Steam Boilers

Gas, Oil, Wood, Biomass, Coal, and Solid Fuel fired Steam & Hot Water Boilers

Hurst Boiler & Welding Company has been designing, engineering and servicing a complete line of solid fuel, solid waste, biomass, gas, coal and oil-fired steam and hot water boilers since 1967, for thousands of satisfied customers.

Co-generation

DIGESTER GAS

GAS

Hurst also manufactures a complete line of boiler room peripherals such as blowdown separator surge tanks, and pressurized make-up feed water tanks.

PURPOSE DESIGNED

The leading manufacturer of GREEN Project Wood-Fired and Biomass Boiler Systems.

CANADIAN BIOMASS

10 POWERING NOVA SCOTIA

Nova Scotia Power fires up in Point Tupper using locally sourced woody biomass to provide a new source of clean energy for the province.

16 Feeding the Grid

Laforge Bioenvironmental uses organic waste to provide a new power source for commercial and residential properties in New Brunswick.

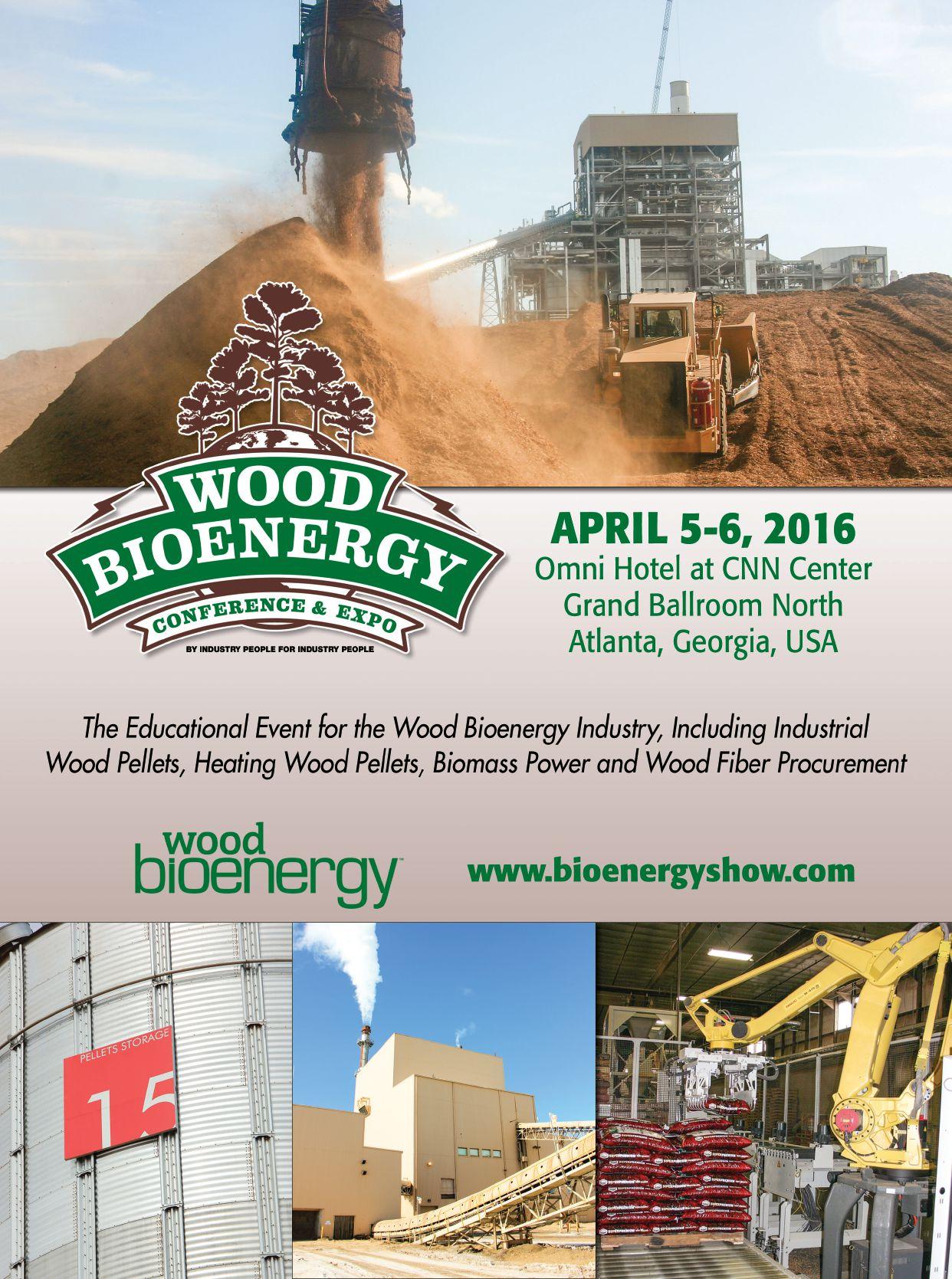

22 WPAC Show Guide

Your exclusive guide to the upcoming Wood Pellet Association of Canada Conference and AGM, November 3-5 in Halifax.

28 Integrated Production

Resolute Forest Products adds pellet production to its Thunder Bay sawmill to provide biomass fuel for OPG Atikokan.

30 Boiler Showcase

Learn about the newest technologies and innovations in biomass boiler technology.

34 Healing while Harvesting

One man’s passion for revitalizing New Brunswick’s forests turns into big business.

“Within 24 hours of the announcement, RFP announced its plans for construction of a pellet plant in Thunder Bay...”

the full story on page 28

COLUMNS

Demands

TBiochemical benchmark

BioAmber

he grand opening of the BioAmber bio-succinic acid facility in Sarnia, Ont. was an important benchmark for Canada’s biochemical and biorefining industry.

The company, which chose Sarnia over approximately 100 other sites throughout North America, created the largest succinic acid production plant in the world.

What made the proposed project so solid in the beginning was the fact that it was a rare business opportunity where a biobased version of a chemical was actually cheaper to build than the petroleum-based version.

But that was when oil was around $100 per barrel and gas prices in the Greater Toronto Area hovered around the $1.40/litre mark. Now oil sits in the $45 per barrel range and gas near $1.00/litre. Certainly, the business model for BioAmber has seen some wild fluctuations since the project got off the ground just a few years ago.

Granted, all businesses have been impacted in one way or another by the volatility in the oil and gas sector. But when a project that costs over $140 million to build is reliant on a model that has oil prices at or near the peak conditions of a few years ago, the impact is even greater.

It would have been easy for BioAmber to pack its bags and shutter the project until the oil and gas market once again settles in at a higher price point. But they didn’t. They kept building, and that deserves our recognition.

BioAmber has forged ahead and, in August of this year, officially opened its bio-succinic acid facility. The acid, which is transported in a crystalline form, is used

as a building block chemical with applications in the making of plastics, automotive parts, electronics and lubricants just to name a few. The bio-production of the product is based on fermentation technology and, at the end of the day, is arguably a better quality succinic than its petroleum-based counterpart.

Then there is the environmental impact to take into account. According to information provided by the company, the production of bio-succinic acid versus petroleum-based succinic acid, at the capacity volume that BioAmber will produce in Sarnia, produces 210,000 tons less greenhouse gas emissions or the equivalent of taking 45,000 cars off the road.

On the business side, the company had already established take-or-pay contracts for over 50 per cent of its production, and additional supply agreements will cover the majority of the outstanding production volumes.

The BioAmber model, from the financial structure utilizing government funding to the establishment of a solid customer base before the first crystal of acid is produced, has become the example for other biochemical and biorefining operations to follow. Companies in Canada looking to commercialize their products at a national or global scale now have the example they need to build a successful gameplan for moving forward with expanded operations. BioAmber has done the legwork on this one, and now others can, in theory, follow their lead. •

Volume 15 No. 4

Editor - Andrew Macklin (905) 713-4358 amacklin@annexweb.com

Editor - Andrew Snook (905) 713-4301 asnook@annexweb.com

Contributors - Gordon Murray, Jen Hedrick

Editorial Director/Group Publisher - Scott Jamieson (519) 429-3966 ext 244 sjamieson@annexweb.com

Market Production Manager

Josée Crevier Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@annexweb.com

National Sales Manager

Ross Anderson Ph: (519) 429-5188 Fax: (519) 429-3094 randerson@annexweb.com

Quebec Sales Josée Crevier Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@annexweb.com

Western Sales Manager Tim Shaddick - tootall1@shaw.ca Ph: (604) 264-1158 Fax: (604) 264-1367

Director of Soul/COO - Sue Fredericks

Media Designer - Emily Sun

Canadian Biomass is published six times a year: February, April, June, August, October, and December.

Published and printed by Annex Business Media.

Printed in Canada ISSN 2290-3097

Circulation Carol Nixon e-mail: cnixon@annexweb.com P.O. Box 51058 Pincourt, QC J7V 9T3

Subscription Rates: Canada - 1 Yr $49.50; 2 Yr $87.50;

(Canadian prices do not include applicable taxes)

Occasionally, Canadian Biomass magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission ©2015 Annex Business Media, All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.canadianbiomassmagazine.ca

There’s a saying that gets tossed around a lot here:

“It just runs.”

