interested in the oil being produced by the soybean press than by the meal. But by processing neighbouring dairy farmers’ soybeans for their own feed, Chambers is able to market their unwanted oil with his own and produce consistently large volumes. Chambers says his neighbours could

start running their own presses but their current arrangement is pretty mutually beneficial, even with the processing fee he charges.

“They tell me how much they feed and then I make the feed as fresh as I can for when they come,” says Chambers. “The press will do much more than they need [individually] and they can still save money by using their own beans.”

When he first got started, Chambers had to find his own market to sell oil to and was able to find a buyer in Montreal. But now he sells back to e nergrow. Hofer says this is a service e nergrow started to offer this past april after receiving feedback from some customers that they simply didn’t have the time to farm, process the beans, and market them. So Hofer sought out two mills that were interested in a steady supply of oil for their feed products and has been offering contracts to customers who are prepared to provide set volumes at regular intervals. a s with any new program, Hofer says, there are still some kinks to sort out, but the company has been pleased with the program so far.

On farm, if you can produce some of your own meal, that can be pretty attractive.

The next thing she hopes to do for her clients is to help them access more high-value markets. a s a livestock feed additive, extruded soy oil might only be worth $0.80/L but some of her customers have sold oil, for example, as concrete forming spray for $1.30/L. Hofer says it seems she learns about another new use from almost every client she has. She is particularly interested in the possibility of producing the oil for human consumption.

“We’d really like to see the oil go out and get more value in the food chain, so we’re working with CFI a and the district health unit at the moment to set up a process to do that,” she says. “I think that if the cash crop guys can get paid more for the oil, it makes it that much more worthwhile to press.”

Because research shows cold pressed soy oil contains vitamin e , Hofer says they know it will have an extended shelf life and maintain its original flavour longer when used for things like deep frying. perhaps there may even be marketable health traits. If she’s successful in getting farm pressed oil to the food market though, who knows, one day soon farmers really might sell their vegetable oil at roadside stands after all.

by Jeanine Moyer

Anew soybean virus confirmed in ontario is presenting pathologists with more questions than answers.

Soybean vein necrosis virus (SVnV) was confirmed in southwestern ontario in late September 2012. Very little is known about this disease, which is relatively new in both Canada and the United States, but ontario Ministry of agriculture, Food and rural affairs field crop pathologist albert Tenuta assures ontario growers that it’s here to stay.

