The latest pellet mill type 65 – 1500 with 630 kW drive power reaches up to 12 t / h high quality level. It is the largest industry proven wood pelleting press in the market today. More than 60 large Kahl pelleting presses are installed just by the well-known US market leader. Recently pellet producers in Brazil (400.000 tons hardwood per year), Russia (2 × 150.000 tons per year) and Asia Pacific (already more than 40 large scale presses) have decided to install Kahl technology.

AMANDUS KAHL USA Corp.

105 Hembree Park Drive, Suite L Roswell, GA 30076 · USA · 001-770-521-1021 sales@amanduskahlusa.com · akahl.us

AMANDUS KAHL GmbH & Co.KG SARJ Equipment Corp.

29 Golfview Blvd · Bradford · Ontario L3Z 2A6, CANADA 001-905-778-0073 · rbmacarthur@sympatico.ca

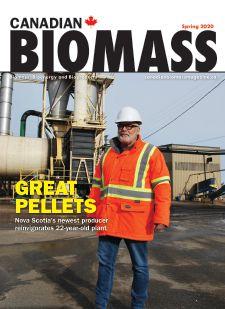

Nova Scotia’s newest wood pellet plant is humming away in Upper Musquodoboit. Pellet mill production manager Miles Wright gave Canadian Biomass an inside look at the investments that have allowed the plant to produce 100,000 tonnes of wood pellets per year.

FutureMetrics president William Strauss shares insights about how COVID-19 will impact the industrial wood pellet industry.

The Esk’etemc people are installing biomass boilers to help reduce their reliance on fossil fuels. FESBC’s executive director Steve Kozuki shares some insights into the project.

When Whitecourt Power found its inventory of sawmill residuals running low, they teamed up with Millar Western and Whitecourt Transport to trial separating debris from hog fuel piles.

The City of Toronto is upgrading an organics processing facility to convert food waste into RNG, which will then power Toronto’s garbage truck fleet and eventually heat buildings.

Cleantech company Sustane Technologies is turning household garbage into biomass pellets, biofuels and recyclable material. Canadian Biomass takes readers inside the project.

“We are diverting 90 per cent of the waste that is not already diverted. That is going to

Miles Wright, operations manager for Nova Scotia’s newest pellet plant, Great Northern Timber Resources, says the new owner’s supply chain integration will give them fibre security.

t’s strange to think that just two months ago, in February, I was on vacation, sipping drinks on a beach. Today, that seems unthinkable as Canada and countries around the world work to ‘flatten the curve’ of COVID-19. Just one month ago, most of us had never heard the term ‘flatten the curve,’ or given much thought to what would happen if the novel coronavirus became a problem in Canada.

Fast forward to today – some of us are working from home and everyone is social distancing in an effort to minimize the strain on our healthcare system and buy time to develop a vaccine. We’re also wondering what the impact of this pandemic will be on our sector and the economy as a whole. The news so far has been grim, with many experts predicting a global economic recession, if not a depression.

Pellet Association of Canada, called “Pellet Pulse: Analyzing the impact of COVID-19 on the industrial wood pellet industry.”

William (Bill) Strauss, president of FutureMetrics, shared insights about how the pandemic could impact wood pellets’ supply and demand, as well as the impact of different countries’ policies.

But there are some silver linings. Forest products companies across Canada, including wood pellet producers, have been deemed ‘essential’ and continue operating, following recommended health guidelines. Many manufacturers in Canada have pivoted their operations to produce much-needed personal protective equipment (PPE) and hand sanitizer, such as biofuel producer Greenfield Global. Communities are coming together in creative ways to support each other and frontline workers. Organizations are finding ways to continue sharing information and connect with their members.

In fact, my team and I have been exploring different ways to continue connecting with you, our readers, as conferences and tradeshows around the world have been postponed or cancelled. On April 13, we hosted a webinar, sponsored by the Wood

Given the poignant topic, I expected a fair number of people to tune in, but was pleasantly surprised to see that 383 people registered for the webinar! Bill gave a great presentation and was able to answer many attendees’ questions. It made me realize that although I can’t meet with industry stakeholders and professionals in person, there are still many ways to connect. If you missed our webinar, don’t worry, Bill also wrote an article summarizing the potential effects of COVID-19 on the industry, which you can read on page 14.

In the meantime, life continues, albeit in a different way than any of us ever could have expected. Bioenergy projects continue to come online, including Nova Scotia’s newest pellet plant and Sustane Technologies’ new demonstration plant, which is converting household waste into usable material. Read more about those projects on page 10 and page 28.

As the situation with COVID-19 evolves, we will continue to look at different ways to connect, including additional webinars. Hopefully we will begin to reopen the economy soon and start making our way back to “normal.” Until then, stay safe.

Volume 20 No. 2

Editor - Ellen Cools (437) 922-3026 ecools@annexbusinessmedia.com

Associate Editor - PJ Boyd (416) 728-6209 pboyd@annexbusinessmedia.com

Contributors - Maria Church, Gordon Murray, William Strauss, Martin Engineering, Tim Hoy

Group Publisher - Todd Humber 416-510-5248 thumber@annexbusinessmedia.com

Account Coordinator - Stephanie DeFields Ph: (519) 429-5196 sdefields@annexbusinessmedia.com

National Sales Manager - Rebecca Lewis Ph: (519) 400-0332 rlewis@annexbusinessmedia.com

Quebec Sales - Josée Crevier Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@annexbusinessmedia.com

Western Sales Manager - Tim Shaddick tootall1@shaw.ca Ph: (604) 264-1158 Fax: (604) 264-1367

Media Designer - Curtis Martin

Circulation Manager – Jay Doshi jdoshi@annexbusinessmedia.com Ph: (416) 442-5600 ext. 5124

COO Scott Jamieson sjamieson@annexbusinessmedia.com

Canadian Biomass is published four times a year: Winter, Spring, Summer and Fall. Published and printed by Annex Business Media.

Publication Mail Agreement # 40065710

Printed in Canada ISSN 2290-3097

Subscription Rates: Canada - 1 Yr $57.00;

(Canadian prices do not include applicable taxes)

CDN

CIRCULATION jdoshi@annexbusinessmedia.com Tel: (416) 510-5124 Fax: (416) 510-6875 or (416) 442-2191 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

Occasionally, Canadian Biomass magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. No part of the editorial content of this publication may be reprinted without the publisher’s written permission ©2020 Annex Business Media, All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.canadianbiomassmagazine.ca

in their

Lewis I

Josée Crevier I Quebec Sales I 514-425-0025 I jcrevier@annexbusinessmedia.com STRATEGIC PARTNER OptiPellet is co-located with the 2020 WPAC AGM & Conference, and will be the only activity running on Sept. 21. Make the most of your time in Vancouver by registering for both events!

I 519-400-0332 I

Over the last 50 years, Demo International has become North America’s largest and most recognized ‘live, in-woods’ forestry equipment show; this year’s event scheduled for Sept. 24-26, 2020 in Venosta, Que., in the Gatineau Valley Region was shaping up to be an excellent show.

As part of DEMO International, the pre-show conference entitled, “Digital Transformation in Forest Operations: A leap forward in driving business growth & competitiveness,” was also scheduled for Sept. 22-23 at the Delta Ottawa City Center, Ottawa. The program was 90 per cent complete and delegate registration was about to be launched in April 2020.

However, the COVID-19 pandemic has created an unprecedented level of uncertainty and has had a profound impact on people’s health, livelihoods and travel, both globally and across Canada.

Based on the current circumstances and uncertain timelines, and to comply with the stated policies and requirements from public health authorities throughout the country, the Canadian Woodlands Forum, in partnership with SBC Cedar and show and conference partners, have decided to postpone DEMO International 2020 until 2021.

