MODERN.CLEAN.SAFE

Wood biomass heating technology

from Viessmann

Viessmann offers state-of-the-art wood biomass heating solutions for both residential and commercial applications.

Innovative combustion technology ensures high efficiency. This leads to lower fuel consumption and emissions.

Numerous automatic functions ensure comfortable, reliable, and consistently efficient system operation.

Wood biomass heating systems from 37.4 to 4265 MBH

Over 80 biomass system installations across Canada

Residential & commercial applications

Wood-fired biomass heating systems for residential and commercial applications (outputs from 37.4 - 4265 MBH)

CANADIAN BIOMASS

14

Biomass and bandages

BSB builds biomass-fuelled solution for Grand Falls General Hospital. 16 An

education in biomass heating

New Brunswick schools choose biomass boilers for heating the halls. 18

Co-firing China

Beijing is getting serious about biomass power.

Maximizing conveyor operation

Belt basics that can provide enhanced conveyor performance outcomes

24 Pellet Gear Buyers Guide

Canadian Biomass’ annual Pellet Gear Buyers Guide rounds up suppliers of pellet production equipment available for the Canadian industry.

.

WHeating north of 60

e know the majority of Canadians live within 160 kilometres of the U.S. border. I’ve read various stats, most of which peg the number between 70 and 90 per cent. And less than one per cent of the population lives in Canada’s northern territories, which represent about 40 per cent of the country’s land mass.

A few years ago I lived and worked in Fort Smith, N.W.T. – a town of 2,500 a stone’s throw above the 60th parallel. As with almost all northern communities, home heating options in Fort Smith are limited to oil, electricity or wood. Without the luxury of natural gas line and faced with expensive heating oil, many there opt for wood, the laborious but cheapest option.

and consumed locally in the rural areas. These results led the researchers to suggest that many rural communities across North America would benefit from local production and consumption of wood pellets. We’ve published their research report on page 11.

But there are some challenges, the researchers note. Alaska has limited infrastructure needed to harvest, process and dry wood fibre. At the moment there are no commercial wood pellet mills in Alaska. The territories face the same challenges. It goes without saying that this report is good news for Canada’s pellet producers in the domestic market. In the N.W.T. alone 24 per cent of the territory’s market share is nothing to sneeze at.

Volume 17 No. 5

Editor - Maria Church (226) 931-1396 mchurch@annexweb.com

Associate Editor - Tamar Atik (437) 990-1107 tatik@annexweb.com

Contributors - Gord Murray, Andrew Snook, Allen M. Brackley, David Nicholls, Maureen Puettmann, Elaine Oneil, Vaughan Bassett, Michael Cremeens, Dick McConnell, John Marrone

Editorial Director/Group Publisher - Scott Jamieson (519) 429-3966 ext 244 sjamieson@annexweb.com

Account Coordinator

Stephanie DeFields Ph: (519) 429-5196 sdefields@annexweb.com

National Sales Manager Ross Anderson Ph: (519) 429-5188 Fax: (519) 429-3094 randerson@annexweb.com

Quebec Sales Josée Crevier Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@annexweb.com

Western Sales Manager Tim Shaddick - tootall1@shaw.ca Ph: (604) 264-1158 Fax: (604) 264-1367

Media Designer - Alison Keba

Circulation Manager Carol Nixon – cnixon@annexweb.com 450-458-0461

COO Ted Markle – tmarkle@annexweb.com

President/CEO Mike Fredericks

Canadian Biomass is published six times a year: February, April, June, August, October, and December. Published and printed by Annex Business Media.

Publication Mail Agreement # 40065710

The government of the Northwest Territories has been transitioning community buildings in Yellowknife to wood pellets for years. In a 2016 report the government of the Northwest Territories estimated that after the installation of new boilers in 2017, biomass will contribute 24 per cent of the total space heating requirements for the territory. That’s an impressive number for sure.

For the N.W.T. biomass is the affordable heating option, but what about the climate benefits? Two researchers with the USDA Forest Services undertook a study recently that compared the environmental impact of heating fuels in southwest Alaska: heating oil, cord wood and wood pellets. Their research takes into account the entire lifecycle of each fuel.

In all test scenarios, the global warming impact was lower when the solution involved wood pellets. Impact was at its lowest when wood pellets were produced

Beyond that, the research confirms what many consultants and scientists have been saying for years: that wood pellets make sense in Canada, particular in remote, rural areas that aren’t tapped into the natural gas network.

Northerners know it too. In Hay River – a neighbouring community of Fort Smith (In Northern terms at least, it’s about a three hour drive northwest) – an enterprising individual has created a wood pellet dispensary system that can be installed in a home to eliminate the need to carry in heavy pellet bags. Robert Chenard told the Hay River Hub he plans to start selling and installing the new systems soon. Easy, cheap, and better for the climate, heating with wood pellets north of 60 is a natural choice. •

Printed in Canada ISSN 2290-3097

Copy - $9.00 (Canadian prices do not include applicable taxes) USA – 1 Yr $60 US; Foreign – 1 Yr $77 US

CIRCULATION

Tel: (416) 442-5600 ext 3552 Fax: (416) 510-6875 (main) (416) 510-5133 blao@annexbizmedia.com 80 Valleybrook Drive, Toronto, ON M3B 2S9

Occasionally, Canadian Biomass magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission ©2017 Annex Business Media, All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.canadianbiomassmagazine.ca

A

paper company that knows how to save. They spend.

A German paper company that uses electric motors every day experienced excessive bearing damage from their previous grease. By switching to a Mobil SH C™ synthetic grease, the company reduced damage, and saved over $145,000 annually.* Energize your business at mobil.ca/industrial

BIOMASS update

COMMITTEE PROPOSES AMENDMENTS TO EU’S RED II

The environment committee of the European Parliament (ENVI) is suggesting amendments to the European Commission’s proposal on the use of energy from renewable sources (RED II), removing the option for countries that are not party to the Paris climate agreement to demonstrate sustainability of biomass at the forest holding level.

The ENVI committee published two amendments to article 26, paragraph six of RED II, which deals with biofuels, bioliquids and biomass fuels produced from forest biomass. One of the amendments removes the

entire second subparagraph, which was an option for those countries that are not signed on to the Paris climate agreement to provide evidence that management systems are in place at the forest holding level to ensure carbon stocks and sinks levels in the forests are maintained.

If RED II passes with the amendment, it has the potential to prevent U.S. pellet producers from meeting the criteria to export to the EU. U.S. President Trump withdrew from the Paris agreement earlier this year.

Gordon Murray, executive director of the Wood Pellet Association of Canada, said in

GREENFIELD EVALUATES MAJOR BIOFUEL PRODUCTION EXPANSION

Canada’s largest ethanol producer Greenfield Global has commenced a feasibility study to significantly expand operations for sustainable biofuel production at its biorefinery in Varennes, Que.

The first ethanol plant built in Quebec, the Varennes distillery is a model for waste water management and energy efficiency. The plant already produces some of the lowest carbon fuel ethanol in North America and is on its way to becoming part of a state-ofthe-art biorefinery complex. The potential expansion stands to increase its annual ethanol production capacity by 70 per cent (from 170 mly to 300 mly). The feasibility study will also incorporate the adaptation of emerging advanced biofuels technologies using non-traditional feedstocks and processes.

an interview the amendment would be catastrophic for both U.S. and Canadian pellet producers.

“I don’t think there is any doubt the U.S. has a sustainable wood pellet industry. But a technical requirement within the proposal that requires you to be a part of Paris in order to qualify would remove the opportunity for them to demonstrate forest management at the holding level,” Murray said.

“We’re worried that if that ENVI opinion is accepted, it has the potential to destabilize the international pellet market,” he said. “We need the Americans to have a healthy

pellet industry in order for us all to prosper because they make up such a significant amount of the world’s supply.”

Murray said he doesn’t have a clear idea what the likelihood is the amendments will be passed. The ENVI committee is expected to vote on the proposed amendments to RED II in mid October.

RED II (Renewable Energy Directive) is a part of the European Commission’s Clean Energy Package, which, once passed by the European Parliament and European Council, will determine the EU’s clean energy rules up to 2030. The current package expires in 2020.

Enerlab to produce insulation panels using lignin

An insulation manufacturer based in St-Mathieu de Beloeil, Que., has received federal funding for its project to replace petroleum-based raw materials with lignin.

Enerlab 2000 plans to use its iso-lignin technology to produce insulating and structural panels made with lignin from pulp and paper processes. The project is expected to cut Enerlab’s production cost of raw materials by 20 per cent, as well as reduce the company’s environmental footprint.