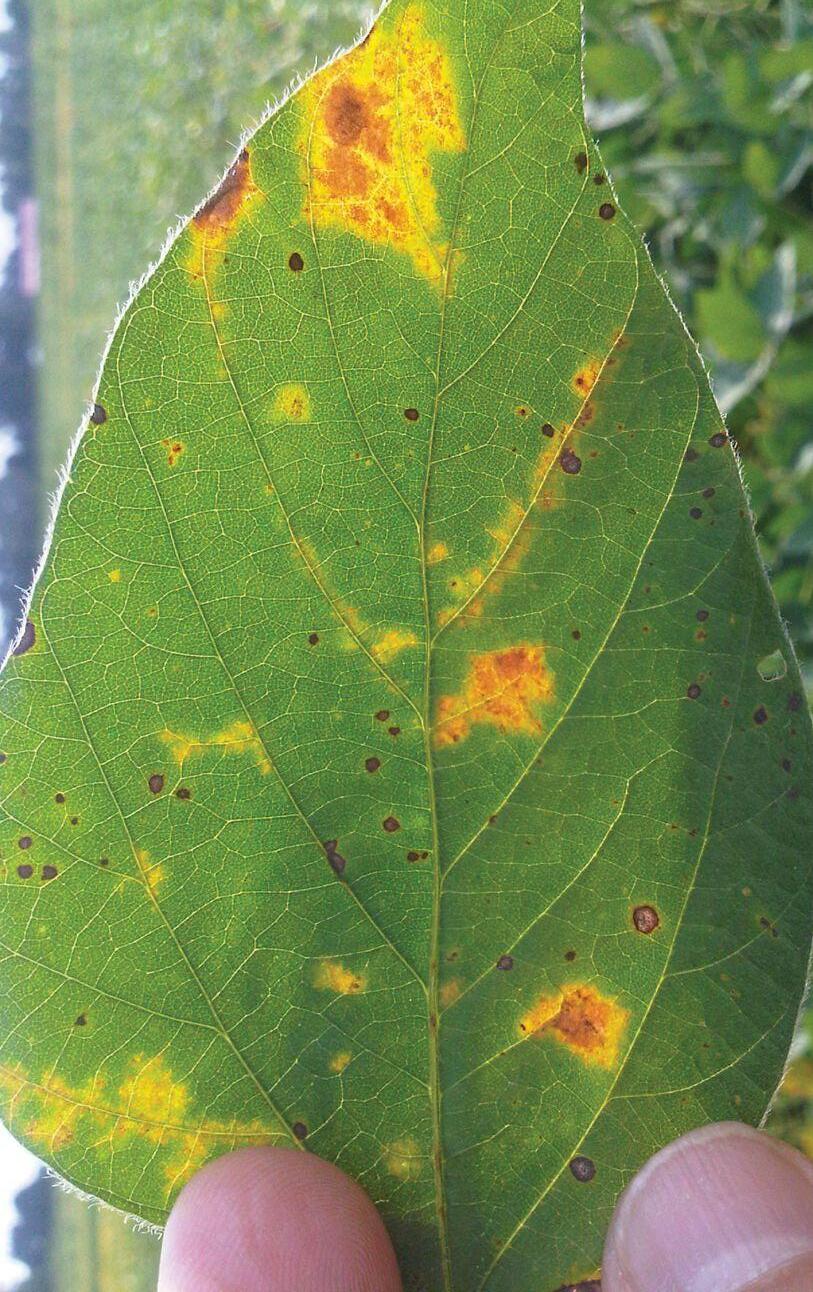

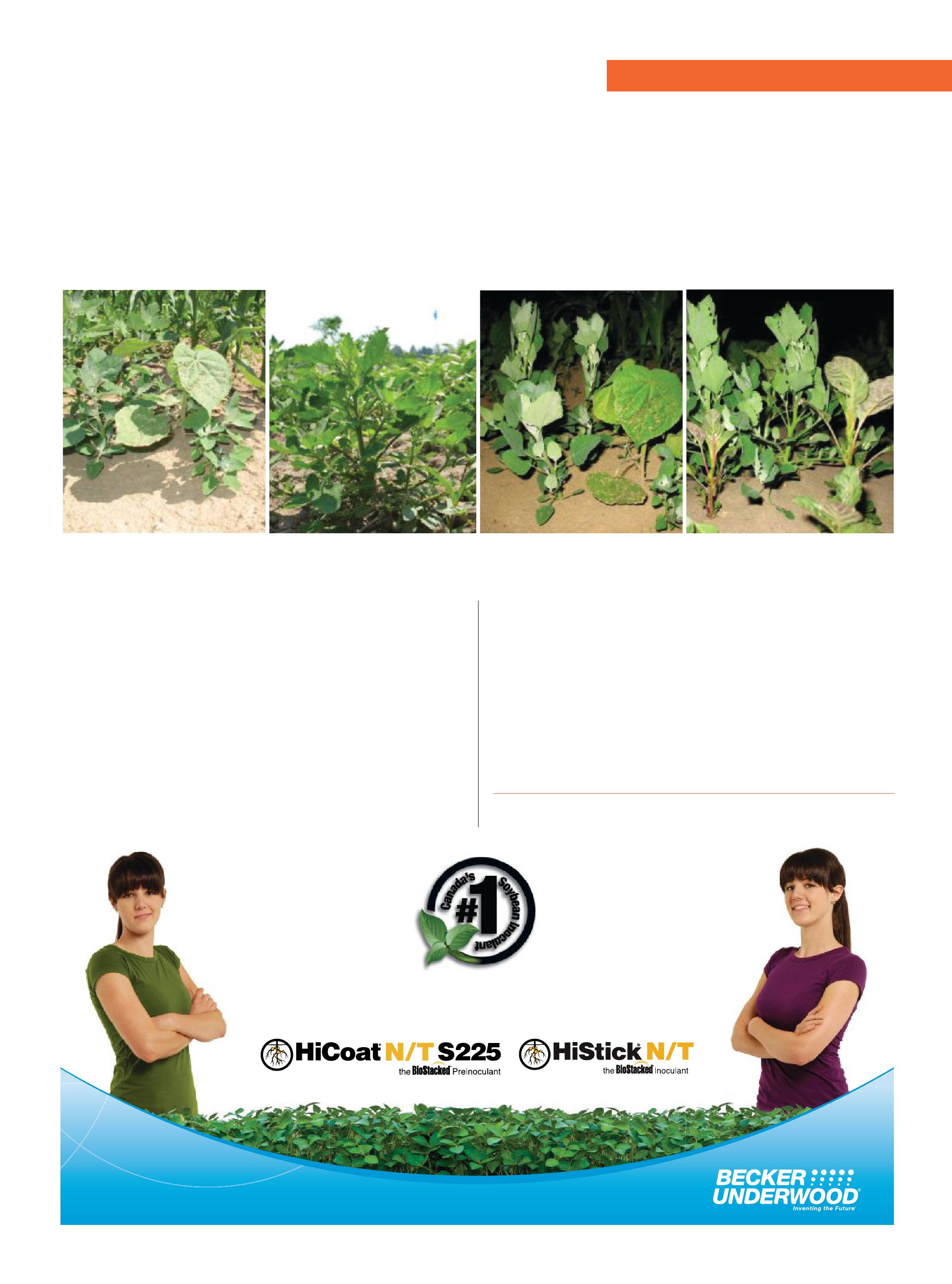

First identified in Tennessee in 2008, the virus spread north across soybean producing areas and recently into US states bordering the great Lakes, and now, southwestern ontario. “SVnV has likely been here for some time prior to the recent detection, but has been misdiagnosed,” says Tenuta, explaining that the virus was likely associated with symptoms of other diseases that look similar, such as Cercospora leaf blight, scald and plant stress. Just as its name describes, SVnV affects the veins of the soybean leaf beginning with light green or yellow patches near the main vein, turning to brown as they get larger. The vein may appear clear, yellow or dark brown in colour in affected plants, and the browning of the veins may be especially noticeable on the lower leaf surface.

Fortunately for ontario growers, there was no impact of the disease on the 2012 soybean crop. But the potential impact of this new disease is

still unknown. So far, SVnV has been infecting crops late in the season in fields within US states bordering the great Lakes, resulting in minimal injury or loss. However, Tenuta points out that, since the disease is here to stay, growers shouldn’t discount the potential impact SVnV could have on yields. “While we won’t see any great impact immediately, there is likely some risk potential over the next few years,” says Tenuta. The disease will likely become more prevalent over time and its effect on production and yields will also be determined on any existing diseases and insect pressure within a field. Currently SVnV poses a low economic or yield risk to ontario soybean fields. But further studies are needed, especially in areas such as Tennessee, where infection or defoliation of fields is occurring earlier in the soybean growth cycle.