Gevo, Inc. announced at the end of March that, due to the impact the COVID-19 virus has had on the economy and Gevo’s industry, Gevo has suspended production operations at its production facility in Luverne, Minn., for the foreseeable future. In connection with the suspension of operations and the overall economic disruption caused by COVID-19, Gevo also made the difficult decision to terminate 30 employees, cutting across Agri-Energy’s operations at the Luverne facility and Gevo’s headquarters in Colorado. The remaining employees that earn above a certain dollar threshold, including senior executives, have agreed to take a 20 per cent salary reduction over the next three months, with the 20 per cent portion to be paid in stock. With these steps, Gevo expects to save several million dollars of cash burn during 2020.

Gevo expects to continue the production of renewable isooctane and sustainable aviation fuel from the plant in Silsbee, Tex. Additionally, Gevo intends to continue developing its hydrocarbon business, including the planned expansion of the Luverne facility, and will continue to move forward in securing the project funding needed to expand the Luverne facility. The expansion is designed to allow Gevo to produce large quantities of low carbon isobutanol, sustainable aviation fuel and renewable isooctane.

Gevo also expects to continue engineering efforts for the expansion of isobutanol production and the construction of a commercial renewable hydrocarbon production facility, as well as additional decarbonization projects at the Luverne Facility. Furthermore, Gevo plans on continuing the development of its biogas projects in Northern Iowa..

Greenfield Global Inc. has been producing and shipping vital alcohols and solvents at a record pace to combat the worldwide spread of COVID-19 since the beginning of the pandemic.

As part of this effort, the company has adjusted its production to maximize disinfectant, hand sanitizer, pharmaceutical and food processing materials to supply the North American market at this time of increased need via its Pharmco and Commercial Alcohols brands.

The 30-year-old company, which produces over 700 million litres per year of high-quality beverage alcohol, high-purity pharmaceutical and industrial alcohol, and fuel ethanol has maximized its production to keep up with increasing demand. This includes prioritizing its efforts to support indispensable front-line workers fighting the spread of COVID-19 (i.e., hospitals, pharmaceutical companies, research labs, janitorial services, etc.), as well as other customers involved in meeting the demand for disinfectant products. Internal teams have also been tasked with developing plans to quickly increase production to satisfy the growing demand.

In cases where community funds or supplies have run dry, Greenfield is donating product to improve the health and safety of residents who have resorted to using improvised sanitizers and disinfectants.

As Canadians adjust to the new norm of social distancing and non-essential business closures, wood pellet plants and supply chain services remain open across the country. But the conditions for ‘essential’ businesses such as wood pellet production differ from province to province.

Under non-health essential service providers, B.C. lists businesses that “ensure global continuity of supply of primary and value-added forestry/silviculture products.” This includes wood fuel, along with lumber, pulp, paper and soft-pulp products. Transportation is also considered essential, allowing wood fuel to reach the desired markets.

Alberta released its list of essential businesses on March 27, which includes businesses that ensure the global continuity of supply of forestry products. This includes wood fuel, lumber, pulp and paper. It also deems transportation as essential.

Ontario shut down non-essential businesses as of March 23. The province’s list of essential workplaces includes companies that ensure the global supply of forest products, including wood fuel.

Under “maintenance and operation of strategic infrastructures,” Quebec has declared the production, supply, transmission, transportation and distribution of bioenergy essential.

New Brunswick is allowing production and manufacturing operations to remain open provided they “apply all the social distancing and hygiene recommendations of the Chief Medical Officer of Health.” Commercial transportation is not explicitly listed, but is also exempt from closure.

Nova Scotia has declared that transportation and manufacturing are essential. These businesses are exempt from the province’s limit on gatherings of more than five people, but employees are required to maintain social distancing.

Saskatchewan released a list of critical public services and allowable businesses on March 26. Production, processing and supply chains of the forestry sector were included in the list of allowable business services, as well as the transportation, storage and distribution of goods.

Manitoba released a list of essential services on March 30. It includes transportation and businesses “engaged in the extraction or processing of natural resources” such as forest products and aggregates, including businesses engaged in the production or sale of biofuels.

On March 27, P.E.I. ordered the closure of non-essential government services and businesses. Supply chain businesses, including industrial manufacturers, are on the list of essential services.

Newfoundland and Labrador closed all businesses providing in-person service on March 23. Non-retail businesses are allowed to stay open provided workers maintain six-feet of distance between themselves.

Pinnacle Renewable Energy and Enviva have both issued statements in response to COVID-19, outlining how they are minimizing risks to their employees, stakeholders and communities in which they operate. Both companies reported that they are able to continue operating, following appropriate practices to ensure employees remain safe.

John Keppler, chairman and CEO of Enviva, reported that the company expects to make every delivery required under its current long-term off-take agreements.

“Although the current COVID-19 environment remains fluid and uncertain, we believe the flexibility and resiliency of our operations, the designation of our business as critical infrastructure by government authorities, and the decisions we are making to protect our people and our communities, will enable us to continue to safely, stably, and reliably maintain production levels and deliveries,” he said in a statement.

Pinnacle is moving ahead with capital projects at its High Level, Alta., and Demopolis, Ala., facilities, following the appropriate precautions for COVID-19. However, the dryer upgrade at the Williams Lake, B.C., facility has been put on hold until equipment vendors can be onsite for commissioning purposes without any restrictions.

The company also reported that it does not expect demand for pellets to be impacted, given its long-term take or pay contracts with customers. If demand for lumber is reduced, thereby impacting the supply of sawmill residuals, Pinnacle will use harvest residuals and increased inventories, which the company has already been implementing as a result of sawmill curtailments in B.C.

Rob McCurdy, Pinnacle’s CEO, was set to retire as of May 5, 2020. However, he will now stay on with the company until Oct. 31, 2020, to help Pinnacle manage the crisis.

Effective April 3, Kruger Specialty Papers shut down its Brompton, Que., newsprint, specialty papers and biomass facility, affecting 272 jobs, for an indefinite period of time.

In a statement, the company says the decision is due to unfavourable market conditions hampered by the COVID-19 outbreak, which have affected the mill’s operations and financial performance.

The production of both newsprint and specialty papers for the flexible packaging industry will be curtailed, and the facility’s biomass cogeneration plant will also be shut down.

By Gordon Murray

rom Feb. 25-27, I attended the IEA Clean Coal Centre (IEACCC)’s annual workshop on co-firing biomass with coal in Kokura, Japan. WPAC was a platinum workshop sponsor. Participants included government agencies, regulators, power utilities, biomass and equipment suppliers, consultants and academia. At the workshop, I gave a presentation called, “Demonstrating that electricity production from solid biomass is both low-carbon and sustainable.” The presentation was intended to further burnish Canada’s reputation as a reliable supplier of high-quality pellets produced from sustainably managed forests.

The IEACCC is a UK-based organization organized under the auspices of the International Energy Agency, dedicated to finding ways to make coal a cleaner energy source. Members include Australia, the European Union, Germany, Italy, Japan, Poland, South Africa and the U.S.

Some readers will be morally indignant about the concept of “clean coal.” However, the world still consumes seven billion tonnes of coal annually, accounting for about 40 per cent of the world’s electricity. In many countries, coal use is rising. So, as

Globally, biomass co-firing is moving from west to east as European plants have increasingly adopted dedicated biomass firing while the majority of biomass power in Asia is presently produced from co-firing.

long as coal is going to be with us, we need an organization like the IEACCC to work on ways to make coal a cleaner source of energy. These include initiatives such as carbon capture and storage, high-efficiency-low-emission (HELE) technology, and biomass co-firing. To advance knowledge about biomass co-firing, IEACCC hosts this annual workshop, as mentioned above.

Day 1 of this year’s workshop included two site visits.

The first was to Nippon Steel Engineering’s Kitakyushu Laboratory. Nippon Steel engages in research on clean coal technologies such as reforming, pyrolysis, gasification, catalyst uti-

lization and improving low-rank coal qualities. The laboratory also works on pre-treatment, saccharification and fermentation processes for cellulosic biomass.