Natural Resources Canada’s Investments in Forest Industry Transformation (IFIT) program announced today $1.34 million in funding to Enerlab 2000 to support the lignin project.

“Today’s announcement is a further example of our government’s dedication to supporting renewable resources to further the advancement of clean technology in Canada. By using a waste product of the pulp and paper process in place of petroleum-based raw materials, Enerlab is helping address the challenge of climate change,” Michel Picard, MP for Montarville, said in a news release.

NEW NAME, NEW FOCUS FOR CANADA’S LONGESTRUNNING BIOENERGY EVENT

The International Bioenergy Conference and Exhibition is being reborn as the Canadian Bioeconomy Conference and Exhibition.

The new name reflects a growth in the use of woody biomass from legacy industries such as wood pellet production and cogeneration to a full menu of products such as biofuels, biogas, biochemicals, biopharmaceuticals and other bioproducts.

“The original name and mandate were chosen to focus attention on the emerging bioenergy industry in Northern BC and on creating a venue for Canadian wood pellet producers to connect and network with their customers and colleagues in other parts of the world,” explained Jim Martin, chair of the Board of Directors of the conference.

“The bioenergy industry in Canada has grown and matured since we founded the conference in 2004. We felt it was important that, as the leading conference of its kind in Canada, we should reflect the diversification in the use of woody biomass across the full value chain of bioproducts.”

North-Central British Columbia continues to be the largest producing region in Canada of wood pellets, and one of the largest in the world. It is home to Pinnacle Renewable Energy, Pacific Bioenergy and Premium Pellets, as well as to some of the longest-operating pulp mill cogeneration facilities in North America and a number of district energy systems.

But with projects such as the groundbreaking Canfor-Licella biofuels project in conference host city Prince George, the industry is now moving quickly toward new technologies and new innovations in wood-based products that are fuelling the new bioeconomy.

The new conference will continue its predecessor’s legacy of excellence in showcasing the innovation of the companies, organizations and researchers who make Canada a global leader of the bioeconomy.

In addition to being home to numerous pellet companies, pulp and paper and cogeneration facilities, Prince George is also home to a wood-based district energy system connecting eleven buildings through its downtown, including the conference venue. In addition, bioenergy facilities at the Prince George campus of the University of Northern British Columbia are venues for research and have reduced the University’s consumption of fossil fuels for heating by about 85 per cent.

The new Canadian Bioeconomy Conference and Exhibition will take place in Prince George June 6-8, 2018. Register at www.bioeconomyconference.com.

S2G BEGINS WORK ON SARNIA ADVANCED BIOREFINERY

S2G BioChem (S2G) has begun work on the company’s first standalone biorefinery demonstration plant in Sarnia, Ont.

The commercial-scale facility will refine local, sustainable forestry and agricultural residues using S2G’s patented process to produce food ingredient xylitol available on the market today while co-producing value-add bioglycols for a new generation of consumer, industrial and packaging and products.

“This is a very exciting time for S2G BioChem as we begin to execute our growth strategy to generate revenues from the production of fossil-free, value-add products,” Mark Kirby, president and CEO of S2G Biochem, said in a news release. “Locating this new biorefinery in Canada is important as its high efficiency and use of sustainable feedstocks will reduce greenhouse gas and effluent emissions. We will bring increased revenue to local feedstock suppliers; and we will gain invaluable experience before replicating this high-yield facility throughout North America and the rest of the world. The support from Bioindustrial Innovation Canada is an important step in securing funding for the project.”

The biorefinery demonstration plant, projected to cost $20 million, will be funded by S2G and a network of investors and partners, including previously announced support from food giant Mondelëz International, who shares the vision and value of this renewable energy project. Funding will be provided by Bioindustrial Innovation Canada’s Commercialization of Sustainable Chemistry Innovation fund (COMM SCI).

The biorefinery will have the capacity to produce over 2,000 MT/year of high-value xylitol and coproducts utilizing a range of feedstocks from forestry and agricultural residues.

Basic engineering for the facility is underway and construction is expected to begin in 2018.

RENTECH TO CANCEL REMAINING SHIPMENTS TO DRAX

Rentech is in the midst of negotiations with U.K. utility Drax to cancel its outstanding wood pellet shipments for 2017, which amount to 193,000 metric tonnes, the company said in its quarterly report.

Rentech idled its Wawa, Ont., facility and lowered production at its Atikokan, Ont., facility earlier this year in response to equipment and operational issues.

The pellet producer has since emptied its Wawa facility to deliver 12,000 metric tonnes of pellets to Drax,

and is now looking to cancel its remaining obligation of 193,000 metric tonnes for this year.

“We are currently negotiating with Drax to cancel the remaining shipments in 2017. At this time, we cannot make a determination if any penalties will be associated with future changes to the contract. Rentech, Inc. has guaranteed the payment obligations of the Drax contract up to a maximum amount of CAD$20 million,” the company stated in its quarterly report.

Domestic support

SGovernment organizations contribute to the success of Canada’s pellet producers

By Gord Murray, WPAC executive director

ince 2010, Canadian wood pellet exports have increased by 240 per cent, from one million tonnes in 2010 to 2.4 million tonnes in 2016. Last year’s exports totalled $408 million. Pellet producers have invested in new plant capacity, employed more people and paid more taxes while continuing to grow an industry using a raw material that was formerly a waste product of the sawmill industry.

Obviously, the lion’s share of credit must go to pellet company owners, investors, and management for leading the way. However, not many people know that two government organizations have played a key role in our industry’s success, namely Natural Resources Canada (NRCan) and Forestry Innovation Investment (FII).

NRCan and FII each manage programs that support the export marketing efforts of Canada’s forest industry, including the wood pellet sector. NRCan operates the Expanding Market Opportunities Program (EMO) with the goal of maintaining and growing international forest product markets while promoting Canadian forest products as an environmentally responsible choice. Projects funded under EMO are cost-shared with industry and provincial government partners. FII operates the Market Initiatives Program (MIP). FII is the B.C. government’s market development agency for forest products. FII works with industry and the federal government to help maintain, create and diversify markets for B.C. forest products. FII’s MIP encourages the development of export markets and new market segments so as to diversify the forest industry and sustain employment. Like NRCan’s EMO, MIP-funded projects are cost shared

with industry and other levels of government.

Each year in November, NRCan and FII co-operate in calling for proposals from industry associations for the following year’s export marketing projects. Proposals are reviewed by an advisory panel that includes NRCan and FII representatives, as well as independent forest industry experts. Since 2010, WPAC has participated in the annual call for proposals and has successfully obtained funding for export marketing initiatives in Europe and Asia. Usually these projects are cost shared 40 per cent by NRCan, 30 per cent by FII, and 30 per cent by WPAC. Total annual spending has been about $200,000.

Some of the WPAC projects that NRCan and FII have supported include:

• WPAC’s participation in the organization and execution of international wood pellet conferences in Europe and Asia where we meet regularly with existing and prospective customers, we monitor our competitors, and promote Canada as a source of high-quality, sustainably-produced wood pellets;

• WPAC’s participation in developing the ENplus wood pellet quality certification program and our continued engagement in ENplus governance;

• WPAC’s participation, together with the US Industrial Pellet Association and the European Biomass Association in negotiations with European power utilities regarding standard contracts, industrial pellet standards, and sustainability certifications;

• WPAC’s participation, together with the US Industrial Pellet Association, the UK Renewable Energy Association and the European Biomass Association,

and with our power utility customers, in operating pro-biomass campaigns in Europe and the U.K. and our engagement in impacting the post2020 EU Renewable Energy Directive that will set the rules for bioenergy for the following 10 years;

• WPAC’s negotiations with the South Korean government to change shipping documentation rules so that Canadian wood pellets could be legally shipped to that country after being temporarily halted;

• WPAC’s promotion of Canadian forest management certifications to the Government of the Netherlands and Dutch NGOs so as to open that market for wood pellet co-firing;

• WPAC’s organization of trade missions to Italy, Ireland, and the U.K.;

• Completion of a study on the emissions of gases from wood pellets in ship holds and convincing the International Marine Organization to change its rules regarding fire extinguishing systems on ocean vessels;

• Completion of a study on the phyto-sanitary characteristics of wood pellets so as to ensure that Canadian wood pellets are not considered as a pest hazard in export markets;

• WPAC’s participation in a major European torrefaction research known as the SECTOR Project;

• WPAC’S chairing and participation on an ISO committee to establish uniform international procedures for the physical and chemical testing of wood pellets;

• WPAC’s cooperation with allied international pellet associations and European power utilities in completing a peer-reviewed study on the sustainability and carbon balance of wood pellets;

• WPAC’s participation on an advisory board with European universities and research institutions to establish recommendations to the European Commission regarding guidelines for the development of a European Bioenergy Trade Strategy for 2020 and beyond; and

• WPAC’s development of a safety data sheet for bulk and bagged wood pellets.