The disease is vectored, or spread, by thrips and possibly other insects, says Tenuta. The hot, dry growing season of 2012 provided great conditions for thrips to thrive and transmit SVnV. The mobility of thrips as vectors is affected by currents and wind movements, making further transmission of the disease dependent on weather patterns. More research and information on the transmission of SVnV is currently being sourced. Tenuta says more research on disease movement and infection is necessary, and explains there is also the potential for

ABOVE: SVNV-affected soybean leaf.

’

Soybean cyst nematode must be managed.

by Jeanine Moyer

Commonly referred to as the hidden yield robber, soybean cyst nematode (SCn) is the most important yield-reducing pathogen throughout Canada and the United States. and yet, growers continue to be surprised each year when this disease is identified in soybean fields across the province.

The key to controlling this invasive disease is proper field management, something oMaFra field crop pathologist albert Tenuta confirmed in a multi-year study spanning ontario and the northcentral United States.

“While SCn is the most yield limiting disease of soybeans in Canada and the US, not all soybean growers are properly managing it,” says Tenuta. a challenging disease to identify because it shows no visible symptoms, SCn is a significant threat, reducing yields by 30 percent or more. and by the time growers notice the diseases’ effect on yields, SCn population numbers are often so high it can take years of proper field management to gain control again, says Tenuta.

resistant soybean varieties, pI 88788 and peking, are the most commonly used SCn sources of resistance in ontario. These resistant varieties reduce the reproduction of SCn in fields compared to that

of susceptible varieties. But controlling SC n populations is becoming increasingly challenging with the development of SC n H g Type 1 and 2 populations; these new strains of SC n are able to reproduce on varieties with the p I 88788 (Type 2) and peking p I 548402 (Type 1) sources of resistance at rates similar to reproduction on susceptible varieties. and SC n Types 1.2 field populations can reproduce on both p I 88788 and peking. Tenuta reassures growers that the reproduction of SC n H g types (new races) isn’t as high in o ntario when compared to that in US soybean fields, as shown by Tom Welacky’s work with a griculture and a gri-Food Canada, but they still pose a threat. H g types (Heteroderaglycines, the Latin name for SC n ) identify the ability of the SC n population to reproduce on each of the resistant sources. and while the industry eagerly awaits an additional SC n -resistant variety – Hartwig, still in early stages of release – Tenuta recommends growers step up their SC n field management techniques to control existing SC n populations, reduce the development of further SC n H g types and moderate future SC n risks.

ABOVE: Soybean field affected by SCN.

Soybean pathologists, along with research and extension personnel from ontario – representing oMaFra and aaFC – and the north-central US states came together in this multi-year study to improve SCn awareness and management. Large on-farm demonstration plots in ontario and 12 northern US states were established each year using resistant varieties with various SCn resistance genes. The results of this north american study to increase awareness, reduce losses and improve SCn management, confirmed growers who demonstrate active SCn field management can reduce the diseases’ impact and improve their bottom line. Successful management of SCn can not only provide economic benefits through better yields, but also reduce SCn populations and new SCn Hg type development, while reducing the overall risk of SCn to a grower. These results emphasize:

• the importance of managing SC n (to reduce yield-loss potential)

• the effectiveness of SCn-resistant varieties and new resistance sources such as peking

CONTINUED FROM PAGE 17

host crops, or multiple host species, that could carry the disease and increase movement.

The virus belongs to the Tospovirus group that includes tomato spotted wilt virus, and it is possible SVnV could affect other crops such as tomatoes, or even use them as host plants. SVnV belongs to a group of viruses that are not known to be transmitted by seed, but further research will be necessary to verify this claim. Symptomless carriers, such as weeds that could be a constant inoculum source, are also being researched. “It’s important to find the source of SVnV because, if we don’t know the source, it reduces efforts to eliminate the virus,” says Tenuta.

This winter, plant pathologists, researchers and extension personnel from soybean-producing areas in ontario and the United States

• the need for a long-term on farm strategy incorporating not only SCn-resistant varieties, but also other best management practices such as crop rotation, pest management, soil sampling, weed control, etc.

• the primary SCn resistance source pI 88788 is still effective in most of the soybean production areas of north america and especially in ontario

Study results, in combination with previous findings, led to a checklist of recommended SCn field management tools for soybean growers. “We are re-emphasizing the importance of good field management,” says Tenuta. “The battle against SCn will never end, but at least we can be prepared with the right weapons.” recommended SCn field management tools:

• always use an SCn-resistant variety in infested fields with any SCn population density. Hr (highly resistant) rated varieties are recommended.

• Minimize plant stress. The potential for SCn losses increase with plant stress, even at lower SCn population densities.

• Monitor field SCn densities every five to six years to make sure your management strategy is keeping population densities low. even in fields with populations that could reproduce on the pI 88788 resistance sour ce, the study found the pI 88788 source was still effective. High levels of SCn reproduction were not observed on pI 88788, but they were on the susceptible varieties.

The collaborated project emphasized the importance of managing SCn to reduce yield-loss potential, the effectiveness of SCn-resistant varieties and available SCn resistance genes, the importance of remaining proactive and developing new SCn sources for the future, and the need for a long-term farm management strategy.

Long-term, active field management of SCn is the only way to stay ahead of the disease. ontario growers are often surprised when they find SCn in their fields, but the tools and management techniques to control the disease shouldn’t come as a surprise. “We can’t assume SCn isn’t there, we just have to plan for it,” says Tenuta.

will be meeting to share information and learn more about SVnV. It’s hoped this discovery process will lead to a better understanding of the virus, its impact on yield, and field management tools to treat this new disease. “We’re all in information collection mode,” says Tenuta, who is already working with representatives from affected SVnV areas in the United States to share information and learn more about the disease. Currently, projects in the US are looking at the impact of early exposure to the disease, conducting molecular testing to identify SVnV and researching soybean variety tolerance. Tenuta advises ontario soybean growers not to panic about the discovery of SVnV. He assures them that as more information is shared and the industry gains a better understanding of this new disease, recommendations on management tools and any resistant varieties will be shared to help growers combat this additional production challenge.