Our pellet mills and hammermills aren’t the prettiest. But they’re rock-solid. And they run—year after year after year.

But “It just runs” isn’t just about our products.

It’s about our company, which literally spans centuries.

And it’s about our ongoing relationships with our customers— how we’ll always be there for you.

Give us a call, and find out just how CPM can run for you.

BIOMASS update

ENERKEM BEGINS COMMERCIAL

Waste-to-biofuels and chemicals producer Enerkem Inc. has raised $152.6 million and initiated the production of biomethanol from non-recyclable household garbage at the Enerkem Alberta Biofuels full-scale facility in Edmonton, Alta.

“I must say a huge thank you to our financial partners,

employees, as well as the City of Edmonton and Alberta Innovates – Energy and Environment Solutions who believed in us and have accompanied us while we were reaching this pivotal operational milestone,” said Vincent Chornet, president and CEO of Enerkem. “We are about to fundamentally trans-

ATLANTIC BIODIESEL UP AND RUNNING IN WELLAND

Atlantic Biodiesel officially opened its state-of-the-art renewable fuel facility located in Welland, Ont.

“This is an important day for Atlantic Biodiesel and for the greater Welland community,” said Michael Paszti, chief operating officer of Atlantic Biodiesel. “Our world class facility is up and running. We are excited to be a part of this community and to support the local economy.”

The new Atlantic Biodiesel facility is one of the largest biodiesel facilities in North America and produces 170 million litres (45 million gallons) per year of renewable, clean-burning biodiesel and 15 million litres (4 million gallons) per year of highgrade glycerin. The facility is strategically located within close proximity of rail infra-

PRODUCTION IN EDMONTON

form the waste industry over the coming years and allow energy and chemical groups access to a new and competitive source of renewable carbon.”

The financing is comprised of a recently accessed $29 million debt facility from Integrated Asset Management Corp.’s Private Debt Group as

structure, providing for storage and shipping ability to a range of North American markets.

“The City of Welland is thrilled to welcome Atlantic Biodiesel to the community,” stated Welland mayor Frank Campion. “The facility will bring approximately 25 direct

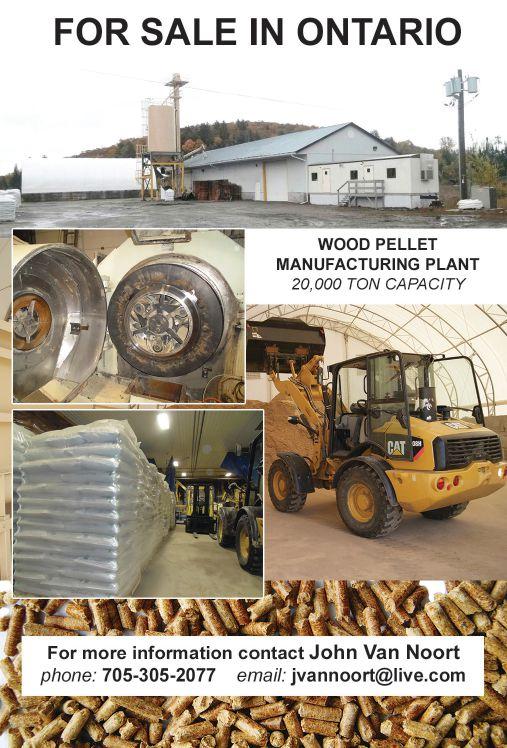

Astec sells its first pellet plant

Astec Industries, Inc. has entered into an agreement to build, deliver and install the first production line of a new turnkey wood pellet production facility.

The $30-million agreement with Highland Pellets, LLC includes the option to add additional production lines, related equipment and installation services, which could

jobs and significant indirect business to the area. Every job is valued and needed in our community. I strongly encourage the federal, provincial, and local governments to join me in supporting this local company as they work to bring jobs and economic prosperity to Welland.”

well as $50 million in private placements from current investors and C$73.6 million of debt from two other lenders, closed over the past year. This funding will be used for the product expansion of the Edmonton facility and the company’s global growth.

GEVO, BUTAMAX SETTLE LAWSUIT

A multi-year legal battle over patent issues between Gevo Inc. and Butamax Advanced Biofuels LLC has been resolved.

According to Bloomberg Business, the agreement will see Gevo focus on isobuthanol bio jet fuel development while Butamax will focus on isobuthanol fuels for blending with gasoline for use in vehicles. Also as part of the agreement, both companies have agreed to license their patents to each other.

Both companies produce isobuthanol from corn waste. Both companies had been fighting over patents for the technology for the past four years.

bring the total order amount to $143 million. Astec expects to deliver the first production line and related equipment no later than early 2016.

Although Astec has received an order and a down payment on the first $30 million portion of the facility, the remaining $113 million worth of goods and services is optional.

RENTECH FACILITIES ENCOUNTER DELAYS

Rentech’s pellet plants in Atikokan, Ont. and Wawa, Ont. have encountered delays in wood pellet production due to equipment failures and issues with material handling equipment.

“The Atikokan plant has been generating positive EBITDA since May,” stated Keith Forman, president and CEO of Rentech. “At Wawa, we are producing a limited quantity of pellets. We will need to modify and replace the log in-feed equipment and a signification portion of conveyance systems at the Wawa plant this fall and into next year, to address the construction flaws we discovered during ramp-up.”

WAWA FACILITY – Most of the equipment at the Wawa facility has been commissioned and the plant is producing a limited quantity of wood pellets. However, Rentech discovered that it needs to modify the front end system of the facility that handles logs and feeds them into the chipper, and modify or replace a significant portion of the conveyors that handle chips and pellets.

“These issues are preventing us from ramping up the plant to expected production levels,” the company stated. “We expect to correct these issues during this fall and the first half of next year. We currently estimate that correcting these problems

OKANAGAN PELLET COMPANY BEGINS PLANT UPGRADES

Viridis Energy Inc., recently announced that its whollyowned subsidiary, Okanagan Pellet Company Inc. (OPC), has commenced a major oneto two-year plant upgrade that will be conducted in three phases. The OPC plant upgrades are intended to address new regulatory requirements for safe storage and management of wood pellets and ensure the plant complies with the National Fire Protection Association and B.C. Fire Safety code.

The first phase is underway and will provide for a separation of the two main production lines, pellets and shavings, so they can be operated independently. This phase, which is expected to take eight to 10 weeks during which production will be suspended, also includes

will increase our total expected project spending for the Canadian pellet plants to approximately $145 million, which is $5 million above the high end of our previous guidance range of $131 million to $140 million.”

Rentech expects the Wawa Facility to be operating at full capacity by sometime in the second half of 2016.

ATIKOKAN FACILITY – The Atikokan facility has completed commissioning and is in the ramp-up phase. However, the facility experienced a transformer failure and has been temporarily using a smaller transformer that causes the facility to operate at reduced rates. Rentech plans to install a larger permanent transformer in the third quarter of 2015, which will allow Atikokan to operate at full rates.

During the ramp-up phase, Rentech identified the need to replace or repair the truck dump conveyor and hopper at the facility, and the need to modify some of the conveyors at the plant. Atikokan may still reach full capacity in February 2016; however, the timing could shift by several months depending on the degree of modifications needed to correct the material handling equipment issues and any other possible issues that may arise during ramp-up.

substantial improvements in the wood dust management system to ensure continued compliance with the increasingly stringent safety guidelines for the wood industry, implemented in British Columbia.

The second phase includes the addition of new, semi-permanent tent structures for the safe storage of wood fiber. The storage systems will substantially increase OPC’s fibre capacity and include the de-commissioning of the current storage building, improving production efficiencies. The third phase of the upgrades will include the addition of a new pellet press and state-of-the-art dryer that will expand the facility’s capacity

by approximately 50 per cent. Planning for the third phase will begin in Q4 2015.

This will mark the first significant enhancements of OPC’s facility since the plant was acquired by Viridis in April 2010 and are expected to create midterm and long-term increases in revenue and profitability. In the short term, the company anticipates incurring a production shortfall of approximately 10,000 tons of pellet production; however, it is expected to have less of an impact on sales. OPC is covering its wood pellet delivery obligations through a combination of existing inventory and additional product acquisition via Viridis Merchants Inc. (VMI).

BIO-FUNDING

Alberta Innovates Bio Solutions (AI Bio) has launched a new funding program, “Alberta Bio Future, Research and Innovation,” aimed at advancing knowledge that accelerates growth of new bioindustrial products or bioindustrial technologies for the benefit of Albertans.

The ABF Research and Innovation program has a total $4.5 million in available funding. Project funding amounts will be determined on a case-by-case basis, depending on the quality and scope of the project. In addition to funding, AI Bio assists researchers and companies with advice and connections. Researchers, companies or industry groups based in Alberta, and researchers conducting projects that benefit Alberta, are invited to apply by submitting a Letter of Intent.