As part of their call for proposals, NRCan and FII each set out the annual objectives for each program. Project proponents are advised to have their own strategic marketing plans. Proposals

•

•

•

•

•

•

•

TC-15 TREE CHIPPER

are required to show how they comply with such NRCan and FII’s objectives, how they align with strategic marketing plans, and must include measurable indicators of success. Successful applicants are required to enter into written contracts with NRCan and FII and to submit financial and project reports every four months.

FII and NRCan conduct financial audits on a sample of industry associations each year to ensure that money is spent strictly in accordance with the contracts. Since the 2011/2012 fiscal year, NRCan and FII have audited WPAC’s program expenditures approximately every second year – sometimes two years in a row, but never more than three years between audits. Currently NRCan and FII have engaged an independent consultant for a detailed program review of the effectiveness of WPAC’s activities over the past five years. While all this reporting, auditing, and reviewing can be painful for us, I have to admit that it helps WPAC to keep a laser focus on complying with our contracts and on meeting the NRCan and FII’s objectives.

We know that government programs can come and go as priorities change with time. Both NRCan’s Expanding Market Opportunities Program and FII’s Market Initiatives Program have been working successfully for about 15 years and we urge both the Government of Canada and the Province of British Columbia to continue their programs for the long term. Certainly, these programs have been highly beneficial to the wood pellet sector as evidenced by a 240 per cent increase in exports since 2010 and with every indication that such growth will continue. And, of course, the Canadian and provincial governments have benefited financially and will continue to benefit though the resulting increases in corporate and personal income taxes, GST, provincial sales taxes and so forth. •

Heating the North

Using wood energy for residential heating in rural regions

By Allen M. Brackley, David Nicholls, Maureen Puettmann, and Elaine Oneil

Southeast Alaska is a remote island chain, located about 1,100 kilometres north of Seattle, Wash. Most of the region’s goods are imported by barge, creating logistical and economic challenges not faced by many other parts of the U.S. This also applies for many types of wood products. Although the region is heavily forested (including the 17 million acre Tongass National Forest), there are no commercial wood pellet mills capable of supplying the region’s needs. Thus, pellets for residential heating must be imported, often from Washington or Oregon. Given the long shipping distances, and the need for fossil fuels to power barges, the net environmental benefits are uncertain, and worthy of further analysis. It is within this context that we used life cycle assessment to evaluate the environmental impacts on global warming potential associated with converting home heating systems from heating oil to wood pellets in southeast Alaska.

SOUTHEAST ALASKA CONTEXT

Limited industrial development makes it necessary to import almost all goods into southeast Alaska, primarily by barge. Accounting for carbon associated with heating oil, for example, must include the carbon chemically bound to the product, as well as the carbon resulting from the energy to move the raw product from the north slope of Alaska to Seattle where it is refined and the transportation back to southeast Alaska where it is consumed. Accounting for these energy flows is an important part of comparing alternatives in life cycle analysis.

When planning wood energy applications, it is often desirable to quantify the environmental impacts of harvesting, transporting, and combusting woody biomass compared to alternative fuel sources (typically fossil fuels). Over the past 10 years, close to 10 small industrial scale wood energy systems established in southeast Alaska. Although most of these

systems are small (typically burning less than 100 cords of wood or 1,000 tons of chips per year), the cumulative effect is substantial for the rural communities served. This motivation guided our research to perform life cycle assessment on region-wide wood energy use for residential heating under scenarios that compare local fuel production to wood fuel being transported from the continental U.S.

RESEARCH OBJECTIVES

Our research objectives were to evaluate the environmental impacts of residential fuel scenarios in southeast Alaska, including:

1. importing wood pellets into southeast Alaska from the Pacific Northwest, versus

2. local production of wood pellets in southeast Alaska to supplement current cordwood use.

We compared heating oil, current cordwood use in southeast Alaska (status quo),

The Alaska landscape is characterized by remote mountains,

Photo by David Nicholls.

and the substitution of heating oil versus use of wood pellets. Two scenarios were explored for wood pellet use: imported pellets from Washington state, and local pellet production in southeast Alaska.

LIFE CYCLE ASSESSMENT MODEL DEVELOPMENT

Life cycle assessment quantifies every stage in a product’s life and its interaction with the environment. The outcomes of a life cycle assessment can accurately target the source of environmental impacts throughout a product’s life. In this research we used life cycle assessment to evaluate residential heating scenarios that included heating oil, cordwood, and wood pellets. We considered use of pellets, heating oil, and cordwood energy for residential heating. We followed the methods in the ISO 14000 standards (https://www.iso.org/) and used Sima Pro software version 8.03 (https://www.pre-sustainability.com/).

Environmental impacts were quantified for global warming potential, smog, eutrophication, and acidification using the North American “Tool for the Reduction and Assessment of Chemical and Other Environmental Impacts” (TRACI). Once the current level (status quo) was established, we evaluated imported pellet utilization at 20, 40 and 100 per cent penetration into the residential heating oil markets. We also modelled wood pellets that were produced and consumed in southeast Alaska, assuming a 20 per cent penetration into the residential heating market.

We considered wood pellet production from both undried and dry mill residues from softwood lumber produc-

1/ as a percentage of non-cordwood energy use for residential heating

2/ as a percentage of Scenario 1 heating oil use for residential heating

tion in the Pacific Northwest and also from whole tree chips. The base model assumed that pellets were first produced in the Seattle, Washington area then shipped by barge from the Port of Seattle to the Port of Ketchikan, Alaska, then by barge to destination communities within southeast Alaska, and finally by truck for local delivery. Our analysis was based on modelling assumptions for pellets, cordwood, and heating oil, which included specifying moisture content, heating values, and stove efficiencies (Table 1).

Transportation flows for cordwood, heating oil, and imported pellets were determined as well as distances transported both regionally and locally. Our model assumed that locally produced pellets would be shipped by barge to Ketchikan, and then distributed to destination communities similar to imported pellets. Net global warming potential was calculated by subtracting the CO2 absorbed during tree growth from the total CO2 emissions (both fossil and biomass based), using the TRACI version 2.1 method within SimaPro.

KEY FINDINGS

Scenario 1 (the base case), modelled heating oil and cordwood current use (status quo) for home heating in southeast Alaska, but assumed no use of wood pellets. For Scenario 1, net GWP for cordwood was 3,568 tonnes CO2 eq., while for heating oil the net GWP exceeded the total GWP for cordwood at 181,822 tonnes CO2 eq. (Table 2). In Scenario 2, residential cordwood use remained constant, while 20 per cent of household energy from heating oil was substituted with wood pellets. The pellet

production for this scenario originated from a hypothetical pellet plant located in the vicinity of Seattle, Washington. The total global warming potential for southeast Alaska under this scenario was 166,491 tonnes CO2 eq, a 10.2 per cent decrease versus the base case (Table 2). In Scenario 3 wood pellets represented 40 per cent substitution of heating oil use for residential heating. Under Scenario 3 the net global warming potential was lowered by 20.5 per cent versus scenario 1 (Table 2). When wood pellets were 40 per cent of the heating oil energy use, total global warming potential for pellets was slightly above that for heating oil (109,163 tonnes CO2 eq. for heating oil and 125,337 tonnes CO2 eq. for pellets). Scenario 4 assumed that 100 per cent of non-cordwood residential energy demands were met by imported wood pellets. This scenario produced a net carbon benefit by reducing net global warming potential in southeast Alaska by 51.0 per cent from Scenario 1 (Table 2).

Total primary fossil energy consumption decreased 38 per cent from Scenario 1 while total primary fuels only decreased by 16 per cent. Scenario 5 was the only one to consider local pellet production in southeast Alaska. The primary distinction between Scenarios 5 and 2 is the need in Scenario 2 for pellet transportation by barge from Seattle, Wash., to Ketchikan, Alaska. Here a reduction of 14.0 per cent in GWP was realized by replacing only 20 per cent of the heating oil use with local pellet production (Table 2). Locally produced pellets reduced global warming potential only four per cent versus imported pellets under the same usage level.

