SOLUTIONS POULTRY

IN A POULTRY SPONSOR SHOWCASE

Presented by:

Presented by:

canadianpoultrymag.com

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Services Administrator

Tel: (416) 510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Audience Development Manager Anita Madden amadden@annexbusinessmedia.com

Editor Brett Ruffell bruffell@annexbusinessmedia.com 226-971-2133

Brand Sales Manager Ross Anderson randerson@annexbusinessmedia.com Cell: 289-925-7565

Account Coordinator Alice Chen achen@annexbusinessmedia.com 416-510-5217

Group Publisher Michelle Allison mallison@annexbusinessmedia.com

Welcome to the first edition of Solutions in Poultry, Canadian Poultry’s new annual resource guide from our brand partners in the chicken, egg, turkey and hatching egg sectors.

This publication is designed to inform producers about the latest innovations and solutions in this vital industry. In these pages, you’ll find information – produced in collaboration with leading suppliers – on products, technologies and systems that

are advancing the poultry sector and making farmers’ jobs easier.

This special brand showcase will be published each year and is also available online so you can share it with colleagues or refer to it anytime you’re looking for more information.

We hope you find it useful, and we encourage you to share your thoughts with us on this new publication. At Canadian Poultry, we’re always open to suggestions and are

continuing our push to provide news, information and content to poultry producers in every media format.

We’re already working on next year’s edition, and we look forward to continuing to bring you content that improves your poultry farming operation and helps you improve production.

Thank you for reading!

Brett Ruffell

When comparing application methods, one must account for the way disinfectants kill pathogens.

The ability of the disinfectant relies on wetting the surface, and the surface remaining wet for the necessary contact time so that the disinfectant does its job of killing bacteria and viruses. Contact time can vary depending on the product, from 5 minutes with Accelerated Hydrogen Peroxide based disinfectants to 10 minutes for some quat or chlorine-based solutions.

Spraying - Spraying is the most widespread method used, especially for small surfaces.

• Pros: Cost effective when it comes to labour.

• Cons: Uses the most disinfectant per square meter therefore is the costliest when it comes to product. Because the liquid can be difficult to see, it is difficult to ensure that all surfaces are covered, especially in low light conditions or on dark surfaces.

Foaming – Often used to disinfect large areas, foaming is achieved through the introduction of air and agitation to the solution.

• Pros: Visibility: Foaming makes it easy to see which surfaces have been disinfected.

• Increased surface adhesion: This allows for a greater contact time especially on vertical surfaces.

• Increased coverage which means less disinfectant is needed to cover an area.

• Foaming equipment such as portable pump up foamers or pressure washer attachments, can reduce the labour needed.

• Cons: Some disinfectants will not foam limiting their ability to be applied in this manner.

Fogging - Fogging disinfectants is used widely especially in the agricultural industry.

• Pros: Fogging allows a small amount of disinfectant to be used due to the small size of droplets, therefore is cost effective.

• Cons: Seeing which surfaces have been treated can be difficult. Fogging can exacerbate the toxicity implications of more hazardous disinfectants due to the fine mist being generated.

ABOVE Pressure washer equipped with a foaming system for applying Prevail disinfectant in a poultry barn.

LEFT Foaming makes it easy to see which surfaces have been disinfected.

Electrostatic Spraying - Electrostatic sprayers charge the particles in the solution.

• Pros: Charging effect allows the disinfectant to “wrap around” surfaces, include those that are not in direct line of sight of the sprayer.

• Cons: Some disinfectants can’t easily be charged which limits the wrap around effect. Cost is also an issue, as units can be expensive, and the labour needed to apply to large areas is greater than spraying or foaming. No matter what method is being used, make sure that the correct dilution is used to cover all surfaces and that the surface remains wet for the contact time needed.

For more information on disinfection methods and equipment, visit www.viroxanimalhealth.com

As producers become more knowledgeable, they’re leveraging technologies to improve air quality at a lower cost.

By Treena Hein

These days, whether producers are retrofitting a barn or building a new one, they will face the same ventilation challenge – they must ensure capacity is adequate to safeguard bird comfort year-round while also minimizing energy costs. That said, here are some of the ways Canadian experts suggest accomplishing this feat.

Increasing knowledge

Producers are becoming more knowledgeable about how the different aspects of barn ventilation interact. Experts would like to see that trend continue. “There are some producers who really understand how everything should work together,” explains Kevin Weeden, president of Weeden Environments, a barn environment specialist company in Ontario. (Note: Since this interview, Weeden has since sold its equipment division to Harkness Equipment of Harriston and Hickson, Ont.) “But many need to increase their understanding so that they can make educated decisions.

“In Canada, barn fans, inlets, cool cells, heating and more must all be set up to ensure birds are kept comfortable when the external weather is extremely cold or hot. The importance of minimum ventilation in the winter is often discounted when considering barn ventilation design. In the first

week of February in Canada, every producer needs to make sure the barn is capable of providing adequate air exchange.”