By Karen Daynard

Asearch on the Internet for WBC used to bring up information on white blood cells. More likely today, it refers to the western bean cutworm (WBC) – a pest that is native to north america, but which, since 2000 has been successfully migrating north. Starting in 2008, WBC moths (adult phase) were seen all across ontario.

WBC overwinter as larvae within the soil. adult moths emerge in late June and begin laying their eggs on the upper side of corn leaves, usually near the top of the plant in the pre-tassel stage. as corn starts to tassel, WBC can move to neighbouring edible bean fields to lay eggs on the underside of leaves deep in the canopy.

after hatching, young larvae will feed on the tassels and silks of corn until they are large enough to burrow into the ear and eat the kernels. once this has happened, any pest control methods are useless and estimates of yield loss from one larva per ear can cause a 3.7 bu/ac loss (figures based on yield data from US regions).

In beans, the larvae feed on leaves until they are a half-inch long and then move on to eating pods (chewing into them). When not feed-

ing, the insect burrows into the soil.

Yet, the arrival of this new pest has led to a new network consisting of farmers, farm organizations, oMaFra and the University of guelph working together to learn as much as they can about the WBC life cycle, feeding behaviours, damage, control methods, timing of controls and more, much of the funding being provided by the agricultural adaptation Council programs.

one very successful outcome of this new network has been the WBC Trapping program. Farmers from all regions of ontario and into Quebec have set up “milk jug traps” on their operations. pheromones in the top of the trap attract the moths to the jugs, where they drown in a mixture of antifreeze and water. From June 20 to Sept. 14, each participant tallied the total number of moths captured in their trap site each week, and the data was sent in to the WBC trap network website at www.cornpest.ca. In 2012, WBC continues to be present in regions

ABOVE: Western bean cutworm damage in corn.

as far north as the Timiskaming region in ontario and as far east as the Témiscouata region in Quebec, although fewer moths are trapped in eastern ontario and Quebec. after four years of trapping, here are some of the numbers collected through the network.

as shown in Table 1, the number of moths trapped has steadily grown, despite the change in number of traps over the years.

This year, WBC traps were put up two weeks early in ontario in anticipation of an early emergence of moths considering the warm winter and early spring. as could be expected, the peak date was also one to two weeks early, similar to the growing season where corn and beans were running early.

Determining the first moth caught was more difficult this year due to the presence of a large number or yellow stripped armyworm (YSa) caught in the WBC traps. YSa and WBC share a pheromone component. The first verified WBC moths were caught in essex county in Week 3 (June 3-9), which coincided with 2010 and 2011. There is a chance, however, that the first WBC moth may have been earlier and got lost in the large numbers of YSa trapped. The last moth captured was in Week 15 (Sept. 1).

although analysis of the 2012 data has not yet been completed, results as of 2011 indicate that when separated out by crop type, those traps located in sweet corn fields had the highest per trap moth captures during Week 11 of any other host crops with traps. overall though, dry beans had the highest per trap average for all 14 weeks of trapping combined. See Tables 1 and 2.

The number of moths captured at each trap site does not seem to relate to infestation levels and feeding damage found in the adjacent fields, indicating that other factors are involved in field preference. In fields where over 100 moths were trapped, scouts were sent to monitor levels of egg masses and larvae. In the fall, scouts returned to fields where egg masses were found to assess for damage. In 2011 feeding damage was observed in Chatham-Kent, Lambton, elgin, Middlesex (primarily in a location where these four counties meet) and norfolk counties and loss estimates indicated a 3.4 percent yield loss due to WBC feeding damage. Feeding damage by insects such as WBC can also contribute to pathogen infections, which was seen in relatively high levels in corn in some areas of ontario in 2011.

Table 1. Change in trap and moth numbers from 2009 to 2012

Source: OMAFRA

*For purposes of comparison, May results for 2012 have been excluded and Week 1 represents the June start date in all years

Though traps do not seem to indicate which fields are experiencing threshold levels of WBC infestations, they do indicate when peak moth flight occurs and therefore peak egg laying shortly thereafter. growers should still consider using traps to help indicate the presence of moths in their fields and the appropriate time to scout for WBC eggs. In addition, it was confirmed that WBC successfully overwintered in 2012 in the Bothwell area. Fields with high trap captures and feeding damage tended to have sandier soil types, indicating that the sandy soil may assist WBC in successfully overwintering.

observations were made of a high rate of parasitism of WBC eggs through the growing season within some of the infested areas of Bothwell. This demonstrates that there are natural enemies in the area and there is potential for some additional biological control for WBC.

What’s next?

The trap network will continue through 2013 and will contribute to learning more about this pest, its damage, its spread and control methods. a thank-you is extended to everyone who participated in the 2012 trap network.

Both HiStick® N/T inoculant and HiCoat® N/T S225 preinoculant are BioStacked®. This means these inoculants deliver multiple beneficial biologicals to enhance the performance of your soybeans. The end result: higher yields and an exceptional return on investment.

More rhizobia working for you. With HiStick® N/T Liquid you get 3 billion nitrogen-fixing rhizobia per gram. That’s 50% more Bradyrhizobium japonicum than any other commercial soybean inoculant, for greater root biomass and more nitrogen-fixing nodules.

Longer-lasting potency. The rhizobia in HiStick® N/T Liquid + Extender survive 30 days on treated seed. HiCoat® N/T S225 preinoculant system lasts up to 225 days alone or 125 + days with industry-leading seed treatments.