Table 1. Life cycle assessment modeling scenarios for energy system comparisons

Remote Alaskan sawmills often do not have viable markets for wood residues (background), and wood energy provides an excellent outlet. Photo by David Nicholls.

ALASKA SUMMARY

AND NATIONAL PERSPECTIVES

Wood pellet use for residential heating in southeast Alaska was evaluated as a cradle-to-grave life cycle analysis. When comparing the global warming potential of pellets, locally produced cordwood, and heating oil, we found that global warming potential was lower for all scenarios that included wood pellet substitution. These findings support the environmental advantages of increased use of wood fuels in southeast Alaska for residential heating. Environmental benefits can be further enhanced when wood pellets are produced locally to alleviate the transportation burdens due to importing goods to southeast Alaska. These findings are important because locally produced and utilized wood pellets could provide economic benefits to communities in addition to the environmental benefits described earlier. However the limited infrastructure needed to harvest, process and dry wood fibre would first need to be expanded. In the meantime, importing pellets from the lower 48 could be a bridge strategy, after which all forest growth, processing, and bioenergy utilization could occur in southeast Alaska.

Forest resource use is a continually evolving issue in southeast Alaska, and estimating future timber harvest and the availability of material suitable for energy use in southeast Alaska has large uncertainties. The Tongass National Forest transition to young growth is underway, and over the next few decades this resource, and its ability to generate wood energy feedstocks in the form of harvesting residues, small diameter timber, and sawmill residues, will have a major impact on the regions ability to locally produce forest products. Therefore wood energy utilization will continue to be important in creating markets for forest residues from sawtimber.

From a national perspective, many rural communities could benefit from similar strategies in which wood energy products are produced and consumed locally. For example, throughout the western U.S. many sawmills generate significant residues that could be used for fuel. Further, wildfire mitigation thinnings are creating large volumes of in-woods residues that could potentially be used

Table 2. Total global warming potential,

1 Cordwood

2

3

locally. And, in the southeast U.S. large pellet mills are producing large quantities of wood pellets, some of which could be used locally. •

Allen M. Brackley, Ph.D., is currently a research forester located in Sitka, Alaska as part of the USDA, Forest Service, Pacific Northwest Research Station Goods, Services, and Values Team.

David L. Nicholls, Ph.D., is a Forest Products Technologist with the USDA Forest Service, Pacific Northwest Research Station, and is based in Sitka, Alaska.

Elaine Oneil, Ph.D., is the Executive Director of the Consortium for Research on Renewable Industrial Materials, a position she has held since 2009.

Maureen Puettmann, Ph.D., is the owner of WoodLife Environmental Consultants, LLC.

Biomass and bandages

BSB builds biomass-fuelled solution for Grand Falls General Hospital

By Andrew Snook

Formany of the people who reside in the northwestern region of New Brunswick, the name Groupe Savoie is well known. In addition to being a major employer in the area, the specialty hardwood products manufacturer is very active within the communities it operates and runs Fondation Hector Savoie, a non-profit organization that assists low-income families throughout northwestern New Brunswick.

One of the ways the foundation assists people is by paying for their trips and meals to and from hospitals when they need to travel to receive treatments for various ailments. One of those hospitals is the Grand Falls General Hospital in Grand Falls, N.B., located just over 70 kilometres south of Groupe Savoie’s headquarters in Saint-Quentin, N.B.

In 2013, the Province of New Brunswick was looking for a solution that would replace the hospital’s outdated oil heat boiler system – which was burning more than 300,000 litres of oil annually – while reducing the facility’s greenhouse gas emissions. The province decided to put forth a pilot project that would have the hospital replace its primary oil heat unit with a biomass boiler system, which opened up a new market for the local forestry sector’s wood residuals. The contract for the project ended up being awarded to Biomass Solutions Biomasse (BSB), which is a partnership company formed by Groupe Savoie and Compact Appliances out of Sackville, N.B.

The BSB team was well equipped to provide a biomass-fuelled solution. Groupe Savoie are a major producer of wood pellets in

New Brunswick. The pellets are created from the residuals of the company’s wood product plants in New Brunswick and Nova Scotia, which process more than 430,000 cubic metres of hard maple, red maple, aspen yellow and white birch harvested from a combination of Crown lands and private wood lots.

The contract for the project was awarded and confirmed in January 2013 with construction starting in August 2013 and commissioning taking place in January 2014.

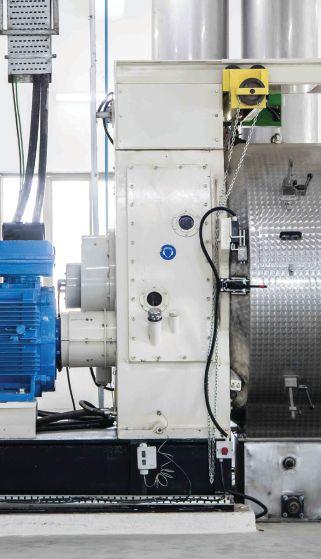

BSB decided to go with an 850kW Binder biomass boiler for the primary heat at the hospital.

“The capacity of the proposed boiler was based on fuel consumption information provided from our discussion with existing oil boiler operators and historic oil consumption,” explains Théo Losier, development agent for BSB and Groupe Savoie. “The objectives were to obtain a viable conversion project and attain the adequate heat load requirement demand for the hospital.”

Losier says that the Binder boiler chosen for the project uses the latest in moving grate technology and provides advanced combustion performance complete with automatic de-ashing, flue gas recirculation and clean air emissions.

“This system included a large buffer storage tank properly sized for the application at hand,” he says. “Boiler controls included a tank management system for optimum boiler performance and efficiency. The actual customer heat usage is monitored using a BTU meter located inside the hospital, which measure the hospital heating demand by gigajoules.”

Grand Falls General Hospital’s new boiler system consumes about 400 metric tonnes of wood pellets annually, displacing more than 300,000 litres of heating oil.

Since its installation, the average annual wood pellet consumption for the boiler system has been about 400 metric tonnes.

PROJECT CHALLENGES

Several challenges needed to be overcome for the successful completion of the pilot project. Losier says those challenges included sizing a hot water boiler based on a historic fuel consumption with a steam boiler; sizing the buffer tank to obtain a maximum efficiency when you have different theory of measurements per kilowatt; sizing the boiler room building; and designing the building to meet heating efficiency targets while meeting the targeted budget cost.

This was the first time BSB had worked on an installation project that involved a Binder boiler, which are manufactured in Austria. Losier says his team relied on Binder to help guide the project along when it came to the boiler concept and accessories needed to get the most efficient heating system for the heating demand.

Meeting all the necessary requirements to meet ASME and CSA certification standards was also a challenge, Losier adds.

BSB decided to go with an 850kW Binder biomass boiler for the primary heat at the hospital.

GREEN OPERATIONS

In addition to displacing more than 300,000 litres of heating oil annually, Groupe Savoie ensures that the fibre harvested from Crown lands for its wood products plants is done so in accordance with environmental regulations and the principles of sustainable development.

“The ISO 14001 and SFI [Sustainable Forest Initiative] certifications provide assurance of resource renewal for future generations and clearly attest to Group Savoie’s commitment toward the environment,” Losier says.

With the Grand Falls General Hospital no longer dependent on fossil fuels for its primary heat and a new market generated for New Brunswick’s wood pellets, this pilot project is helping the province soar to new heights in terms of GHG reduction levels while helping stimulate the local economy. •

• Warm water boilers, hot water boilers, steam boilers

• Boilers for non-standard fuels

• Hot air (drying) systems

• Thermal oil systems

• CHP-systems

The Canadian specialist for renewable energy systems

BSB

251, Route # 180, Saint-Quentin, NB. Canada. E8A 2K9 T 506 235-2228

theo.losier@groupesavoie.com www.bsbheating.com

An education in biomass heating

New Brunswick schools choose biomass boilers

By Andrew Snook

TwoNew Brunswick high schools are receiving an education in biomass boiler heating systems thanks to an initiative by the province to reduce its carbon footprint and promote the use of locally sourced wood.

Sussex Regional High School in Sussex, N.B., a school of approximately 741 students ranging from Grade 9 to Grade 12, and Caledonia Regional High School in Hillsborough, N.B., which has approximately 310 students ranging from Grade 6 to Grade 12, both had the same issue that needed to be addressed: aging oil-heat boiler systems that required replacement. Instead of purchasing new oil-fired units, both schools opted to take advantage of the province’s Green Building Policy, under the direction of DTI (Department of Transportation and Infrastructure) and replaced a significant portion of their fossil fuel load with biomass-fuelled boiler systems.