The deadline is Oct. 28, 2015 at 4 p.m. MT. Eligibility requirements are available at bio.albertainnovates.ca.

TKorea coming back?

Working to re-establish the South Korea pellet market

By Gord Murray

he top five export destinations for Canadian wood pellets in 2014 were United Kingdom, United States, Italy, South Korea, and Japan. However, in the spring of 2015, South Korea took itself off this list by imposing new wood pellet import restrictions. The result was that Canadian producers could not legally comply with South Korea’s new requirements and pellet exports from Canada to South Korea all but dried up.

South Korea’s objectives were to ensure that the raw material used to make pellets were legally sourced and comprised of pure wood fibre. The country had been receiving imported wood pellets that were contaminated with refuse (contaminated waste matter), and wanted to prevent air pollution from such waste matter.

To meet its objectives, the South Korean government implemented new requirements for pellet exporters to provide copies of government-issued tenure documents for all fibre sources in each wood pellet shipment, as well as copies of fibre purchase contracts. All documents were to be authenticated by the exporting country’s government as per an international treaty known as the Apostille Convention – an international certification comparable to notarization in domestic law. Canadian producers not only found this process unreasonably onerous; they could not legally comply because Canada is not a member of the Apostille Convention.

Wood pellet exports slowed to a trickle. A few Canadian containers continued to slip into South Korea when some exporters found the Korean embassy in Vancouver willing to accept unauthenticated documents.

A second issue arose in the spring of 2015 when South Korea issued a notice regarding national forest products standards

– including wood pellet standards – to the Technical Barriers to Trade Committee of the World Trade Organization. Under the notification process, the Wood Pellet Association of Canada (WPAC) reviewed the South Korean standards and found that neither the wood pellet grades, nor the physical and chemical testing procedures, aligned with the international standards developed by ISO.

To address these issues, WPAC asked for help from Canada’s Department of Foreign Affairs and Trade Development (DFATD), Natural Resources Canada (NRCAN), and the BC Ministry of International Trade (BCMIT). All three organizations responded immediately, vigorously and with the highest degree of professionalism.

The organizations managing these issues on behalf of the Government of South Korea include Korea Forest Service (KFS), Korea Forest Promotion Institute (KOFPI), and Korea Forest Research Institute (KFRI). From June to September,

despite two face-to-face meetings in Seoul, a web conference, and several letters (including a letter from Canada’s trade minister, The Honourable Ed Fast), Canada seemingly made little progress in convincing South Korea to move on either the import restrictions or the wood pellet standards.

Meanwhile, like the pellet sector, the sawn lumber and engineered wood sectors were experiencing similar trade issues. DFATD and NRCAN arranged for another round of meetings to take place from September 9 to 11 in Seoul. The Canadian delegation included representatives from DFATD, NRCAN, WPAC, the Council of Forest Industries, the Engineered Wood Association (APA), the National Lumber Grades Authority, and the Canadian Lumber Grades Accreditation Board. The Korean delegation included representatives from KFS, KFPI, and KFRI.

The three days included both plenary and sector-specific meetings. During the sector-specific meetings, the Canadian

The delegates in the Canada-Korea forest products standards discussions.

wood pellet sector achieved significant progress. Subject to ratification by KFS management, the parties agreed to the following:

• Wood pellets will be made from pure wood and fall under the jurisdiction of the Ministry of Forests.

• Sawmill residues may be used as a raw material, provided that the sawmill owner states that the sawmill residues are one of the primary products of the mill (along with lumber and chips) and not a waste product. If the sawmill residues are not a primary product, then if used to make pellets, they are considered to be waste and classified as biomass solid refuse. As such, their use is restricted and falls under jurisdiction of the Ministry of Environment.

• By mid-October, KFS intends to eliminate the Apostille requirement for verifying wood pellet fibre sourcing.

importer will be responsible for verifying the legality and appropriateness of the source of fibre supply for wood pellets. Data to be collected by the importer will include type of raw material (chips, logs, or sawdust), description of storage facilities, description of manufacturing facilities, import volumes and dates, the type of packaging (bags, totes, or bulk) and the intended end use.

• The new verification process will be implemented for a trial period in the month of October. As soon as the process is finalized, Korea Forest Service will provide the Canadian Embassy with more details.

• KFS will implement a spot-checking process to ensure that importer data is accurate.

• KFS will re-consider whether to accept third party chain of custody certification as evidence of fibre sourcing.

requirements on other countries. Korea’s main forest management concern is to ensure elimination of illegal logging.

• Korea will modify its pellet quality and testing standards to align with ISO; while ensuring that agro material and recycled wood are not accepted for wood pellets and are instead classified as BioSRF. Korea recently established a mirror committee to consider the ISO standards, to analyze them against Korean law and to adapt the ISO standards to the Korean situation. Korea will provide documentation to Canada once this process is complete.

We are pleased with the results of the recent meetings and optimistic that Canada will be able to re-establish a mutually beneficial wood pellet trade with South Korea.

CanBiom0915-Kahl-5 21.11.14 10:24 Seite 1

• The responsibility for verifying fibre sourcing will shift from the exporter to the importer. The

• Other than insisting on compliance with local laws, Korea does not intend to impose forest management

WPAC would like to express special thanks to NRCAN’s Wendy Vasbinder, Robert Jones, Lesley-Ann Reed and HyunMi Park of the Canadian Embassy and to BCMIT’s Jae-Jung Huh. •

KAHL Wood Pelleting Plants

Powering Nova Scotia

Biomass power at Point Tupper helping sustainability targets

By Andrew Macklin

Evenbefore the Government of Nova Scotia introduced its Renewable Energy Plan in April of 2010, Nova Scotia Power understood the opportunity that was in front of them in Point Tupper.

It was 2009 when the original project was conceived, recognizing that the biomass boiler at the Point Tupper site had been under-utilized by NewPage. Stora had installed the system in 1983 as a way to burn excess bark and spruce budworm-killed wood.

The initial agreement negotiated with NewPage stated that Nova Scotia Power would absorb the entire capital cost of the project, pegged at $208 million, with NewPage providing the personnel to operate the facility.

But in 2011, amidst the continued decline for demand of paper products on a global scale, NewPage filed for CCAA protection. CCAA, Companies’ Creditors Arrangement Act, allows companies owing a minimum of $5 million to creditors to restructure its business and financial affairs while avoiding bankruptcy. The mill shut down in September, forcing NSP to re-evaluate the merits of the Point Tupper project without having the NewPage infrastructure in place.

After careful consideration the project was re-started independent of NewPage’s involvement. Shortly thereafter, the mill was sold to Pacific West Commercial Corp., and the mill was re-started in October of 2012 with the supercalendared paper and thermomechanical pulp lines in operation.

MOVING TOWARDS OPERATION

The boiler potential and the need for firm, consistent renewables to meet the targets of the Renewable Energy Plan were driving the $208 million investment forward. That was then complimented by successful negotiations with the new tenant, operating the mill as Port Hawkesbury Paper, for both the sale of steam, and fuel management throughout the site.

The $208-million investment included three basic components. The single largest investment was the construction of the turbine hall and the installation of the turbine. The 150-metric tonne steam turbine was built by Mitsubishi Heavy

LEFT MAIN: The installation of a second chip dumper was one of the primary components of the $208-million investment.

INSET: The bioenergy plant at Point Tupper is regulated by the Department of Natural Resources, the Renewable Energy Standard, the Department of the Environment and the URAB.

Industries at its facility in Yokohama, Japan, and was delivered to the site in April of 2012.

A second truck dumper and chip silo were necessary for primary biomass handling, along with the associated conveyors and secondary infrastructure necessary.

There was also the need for a significant modification of the boiler. The boiler was originally designed for an output of 60kg/sec of oil and gas, but only 40kg/sec when using biomass. Upgrading the boiler to the desired 60kg/ sec output using biomass meant bigger drives for the ID fans, as well as reinforcement of the duct work to handle the higher air flows.

The 60kg/sec output is equal to the 60MW of power that NSP wants to be able to generate at capacity. According to NSP, 60MW will provide the power needed for approximately 50,000 homes. However, there are also the demands of Port Hawkesbury Paper to take into account, which uses approximately 25 per cent of the produced power when the mill is operating at capacity. Overall, the

entire power production represents as much as 3.5 per cent of the province’s power-generation needs.

ACQUIRING FIBRE

One of the biggest hurdles with meeting the desired output is the acquisition of fibre. Producing 60MW on a consistent

basis, and an estimated 350-gigawatt hours per year, means consuming up to 2,000 green metric tonnes of biomass per day and a total of up to 500,000 green metric tonnes per year.

“We actively buy bark from other sawmill producers,” says Jeff Campbell, plant manager for Nova Scotia Power at

Chips are brought in from sources throughout Nova Scotia, but the facility has grinding equipment onsite for cut-to-length wood purchased by NSP.

Point Tupper. “We also have woodland contractors that are out securing biomass for us, primarily from the seven counties surrounding our site.”

