Drax’s Burns Lake facility offering much-needed support to B.C.’s northwest

Drax’s Burns Lake facility offering much-needed support to B.C.’s northwest

By Andrew Snook

Every year around springtime, the federal, provincial and municipal governments begin preparing for wildfire season. These days, preparing for the season is more important than ever as the size of the fires has increased significantly in recent years.

According to Natural Resources Canada, the 2023 wildfire season was a historic one. There were 6,623 wildland fires that year, which is less than the average of about 8,000 that normally occur annually. However, these wildfires raged and burned more than 15 million hectares (ha) of Canada’s managed forests – a far greater number than the 2.1 million ha. that burn on average each year. There were more than 230,000 people evacuated due to danger to their health and lives from wildfires in 2023.

levels of government.

But what if we could slow down the spread of some of these massive wildfires by reducing the fuel load on the forest floor? This isn’t a new strategy. A few municipalities in northern B.C. that are located in areas sensitive to wildfires have already started up initiatives where they remove biomass from the forest floor and use it as fuel in district heating systems. When you consider the cost of wildfire suppression and the evacuation of entire towns, government investment in slowing the spread of wildfires through biomass harvesting should be a no-brainer.

Government-funded biomass harvesting and energy initiatives in remote northern regions of the country also have the potential to yield additional benefits to the Canadians who call these places home.

Volume 25 No. 2

Reader Service Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Service Ph: (416) 510-5113 Fax: (416) 510-6875 Email: apotal@annexbusinessmedia.com Mail: 111 Gordon Baker Rd., Suite 400 Toronto, ON M2H 3R1

Interm Editor - Andrew Snook Ph: (416) 510-5239 asnook@annexbusinessmedia.com

Contributors - Gordon Murray, J.P. Antonacci, Joel E. Dulin and Ian Thomson

Group Publisher - Anne Beswick Ph: (416) 510-5248 Mobile: 416-277-8428 abeswick@annexbusinessmedia.com

Account Coordinator - Shannon Drumm Ph: (416) 510-6762 sdrumm@annexbusinessmedia.com

National Sales Manager - Rebecca Lewis Ph: (519) 429-5196 rlewis@annexbusinessmedia.com

Quebec Sales - Josée Crevier Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@annexbusinessmedia.com

Western Sales Manager - Tim Shaddick twshaddick@gmail.com Ph: (604) 264-1158 Fax: (604) 264-1367

Audience Development Manager - Layla Samel Ph: 416-510-5187 lsamel@annexbusinessmedia.com

Media Designer - Emily Sun

CEO - Scott Jamieson

Canadian Biomass is published four times a year: Winter, Spring, Summer and Fall. Published by Annex Business Media.

Publication Mail Agreement # 40065710

Printed in Canada ISSN 2290-3097

The costs related to wildland fire protection have ballooned over the last decade and range between $800 million and $1.4 billion annually. The cost of wildfire suppression has increased approximately $150 million per decade since data began being collected in 1970 (Learn more about it here: https://natural-resources.canada. ca/climate-change/climate-change-impacts-forests/cost-fire-protection#why).

While Canada could be more aggressive in finding ways to prevent wildfires and punish those responsible for human-related incidents (approximately half of all wildfires are caused by people), about 50 per cent are caused by lightning strikes. This means wildfire suppression will always be a significant expense at all

One of the biggest expenses related to living in northern regions of the country is energy costs. If the biomass being collected can be processed into wood pellets (or other useable forms of biomass) for district heating systems, this could lower the overall energy costs for many residents who are currently reliant on more expensive forms of energy, lowering their cost of living. Would this mean the federal and provincial governments stepping in to assist municipalities with the costs related to the biomass harvesting, as well as the design, purchase and installation of district energy systems and other bioheat systems? Absolutely. But if initiatives like this have the potential to slow down wildfires, they are worth considering.•

Subscription Rates: Canada - 1 Yr $58.14; 2 Yr $104.04 Single Copy - $9.00 (Canadian prices do not include applicable taxes) USA – 1 Yr $123.93 CDN; Foreign – 1 Yr $140.76 CDN

Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

Occasionally, Canadian Biomass magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2025 Annex Business Media, All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.canadianbiomassmagazine.ca

The Province of Nova Scotia recently celebrated the opening of the Neptune BioInnovation Centre in Dartmouth, N.S.

The province is hoping that the bioinnovation centre will become a world leader in biofermentation and be a key factor in growing Nova Scotia’s bioindustrial sector. The province stated that it hopes the Neptune BioInnovation Centre will help Nova Scotia compete globally, strengthen domestic supply chains, and foster biotechnology advancements across critical sectors, including life sciences, pharmaceuticals, forestry and agriculture.

“The Neptune BioInnovation Centre is not just changing the game for bioinnovation in Nova Scotia, it is creating a whole new one,” said Colton LeBlanc, Minister of Growth and Development. “This investment will attract the best and brightest minds and companies in this sector to Nova Scotia. Their groundbreaking work will commercialize clean technologies for a more sustainable and prosperous future.”

The multi-user facility is the first of its kind in Canada and currently one of three facilities worldwide. The province estimates that the centre will generate more than 2,400 jobs; $175 million in salaries; $74 million in tax revenue; and contribute $334 million annually to Nova Scotia’s annual GDP.

“This Neptune asset and planned expansion are a game-changer for the N.S. and Canadian biomanufacturing sector, building the largest capacity in Canada. This will ensure companies scale and build commercial plants here, generating a critical domestic green supply chain for Canadian manufacturers to compete here

and in Europe,” stated Beth Mason, director of the Neptune BioInnovation Centre.

The Province of Nova Scotia announced it is investing $5 million towards the transformation of the 4,738-square-metre (51,000 square feet) facility into state-of-the-art wet and dry labs that will offer commercial-scale precision fermentation and spray drying capacity.

The Neptune BioInnovation Centre is an $18-million public-private partnership with funding committed by the Province of Nova Scotia, Atlantic Canada Opportunities Agency (ACOA), Next Generation Manufacturing Canada (NGen), and cleantech firm Dispersa.

For more information on the Neptune BioInnovation Centre, visit: https://neptunebio.ca/.

SBP recently published its Annual Review 2024, capturing a year of growth, strategic progress, and continued delivery as the biomass certification scheme of choice.

With 2024 marking the second year of its current three-year strategy, SBP has consolidated its position in a rapidly evolving sustainability landscape, while laying firm foundations for the years ahead.

“2024 outcomes reflect a busy and productive year for SBP. We saw significant growth in certified biomass volumes and certificate holder numbers, but equally important we took proactive steps to define our contribution to global challenges, from carbon and climate to regulatory compliance and sustainability governance. With growth comes an increased responsibility to ensure that assurance and oversight of compliance are rigorously maintained,” stated Carsten Huljus, CEO of SBP.

Highlights from 2024 include:

Record-high biomass volumes: 19.15 million tonnes of SBP-certified biomass produced and sold – a 28-per-cent yearon-year increase. Of that, 17.65 million tonnes were consumed in Europe, a 30-per-cent increase.

Certificate holder growth: a 25-per-cent rise in certificate holders, ending the year at 340.

Global expansion: SBP’s geographic reach grew to 35 countries, with new market entrants including Australia, Chile, China, Colombia, Indonesia, Ireland, and Luxembourg.

Market diversification: Continued expansion beyond pellets and chips to include biocarbon and biochar, with promising developments in agricultural biomass certification.

A major focus in 2024 was supporting the transition to SBP Standards v2.0, with comprehensive training, auditor support, and the rollout of updated Regional Risk Assessments. The revised Standards have now received positive recognition from both Ofgem (U.K.) and the Government of Japan.

“Our revised standards are in force, and we are now fully focused on their implementation,” said Huljus. “We’ve made great strides in ensuring a smooth transition for Certificate Holders and demonstrating the robustness of our scheme to regulators and stakeholders alike.”

The SBP Annual Review 2024 is available to download at: https://sbp-cert.org/documents/annual-reviews/. • – Source: SBP.