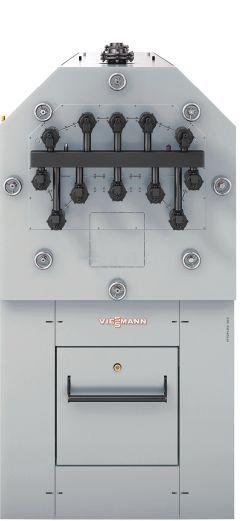

After a thorough bidding process, the biomass projects were awarded to Thomas Industrial Sales, a local company headquartered in Fredericton, N.B. that has been servicing Atlantic Canadians since 1968. For both boiler replacement projects, the company opted to install Viessmann Vitoflex 300-RF 540kW biomass boilers. The boilers for the two projects were delivered in March 2016 with commissioning taking place in the fall of 2016.

The biomass boilers now serve as both schools’ primary heat sources, replacing their older oil-fired units that still serve as backups in case additional heat load is needed during harsh winters, or the biomass boilers are down for routine maintenance or require servicing. The biomass systems heat the schools through a mixture of forced air hydronic heating coils and hydronic heaters at entryways. Neither school had any modification to the heat distribution system.

Although still early into their use, the biomass boilers have been extremely successful to date in reducing the amount of oil being burned. Daron Thomas, president of Thomas Industrial Sales, says the schools have significantly impacted the burning of heating oil, with the Caledonia School achieving a reduction in oil consumption of about 95 per cent.

Thomas says both installs went fairly smooth with a few minor hurdles to overcome at the Sussex project.

One challenge that came up during the project was a bylaw prohibiting the burning of solid fuels in the Town of Sussex.

Thomas says there was some concern at first in regards to burning wood pellets, but Steve Tweedie of TACE, the design engineer, met with town officials and ensured them the emissions levels exceed all required federal and provincial legislation, and is cleaner than many fossil fuels. The Viessmann unit was tested and no emissions or air quality issues were discovered, during commissioning.

“It was a $1-million investment in the community that uses New Brunswick provided energy,” says Thomas.

Although pellet silos might look out of place in some areas of the country, Sussex isn’t one of them. Thomas says attaching the 60-ton wood pellet silo to the school did not look out of the place in the area, since the town is the self-proclaimed dairy capital for Atlantic

The biomass boiler system at Sussex Regional High Scool includes a 60-ton wood pellet silo.

Canada and silos are commonplace throughout the region.

Installing the biomass boiler system in an existing mechanical space is a difficult endeavour so both schools had the boiler system installed in its own separate building next to the school. This allowed for “clean slate” design for Tweedie and DTI, whom took advantage of the additional space and doubled the size of the buffer tank, allowing for longer run times that increased the efficiency of the biomass boiler.

“It’s just shy of a 10,000-litre tank,” Thomas says.

A remote monitoring panel was installed in the existing mechanical rooms, and Ethernet connection to the biomass panels allow for remote monitoring, and adjustments, to optimize the operation.

Jurisdictional codes including ASME, CRN, CSA, ULC, are priority. Controls, motors, and electrical panels require CSA approval and labelling, and the boiler package must adhere to strict CSA package approvals.

“Biomass technology might be new but the rules and regulations are in place and enforced, like any other heating appliance regardless of the fuel,” Thomas says, adding “The province of New Brunswick has a requirement to ensure compliance to all codes.”

Thomas Industrial Sales were not the only locally sourced company for the projects. Groupe Savoie, which is based in SaintQuentin, N.B., supplies the wood pellets for the biomass boilers; and the mechanical contractors for the projects were local too –with Silvio Landry of Georges Plumbing & Heating of Moncton

looking after the Hillsborough project, and Ian Flowers of Master Mechanical of Saint John, looking after the Sussex project. By keeping he projects sourced locally, the province has been able to reduce its carbon footprint while supporting its mechanical and wood products industries, a winning combination. •

For the latest news, equipment and project profile features, visit www.canadianbiomassmagazine.ca.

WOOD PELLETING PLANTS

AMANDUS KAHL USA Corp. 105 Hembree Park Drive, Suite L Roswell, GA 30076, USA 001-770-521-1021

sales@amanduskahlusa.com akahl.us

KAHL GmbH & Co. KG SARJ Equipment Corp. 29 Golfview Blvd Bradford, Ontario L3Z 2A6, CANADA 001-905-778-0073

rbmacarthur@sympatico.ca

Instead of purchasing new oil-fired units, two high schools in New Brunswick replaced a significant portion of their fossil fuel load with biomass-fuelled boiler systems.

Co-firing China

Beijing is getting serious about biomass power

By Vaughan Bassett

Chinahas been a bit of a mystery to Canadian wood pellet producers. The Canadian wood pellet industry has traditionally relied on the European power market and more recently has penetrated Japan and South Korea. From time to time we have had casual inquiries from potential Chinese buyers, but nothing serious materialized. We believed that with its large population, its reliance on coal, and its insatiable energy demand, China would eventually see the benefits of using wood pellets to lower GHG emissions and reduce pollution. On June 7 to 8 I travelled to Beijing to attend a two-day biomass co-firing workshop and to promote Canadian wood pellets.

The workshop was organised by the

IEA Clean Coal Center in conjunction with the China Electric Power Planning & Engineering Institute (EPPEI). There were about 320 attendees, representing government, utilities (the Chinese being all state owned), universities, various think tanks, technology providers, consultants and biomass interests.

It was gratifying to see that the Chinese government has taken its pollution issue so seriously. In its 13th 5 Year Plan (2016 to 2020), China intends to achieve an electrical mix that includes 20 per cent “non-fossil fuel” with an overall target of emitting less than 550g CO2 per kWh of electricity produced. The cynical will see that their categorisation as non-fossil, would catch everything including hydro and nuclear, so the 20 per cent target is

perhaps not as meaningful as it could be. However, the same 5 Year Plan targets 50 per cent non-fossil fuel by 2050, and whilst this might be a long time in the future, this is a very meaningful number that will require biomass in the mix in a serious way.

The electrical capacity in China is currently 1,650 GW, of which biomass currently makes up 0.7 per cent (12 GW), so lots of room to grow. At a 25 per cent cofiring rate (a high-side number), this could become 275 GW for example. Coal is used to fuel about 1,100 GW of the national grid. The 5 Year Plan also contemplates running about 100 demonstration plants to kick off the co-firing of biomass. Some of these have already started.

As the discussions and presentations took place, it was clear that wood pellets

were the best technical and logistical biomass option. However, the subject is politically sensitive. The issue in China today is that they claim that a significant portion of their particulate pollution comes from farmers burning their stover/stalks after harvesting. Therefore, the Chinese government is trying to kill two birds with one stone by co-firing these agricultural residues to both lift the Chinese nonfossil percentage, whilst simultaneously addressing the farmers’ pollution problem. A beneficial side effect of this strategy is that by providing farmers with another revenue stream (for their biomass), the government hopes to arrest the human migration from rural into urban areas. So the emphasis in China is currently on agricultural biomass. They believe that there are some one billion tons of the stuff available, which theoretically could fuel their entire electricity requirement. So another political objective is for the country to reduce its energy dependence on imports, which is already low in percentage terms.

On the technical front, there was consensus that direct co-firing of these agri residues would create slagging and fouling of the boiler tubes and associated de-rating of the boilers. The root cause of this ash deposition has been identified as high alkali elements (mainly potassium) combining with chlorine in the fly ash. Apparently this can be mitigated by the introduction of sulphur in the boiler. To avoid this issue altogether however, they

are looking hard at first gasifying the biomass, then co-firing the gas indirectly.

In addition, there is the issue of logistics. A university study suggested that if every power plant were given a 50-kilometre collection radius around itself, it could secure enough agricultural biomass to cofire at the required level, albeit seasonally. However, this would require the physical movement of huge amounts of biomass. The cutting and hauling requirement alone is daunting, never mind the storage required at either end.

Wood pellet imports are currently banned (to keep the focus on domestic agricultural residues), but it seems that if the Chinese government wishes to get really serious about biomass, wood pellets cannot remain in banned indefinitely. It might take a while, but expect to see changes in policy in this respect.

