Reduction of heating costs by up to 65%

Improvement of animal welfare

Fast payback (ROI of 2 to 3 years)

Reduction of CO2, humidity and ammonia levels

Better returns, more income

Justin Montreuil, agr. (Sollio & Avantis)

« I was amazed to find that ESA-3000 heat exchangers are very quiet. In the first few weeks of use, we managed to recover 72% of the heat from the buildings thanks to the ESA-3000 heat exchangers. »

Contact IEL Technologie Agricole for the full testimony!

Summit Technologies Inc. 26 Millwork Dr, Steinbach, MB, R5G 1V8 Phone: (204) 320-3276

www.summittechnologies.ca

Equipment

Energy Solutions Air 4350 Robitaille Street, door B Sherbrooke (QC) J1L 0B5, Canada esaseries.com info@esaseries.com

1 855 573-2877

Fraser Highway, Abbotsford, BC, V4X 1K9 Phone: (604) 857-2000 www.jonkmanequipment.com

by Brett Ruffell

As the editor of Canadian Poultry magazine, I am thrilled to introduce the latest honourees of our Top 4 Under 40 podcast series.

Now in its fourth year, this program celebrates the outstanding young leaders who are shaping the future of Canada’s poultry industry.

Each of these honourees exemplifies exceptional leadership, innovation, and community involvement, and their stories offer invaluable insights and inspiration for our readers.

First, let me introduce Thomas Hyde from Mill Bay Farms in Mill Bay, B.C. Hyde has shown remarkable resilience and innovation since he began farming poultry in 2015. Initially focused on dual-purpose ducks, he expanded his operations to address a critical gap in Vancouver Island’s food security by establishing a state-of-the-art poultry processing facility. Hyde also owns and operates a licensed hatchery, is a registered livestock broker, and holds an abattoir’s license.

His efforts to revitalize local poultry farming have garnered attention, including a visit from the B.C. Minister of Agriculture. Hyde is not only a leader in the industry but also deeply committed to community outreach, supporting those less fortunate and encouraging local farmers.

Next, we have Tory Shynkaruk, a research assistant at

the University of Saskatchewan. Shynkaruk’s dedication to poultry science is evident through her extensive work in research, data interpretation, and animal welfare. Her leadership extends beyond the lab, as she fosters a supportive environment for graduate students and excels in teaching poultry sciences.

Shynkaruk’s innovative approach includes adopting new technologies and completing PAACO training to ensure high standards in animal welfare. Her involvement in student engagement, community tours, and industry collaboration highlights her passion for agriculture and her commitment to the broader community.

“Each has found unique ways to overcome challenges and make meaningful contributions to their fields.”

Mark Ronald, an egg farmer from Portage la Prairie, Man., represents the next generation of poultry farmers. As a first-generation egg farmer and third-generation crop farmer, Ronald has already made significant strides in improving farm operations. He has been recognized for exemplary egg production practices and community service, earning the 2022 Farmer of the Year award from Manitoba Egg Farmers. Ronald’s innovative solutions, such as upgrading cooling fans

and implementing biological control for fly populations, demonstrate his problem-solving skills. His dedication to working with troubled youth and serving at a summer camp further showcases his commitment to giving back to the community.

Finally, Hinke Therrien, owner of Ment2B Farms in Red Water, Alta., has been a driving force in the Alberta turkey and chicken industries. Raised on a poultry farm, Therrien has grown her own operation with a focus on raised without antibiotics broilers. Her leadership and advocacy efforts have made her a prominent voice in the industry, speaking at various events and participating in community initiatives.

Therrien’s farm continually works towards improving flock health management and data analysis, reflecting her innovative mindset. Her involvement in television commercials and community events highlights her dedication to promoting poultry production and supporting her community.

What stands out about these four honourees is their shared commitment to advancing the poultry industry through innovation, leadership, and community involvement. Each has found unique ways to overcome challenges and make meaningful contributions to their fields.

I encourage you to visit canadianpoultrymag.com/podcasts to listen to my conversations with these inspiring young leaders. Their stories offer valuable lessons and insights that can benefit us all as we work towards a brighter future.

canadianpoultrymag.com

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Service Rep. Tel: (416) 510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Brett Ruffell bruffell@annexbusinessmedia.com 226-971-2133

Brand Sales Manager Ross Anderson randerson@annexbusinessmedia.com Cell: 289-925-7565

Account Coordinator

Julie Montgomery jmontgomery@annexbusinessmedia.com 416-510-5163

Media Designer/Team Lead Brooke Shaw

Group Publisher Michelle Bertholet mbertholet@annexbusinessmedia.com

Audience Development Manager Anita Madden amadden@annexbusinessmedia.com 416-510-5183

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATION MAIL AGREEMENT #40065710

Printed in Canada ISSN 1703-2911

Subscription Rates Canada - Single-copy $10.00 Canada – 1 Year $33.15 Canada – 2 years $56.61 Canada – 3 years $78.54 (plus applicable taxes)

USA – 1 Year $93.33 CDN Foreign – 1 Year $105.57 CDN

GST - #867172652RT0001

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2024 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

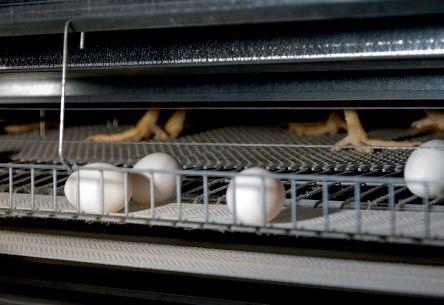

We process roughly 7,000,000 eggs per day and needed many curves, inclines and declines, and LUBING delivered a system that exceeded our expectations.

Brennan Dowsett - Herbruck’s Poultry Ranch

Our egg conveying systems safely transport a large volume of eggs from the nest to the processing area, which is why the majority of all eggs produced in the North America are riding on a LUBING egg conveying system.

Our conveying systems are flexible, and can be adapted to nearly any configuration with curves, angles, heights and distances.

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664-3811

Fax: (519) 664-3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

Les Equipments Avipor Cowansville, Quebec

Tel: (450) 263-6222

Fax: (450) 263-9021

Specht-Canada Inc.

Stony Plain, Alberta

Tel: (780) 963-4795

Fax: (780) 963-5034

KFC has been serving halal chicken at most of its Ontario locations since May, though this has only recently come to light. While the restaurants in Thunder Bay and Ottawa are not yet included, the entire Canadian chain is expected to be halal by the end of 2024. Although many argue it makes good business sense, the decision by KFC Canada to switch to halal chicken has upset some customers.

As of early July, Canada has lifted all highly pathogenic avian influenza (HPAI) control zones except one in Prince Albert, Sask., affecting a backyard poultry flock. The World Organisation for Animal Health (WOAH) confirmed that zoning restrictions have been removed in all other provinces, including zones around commercial and non-commercial operations in Alberta.

The Canadian poultry and dairy industries have collectively denounced a recent Fraser Institute editorial advocating for the dismantling of Canada’s supply management system, arguing it could lower grocery bills. Industry leaders contend this view is overly simplistic and misleading, highlighting the stability in farm gate prices for supply-managed products, which have generally remained in line with or below inflationary trends.

Lloyd Weber, a pioneering figure in Canada’s poultry industry, leaves behind a legacy of dedication and innovation.

The Canadian poultry industry is mourning the loss of Dr. Lloyd Joseph Weber, a pioneering veterinarian, educator, and esteemed Ontario chicken farmer. Weber passed away surrounded by his loved ones at the age of 80.

