No matter how challenging your needs, BKT is with you offering a wide range of OTR tires specifically designed for the toughest operating conditions: from mining to construction sites.

Sturdy and resistant, reliable and safe, able to combine comfort and high performance. BKT is with you, even when work gets tough.

One of my favourite times of the year is upon us again, it’s time to announce the winners of Rock to Road’s Top 10 Under 40 Awards!

Thank you to everyone that submitted entries to this year’s awards program. Although all nominees were worthy entries, we could only select 10 of these great individuals.

So, without further ado, here are the winners of this year’s Top 10 Under 40:

• Valerie Snowdon, Operations Manager, Nelson Aggregate, Cambridge, Ont.

• Sarah Bond, Mine Manager, Aracosa Imperial Limestone, Texada Island, B.C.

• Paul Leveille, Chief Technology Officer, TerraShift Engineering, Edmonton, Alta.

• William Threlfall, Asphalt Plant Manager, Mainland Construction Materials, Vancouver, B.C.

• Jared Kuepfer, Owner, ARRO Crushing, Millbank, Ont.

• Victor Giordano. Land & Environment Manager, Vicdom S&G, Uxbridge, Ont.

• Troy MacBeth Abromaitis, Director of Development, Bucci Construction, Vancouver, B.C.

• Chris Foreman, Territory Manager, Foreman Equipment, Chilliwack, B.C.

• Joseph Gvildys, Cement Industrial Director, Western Canada & Pacific Northwest U.S., Lafarge Canada, Exshaw, Alta.

• Pavan Sidhu, General Manager, Saskatchewan, Lafarge Canada, Saskatoon, Sask.

Want to learn more about these young up-and-coming leaders?

Turn to page 18 and read about why they were nominated and their amazing achievements.

Miss out on this year’s contest to nominate a great employee or colleague? Have no fear, entries for the 2023 edition of the awards are now officially open!

What are the qualifications to nominate

an individual, you ask? Here are the guidelines to the Top 10 Under 40 contest:

• Nominees must be younger than 40 before Dec. 31, 2023.

• Nominees must either be working in Canada or of Canadian nationality.

• Nominations are due by Sept. 15, 2023.

Must the nominee be Canadian?

No. The nominee can be of any nationality, but must be employed in Canada. We also encourage the nominations of Canadians working outside of the country.

Who can nominate someone?

Nominators can include advisors, supervisors, coworkers, or colleagues familiar with the nominee’s work and character.

What type of information should be included about the nominee?

Potential information to submit about the nominee can include (but is not exclusive to): Projects or initiatives the individual is or has been involved in; results from past projects; day-to-day job responsibilities; workplace initiatives outside of regular job duties; and community involvement.

All nominees selected for Rock to Road’s Top 10 Under 40 program will receive a framed certificate recognizing their achievement and will be featured in the November/December 2023 issue of the publication.

Who knows, one lucky individual might even have their photo end up gracing the front page!

Still have more questions?

For more information on the Top 10 Under 40 program, contact editor Andrew Snook at asnook@annexbusinessmedia.com.

Congrats again to all of this year’s winners!

durable building materials.

From skyscrapers to roads to parking garages to dams and more… construction projects depend on an available supply of quality concrete mix. To meet our vision of connecting people, processes and products, advancing innovative solutions from Rock to Road®, our line of concrete production equipment includes a full range of mobile and stationary concrete batch plants. It is unquestionably the most comprehensive line of concrete production equipment in the industry.

Deere & Company recently announced the appointment of Justin Rose to president of lifecycle solutions, customer support and supply Management. He will be based in Austin, Texas, at one of Deere's newest offices. Rose succeeds Marc Howze, who will become senior advisor, Office of the Chairman.

Rose will be responsible for leading the company's worldwide aftermarket, customer support, and supply management and logistics groups. He also will oversee the recurring-revenue and customer-success goals outlined in the company's Leap Ambitions announced in early 2022.

Rose is joining Deere from Boston Consulting Group (BCG), where he served as a senior partner and managing director and worked with Deere on a series of high-profile projects, including development of the company's Smart Industrial strategy and

operating model. Most recently, he headed BCG's North American industrial-goods practice and was a member of its global leadership team. Rose started his career with BCG in 2002 and worked in offices around the world, including Chicago, Thailand, Japan, and Mexico.

"Justin's exceptional background, broad global perspective, and prior work with Deere – including his instrumental role helping develop our new strategy and operating model – make him highly qualified to serve in this capacity," said John May, Chairman and CEO of Deere & Company. "His outstanding record working with clients across the globe and deep industry insights will provide vital leadership toward the achievement of our ambitious business goals and efforts to provide best-in-class customer service and support."