The second visit was to Chugoku Electric Power Company’s Shin Onoda Power Station in Sanyo-Onoda, Yamaguchi Prefecture. This plant consists of two 500 MW supercritical units currently burning 2.6 million tonnes per year of bituminous coal and 20,000 tonnes per year of wood chips. Chugoku plans to increase the rate of co-firing to 10 per cent, using 300,000 tonnes per year of wood pellets sourced from Canada, the U.S. and Australia. This will require modifications to one of the mills and alterations to the burners.

The following two days of the workshop were devoted to presentations and papers from participants.

Andrew Minchener of the IEA Clean Coal Centre gave the opening presentation. He emphasized his organization’s support of the UN Sustainable Development Goals. He pointed out that the IEA Clean Coal Centre’s role is to identify and publicize the best practice in every aspect of coal production, transport, processing and utilization chain while striving to balance energy security, affordability and environment. Using biomass is an important contributor in achieving this balance.

Mukoto Nunokawa of Japan’s New Energy and Industrial Technology Development Organization (NEDO) then discussed the Japanese government’s policy regarding the New Energy Mix. Japan’s 2030 target for coal power is 26 per cent, down from 30 per cent currently. Renewables are set to more than double from 11 per cent to 22-24 per cent, with a 3.7-4.6 per cent share for biomass. NEDO is focussed on commercializing carbon capture, storage and utilization (CCUS), as well as further developing biomass co-firing in Japan.

Takanobu Aikawa of the Renewable Energy Institute in Japan and a member of Japan’s ministry of economy, trade and industry’s committee working on biomass sustainability, showed that Japanese biomass power output has doubled since the introduction of a feed-in-tariff in 2012. In that same period, biomass imports have increased tenfold. Japan is developing biomass sustainability criteria and rules to govern imports. So far, the criteria look similar to those that have been adopted by European countries. There will be requirements for third-party verification, including chain of custody. Canada appears to be well positioned for when Japan imposes its new rules.

Aikanwa also reported that Japan is currently co-firing in 34

plants for a total of 1,500 MW of biomass power capacity. Dedicated biomass firing is taking place in just six plants with a total capacity of 700 MW.

At the workshop, Hu Wenping of the China Electric Power Planning and Engineering Institute, described China’s biomass co-firing experience. Chinese co-firing has not progressed due to a lack of government support policies. But, the Chinese have been able to make co-firing of sludge work by charging municipalities a fee for sludge disposal.

Wenping reviewed numerous examples of conventional agricultural and forestry-related co-firing projects, but none were profitable. There is a preference in China for co-firing by pre-gasifying the biomass and injecting the syngas into the boiler as opposed to the conventional method of co-firing by feeding pulverized biomass power into the boilers. This preference is due to China’s high proportion of agricultural feedstock, which is prone to causing slagging and corrosion if fed directly into the boiler as powder. This means there is no prospect of China becoming a market for Canadian wood pellets any time soon.

Finally, Debo Adams of the IEA Clean Coal Centre gave a presentation on technologies for biomass co-firing. The presentation had been prepared by her colleague Xing Zhang, but she had to cancel her attendance at the last minute.

Globally, biomass co-firing is moving from west to east as European plants have increasingly adopted dedicated biomass firing while the majority of biomass power

in Asia is presently produced from co-firing. The majority of Japan’s power plants are co-firing at a ratio of just two to four per cent biomass, with six plants co-firing at ratios between 20 to 40 per cent.

Most power plants burning woody biomass are using direct co-firing technology. Plants with agricultural biomass use indirect co-firing where biomass is gasified into syngas, which is then fed into the coal boiler, or parallel co-firing where biomass and coal are each fed into their own boilers and steam from both boilers is combined to power a turbine. Indirect and parallel co-firing are very expensive.

There are also numerous operating issues related to co-firing that must be considered by operators, Adams explained. Some of these include: fire and explosion risk during biomass handling and preparation, pulverizer capacity and performance, burner blockage and ignition characteristics, boiler slagging, fouling and corrosion, improved flue gas emissions, and changes to the characteristics of fly ash.

There were numerous other excellent presentations at the workshop focussed on relevant topics including: torrefaction, fuel preparation, fire and explosion prevention, carbon capture and storage, optimizing pellet handling and transportation, and many other highly technical issues related to biomass performance within power plants.

All in all, the workshop presented WPAC with an excellent opportunity to network with Japanese utilities, government and regulators to promote Canada as a source of high-quality, sustainably produced wood pellets. I was able to present the Canadian perspective on demonstrating that electricity production from solid biomass is both low-carbon and sustainable. It was a great learning experience for all participants.

Note: Gordon’s presentation can be downloaded at https://tinyurl.com/vorgyxr. •

Gordon Murray is the executive director of the Wood Pellet Association of Canada.

By Maria Church

Nova Scotia’s newest wood pellet producers are taking measured steps to reinvigorate a 22-yearold plant with a shaky past but a bright future under new ownership.

The plant, located in Upper Musquodoboit about 90 kilometres north of Halifax, first opened in 1998 and saw a succession of owners before local Nova Scotia company Great Northern Timber Resources Inc. took the reins in 2018.

“It’s an older mill but it’s in good shape and we have good people,” says Miles Wright, operations manager for Great Northern Timber Resources’ pellet operation.

The new owners are well-known players in the province’s forest industry and are committed to keeping the 100,000-tonne capacity industrial wood pellet plant running safely and efficiently for the long-term.

Upper Musquodoboit was once home to Eastern Canada’s largest sawmill ¬– a thriving 250 million board feet operation owned by MacTara Lumber. In 1998, the operation expanded to include a pellet plant, built directly across a secondary highway from the sawmill site.

The two operations ran successfully for nearly a decade before MacTara, struggling with the global downturn in 2007, went into receivership. Germany’s Enligna purchased the pellet plant assets a year later, but the sawmill did not fare as well and was eventually emptied and demolished.

There are a few tell-tale signs of the former lumber operation visible today when driving up to the site. The main one is a still-standing, bright blue truck loading hopper.

Wright himself has history with the MacTara site. He was the original pellet mill manager back in 1998. Sitting at his

desk in the office that once oversaw both the sawmill and pellet plant operations, Wright points out various other signs of the old sawmill – a piece of embedded concrete here and there that once supported the mill structure or the old staff parking lot.

“We had a 145-foot Fulghum log crane, stud mill, sawmill, two planer mills and five dry kilns. It was probably one of the larger mills in Eastern Canada,” Wright says.

Luckily for the pellet plant, its new German owners committed to running it for another three years, from 2008 to 2011, before they, too, went into receivership. In 2012, Vancouver-based Viridis Energy bought the plant and formed Scotia Atlantic Biomass Company.

Four years later, the pellet plant was once again for sale in 2017. Enter Great Northern Timber.

Great Northern Timber is the first Nova Scotia company to own and operate the pellet plant since MacTara. Based in Halifax, the forestry firm runs a chipping facility and shiploading terminal in Sheet Harbour, and operates its own woodlands division.

“We’re very integrated in our ability to bring in fibre. They know the industry very well and have those relationships to partner on fibre supply in the province,” Wright says.

The plant itself has several unique features that distinguish it from other pellet operations in Canada. One is feedstock versatility.

“This was one of two bark pellet plants in the world when it was built. The other was in Sweden at that time. This type of mill is very versatile, designed to process various sizes and types of raw material. It was designed for pretty much whatever you can throw at it and it still has that capability. Although there is no substitute for good clean material,” Wright says.

Much of the original equipment is still on site and a few smart investments and equipment modifications from Great Northern allows the plant to adapt to a changing supply and market base.

One notable visible difference is the plant layout. Rather than sitting under one roof, each of the production processes are housed in self-contained buildings and material is conveyed between them.