Weber’s remarkable journey began on May 13, 1944, in Carrick Township.

Weber was known for his exceptional work ethic, integrity, and dedication to both his profession and his family farm.

After completing his early education in Formosa and Walkerton, he graduated from the Ontario Veterinary College in 1969 with a degree in Veterinary Medicine.

Weber quickly made his mark by founding a private poultry veterinary practice in Ontario in 1970. Over the next 53 years, he became a cornerstone of the industry, known for his exceptional work ethic, integrity, and dedication to both his profession and his family farm.

Throughout his illustrious career, Weber’s contributions were recognized with numerous awards and accolades. His status as a diplomat with the American College of Poultry Veterinarians, along with honours such as the Ontario Poultry Industry Council Health Worker of

the Year and the University of Guelph’s OAC Outstanding Service Award, underscored his significant impact.

He was also celebrated by the Turkey Farmers of Ontario and nominated for the Poultry Service Industry Award for Lifetime Achievement and the Canadian Poultry Research Network Hall of Fame.

Weber’s influence extended beyond Ontario, as he shared his expertise globally, including advising on poultry farming in Saudi Arabia. His role as an adjunct professor at the University of Guelph allowed him to mentor countless students and professionals, leaving a lasting legacy in the field of poultry veterinary medicine.

Weber’s battle with an aggressive blood cancer affecting his heart demonstrated his resilience and dedication.

Even in his final days, he continued to offer advice and support to those in the industry. His passing leaves a profound void in the poultry community.

Chicken farmers were thrilled to participate in two CFO Cares: Farmers to Food Banks events in Windsor and Amherstburg, celebrating a significant donation of over 1,800 kilograms of safe, healthy, locally-grown chicken to the Windsor Essex Food Bank Association. Additionally, the farmers provided a chicken lunch to seniors at the Amherstburg Food Bank.

“Chicken farmers were thrilled to announce a donation of nearly 1,800 kilograms of chicken throughout 2024, which will contribute to over 16,000 meals for families and individuals in need, through the Windsor and Essex Food Bank Association. This is all possible thanks to the continued dedication of the Ontario chicken farming community who donate their chicken to food banks year-round,” says Brian Lewis, CFO Board Director for District 3.

“Chicken farmers were also proud to partner with the Amherstburg Food Bank to provide chicken for the ‘Feast with Friends’ lunch. Proteins, like chicken, are some of the most-needed items at food banks across Ontario. For seniors, research suggests that their protein requirements exceed those of younger adults – making

it essential that chicken is easily accessible to individuals in need.”

MPP Andrew Dowie, Member of Provincial Parliament for Windsor–Tecumseh, and MPP

Lisa Gretzky, Member of Provincial Parliament for Windsor West, joined local chicken farmers to celebrate the donation of 1,800 kilograms of chicken for the Windsor and Essex Food Bank Association.

MP Chris Lewis, Member of Parliament for Essex, MPP Anthony Leardi, Member of Provincial Parliament for Essex, Mayor Sherry Bondy, Mayor of Essex, Mayor Michael Prue, Mayor of Amherstburg, and Councillor Molly Allaire, Councillor for Amherstburg, joined local chicken farmers to provide a chicken lunch to seniors at the Amherstburg Food Bank.

These separate donations of chicken were made by the Chicken Farmers of Ontario (CFO) through the CFO Cares: Farmers to Food Banks program, which enables chicken farmers to donate their chicken to food banks across Ontario. The CFO

Cares: Farmers to Food Banks program contributes over 1 million meals a year to local food banks and works in partnership with Feed Ontario.

SEPTEMBER

SEPT. 1, 2024

National Chicken Month Kickoff, Nationwide chickenfarmers.ca/national-chicken-month

SEPT. 3, 10, 17, 24, 2024

Canadian Poultry Broiler School Webinar Series canadianpoultrymag.com/webinars

SEPT. 4, 2024

PIC’S Golf Tournament, Baden, Ont. poultryindustrycouncil.ca

MPP Andrew Dowie, Member of Provincial Parliament for Windsor–Tecumseh, and MPP Lisa Gretzky, Member of Provincial Parliament for Windsor West, joined local chicken farmers to celebrate the donation of 1,800 kilograms of chicken for the Windsor and Essex Food Bank Association.

SEPT. 4, 2024

PIP Innovation Showcase, Webinar poultryinnovationpartnership.ca

SEPT. 10-12, 2024

Canada’s Outdoor Farm Show, Woodstock, Ont. outdoorfarmshow.com

SEPT. 17-19, 2024

SPACE 2021, Renees, France uk.space.fr

SEPT. 23, 2024

PIC’S Science in the Virtual Pub poultryindustrycouncil.ca

OCTOBER

OCT. 1-3, 2024

Shell Egg Academy Lafayette, Ind. shelleggacademy.org

OCT. 2, 2024

PIP Innovation Showcase, Webinar poultryinnovationpartnership.ca

OCT. 2-4, 2024

is how many kilograms of safe, healthy, locally-grown chicken producers donated to the Windsor Essex Food Bank Association.

Poultry Service Industry Workshop, Banff, Alta. poultryworkshop.com

OCT. 24, 2024

PIC’S AGM, Elora, Ont., and Webinar poultryindustrycouncil.ca

By Dr. Gigi Lin

Dr. Gigi Lin is a board-certified poultry veterinarian. She provides diagnostic, research, consultation, continuing education, and field services to all levels of the poultry industry in Western Canada. In this column, she will share case-based reviews of brooding best practices.

Case Summary: A five-day-old broiler flock experienced a sudden mortality spike with necropsies revealed starve-out condition. I visited the barn to help identify the underlying cause and found an unexpected issue with the feed system. Following some corrective actions, fortunately, the mortality rates returned to normal level. The farm team also implemented preventative measures to avoid future occurrences, highlighting a critical lesson in brooding management.

Case History and Postmortem Exam Findings: In the summer of

2022, I received a necropsy submission from a five-day-old conventional broiler flock due to a sudden increase in mortality. Among the 15 dead chicks submitted, most had lesions that were consistent with typical starve-out conditions. The chicks did not have any external lesions; their navels were healed, and their yolk sacs were well-absorbed. Their crops and gizzards contained only small amounts of feed materials and were mostly filled with varying amounts of litter. Only two out of the 15 chicks submitted showed

1. Inspect the entire feed system regularly, including the feed bins, hopper, feed augers, and individual feed pans. Repair or replace broken pans immediately.

2. Ensure thorough feed clean-out after each depletion. Remove leftover feed from the bins and the rest of the system to avoid accumulation of old feed that may become rancid or moldy. Ensure feed augers are functioning normally.

3. Pay extra attention to the trigger pans. Ensure the trigger pans are well-lit to attract chicks to feed sources and help them locate feed right away upon placement.

4. Inspect feed quality before chick arrival and ensure feed size is appropriate. Crumbles that are either too powdery or too large are not ideal and should be replaced.

5. Have extra creep feed available in supplementary pans or chick papers on the first few days to improve feed access.

signs of bacterial infection. The farm manager reported normal environmental conditions, with no recent drastic changes in management.

Field Evaluation: As with any early mortality and starve-out cases, I started the investigation by trying to identify the underlying cause, particularly to evaluate if the chicks were exposed to any external factors preventing regular feed intake. The next day, I visited the barn to perform a routine brooding investigation. Upon entering the barn, the flock was bright and alert, spread out evenly in the barn. I conducted a comprehensive brooding assessment, evaluating temperature, feed, litter, air quality, water, and sanitation (TFLAWS).