Astec has joined The Road Forward, an industry-wide initiative of the National Asphalt Pavement Association (NAPA), to engage, educate, and empower the U.S. asphalt community to produce and construct net zero carbon emission asphalt pavements by 2050.

“Sustainability is embedded in our strategy,” said Jaco van der Merwe, group president, Astec. “We have a responsibility to do what is right for society and our planet, and that includes doing our part to help combat climate change.”

Launched in January 2022, The Road Forward is a multi-year effort of collaboration and cooperation among the asphalt industry that will help pave the way toward innovation and implementation of sustainable solutions.

“It is significant that Astec has committed to The Road Forward,” said NAPA president and CEO Audrey Copeland. “Since its founding, the company has demonstrated leadership on issues that ad-

vance our industry, the communities they serve, and our shared climate. Astec’s support of The Road Forward propels our collective vision for the future: sustainable communities and commerce, connected by net zero carbon asphalt pavements.”

In supporting The Road Forward, Astec is providing industry leadership on climate action. The company’s support will help fund ongoing research and education to aid the entire U.S. asphalt industry in producing net zero carbon emission asphalt production and construction by 2050.

“Our partnership with NAPA and The Road Forward reaffirms our public commitment to design and manufacture heavy equipment that helps promote a healthy environment for generations to come,” van der Merwe said.

For more information about The Road Forward, visit AsphaltPavement.org/Forward.

BY GRANT cameron

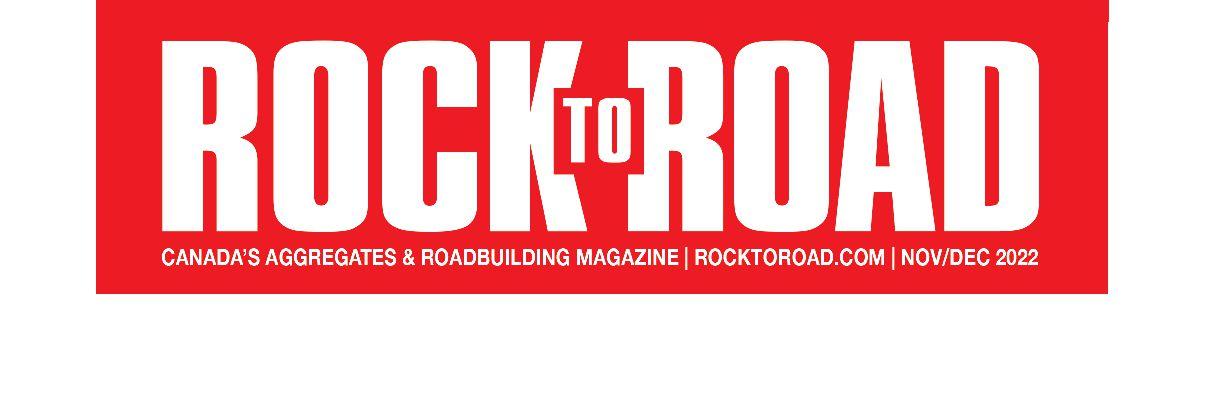

> Transportation officials in British Columbia are looking at the best way to repair and reconfigure 10 road sites along the Highway 97 corridor in the Cariboo region that have been hard hit by landslides and wildfires brought on by changing weather patterns.

Very wet spring and summer months over the past couple of years in the region between the communities of Quesnel in the north and Williams Lake in the south, combined with snow melt, has resulted in more water in the ground than normal which has caused unprecedented slides and road washouts.

The Cariboo region experienced extremely wet conditions in July 2020. The summer of 2021, meanwhile, marked B.C.’s worst wildfire season on record. Because much of the area was destroyed by fires, the ground soaks up water and causes landslides that are extremely complex and challenging to

stabilize and mitigate.

Some slope stabilization and interim paving work has already been completed at seven of the sites along the route to improve access and safety. The other three sites are currently closed.

David Crebo, spokesperson for the B.C. Ministry of Transportation and Infrastructure (MTI), says roads in the Cariboo region have suffered as a result of the wetter than normal conditions and landslide events.

“These events resulted in localized impacts in the Cariboo as well as to regional routes, including Highway 97, that connect many communities and play a key role in B.C.’s northern natural resource sector,” he explained. “Cariboo roads have been impacted by changing weather patterns and our focus is on developing and building safe, long-term solutions that are adapted for climate change.”

Over the coming months, project teams will be engaging with communities, local governments, First Nations, and stakeholders to discuss the potential transportation solutions at each project site.

“The Cariboo road recovery projects are undergoing an analysis of shortlisted options for each of the 10 sites,”

said Crebo. “Through this process, each potential alignment is being assessed using key technical, policy, community and cost considerations to help guide decisions on a preferred option.”