“When you’re dealing with fine, dry wood material, distance is sometimes a great safety. We were well laid out in that respect and it’s been a benefit over the

years,” Wright says.

Each process has explosion venting and a GreCon spark detection system is used in dryer, hammermill, and dry conveying systems. A Scientific Dust Collectors dust collection system adds to the safety measures in the hammer mill building.

“We bristle with explosion venting, water sprinklers, deluge systems,” Wright says. “Rule of thumb, I’ve always thought, in a pellet mill environment is that it’s not if, it’s when. If a fire or dust explosion were to happen in a building or equipment, what is in place to eliminate risk to employees, equipment, and structures?”

An example of those safety precautions is that the hammermill building is closed to employees unless the process is shut down.

Adding to the safety of the plant is a readily available water supply. Two large

dams of water sit a kilometre-and-a-half uphill from the site. “It’s gravity-fed so we have several million gallons of water available to us with no pumps needed,” Wright says.

The 20-year pellet veteran says safety knowledge is important to share within the industry, and the Wood Pellet Association of Canada (WPAC) is an important conduit for best practices.

Wright, representing MacTara, was among the original founders of WPAC in the ’90s. Today, he’s a member of WPAC’s Safety Committee, which has members from pellet companies across Canada.

When Great Northern officially took over the site in early 2018, the team, led by Wright, did a thorough inspection and revamp of all equipment.

“We went over the complete mill from one end to the other. Since it had been sitting mothballed for more than a year-and-a-half, that involved overseeing everything mechanical, electrical, and programming,” Wright says. “There was a major investment to get it back into shape before we started.”

The investment, totalling $6 million, included replacing or purchasing a few major items such as new replacement dryer cyclones, a new replacement Oliver Manufacturing de-stoner and a new Jeffrey Rader truck dump installation.

Existing equipment was carefully inspected and serviced as needed.

Feedstock for the plant is mixed in

outdoor piles by Volvo wheel loaders and fed into a live floor infeed system. A separate infeed for hog fuel supplies bark to a GTS biomass burner (serviced by Sigma Thermal). Pellet feedstock is then fed up belt conveyors equipped with a belt magnet before heading to a Jeffery WB-66 hog. Homogenized fibre flows onto another conveyor which takes the material to the MEC drum dryer.

Dried material passes through two de-stoners before it is processed through two 60-inch Andritz hammer mills. A series of screw conveyors transport the dry fibre to dry fibre bins over top of five Andritz pellet mills. Pellets are then conveyed by belt to the cooling building where a Law-Marot MilPro counter-flow cooler and screener are located. The final product is conveyed to overhead storage and loadout bins, ready for shipping.

A CBI Magnum Force chipper on site is used to process low-grade round wood – a mix of poplar and various softwood species. Chips are then added to the pellet mix at the infeed.

Now that the plant is up and running at full capacity, with 27 staff members in place for a 24-hour operation, the team has been able to look at new ways to improve the process. A recent focus is lowering the pellet ash content to increase its production of premium pellets.

“We’re in the middle of an ash reduction project on our furnace. We’re re-routing the air flow so we can better collect the dust and fines from the furnace,” Wright says. The equipment is already in place and the team was testing and measuring the results in February.

Once the project is completed, the plant should be able to produce a much higher volume of premium wood pellets.

The pellet plant is currently certified under ENplus/CANplus and SBP certification schemes. A fully equipped testing lab on site allows staff to continually check the quality of the pellets. That equipment includes two Ametek Max 5000XL ash analyzers, Ohaus moisture analyzers, and a test oven.

Further plant improvements are on

the horizon, Wright says. “There are always projects. We’re going to work at improving our process and our run time. We’ve done a good job on that already but there is always room for improvement,” he says.

Support from Great Northern Timber Resources’ other branches – the woodlands division and the chipping and shipping facilities – is a huge component of the pellet plant’s new identity and will likely contribute to its future success. The company has deep roots in the province’s forestry community, and long-standing relationships with fibre suppliers such as sawmills and wood lot owners.

In January, Nova Scotia’s forestry supply chain took a hit with the hibernation of Northern Pulp – a large pulp mill in Pictou County, N.S. In spite of this, Wright says he’s confident the supply chain will stabilize and Great Northern Timber will continue to play an important role in it.

“I think we’re a good fit in the wider forestry industry here,” Wright says. •

By William Strauss

The COVID-19 pandemic is likely to cause a global economic depression. The magnitude and reach of this crisis are huge and will inevitably impact the industrial wood pellet industry.

The two primary pathways for the evolution of this pandemic are: (1) The pandemic accelerates uncontrollably and millions of people die; or (2) The pandemic is attenuated by policies and rules restricting contact with other people that limits the spread of the disease and greatly reduces the number of deaths. Both pathways will shock national economies. If policies are aggressive and people are compliant, and if the rules are enforced, pathway 2 will limit the medical consequences. But there is no avoiding the economic consequences.

However, the demand for industrial wood pellets is somewhat independent of drops in economic activity. Power demand will decline in a major economic slowdown, but the power generated by wood pellets in the key European, UK, and Japanese importing markets will have a place in the grid even if other sources such as natural gas have to turn down to meet lower aggregate electricity demand. The potential exception is South Korea (more below on South Korea).

Backed by long-term offtake agreements, it is unlikely that fundamental demand for industrial wood pellets will decline significantly in the markets supplied by North American and European pellet producers as a result of the COVID-19 pandemic. However, as noted below, policy changes could impact demand.

On the supply side, many highly automated wood processing plants such as sawmills and pellet mills should be able

to operate without compromising worker safety or the safety of their families and their communities. FutureMetrics has spoken with several sawmills and pellet mills that have implemented protocols that allow operations to continue with no close personal contact and with comprehensive and continuous attention to working with and sanitizing at-risk surfaces.

Lumber and wood pellet operations should be able to adapt to the current health guidelines and requirements with little impact on output and only a marginal increase in operational costs.

The wood supply chain is dominated by machinery operated by single individuals. Sawmills and wood pellet plants are highly automated. For the operations and maintenance staff, social distancing and frequent hand sanitizing will be the new normal until the pandemic is quashed. Office staff may have to work remotely.

In all cases, normal routines that include close social interaction will have to be changed. But it is likely that production

of pellet fuel for export can continue.

While the in-woods and transport logging operations should be able to continue to meet demand, many sawmilling operations will likely slow as lumber demand falls. Some pellet factories dependent on sawmill residuals will experience higher costs for alternative feedstocks or will have to move to lower production rates (or both). B.C. pellet mills are already using an increased proportion of forest residues due to unrelated changes in the sawmilling industry there.

A drop in lumber demand will also impact the demand for sawlogs. Some of the roundwood on the upper part of the tree harvested for sawlogs is not suitable for conversion to lumber and typically goes to pulp and paper mills or pellet mills. A drop in sawlog demand will likely change the dynamics of supply and the cost of feedstock for pellet mills that depend on roundwood byproducts. The drop in sawlog demand may also impact the supply of forest residuals. A worst-

case scenario is that no sawlog harvesting results in no pellet feedstock grade wood fibre. The cost of buying sawlog-quality wood for making pellets would be punishing to the profit margins.

Most North American port operations for bulk cargo shipping are likely to continue operating. Given the automation of the systems, close contact between people is not necessary. Imports and exports of all types of bulk goods and commodities are fundamental to social stability and for the support of those manufacturing sectors that remain active. Container and breakbulk shipping may be impacted. Some container and breakbulk cargos will be quarantined and possibly subject to decontamination procedures to prevent the spread of the virus. But wood pellets in bulk ship holds should not be impacted.

Unless recommended workplace procedures and protocols change with new information on the transmission of the virus, the supply side of the industrial wood pellet industry should weather the pandemic without putting workers and their communities at risk.

For pellets shipped in containers (mostly to South Korea from Vietnam), there will be disruptions due to evolving changes in the flow of shipping containers. Some ports do not have the typical inventory of empty containers anymore.