After the initial evaluation, I did not identify any abnormal brooding conditions. The feed pans and feed lines were at good levels, with adequate feed volume in each pan. I spoke with the farm manager again to obtain more history. This is a well-managed farm, and the flock appeared normal for the first three days after placement. The mortality level increased by 0.4 per cent between four to five days of

age. I also necropsied more dead chicks on-site and confirmed again that most of the mortalities were due to starve-outs.

Based on the history and necropsy findings, I was convinced that there were likely some underlying factors hindering feed intake. I decided to conduct another more thorough inspection, particularly focusing on the feed and feed system. I started by examining the feed from three pans of each feed line (the trigger pan, center, and end of the line).

I discovered that the first 10 to 15 pans of each feedline were filled with large pieces of feed pellets consistent with finisher feed instead of chick crumble. The rest of the feedline contained normal chick crumble. This was most likely caused by incomplete clean-out of finisher feed from the previous cycle, leaving finisher pellets in almost 15 per cent of the line. The young chicks, preferring a smaller feed size, refused to eat the larger pellets, leading to feed refusal and increased starvation in some of the chicks.

Management Plan and Clinical Outcome: The solution was straightforward once the primary problem was identified. The farm team cleaned out most of the finisher pellets from the system and ensured the rest of the lines were filled with chick crumbles. To improve feed access, the team also placed extra crumbles in supplementary feeding pans throughout the barn. This immediate intervention resolved the starve-out issue, and the mortality level quickly returned to normal the next day, with no subsequent problem reported.

Lesson Learned: The farm manager reported that a new summer worker who was not familiar with the barn system was hired to help with barn clean-out and set-up. To prevent future occurrences, the farm manager has added a section on feedline clean-out after depletion on their new employee training section. This was not only a great lesson for the farm team but also a reminder for me that many aspects of brooding management can go wrong and require close attention to details.

• Agri-fan- Exacon’s brand name since 1987!

• Flush Mount Direct Drive and Belt Drive Exhaust Fans

• Energy Efficient Multifan Motors

• Canadian made with 14 gauge stainless steel

• Allows direction of airflow into corners and dead spots

• No CO2 production and reduction of ammonia

• Nonhazardous with no open flame

• Specialized polyurethane formula

• For exceptional insulation properties

• Creates a uniform climate

• Controls humidity at animal level

• Generates real time data

• FarmQuest Online Farm Management allows

• Access to data 24/7

By Mary K. Foy

Avian influenza – it feels like we have talked this issue to death.

Yet, it is still a dark cloud over all we do to keep our birds healthy. Although AI (and, more specifically, highly pathogenic avian influenza [ HPAI]) has been around for hundreds of years, it feels very current. That is because the last two decades have been full of learning what this virus can do, how it is spread and how it survives. How does your water relate to anything that has to do with HPAI? Well, it can be a lot. Or it can be nothing. That will be up to you.

HPAI has been known to be spread through contaminated surfaces (trucks that were not properly cleaned between farms, for example), wind that carries the virus from a contaminated flock or truck of birds to a new farm, and, of course, an open water source that migrating birds have contaminated. Knowing that

there are some potentially contaminating circumstances that we cannot completely control (like migrating wild birds moving over your property) should give us the motivation to do all we can on our own farm to control the things we can. Water is one of those things.

Just a little interesting fact: the highly pathogenic H5N1 strain of AI survives well in the trachea of the bird. This allows for a higher possibility that it will be found in the drinking water. There are thousands of other viruses and bacteria that can be transmitted to the drinking water from the birds themselves.

What can you do?

Maintain control over the water your birds drink by consistently treating it. Use an oxidizer such has hydrogen peroxide or a chlorine-based product to have continual water treatment going into

Ensuring

your birds have access to clean, treated water helps safeguard their health and biosecurity.

your water line.

Just because you have a well or are on a municipal water supply does not mean that the water your birds are drinking is clean.

You may be less susceptible to the wild migratory birds that are flying over contaminating your water supply, but the wind or the truck tires that were not properly sanitized or the boots you wore to town can bring disease onto your farm just the same.

Once it is in your barn it is going to wind up in the water line. The birds put it there every time they get a drink. The fans blow it onto the drinkers when they kick on. You put it there when you walk the barn and the litter dust and bird dander float around. Have something in that water line to fight it.

2. Clean your water lines when the barn is empty

Even if you used a daily water treatment during the flock, you still need to clean your water lines when the facility is empty. Why? The level of oxidizer (hydrogen peroxide or chlorine) we use while birds are present is intended to counteract the contaminants reintroduced into the water line by the birds each time they drink. There will be bends in the water line and hiding spots in the regulators that allow for the attachment of bacteria, yeasts and molds that the low ppm we use with birds present just can not fight as effectively.

You need a higher ppm of that oxidizer to really clean the entire system when the facility is empty. Also, we often end a flock using an organic acid product to lower the pH. When the water lines are left with an organic acid product in them for days or weeks while the barn is empty, we set up the perfect environment for a mold or algae bloom in that water line. That is not something we want the next flock drinking right off the bat.

Although HPAI is often the subject when we talk about biosecurity lately, there are hundreds of other diseases that can devastate our flocks when our biosecurity vigilance lapses.

Water is often the unseen culprit in promoting the survival and facilitating the spread of those diseases. Don’t forget about it just because you don’t see it every day.

The highly contagious disease that started in Ontario turkey flocks has spread to other regions. Here’s how to protect your flocks. By Treena Hein

Avian metapneumovirus (aMPV) has been spreading across Ontario in recent months, with cases reported across about dozen counties and municipalities in the southern part of the province. There are also positive cases in Manitoba (a turkey farm in Hanover) and the U.S. (various locations).

The common names for this disease (based on clinical signs) are turkey rhinotracheitis in turkeys, swollen head syndrome in broilers and egg drop syndrome in layers and ducks.

The disease is highly contagious and affects most poultry species. Wild birds serve as a reservoir, including mallards, black ducks, gulls, sparrows and wild turkey.

As a viral disease, there’s no treatment, nor vaccine approved in Canada, but there is some evidence that treatment for secondary infections helps reduce bird death. Of course, prevention through strict biosecurity is paramount.

An article recently published by Hybrid Turkeys adds that the first step in prevention of this disease is to properly manage flock environment in terms of proper ventilation, optimal humidity and other air quality parameters. “Be sure to keep a close eye on how the birds are behaving and performing. If you’re questioning whether something seems wrong, call your veterinarian for support.”

Hybrid also explains that “being proactive can make the difference in avoiding losses and keeping secondary bacterial

infections at bay, but it’s important to keep in mind is that this disease is extremely volatile and difficult to contain.”

As explained in an Ontario Ministry of Agriculture, Food & Rural Affairs (OMAFRA) Veterinary Advisory from early July, there are four distinct subtypes (A, B, C, D) of the virus.

“Canada has had subtype C present for many years without significant problems, although aMPV is frequently complicated by secondary infections that may cause high mortality. In 2023, subtypes A and B have emerged in the U.S. as highly virulent infections. Ontario has seen outbreaks of aMPV-B and mixed A+B since May 2024 and Manitoba has had a few outbreaks of aMPV-A.”