The venture is officially known as the Cariboo Road Recovery Projects (CRRP). The sites are Highway 20 at Hodgson/ Dog Creek Road; Soda Creek-MacAlister Road; Highway 97 at Cuisson Creek; Durrell Road; Bastin Road at Bastin Hill; Kersley Dale Landing Road; QuesnelHydraulic Road; Blackwater Road at Knickerbocker Road; Highway 97 at Cottonwood Hill; and Quesnel-Hixon Road.

At Quesnel-Hixon Road, for example, a landslide in 2021 caused complete loss of the road, and at Cottonwood Hill, a historic landslide caused ground movement affecting Highway 97. At Kersley Dale Landing Road, where multiple slides occurred in November 2020, the original alignment was deemed unsafe for public use and a temporary, singlelane gravel road is open for local traffic. Meanwhile, at Durrell Road, a landslide that occurred in 2021 made the road unsafe for public travel. The existing road moved three to four metres vertically and 10 to 12 metres horizontally and is geotechnically unstable.

Feedback from local residents and oth-

er vested groups will help transportation officials decide on a course of action. They are taking a very cautious and thorough approach to the project and each site is undergoing a multi-phase, technical-driven process, according to Crebo.

The problems have been defined for each site and a needs assessment has been done. Teams considered existing and future project conditions at each site to help inform the direction of potential options.

Concepts have also been generated, and options have been shortlisted for each site and evaluated. A technical analysis was done for each option and they were assessed against multiple criteria to help narrow the list.

“We are currently in phase three, in which short-listed options are going through a detailed analysis known as a Multiple Account Evaluation,” says Crebo. “As part of our design process, engineers and consultants are considering how future climate events will affect infrastructure and what can be done to make our roads more resilient, so they remain reliable and open.”

The final phase will be implementation.

“Once a preferred solution, which could include further stabilization, additional restoration, road relocation or

potential permanent alternative access, receives approval we will develop work plans to deliver the project,” says Crebo.

The plans could include further stabilization of slopes, additional restoration, road relocation or potential permanent alternate access routes.

In addition to longer-term studies and evaluations, works to improve rideability and access are ongoing at the sites. Significant efforts have also been made to reduce further regression of landslide sites and restore access where possible, or provide an alternate access route, says Crebo.

Works have included surface and drainage improvements at various sites, construction of a temporary access route at Kersley Dale Landing that opened in December 2021, and the re-

opening of a single-lane temporary access road through the slide zone of Quesnel-Hydraulic Road, about 20 kilometres south of Quesnel, in September 2022.

Interim paving was also completed at Highway 97 at Cottonwood and drainage improvements were made on Bastin Road at Bastin Hill.

Long-term, MTI officials are intent on exploring climateresilient solutions to keep the Cariboo roads open and safe.

“In keeping with the ministry’s efforts across B.C., our design engineers and consultants are also considering how future climate events will affect infrastructure and what can be done to make our roads more resilient, so they remain reliable and open,” says Crebo. “Some works may include upsizing culverts, bridging areas of concern where culverts are no longer suitable, redesign of drainage channels for future flow and better armouring of slopes.”

To that end, and to help inform area solutions, ongoing geotechnical investigations, including aerial LiDAR surveys, drilling and ground movement monitoring are taking place.

Sites continue to be monitored and the MTI states that information gathered through its investigations and analysis will influence next steps at each of the sites.

Currently, $146 million has been committed to the CRRP for engineering work for nine sites and construction of one site.

“The ministry is doing a thorough, multi-phase and technical-driven process and timelines will vary due to the nature and complexity of each site,” notes Crebo. “There is a significant amount of information that needs to collected, analyzed and discussed with residents, road users, local government and Indigenous communities as needs are identified and options assessed.

“All 10 projects are independently moving ahead and the intention is to provide solutions as soon as possible.”

Low res 215 PPI

BY HEATHER polowyk

> Bank swallows in pits and quarries. Do you dig it? Bank swallows do, too! Bank swallows are federally threatened birds that can make their summer homes in pit and quarry operations. In Canada, bank swallow populations have declined by 98 per cent over the last 40 years. Pit and quarry operators like you can help conserve bank swallow populations.

Bank swallows are small birds that feed entirely on insects they catch while flying. They have brown upperparts and white underparts with a large brown band across the upper chest. They breed in Canada during our summer months (May to late August) and fly to South America during winter. For nesting, bank swallows dig burrows about 65-cm deep into loose substrate embankments with a near vertical face (70 degrees or more) along ocean coasts, lakes, streams, rivers, and wetlands. They will also nest in human-created

habitats such as piles and cut faces in aggregate pits and quarries. Bank swallows are colony nesters with colony sizes ranging from a few individuals to several thousand nesting at one colony. They often return to the same nest site year after year.

Act. Under these acts, individual birds, nests, and eggs are protected.