The cost of shipping via container from Vietnam to South Korea, which has traditionally been very low due to surplus empties in Vietnam, is therefore likely to increase. The South Korean pellet market exhibits a very high risk for unstable pellet demand even without the impacts of a pandemic. Almost all pellet imports to South Korea are not based on long-term offtake contracts. If the delivered cost of pellets rises significantly due to shipping cost increases and South Korea does not intervene in the Renewable Energy Certificate (REC) markets, South Korean demand will fall and heavily impact Southeast Asian pellet producers.

What is most difficult to forecast is the impact of policies. Many jurisdictions have mandated that all non-essential businesses close. In Malaysia, for example, that included pellet plants. Policy can impact the industrial pellet

sector in two distinct ways.

The first is due to policies and rules that impact business activities, and how a business is determined to be allowed to operate or not. It is possible that government policy could designate elements of the wood processing sector non-essential and mandate shutdown. Government rules for business closures are already in place for many serviceoriented businesses. Many automated manufacturing and logistics operations can function without close personal interactions and with enforceable rules for preventing spread by contact. Even so, some governments may invoke the precautionary principle and opt for policies that would impact the production and transport of pellets.

The second way that policy can impact the industrial wood pellet industry is from government decisions about renewable energy policies in major importing countries such as the UK. Power generated from pellets is costlier than power from fossil fuels. It is possible that, as part of fiscal stimulus packages, temporary reductions are put in place on higher cost generation sources to, ostensibly, lower the cost of electricity. FutureMetrics thinks this is highly unlikely for two reasons.

First, the proportion of power from pellets on average is about eight per cent in the UK and less in other countries. Stopping pellet baseload generated power would have a very small impact on the overall average cost of generation. Fiscal stimulus packages are very large. The impact of the cost of pellet fuel versus fossil fuel is relatively tiny.

Second, the consequences of that demand dropping out would be far reaching and harmful to many stakeholders. The ripple-effect economic consequences to rail, ports, shipping, producers, and producer supply chains associated with curtailing pellet use, combined with the multiplier effects of the loss of jobs, are far larger than the marginal cost of making electricity with pellet fuel. Much of those negative economic and jobs effects would be in countries using pellet fuel for power generation.

Furthermore, the entire supply chain is based on long-term offtake agreements that provide legal protection to the flow of the pellets and payments for the pellets.

Overall, the tonnages of wood pellets flowing under long-term offtake agreements should not be significantly affected by the COVID-19 pandemic. That conclusion assumes that the mitigation measures to limit the number of infections and deaths are successful, and that the procedures and protocols for controlling the virus and assuring the safety of workers and everyone they contact, are similar to what they are as of April 11, 2020.

While production volumes for most North American and European pellet producers are likely to be sufficient to fulfill their offtake agreements, the cost of production is expected to increase during the crisis. Profit margins for some producers may be seriously challenged. However, losing a few dollars per tonne may be better than the alternative of not delivering on an offtake agreement. While “force majeure” may be possible for those producers whose feedstock costs are punishing, usually an event that impacts profitability but not the ability to produce does not qualify. (FutureMetrics is not qualified to make legal opinions.)

For Southeast Asian producers, demand from South Korea will likely fall if container freight rates increase significantly.

Spot markets are difficult to predict. The summer months typically bring a drop in monthly demand and spot prices drop. However, if producers are reticent to make pellets due to poor (or negative) margins then there will be no excess production beyond what is contractually obligated. That would push up spot prices.

Some future pellet demand in Japan will likely be delayed. Construction activities on FiT (feed-in tariffs)-approved power plants have, for the most part, stopped in Japan for the duration of crisis.

Let us all work together to get COVID-19 to peak and pass sooner rather than later. That means we all have to be careful and be considerate of the possibility of contagion almost all the time. We have to protect ourselves to protect our communities and countries. With that as a foundational condition, it is still rational and responsible to keep making and moving pellet fuel to power stations to help keep the lights on. •

William Strauss, Ph.D., is the president of FutureMetrics, www.futuremetrics.com.

With increasing heating costs and climate change becoming top of mind, communities are taking a more serious look at energy alternatives. One of the top choices for energy alternatives is bioheat from modern wood heating technology. Bioheat systems are reliable, efficient and can supplement or replace current fossil fuel and/or electric heating systems with local, sustainably sourced, and renewable solid woody biofuels.

A guide has thus been developed to provide people in Ontario’s rural and remote communities with the information and confidence they need to use wood from Ontario’s sustainably managed forests to produce space heat and domestic hot water. It is aimed at community leaders such as those found in municipal governments, band councils, school boards, churches, not-for-profit organizations, and small businesses, as well as private homeowners. While it is tailored to Ontario regulations and resources, much of the guide is technical and applicable elsewhere.

Biomass includes all biological matter and can originate from forestry, arboricultural, agricultural, horticultural, or aquacultural operations. When biomass is processed into a fuel used to produce heat or power, it is called biofuel. Bioheat is the heat produced when biofuel is combusted.

The guide discusses only solid woody biofuel produced from forest resources. It refers to four categories of solid woody biofuel which are cordwood (firewood) (Figure 1), wood chips (Figure 2), wood briquettes (Figure 3), and wood pellets (Figure 4).

Ontario has a large supply of woody biomass sourced from sustainably managed forests (mill and harvest residues and unmerchantable standing timber) that could be used to produce solid woody biofuel.

What are modern bioheat combustion systems?

Modern bioheat systems are well-developed and highly engineered mechanical systems with sophisticated controls. They are ideal for providing space heat and domestic hot water for community buildings and businesses, as well as for private homes. The technology is widely used in Europe, Alaska, and the northeastern United States, as well as across Canada. Bioheat systems are relatively new to Ontario, which is why this guide has been developed.

The guide is applicable to systems that are factorybuilt and less than 1 MW in size that use solid woody biofuels to produce heat.

What are the benefits of switching to bioheat?

• Low and stable energy costs

• Biofuels are renewable and low-carbon

• Lower environmental risk than fossil fuels

• Reliable fuel supply

• Bioheat systems are reliable and easy to operate

• Support for local jobs and economic development

• Stimulation of community development

• Funding for local forest stewardship activities

What is included in the guide?

• Section 1: Introduction

• Section 2: Benefits of choosing bioheat

• Section 3: Solid woody biofuels

• Section 4: Bioheat combustion systems

• Section 5: Important factors to consider when choosing bioheat

• Section 6: New-build bioheat installations compared to retrofit installations

• Section 7: Residential bioheat projects

The three types of combustion systems included in this guide are stoves (Figure 5), furnaces (Figure 6), and boilers (Figure 7). The major considerations for sourcing and using each type of biofuel for institutional/ commercial and residential applications are outlined in the guide. The guide addresses the planning steps and funding options for bioheat systems.

• Section 8: Institutional and commercial bioheat projects

• Section 9: Other bioheat systems

Financial support for this guide was provided by the Northern Ontario Heritage Fund Corporation, FedNor, Ontario’s Ministry of Natural Resources and Forestry, and Natural Resources Canada.

By Steve Kozuki

The transition from fossil fuels to sustainable sources of energy has been slow, but one small community recently made a big leap toward energy efficiency by installing biomass boilers to provide heat energy for its people: the proud community of Esk’etemc (pronounced ess-ke-tem) people in Alkali Lake, located approximately 50 kilometres south of Williams Lake, B.C.

The Esk’etemc are forward-thinking with strong cultural values and connection to the land. The overall project started in 2016 with a feasibility study. Phase 1 of their project to convert from propane to biomass was completed in the summer of 2019 with the installation of two boilers which heat eight buildings in the community. The boilers are manufactured by Austrian company Froling and distributed and installed by Vancouver-based Evergreen Bioheat. The wood chips go to the boiler from a Heizomat mobile chipper.