OMAFRA poultry specialist Al Dam notes that, as of late July, positive test results for the disease were still occurring. “And, because it knocks down the bird’s immune system, we see secondary infections as well, usually bacterial,” he reported.

“The problem with that is that farmers may suspect they have cases of avian metapneumovirus but then it develops into bacterial/viral or other infections and the test at that point is not positive for metapneumovirus. So, we should be testing as soon as we suspect.”

He adds, “It’s a disease that’s immediately notifiable to the Canadian Food Inspection Agency and OMAFRA. Communication of disease spread is very important.”

In an avian metapneumovirus factsheet, Dr. Jose Linares at Ceva Animal Health further explains that that the virus is difficult to isolate, as it’s only present for a short time.

“Sampling during the early stages of infection is critical. Look for any respiratory signs or wet eyes, depression. By the time a bird looks sick it is too late to

• Location: aMPV has been reported in about a dozen counties and municipalities in southern Ontario, a turkey farm in Hanover, Man., and various locations in the U.S.

• Affected Species: The virus affects most poultry species, including turkeys, broilers, layers, and ducks. Wild birds such as mallards, black ducks, gulls, sparrows, and wild turkeys serve as reservoirs.

• Other Names: Known as turkey rhinotracheitis in turkeys, swollen head syndrome in broilers, and egg drop syndrome in layers and ducks.

• Subtypes: There are four subtypes (A, B, C, D). Canada has subtype C, while subtypes A and B have emerged in the U.S. as highly virulent.

• Transmission: Extremely contagious via aerosols, direct contact, and contaminated materials. Horizontal transmission is more significant than vertical.

• Outbreaks: At the time of publishing, there have been over 42 Canadian outbreaks in total, with several in Manitoba and the rest in Ontario.

• Biosecurity: Key measures include restricting barn access, cleaning and disinfecting, maintaining farm entry procedures, and preventing wild bird, insect, and rodent access.

sample, so it is best to sample normal birds in an affected house or birds from a house at the same farm with no clinical signs. Ideal samples are swabs from eyes, sinus, choanal cleft and trachea.”

However, labs might want the whole head. Dam, therefore, urges farmers and veterinarians to check with their lab to see what samples are needed. “Some labs want a whole head as well as the usual swabs and biopsies,” he explains. “With some of the secondary infection scenarios, the virus creates a deep bone infection in the sinuses and the ears, and you need the whole head to detect it there.”

Meanwhile, the Feather Board Command Centre (FBCC) continues to monitor aMPV in Ontario.

“We are also actively communicating with stakeholders and encouraging everyone to continue to practice enhanced biosecurity measures and be vigilant with seeking assistance if they suspect a flock may be infected,” says FBCC executive director Dr. Harold Kloeze. Dam concurs. His main message to producers about aMPV is to keep biosecurity tight. “Biosecurity is the

only thing that will get us through this,” he says.

OMAFRA’s Office of the Chief Veterinarian highlights that the spread of aMPV between premises is linked to poultry density, hygiene, and biosecurity standards. The virus is extremely contagious via aerosols and direct contact, as well as by contaminated material such as bedding, feeders, waterers, and employee clothing, footwear, and equipment.

While aMPV-C has been isolated from eggs from SPF-infected turkeys in experimental conditions, the vertical route is suggested to be less important than horizontal transmission.

“Keep people out of your barn that don’t need to be there,” says Dam. “People are the best fomite, the most common object, if you will, for disease transmission.”

Proper cleaning and disinfection are crucial. Maintain strict biosecurity in farm entry procedures. Wild birds are a reservoir, so it’s important to keep them away from poultry barns as much as possible. Also, take measures to keep insects and rodents out of barns.

Signs of avian metapneumovirus (aMPV) in poultry: a turkey with crusting nasal exudate (left) and a broiler chicken with a swollen head (right).

Avian metapneumovirus (aMPV) may present with a range of upper and lower respiratory disease symptoms. The incubation period is three to seven days and can affect birds of any age. Clinical signs may be more severe with concurrent infections such as E. coli, Ornithobacterium rhinotracheale, Pasteurella multocida, Mycoplasma spp., infectious bronchitis virus, and infectious laryngotracheitis.

TURKEYS:

• Age Affected: Typically, between three and 12 weeks.

• Symptoms: Cough and sinusitis in younger birds, conjunctivitis, wet eyes, lethargy/huddling, and decreased water consumption.

• Egg Production: Older hens show a marked decrease in egg production, poor shell quality, and increased egg yolk peritonitis.

• Mortality: 14 to 40 percent.

• Age Affected: Typically between four and six weeks.

• Symptoms: Mild respiratory signs, sinusitis, wet eyes. In broiler-breeders and broilers, clinical signs include swollen heads, nasal discharge, torticollis/opisthotonos, depression, and lethargy.

“Biosecurity is the only thing that will get us through this.”

• Egg Production: Drops in layers and breeders (up to 70 percent in layers).

• Mortality: Slight mortality risk.

New research uses light source, charged water particles, to wash eggs safely.

By Lisa McLean

Egg processors and egg graders may soon have new tools for reducing food safety risks, thanks to an egg washing process that uses tiny water droplets with high-voltage electricity to fully decontaminate the shell.

The project, developed by researchers at the University of Saskatchewan, uses the Canadian Light Source synchrotron, a technology that produces light by accelerating electrons, to obtain highly detailed 3D scans of the eggs. The scientists involved include principal investigator Lifeng Zhang and co-investigators Karen Schwean-Lardner, Shelley Kirychuk and Mehdi Heydari.

“We tested our new technologies on a surface that was inoculated with E.coli and Salmonella, and we got promising results in reducing bacteria on the egg’s surface with 99 per cent efficiency,” says Mehdi Heydari, a postdoctoral fellow with the University of Saskatchewan’s College of Engineering.

“We also checked for adverse effects on nutrition or egg quality, and we confirmed there was no damage.”

North American consumers buy eggs that have been washed with warm water and a sanitizing agent. It’s a process that removes harmful bacteria from the outside of the egg, but it can also compromise the natural protective barrier on an egg’s shell. Once eggs have been washed, they are refrigerated for food safety reasons.

“The cuticle is a natural barrier to prevent microbial invasion of the egg. We prefer to keep it as intact as we can so it can naturally do its job of protecting the egg,” says Heydari. “When we used our technology on the egg’s surface, we were able to successfully remove pathogens, and we confirmed there was no damage to the egg’s shell.”

Heydari notes in many other places in the world, including Europe, refrigerated eggs are less common. Eggs are generally not washed with water and cleaning agents, and with uncompromised shells, they can be stored at room temperature. When eggs are washed in Europe, they are reduced from grade A to B, and are kept in the refrigerator.

“The technology we have developed is a non-chemical, non-thermal emerging technology, and because it uses a low amount of energy, we consider it a green technology,” says Heydari.

The team used different methods to sanitize the eggs while keeping the protective barrier intact, using electrospray and water nanostructures to remove pathogens. They also engineered a plasma option that he says could be integrated most easily into current processing systems.

Because cuticles are invisible, the team required highly specific tools to confirm the egg’s shell quality was intact. They used Canada’s only synchrotron light from Canadian Light Source to collect detailed scans of the treated eggs.

With the pilot project complete, now is the time to scale up and showcase the technology for processors. He says any new technology needs to fit within current food safety standards and be able to integrate with current practices. Processors have also expressed consumer feedback that there is a market for eggs that are processed with fewer chemical cleaning agents.