Greater plant vigour. When soybeans are inoculated with BioStacked® inoculants, the crop canopy closes up to five days earlier. Research also shows a 206% increase in nodule weight compared to no inoculant.

Root disease suppression. The BioStacked® biological, Bacillus subtilis, forms a “protective sheath” around the root system that can suppress seedling diseases caused by Rhizoctonia spp. and Fusarium spp.*

More yield, great return on investment. The roots and nodules of the soybean plant are the engine that produces yield, and no other inoculant enhances their performance like the BioStacked® inoculants. Research conducted by the University of Guelph shows that BioStacked® inoculants produce a 1.5 bu./ac. to 1.8 bu./ac. (roughly 5%) yield increase compared to non-BioStacked® products. This is a significant yield increase at a modest cost, for an exceptional return on investment.

Continued from page 11

have from five to 10 furrows with the option of a cart. all of rabe’s plows can be equipped with any of its moldboard options, including three solid body boards and two slatted body boards. rabe VHa 120 MS requires the use of a 120- to 150-horsepower tractor. It has a hydraulic stone protection system and a shear bet on every furrow, keeping the plow well protected. “The working width adjustment is hydraulically operated from the first furrow and has a hydraulic angling device to adjust the traction point and to gain clearance for the rollover process,” says rabe’s writeup. “The combiwheel is not only used as a depth wheel, but can also be used as a transport wheel.”

Model: Kverneland PG Plow

The Kverneland pg plow offers good stability in both work and transport, a tight-turning circle for narrow headlands, and the ability to plow right up to field boundaries. This plow features VariWidth ® hydraulic on-the-move furrow width adjustment, making it easy to immediately adapt the plow to different soil types, ground conditions and finish requirements.

The furrow width can be increased from 14 to 22 inches, increasing the work rate by as much as 40 percent. This, says Kverneland’s sales rep, o wen Kitsemetry, increases seasonal capacity and enables significant cost reductions, including up to

20 percent less fuel consumption.

pg plows are available in various sizes from five to eight furrows. They can be used in varying soil types within a field, and are able to work up and downhill, ensuring a neat finish around obstructions, including trees and telephone poles. Its mid-frame wheel position and compact headstock design ensure tight turning ability on headlands and narrow gateways.

Manufactured in France, the Sper 8 is one of four models by gregoire-Besson. This variable plow ranges from 12 to 20 inches with the ability to add furrows later. It features a hydraulic safety device with double articulation to reach clearance of up to 32.5 inches under the point. It is possible to adjust the sensibility from 600 kilograms to 2300 kilograms of hydraulic pressure, if necessary.

“The turnover device features the gregoire-Besson patented rack and pinion system operated by two hydraulic rams that turn the plow from side to side with little stress load on the tractor,” writes company rep Bill Vermilyea. This model is available in an on-land version for larger tractors with dual tires. This plow offers some additional options, including an anti-plug kit, coverboards, skimmers and moldboards.

HylandTM Seeds’ Roundup Ready 2 Yield® soybeans continue to lead the next wave of advances in soybean technology. Hyland TM Seeds – redefining the seed business.

by rosalie Tennison

Imagine growing a perfect high-yielding crop with no pest or disease damage. now, imagine that achievement can be reached without the use of pesticides or tweaking fertility. It’s not a far-fetched idea. In fact, several companies have developed biological inoculants by harnessing micro-organisms that are present in the soil. It’s a matter of identifying the organisms, determining how they operate and then finding a way to reproduce, package and apply them in order to reap the benefits.

While crop protection companies are dabbling in “biologicals” that will work alongside their other products and seed companies are seeking biologicals that will work with their seed products, other companies have been focusing exclusively on identifying organisms that will benefit crop production. one company, Becker Underwood of ames, Iowa, has a number of inoculant and biological plant health products that it is marketing to north american farmers. Company Ceo Dr. peter Innes says successful crop production in the future will rely on the harnessing of micro-organisms that will assist in reducing disease and insect damage, enhance nutrient availability and uptake, and improve overall well-being and productivity of the crop.

“The increasing complexity in agriculture brings challenge, and challenge brings opportunity,” Dr. Innes says. “Innovation is important.” He adds that, by identifying the organisms in the soil that assist in crop production and then making them available more efficiently to the crop as a seed treatment or a spray, we help the crop more effectively realize the value of the organisms.

another company that has been active in the biological industry for years is novozymes Bioag of Saskatoon, Saskatchewan. The company had initial success with JumpStart, one of the first truly biological products that enhances phosphate fertility. They now have a number of Multiaction inoculant products in various formulations for various crops that offer nitrogen fixation in addition to the phosphate inoculant sold as TagTeam.

“The cost of doing genetic sequencing has come down, making it easier to identify material and get it to farmers,” says novozymes’ Bioag division president Trevor Thiessen. “The cost is a fraction of what it was 15 years ago.” He adds that there has been an acceleration towards combining technologies, such as seed treatments with biologicals.

The chatter about biological treatments is not new and some have reached the marketplace, but, because they are living organ-

Harnessing of micro-organisms will assist in reducing disease and insect damage, enhance nutrient appealability and uptake, and improve overall productivity of the crop.

isms, there have been challenges. The products rely on fermentation and formulation and, once created, they must be kept alive through the entire crop planting process. as well, the products must be safe and work effectively with seed and other products. In the past, storage was an issue, as was shelf life, and care in application was imperative. But, companies working with these organisms are quickly finding ways to overcome the limitations.