Custom installations at a New Brunswick tree nursery and elementary school highlight the versatility of pellet heat

By Gordon Murray, Executive Director, Wood Pellet Association of Canada

Two new installations for Biomass Solutions Biomasse (BSB) at Kingsclear Tree Nursery and nearby Hanwell Park Academy school use low-carbon, locally sourced wood pellets to help reseed tomorrow’s forests and educate future community leaders in central New Brunswick.

“We’re helping to fuel the future… At the nursery, it’s the full cycle, growing trees and using waste wood to help them grow. At the school, we provide a low-carbon heat source for New Bruns-

wick children who will need a society less dependent on non-renewable energy,” said Jonathan Levesque, BSB general manager. “The potential of biomass to help our future in Canada is bigger than people imagine.”

The New Brunswick Climate Change Action Plan aims to reduce the use of fossil fuels in public buildings. The province decided to tender a low-carbon biomass

heating system retrofit at the nursery.

The Kingsclear Tree Nursery, located in Island View on the outskirts of Fredericton, grows and ships approximately 19 to 20 million tree seedlings annually for reforestation on Crown land and private woodlots. Martin Noël, nursery manager, said the BSB installation replaced numerous oil-fired boilers, including some equipment that was more than 45 years old.

“We had redundancies, so we have more than one boiler in case one went

down… Today, we still have redundancies and oil boilers to help with the peak heating,” Noël said. “In the winter, we are trying to maintain overnight temperatures of 23 degrees (C) when the outside temperature can be as low as minus 25 degrees (C).”

Noël said the project was tendered in the summer of 2024 and completed in time to be fired up in February. The installation included reinforced concrete pads, new buffer tanks, new external silos and new exhaust flues.

“The system is new to us, and over time, we will get a good sense of fuel consumption and pellets…. This year will be a good testament to that,” he said.

Three Herz Firematic 350 wood pellet boilers were installed at the nursery in separate heated greenhouse complexes. The Herz boilers are designed to be compact and sized to fit inside a normal boiler room. In the Kingsclear retrofit, the units were installed with a forklift. The twopiece boiler was assembled on-site.

Noël explained the provincial greenhouses aren’t usually heated in February, but scheduling required an early start up. Feb-

“We were quite surprised to see the system can handle close to 100 per cent of the nursery load. It has managed to handle the load quite well.”

ruary 2025 was also the coldest in New Brunswick for years, with temperatures dipping below -20C over numerous nights.

“Production costs for greenhouse seedlings in February are prohibitive with oil heating. This year, we had to start a crop in February to make up some losses we had with a crop from last year.”

“Greenhouse boilers have a busy night shift keeping the cold air from the seedlings,” Levesque said. “We were quite surprised to see the system can handle close to 100 per cent of the nursery load. It has managed to handle the load quite well.”

Almost 3 million seedlings were seeded in the greenhouse complexes this February, depending on biomass heat to keep the cold temperatures at bay. The seedlings are destined for reforestation on Crown Lands and helping private woodlot owners with their silviculture programs.

“These seedlings sown in February will be shipped for planting in late June. Only one-third of our crops are grown in heated conditions and planted the same year,” Noël explained.

Noël said using wood pellets to give the delicate seedlings a head start makes sense at the nursery.

The Kingsclear Nursery, which has operated for more than 45 years, includes eight growing complexes with 85 greenhouses and 19 outdoor crop-holding areas. The 90-hectare facility employs up to 65 workers.

Noël said the greenhouse modernization will include a new 110,000-square-foot expansion to be heated with wood pellets. The new complex, now under construction,

will be more than 1.5 times the size of the existing heated greenhouses at Kingsclear.

Noël said the nursery officials are eager to chart the cost savings over the next year, but initial impressions show a sizable saving over oil heat at the facility.

BSB has installed other wood pellet units in greenhouses, including the New Brunswick Botanical Garden in St. Jacques and the Nadeau Greenhouse in Laurierville, Que. Levesque predicts more greenhouses will utilize efficient, low-carbon pellet heat in the future.

“Nurseries and greenhouse installations are a promising market for biomass. There are usually no space limitations in a greenhouse application compared to an existing commercial building. There’s no cooling needed, which eliminates other considerations,” he said.

Hanwell Park Academy, located in the vibrant Hanwell rural community near Fredericton, is one of New Brunswick’s fastest-growing municipalities. The new 10,500-square-metre school accommodates 550 students and 65 teachers and support staff. The expansive facility includes 37 classrooms, two gymnasiums, music rooms, performing arts, library commons, breakout spaces, project rooms, early childhood spaces, and an adult training centre. The school features a nature-themed palette and a large outdoor recreation area, which includes access to the community’s extensive walking trail system.

Levesque said the school needed a reliable and efficient heating system that requires minimal maintenance. BSB installed a Herz Firematic 350 wood pellet boiler in the school with an outside silo. The Hanwell school burns about 80 tonnes of wood pellets annually.

“Hanwell was new construction, so the boiler room was designed for wood pellets. Our bulk fuel drivers have easy access to the outdoor storage silo. It’s a seamless system for the school. BSB provides annual maintenance and ongoing support for any issues,” Levesque said.

BSB has installed wood pellet sys-

“Nurseries and greenhouse installations are a promising market for biomass. There are usually no space limitations in a greenhouse application.”

tems in three other schools, the community college (CCNB), and the Université de Moncton (UDM) at the CCNB-UDM Shippagan Campus in New Brunswick.

“Schools are out during the hottest New Brunswick months, and most don’t have widespread cooling systems... more New Brunswick schools could utilize pellet heat.”

Levesque said using waste wood to heat public spaces like Hanwell Park Academy School shows a commitment to New Brunswick’s future.

Canada’s forest industry is highly integrated and maximizes the value of every tree harvested. Canadian wood pellets are produced entirely from sawdust, shavings, harvest residues, and low-quality pulp that have been rejected by the other traditional forest sectors—sawmills, pulp mills, and panelboard plants.

BSB uses third-party contractors to deliver most of its pellets but does have a truck with a scale for smaller bulk delivery. Pellets to fuel Kingsclear and Han-

well boilers come from the Group Savoie pellet mill, which has a 90,000-tonne annual capacity. BSB uses other producers to provide fuel for other installations, if needed.

Levesque said the more cost-efficient Herz boiler system has made biomass heating more competitive compared to customized alternatives BSB used in institutional facilities. The Herz units are new to North America, but the systems are heating mainstays throughout Europe and around the world.

Levesque said the momentum of adopting biomass heating solutions for New Brunswick public spaces is increasing. Governments and communities are recognizing the advantages of wood pellets—a sustainable local fuel source, efficient heat and low carbon output for schools, hospitals and other facilities.

“New Brunswick currently exports 90 per cent of wood pellets produced. We

don’t need to export fuel that can be used at home. Biomass can offer New Brunswickers energy independence from imported fossil fuels. It is also way cheaper,” Levesque said.

He said the push to “electrify everything” in the province has dampened, with rising power rates and utilities straining to meet increased electrical demand and peak loads.

“Biomass is there to help shave the (electrical) peak during winter for New Brunswick and other provinces. Pellets or wood chips are like mini batteries, an on-demand type of heat.”

He pointed to Yellowknife, N.W.T., as an example of a community taking advantage of the energy stored in biomass. Yellowknife has become one of the most biomass-intensive cities in Canada.

“There’s no reason why New Brunswick and a lot of places in Canada shouldn’t be using our local resources. We have the resource; we just don’t use it at home. We like to ship it away.” •

Heat and Energy Specialists in the Forest Products Industry wellons.ca

Sponsored by

In 2017, the Elephant Hill wildfire burned over 190,000 hectares in the South Cariboo. On November 12, 2023, Central Chilcotin Rehabilitation Ltd. (CCR) embarked on the first phase of its largest wildfire rehabilitation project – the Pressy Lake Pilot Project. This innovative project challenged long-held beliefs in the forest industry about wildfire salvage logging, reflecting a paradigm shift from the prevailing attitude that burnt wood is detrimental to pulping.