“We hope this new technique will be added to the existing egg processing line, to ensure the eggs are truly clean,” says Heydari. “We are working for cleaner eggs with less damage to cuticles, so eggs are as safe to eat as possible.”

This project was supported by the Natural Sciences and Engineering Research Council of Canada, the Saskatchewan Ministry of Agriculture, and the Canadian Poultry Research Council.

A

By Melanie Epp

In March, HatchTech launched a new incubator, SetCare, that has caught the attention of hatchery owners around the world. Contrary to industry standard, HatchTech increased incubation time from 21 to 24 days. Doing so reduces embryo death by three per cent, they say, and improves hatchability and the long-term performance of hatched chicks.

Across the industry, early embryonic death is a commonly accepted loss. During incubation, on average, 17 per cent of embryos die at various stages and for a number of reasons, but the majority are lost during the first three days of the incubation process. On average, early mortality sits at approximately 8.8 per cent, and of those deaths, 50 per cent take place during the first three days of incubation. In younger flocks and for longer egg storage, these numbers are even higher. For HatchTech’s head researcher and poultry incubation specialist Dr. Jan Wijnen, this number was not acceptable.

“These high losses during the first stages of incubation have always been accepted in our industry because we believed it was normal and unavoidable,” Wijnen says. “However, we questioned ourselves if this is really the case.”

Over the course of five years, Wijnen and his team at HatchTech conducted 51 studies that involved some 1.1 million eggs. The conclusion of those studies is that warming eggs much more slowly minimizes early death and maximizes hatchability. This extreme slow warming stretches total incubation period to 24 days.

Traditionally, eggs are moved from cold storage and pre-heated to an incubation temperature of 100°F. Across the industry, it is generally accepted that embryonic development begins at this temperature. “This is where we go wrong because it overlooks embryo development below 100°F,” says Wijnen. “We found that significant development of an embryo already starts at 85°F. Forget pre-heating, incubation starts at 85°F.”

It’s not just the starting temperature that impacts survivability,

though. How quickly the temperature rises also matters. Current systems warm eggs by about 1.5°F (or more) per hour. This is at least 15 times more than HatchTech’s recommendation of no more than 0.1°F per hour.

To accurately warm the incubator slowly, Wijnen says it’s necessary to control the air temperature within in the incubator very precisely. Air temperature must be uniform throughout the entire machine. This control is achieved through proprietary HatchTech technology that pairs with the incubator.

“This uniformity within one large incubator, as are used by our industry, can only be achieved if heating and cooling are controlled per setter trolley,” Wijnen says. “If not, the benefit for the embryo is lost and early embryo mortality cannot be prevented.”

Beyond temperature, high relative humidity and high CO2 levels are also important and require precise control.

HatchTech’s studies show that lengthening incubation from 21 to 24 days increases hatchability by at least three per cent in an average flock with short egg storage (under seven days). “In longstored eggs the benefits will be even bigger,” says Wijnen.

Beyond improved hatchability, lengthening and slowing incu-

bation has shown to improve overall chick quality as well.

“At our research and testing centre in The Netherlands, we have compared traditional incubated chickens with SetCare chickens,” Wijnen says. “Trial results show that chickens incubated with SetCare demonstrate improved uniformity, higher slaughter weight, and improved feed conversion rates.”

“These years of research with numerous studies and consistent findings of better hatchability, better chick quality and better field performance, proves that optimal incubation of chicken eggs does not take 21 days, but 24 days,” Wijnen concludes.

Based in The Netherlands, HatchTech used European standards to calculate the economic benefits of switching to SetCare. By their calculations, the average hatchery produces two million chicks per week. An increase in hatchability of three per cent from the same resources means an additional 60,000 chicks each week.

At an average value of €0.35 per chick, EU-based hatcheries have the potential to increase profits by more than €20,000/week or €1 million/year. In Canada, where the average chick price is $1, savings could be even higher, according to Michiel van Veld-

huisen, HatchTech’s international sales manager.

“In a quota market, the hatching eggs will only increase by a certain percentage,” Van Veldhuisen says. “And from that total egg bank, if you can utilise these eggs by transforming them into more chicks, it’s a great benefit.”

SetCare is an entirely new system, which means replacing both hardware and software. “You cannot run a SetCare incubation profile in an existing 40-year-old machine,” Van Veldhuisen says. “You need to replace that.

“But every hatchery will understand that increasing hatching percent by three per cent is a game changer,” he adds.

In terms of the improved long-term performance of hatched chicks, HatchTech is in the process of conducting trials. Performance data is not yet available, but preliminary results around feed conversion and slaughter weights have been “really positive,” Van Veldhuisen says.

A 1.2-million egg hatchery in Poland was the first to place an order for SetCare. HatchTech expects the system to be operational by early 2025. “This is really a tool that can increase the business model of the hatchery itself directly,” Van Veldhuisen says in conclusion. “It’s the biggest revolution that I’ve encountered in the last 15 years, based on the incubation technology.”

Ronda Payne

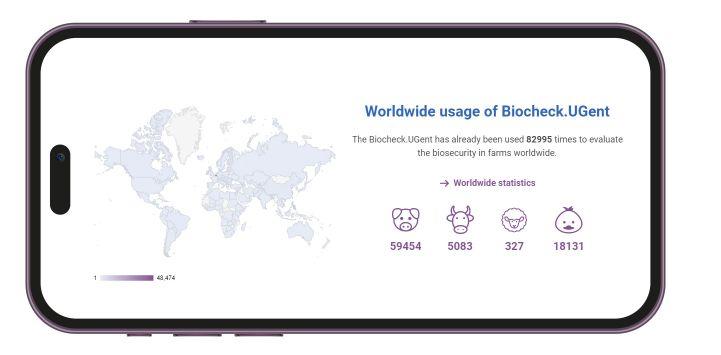

In a world where apps reign supreme, it’s no surprise that an online tool has emerged that allows farmers, researchers and livestock industry specialists to better navigate the landscape of biosecurity and its management. Prior to the launch of Biocheck.UGent, there were no metrics for biosecurity.

This left the question of good biosecurity vs. bad with nebulous answers and a gap in knowledge.

If biosecurity can’t be measured, it runs the risk of being stagnant at best and ineffective at worst because improvement (or decline) can’t be tracked.

Jeroen Dewulf, professor at Ghent University in the Faculty of Veterinary Medicine, led a team to develop Biocheck.UGent, which is a scoring system based on questions farmers answer online, to better understand their biosecurity position and areas for improvement. Not only does the tool allow for scoring based on an individual’s farm, it also illustrates where the farm sits in comparison to other same species and same production method farms in the country and around the world.

What’s good for the swine is good for the hen

“It started with a scoring system for biosecurity in pig farms, then expanded to broilers and layers and later to different types of cattle production,” Dewulf says. “Currently, we have no less than 16 different biosecurity scoring tools for different production systems.”

This includes conventional broilers and layers, broilers and layers with outdoor production, breeders, turkeys, ducks and backyard poultry production. The tool is free to use and works anywhere in the world to guide improved animal health by reducing infection risks. There is an Advanced User paid plan that includes personalized feedback, e-learning, the ability to export reports and more.

He adds that multiple scientific publications have confirmed the tool demonstrates and quantifies the positive effects of good biosecurity. Because it’s free, numerous research groups around the world are using it, creating a more robust pool of data on the positive effects of biosecurity.