Becker Underwood has introduced BioStacked inoculants, which combine a number of complementary biologicals that increase the possibility of better consistency and greater efficacy. The company introduced a range of products that are available in Canada for soybeans that combine rhizobium inoculants with a registered biofungicide. The goal of combining products is to improve plant vigour, nutrient uptake, plant growth, rooting and rhizobial nodule develop -

ment, all of which encourage higher yield. application is possible with conventional seed treatment equipment. Meanwhile, other companies continue to make progress developing their own formulations of biological products. BrettYoung entered the biological business more than 10 years ago when it started its research program to commercialize a unique plant growth promoting rhizobacteria – Delftia acidovorans. The research originally focused on the sulphur-

oxidizing capabilities of the organism, but it has proven to have a number of other beneficial modes of action resulting in higher yields. The organism has been commercialized for canola and for soybeans under the BioBoost brand name. The soybean product also contains Bradyrhizobium for nitrogen fixation.

“The value of biological products for producers is measured in better yield and better performance,” says rene Mabon, regulatory and agronomic manager for BrettYoung. “We are seeing positive yield effects in both canola and soybeans with our BioBoost products.” He adds that the company has increased its research into biological products within the last decade because of the connection to the company’s seed business and the possibility of providing customers with products that will increase the seed’s success in the field.

Those companies that invested in the technology in the early years of the industry are now well placed to assist growers in this next evolution of crop production. The combination of biologicals such as novozymes’ TagTeam and BrettYoung’s BioBoost is one example of this next step. nutrient enhancement, pest control and seed protection in various combinations are all being researched, with effective results available or soon to be available.

“This is an area that will continue to grow,” Mabon says. “as we understand how biologicals work and how they can be incorporated into crop production, we will see more and more microbial products in the market.”

Thiessen agrees. “The combination of products is getting better and we have learned how to stabilize the micro-organisms,” he says. “The technology has improved and we have more resources today. The cost to develop new genetically modified seed is huge compared to finding a new biological product and we are also seeing markets shifting with large ones, such as the european Union, demanding less chemistry in crop production.”

The trick is understanding how biologicals work and then learning how to harness them, give them shelf life and get them into fields where they can be put to use. There is no doubt they work, but consistency is imperative. For these companies, mastering the process is giving them an acceptance in the agricultural world that was only dreamed of a decade ago.

How your insect traits perform this summer can be measured right here this fall.

Put more grain in the bin with Agrisure Viptera® 3111, the most complete, season-long protection of 14 above- and below-ground insect pests. Ask your seed retailer or dealer which Agrisure Viptera trait stack is right for your farm.

Performance Plants Inc. continues to make groundbreaking progress on an international scale.

by Treena Hein

Not everyone has heard of Kingston, ontario-based performance plants Inc. (ppI) – but those who are not yet familiar with the company are likely to hear about it sooner rather than later. Simply put, ppI is an agbiotech superpower with growing international ties, holding more than 100 global patents for breakthrough gene technologies.

In 2005, several years after ppI started, the Canadian biotechnology industry recognized it as the country’s ‘Most promising early Stage’ company. Two years later, ppI became the first Canadian agricultural biotech firm to license intellectual property (its YpT trait in white maize) to africa for noncommercial purposes. (ppI has also entered into a noncommercial agreement with africa Harvest Biotech Foundation International). over the last few years, ppI has partnered with a Chinese research centre to acceler-

CURRENT

ate canola seed product development, and is also working with two of China’s largest ag companies to develop crop varieties with ppI trait technologies. This year, ppI’s heavy-hitting north american commercial partners (such as pioneer Hi-Bred, Bayer CropScience and riceTec) will continue their evaluation of licensed ppI tech.

ppI has made these giant strides through creating and employing a unique molecular trait identification process. “Using advanced genetic screening tools, our scientists identify specific gene modifications that produce improved traits,” says ppI president Dr. Yafan Huang. “Crops with improved traits are developed using one or more approaches, such as conventional breeding, markerassisted selection and biotechnology.”

The company’s “Yield protection Technology” (YpT) trait, for example, enables plants to better tolerate drought conditions, and

Yield Protection Technology (YPT)

YPT enables plants to better tolerate drought conditions and to recover faster when watered. It was the first genetic enhancement identified and developed by PPI and will be commercially available by 2013. In five years of field trials, canola enhanced YPT has shown yield increases of up to 26 percent. YPT has been licensed to some of the world’s leading seed companies such as Bayer CropScience and Dupont-Pioneer.

Heat Tolerance Technology (HEAT)

HEAT is the first and only heat tolerance trait that protects plants from excessive heat. In controlled growth chamber experiments, HEAT plants have produced up to 23 percent higher yields when challenged with typical periods of hot growing conditions. This technology is currently being assessed in canola and other crop species.

Water Efficiency Technology (WET)

WET is a genetic trait technology that allows plants to grow with less water. Greenhouse experiments have shown that WET plants produce 22 percent more growth with limited water. WET is ideal for crops that are rain-fed or grown with less than optimal irrigation. Demonstrations of this technology in canola and other crops are currently underway.

Biomass Enhancement Technology (BET) is an ideal trait for biofuel crops as it has been shown to deliver 50 percent more biomass by boosting vegetative plant growth.

Enhanced Conversion Technology (ECT)

Making the plant’s cell-wall sugars more easily converted to biofuel is crucial to creating biofuels. Studies with model plants have shown that certain ECT lines are almost twice as efficient in releasing fermentable sugars from biomass, showing potential to significantly reduce the cost of producing cellulosic biofuels.

to recover faster when water again arrives. It was the first genetic enhancement identified and developed by ppI and will be commercially ready by 2015. The trait allows plants to close their stomates (leaf and stem pores) earlier and more tightly as a drought sets in, preventing transpiration moisture loss. “The devastating drought this season that occurred in many parts of Canada and the United States has definitely created tremendous interest in developing drought-tolerant crop varieties,” Huang says. “Furthermore, drought often comes with high temperature conditions, and with these two factors, crop yields suffer.” (ppI has already created Heat Tolerant Trait Technology, and Heat & Drought Dual Tolerance Technology.)

over five years of field trials, canola with YpT has achieved yield increases of up to 26 percent. Huang says ppI’s leading YpT canola has an average of 17 per cent higher yield than its parental control (same seed without the YpT trait) in three consecutive years of controlled irrigation field trials done in Southern alberta. “The YpT trait was transformed into the elite DH12075 canola variety, which was developed and commercialized by agriculture and agri-food Canada,” he says. “results from these field trials suggest that with adequate water, transgenic YpT canola produced the same amount of seed as the parental control. However, under moderate water stress conditions at flowering, the seed yields of transgenic canola were significantly higher than the control.” There are many factors that can cause difference in yield in the field trials, Huang notes, such as the amount of water received during flowering and the timing of drought stress.