That’s not an easy task when considering the state of the forest industry in Nova Scotia. The combination of the recession and the weakening global demand for

paper proved to be more than many contractors could survive.

“The demise of the CCAA with the paper mill (NewPage) turned out to be very challenging for the woods contractors,” Campbell stated. “There were a lot that went out of business during that period. So even with the paper mill starting back

Rising

viessmann.ca

1-800-387-7373

biomass@viessmann.ca

up and us shortly thereafter coming online, many of the contractors chose not to return to the wood harvesting industry. So the biggest challenge has been a combination of contractor availability and the overall decline in the forestry sector in the province.”

That has led Nova Scotia Power to look elsewhere for fibre, both for availability and for the best price point. In 2014, NSP imported approximately 55,000 green metric tonnes of bark from sawmill operations in Quebec. The bark was shipped by barge, which was then offloaded at the dock facility shared by NSP and Port Hawkesbury Paper.

“The choice to go to Quebec was primarily an economic one, as we do strive to find the lowest overall cost fuel supply,” Campbell says. “It was an attractive economic proposition for us.”

The price point that NSP offers to purchase biomass for has not changed since startup in 2013. And while there is not an overabundance of biomass currently in Nova Scotia, NSP has managed to keep its supply at the levels it set out to maintain.

energy costs, concerned about your heating bills in 2016? Be proactive with a Biomass boiler.

Computer controlled and fully-automated, biomass systems from Viessmann feature industry-leading wood heating technology for safe, reliable, and troublefree operation.

More than 60 Commercial Biomass boiler installations across Canada

Outstanding Efficiency of up to 85%

Eco-friendly and CO2-neutral

Sustainable and Economical, wood is renewable and free of wide price fluctuations

Stringent safety - built to ASME, Section IV and tested to CSA/UL Safety Standards

Two Types Available - Vitoflex RF (formally Pyrot - 5 models) 5121843 MBH, and Vitoflex UF (formally Pyrotec - 5 models) 1330 - 4268 MBH

Biomass industry creates jobs in Canada.

The plant is situated on the southern tip of Cape Breton Island, providing easy access for receiving chips, bark and sawdust from barges.

BIOMASS FIBRE ONLY

It has been speculated at various times throughout the past few years that NSP was supplementing its supply of biomass wood with higher-value logs that should actually be shipped to pulp and lumber producers.

But according to Campbell, the numbers just don’t add up: “There is a strong economic motivator for logs to go to the right buyer. The next closest competitor to biomass would be Grade Three hard-

wood sawlogs, which commands a 30 per cent premium in the market. The highest quality Grade One hardwood sawlogs are worth three times as much as biomass.”

The operation has also been subject to a series of audits intended on, in part, ensuring that the company is using the right type of fibre for power generation.

“We have an extremely aggressive auditing program,” Campbell says. “We are regulated by the Department of Natural Resources, the Renewable Energy Standard,

WE FACE EXPLOSIONS EVERY DAY

HAVE TO.

the Department of the Environment and the NSUARB (Nova Scotia Utility and Review Board). We meet all of our regulated requirements.”

NSP has also conducted extensive audits of its own in the first two years of operation. The company’s own team has conducted 132 audits, and two procurement managers have conducted an additional 230 inspections over and above, a sharp increase above the industry standard. To this point, there have been no significant findings of misallocated fibre.

Between the hauling and harvesting operations, it is estimated that approximately 200 jobs are partially or fully reliant on the fibre provided to NSP. That is complemented by 34 full-time Nova Scotia Power staff, as well as 10 full-time contract staff responsible for the fuel handling and wood yard.

Staffing requirements at the site have not been an issue thanks to a program available at Nova Scotia Community College in Port Hawkesbury. The College offers a Power Engineering program, which graduates students as 3rd class power engineers. Of those students, approximately 20 each year are welcomed to the NSP site to fulfill their eight-week work placement requirement, and NSP has had success hiring some of the best and brightest students from the program, many of whom are looking for solid employment in the field within the community. That has been a significant contributor to the early success of the bioenergy project at Point Tupper.

But admittedly, the team at Point Tupper is still learning, refining the operation and finding efficiencies when possible. Nova Scotia Power officials have experience handling fuels like coal, oil, and natural gas, but not as much with biomass. That’s why operational leaders are working on taking an active role in the Canadian biomass industry, learning from industry experts from across the country and around the world.

So far, the success of the Point Tupper operation has provided a new example for successfully providing renewable, clean energy for thousands of homes and businesses throughout Nova Scotia. •

WPAC AGM & CONFERENCE 2015 FUELLING THE FUTURE

November 3-5, 2015

Cunard Centre, Halifax, Nova Scotia

At the WPAC AGM & Conference, you will receive the insider information you need to meet the demands of today’s and tomorrow’s markets.

Get the insider news and make connections by joining us at this must-attend event!

Gain comprehensive insight from industry experts on the following:

• Market Outlooks with perspectives from Canada, North America, Europe and Asia

• Developments in North American heat markets

• The latest in health and safety for the pellet sector

• Transportation and logistics

• A pellet producer and utility panel discussion

• What’s new in competition and innovation

• Optional port and plant tour

• Optional Wood Pellet Quality Certification Workshop and much more

PLATINUM Sponsor GOLD Sponsor

RECEPTION Sponsor

Feeding the Grid

Laforge uses organic waste to power New Brunswick

By Andrew Snook

Reducedcarbon emissions, green energy production and other environmentally-friendly initiatives are hot topics for the federal, provincial and municipal governments these days. So it comes as little surprise that a variety of green energy projects are popping up across Canada. One of those projects is Laforge Bioenvironmental’s commercial biogas production plant in Saint-André, N.B.

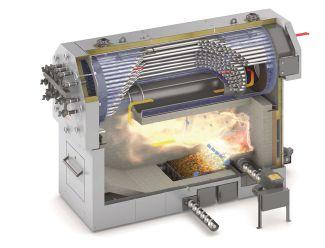

The facility operates two anaerobic digesters on a dairy farm with approximately 90 cows, and is fuelled by a combination of cow manure and organic waste from regional food processors.

The digesters are 12,000 m3 and 1,500 m3 in size. The overall energy production capacity of the site is 1.4 MWh, which is the amount of power that Laforge Bioenvironmental is allowed to put

on the grid under their contract with NB Power (also a function of local power demand). However, the site has the potential to produce 2 MWh with the available feedstock in the region.

The site currently process about 30,000 to 40,000 metric tonnes of waste per year.

The $7-million project was done in two phases with 80 per cent of the financing coming through farm credit and the remaining funds coming from a combination of a few green energy grants and a zero-interest loan from the provincial government.

The project is expected to pay for itself within the next six years through electrical generation and tipping fees, according to Kevin Shiell, business development and sales manager for Complete Senergy Systems, the consulting firm that worked on the second phase of the project’s construction.

Kevin Shiell, manager of business development and sales for technical support of digester operations at Complete Senergy Systems, discusses the breakdown process within the anaerobic digester during a tour of the biogas facility.

Laforge Bioenvironmental’s anaerobic digester operates on a dairy farm with approximately 90 cows, and is fuelled by a combination of cow manure and organic waste from regional food processors converting it to electrical energy, heat and liquid organic fertilizer.

The expected lifespan of the anaerobic digesters is between 20 to 25 years.

“But like any infrastructure, if you maintain it, replace parts when needed, you can probably make it last longer than that,” Shiell says.

RAW MATERIALS

The raw materials used to create the sediment sent to the anaerobic digesters is a combination of manure from the 90 cows at the dairy farm; French fries and potato skins from local food processors; slaughterhouse waste and sugar beets.

“The peels from the potatoes are all steam peeled so the starch is mostly washed off of them. It’s almost all just cellulose,” Shiell explains. “There’s not a lot of biogas value to it, but it’s good organic material. The French fries have a lot of energy in them.”

Fifty acres of sugar beets were grown on the farm last year and are used as an energy crop for the sediment. However, other projects are being considered for the sugar beets, such as the creation of sugar and ethanol.

Two tankers haul dissolved air floatation sludge (DAF) that comes from the slaughterhouse that comes off of primary waste.

“The liquid DAF sludge has a lot of fat, it’s actually really good stuff,” Shiell explains. “It’s over 115,000 COD, so there’s a lot of gas that comes out of it.”

The liquid DAF is mixed with all the dry materials to create a 10 per cent total solids mix, which is then pumped into the anaerobic digesters. The digesters run between five and eight per cent total solids.

Manure is only a small part of the mix,

mainly used as a dilutant.

“If the pH of the digester or the buffering capacity of the digester is a little low, we’ll shovel a little manure into it,” Shiell says. “We’re only putting about 30 tons of manure in a day, and about 150 to 180 tons of other materials.”

All of the ingredients are fed into the facility’s two 100-ton receiving tanks that fuel the anaerobic digester system. The floors of the tanks are heated at about 10°C except during the wintertime, when it is heated to the same temperature as the anaerobic digesters.