Indeed, in providing barn ventilation design across Ontario and parts of the U.S., Weeden and his team talk to many producers who have barns that lack adequate ventilation. For example, they often speak to farmers who have had tunnel barns built without anywhere near the fan capacity needed to produce the wind speeds for tunnel ventilation to function properly during times of heat stress.

Bill Van Heyst, a professor of engineering at the University of Guelph in Ontario who studies barn ventilation, agrees. “Simply putting on larger or more fans in a tunnel-ventilated system may not do the trick,” he says.

Van Heyst and one of his graduate students have been working on modelling air-flow in a poultry barn using computational fluid dynamics under minimum and maximum ventilation scenarios. He believes modelling wwill provide a better understanding of the indoor barn environment, which in turn will lead to enhanced spatial analysis of wind velocity, enhanced prediction of ammonia and particulate matter generation and other factors.

Ian Rubinoff, a veterinarian and director of global technical services at Hy-Line International, adds that when converting flat deck houses to aviary house layer barns, producers must upgrade their ventilation. Aviaries require more ventilation because of physical barriers and the greater number of birds they house, he explains.

“I would actually argue that in an aviary or a free-run layer barn, two ventilation

Poultry farmers across Canada are no doubt excited about the federal government’s $630 million Poultry and Egg On-Farm Investment Program. But navigating the application process can be complicated and time consuming. Our expert, Jonathan Giret from Elite Agri Solutions Inc. will detail how to take advantage of this program. He will also highlight several different projects, provide an overview of how the program works and much more! Don’t miss this unique and valuable learning opportunity.

www.canadianpoultrymag.com/webinars

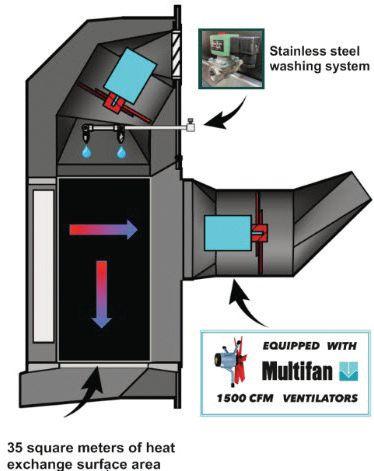

• Provides up to 50% fuel savings

• Lowers energy consumption

• Reduces CO2 and ammonia emissions

• Lowers relative humidity which improves air quality resulting in drier litter

• Automatic washing system

• Energy efficient variable speed motors

Multiheat Hot Water Heaters

• No CO2 production

• Drier Litter

• Reduction of ammonia

• No open flame

• Lower energy costs

• Easy to clean

• Available up to 375,000 BTU

• “W” shape produces 2 jets of fresh incoming air allowing for optimal performance during minimum ventilation

• When flap is open over 35% (maximum ventilation) air is directed downwards providing a cooling effect AERON Wall Inlet by TPI For a quote contact your local dealer or call us for a dealer near you. Exeter, ON 1 866-335-1431 (519) 235-1431 sales@exacon.ca

systems are best – a minimum ventilation side wall system for winter and a tunnel ventilation system for summer,” Rubinoff says. “Producers can switch back and forth and always have the ventilation needed for proper temperature control and to keep litter dry to ensure good air quality and welfare. Many smaller cage-free houses (with less than 100,000 birds) being built in the Midwest U.S. at this time are putting in dual ventilation systems.”

Another common ventilation issue that producers sometimes don’t understand is that adding a cool cell is going to require 20 per cent more ventilation power, explains Bryce Bramhill, operations manager at Weeden. Because the cool cell increases air pressure, this acts to lower windspeed. Thus, more fan power is required to achieve the same speed. And whereas five years ago cool cells were unique in Canada – at least in Ontario –Bramhill says they are very common now with the hot summer weather that’s becoming the norm.

“A cool cell is part of every quote now,” he observes. “We always recommend that every producer sits down with an experienced person who can explain ventilation so they can make educated decisions and select the best design. Producers need to understand whether or not they actually need a cool cell, cross flow versus tunnel systems, what continuous baffle or modular sidewall inlets provide, what attic inlets can do, etc. They need to understand their particular barn and also the weather that’s typical in their geographic area as well.”

In terms of fan performance, Weeden advises producers to compare the results of the annual tests at BESS Lab at the University of Illinois, a well-known and trusted fan analysis facility.

Due to their high performance, lower maintenance requirements and their now-lower costs, direct-drive, variable-speed fans are becoming much more common. They generally produce higher air volumes per minute per watt than similar single-speed, belt-driven fans.

“The use of more of these fans is great for low-ventilation scenarios like winter when you want to have more incremental increases in your ventilation,” Van Heyst explains. “This helps prevent excessive heat loss due to over-ventilation with simple on/off type fans.”

Overall, many experts consider large, direct-drive variable-speed fans a new, exciting development that can save producers a ton of money. For example, the Weeden team says that a producer running two 54-inch VAL-CO V-Fans running at 50 per cent speed can move 13,400 CFM (cubic feet per minute) at 0.05 static pressure while achieving 53.8 CFM/watt, which is more than a 300 per cent increase in efficiency.