Like ppI’s other traits, YpT is a broadbased technology that is applicable to all major crops. “as most staple crops are sensitive

to drought stress, application of YpT should result in some profound effects on enhancement of productivity of these crops,” says Huang. all of ppI’s technologies use only the traits of the native crop involved. The company has identified traits that protect the plant from adverse growing conditions and it manipulates these traits like an “on / off switch,” as described in the earlier paragraph on YpT, using the plant’s own responses to “weatherproof” the crop and yield returns despite such adverse environmental changes as drought and heat stress conditions.

“according to many classical agronomic studies, on average, farmers in north america are harvesting only 21 percent of the yield that crops can produce genetically,” says Huang. “nearly 70 percent of yield is lost through suffering abiotic stresses such as lack of water, excessive heat, cold, salt, heavy metals and others. There are therefore tremendous opportunities for plant geneticists to discover different mechanisms to deal with these stresses and create new super high-yielding varieties for growers.”

ppI is also doing work outside the arena of food crops. For example, the firm describes its Biomass enhancement Technology (BeT) trait as “ideally suited for large biomass applications such as biomass feedstock for cellulosic ethanol and coal replacement, as well as fibre and forage.” BeT works by boosting vegetative plant growth. another example is the enhanced Conversion Technology (eCT) trait, which “resolves the second half of the biofuels dilemma – making a plant’s tough cell walls more easily converted to biofuel.” as it grows in partnerships, patents and breeding expertise, ppI as a company will also grow. It intends to be worth $420 million by 2020.

One Simple Solution for Higher

One Bag Industry leading genetics

One Bag Automatic refuge compliance

One Bag Broad spectrum insect control

One Company Experience the Advantage

Ask for the one bag solution with PRIDE and PRIDE G2 hybrids. Increase your in 2013.

Continued from page 6

“We can’t expect the public to respect agriculture unless we’re willing to respect ourselves first,” says Stewart. “pay attention to what you say about agriculture, speak up and speak positively about the industry.”

Stewart says it’s not uncommon for farmers to become almost apologetic in their discussions with him when they talk about their successes in recent years. While he admires that many don’t want to be boastful, Stewart says the tendency to gravitate to discussions about what could be going better, whether it’s markets or weather, is having a negative impact on the industry’s image. It’s hard to quantify just how much damage is done by negative banter about that “greedy neighbour buying all the land” or rival commodity groups but he suspects it’s not nearly as harmless as people may think. Kim McConnell, the founder of adFarm, a company which is also a campaign partner, believes this destructive behaviour undermines the trust that studies show most consumers already have in farmers. He believes that if farmers can learn to speak well of the industry, and one another, there’s a real opportunity to fight back against illwilled activists who target agriculture.

“The people who are against our industry are bloody good and they know how to articulately get their message across,” says McConnell. “Well, we can be the same and, to be quite honest, we can be better.”

roberta galbraith is an example of a farmer who can be a great spokesperson for the whole industry. She farms 3,000 acres of grains and oilseeds near Minnedosa, Manitoba, with her husband, neil, and son, ryan, and she works for the Manitoba Canola growers association. She believes it’s better for farmers to engage one another instead of competing with one another, and for them to become more understanding and empathetic to one another’s plights. Her secret to positively representing all farmers is to focus on the commitment that other farmers have to their own operations and recognize it as the same passion she has for her own farm.

“I’m still an advocate for agriculture regardless of whose story it is because it’s a great industry to be in,” says galbraith. “Collectively we have a voice that’s much stronger together.”

galbraith admits that she sees, as an industry, how we do get a little insular at times. She points out that it’s not the consumers’ fault they’ve become so far removed from the farm but more a result of modern agriculture’s ability to replace

so much physical labour through mechanization. But galbraith says farmers need to engage with consumers and explain not only how their food is produced, but also why it’s being produced that way. even if it means taking the conversation beyond personal comfort zones.

“We’re passionate about the production of food and believe in what we’re doing, so when we get asked questions it’s sometimes difficult to separate the production, and the science, from the passion of growing food,” says galbraith. “It’s easy to talk to other farmers but it’s not to other people because they’re not speaking from the same frame of reference.”

galbraith offers explaining farm finances as a perfect example of a consumer’s frame of reference being a critical obstacle. Many consumers can’t understand how a farmer could invest thousands of dollars every spring and hope it pays back dividends each fall, when they’ve always relied on a paycheque coming every two weeks. But it doesn’t stop them from trying. galbraith says she finds it really interesting that when she says she’s a farmer, everybody seems to want to share their familial connection to a farm, whether it’s a grandfather or a great uncle. It tells her that many consumers not only want to engage in discussions about farming, but also want to connect to what they must believe is a great way of life. But it’s a life, and a business, farmers are generally very good at and should be proud of, says Snyder.

“Do not sell yourself short on what you know about your business; nobody knows your business like you do and you should be very proud of it,” says Snyder. “I mean, what more honourable profession could there be in the world than the production of food?”