“In the wintertime, all this material is frozen,” Shiell says. “When you mix it up and pump it into your digester at 5°C it’s hard to keep your digester at 40°C.”

THE PROCESS

The cow manure is collected under the holding pen and is then pumped over to the receiving tanks in measured amounts, where it is mixed with other organic waste and churned into sediment. French fries and other organic waste are then added to the mix. The sediment is then pumped over to the anaerobic digester, where it fills the base of the dome.

The sediment in the dome is constantly turned by a motorized mixer and is then heated to 40°C. This process makes the biogases rise up out of the sediment, inflating the dome.

The biogases include carbon dioxide, methane and hydrogen sulfide. The hydrogen sulfide crystallizes during the process and drops back into the sediment, leaving only the carbon dioxide and methane in the air. Those two gases

are removed from the anaerobic digesters and fed into nearby biogas engines. The leftover sediment is then transferred to a nearby reservoir, where it is stored for future use as fertilizer.

The biogas engines – a Guascor 600 Kwh engine and a Jenbacher 1.2 MWh engine – generate outputs upwards of 650 kW per hour or 250,000 kW a month. The electricity is fed into the NB Power Grid where it can power upwards of 300 homes, while generating approximately 4.5 million BTUs, which is used to heat an on-site farmhouse, the anaerobic digesters, hot water tanks, the shop and the dairy barn through the use of an in-floor hydronics system installed underneath the cement floor.

“We have lots of extra heat in the summer but not a lot of extra heat in the winter,” Shiell explains. “This is because it takes all the heat to heat the digesters in the winter.”

Martin Machinery out of Missouri assembled both containerized generation systems. Complete Senergy works with them to assemble custom units that meet the CSA Biogas code required by New Brunswick and Nova Scotia. Complete Senergy Systems also manufactured the mixers, hydronic heater and feed pumps.

BIOSOLIDS

The biosolids generated in the electricity generating process are spread out over 1,500 acres of land.

“You apply about 2,000 gallons per acre,” Shiell explains. “We take about two or three months in the spring and pretty much spread it all summer. We’ll stop for a couple months during haying season. Then once the grass has been cut, we’ll put some on afterwards and then we’ll keep spreading until November to get the digester down as low as we can because we have nowhere to put it during the winter.”

One challenge with producing large amounts of biosolids is that the company has to go upwards of 20 kilometres away from the biogas plant to spread it on land, which can become relatively costly.

WILDLIFE CHALLENGES

One challenge that the operation has experienced is a problem with birds where the organic waste is being stored. To counter this issue, the company is installing tarp curtain doors to keep them out. They

Now’s not the time to find out your work wear isn’t as tough as you are.

With exclusive brands like DAKOTA and a wide range of flame resistant work and safety apparel designed for the most challenging workplaces, companies across Canada count on Imagewear. From the drilling platform to the refinery, we can outfit your entire workforce from head to toe with high performance work apparel and footwear, uniforms and branded attire. Visit imagewear.ca or call 1-(844) 359-9466 to find out more.

2015 AGM & CONFERENCE

Our decision to move the popular Wood Pellet Association of Canada annual event to the East Coast was driven largely by the proximity to our members’ two major markets – Europe and the Northeastern U.S. Our members are concentrated in regions across the country, with production railed, trucked and shipped across the ocean to power generators, distribution centres, stores and businesses in almost a dozen countries.

For product bound for Europe, the Port of Halifax offers an ice-free, year round, deep water port, served by most of the world’s major shipping lines and is among the shortest distances to central Europe through the eastern ports.

This year’s conference is kicked off with a spectacular tour of the Port of Halifax including three specialized terminals – Ocean, Richmond and Halterm – which feature the Halifax Grain Elevator dry bulk storage silos and the CN rail yards. The Halifax Grain Elevator is situated west of Ocean Terminals and is connected to Pier 26 and Pier 28, which is equipped with six towers capable of delivering up to 900 tons of pellets per hour.

The port tour then continues on by bus to visit both of Nova Scotia’s wood pellet production facilities, Shaw Resources in Shubenacadie and Scotia Atlantic Biomass in Middle Musquodoboit. The tour begins promptly at 10 a.m., immediately following this year’s AGM held at the beautiful Halifax Seaport Market at 7:30 a.m. on Tuesday, November 3.

An alternative to the port and plant tour is also offered on Tuesday afternoon; the Wood Pellet Quality Certification Workshop, with moderators Chris Wiberg of the Biomass Energy Laboratory and Gilles Gauthier of the European Pellet Council. This three-hour workshop will provide an overview of the international pellet standards such as ISO, CSA, ENplus, CAN Plus, PFI, where they are applied and a review of pellet quality certification schemes and how to obtain certification.

No matter how informative and useful the workshop and tour may be, the highlight of Day 1 is sure to be the East Coast Kitchen Party, held in the Alexander Keith Brewery District. For our European, U.S. and western Canadian delegates, this will likely be your first experience at an east coast kitchen party, but we promise it will be unforgettable. Local live music, food and drink will be plentiful as you experience true local culture!

This year’s conference theme is Fuelling the Future, as we explore the growing number of sectors utilizing wood pellet biomass. The conference features some of the top speakers in the industry, including William Strauss who will be presenting, A Strategy to Decarbonize the American Power Sector. Don’t miss the Commercial Biomass Solutions segment, which will explore the opportunities for growth and existing applications of biomass in business and industry.

The Fuel of the Future session features Deborah Keedy of Drax Power on the ever-important topic of sustainability. This segment will also cover vital facts on the sustainability requirements in the Netherlands.

Threats and Opportunities and a unique session on the economics of the supply chain will be compelling for producers and pellet consumers alike. And back by popular demand – the Power Panel! This unique session combines some of the leading European industrial pellet consumers with some of the largest pellet producers for a lively and informative debate. (Any panel with Henry Pease, RWE is always lively!)

And new to the conference, Biomass Solutions Biomasse will be showcasing their new pellet delivery truck, which will be parked inside the Cunard Center.

As we prepare for another robust heating season in North America and a year of changing regulatory, subsidy and sustainability issues, the WPAC Conference is the navigation tool you need for Fuelling the Future!

Meet us in Halifax to network, inform, educate and enjoy!

Look forward to seeing you there.

MICHELE REBIERE President, Wood Pellet Association of Canada

Welcome to Halifax!

Airoflex

Airoflex Equipment has been supplying innovative engineering concepts for hydraulic truck dumpers/tippers since 1947. Airoflex products have been installed throughout the United States, Canada, Mexico, Central America, South America, and in the Middle and Far East for industries such as biomass, pulp and paper, energy generation, cogeneration, and recycling industries.

Altentech Power

The Altentech Biovertidryer offers a new solution to remove moisture from biomass. It has been engineered to address the serious drying challenges facing the pellet industry, including operating costs, emissions and safety.

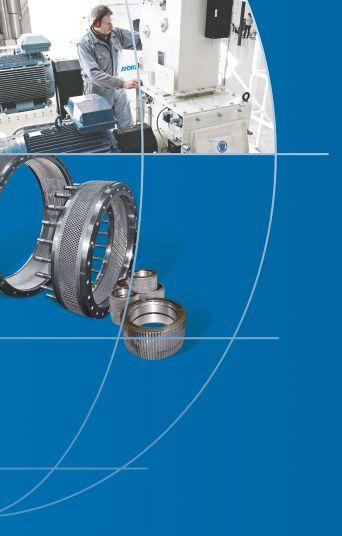

Andritz

Andritz is a leading supplier of technologies, systems, and services relating to the equipment for the biomass pelleting industry. Andritz has the ability to manufacturer and supply each and every key processing machine in the pellet production line.

Biomass Energy Lab

Biomass Energy Lab (BEL) specializes in solid biofuels testing. ISO 17025 Accredited for CEN/EN methods, BEL provides analytical certifications for export shipments of wood pellets and other solid biofuels to help meet contractual needs. Along with testing services, BEL also

offers EN plus auditing and consulting, and can assist with internal lab design/setup.

Biomass Solutions Biomasse

Biomass Solutions Biomasse is a leading energy provider, offering the sale of BTUs and heating equipment. BSB will provide a profitable solution to replace fossil fuel, while supporting the growth of the local economy. Visit us at www. bsbheating.com.

Bruks Rockwood

Bruks is a global leader in mechanical engineering and equipment supply for the bulk materials handling industries. Customer service and product performance are at the heart of its corporate culture. The company provides specialized customer solutions, including the development of custom machines and systems.

Canfornav

Founded in 1976 with its headquarters in Montreal, the company’s beginnings were in the lumber trade, which gradually extended to steel and bulk commodities. Today, Canfornav operates over 40 vessels, owned and on longterm time charter, ranging in size from 27,000 to 57,000 dwt vessels, with further new orders pending from Chinese yards for one more 36,000 dwt and two 64,000 dwt vessels. Five 36,000 dwt vessels have already been delivered for use in special bulk trades.