Often, the question comes up as to

Biocheck.UGent is an online tool that assesses farm biosecurity through a series of questions, providing a detailed score and benchmarking against national and global standards to guide improvements and track progress.

whether the tool developed in Belgium is applicable in production systems in other countries and the answer is a resounding yes. In fact, used in more than 130 countries, Biocheck.UGent is the largest database on biosecurity in the world, which allows for continuous improvement and benchmarks in many countries.

“All Biocheck.UGent scoring tools are based on a questionnaire. You simply fill in the questions online and the answers are translated into a score,” Dewulf explains. “The score is subdivided into an overall biosecurity score and separate scores for external biosecurity... and internal biosecurity.”

External biosecurity scores are related to the prevention of the introduction of infections to the farm while internal biosecurity scores are measures around avoiding infections spreading on farm. Each of these scores is further subdivided into components that get a score of between one and 100 on things like entrance of persons, cleaning and disinfection, and more.

“In this way, you receive an entire report

What if you could manage your flock through light recipes?

CONTROLLED VIA SMART PHONE OR FARM COMPUTER

LIGHT RECIPES DESIGNED BY POULTRY SCIENTISTS

MADE FOR HARSH CLEANING ENVIRONMENTS

Introducing NatureDynamics Dome, a fully controllable lighting system that allows you to adjust the spectrum and intensity through light recipes. Our patented light recipes stimulate bird activity in a controlled way, giving you optimal control over your production results.

of the biosecurity situation in your farm , which immediately indicates the strong and weak points of your biosecurity,” he says. “These results are also benchmarked against the national and global average scores to allow you to assess how the score for a specific farm compares to other farms. Measuring the biosecurity situation in a farm is, thus, a first step that needs to be followed by advice on improvements and an action plan to execute these improvements.”

Once 40 questionnaires for a species and country are completed, the country-level comparison becomes available, says Manon Racicot, senior veterinary epidemiologist, with the science branch of the Canadian Food Inspection Agency. Her involvement with Biocheck.UGent began with the avian influenza outbreak in Canada in December 2021. “The tool assesses the adoption of biosecurity measures intended to control a variety of infectious diseases,” she says.

She’d learned about the tool when reading scientific papers on biosecurity.

Easy to use, Biocheck.UGent only needs a device with an internet connection for a farmer, consultant or livestock manager to get started answering questions. It is also anonymous, while still being based on rigorous scientific methodology.

“A huge amount of information on the level of application of different biosecurity measures in different species can be found on our website at biocheckgent.com,” Dewulf says. “We only ask the country and state where the farm is located, but do not ask for any name, address, identification number. As a result, it is impossible for us

to trace back to which farm is at the origin of the data.”

For example, average results in more than 6,000 broiler flocks show that measures like feed and water safety are not as well performed as infrastructure and biological vectors. While this high-level information is interesting, the tool was designed more for the ability to evaluate at the farm level. However, the high-level data helps outline levels of biosecurity in different production sectors, countries and regions for education, animal health services, researchers and others.

Racicot saw the opportunity for the tool to assist with comparisons between the practices on AI-infected farms and non-infected farms. Quebec was the first province to implement a case-control study like this, starting with turkey farms in 2023. A significant-sized project, researchers used a modified Biocheck.UGent questionnaire with more questions and changes to the tool based on AI risk factors investigations found. The turkey phase is now complete

With more than 80,000 worldwide uses in swine, poultry cattle and sheep, Biocheck.Ugent is growing in popularity.

Swine is the most used at nearly 60,000 uses and poultry is gaining ground quickly with nearly 20,000.

Through Canadian tests to help with poultry cases of AI, Manon Racicot, senior veterinary epidemiologist with the science branch of the Canadian Food Inspection Agency, and a team has used the tool to collect data on differences between AI-impacted farms and non-AI-impacted farms based on their biosecurity practices. The data analysis of all types of poultry studies will be conducted in the fall.

Early results indicate that turkey farmers sending birds in multiple batches to slaughter – known as thinning – are more likely to be an infected farm.

“This likely creates an opportunity for increased exposure to HPAI during catching activities,” she says.

“Similarly, the proportion of producers moving turkeys between barns on a premise is higher on infected farms compared to non-infected farms.”

This points to a need for cleaning and disinfection procedures for equipment used to transfer birds.

and layers, breeders, broilers and ducks should be completed by the end of the summer.

“Having a standardized tool able to compare biosecurity across species and production types was needed for these projects,” she says. “It is, to my knowledge, the only available tool with a scoring system applicable to multiple species with benchmark capabilities. When HPAI impacted Canada, it was the perfect opportunity to try this tool.”

Biocheck.UGent gives the quantitative data to the researchers and Racicot and others on the Canadian project team created graphs to illustrate the findings. They

can then identify biosecurity recommendations specific to producers to reduce infection risks.

“For the duck study, [Quebec] was interested in benchmarking current biosecurity adoption. So, we decided to have two assessments per farm: one for biosecurity before HPAI outbreaks and one for current biosecurity,” she says.

“Having this comparison is very impactful to producers, as they can clearly see their improvements, which is quite motivating.”

She adds that the tool allows producers to do biosecurity self-assessments that can provide data on the start of measurement, identifying improvements, planning for the future and seeing how the changes improve results.

The challenge Raciot sees with Biocheck. UGent is each scoring tool is specific to species and production type.

“In Canada, it is common to have multiple species or production types on the same site; such as turkey and broilers, or

chicken layers and breeders, duck breeders and duck meat, etc.” she says. “The tool is not designed to assess the risk of multiple productions.”

She feels that poultry associations could learn from the tool to create other customized questionnaires to allow for centralization of data, comparisons of data and sharing. She refers to Vigil-vet as a comparative example for the centralizing, scoring and documenting of questionnaires done biannually by Dairy Farmers of Canada.

The VOLO BABY AREA is the ideal aviary housing system for pullets, with all the main components integrated, while the SPACE COLONY, an enriched cage for raising laying hens, allows you to customize the multi-level configuration from 3 to 12 floors.

Valli-Italy operates on the premise of passion and quality to ensure each producer receives the ideal system for their operation.

By Jane Robinson

Peat moss has become a bedding alternative in broiler barns based on availability and price, compared to other options. Canada contains 25 per cent of the world’s peatlands, according to the Wildlife Conservation Society Canada. But the rise in peat moss use has also given rise to some concerns from the poultry service industry about the increased dust levels inside the barns that can come from the peat moss bedding.

“We had calls from catcher crews and hatchery drivers who had worked in straw bedded barns for years complaining about feeling ill – shortness of breath, flu-like systems and eye irritation – after working in barns with peat moss,” says Al Dam, provincial poultry specialist with the Ontario Ministry of Agriculture, Food and Agribusiness (OMAFA).

Concerns for bird and human health ultimately brought together a collaborative team to investigate air quality and bird health in commercial broiler barns in Ontario by comparing peat moss and chopped straw bedding. That research is now complete, and the results and recommendations are being shared throughout the sector.

Dr. Bill Van Heyst, Dean of Engineering at the University of Windsor, led the project, with his master’s student Seif Ali at the University of Guelph, along with Dam and his OMAFA colleague and agricultural engineer Daniel Ward.

Their objective was to quantitatively compare levels of particulate matter, litter

quality indicators and broiler bird performance on peat moss and chopped straw bedding.

Finding a producer to work with was key. “It was a bit of unicorn, finding an operator with two identical barns who was willing to use straw bedding in one and peat moss in the other,” says Van Heyst.