Phase 2 started in the fall of 2019 and will be completed in the spring of 2020 with the installation of more boilers to heat five additional buildings and the construction of a biomass drying shelter. A drying shelter is needed to keep the moisture content of the fuel below 30 per cent, as the ideal moisture content of the material is 15-30 per cent. Phase 3 will deliver heat to additional institutional buildings as well as several residences in the community. Although the operating costs of heating buildings with biomass is sometimes on par with propane, there is an environmental benefit to utilizing secondary fibre, shifting from propane, a fossil fuel, to biomass utilization, a sustainable green energy.

Capital funding for the project was provided largely by the government of Canada. The federal government provided the majority of the infrastructure funding

for the project. The Forest Enhancement Society of BC (FESBC) approved funding for a portion of the biomass that would otherwise be uneconomic to utilize.

The government also created the Low Carbon Economy Leadership Fund to achieve Canada’s climate change targets, along with subsequent agreements with the province of B.C. and FESBC, respectively. Under these agreements, forestry is helping to achieve climate change targets in three ways:

1. Planting trees in areas that otherwise would not be reforested and are not under a silviculture obligation, particularly areas of Crown land that have been devastated by insects and disease. These trees will sequester atmospheric carbon

dioxide as they grow.

2. Fertilizing trees to make them grow faster and hence sequester carbon faster.

3. Utilizing biomass that otherwise would have been slash burned to avoid some greenhouse gas emissions and potentially make green energy that displaces energy otherwise generated from fossil fuels.

The potential displacement of fossil fuel use by using sustainably sourced biomass from local forests and the avoided greenhouse gas emissions associated with the open burning of logging slash piles aligned with FESBC’s purposes. The greenhouse gas emissions from open burning contains some very potent greenhouse gases, while controlled combustion at high

temperatures is much cleaner.

Consequently, FESBC is providing funding to the Esk’etemc to utilize woody biomass from a wildfire-risk reduction project, rather than open burning the piles of slash. FESBC was already funding the wildfire treatment to protect the community, so it made sense to also partially fund the grinding and hauling of the slash to avoid open burning and instead feed the biomass boiler.

The Esk’etemc own two forestry companies, Ecolink Forest Services and Alkali Resource Management Ltd. (ARM).

Ecolink was established in 1990 as a joint venture business arrangement between the Esk’etemc and Lignum Ltd., and later with Riverside and Tolko Industries Ltd. The company began with a silviculture division, and, in 1994, timber harvesting services were added. Today, the company continues to seek innovative ways to grow to meet community and customer needs.

The latest example is grinding biomass, not only for their community’s biomass boiler, but also grinding significant volumes of forest slash for Pinnacle Renewable Energy and Atlantic Power - 25,000 tonnes per year and 10,000 tonnes per year, respectively. Pinnacle Renewable Energy makes wood pellets, most of which are exported, and Atlantic Power produces electricity, enough to power 20,000 homes. Historically, the companies were able to source their biomass fibre from sawmill residuals. However, as many sawmills in British Columbia have been curtailed or permanently shut down, the secondary fibre consumers have been sourcing an increasing proportion of their biomass from forest slash.

Meanwhile, ARM is an integrated forest management company established in 2001 to manage the forest licenses, woodlot and community forest on behalf of the Esk’etemc. ARM currently manages a 27,000-hectare community forest, a 60,000-hectare First Nations woodland tenure, a 400-hectare woodlot, as well as several other forest licences. The mission is to manage Esk’etemc forest resources in a manner that ensures a balance of economic, social, and environmental values that will provide increased benefits

for Esk’etemc members, other forest users, and neighbouring communities.

“The Esk’etemc elders have told us that the forests are sick because there are too many trees growing,” said Gord Chipman, manager of Alkali Resource Management. “Today’s foresters say the issue is resiliency. The biomass project will benefit the lands and the ARM business to expand the utilization of the overstocked forests. This is one more step towards achieving resilient forests for future generations”

Polling consistently shows that climate change is an important issue for people, and this concern is manifested in the climate strikes and protests seen in the news. The good news is there are communities, forest workers, equipment suppliers, pellet plants, co-gen facilities, pulp mills and governments making real and meaningful contributions toward achieving climate change targets while also generating social and economic benefits, including the Esk’etemc.

FESBC was created to help British Columbia fully realize the potential of its publicly owned forests. The goals of the society are to help reduce wildfire risk, enhance wildlife habitats, improve low-value and damaged forests, and improve the management of greenhouse gases in our forests. With funding from the B.C. government and the government of Canada, B.C.’s forests are being enhanced to create a triple-win for British Columbians, socially, economically, and environmentally. Perhaps the tensions and polarizations around the economy versus the environment debates could be reduced if success stories like that of the Esk’etemc were shared more broadly. •

Steve Kozuki, RPF, is the executive director of the Forest Enhancement Society of BC. He has worked within the forest industry since 1984. He graduated with a Bachelor of Science in Forestry in 1994 and has held various positions from timber valuation coordinator for Weldwood, general manager of forestry for the Council of Forest Industries to working in BC Timber Sales and timber pricing for the B.C. Public Service. He is passionate about the work FESBC does to advance the environmental and resource stewardship of B.C.’s forests.

Every year, millions of tons of industrial waste are turned into millions of dollars of reusable materials. CPM and Di Più Systems help make that happen.

We’ve joined forces to bring you the world’s best mechanical and hydraulic briquetting technology.

Together, we’re taking the fossil out of fuel.

By Ellen Cools

With constrained fibre supply in Canada’s western provinces causing concern on one front, and the need to deal responsibly with mill waste and derive maximum value from residuals on another, some power producers and their suppliers are getting innovative.

Capstone Infrastructure’s Whitecourt Power facility in Whitecourt, Alta., is one such power producer. For 25 years, the company has utilized waste wood from Millar Western’s Whitecourt and Fox Creek, Alta., sawmills, delivered by regional transportation service provider Whitecourt Transport.

But in September 2019, Whitecourt Power found its inventory was running low. This was due to multiple compounding factors.

“We had an agreement with Millar Western to consume residual material from both their sites, but our plant ended up in a shutdown in 2017 for facility repairs and upgrades. While it was down, we accumulated a large stockpile of fuel, and we maxed out the storage at our own site,” Brennan Anderson, steam chief and operations manager for Whitecourt Power, explains.

Consequently, Whitecourt Power asked Millar Western to stop sending its Fox Creek residuals to the power plant. But accumulating the waste at the sawmill could have created a fire hazard. Instead, Millar Western obtained a variance from the provincial government to temporarily re-start a decommissioned burner at the facility.

Meanwhile, from 2017 through September 2019, Whitecourt Power used up its accumulated stockpile of wood waste while continuing to consume residuals from Millar Western’s Whitecourt mill.

As their on-site stockpile declined,

instead of travelling further to get waste wood, Whitecourt Power decided to take on a new project with Millar Western and Whitecourt Transport: taking material from a 20-year-old yard waste pile at the Whitecourt sawmill.

“We had a historical legacy pile of wood waste, both hog and log-yard debris, that had built up over a significant number of years,” Tom Thompson, general manager of wood products for Millar Western, says.

“But, when we started delivering this material to the power plant, we found that it was highly contaminated with rocks and debris,” he explains. “We tried a number of methods to find veins of clean material and send that over to Whitecourt Power.”

Initially, Whitecourt Power agreed to take the material without removing rock or debris, but this material was “by the far the most contaminated we’ve seen,”

Anderson says.

“A large piece of trap metal had made its way into the supply, ended up going into our wood crusher and causing pretty good damage,” he explains. “So, we were down for about a week. It was during that week that we decided we had to try to do something more.”

That’s when Frontline Machinery got involved. Whitecourt Transport, which hauls all the hog fuel from Millar Western to Whitecourt Power, knew Frontline might have equipment that could help clean up the legacy pile. Jeff Rosnau, Whitecourt Transport’s vice-president of operations, put the manufacturer in touch with the power plant and mill managers.