NICE TOUR

The international contingent was invited to visit a research institute called NICE, an anagram for National Institute for Clean and low carbon Energy, situated on the campus of Shenhua Group, China’s largest mining and energy company. Shenhua is state owned. It started as a coal mining company, but has diversified into power and transportation. Today it runs the country’s largest fleet of coal fired thermal power stations, owns 2,000 miles of railroad and a couple of ports. The company has made huge investments in wind and solar, which currently amount to 7GW of its 80GW

capacity. Shenhua is in discussions to merge with two other large state-owned utilities, which will probably make it the largest power company in the world.

Shenhua is not focused on biomass cofiring. Many of its thermal power stations are in the north (near its coal mines) and reasonably removed from any material biomass sources. It is growing its renewable portfolio in wind and solar and is doing a lot in hydrogen. The company will supposedly be rolling out 300 hydrogen filling stations across the country in the next five years. However, at some stage post-merger (due to size alone), Shenhua is likely to become a target of government pressure to co-fire. Its generally poor proximity to agricultural residues could make it an ideal candidate for imported wood pellets. Furthermore, Shenhua’s port ownership should help the logistics of importing wood pellets once that ban is lifted.

Shenhua set up NICE in 2009 initially to find new commercial applications for coal. It has an imposing line up of technology, from mass spectrometry labs to a FischerTropsch pilot plant. Its efforts have lead to the discovery of an ultra-strong plastic, a revolutionary water treatment process and a quick charging soft carbon battery technology, amongst others.

This visit was an impressive window on what is possible in China today. Despite the easy rhetoric, we would be wise to not discount the Chinese efforts and we should continue to pay close attention to what is going on there. •

Maximizing conveyor operation

By Michael Cremeens and Dick McConnell

Seeingvs. understanding – a common conundrum when it comes to truly understanding challenges. When applied to conveyor operation, “seeing” is most commonly expressed as, “That’s the way we’ve always done it,” or, “This is the way I was taught.” Not necessarily wrong, but perhaps not completely right either.

In contrast, when we have an “understanding” of the events occurring during effective conveyor operation, maximized performance can be achieved. From belt construction, to structural composition to splicing considerations, having fundamental knowledge (or understanding) can provide enhanced belt performance outcomes.

GETTING TO KNOW YOUR BELT

Belt selection is critical. Knowledge of the workload expected, pulley diameters on the structure, troughability, load support/ transverse stiffness, impact loads, and rubber compound requirements are but a few of the prerequisites of choosing the right belt. If this sounds a little overwhelming, be advised that you need not worry; every key belt manufacturer representative can walk you through these parameters.

The bigger issue, especially in the North American market, is the broad brush of belt specifications.

UNDERSTANDING BELT CONSTRUCTION

Key components of a belt include the fabric, skim coats, and adhesions (collectively known as the carcass). This is the backbone of the belt. The carcass does all the work involving carrying the load, cycling from peak to low operational tension, and performance longevity. The other key component is the top and bottom covers. They are there to protect the carcass. Different compounds are available to meet the needs of application.

The North American market unit of tension is measured in pounds per inch of width (PIW). The plies of fabric, usually made of nylon or polyester, have a rated tension. Common fabric tensions are: 110 lb., 125 lb., 150 lb., and 200 lb. So, adding the number of plies with the rated fabric strength provides the belts rated tension in PIW. For example: three plies of 110 lb. fabric equals a belt rated at 330 PIW. This is the rated tension – a key component in belt selection.

But, here’s the issue and one that is recommended to be resolved. The belt also has a safety factor. The service factor

of the carcass is directly proportionate with the safety factor. Higher quality belts will have a 10:1 break strength or higher while lower-end belts can be 6:1 or less. Independent pull tests can verify the break strength.

TRANSITIONS AND YOUR BELT

Now that you know belt construction and conveyor drive system affect performance, what other operational considerations are in play? A prominent part of conveyor design, one for which the conveyor belt is engineered to accommodate, is the transition distance. Located at the load zone, or tail section, and the discharge point, or head section, the transition distance is the dimension from the top of the respective pulley to fully troughed. In other words, the distance from the top of the tail pulley (at the load zone) to the first full troughed idler set (usually 35 degrees or 45 degrees).

Conveyor belts are designed to stretch into these troughed positions while carrying loads. However, meeting or exceeding the recommended distance in this transitioned area is critical to maximizing belt life. Violating this specification will result in premature fatigue. This will be represented in the form of belt cupping (curved belt edges identified on return idlers), wear patterns in top and bottom covers following the load side idler junctions (the space between the flat centre roller and the two canted rollers), and, most damaging, extreme compression folding of the centre of the belt at the transition. All of these preventable events can cause tracking issues, premature splice failure, and will abbreviate belt life. (See full trough transition table)

There is a relationship between the length of transition distance and the percentage of the belt’s rated tension. This means we need to understand the operating tension of the belt. There are several sophisticated ways to calculate the operational tension; your chosen belt manufacturer can make these available. By knowing the percentage of the belt’s rated tension versus the operational tension, belt performance can be maximized once again. Ideally, operating a belt at 50 per cent to 60 per cent of rated tension is desirable. (See full-motor method table.)

3.26.8 60to902.45.2 Lessthan601.83.6

48 60to903.26.4 Lessthan602.44.4

One quick check method is referred to as the motor horsepower calculation. This presumes 100 per cent of the horsepower on the nameplate of the motor can be engaged in the drive system. As such, this is a conservative means to calculate operational tension.

OPERATIONAL VS. RATED TENSION

(See NIBA – minimum pulley diameters table.) The percentage

CONVEYOR DRIVE SYSTEMS AND BELT PERFORMANCE

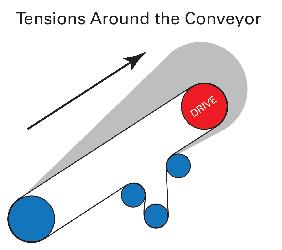

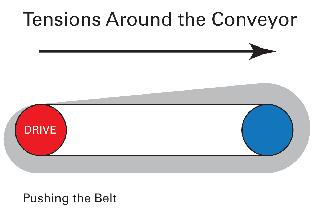

The operation forces of any conveyor directly affect belt performance. The following illustrations demonstrate how drive systems affect the load stresses on the belt. Obviously, higher quality belt will cycle longer and with greater performance value. A simple, flat, single head pulley drive conveyor has a basic force pattern. The tension escalates toward the head pulley. As the belt discharges the load, the tension profile is returned to a neutral tension.

of operational tension to rated tension affects several key performance characteristics. As mentioned, transition distance recommendation is decreased as the operational percentage is lowered. The same goes with recommended minimum pulley diameters. This includes any pulley in the conveyor system having more than 90 degrees of wrap. The head pulley, tail pulley, and gravity take up pulley are included in this consideration. On higher percentage operating PIW belts, especially when inclined, the bottom side bend pulley following the gravity take up system may come into

play. Like transition distances, the concern lies not in being too big but rather exceeding minimums.

IS YOUR SPLICE RIGHT?

So far, many critical belt performance considerations have been discussed, but how your belt is held together also need to be considered. There are several options when it comes to splicing your belt, so make sure the right method and correct tools are chosen for the application. Once the method is selected, make certain the splice is installed at a true 90-degree angle to

the travel of the belt. This will equalize the tension across the width of the belt, preventing tracking issues once the belt is under tension.

The first consideration in splice choices is vulcanized versus mechanically fastened. Vulcanizing is the process of prepping belt ends with either a “step” style splice of a “finger” style splice. The splice kits for both include the rubber material and solutions necessary to prep the belt prior to “cooking” the belt ends in a vulcanizer. Of the two, step splices are more common. However, the finger style splice is preferred in special weave fabric belts and higher tension applications. In both cases, the splicing personnel need to be very skilled to assure the very best outcome. The result is a seamless splice joint with a rubber chemistry most closely matching that of the belt manufacturing process. In ideal circumstances, that splice could last the life of the conveyor belt.

The second option is a mechanical splice joint. The process for installing these utilizes a plate or hinged style design held in compression on the belt ends with either a bolt, rivet, or screw. Mechanical joints meet operational tension needs, are cost effective, and can be installed very quickly by the conveyor operator. Mechanical fasteners, when properly selected, have a very significant life cycle. Another benefit of the mechanical splice is that when it does fatigue, the wear pattern is evident during routine inspection. This makes it easy to add to a planned maintenance on a conveyor.

further increase the operational tension profile.

This profile changes dramatically with variations like degree of incline or change in drive location.

HP = motor horsepower (nameplate)

Cw = drive “wrap factor” (also called “K” factor”)

Note: 33,000 is a constant for one strain of belt.