CCR’s forestry superintendent Daniel Persson explains how this opportunity was nearly missed.

“Another license owner abandoned the cutting permit because they saw no prospects. The fibre, having no perceived economic value, was left to degrade and was condemned to remain an impaired forest with limited possibilities for regeneration,” Persson said.

However, Joe Webster, Tsi Del Del Biomass’ operations manager, “looked at the wood instead of a map.” A critical distinction was made between fire-killed and burnt wood. Webster learned how to assess and sort multiple species for multiple products effectively from the first 100 hectares and brought in a chipper, resulting in 700 B-train loads of biomass.

With the current market primed for re-

ceiving biomass from new streams, and leadership from fibre managers like Thomas Hoffman at Kruger Kamloops Pulp LP, the initiative’s timing was impeccable.

“Recently, CCR worked with Kruger on a trial to recover fibre from fire-affected areas, rehabilitating the land base by removing the impacted trees and replanting, contributing to fire resiliency. The fibre recovered was sent to Kruger, where we were able to turn it into green energy and pulp. This pulp then gets converted into

further value-added products including writing paper, electrical grade paper, and fibre cement,” Hoffman said. “Ultimately, this fibre-recovery trial can create innovative solutions transforming silvicultural slums into green power and value-added products, while supporting wildfire mitigation in B.C. Given the climate change challenges, this work is a crucial step in addressing these challenges, and ensuring the long-term viability of the industry. CCR’s emphasis on promoting sustain-

able forestry practices and environmental stewardship is commendable.”

The Pressy Lake Pilot Project offers a fresh perspective on the longstanding issue of wildfire salvage. It has demonstrated that commercial value may be found in wasteland even after seven years. During a period of fibre scarcity, the project provided 40,000 cubic metres of biomass to Kruger and Cariboo Pulp, created jobs, and supported sustainable green bioenergy. The ensuing rehabilitation work effectively closed the loop in the silvicultural system, speeding up forest development by 75 to 100 years.

“This award honours the deep connection First Nations people have to the land. Through CCR, we’re taking the lead to care for our forests and land to create meaningful opportunities for our communities. The Pressy Lake pilot project is more than a biomass success; it’s a reflection of our inherent responsibility to restore what was lost and ensure the land can thrive for future generations,” said

Chief Otis Guichon, Chief of Tŝideldel First Nation and Tribal Chief of the Tŝilhqot’in National Government.

“This recognition speaks to the strength of partnership between Indigenous leadership and industry, driven by innovation,” added Percy Guichon, CEO of Central

Chilcotin Rehabilitation Ltd. “At CCR, we are not only supporting economic growth through forest rehabilitation and the added benefit of fibre recovery but also strengthening our communities by creating good family-supporting jobs and restoring our forests for future generations. The Pressy Lake pilot project shows what’s possible when Indigenous values, invested and trusted supporters like our District, the Forest Enhancement Society of BC, Natural Resources Canada, and good forest management work in collaboration.”

“We’re very pleased and proud to have received this acknowledgement. In terms of biomass projects, we saw an opportunity where others perhaps didn’t,” Webster added. “By distinguishing fire-killed from burnt wood and rethinking how fibre can be assessed and processed, we’ve opened the door to a new stream of biomass. This kind of innovation isn’t just good for business, it’s essential for the future of forestry. Thank you for recognizing our efforts through this award.” •

David Dubois has been a champion of the bioheat sector for much of his career. From working on notfor-profit projects like the Green Heat Initiative and Wood Waste to Rural Heat, to helping developing new standards for biomass boilers, teaching bioenergy at Lakeland College, and his work at Fink Machine, he has been deeply ingrained within the world of bioheat.

It was about 16 years ago that Dubois’ path to championing bioheat began, during market development work he was doing for a not-for-profit related to biomass heating in northern and southern B.C.

“At the time, there was a recognition that there was a gap in the market, and we really needed to do it,” he says. “I was an engineer and I had some technical skills and background in finance, so I applied for the job, and that started me down the path. I did that for six years or so, and then I got into doing broader community energy planning.”

One of most significant projects he worked on was the development of a district biomass heating project in Clearwater, B.C.

“Clearwater was one of the key ones that we were able to get done, and it was really interesting, because it was one of our target communities. It was a community where biomass heating should be able to go,” he says. “It’s a forest-based community. It has a higher cost of energy for the population. The mayor and council at the time were very engaged with the idea, and so, they went forward, and they implemented two projects.”

Dubois was also proud to help develop a project with the village of Telkwa, B.C.

“There was a small district heating system, but that one was tied towards the use of wildfire mitigation materials,” he says.

Several years ago, Dubois participat-

ed in a research group with the Community Energy Association, and a couple of researchers from forest and community planning at UBC, to develop a high-level tool to look at what the amount of biomass material produced from wildfire mitigation would be, and what that would look like as part of a district energy system.

“What the capital cost would be? What the sizing would be? How much fuel would be produced? As a starting point for communities to say whether or not it makes sense,” he says. “That’s something I was quite proud of. It was very tangible. It was very relatable. It was something where people looking at this could see what they, themselves, could do.”

In 2017, Dubois joined Fink Machine as manager of business development and has worked on a wide variety of bioheat projects since that time. He says projects have gotten more complicated as awareness and understanding of the bioheat space grows.

“There’s more of a recognition of what can be done, how we should be doing it, and what are the best practices. So, that

add some layers of complexity,” he says.

Dubois has been very active assisting with the development of standards related to the bioheat space, including ISO/ TC 238 – Solid Biofuels and Pyrogenic Biocarbon.

“The ISO/TC 238 was about looking at best practices for fuel handling and what we need to do to bring it into Canada, because we don’t have a lot of experience doing it. We do it on an industrial level very well, but on a smaller scale, it’s something where there wasn’t a whole lot of a knowledge base. So, being able to participate in that was good,” he says.

Dubois is also working on the incorporation of European boiler standards in Canada, which is related to the acceptance of European equipment for utilization in the North American market.

“I’m part of a working group that’s looking at incorporating the European standards into the current North American standards,” he says.

Dubois spends some of his spare time teaching at Lakeland College so he can pass on his knowledge of the bioheat industry to future generations.

“When I was with the not-for-profit, we were contacted by Lakeland College. They wanted to develop a bioenergy and biogas course. So, as part of my work with the not-for-profit, I helped develop the course content for it. I’ve been teaching it for the past number of years now,” he says. “Being able to teach a course on it and trying to get people excited about it, that next generation of knowledge, I think is quite cool. I like the idea that I can say to my grandkids, when they look at this as really mainstream, that it wasn’t. I was part of the reason that helped that to change. That means a lot to me.” •

Operational since May 2022, Sissons Court’s biomass district heating plant provides sustainable wood pellet heat for public housing units in Yellowknife, N.W.T. The system replaced 46 fuel-oil furnace systems heating 53 residential units with fan coils heated by a centralized Viessmann 300kW wood pellet boiler with a propane backup system consisting of three propane boilers to meet peak demand and provide backup when needed.

The project was very much a locally driven and supplied initiative. The system was designed by a northern consultant team, TAG Engineering, with assistance from the technical team at the Government of the Northwest Territories. The wood pellet boiler was supplied by Fink Machine, while the installation was performed by local mechanical contractor Taylor & Company, based out of Hay River, N.W.T. Most of the wood pellets are supplied from northern Alberta at pellet mills in La Crete and Slave Lake.

“Here in Yellowknife and N.W.T., wood pellets have slowly been adopted more and more since the first few installations happened in 2007,” says Mischa Malakoe, manager of energy planning and projects at Housing Northwest Territories (Housing NWT). “There’s been quite a number of projects since then, both in the private sector and government.”

Leadership Fund, demonstrates a commitment to sustainable in frastructure within the community and sucessful collaboration between Housing NWT and local contractors.

generate significant reductions in energy costs and emissions.