“Frontline was pretty confident that they’d have an assembly of equipment that would do the job,” Rosnau says.

Ultimately, Whitecourt Power and

Millar Western agreed to trial a Keestrack K4 Scaling Screener and Edge Innovate MC1400 Material Classifier. Millar Western rented the equipment from Frontline.

Millar Western and Whitecourt Power split the cost of the Frontline equipment rental, with Millar Western paying 60 per cent and Whitecourt Power paying the remaining 40 per cent.

Whitecourt Transport moved the Frontline equipment onto the power plant site and resumed hauling the yard waste with their fleet of Tycrop and Titan livefloor trailers. The company also supplied a Caterpillar excavator to sort and feed material to the Keestrack K4.

Other costs associated with the project included fuel for the rental equipment and salary for an additional operator who operated the equipment and a front-end loader that moved the rock to a waste pile and the clean material to Whitecourt Power’s conveyors.

The equipment began operating on Sept. 25, 2019. The project ran until Nov. 2, with about 300 operating hours put on the equipment.

The Keestrack K4 was set up with a four-inch top screen deck to screen out rocks and wood pieces over four inches. Any rocks under four inches went to the Edge MC 1400 density separator, which separated out the majority of the rocks, Anderson says.

However, the wood material coming out of the density separator didn’t meet Whitecourt Power’s size specifications, so it had to be re-processed through their existing wood hog.

According to Anderson, the Edge MC 1400 was around 80 to 90 per cent effective. Unfortunately, this meant there was still some rock in the material going into Whitecourt Power’s boiler.

The material itself also had a moisture content of 60 per cent or more, but Whitecourt Power’s material typically has a moisture content of 43-45 per cent.

An approximate analysis on the material also revealed that it had lost 50 per cent of its volatiles and produced eight times more ash than the company’s normal supply.

These problems meant that the cleaned hog fuel could not be fed directly into the company’s boiler. Instead, one loader bucket of the cleaned material had to be mixed with three loader buckets of their regular waste supply.

“That’s not without cost, because we still had the rock to contend with. Due to the design of our furnace, we have to somehow get rid of the rock, because if the inventory of the rock in our furnace gets too high, it stops our process and we have to shut down or reduce our output in case it causes other issues,” Anderson says.

To combat that issue, the company drained some of the material from their bubbling fluidized bed boiler. The boiler has approximately 60 tonnes of sand in the furnace heated up to 800 C, which allows Whitecourt Power to burn higher moisture content material because it provides a large heat sink, Anderson explains. But draining some of the rock meant they were also losing some of the sand, which they then had to replenish.

On top of that, the higher ash content overloaded the plant’s flue gas bag house,

so once that entered their ash silo, it had to be removed. Of course, there’s a cost to removing it, Anderson says.

“It creates a whole trickle-down effect from using this material,” he says.

Overall, Whitecourt Power processed 15,556 tonnes of contaminated material, separating out about 1,000 tonnes of rock.

This resulted in 14,000 tonnes of clean material, approximately half of Whitecourt Power’s monthly supply, Anderson says.

“The success of this type of project is really dictated by the fuel,” Anderson says. “In this case, the material had degraded to the point where it’s not really fuel; it’s more some sort of composted mixture. With the added processing steps, this ended up being a pretty costly fuel, considering its

loading costs were significant. On the other hand, “it was a very successful project in that it was well executed and well handled by all four partners – our company, Whitecourt Power, Whitecourt Transport and Frontline Machinery. And, it definitely delivered results,” he says.

“We still have approximately half the legacy pile that we have to manage,” Thompson adds. “So, we’ll be looking to put together another project of a similar nature.”

Whether and when that happens will be dependent on market conditions, he says.

Despite the difficulties the material presented, Anderson, Rosnau and Thompson all agree that the equipment worked well.

“Overall, I was fairly happy with the equipment side of it – it functioned pretty much as expected,” Anderson said.

“It was a great opportunity to use a piece of mobile equipment to test out a certain technology that may find its way into becoming built-in mill infrastrucutre.” - Jeff Rosnau, vice-president of operations, Whitecourt Transport

relatively low energy value.”

The project taught all of the participants some important but “expensive” lessons, Anderson says.

For Millar Western, Thompson indicated that the equipment rental, labour and

“The Frontline equipment is mobile, and that’s not necessarily a requirement in this case,” Rosnau adds. “I think that it worked well as a test case for us all to look at the efficiency of air separation to remove rock.

“It was a great opportunity to use a

piece of mobile equipment to test out a certain technology that may find its way into becoming built-in mill infrastructure.”

The project “gave us some insight into the cost and what we’d do differently if we ever had another legacy pile,” Anderson adds.

For example, he would take multiple samples of the material to be analyzed first, before determining whether to proceed with cleaning it up.

His advice for sawmills or power producers looking to do something similar is to ensure they know what the material is and whether their boiler can handle it.

But looking at the bigger picture, this project is emblematic of a larger trend in the industry: the need to use as much fibre as possible.

This trend is “really taking off in B.C.,” Rosnau says. “The pellet industry is really driving this, and with this industry moving into Alberta, utilization of residual wood fibre will increase. The low-hanging fruit is all the sawmill residuals, but eventually this supply will dry up and the pellet and energy producers may be looking at forest residuals.”

Whitecourt Transport plans to facilitate similar projects for other clients in the future.

“We are getting more active in the grinding and wood separating business. Forest residuals have become an important part of the fibre basket in British Columbia and I think they will become a bigger part of the mix in Alberta,” Rosnau adds. •

By Ellen Cools

Ever wondered where your leftover food ends up? Well, in Toronto, that food waste will soon be turned into renewable natural gas (RNG).

The City of Toronto, in collaboration with Enbridge Gas Inc., is installing equipment at its Dufferin Solid Waste Management Facility, which will upgrade the biogas produced from processing food waste into RNG. Through its partnership with Enbridge, the city will be able to inject the RNG into the natural gas distribution grid and potentially use it to power its waste collection trucks, among others, as well as heat city buildings and facilities.

“It’s one of the first of its kind in North America and will allow the city to reduce its carbon footprint,” says Carlyle Khan, director of infrastructure and resources management, solid waste management services, for the City of Toronto.

The driving force behind this project? The city recognized that the Dufferin

Solid Waste Management Facility was producing a waste stream, which was managed by flaring biogas. “We basically had a watershed moment where we said there has to be a better way (to manage our biogas) than flaring,” Khan says.

“Flaring is the everyday accepted common practice in terms of destroying biogas,” he continues. “But we asked ourselves, is there a way to take the biogas and convert it into something that is a more valuable and useful commodity?”

The idea to convert organic waste into RNG was first put forward in early 2014. The construction phase of the project began two to three years ago after the city spoke with Enbridge to ensure the project’s viability.

The collaboration with Enbridge was an obvious choice, Khan says.

“When we said, ‘OK, we can convert our biogas into renewable natural gas,’ the question, ‘Then what?’ was posed.

The easiest way to use the RNG was to get it into the pipeline. So, that triggered us asking, ‘Who owns and who controls the pipeline and distribution grid?’ That was Enbridge,” he explains.

Enbridge is designing and installing the biogas upgrading infrastructure next to the Dufferin Organics Processing Facility (OPF), along with an injection station. Construction of the facility started in 2018 and will be complete by the third quarter of 2020. Enbridge will operate and maintain the facility for the next 15 years on behalf of the City of Toronto.

On a high level, the process for turning food waste into RNG is fairly simple.

Material from Toronto’s green bin program – separated organics – is taken to the Dufferin OPF, where it is preprocessed to remove contaminants and prepare it for the next step, Khan

explains. It is then fed into anaerobic digestors where, in the absence of oxygen, it breaks down and produces biogas, which is made up of approximately 60 per cent methane.