TIMBER PRODUCTS INSPECTION

EXHIBITORS

Control Union

Control Union is a global network of inspection operations and dedicated laboratories specializing in independent worldwide cargo surveying and superintendence. Through innovative solutions, specialized services and product knowledge, they offer complete packages for logistics, quality and quantity management from the country of origin to the final destination.

CPM Global Biomass Group

CPM has been a leader in biomass pelleting for over 20 years. With the formation of the Global Biomass Pelleting Group, we can now call on all of our resources worldwide to ensure that you receive the highest quality equipment along with the highest quality support worldwide.

CPM Wolverine Proctor

CPM Wolverine Proctor has over 100 years of experience in conveyor drying: offering customized solutions in a modern and efficient facility devoted exclusively to the manufacturing of thermal processing equipment.

Dansons

Dansons Inc. is the leader in the field of supplying specialty lubricants to the biofuel industry. Not only have we developed and supplied specialized lubricants to the pellet mill industry, we also provide technical support and expert advice on how to get maximum life out of wear components.

Fike Canada Inc.

Fike has over 65 years of field experience and a team of engineers, application specialists and combustion researchers delivering a complete line of products and innovative technologies to the explosion protection market.

Kahl

Kahl plan, design, and build machines, plants, and turnkey production factories for conditioning and compacting of many different products for a wide variety of industries. The flat die pelleting press and the annular gap expander are the most successful products of Kahl. Amandus Kahl is a medium-sized family-owned company managed by its proprietors. It was founded in 1876 as a manufacturer of mills and pelleting presses.

M-E-C Dryers

M-E-C designs, engineers, manufactures and services single pass dryers, triple pass dryers, flash tube dryers, fuel storage systems, material handling, fuel preparation and wet and dry wood combustion systems. M-E-C delivers total turnkey system responsibility for the processing of wood fuel pellets since 1983. That’s our difference.

Player Design Inc.

The philosophy behind PDI is simple – design and supply state-of-the-art, reliable equipment to enable our customers to succeed in today’s manufacturing markets. By combining innovative engineering and practical experience, we have created a line of machinery that delivers substantial economic benefits, superior finished product quality, and some of the lowest emissions in the industry.

Port of Belledune

Port of Halifax

Port of Belledune is a modern, year-round marine transport facility and deep-water point of access that is innovative in developing its services and facilities to the fullest. The port has proven itself capable of handling any and all goods, offering flexible services, creative solutions and excellent rates. Additionally, the port specializes in the handling of bulk and break-bulk cargoes and is the only existing point of export for wood pellets on the east coast of Canada.

The Port of Halifax is a regional economic engine, generating more than 11,800 jobs and contributing over $1.6 billion in economic impact. The world’s largest shipping lines call on the Port of Halifax, connecting the port to more than 150 countries. The beautiful Halifax Seaport is a premier destination, attracting more than 1.2 million visitors each year. Collaborating and working with strong partners and stakeholders, the port community continues to deliver excellent service.

Prodesa

Prodesa is a well-known supplier of wood pellet facilities and biomass-fuelled CHP plants based on ORC (Organic Rankin Cycle). We are manufacturers of drum dryers, low temperature belt dryers, hammermills, pellet mills, etc. We have over 20 years of experience and dozens of references all over the world.

Signode Industrial Group

Signode is a $2.4 Billion Global Packaging manufacturing company with 88 manufacturing facilities across six continents. Our value added products and services are designed to provide the wood pellet industry with cost effective and efficient options to your current packaging requirements.

TSI

TSI designs and builds equipment for today’s highly automated plants in the engineered wood and biomass industries. TSI offers solutions for dryer islands, (heat energy, drying and emission control) and finishing lines. Designed with the customer needs in mind, the systems are customized for specific applications.

Viessmann

With a complete line of high-efficiency oil and gas-fired boilers, solar thermal systems, advanced biomass heating and control technology, Viessmann can offer an innovative heating solution to meet the requirements of any application. Whether as a fully-integrated system or single-energy installation, our products deliver maximum energy savings and performance.

Viridis Energy

Viridis Energy is a publicly traded manufacturer and distributor of biomass fuel that operates two wood pellet manufacturing facilities: Okanagan Pellet Company in B.C. and Scotia Atlantic Biomass in Nova Scotia, with total production of approximately 200,000 tons. It is the only pellet company in North America on both coasts.

*Exhibitor list at press time.

AGENDA

NOVEMBER

3, 2015: PRE-CONFERENCE EVENTS

7:30 – 10:00 am AGM & Board Meeting

10:00 am – 4:30 pm

Location: Halifax Seaport Market Building

Option A: Halifax Port & Plant Tour

• Port of Halifax

• Shaw Resources pellet plant

• Scotia Atlantic Biomass pellet plant

Option B: Wood Pellet Quality Certification Workshop

Chris Wiberg, Biomass Energy Laboratory & Gilles Gauthier, European Pellet Council

• International pellet standards and where they are applied (ISO, CSA, ENplus, PFI, industrial)

• American New Source Peformance Standards

• Review of pellet quality certification schemes (ENplus, CANplus, PFI)

• How to obtain ENplus and CANplus certifications

• How to obtain PFI certification

5:00 – 7:00 pm East Coast Kitchen Party - Networking Reception

NOVEMBER 4, 2015: CONFERENCE DAY 1

7:30 – 8:00 am

Breakfast, registration, exhibits open

Welcome to Atlantic Canada

8:00 – 8:10 am Michele Rebiere, Wood Pellet Association of Canada

Dignitary welcoming address

Shifting Markets

8:20 – 8:50 am Fiona McDermott, Hawkins Wright, Global Pellet Outlook

9:10 – 9:30 am Gilles Gauthier, European Pellet Council, European Heat Markets

9:50 – 10:30 am Networking coffee break, exhibits open

Heat and Power Canada - Commercial Biomass Solutions

Moderator: Gord Murray, Wood Pellet Association of Canada

Moderator: Michele Rebiere, Viridis Energy

8:50 – 9:10 am Bill Strauss - North American Pellet Market and Strategy to Decarbonize the American Power Sector

9:30 – 9:50 am Mike Burns, Government of Northwest Territories - Developments in Northwest Territories

Moderator: John Arsenault, WPAC/QWEB

10:30 – 10:50 am Jonathan Levesque, Groupe Savoie - Pellet Projects in New Brunswick

10:50 – 11:10 am Daron Thomas, Thomas Industrial Sales - Installing Commerical Pellet Boilers in Atlantic Canada

11:10 – 11:30 am Dutch Dresser, Maine Energy Systems - What will it take to grow the Canadian pellet heating market? 11:30 – 11:50 am Ilaria Peretti, Turboden - Turboden’s ORC Turbogenerator in the Pellet Industry

11:50 am to 1:30 pm Lunch

Fuel of the Future - Quality and Sustainability

1:30 – 1:50 pm Deborah Keedy, Drax Power - Sustainability at Drax Power

Moderator: Arnold Dale, Ekman

1:50 – 2:10 pm Gordon Murray, WPAC - New biomass sustainability requirements in the Netherlands

2:10 – 2:30 pm Chris Wiberg, Biomass Energy Laboratory - Certification implications of U.S. new source performance standards

2:30 – 3:00 pm Panel discussion

3:00 to 3:30 pm Coffee break

Keeping our People Safe

Moderator: Rene Landry, Shaw Resources

3:30 – 3:50 pm Scott Bax, Pinnacle Renewable Energy - Creating a safer pellet sector

3:50 – 4:10 pm Rob Moonen, BC Forest Safety Council - Lakeland and Burns Lake inquests: Coroner’s verdicts and implications for the pellet sector

4:10 – 4:30 pm John Bachynski, EPM Consulting - Managing combustible dust

4:30 – 4:50 pm Jeff Mycroft, Fike - Dust Explosion Protection Strategies – An Overview

5:00 – 7:30 pm Cocktail reception

NOVEMBER 5, 2015: CONFERENCE DAY 2

7:30 – 8:00 am Continental breakfast

Power Panel - Producer and Utility Viewpoint

8:00 – 9:00 am

• Deborah Keedy, Drax Power

• Henry Pease, RWE Supply and Trading

• Jonathan Levesque, Groupe Savoie

• Vaughan Bassett, Pinnacle Renewable Energy

• Michele Rebiere, Scotia Atlantic Biomass

Off to Market - Transport and Logistics

9:00 – 9:15 am Rayburn Doucett, Belledune Port Authority

9:15 – 9:30 am Patrick Bohan, Port of Halifax

9:30 – 9:45 am Chris Walsh, Fednav

9:45 – 10:15 am Panel Discussion

10:15 – 10:45 am Coffee break

Threats and Opportunities

Moderator: Scott Jamieson, Canadian Biomass Magazine

Moderator: Bill Strauss, FutureMetrics

Moderator: Vaughan Bassett, Pinnacle Renewable Energy

10:45 – 11:05 am Brodie Govan, PMV Environmental Products - Asian pellet competition

11:05 – 11:25 am Arnold Dale, Ekman - Russian and Baltic pellet competition

11:25 – 11:45 am Tim Gammell, Wood Resources – U.S. competition

11:45 am – 12:00 pm Brent Boyko, OPG - Biomass progress at Ontario Power Generation

12:00 – 12:15 pm Arne Erik Kristiansen, Arbaflame - Black pellet use in Ontario

Closing Remarks, Gordon Murray, Wood Pellet Association of Canada

Efficient drying of biomass

Stela low temperature belt dryer

• 93 years of history, 45 years of experience in manufactoring drying plants

• more than 450 belt dryers in more than 60 countries all over the world in the most various sizes

• lowest emissions rates, energy-saving air technology

• dryers for produktion capactiy of 5.500.000 t/a pellets

supplied

• no need of wet electrostaticfilters (WESP) to achieve low emisson values

Industrial IP Cameras

Laxhuber GmbH Öttingerstr. 2 D-84323 Massing Tel. +49 8724/899-0 E-Mail: sales@stela.de www.drier.com

Integrated Production

Resolute creates a simplified solution for adding pellet production

By Andrew Macklin

Whenthe Ontario government announced that the use of coal would be phased out of its energy portfolio in the province, it opened a window of opportunity for the biomass industry to be recognized as a source for clean, renewable energy.