Malakoe says on a per energy basis, fuel oil typically costs about 15 to 17 cents per kilowatt hour, while wood pellets typically cost about seven cents per kilowatt hour. They are still in the early stages of estimating the annual savings, but based on its first year of operation, the project generated 300 tons of GHG offset and about $125,000 of savings.

“As northerners, we’re hyper cognizant of energy costs. The energy consumption is so high. We’re all very aware of how much it takes and costs to heat a home, so we have a lot of buy-in. A lot of people burn wood pellets as a cost savings measure and a GHG reduction,” Malakoe says. “In certain parts of the N.W.T., such as mafrost degradation, coastal erosion – it’s the immediate effects of climate change. People are aware of it, so it helps us make our

There are few people whose names are more synonymous with biofuels in Canada than Ian Thomson. Just ask Fred Ghatala, president of Advanced Biofuels Canada.

“Ian is a pioneer leader in the development of Canada’s renewable and low carbon fuel sector,” he said.

Ghatala cites Thomson’s dedication to the industry since 2002, when he first focused on the potential use of biodiesel for reducing emissions from diesel fuel engines.

“In 2002, I started looking at fuels and alternatives and zeroed in on biodiesel as something that had potential, but nobody was really doing anything with it in Western Canada,” Thomson said.

Over his impressive career, Thomson has been a key player in the establishment of the Canadian renewable fuels industry. One of his many career highlights was establishing the BC Biodiesel Association (2005) and the Alberta Biodiesel Association (2006).

“These two entities led industry development in Western Canada, eventually becoming the Western Canada Biodiesel Association in 2014. In 2015, the scope of representation expanded, and the association became Advanced Biofuels Canada Association (ABFC). ABFC is Canada’s leading renewable fuels industry organization, promoting the production and use of sustainable, low carbon fuel alternatives to gasoline, diesel, and jet fuels,”

Ghatala said.

Thomson served as president of the association from 2005 to 2024, stepping aside in 2025 to serve as past-president to assist the new executive team.

In 2005, Thomson co-founded the Canadian Bioenergy Corporation (CBEC), the first biodiesel distribution business in B.C. Ghatala said the company “quickly grew from importing 1,000 litres totes of U.S.-made biodiesel to establishing tankage at terminals in North Vancouver and Calgary, and shipping railcars as far east as Nova Scotia.”

While serving as president of CBEC, Thomson also worked on the Canadian biodiesel sector’s testing and standards work with the Canadian General Standards Board.

“The first quality standards for biodiesel and biodiesel blends were finalized around 2011, which were key to providing function-

“Ian is a pioneer leader in the development of Canada’s renewable and low carbon fuel sector.”

al fuel assurance,” Ghatala said.

That same year, Thomson and his partners shut down CBEC to co-found Waterfall Advisors Group, which staffs ABFC’s operations and serves the Canadian biofuels sector with consulting expertise and coast-to-coast coverage.

Between 2010 and 2012, Thomson led the industry associations in assisting governments with adopting the first diesel fuel RFS blending regulations in B.C., Alberta, Saskatchewan, Manitoba, and federally with the Canadian Renewable Fuel Regulations.

“In 2013, B.C. finally implemented its ground-breaking Low Carbon Fuel Standard; and Ontario followed with its hybrid (RFS/LCFS) Greener Diesel Regulation in 2014,” Ghatala notes.

Thomson has also played a key role in helping develop what eventually became Archer Daniels Midland’s biodiesel project, which commissioned Canada’s largest biodiesel facility (320MLY) in Lloydminster, AB. in October 2013.

“At that point we had enough demand, we reckoned, to build a plant. So, with a small group of other colleagues, put together a company that eventually co-adventured with a large global agribusiness company to build the Lloydminster biodiesel plant run by Archer Daniels Midland,” Thomson recalled.

Over the next 12 years, Thomson continued to lead the way in the growth of the renewable fuels sector with milestones such as:

• Assisting with the six-year regulatory development phase of the Clean Fuel Regulations that were finalized in June 2022, and became effective July 1, 2023;

• Helping develop the first low carbon fuel regulations in Quebec (2023); and

B.C.’s new LCFS statute and regulation (2024); which is Canada’s most stringent fuel regulation, and includes the first SAF (sustainable aviation fuel) mandate in the Americas.

“The regulations referred to above were ground-breaking achievements in Canada, and, over 2010 to 2024, they have proven to be the most successful mechanism to reduce GHGs from fossil fuel use in transportation,” Ghatala said.

Thomson gives kudos to his colleagues of two decades including dedicated and deeply knowledgeable association staff. He also flags the indispensable work of provincial governments, especially B.C., Alberta, Ontario, Manitoba, and Quebec, and the federal government for helping create a friendlier environment.

“The provinces have taken real leadership in getting regulations that give the kind of assurances that people who have capital and aspirations to build production assets need,” Thomson said. “The federal government undertaking the Clean Fuels Regulations starting in 2016, and wrapping up in 2022, was great work. It took longer than we had hoped, and ended up coming full circle back to a pretty basic local carbon fuel standard, but that was a real highlight.”

Seeing the clean fuel sectors collabo-

rating recently has also been a highlight.

“It’s way too easy for people in the alternative fuel space to feel like they have to compete with each other,” he said. “I mean, at the end of the day, they compete. But first you’ve got to collaborate to get a market, and I think we’ve seen some really effective collaborations in Canada.”

When asked what advice he would offer the next generation looking to become active in the renewable fuels sector, Thomson says to be prepared for two steps forward and one-and-a-half steps back.

“I talk with people who are graduating from engineering programs or getting into them, or wanting to get into this space, and they think everything’s going to go hydrogen. They think everything is going to go electrification,” he said. “The view that many of us in the clean fuels space have is there’s going to be a long road for high energy density, low carbon liquid fuels. Whether those are fossil fuels with significantly lower their carbon emissions, biofuels produced out of refineries with co-processing or renewable diesel, or biofuels produced in standalone biofuel plants with low carbon intensity increasingly made from a wider range of feedstocks than just agricultural crops, the need to fuel internal combustion engines is going to be around for a long time.” •

FEATURES:

• Heavy duty construction

• High inertia solid steel rotor

• Replaceable strikers

• Shear pin protection

• Swing away anvil with bolt-on liner

• Oversize shaft and bearings

Powered feed works

Large rear access

door for easy and safe maintenance

• Three-piece grate

• Large rear door access

• Four rows of fixed strikers coated with tungsten carbide

• Available in widths 40" 52" & 64"

• Ideal for biomass and pellet mill applications

By Andrew Snook

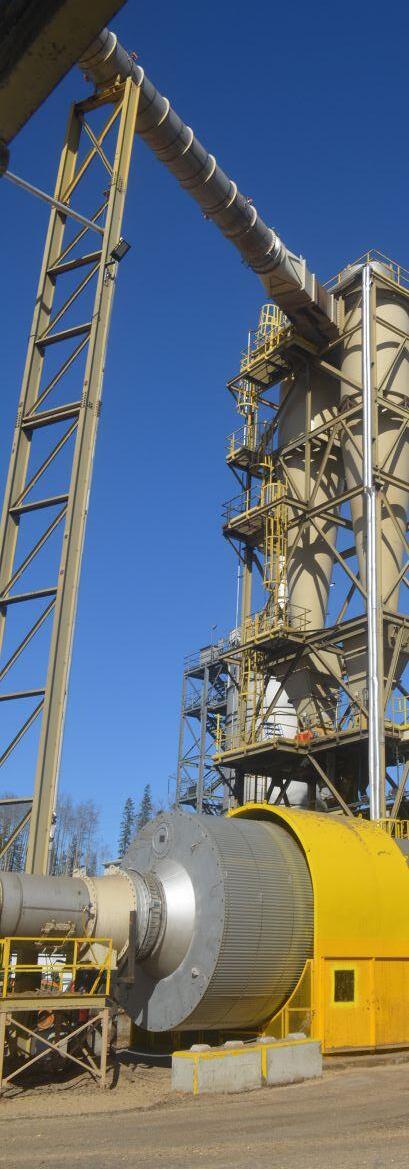

When you hop in a car and drive throughout the northwest region of British Columbia, it’s easy to see the impact that shuttered sawmills and other wood products plants have had on the region. Few areas have been hit harder by the challenges facing the province’s forest products sector. However, there are still some bright spots in the region that are helping the region offer meaningful employment while offering a sustainable solution to the world’s energy crises. One of those bright spots is Drax’s Burns Lake wood pellet manufacturing plant.