A farmer with two barns (120 m x 20 m x 3 m ceiling) agreed to participate in the trial. Four flocks were monitored over the course of a year to compare the effect of different seasons on barn condition, and factor in weather conditions. Barns were rotated to alternatively house a flock of birds with peat moss or chopped straw bedding for the entire 35-day grow out period.

All other barn conditions were kept constant, including temperature, humidity,

ventilation rate, feeding times, lighting schedule, number of birds at placement, hatchery source, type of monitoring devices used and placement of monitoring devices within the barn.

Barn air was continuously monitored for temperature, humidity and dust levels. Litter samples were taken twice a week throughout the grow out period. Birds were monitored for average daily weight and mortality.

During the trial, five birds were collected from each barn at placement in the barn, and on days 10, 21 and 35 (shipping). Birds were euthanized and lung tissue samples collected for lab analysis.

“It was a great learning process for everyone on the team,” says Ali, who completed his master’s degree in April 2024 as part of the project. “We had a great poultry produ-

Ryan Kuntze has been a poultry producer for 20 years. He uses peat moss exclusively in his broiler barns after he switched his operation from layer pullets to broilers a few years ago.

He’s now an Ontario distributor of Naturesorb, peat moss that’s harvested, packaged and shipped from Quebec, the same product used in the research project.

“Peat moss has an ability to absorb moisture that’s considerably higher than other bedding and I see the birds able to express their natural foraging behaviour,” says Kuntze of R. Kuntze Enterprises. He says it also makes excellent manure.

Kuntze encourages customers to use proper PPE with peat moss bedding.

“There can be more dust with peat moss because it is a finer product, but that’s also what gives it strength as a highly absorbent bedding. It does take some management and it’s surprising how little you need to keep birds dry.”

cer to work with who was curious about peat moss and did a fantastic job to manage the barns identically.”

There was very little difference in bird weight and mortality between bedding types. The litter moisture content was always higher in chopped straw than peat moss barns, but both barns saw an increase in litter moisture content over the production cycle.

“Chopped straw retains more moisture which probably led to lower particulate matter levels in the barn,” Ali explains.

Peat moss bedding stays drier but produces more dust than straw bedding. “Peat moss dust contains more particles that are 2.5 microns, and these small particles get into the lower respiratory system and are

too small to be expelled or cleared,” says Vay Heyst. They took special interest in these smaller particles because they accumulate at gas exchange sites in the lungs that bring oxygen to the body.

When they examined particulate matter in bird lungs, the birds on peat moss had consistently and significantly higher levels of particulate matter embedded in their lungs compared to birds on chopped straw. Particulate levels in the bird lungs when normalized by the bird weight were highest in the first 10 days of the bird’s life.

“Young birds are breathing in a lot of air, and it’s dustier with the peat moss because it is drier and there isn’t much moisture built up in the litter – plus, the birds don’t have a fully developed immune system,” says Ali.

They also found broilers raised during winter months had higher levels of particu-

late matter in their lungs, likely due to lower barn ventilation rates during colder temperatures.

While the team didn’t study human health in the different bedding environments, the reality is that while broilers only spend 35 days in the barn, people working in these barns would be exposed to the dust over longer periods of time during the year with multiple flocks. It’s why one of the big recommendations from everyone on the team is the importance of using personal protective equipment (PPE) while working in the barns.

“We know peat moss creates a dirtier environment,” says Van Heyst. “And we’ve come a long way with biosecurity measures on poultry farms, and this research highlights another step in terms of whole farm

•

•

•

•

management.”

He knows there’s a reluctance by many to wear PPE in barns, but it’s about protecting anyone working in the barn with fitted N95 masks.

Based on the amount of particulate matter found in the lungs of birds on peat moss, the bedding material may not be appropriate for birds that live longer than broilers.

And for those using peat moss, consider a sprinkler system to reduce the amount of dust in the barn.

“The drive for peat moss is largely because of the higher price for straw,” says Dam. “What we found from this project is the choice to use peat moss is about balance. Understand the product, use the correct amount, ventilate barns properly and wear an N95 mask.”

The research team acknowledge there may be benefits to blending peat moss and chopped straw to get the best of both, but that work has yet to be done.

“This project really shows the strength of how to move research forward,” says Van Heyst. “We got the research done and are now communicating the results back out to the industry, closing the circling on knowledge translation to make sure the information gets back to the users.”

Ali continues to make representations on the research findings through the industry. And OMAFA are preparing a new fact sheet to share research results with the poultry sector.

Check out this amazing opportunity to step right into the BC Turkey Industry. This fully operational farm with extensive frontage on 40th Ave and 228 St is being sold with 1,231,888 kgs of BC Turkey quota. The barn is an absolutely immaculate 3 stage turkey barn with tunnel ventilation, Maximus computers, Choretime feeding, lubing watering, tube heaters, Sentinel scales, and more. Pride of ownership abounds. City water for the barn and newly drilled well and hydrants for your field. This is a beautiful parcel of land with plenty of room for expansion as it totals 24.7 acres in a fantastic Langley location. The land is level, cultivated, and awaiting your new Estate home. Call Greg at 604-864-1610 for more information.

Amazing opportunity here to acquire one of BC’s largest commercial Egg farms! This offering is a going concern farm that includes over 86,000 birds of transferable quota (at additional market price) and barns and buildings to house up to 145,000. The newest barn is only 3 years young and can house just under 46,000+ hens in Big Dutchman Enriched housing. Two great homes on the property, management in place, and another huge bonus, the land is located in Abbotsford’s “Special Study Area B” for future Airport Industrial development. This is a great Industry with consistent growth and great long term future potential. Call Greg at 604-864-1610 for more information.

Salmon Arm - Broiler Farm

9.42 ACRE OPERATING BROILER FARM located in the Shuswap, Within the city of Salmon Arm, home 3100 sq.ft with suite in basement, 4 bedroom, 7 Bay equipment shed, Shavings storage, 2-204’ x 40’ Newer Tunnel Barns and 1 40′ x 212’ double-decker broiler barn completely equipped, ziggity water, Cumberland feeders, Chicktron T900 computer system in double decker and Expert 4×4 computer system in the two other barns. City water, Great Location close to lots of outdoor recreation, 24,500 Bird Quota available at market value. Call Gordie Blair at 250-517-0557 for more information.

5.21 ACRE OPERATING BROILER FARM located in the beautiful East Chilliwack, Fairfield Island. Property improvements include a family home, quanset storage, and double-decker barn. The home totals 3,650 sq ft with 2 bedrooms and 2 bathrooms on the main, full basement (partially

Greg Walton, 604-864-1610, greg@bcfarmandranch.com

Blair, 250-517-0557, gtblair@live.ca

Vaccinating against avian influenza is not new. Poultry producers in Mexico have been vaccinating their flocks for nearly 30 years now. In Canada, vaccinating against avian influenza has become a hot-button issue that has no clear answer. In a recent Canadian Poultry webinar on biosecurity, Jean-Pierre Vaillancourt, professor at the University of Montreal, talked through the pros and cons of vaccination, provided an update on the situation in France, and offered insight into what could be involved in a vaccination strategy in Canada.

The pros and cons of vaccination

Around the world, many countries have been vaccinating flocks for years, particularly against the H7 and the H5N2 viruses, and now against the H5N1 virus. Some of the countries that currently vaccinate their flocks against avian influenza include

China, Hong Kong, Indonesia, Mexico, Vietnam and France. The latter began its efforts in October 2023. With less than a year of experience under its belt, France serves as a strong test case for Canada, as the country’s poultry sector discusses whether or not it wants to develop its own strategy.