In September of 2008, then Energy Minister George Smitherman directed the Ontario Power Authority to explore the idea of burning biomass as a potential replacement for coal at some of its generating stations scattered throughout the province.

Fast forward to 2010. The tests have been completed and the window of opportunity officially swung open for forestry companies in northern Ontario as Ontario Power Generation put out the call for suppliers of white pellets to replace coal at the Atikokan generation station.

One of the companies that lined up to try and capture part of the contract for 90,000 tonnes annually of white pellets was Resolute Forest Products. At the time, the company’s sawmill operations were seeing the tide turn favourably towards a resurgence of forestry in the region despite decreasing demand for paper products.

Before the province directed the Ontario Power Authority, in September of 2010, to pursue fuel sources for Atikokan, Resolute was not in a position to add a wood pellet manufacturing facility to its Thunder Bay sawmill operations.

“It started with the demand from OPG,” says Maxime Langlais, general manager of the Thunder Bay sawmill and pellet plant. “The OPG request gave us an opportunity to look at a solution for our sawdust.”

Previously, the sawdust from the sawmill was sold externally or was transported to the Resolute paper mill, located east

The pellet plant at Resolute Forest Products in Thunder Bay has the capacity to produce the 45,000 tonnes of pellets it is contracted to supply OPG.

of the sawmill on the other side of the Kaministiqiua River.

“We were producing energy with our sawdust at the paper mill,” says Langlais. “But with the pellets, it was an opportunity for a higher value use of the sawdust.”

BUILDING NEW REVENUES

When it was officially announced in November of 2012 that Resolute had been awarded half of the total supply contract for OPG Atikokan, just a few weeks after the plant had burned its last piece of coal, the company was quick to begin preparing its operation for pellet production. Within 24 hours of the announcement, Resolute announced its plans for construction of a pellet plant in Thunder Bay.

The volume being produced for OPG would be 45,000 tonnes which, as calculated by Resolute, was achievable given the amount of sawmill residue that it had available for pellet production based on sawing volumes.

“While we have the capability to bring shavings and sawdust from other mills for the pellet operation, our current plan is to use only our on-site residuals,” says Langlais.

With the contract secured, the company moved forward with the construction of a pellet plant that was capable of meeting the volume for OPG. Knowing that it was going to use its own sawmill fibre, they were able to extend the existing conveyor system to run to the small footprint within the mill operation that would house the new pellet equipment. Because of this, there was no need to add the cost of magnetics or destoning equipment since the residues would never hit the mill floor.

For the construction of the pellet mill,

Andritz and Law Marot MillPro (LMM) worked with Resolute to provide the right components for the footprint and production demands of the mill. Andritz supplied a hammer mill for reducing sawdust and shavings, two 1260 Feed Screws, two 18x56 Conditioners, and two 26LM pellet machines. LMM were responsible for supplying the shavings screener, cooler and pellet screener to round out the project.

The result is a small white pellet made from jackpine and spruce sawdust and shavings that exceed the quality specifications of the OPG contract. Once produced, the pellets are again conveyed, this time to a trio of storage bins from Westeel. The three bins are lined up sideby-side on the outside of the pellet plant with easy access for trucks to drive underneath and efficiently fill up for transport to the OPG Atikokan site located approximately 190km west of the mill.

The overall investment in the pellet mill was around $10 million. The con-

struction of the mill was completed in the third quarter of 2014, and the plant has continued to ramp up its production over the past year. That has included the recent insertion of shavings into pellet production, which originally started by just using sawdust residues from the sawmill.

With increased production volumes at the sawmill - a recent upgrade just took potential annual production from 250mbft to 300mbft – Resolute is well positioned to reach capacity at its pellet plant without ever having to import fibre from a secondary mill site. That bodes well for keeping the bottom line in check and continuing to make the pellet mill a profitable venture.

Moving forward, the mill has the footprint available to expand its operation, but there is no reason to do so at this time. Until there is a significant uptick in domestic demand, Resolute will continue to use its Thunder Bay pellet mill as an added-value resource that helps provide clean, renewable energy for northern Ontario. •

The pellets produced at RFP Thunder Bay are smaller white pellets based on the requirements of its contract with OPG.

Boiler Showcase

New technologies and innovations in boiler technology

By Staff Report

BIOMASS COMBUSTION SYSTEM

The BCS 300 HP, hot water, wood boiler from Biomass Combustion System features the company’s horizontal zoned grate combustion system, which strictly regulates under fire air for gasification with low bed turbulence. The boiler burns dry sawdust and chips from the facility to heat dry kilns, but green wood fuel can be burned efficiently with adjustments to air and fuel delivery. The boiler is rated for 10 million BTU output and can maintain a 10 to 1 turndown ratio on dry fuel so it can operate at one million BTU/hr without losing the fire.

HURST BOILERS

Hurst Boiler provides its clients with the support and expertise necessary to design, fabricate and install complete solid fuel boiler systems, from the fuel storage system through to exhaust gas emission mitigation.

Various boiler designs are suitable for applications to produce high-pressure steam or hot water in ranges from 3,450 to 60,000 lbs/hr (3.4 mmBTU to 60 mmBTU) output from 100 to 900 psi. Hurst systems are capable of burning material with 0 to 50 per cent moisture content. The systems also feature an automatic ash removal system, high temperature cast refractory ceramic lining and PLC controls.

VIESSMANN

Viessmann’s Pyrotec fully-automatic underfeed combustion wood-fired boiler is available in five models with inputs raining from 1,330 to 4,268 MBH. It is designed for wood fuels with maximum water content of 50 per cent. The combustion chamber is lined with compressed firebricks with high alumina content for added durability. All grate elements are made of durable cast chrome steel. The boiler is built with a classic triple-pass heat exchanger design for maximum heat transfer and efficiency and a modulating output control with a 4:1 turndown ratio. It is available with a maximum operating pressure of 30 or 60 psig.

flexibility can be obtained in combustion system selection for a variety of biomass fuel types and moisture content. A large selection of boiler sizes is available, ranging from 500 kW to more than 5,000 kW.

ANDRITZ

Andritz state-of-the-art bubbling fluidized bed (BFB) boilers are fuelled by woody biomass with 40 to 60 per cent fuel moisture. They offer a heating value range of 5.5 to 10.1 MJ/kg and have a fuel consumption of 100 t/h. The boilers convert woody biomass into superheated steam with a capacity of 295 t/h steam, a steam temperature of 524°C and a feed water temperature 232°C.

the 6,000 Kw high-pressure steam assembly shown here. All components were designed and fabricated at our plant.

WOODMASTER

WoodMaster Commercial Series boilers feature automatic fuel feeding with wood pellets or wood chips, and ash extraction and soot blowing to reduce maintenance. They are designed to achieve 92% LHV efficiency and are available in 14 models ranging from 45kW to 2,000kW. The units have ASME and CRN certified pressure vessels and have CSA certification. The boilers are built with a 10.4” touchscreen PLC/HMI full colour control panel with remote access. Custom options are also available. Boilers are built in the U.S.

TRANSFAB ÉNERGIE

Transfab Énergie designs and fabricates

ASME certified custom biomass-fired energy systems from 200 Kw to 10,000 Kw to meet the needs and requirements of its customers. We are especially proud of our successes in efficiently burning wood bark with high moisture content such as

BOILERSMITH

Boilersmith Ltd. is a manufacturer of premium, Canadian manufactured, firetube, firebox style hot water, low-pressure steam and high pressure steam boilers, that are suitable for a variety of biomass-fired combustion systems. Other boiler design types are also available, and all are customized to match our customer’s requirements. In this way, maximum

DETROIT STOKER

Detroit Stoker Company’s GTS Reciprocating Biomass Stoker features inclined reciprocating grates that push the fuel down the length of the grate through distinct drying, gasification, combustion and burn-out zones. The grates are high alloy material so air cooling is sufficient. The ash is automatically discharged off the end of the grate into an ash conveying system. The reciprocating grate handles a wide range of feed materials including wood chips, bark, sawdust, forest waste and agricultural waste. It handles low heat value fuels and offers conservative sizing for assured capacity and low emissions.