Drax has a major economic impact in northwest B.C. In addition to having 127 full-time employees in the region (70 full-time employees at Burns Lake), the company has spent $68 million in the northwest on fibre, wages and salaries, rail and external contractors. It has also spent $4.61 million on capital expenditures,

$7 million in direct total taxes, and generated $20 million in total tax revenues from spending within the region. Of Drax’s $119 million in operating expenditures, 57 percent was spent at suppliers within B.C.’s northwest region. In total, the company has generated $77 million in direct, indirect and induced GDP contributions within the region.

While the Burns Lake facility isn’t the company’s sole pellet plant operating in the northwest region of B.C., it is one of the largest producers of wood pellets for the company with production targets of 320,000 MT pellets annually.

All of the wood pellets produced at the plant are shipped overseas to supply the growing Asian market as well as Drax Power Station.

When driving up to the plant, the first thing you see are wheel loaders working tirelessly to supply the

plant from its fibre yard. All of the biomass is sourced from harvest-designated B.C. forests through a combination of sawdust and sawmill residuals (81 per cent) and low grade roundwood, tops, branches, and bark (19 per cent).

To meet an annual production target of 320,000 MT of wood pellets, the team at

Burns Lake is always busy finding ways to source the fibre needed. That being said, Drax only purchases fibre that meets the local, international and company level sustainability requirements for biomass. These requirements ensure the biomass sector helps to create positive outcomes for people, nature and the climate by sourcing biomass. Drax’s biomass sourcing policy, recently updated in March 2025, provides insight into the biomass sourcing requirements for all of Drax’s pellets mills, including Burns Lake, as well as other Drax

In addition to the economic impact of the Burns Lake facility on the region, Drax also regularly gives back to the community through a wide variety of initiatives. The company has a total of $52,000 in community fund donations and an additional $50,000 in corporate fund donations since 2023. These donations support local schools, STEM education, Indigenous groups, local food banks, and more.

operating assets that use biomass.

One advantage that the Burns Lake facility has over some other pellet plant operations is that it has always ran a rough mixture of fibres.

The ability to process a wide variety of fibre gives the team at Burns Lake more options in terms of being able to change up its recipes for making pellets, and will offer the other Drax plants in the area that flexibility in the future. However, the rougher fibres are harder on the equipment.

“The course fibre wears out equipment a lot faster. That is the biggest challenge and plant teams need to be set up and prepared for that. We run most of the same equipment at each of the sites, however there are customizations based on the type of fibre breakdown required,” says Rodney Bedford, plant manager at Drax Burns Lake.

The key to successfully using a wide variety of rougher fibres is a strong preventative maintenance program, good fibre mix production planning, and always looking ahead.

“Luckily for us, we have a good team. Drax has really stepped up its game when it comes to paying a competitive rate – not just for our site, but all the sites,” Rodney says. “We pay a good rate that compares and sometimes exceeds most of the sawmills in the area, but also compares and exceeds a lot of the mines.”

The pellet production process begins in the yard, where loaders feed three different fibre decks: shaving, hog, and the sawdust deck. The various materials are conveyed to a hogger that processes the fibre through a grate below the rotor into hog discharge number one conveyor. The small material, sawdust and chips, will

fall through the high scalping rolls into the hog discharge conveyor number one.

A second downsizing of the material occurs with a similar process using additional equipment, specifically the biosizer, which further refines the material. This ensures that the final product meets the necessary specifications while maintaining proper drying alignment.

A surge bin is located at the end of this process to ensure a steady uninterrupted flow is maintained at the dryers. Product is conveyed from there directly into two rotary drum recycling dryers. Once the material has been adequately dried, it is then resized by hammermills and conveyed to 12 Andritz pelletizers. Once this process is completed the pellets are sent by conveyors to the railcar loading area and transported to the Port of Prince Rupert or Fibreco in North Vancouver to be shipped overseas to the Asian market.

“We have a burner that we make our own fuel for from the excess during the production process. We have different screens in power number two for that, and that’s how we heat up the burner to dry the product,” Bedford explains.

To ensure a safe production process, each pellet line is equipped with CV Technology spark detection equipment and dust is managed by Allied Blower technologies.

Since taking over ownership of the Burns Lake facility in 2021 from Pinnacle Pellet, Drax has invested heavily in improving safety and reducing emissions throughout the plant’s operations.

“The safety systems we have here are pretty incredible,” Bedford says.

Another area where Drax focused was emissions control. In addition to investing in spark and explosion detection systems,

the company invested in a $2.5 million baghouse project to further reduce emissions and ensure they are operating well within permit limits and maintaining the highest levels of compliance standards.

“We have invested in several baghouses here at Drax Burns Lake, as well as many safety devices for explosion protection and mitigation on the equipment. But the big dollar values were the emissions related items,” says Liezl van Wyk, vice-president of northern operations. “Staying in compliance and making sure that we are compliant with all of our emissions controls is of utmost importance to us at Drax.”

Prior to the baghouse project, the plant was already complaint with emissions guidelines, but Drax wanted to take it one step further. They installed another baghouse to manage exhaust emissions off a dry product cyclone which was not being tested for emissions at the time.

“A lot of our plants are centrally locat-

ed within the communities. That means they can be right next to retail stores or elementary schools. So, another reason to go above and beyond is because we are dedicated to being a good neighbour in our communities,” says Caroline Bleay, Drax’s communications manager for

Canada.

While the annual production target is currently 320,000 MT, the plant has the potential to produce a higher capacity. However, meeting emissions targets places a cap on production targets.

“We try and put out as much as we

“We have 70 employees here. So, it’s a lot of people to ensure understand what we’re trying to put out and to understand the safety process.”

can. But with our dryers, for example, we can only put so much through them. They have a point where we can’t go any higher because of emissions,” Bedford says. “We are balancing meeting our production targets while also staying in compliance, we’ve basically put a ceiling on all of our temperatures and anything from the dryer that puts the WESP (Wet Electrostatic Precipitator) at risk of being out of compliance. We’ve done multiple performance tests to get the balance right on production and emissions. Right now, where we sit is where we need to be as far as hitting compliance.”

Safety is of utmost importance at Drax. The Burns Lake facility has a significant number of first aid trained employees on site anytime the plant is in operation.

“We have Level 3 First Aiders on site. We do not run if we do not have a Level 3 on site,” Bedford says, adding that all employees are required to do some computer-based training. The site also has a Joint Health and Safety Committee that works on safety initiatives and training. The staff have mandatory daily safety meetings.

Paul Fletcher, HS&E manager for Drax’s Burns Lake and Meadowbank plants, focuses much of his time on pushing compliance and performing safety audits on site.

“It’s to help build that safety culture and make sure everybody understands the training, that everyone’s on the same page,” he says. “We have 70 employees here. So, it’s a lot of people to ensure understand what we’re trying to put out and to understand the safety process.”

To promote employee engagement related to safer operations, the plant’s central system allows employees to enter hazard IDs.

“All employees have access to it. So, if they see something out in the field that

they feel is a concern, they put in the hazard ID in the same place we do our investigations. They can see our investigations, any of our observations, which we require weekly,” van Wyk explains. “Our plant management teams do multiple observations and audits throughout the week in the same system. It’s one system where all of our safety documentation goes.”

Drax has also put a system in place where the company’s various production plant safety teams in the region can communicate with each other.

“We have a really good system within our plants,” Bleay says. “Our plant man-

agers are all connected through a communications program for HS&E (Health, Safety & Environment), making sure everybody’s on the same page when it comes to what is going on at other plants. As well, all the guys have lockout/tagout. Everything from the first aid to health and safety systems are connected across the board. Our operations team has noticed a palpable increase in safety from the preDrax days.”