And, as poultry barn size has increased, companies are marketing larger and more powerful fans to ensure efficient air movement. In 2020, the Weeden team installed exhaust fans as large as 72 inches. They recommend only using smaller fans if absolutely needed and to, conversely, use as many larger fans as possible. That’s because larger fans are more efficient.

In terms of incoming air, Bramhill says most producers are still battling with both continuous baffle and modular side wall inlets freezing up during the coldest parts of winter. To avoid this situation, which can negatively affect both bird health and power consumption, he recommends one of two solutions.

The first is to use a side wall inlet designed for good performance in frigid temperatures. “The other is to use attic inlets where tempered air from the attic is introduced to mix with the warmest air in the barn having risen to the ceiling, and then it’s gently mixing that air over heaters,” Bramhill says. “More and more growers are using attic air, and I don’t think we’ve equipped a barn in the last two years without them.”

Van Heyst believes any method of preheating air is always good, and that a lot of barns are designed with the incoming air first entering the attic space and then being dropped through the ceilings as a way of heating the air up a bit. “Pre-heating the incoming air does require specialized equipment, usually in the form of an air-to-air heat exchanger,” he adds. “These range in size to units that are mounted single fans to larger centralized heat exchangers.

“We have measured ammonia and particulate matter in one broiler barn with a centralized heat exchanger and found that the litter was drier (and hence had more particulate generation) as a result of low moisture content of the cold outside air and the higher ventilation rate that was used (venting out the moist barn air).”

In the next five to 10 years, Weeden expects that remote control of the barn environment will continue to improve. “Already, the communication between the barn systems and the producer is improving,” he says. “You used to get an alarm with very little information provided. And now with controllers linked to your smartphone, you have instant and detailed information pertaining to which specific heater is producing too much heat or which individual fan motor has died.

“I also think that artificial intelligence will be coming in the future where controllers will begin to learn and anticipate user preferences to automatically make improvements in environmental parameters. Sensors are also evolving and I believe ammonia level, for example, will be another parameter that will soon

be commonplace in any ventilation set up. And there will clearly be much more use of wireless systems.”

As the genetics of broilers, layers and turkeys evolve to enable faster growth and climate change effects worsen, Weeden says ventilation systems will continue to adapt. He says that even with modern technologies, producers still need to carefully plan what they select and how it will interact with existing equipment.

“Overall, it’s about the birds being comfortable, so educate yourself before you make your decisions to maximize flock health and avoid costly retrofits.”

You deserve an advisor who really gets what’s

the

Drugs alternatives are needed for the poultry industry not only for organic production but also for limiting drug resistance and for complying with upcoming regulations and consumer demands. Coccidiosis, a common infection in broilers, decreases nutrient absorption, increases feed conversion ratio (FCR) and is the main risk factor for necrotic enteritis.

NUTRI-GRO® and TECNOCOK® are effective complete gut health solutions as an alternative to anticoccidials for broiler production. These two products have been recently evaluated at Deschambault Animal Science Research Center (CRSAD) in Quebec and in real conditions of commercial farming in Manitoba.

As part of product evaluation at CRSAD, the method used was a 34-day cage trial with 10 replicates of 12 Ross 308 males/cage to compare the impact on growth performance, feed conversion and mortality. Birds received oral administration at d14 of 2x105 sporulated oocysts of mixed Eimeria species from field isolates. The comparative treatments were, T1) Decoquinate/Zoalene shuttle program; T2) 2 kg/t NUTRI-GRO® feed additive; T3) 3 L/1000 L TECNOCOK® in drinking water from d14 to d20.

Results:

The evaluation of NUTRI-GRO® feed additive used alone at 1.5 kg/t performed last winter on two flocks of 28 000 Ross x Ross in commercial farming in Manitoba has confirmed the results of the trials carried out on the research farm (CRSAD). Flock #1 has been shipped at 33 days, 2.3 kg of weight, feed conversion of 1.45, 2.78% of mortality from d10 to shipping and 105 birds (0.38%) total condemnation. Flock #2 has been shipped at 35 days, 2.52 kg of weight, feed conversion of 1.48, 3% of mortality from d10 to shipping and 98 birds (0.35%) total condemnation.

Following these trials, it was clearly demonstrated that the products NUTRI-GRO® and TECNOCOK® limit coccidiosis impact resulting in improved overall growth performances in Eimeria-challenged broilers, decreased mortality and feed conversion comparable to the anticoccidials treatment. In addition, the economic impact of improving these parameters allows a return on investment.

These supplements are essential tools in a strategy aimed at reducing the use of anticoccidials in broiler production.

BENEFITS of NUTRI-GRO® and TECNOCOK®:

• IMPROVE OVERALL GROWTH PERFORMANCES

• DECREASE MORTALITY AND FEED CONVERSION

• COMPLETE GUT HEALTH

PROVIDING A RETURN ON INVESTMENT

Come see us to discuss all the benefits of our complete gut health solution as an alternative to medicating ingredients and antibiotics.