Vaillancourt laid out the obvious pros to adopting a vaccination strategy during his biosecurity webinar. Protecting animals from mortality, reducing the need for poultry depopulation, and reducing viral excretion and animal susceptibility to infection came out as strong reasons to vaccinate. In recent months, the focus has shifted from protecting animal health to reducing human exposure to avian influenza viruses to protect human health.

At the time of writing, the U.S. Centers for Disease Control and Prevention had just issued a statement reporting three new cases of bird flu infections in Colorado

poultry farm workers, taking the total number of human cases in the U.S. to 13 this year.

“There’s a big growing concern internationally that this virus could become zoonotic,” Vaillancourt says. “It cannot be easily transmitted from infected animals to humans, and it cannot be transmitted right now between humans. But this could change.”

The decision to vaccinate does come with consequences, though, Vaillancourt pointed out. The risk of silent virus circulation in vaccinated poultry populations and potential trade restrictions as strong reasons not to vaccinate.

Trade restrictions are not out of the ordinary. Following France’s decision to vaccinate its duck flocks, both Canada and the U.S. announced trade restrictions. The Canadian government suspended poultry imports from France, but did not extend that suspension to the rest of the European

Poultry Trade Region. At the time of the announcement, the Canadian Food Inspection Agency said it was working with the French authorities to conduct an assessment to evaluate the potential risks of the vaccination campaign.

Vaccination comes at a hefty cost, too, and implementing a robust surveillance program has its challenges. No one knows this better than French poultry producers.

In a recent interview, Jean-Luc Guerin,

an avian virologist based in France, provided an update on France’s ongoing vaccination efforts. Guerin is a man who wears many hats. He is a professor of poultry production and medicine at the national veterinary school in Toulouse (ENVT). He is director of the IHAP joint unit at INRAE-ENVT, a multidisciplinary public research institute for animal infectiology. He is also head of the VIRAL group and director of the avian biosecurity chair. In a nutshell, he understands what Canada is up against should its poultry sector decide to

take the same route.

The first setback France faced was the cost of implementation. The ministry of agriculture projected the annual cost at 104.82 million euro ($157.14 million), 85 per cent of which was to be paid for by the state. Industry paid approximately 15 per cent or 15.7 million euro ($23.54 million) of the overall cost to vaccinate; the state paid the rest.

It wasn’t the vaccine itself that made up the bulk of the cost, though. What really set both industry and the state back was the

cost of supervision and surveillance. Purchasing and getting the vaccine to farms cost the state approximately 27.4 million euro ($41.08 million). Surveillance, including vet visits and lab analysis, made up the rest of the costs. The cost to vaccinate alone amounted to 31.94 million euro ($47.88 million).

During the vaccination process, the birds must be handled by trained catching crews and the vaccination process itself must be supervised by a veterinarian. “You need a lot of manpower with training for this,” Guerin says, adding that it’s important that they’re trained on biosecurity protocol.

The two accepted vaccines, one from Boehringer Ingelheim and the other from Ceva, have two different modes of injection. The latter is injected intramuscularly, which requires specific training. A veterinarian must be present to ensure the vaccination is correctly administered, that any leftover

vaccines are properly disposed of, and the crew strictly adheres to biosecurity and traceability protocols.

But it’s not just the vaccination process that requires the presence of a vet. According to EU regulations, ongoing monitoring and surveillance are required. Passive surveillance is based on the detection of dead birds. Up to five dead birds are tested each week using PCR analysis. Guerin says this proved challenging at the beginning of the campagin, as sampling guidelines needed clarification in order to be properly implemented by farmers.

Active surveillance protocols were in place as well. Veterinarians were required to visit the farm each month to conduct a clinical analysis of the flock. During this visit, they were expected to sample 60 birds using tracheal swabs and cloacal swabs.

“Additionally, we are doing 20 blood samples for serology, and this for all the

vaccinated flocks,” Guerin says. “It’s a lot.”

In total, vets are expected to visit a flock two to three times throughout its life cycle. Guerin says scientists and industry experts are looking for ways to simplify the process without affecting its sensitivity, but that would mean adapting the regulation. To do this, they need to demonstrate that alternative sampling methods are just as effective.

One suggestion is to forgo the tracheal and cloacal swabs and, instead, use a targeted sampling of dead birds, associated with dust samples as is done in salmonella surveillance programs. This type of surveillance could be done without a vet present. It’s quick and convenient, and costs significantly less.

“We need to provide robust scientific data to convince the decision makers, and that’s the most difficult part because I know it is very difficult to change this type of regulation,” Guerin says.

Researchers are also looking into vaccinating at the hatchery level. Because the two accepted vaccines are administered in different ways, they cannot be injected using the same machine.

“It’s not a problem of science,” Guerin says. “It’s a problem of investment and training and strategy based on the choice of the vaccine.”

It’s difficult to know if the investment was worth it, especially given the impact on trade. The official assessment is not yet complete. At the European level, avian influenza cases dropped significantly since October 2023 when France began its vaccination campaign.

Between October 2022 and May 2023, France reported 364 outbreaks. Between October 2023 and May 2024, just 10 cases were reported. Of those, three outbreaks occurred on duck farms. Of those three, one outbreak occurred in a completely vaccinated flock. The other was a very young flock with only one of two injections complete, and the other was a breeder flock that was not vaccinated at all. The other seven outbreaks occurred in turkey and layer flocks.

While the assessment is not complete, Guerin says he’s pretty sure that the vaccination campaign successfully reduced the number of outbreaks.

Location

Humboldt, Sask.

Sector

Layers

The business

Harman Farms is a family owned business founded by the Harman family in the 1960s. Shawn Harman has led the farm for the past decade, along with his wife Rose. The farm operates in Saskatchewan and Manitoba, boasting nine barns, mainly focused on layer production.

The need

The need for a new pullet barn arose to support their aviary system. “We wanted to ensure a consistent and high-quality supply of pullets for our aviary production facilities,” Harman says. Before, they purchased pullets from other growers, but the shift to free-run birds made sourcing them challenging. “We started producing our own in 2020,” Harman explains. Deciding to move forward with the next barn, they worked with Western Ag Systems on their equipment needs.

The barn

The new pullet barn features the advanced Volo BABY AREA system from Valli, designed to prepare pullets for aviary systems. “The hens can be placed in the system and learn how to navigate through an aviary before they’re let out,” Harman explains. This reduces training, minimizing the need to pick birds up off the floor at night. The barn also boasts a tunnel ventilation system with controls by Maximus, manageable remotely. It also includes a Hercules conveyor belt for efficient litter management.

EVERY TUESDAY IN SEPTEMBER | 11:00AM ET

Join our comprehensive webinar series designed to explore opportunities, best practices, and strategies for overcoming challenges in commercial broiler operations. Topics include:

· Understanding condemnations

· Lighting and broiler health

· Risk factors for broiler mortality

· And more!

For just $90, gain invaluable insights from more than four industry experts—all from the comfort of your farm. Plus, enjoy on-demand access to all sessions for future reference.

Webinar Speakers:

Gigi Lin, Poultry Veterinarian

Dr. Karen Schwean-Lardner, University of Saskatchewan Benoit Lanthier, Cobb-Vantress And more!

S T R EN G T H EN Y OU R

R OILE R F L OC K

Reduce mortality

Reduce E. coli associated lesions

Potential to reduce antibiotic use