Drax going above and beyond for installing explosion mitigation and protection is something that every employee appreciates, noting that many employees have been around long enough to have seen the side effects of not having these systems in place.

“We’ve also seen the reaction by having them in place. Having put the money – and its millions of dollars – into venting, bottle, suppression, on all of our conveyance and detection, the safety side of things has gone a long ways,” he says. •

By Andrew Snook

Anyone who has ever experienced a hurricane, knows of the destruction they leave behind in their paths. The residents of Halifax are no strangers to dealing with the aftermath of these powerful storms. One resident, Joe Lewis, president of BioBurn Pros Inc., used his experience with a recent hurricane to build a new business that is taking off across Nova Scotia.

“BioBurn was very much born from a hurricane,” he says. “Just about every year in September, October – sometimes as early as August – we get hit with some significant hurricanes; and there’s always some down trees and old growth falling.”

A few years ago, Lewis was using his background in excavation and groundwork to clear some land and build a road for a client. While he was in the process of moving out all of the stumpage and other unmarketable waste wood, Hurricane Fiona hit the province.

“We found ourselves running around the city cleaning up hurricane downfall for people, and we started running all the waste to these municipal drop centres that they opened up for the emergency processing of all the storm debris,” Lewis recalls. “The municipalities were taking on a lot of the cost of the cleanup from this type of event. That same year, we got hit with some of the worst forest fires that ever happened here on record.”

As the waste piled up at municipal drop centres, Lewis and his colleagues started asking themselves if there was a more effective way to remove all the unmarketable wood waste, as well as find a better solution than having it be left to rot in a landfill. While searching for solutions, Lewis came across the Air Burners website and started researching the company’s

air curtain burners technology.

“I reached out to Air Burners and said, ‘I think there might be an application for your technology in Atlantic Canada doing storm remediation,’ so we started talking to them,” Lewis recalls.

From there, he reached out to the Province of Nova Scotia to learn how much money was being spent on hurricane and wildfire remediation. This is when Lewis realized there was a business case for bringing the Air Burners technology to Atlantic Canada to use at municipal drop sites to process the storm debris and other waste wood.

In August 2023, Lewis started up BioBurn Pros and purchased his first Air

Burner technology, a FireBox S223. The principal purpose of the air curtain technology inside these units is for use as a pollution control device for open burning. They reduce the particulate matter, or smoke, which results from burning clean wood waste. The air curtain technology traps the smoke particles and reburns them, reducing them to an acceptable limit per U.S. EPA guidelines. The machines have been tested by the U.S. EPA, the U.S. Forest Service, the U.S. Department of Energy, and the U.S. Armed Forces to prove their specifications and performance. The FireBox S223 is the company’s largest unit that can be built for over-the-road travel without oversize load permits.

Lewis’ company started out in larger industrial-type settings, performing larger burns for municipalities.

“The last couple of years we’ve been really busy out there talking to municipal and provincial governments, talking about wood waste diversion programs to get this stuff away from landfills,” he says. “We’ve been seeing the most success for our contracts in the landfill waste diversion side of things.”

While Lewis admits there are lots of great things going on with biomass, sometimes it’s simply unmarketable.

“We did a little bit of investigating, driving around the province and looking at some of the disposal sites. We were seeing fields of mushy, old, rotten storm and wood debris that was just sitting there doing nothing but rotting away,” he says. “There’s a lot of good going on with biomass, but sometimes the biomass is just waste and has nowhere to go. So, elimination is the best solution to prevent further emissions, and processing costs. So, that’s where we landed with the business in the past two years.”

While BioBurn Pros has been busy servicing municipalities’ storm debris, Lewis has learned that the Air Burners technology also has other forestry applications and has been active performing forest thinnings and land clearing projects.

“We learned the benefits of using it for wildfire cleanups or even wildfire mitigation projects for preventative work,” Lewis says.

BioBurn Pros has met with a few different municipal emergency preparedness managers to discuss how they can work together, helping them with their wildfire mitigation strategies.

“You’re seeing communities actively invest into wildfire mitigation programs like FireSmart, and doing all the preventative work,” Lewis says. “But there’s a huge expense to those residuals… the conversations we’ve had with these municipal managers is that we can open these programs and open up central dump locations for the residents and the businesses to bring all this stuff.”

The company is still in the early stages of discussions with municipalities for work related to fire mitigation strategies, but there is interest from communities. BioBurn Pros recently met with the Town of Truro to offer a demo of their Air Burners technology.

“They said, ‘We love the idea, but we’re scared about the smoke or the idea of fire,’ for where they have all this stuff stored. It’s close to a provincial park and it’s close to communities. So, we said, ‘Okay, if you’re worried about it, how about we do a demo day for you?’ So, we went out there and we found a wood lot, and we burned for four days straight out there. They brought out all the municipal department of natural resources people; the fire marshals were out; the wildfire mitigation officers were out; and they all loved it,” Lewis says.

He adds that his business will benefit the forestry industry and surrounding communities by reducing fees related to hauling wood waste, and lowering CO2 emissions.

“It’s going to benefit not only residents, but it will benefit the forestry industry, all the landscapers and excavating companies doing land clearing. Right now, because we don’t have facilities like this, it’s creating a lot of unregulated and illegal dumping of the products. We’re really trying to help mitigate that,” he says. “We’ve had a lot of people bring up methane off-gassing from rot – the ability to not only provide a carbon neutral process for eliminating the wood waste, but something that avoids the methane. So, there’s some methane diversion discussions going on as well.”

The company now has additional demonstrations scheduled with municipalities booked between all the way into September.

The company recently purchased a second Air Burners unit, a BurnBoss, to service smaller projects.

“We were having a tough time engaging with small residential agriculture and forestry. Those markets, they love the technology, but the budgets for this type of thing are sometimes thin in those industries. So, we decided to go buy another Air Burner so we can engage more with those markets,” Lewis says. •

By Andrew Snook

The BC Council of Forest Industries’ annual COFI Convention took place on April 3 and 4 at the Prince George Conference and Civic Centre in Prince George, B.C. Themed, “Where Do We Stand? Strategies for Competitiveness and Sustainability,” this year’s COFI Convention focused on factors and innovations that can reshape the future of the forest sector in B.C.

Greg Stewart, president of the Sinclar Group Forest Products and Chair of the COFI Board of Directors, welcomed attendees to the convention and introduced Lheidli T’enneh First Nation Chief Dolleen Logan, who spoke to the crowd about the many challenges facing the forestry sector.

“Despite the growing challenges of the forestry sector, I’m encouraged to see so many familiar and new faces attending this week to learn about shared pathways,” Chief Logan told the crowd. “As a nation with deep roots in the forest sector, we’re constantly seeking new, innovative approaches to both the forest sector and the forest policy. It is no secret that the industry is facing its most challenging times in history, from increased costs at home to fluctuating and confusing policies directions.”

Chief Logan’s family has worked for many generations in the forestry sector, including her son, who due to a lack of employment certainty in the local forestry sector, needed to move to Saskatchewan to find work as a millwright.

“We have to find a way to keep our kids at home that love the forestry sector,” she told the crowd.

Chief Logan stated that B.C.’s forestry sector needs to be strategic in how it supports and creates profound change to

the industry.

“There is a tremendous amount of work we can do right here to pivot our industry to fight for the workers that have built this province, our communities, and, like the Wood Innovation and Design Centre, continue to show how the wood construction can still lead the way.”

Chief Logan stressed the importance of partnerships and the forestry sector for the region. The Lheidli T’enneh First Nation has had a long mutual beneficial history of partnerships with forestry companies and biofuels companies, and those looking to innovate and think differently, Chief Logan stated.

“Shared prosperity means building the solutions in B.C. that allows our children and future generations to build a future on the same resources that build opportunities and futures,” she said.

Chief Logan also discussed the need for B.C.’s forestry sector to diversify away from its heavy dependence on the U.S. market.

“We have two ports. We can ship our wood to anywhere in the world,” she told the crowd.