Your global equipment supplier for the biomass industry

ANDRITZ is one of the world’s leading suppliers of technologies, systems, and services relating to equipment for the biomass pelleting industry. We offer single machines for the production of solid and liquid biofuel and waste pellets. We have the ability to manufacture and supply each and every key processing machine in the pellet production line.

KMW

KMW supplies complete biomass systems for the production of hot water, hot oil, low pressure and high-pressure steam for power generation. Boilers range in size from 100 HP to 3500 HP and complete power plants are available in the range of 250 kW to 50 MWe. Construction cost and time are kept to a minimum by shop building and testing all equipment. KMW’s patented grate system provides great fuel flexibility for utilization of low cost fuel including wet bark, mill sludge, bio solids, and MSW.

BELOTEQ

Global Series Uniconfort steel boilers from beloTEQ are built with a refractory coating with high alumina content. They have a refractory steel combustion grill designed for burning solid biomass with high moisture content (up to 150 per cent on a dry basis). They feature a completely dry, large-section combustion chamber with several smoke turns for optimal dust capture in the fumes. The boilers are suitable for the production of heating fluids with maximum pressures of up to 24 bar in the standard version and higher in special versions.

biomass boilers (15 to 150 psig) and direct-fired biomass furnaces. The capacity of the biomass-fired systems ranges from 250 kW to 6,000 kW. They also offer containerized solutions up to 750 kW.

SIM ENTERPRISES

Pyrogenic Industrial Biomass Stokers from SIM Enterprises are multi-fuel combustion systems with high combustion efficiency. The units are equipped with a multi-fuel system for wood pellets, wood chips and agricultural residue; and a multi-fuel feed system. The hot water, low pressure and high-pressure steam boilers are built to ASME code.

OUTOTEC

ANDRITZ Feed & Biofuel A/S Europe, Asia, and South America: andritz-fb@andritz.com USA and Canada: andritz-fb.us@andritz.com

www.andritz.com

BLUE FLAME STOKER

Biovalco Engineers manufactures and implements biomass heating plants under the trademark Blue Flame Stoker, including hot water biomass boilers (30 psig), fired steam

Using biomass and wood-based residue fuels, Outotec solutions can convert industrial waste products, such as bark, pulp and paper rejects, lignin from ethanol production or even agro biomass, into electricity and heat/steam. For residue fuels with a high amount of large inorganic components such as stones, glass and bricks, Outotec fluidized bed technology uses an open nozzle grid design, which allows for a stable combustion process and proper debris removal. Plants using fuels with a high variation in calorific value can be equipped with flue gas recycling and/or combustion air preheating.

COMPTE FOURNIER

Compte Fournier’s Granul’Eco hot water pellet boilers range from 200 to 1,000 kW (20 to 100 HP) and use wood pellets or agro-pellets as fuel. These boilers are ideal for urban or remote setups where constraints in fuel delivery or availability favour the use of pellets. A fully automated solution, from feeding to lighting up to ash extraction, suiting your energy needs in small-scale collectivities, residential buildings and light industries while respecting tight environmental emissions controls.

ADVANCED CLIMATE TECHNOLOGIES

Advanced Climate Technologies (ACT) manufactures high-efficiency wood pellet and wood chip boilers for commercial,

institutional multi-family residential buildings. The boiler systems range in size from 0.5 to 1.7 million BTUs for buildings sized 5,000 to 100,000 sq. ft. ACT Bioenergy Boilers have been specifically designed to optimize customer convenience and ease-of-use to complement or completely replace conventional fossil fuel boilers systems in buildings.

VALMET

Valmet’s Hybex boilers use bubbling fluidized bed (BFB) combustion technology. They offer wide fuel flexibility, high combustion efficiency, high reliability, excellent controllability and low emissions. They are available sizes ranging from 10

to 400 MW and have a combustion efficiency of over 99 per cent, resulting in boiler efficiency typically around 90 per cent, even with high moisture fuels. It is ideal for all types of wood fibre fuels.

DECKER MANUFACTURING

The pressurized industrial Decker Brand Boiler is designed to heat facilities such as greenhouses, manufacturing plants, livestock facilities and machine shops. It is designed for multi-fuels including wood pellets, oat hull pellets and coal; and comes in six sizes ranging from 500,000 to 3,500,000 BTU. They are upwards of 85% efficient. They feature an automated tube cleaning system for maximum efficiency, an automated ash removal system and are fully insulated.

INDECK

Depending on the fuel(s) fired and the design requirements of the boiler, steam capacities can range from 25,000 to 600,000 lb. steam/hr. Solid fuel fired boilers are available in two drum open pass” and a single drum MSW design. •

Healing while harvesting

Passion for revitalizing forests turns into big business

By Andrew Snook

Mathieu

LeBlanc is passionate about restoring the Acadian forests in New Brunswick. So passionate, that he quit his job at a forestry consulting firm in Western Quebec, sold his home, and moved himself and his pregnant wife to the Moncton area. Once there, he started up his forestry restoration and management business, ACFOR – an acronym for “Acadian Forest” – and so far, the gamble has paid off.

ACFOR performs integrated wood harvesting as part of its restoration and management services, where they harvest wood for a variety of purposes for private wood lot owners and the local municipalities in the Moncton area – Moncton, Dieppe and Riverview. The company harvests stud saw logs, poplar for OSB and firewood, in addition to harvesting the waste for biomass-to-energy projects in P.E.I.

ACFOR moves all of its wood through the Southern New Brunswick Forest Products Marketing Board (SNB).

“They negotiate contracts with all the local mills,” LeBlanc explained, while offering a tour of his operation at Turtle Creek in Riverview, N.B.

His goal is to make woodlot management a pleasurable and enjoyable experience for woodlot owners; ensuring that they get the maximum return on their forests for generations to come.

HOW IT ALL STARTED

While living in Gaspe, Que., LeBlanc and his then-girlfriendnow-wife graduated post-secondary schools their respective degrees – LeBlanc with a degree in forestry and his wife with a degree in environmental sciences.

“She was trying to save the trees and I was cutting them down,” jokes LeBlanc.

After graduating, the couple moved to Montebello in Western Quebec and LeBlanc went to work for a forestry consulting firm that specialized in multi-resource planning in recreation, wildlife and forestry management.

“We were in charge in the Outaouais region, the Laurentians, Montérégie and the Ottawa region,” he said. “We mainly worked with private wood lot owners.”

LeBlanc really enjoyed the hands-on, project management experience he obtained while working for the company.

“They put you there with 25 harvesters and said, ‘Listen, you’re going to be in charge of this project,’” he said. “That company gave me a lot of experience in this field. The philosophy of the company was to always improve the quality of the wood lot [through selective harvesting].”

During his six years with the company, LeBlanc went back to

One of ACFOR’s two Ponsse Wisents piles logs at the company’s Turtle Creek operation in Riverview, N.B.

RIGHT: Mathieu LeBlanc is so passionate about restoring the Acadian forests that he quit his job at a forestry consulting firm in Western Quebec, sold his home, and moved himself and his pregnant wife to the Moncton area to start his forestry restoration and management business, ACFOR.

school part-time and obtained a certificate in project management.

When his wife got pregnant in 2006, they had a serious talk about where they want to raise their family and work.

“The sawmills were closing down, all the companies were going bankrupt, and I said to my wife, ‘There’s nobody restoring the Acadian forest [in the Moncton area]. Why don’t we both quit our jobs, sell the house and I’m going to try and start a forestry management company,’” he said. “Without hesitation she said ‘yes.’ I was very lucky that she supported me from the get-go.”

Of course, the fact that Moncton was his wife’s hometown didn’t hurt.

The opportunity LeBlanc saw for his forest management company stemmed from wood lot owners in the area having limited options for their forests.

“Basically the wood lot owners had two options: clear-cut or

conservation, nothing in-between.” he says. “For me, it was the best time to start the business because machinery was cheap, although financing it was a challenge.”

LeBlanc started by managing one wood lot where he performed selective thinning and the business quickly grew ‘like wildfire.’

“People who hadn’t cut their wood lots when the prices were high, those were the people that called me,” he recalls. “They said, ‘You’re doing what we wanted. We’ve been waiting for someone like you for a long time – that cares about the forest and manages the ecosystem, wildlife and recreational [activities].’”

Through word-of-mouth the company was successfully obtaining contracts from a variety of wood lot owners, and eventually landed a three-year contract to manage the municipal forests in Dieppe, Riverview and Moncton.

Halifax Halifax

We’ll see you at the Wood Pellet Association of Canada’s AGM in Halifax November 3-5, 2015

LEFT: Ponsse’s line of harvesters is the equipment of choice for ACFOR’s operations in the Moncton area.

SWITCHING GEARS