Both Snyder and McConnell agree that their lives have been enriched by their agricultural experiences and, like many farmers, can’t imagine having made a career for themselves in any other industry. Today there’s a whole generation out there with no one in their lives to teach them how rewarding a life and love of agriculture can be. With so many to reach, McConnell says the only hope to spread the message is through many voices working together.

“We have the opportunity to share this great story, to address the issues and misperceptions and to further advance the story to make it successful for a long time,” says McConnell, “and whether we make it happen or we don’t, probably rests with us, not with anybody else.”

The demand for anthocyanin-rich foods is steadily increasing.

by agriculture and agri-Food Canada

Discovering the true potential of purple or blue wheat as a natural food colourant and antioxidant source is the goal of an a griculture and a gri-Food Canada ( aa FC) project, in partnership with the University of Saskatchewan, that could lead to more choices for consumers and new market opportunities for Canada’s farmers and food processors.

Until now, much research has focused on fruits and vegetables, paying little attention to the development of this coloured

Monsanto Company is a member of Excellence Through StewardshipSM (ETS). Monsanto products are commercialized in accordance with ETS Product Launch Stewardship Guidance, and in compliance with Monsanto’s Policy for Commercialization of Biotechnology-Derived Plant Products in Commodity Crops. This product has been approved for import into key export markets with functioning regulatory systems. Any crop or material produced from this product can only be exported to, or used, processed or sold in countries where all necessary regulatory approvals have been granted. It is a violation of national and international law to move material containing biotech traits across boundaries into nations where import is not permitted. Growers should talk to their grain handler or product purchaser to confirm their buying position for this product. Excellence Through StewardshipSM is a service mark of Excellence Through Stewardship. ALWAYS READ AND FOLLOW PESTICIDE LABEL DIRECTIONS. Roundup Ready® crops contain genes that confer tolerance to glyphosate, the active ingredient in Roundup® agricultural herbicides. Roundup® agricultural herbicides will kill crops that are not tolerant to glyphosate. Acceleron® seed treatment technology for corn is a combination of four separate individually-registered products, which together contain the active ingredients metalaxyl, trifloxystrobin, ipconazole, and clothianidin. Acceleron®, Acceleron and Design®, DEKALB®, DEKALB and Design®, Genuity®, Genuity and Design®, Genuity Icons, Roundup®, Roundup Ready®, Roundup Ready 2 Technology and Design®, Roundup Ready 2 Yield®, RIB Complete and Design™, RIB Complete™, SmartStax®, SmartStax and Design®, VT Double PRO™, VT Triple PRO™ and YieldGard VT Triple® are trademarks of Monsanto Technology LLC, Monsanto Canada, Inc. licensee. LibertyLink® and the Water Droplet Design are trademarks of Bayer. Used under license. Herculex® is a registered trademark of Dow AgroSciences LLC. Used under license. Respect the Refuge and Design is a registered trademark of the Canadian Seed Trade Association. Used under license. (3701-MON-E-12)

grain as a functional food (a modified food that claims to improve health or well-being by providing benefit beyond that of the traditional nutrients it contains).

p urple or blue wheat bran (495 mg/kg) is more abundant in anthocyanins than, for instance, red cabbage (250 mg/kg) or plums (20-250 mg/kg). a nthocyanins are the phytochemicals responsible for blue, purple or red pigments in highly pigmented grains, fruits and vegetables and have very strong antioxidant activity levels. a ntioxidants, for example, vitamin e or vitamin C, are substances thought to protect body cells from the damaging effects of oxidation and reduce the risk of chronic diseases such as cancer, heart disease and diabetes.

Dr. e lsayed a bdelaal, a research scientist at aa FC’s g uelph Food r esearch Centre, has been instrumental in developing a mechanical-chemical separation process to isolate the anthocyanin pigments from the wheat. o nce separated, the anthocyanins, or pigments, can be used to protect and colour foods and cosmetic products, and/or as a natural source of colour and antioxidants in food products.

“The demand for anthocyanin-rich foods, such as purple and blue wheat, is steadily increasing due to their role in human health and food colouration,” explains Dr. a bdelaal, “and, although Canada’s spring wheat is usually red or white in colour, it is possible to breed high-anthocyanin blue pigments in these wheat varieties.”

o ne of the key goals of aa FC research is to promote human health and wellness through scientific innovation in food products and processes. This focus helps provide consumers with a variety of beneficial choices and opens up new marketing opportunities for Canada’s farmers and food processors.

Case IH Advanced Farming Systems is dedicated to helping producers be ready. AFS delivers an integrated, less complex precision farming solution, built right into our equipment using a single display across machines. Built on open architecture, AFS can interface with your existing equipment, no matter what color it is. And our specialists in the field, AFS Support Center engineers and AFS Academy trainers, are there to help you maximize your operation’s potential and keep you rolling 24/7/365. Visit an AFS Certified Dealer or go to caseih.com/AFS to learn more.

be ready.

With the DuPont™ Guardian® Early Purchase Program, you’ll save up to $5 per acre instantly on Guardian® brand herbicides.

Make a great start on your 2013 soybean profits by pre-buying your two best friends, Guardian® and Guardian® Plus herbicides. Under the DuPont™ Guardian® Early Purchase Program, soybean growers in Ontario and Quebec save up to $5 per acre when they buy 50 acres or more of these Guardian® brand herbicides between November 15, 2012 and February 14, 2013 .

Guardian® brand herbicides help control tough weeds like dandelion, annual sow thistle and Eastern black nightshade – weeds that glyphosate alone can’t handle – getting your soybeans off to a clean start.

Questions? Ask your retailer or call 1-800-667-3925 or visit cropprotection.dupont.ca.