City of Prince George Mayor Simon Yu also welcomed the crowd to Prince Geroge. Yu discussed the importance of the forestry sector to the region, and the need to create fibre certainty so companies operating in the region can invest further into keeping sawmills and other forest products plants running, and possibly, expand and open new mills.

“We need to be innovative and rethink wildfire management, harvesting, and most importantly, thinning,” he said.

Yu added that all the stakeholders in the room – industry, labour, government, First Nations – need to establish trust with each other, and focus on working with each other to find solutions to everyone’s challenges so the sector can grow a healthier value-added industry.

MLA of Prince George-Mackenzie Kiel Giddens also welcomed the crowd to the convention. Giddens stated that he

wanted to see a forest sector that focused on sustainability and the environment but also had a strong focus on economic and socioeconomic sustainability.

“We need your help. We need your ideas, and I look forward to discussing these ideas with all of you over the next couple of days. Now, more than ever, we need resource champions who are willing to take on the partnerships and innovation needed for our prosperity and good family-supporting jobs right here in British Columbia,” he said.

Giddens stated that nearly 90 per cent of people living in British Columbia believe that the forestry sector is vital to the province’s economy, and that 78 per cent believe B.C.’s forest industry is among the world leaders in using sustainable and responsible forest practices.

“We have a really great base and success from the past, but it doesn’t mean that we can rest on our laurels,” he said. “Our success is the result of the hard work and the many contributions of everyone in the forest sector. We are at a crossroads today. Now is the time for all of us in the forest sector to work together to build on our past success and address the challenges we face today.”

The final welcome address came from COFI’s new president and CEO Kim Haakstad, who began her speech by thanking former president and CEO Linda Coady for her hard work and dedication

to B.C.’s forest sector.

“COFI is better off as an organization thanks to you,” Haakstad said to Coady, who was in the crowd. “You spent your time balancing economic and ecological values and championing strategies for wildfire resilience, forest health and efficient wood use. You’re a bridge builder. You brought together all the different forestry associations to have robust conversations about the challenges we’re facing and deepened our connections with groups like the BC First Nations Forestry Council. While working with the provincial government, you worked hard to get the commitment to a target harvest of 45 million cubic metres into the government’s election platform and Minister Parmar’s mandate letter. So, thank you for all of that.”

Haakstad comes to the association with 20 years of leadership experience serving as the Deputy Chief of Staff to the BC Premier, as well as working in North America’s agri-tech sector. She has also served on the board of B.C.’s DIGITAL Global Innovation Cluster.

“I’m excited by taking on and finding solutions to challenges, and I’m pleased to have joined COFI,” Haakstad told the crowd. “Times are tough, but that’s when we can make the most difference. For the last two months, I’ve been focused on learning and action, meeting with the members, and learning about their operations in the industry, and getting feedback on how COFI can better support their businesses. •

By Andrew Snook

More than 200 attendees packed into the Delta Beausejour Hotel in Moncton, N.B. for the Canadian Woodlands Forum’s (CWF) 2025 Spring Meeting. The 106th annual general meeting and conference kicked off with a welcome address from CWF chairman Dirk Nielsen of Weiler Forestry.

Nielsen briefly discussed the CWF’s five-year plan, which was a key focus of the annual general meeting with the association’s 22 board members.

“We set out six general goals that feed into the mission statement and drive the workplan behind what the Canadian Woodlands Forum is all about,” he told the crowd.

The goals of the CWF are to support contractors and operators by promoting professionalism and sustainable practices; improve communication and information to members; improve operational efficiencies of woodland operations; promote and deliver continuing forestry education and outreach; foster cooperation between forest stakeholders; and ensure the means of sustaining and growing the organization.

The CWF’s membership has grown over the past year with the number of contractor members jumping from 137 to 180 members. Nielsen sent a call out to any logging contractors that want to be active members of the CWF Board.

“It’s a great cross-section of people in the industry, from the manufacturing, supply chain, dealers, manufacturers, and logging contractors – obviously, you’re the heart of it. I appreciate when logging contractors can participate and give their voice to what we’re working on. So, if you want to become a board member, we do have a few vacancies,” he said.

Kevin Merriam, executive director of the Maritime Lumber Bureau (MLB), presented, “Opportunities and challenges in a rapidly changing sector,” which featured a discussion on opportunities and challenges regarding domestic and international wood markets, the building and construction sector and tariffs.

Merriam started by acknowledging the constant state of uncertainty surrounding the U.S. tariffs situation, and the concern that poses for the forest sector in Atlantic Canada. Atlantic Canadian annual production since 2021 has been relatively static with just over 1.8 billion bdft. Of that production, U.S. shipments have accounted for 1.2 billion bdft.

“Roughly about 70 per cent of our wood products and lumber products go to the United States from Atlantic Canada,” Merriam said. “You know what kind of a situation that puts us in. I don’t

think I’m surprising anybody when I say that it’s a very serious situation, and we are in a point in our history in this country where we really have to take a strong look at what we’re doing as far as our markets and our American diversification strategies go, because 70 per cent is significant.”

When breaking down forest products production across Atlantic Canada, New Brunswick produces 74 per cent of all forest products in the region, followed by Nova Scotia (23 per cent) and Newfoundland (3 per cent).

Many people in the region are concerned by comments made by U.S. President Donald Trump who has stated that the U.S. does not need any Canadian lumber or wood products. While those comments should be taken seriously, the data shows a need for Canadian wood products to meet U.S. domestic market demand.

The overall Canadian share of U.S. consumption of softwood lumber in 2024 was approximately 12 billion bdft. out of a total U.S. consumption of 49.8 billion bdft., comprising about 24 per cent of U.S. total consumption.

Merriam stated that for the U.S. to remove its dependence on Canadian lumber and source those products from U.S. mills, the country would need to build up significant capacity that could take up to 10 years to generate, not including the additional challenges of finding the capital investment, required fibre supply, and staff. This does not take into account a rise in demand for U.S. housing over the next decade.

However, the upcoming combined countervailing duties (CVD) and anti-dumping (AD) duties from preliminary results of the sixth administrative review are troubling. Many Canadian forest products companies could be looking at total CVD and AD rates ranging from 34.45 per cent to 46.48 per cent as soon as this coming August.

“This isn’t in effect yet. It could be anywhere from August to October before it takes effect. It’s not 100-per-cent guaranteed, but usually when they come out with a preliminary review like this, it’s pretty accurate,” Merriam said.

He added that this would not include any

additional tariffs that the Trump Administration could apply to Canadian products.

“This is something we have to be aware of, and we need industry at large to help sort this stuff out and help with new ideas and thoughts as to how we navigate the world that we live in right now, because our sector is so important to the economy. It’s so ultra-important to our rural communities,” Merriam said.

Merriam also spoke about domestic opportunities during his presentation to help the forest products sector become more self-sustaining. One area he touched on was the relationship between the Canadian population forecast and housing affordability.

“We have growth in this country. We’re currently just over 40 million people in Canada, and we’re growing,” he told the crowd, adding that housing affordability is a major issue in the current federal election. “We’re one of the sectors that can help make that happen. We can find a way. We have the resources, and we certainly have the skill. We just have to have the drive to push it forward and to have the political pull to do so.”

By 2030, Canada could be facing a housing supply deficit of about 3.5 million units. This is an opportunity for the country’s forest products sector to push forward with more mid-rise construction projects, which are on the rise in Atlantic Canada.

“They’re high-performing buildings. They meet code every day of the week, and they are a really a good solution for how to have affordable housing solutions,” Merriam said. “They’re a direct competitor with other building products and the speed of construction is very fast. Developers love it, and now that we’re getting on board with the changes in the codes to allow for six-storey stick frame, you’re seeing them go up all over the place. This is good utilization of our domestic wood products that we make right here in our own backyard.”

Mass timber projects using products like cross-laminated timber (CLT) are another opportunity for Canada’s forest products sector to grow by domestically supplying the country’s construction sector.