1 HP = 33,000 ft/lbs per min.

NIBA - Minimum Pulley Diameters

OTHER BELT PERFORMANCE CONSIDERATIONS

Additional conveyor operation considerations include load zone characteristics and tracking influences. Training for both of these elements can be quite involved. Suffice it to know that the better the product is centred on the receiving belt, the better the chance of keeping the belt tracked. Further, if the product is oriented toward the direction of travel of the receiving belt, at minimum impact, and at similar speed of belt travel, many belt wear issues are minimized. There can be many reasons for belt conveyors to mistrack – structural damage, cambered belt, excessive carryback, over or under tensioned operation – just to name a few. Belts that are not tracking properly will have an adverse effect on performance.

Maximizing conveyor performance can be achieved through an understanding of the performance characteristics of the application. Although there are many reasons why conveyor belt

performance may be less than optimal, the solutions are generally common sense once the groundwork is understood. There are also many dependable reference sources to further understand conveyor operations. Two of them would be the Conveyors Equipment Manufacturers Association (CEMA, www.cemanet.org) and the National Industrial Belting Association (NIBA, niba.org). •

Michael Cremeens is the VP training and technical support at Shaw Almex Industries with 39 years of industry experience in a variety of roles ranging from field technician to rubber processing expert. Mike has authored numerous papers and speaks at many industry gatherings.

Dick McConnell is the national account/ OEM manager at Flexco. His 30 years of troubleshooting conveyor performance in all manner of industries gives him the knowledge and expertise to understand the challenges of both small and large operations, and offer solutions. Full-Motor

Our competitors say we’re old and slow to change. That our machines are ugly. That we’re not on the cutting edge. We say, “Yup.”

“Old” means we’ve been around for over 100 years—and we’ll be here for 100 more.

“Slow to change” means we don’t do fads. Oh, we’ll turn on a dime to make changes that our customers need. But fads? Nah. We’d rather protect your investment.

“Not cutting edge” means we’re proven. We build what works and we stick with it.

And “ugly”? Well. You don’t need to be pretty to make a damn good pellet mill.

Pellet Gear BUYERS GUIDE 2017

Welcome to the 2017 Canadian Biomass Pellet Gear Buyers Guide

The following information has been compiled to provide readers interested in developing or updating a wood pellet manufacturing facility with a reference tool of the major manufacturers and service providers for this industry in Canada. From fibre to pellet, the listing is a comprehensive source for equipment involved in the

pelletizing process.

The Canadian Biomass Pellet Gear Buyers Guide is organized into two sections. The first section is an alphabetical listing of companies that provide the relevant products or services for each of the following categories: dryers, pneumatic conveying, hammermills, pellet mills, screens

and coolers, fire/spark detection and suppression technology, bagging and palletizing, dies and rolls, quality control equipment and services, building contractors and engineering firms and Canadian ports for pellet exports. The second section is an alphabetical listing of all the companies, with contact information for each. •

DRYERS

Altentech

Amandus Kahl

Andritz

Anhydro

Baker-Rullman

Bruks

Büttner

Certified Labs

Dieffenbacher

Duske Drying Systems

Earth Care Products

Energy Unlimited

GEA

Jiansu Yongli

Kesco

Münch-Edelstahl

Muyang

Player Design

Saimatec Engineering

Siempelkamp

Silvana Import Trading

Solagen

Stela

Swiss Combi

Thompson

TSI

Uzelac

PNEUMATIC CONVEYING

Allied Blower

Amandus Kahl

Baum Pneumatics

Certified Labs

Clarke’s Industries

Concept-Air

Fox Venturi

Jeffrey Rader - Terra Source

K-Tron

Kesco

Koger Air Corporation

Rodrigue Métal

Silvana Import Trading

Walinga

HAMMERMILLS

Amandus Kahl

Andritz

Bliss Industries

Bruks Rockwood

Brunette Industries

Buskirk Engineering

Certified Labs

CPM Global Biomass Group

Dieffenbacher

Gemco Energy

Jeffrey Rader/Pensylvannia

Crusher

Kesco

La Meccanica

Münch-Edelstahl

Schutte-Buffalo Hammermill

Silvana Import Trading

West Salem

PELLET MILLS

Amandus Kahl

Andritz

Astec

Bliss Industries

Buskirk Engineering

Certified Labs

CPM Global Biomass

Group

Dieffenbacher

La Meccanica

Münch-Edelstahl

Pelleting Technology

Nederland

Salmatec GmbH

Silvana Import Trading

SCREENS & COOLERS

Amandus Kahl

Andritz

Baum Pneumatics

Bliss Industries

BM&M Screening Solutions

Bruks Rockwood

Brunette Industries

Buskirk Engineering

Certified Labs

CPM Global Biomass

Group

Dieffenbacher

Jeffrey Rader - Terra Source

Kesco

La Meccanica

Law-Marot

Münch-Edelstahl

Pelleting Technology

Nederland

Silvana Import Trading

West Salem

FIRE/SPARK DETECTION & SUPPRESSION

Allied Blower

Amandus Kahl

Clarke’s Industries

Concept-Air

CV Technology

F.E. Moran

Fenwal-IEP Technologies

Fike

Firefly

Flamex

Grecon

Kesco

Rodrigue Métal

Silvana Import Trading

BAGGING & PALLETIZING

Amandus Kahl

Balcan

Bulldog Bag

Certified Labs

Creative Packaging Inc.

Hamer

Möllers North America Inc.

Polypro Solutions

Premier Tech

Primary Packaging

Rethceif Packaging

Silvana Import Trading

Trinity Packaging

DIES & ROLLS

Amandus Kahl

Certified Labs

CPM Global Biomass Group

Dorssers

La Meccanica

Münch-Edelstahl

Silvana Import Trading

QUALITY CONTROL

EQUIPMENT & SERVICES

Amandus Kahl

Biomass Energy Lab

Domosystem

Electromatic Equipment

Grecon

Kesco

Münch-Edelstahl

Twin Ports Testing

Silvana Import Trading

ENGINEERING & CONSTRUCTION SERVICES

Andritz

Buskirk Engineering

DelTech

Dieffenbacher

Earth Care Products

Energy Unlimited

Kesco

Process and Storage Solutions

Solagen

Stolberg Engineering Ltd.

TS Manufacturing

PORTS

Belledune

Halifax

Montreal

Prince Rupert

Quebec City

Saguenay

Trois-Riviéres

Vancouver

MOISTURE ANALYZERS

MoistTech

TEWS of America Corp.

Doescher Microwave System GmbH

GreCon, Inc.

BANDIT BUILDS MORE

ALLIED BLOWER

www.alliedblower.com 604-930-7000

ALTENTECH

BIOVERTIDRYERS www.altentech.com 604-568-9848

AMANDUS KAHL GMBH & CO. KG www.akahl.de 905-778-0073 (Sarj Equipment, Canada)

ANDRITZ GROUP www.andritz.com 457-216-0300

ANHYDRO INC. (SPX FLOW TECHNOLOGY)