“Once the facility is up and running, the biogas collected will be sent to a biomethanization unit, where it will be cleaned and conditioned and then injected into the distribution grid as RNG,” he says.

The OPF facility will, at its core, use technology from Anaergia to process the SSO, including an Oryx press and some standard pumps, motors and centrifuges. The biogas upgrading system is designed by Xebec, and a pressure swing adsorption unit converts biogas to RNG.

Biogas is not the only product produced by processing organics. Digester solids are also created and processed into compost, Khan explains.

From the 160,000 tonnes of organic material the city collects each year, the Dufferin Organics Processing Facility manages approximately 55,000 tonnes, which can produce about 3.2 million cubic metres of RNG. This is the equivalent of taking 1,871 cars off the road, and is enough RNG to power the majority of Toronto’s waste collection fleet, which is about 170 trucks, for 90 per cent of the year.

Toronto is looking at producing RNG at a second site, the Disco Road Organics Processing Facility, which processes approximately 75,000 tonnes of material annually. It is capable of producing over 4.6 million cubic meters of RNG.

Khan and his team don’t plan on stopping there. They are looking at landfill gas to RNG potential, and have also proposed the creation of a third organics processing facility, which the Toronto city council has approved in the 2020 budget process.

These organics processing facilities will not only avoid carbon emissions associated with flaring biogas, but also help offset greenhouse gas emissions from the City of Toronto’s garbage truck fleet, or any other application that the city chooses.

In order to get the optimum value out of the RNG, Toronto plans to blend it with the natural gas it purchases in order to heat city buildings and power city trucks, reducing greenhouse gas emissions, Khan says.

“It can be used anywhere there’s a pipe application, whether it be a furnace or boiler. We are hoping to use it across the city,” Khan elaborates.

Toronto recently declared a climate emergency and, as part of its TransformTO Climate Action plan, is working to reduce its greenhouse gas emissions by 30 per cent by 2020 (based on 1990 levels), by 65 per cent by 2030 and achieving net zero emissions by 2050 or sooner.

“By displacing fossilized natural gas with renewable natural gas, we’re going to help move towards those targets,” Khan says.

Simply not flaring the biogas will result in an avoidance of approximately 9,456 tonnes of carbon dioxide equivalent at the Dufferin site, he adds.

“We’re going to avoid emissions at the facility, and wherever the renewable natural gas goes, you’re also going to have a reduction there,” Khan says. The potential environmental impact is very large, but depends on the ultimate end use.

Economically, the city has not yet determined the impact of this project, since it also depends on how the RNG is used.

Moving forward, the city will continue to promote its Green Bin program to divert organics from landfill, Khan says.

They will also be looking at ways to optimize their RNG yield from organics, and explore whether there are other waste streams from the process that could be recovered into a more valuable commodity.

Toronto is willing to share its experience with other cities and municipalities who are executing similar projects at waste management facilities.

These types of projects will “help us go a long way to achieve our TransformTO targets and address climate change and the climate emergency that we have,” Khan says.

“The public reaction overall has been very positive,” he adds. “I think the public and stakeholders alike see it as a positive call to action, something real that we’re doing.

“In addition, there’s a higher-level of engagement. People are starting to understand and see the connection between participating in the program, what they put into the organics, which then goes to our facilities where we’ll not only be creating renewable natural gas, but also creating environmental benefits by reducing our greenhouse gas footprint.”

In the coming years, Khan believes other municipalities or cities will also adopt this model and set up similar projects. •

By Martin Engineering

Virtually every vehicle on the road today is designed with a hood that can be easily opened for access to the engine so mechanics can perform routine service and diagnose/address problems that arise during its lifespan. Conveyor systems should be designed in much the same way, with convenient points along the length of the belt to allow technicians to inspect its condition, perform service as needed and help prevent catastrophic failure. Unfortunately, this type of access is often overlooked when engineering conveyor systems until a pressing need arises, which increases the difficulty of ongoing inspection that could have allowed technicians to observe and service critical components before a crisis develops. As a result, costs go up and productivity goes down.

Conveyor manufacturers have responded to the need for increased accessibility to system components by developing components and accessories specially designed to reduce labour time, while improving safety during service. Innovative equipment designs such as slide-out cradle frames, belt cleaner assemblies, idler assemblies, as well as sealed heavy-duty inspection doors, offer better access for safer and more efficient maintenance, resulting in fewer injuries, reduced labour time and a lower total cost of operation.

“This is a cascading issue,” Daniel Marshall, product engineer at Martin Engineering, says. “Insufficient access leads to poor maintenance practices, resulting in emergency outages and diminishing the operation’s productivity and safety. From an ownership and management perspective, downtime and injuries affect profitability through loss of production, capital expenditures for new equipment and ongoing insurance implications.”

In the past, managers often decided

against the expense of adding safer and easier access points to a conveyor system beyond what is required by code. However, over the conveyor’s lifetime, safety professionals estimate that poor access adds as much as 65 per cent to maintenance and cleaning costs.

When designing proper access into a bulk materials handling system, there are three easily achieved goals:

• Easy to see – if equipment cannot be seen, neither can the problems.

• Easy to reach – equipment maintenance is likely to be postponed if it is awkward or dangerous to access.

• Easy to replace – broken equipment is likely to remain that way if it is complicated and time-consuming to service.

“Many conveyor transfer points still have an antiquated roller system tasked with absorbing impact and centering the cargo,” Marshall says. “These components often break and seize, causing friction and a

potential fire hazard. To replace them, several workers must remove the skirtboard and break the plane of the conveyor to reach across the stringer with heavy tools to assess and repair equipment.”

To reduce maintenance time and labour, improve safety and extend equipment life, operators should consider trackmounted impact cradles and belt support cradles. Located under the skirtboard and mounted with rugged steel assemblies, the cradles feature large impact-absorbing UHMW polymer “box bars” engineered with smooth surfaces that the belt can slide across with little friction or belt wear. These assemblies can be pulled out by a single worker and – working safely from outside the conveyor and using only a single tool – the box bars can be simply removed and flipped in a matter of minutes to double the service life.

Along the cargo path in the settling zone and beyond, retractable idlers support the belt and maintain the trough angle. Exposed to the punishing environment, gritty dust and extreme

weather, rollers can seize over time. Often set closely together in the loading zone to avoid belt sag, slide-out/slide-in roller frames permit workers to perform idler service outside of the belt plane without the need to raise the belt or remove adjacent idlers.

“Wear parts such as belt cleaner blades need to be monitored, serviced or changed regularly to prevent carryback from causing dust and spillage along the belt path,” Marshall says. “However, blade adjustments and changes can require several hours of downtime.”

Primary cleaners – located on the underside of the head pulley – are mounted on rotating assemblies designed to retain the proper tension between the blade and the belt. Secondary cleaners are located behind the head pulley and raised slightly above the belt line for tension. Specially-designed units can slide in and out by simply pulling a lever and releasing a pin. This allows blade maintenance to be performed outside of the system by a single worker in under an hour.

A tight seal is the key to preventing fugitive dust from leaving any chute. Many current setups require workers to crouch or crawl under the system or even enter a confined space to inspect it or perform maintenance, which can result in serious injuries. Inspection of the system needs to be fast, easy and safe. Small inspection doors –either solid or grated – can allow several observation points. Larger doors can offer access points with ample space for service of specific wear parts.

A coal plant in Eastern China had belt damage, spillage and dust issues at two conveyor transfer points with outdated equipment in the loading zones. Raw coal ore was loaded onto the 40-inch-wide belts traveling 500 fpm. The first chute had a 16.5-foot-high drop chute that loaded into a 40-foot-long loading/stilling zone. The second chute had a similar drop, discharging into an 85-foot-long loading/ stilling zone.

Suffering from an old design, the belts were supported by impact idlers and a troughed roller system, neither of which was equipped to cope with new production demands. Equipment failures happened regularly, and without proper accessibility for routine maintenance, long periods of