“It’s a very high-performing product. It’s garnering a lot of interest and a lot of uptake right now in Canada, and this is a wonderful utilization of our forest products that we make in our own backyard,” Merriam said, noting that a firm in Chicago was able to successfully design a 52-storey building constructed with 100-per-cent CLT for the roofs, floors and walls.

In Nova Scotia, there is currently a mass timber manufacturing facility in the process of being developed.

“It’s well on its way right now to having shovels in the ground pretty soon, and I really hope that happens, because that will really spur a lot of interest in the sector,” Merriam said.

He added that the use of wood products in bridge construction, industrial buildings and educational institutions are other domestic opportunities for Canada’s forest products sector to pursue.

Not that long ago, the majority of wood products produced in Atlantic Canada used to be shipped to the U.K. The MLB, working with other parties, recently developed a new market study and are looking at ways to reinvigorate the region’s forest products sector relationships with the U.K.

Merriam noted that Canada also has good working relationships with the European Union (EU).

“We’ve taken delegations over to Germany and Austria within the last couple of years to work with them on trade,” he said.

Merriam added that Canada has preferred market access to 51 foreign countries.

“We are a global force when it comes to forest products and we’re going to stay that way. We just don’t lay down and decide that we give up, and throw our hands in the air and decide that we’re going to stop everything to do with forestry. This is our livelihoods. This is what we do,” he said.

Merriam concluded his presentation by reminding the crowd that today’s challenging climate is far from the first challenge this industry has experienced in recent history.

“We’ve been dealing with the Canada-U.S. software lumber agreement now for 30-plus years. We’re used to it,” he said. •

By Dutch Dresser, Ed.D. and Gordon Murray

As the world’s coldest country, Canada consumes a lot of energy for home heating. Space heating accounts for 64 per cent of Canadian residential, commercial and institutional energy consumption. The most common energy sources are natural gas, electricity and heating oil.

Compare this with Sweden and Finland, where biomass is the dominant heat energy source. In Sweden, biomass provides 66 per cent of space heating, and in Finland, the figure is 59 per cent. The two countries use district heating networks and modern small-scale biomass boilers designed to the European standard EN 303-5.

Biomass central heating is a mainstay in much of Europe. Western European boiler manufacturers have invested heavily in the research and design of pellet boilers, creating efficient and clean-burning systems that are fully automatic and reliable. The most advanced of these boilers recover heat from flue gas, so even condensation isn’t seen leaving these chimneys on cold days.

These new technologies aren’t generally available in Canada because existing Canadian safety standards are only appropriate for fossil fuel-fired boilers. They do not consider the latest biomass-fired boiler technologies.

The Canadian Standards Association (CSA) is working to adopt the European standard, EN 303-5:2002+A1:2023 Heating Boilers – Part 5: Heating boilers for

solid fuels, manually and automatically stoked, nominal heat output of up to 500 kW as a National Standard of Canada anticipated by Fall 2026.

By CSA adopting EN 303-5, a standard used by 28 countries, Canada will be able to:

• Demonstrate to the standards-user community that this standard has been examined and endorsed by Canada’s top technical standards experts and found relevant to the economic growth of Canada’s emerging sectors.

• Support domestic and global trade as

national standards adopted by Canada meet World Trade Organization obligations and trade agreements such as the Canada-European Union Comprehensive Economic and Trade Agreement and the Canadian Free Trade Agreement.

The rationale for this work is set out in a white paper, Certification of Small Solid Biomass Combustors (SSBC) in Canada (available in English and French). The paper is the culmination of nearly five years of work by experts across the country to address administrative barriers

which restrict the sale of boiler systems that use wood pellets into the Canadian market.

Once adopted, Canada can more easily design, manufacture and import small solid biomass combustors for Indigenous, remote and rural communities across Canada that use fossil fuel heating systems due to accessibility and affordability.

A small solid biomass combustor uses small quantities of biomass materials, such as wood pellets or chips, to generate heat or energy. As a low-carbon and renewable energy source, biomass has great potential to help solve the energy shortage problem and lower energy costs, as well as reduce greenhouse gas emissions from space heating in Canada.

Small solid biomass combustors are typically designed for small- to medium-scale applications such as residential, commercial or institutional heating systems. Over 600 are operational in Canada today, displacing propane, oil or electric baseboard heating systems for many communities.

Draft new CSA Standard: A Working Group is reviewing the EN 303-5 standard to make it more easily understood and usable in Canada and recognize existing Canadian standards that should

be referenced in the adopted standard. It is expected this assessment will be complete by December 2025.

Review and public comment: The draft needs to be reviewed by the Technical Committee, and the draft standard will be distributed for public review.

Canadian adoption: Once consensus has been reached by the Technical Committee under CSA Group’s accreditation, it is expected that EN 303-5 will be adopted as a Canadian standard with the Canadian deviations being currently devised. It is anticipated the standard will be published by Fall 2026.

With adoption, Canadians will have the same access to efficient, low-carbon, small biomass central heating systems (hydronic heaters) that many across the world now enjoy, and more Canadian wood pellets can serve the heating and environmental goals of Canadians. •

This is the third in a three-part series from the Wood Pellet Association of Canada’s participation in the Arctic Energy Alliance’s 2025 Northwest Territories Biomass Week. Other articles include CHP 101 and BEECS Basics. They can be found online at: www.canadianbiomassmagazine.ca. Harry “Dutch” Dresser, Ed.D., is a biomass heating expert and consultant. Gordon Murray is the executive director of the Wood Pellet Association of Canada.

By Diane Cave

ou’ve taken the last article’s advice and you and your team have completed a dust hazard assessment (DHA). Your consultant has done their thing and now you’ve been given a report full of pictures, tables, graphs, and likely, a lengthy list of deficiencies. The deficiency list likely ranges from cleaning/housekeeping and electrical area classification to procedures and installation of new safety equipment or replacement of existing equipment.

Now it’s up to you and your team to figure out what to do with it. There’s plenty of discussion about how to do a DHA, but you don’t always get a clear picture of what to do you with it. How do you take the deficiency list and turn it into actionable items? Don’t worry, you aren’t alone, this is a question a lot of facilities ask. Where do you start? Start by making a plan.

From the DHA deficiency list, you first need to determine what items are requirements and what are recommendations. First, let’s talk about requirements. Requirements are those items that are mandated by NFPA codes/standards, provincial or federal building/fire codes, and/or local requirements. These are items that must be implemented. These are such things a explosion protection and safe blast zones.

The other items that do not fit into this category are recommendations. These are items that are considered good industry practices and/or improve the efficiency/ life cycle of the equipment. This might be something like the installation of additional dust collection hoods, instead of increasing housekeeping in a given area

or installing additional sensors for an extra layer of safety.

Once you’ve nailed down your required list, start splitting this up into two main categories: items that can be done fast, easily or cheaply and those that will take more time and capital to implement.

The fast list is something that you just churn out. Start assigning tasks to people and knock those items out. This will also give you momentum with the longer lead items.

Determining where to start with the longer lead items can get tricky. In an ideal world there is an endless supply of capital and unlimited downtime to implement things. But we all know this isn’t reality, or even close. Not all the recommendations listed will be able to be implemented right away due to equipment lead times, production requirements, accessibility to capital, the quantity of upgrades required or other reasons.

When it comes to the longer lead items you need to look at risk.

If you lucked out, your DHA author ranked your issues, or at the very least gave it a “badness” number. If that’s the case, you can simply start with the worst ranked and work your way up the list. If you didn’t get any sort of ranking, or if everything is equally ranked in your DHA, then you need to start by picking the worst, bad ones. Items that carry the most risk should be address first. If you’re only able to complete one of ten high risk items this year, start with the items that will have the greatest impact. Those are things like having explosion vents that discharge inside, active ignition sources (sparks going into dust collector, hot surfaces covered in dust) or unsafe blast zone.

If there are a bunch of those then look

at how often a piece of equipment is used. The more frequent it’s use, the higher the likelihood of an incident. How often people are around these pieces of equipment? If people are around them all the time, then again there is a higher chance of incident.