www.spx.com/en anhydro/ 704-752-4400

ASTEC www.astecinc.com 423-867-4210

BAKER-RULLMAN

www.baker-rullman.com 920-261-8107

BALCAN www.balcan.com 1-877-422-5226

BAUM PNEUMATICS INC. www.baumpneumatics. com 604-945-4507

BIOMASS ENERGY LAB www.biomassenergylab. com 218-461-2579

BLISS INDUSTRIES, LLC www.bliss-industries.com 580-765-7787

BM&M SCREENING SOLUTIONS www.bmandm.com 800-663-0323

BRUKS www.bruks.com 770-849-0100

BRUNETTE INDUSTRIES LTD. www.brunettemc.com 604-522-3977

BULLDOG BAG LTD. www.bulldogbag.com 800-665-1944

BUSKIRK ENGINEERING www.buskirkeng.com 260-622-5550

BÜTTNER www.buettner-energydryercom 704-522-0234

CERTIFIED LABS www.certifiedlabs.com 905-691-0492

CLARKE’S INDUSTRIES, INC. www.clarkes-ind.com 541-343-3395

CONCEPT-AIR www.concept-air.ca 866-644-0041

CPM GLOBAL BIOMASS GROUP www.cpm.net 800-428-0846

CREATIVE PACKAGING INC. cp22243.tripod.com/ baggingsystems 423-825-5311

CV TECHNOLOGY, INC. www.cvtechnology.com 561-694-9588

DELTECH www.deltech.ca 800-736-7733

DIEFFENBACHER www.dieffenbacher.com 770-226-6394

DOESCHER MICROWAVE SYSTEM GMBH www.moisturemeter.eu 510-420-1716

DOMOSYSTEM www.domosystem.fr +33(0)1 45 87 22 99

DORSSERS INC. www.dorssers.com 519-676-8113

EARTH CARE PRODUCTS, INC. www.ecpisystems.com 620-331-0090

ELECTROMATIC EQUIPMENT COMPANY INC. www.checkline.com 800-645-4330

ENERGY UNLIMITED INC. energyunlimitedinc.com 608-935-9119

F.E. MORAN SPECIAL HAZARD SYSTEMS www.femoranshs.com 847-849-8720

FENWAL-IEP TECHNOLOGIES www.ieptechnologies.com 855-793-8407

FIKE CORPORATION www.fike.com 816-229-3405

FIREFLY AB www.firefly.se +46 (0)8 449 25 00

FLAMEX, INC. www.sparkdetection.com 336-299-2933

GEA BARR-ROSIN www.barr-rosin.com 630-659-3980

GEMCO ENERGY www.agicogroup.com 0086-372-5965148

GRECON, INC. www.grecon-us.com 503-641-7731

HAMER LLC www.hamerinc.com 763-231-0100

HANSENTEK www.hansentek.com 905-607-5780

JEFFREY RADER CORPORATION www.terrasource.com 514-822-2660

KESCO, INC. www.kescosolutions.com 803-802-1718

COMPANY INFORMATION

KOGER AIR CORPORATION

www.kogerair.com 800-368-2096

LA MECCANICA SRL DI REFFO

www.lameccanica.it +39 049 941 9000

LAW-MAROT

www.lawmarot.com 800-461-6276

MOISTTECH

www.moisttech.com 941-351-7870

MÖLLERS NORTH AMERICA INC.

www.mollersna.com 616-942-6504

MÜNCH-EDELSTAHL GMBH

muench-edelstahl-gmbh. de 02103 58996

PELLETING TECHNOLOGY NETHERLANDS

www.ptn.nl +31 (0)73 54 984 72

POLYPRO SOLUTIONS

www.polyprosolutions.ca 514-730-2433

PORT METRO VANCOUVER

www.portmetrovancouver. com 604-665-9000

PORT OF BELLEDUNE

www.portofbelledune.ca 506-522-1200

PORT OF HALIFAX

www.portofhalifax.ca 902-426-8222

PORT OF MONTREAL

www.port-montreal.com 514-283-7011

PORT OF QUEBEC

www.portquebec.ca 418-648-3640

PORT OF TROIS-RIVIÉRES

www.porttr.com 819-78-2887

PORT SAGUENAY

www.portsaguenay.ca 418-697-0250

PREMIER TECH CHRONOS

www.ptchronos.com 418-868-8324

PRIMARY PACKAGING

www.primarypackaging. com 800-774-2247

PRINCE RUPERT PORT AUTHORITY

www.rupertport.com 250-627-8899

PROCESS AND STORAGE SOLUTIONS

www.processandstorage. com 256-638-1838

RETHCEIF PACKAGING www.rethceif.com 866-298-1876

RODRIGUE MÉTAL LTÉE

www.rodriguemetal.com 418-839-0400 ext. 231

SAIMATEC ENGINEERING www.saimatec.fi +358-10 525 8100

SALMATEC GMBH Infosalmatec.de 49 4172 98 97-0

SCHUTTE-BUFFALO HAMMERMILL, LLC www.hammermills.com 716-855-1555

SIEMPELKAMP ENERGY SYSTEMS GMBH www.siempelkamp.com 770-424-4141

SILVANA IMPORT TRADING INC. www.silvanatrading.com 514-939-3523

SOLAGEN INC. www.solageninc.com 503-366-4210

STELA LAXHUBER GMBH www.stela.de +49(0)8724-899-0

STOLBERG ENGINEERING LTD.

www.stolberg.com 604-273-1915

SWISS COMBI www.swisscombi.ch +41 56 616 6030

TEWS OF AMERICA CORP. www.tews-of-america.com 919-240-4425

THOMPSON DEHYDRATING www.thompsondryers. com 785-272-7722

TIMBER PRODUCTS INSPECTION www.tpinspection.com 770-922-8000

TS MANUFACTURING www.tsman.com 705-324-3762

TWIN PORTS TESTING INC. www.twinportstesting. com 715-392-7114

UZELAC www.uzelacind.com 414-529-0240

WALINGA

www.walinga.com 519-824-8520

WEST SALEM MACHINERY CO. www.westsalem.com 800-722-3530

The Sprout gear-driven pellet mills deliver quiet, efficient operation at all production levels. The single-reduction gear system in our Sprout gear-driven mills ensures efficient power transfer, resulting in low energy cost per ton and long service life. The quick-change cartridge assembly allows you to change dies in a matter of minutes and simplifies maintenance.

www.andritz.com/ft ANDRITZ Feed & Biofuel A/S Europe, Asia, and South America: andritz-fb@andritz.com USA and Canada: andritz-fb.us@andritz.com

Grinders and chippers

Staff Report

ROTOCHOPPER

Rotochopper continues to raise the bar with their solutions for high-volume grinding efficiency by releasing a set of enhancements for their B-66 horizontal grinder. The B-66 is now available with up to 1,050 horsepower, increased throat opening, RotoLink monitoring system, the KeyKnife Chipper Knife package, and the only patented grind and colour system in the industry. Add those features on to the existing benefits of grinding with a Rotochopper, and the B-66 continues to be a standout choice for any company that needs big throughput capacity with steady uptime and simplified maintenance. www.rotochopper.com

W.H.O. MANUFACTURING

W.H.O. Manufacturing Company designed and patented the first tub grinder in 1947. This year the company is celebrating its 70th year of producing these grinders. W.H.O. Manufacturing’s wood grinder units are efficient processors of waste wood in cost of cubic yards processed verses cost of operation. Over the years, W.H.O. has constantly improved its grinders with focus on

increased production and durability with ease of maintenance. With over 70 years of experience, W.H.O. has unbeatable knowledge in designing and producing tub grinders for processing waste wood. sales@who-mfg.com

WSM

WSM Vertical Feed Grinders offer a simple yet highly effective design to process a wide range of feedstock at rates up to 150 tons per hour. These rugged grinders feature a heavy-duty rotor with innovative disc and hammer configuration options that make WSM grinders the most efficient on the market. The optional pivot housing provides easy access to main wear components with all infeed components remaining in place.

The latest machines for processing biomass feedstock in Canada

Whatever your output requirements, WSM has the heavy duty Vertical Grinder to get the job done. From fine grinding of wood chips for pellet fuel or chipboard, to coarse grinding of bark or wood waste for mulch or biomass, WSM vertical grinders have the flexibility to provide the best solution for your application. www.westsalem.com

MORBARK

One of the most important features of the Morbark 3400XT is its standard 2.53 m width, making it legal transport width in any country. It accommodates engines from 402 to 596 kW, and is also available with electric power. The infeed features an additional 60.96 cm in length and sloped

sides. Other standard features include an extended platform between the hood and engine for better access for maintenance; removable infeed chain return floor; one 86.36-cm diameter top compression feed roll; a direct-driven internal planetary drive with no chains and sprockets; and four strands of WDH-120 chain in a staggered configuration. www.morbark.com / www.cardinalsaw.com

RAYCO

Horizontal grinders don’t have to break the bank. The RH1754 is designed to be a productive horizontal grinder priced within the reach of the small contractor. With low operating costs and versatility to process a wide range of materials,

Rayco’s RH1754 is the economical solution for reducing green waste, pallets, lumber scraps, etc., and making high quality mulch. A variety of tooth and screen options allow operators to tailor the end product to achieve their result. Despite its compact size, the RH1754 is outfitted with the same features found on larger grinders. A wide infeed opening accepts pallets and bulky material. Easily removable debris screens and reversing fans keep the radiator clear and extend service intervals. A magnetic head pulley on the discharge conveyor sorts out nails and light metals. And the screens can be changed in minutes to minimize set-up time. The towable version is light enough to be easily transported from on job to

the next. For those that want the ultimate in mobility, the RH1754 is available on a heavy-duty steel track undercarriage. www.raycomfg.com

CBI

The CBI Magnum Force 6800BT is specifically designed for land clearing companies and yard waste processors who demand high-volume throughput and maximum reliability. It is capable of processing land clearing debris, pallets, clean industrial waste, stumps and logs as quickly as it can be loaded. It’s well suited to produce highly-marketable mulch through its regrinding capability. The hog box features a clam shell opening to provide more room behind the screens for increased throughput and ease of