So, what happens if bank swallows decide to make their summer home at your pit or quarry operation? A few steps can be

For nesting, bank swallows dig burrows about 65-cm deep into loose substrate embankments with a near vertical face (70 degrees or more).

The reasons for declining bank swallow populations are still being researched, but some of the main pressures bank swallows face include the global decline of insects, habitat loss, and climate change. Loss of breeding habitat happens as coastal and inland waterbody banks are covered in rock (rock armouring), overly eroded during the summer, or developed. Artificial slopes (pits and quarries, road banks) provide another potential habitat to this species when there is no summer disturbance. Due to their decline, bank swallows are considered "Threatened" under the federal Species at Risk Act and are protected under the Migratory Birds Convention

taken to help keep operations going and protect bank swallows.

Before bank swallows arrive (before mid-April):

In mid-April, bank swallows arrive in Canada to begin nesting. Before they arrive, in active work areas, you can:

• Flatten piles to have slopes less than 70 degrees. This makes the pile unsuitable for nesting bank swallows.

• Install scaring devices to deter bank swallows from nesting in active work areas.

For inactive work areas (until at least late-August):

• Provide habitat for bank swallows by creating vertical slopes of at least

70 degrees in sand or dirt piles and faces. This will encourage bank swallows to nest in these areas.

During the breeding season (mid-April to late-August):

In active work areas, you can:

• Flatten newly created vertical faces (to have a slope of less than 70 degrees) at the end of each workday and before weekends to prevent the establishment of new colonies.

If a colony establishes in an active work area, you must stop excavation work in that area and cannot use scaring devices at this point. What you can do is:

• Mark off a buffer zone of at least 50 metres around the colony to prevent the burrows from collapsing. This is the minimum recommended distance for a buffer zone, and louder, more intense activities (e.g., blasting) may require larger buffer zones.

• Reach out to Birds Canada to tell us about your active bank swallow colony – we would like to support and thank operators who can provide habitat!

You can excavate the nesting site at the end of the breeding season, after all the birds have left. However, bank swallows will often return to the same nesting site year after year, so we encourage you to provide alternative habitats in inactive work areas the following year by creating piles with a slope of at least 70 degrees.

If your operation is closing and the piles that bank swallows use are still in good condition and do not pose a safety issue, please consider leaving them for future breeding seasons. If you are obligated to rehabilitate your land, we suggest discussing leaving bank swallow habitat with the permitting authority.

Bank swallows are an important part of our natural world. They provide direct benefits to you by eating pest insects that can carry diseases, harm crops, and annoy us during our outdoor experiences. For any questions, contact Heather Polowyk at hpolowyk@birdscanada.org.

BY SETH ulmer, sales manager, curb roller manufacturing

> For concrete contractors, screeds are an essential purchase and a critical tool for providing the smooth, level finish for concrete work. By carefully considering the screed types available, contractors can see maximum productivity from their investment. The most common screed categories include roller, truss, laser, power and hand screeds. Each screed has unique features that, when aligned with project goals, can improve ROI. Here is a breakdown of the features, benefits and drawbacks of the most widely available screeds on the market.

Roller screeds broadly consist of a detachable pipe connected to a drive head with an extended handle for upright, ergonomic operation. These screeds are known for their minimal setup, low learning curve and the consistent, quality results they provide, with less reliance on the operator’s skill level. Roller screeds use a spinning motion to move concrete, a method that reduces operator fatigue and allows for improved integration of aggregate throughout the pour compared to vibratory methods that cause

the aggregate to settle. These screeds are versatile and can be used for a variety of pours, often up to 22- to 30-feet wide, depending on the power source.

The roller screed’s detachable design also makes for a highly portable option when compared to bulkier and heavier screeds like a laser screed. Some manufacturers even offer linkable pipe sections to increase portability and versatility. General features like a three-way adjustable and lockable handle for improved ease of operation and a kickstand to keep the drive head and handle out of the concrete allow crews to quickly adapt to various jobsite needs. Contractors have four different power options to choose from: battery, corded, hydraulic and gaspowered.

Battery-powered roller screeds are easily maneuverable and can handle pours up to 22-feet wide. These versatile machines can be especially useful for contractors working in basements or factory settings indoors, at farms, or communities in remote locations.

Depending on the slump and pipe length, a contractor can screed off 1,800 to 2,500 square feet of concrete with just one fully charged battery. Since the battery

operation provides fume-free screeding for those working in any closed-off environment where fumes may be a concern, no additional power source such as gasoline, hydraulics or a generator is required. That means fewer transportation needs, reduced setup time and no cords or hoses in the way. Some battery-powered roller screeds can also provide cross-platform use by utilizing the same rechargeable 60-volt lithium-ion battery that is found in common handheld power tools.

For special projects such as circular pours, battery powered roller screeds provide a convenient single push-button directional change. This allows contractors to easily change their screeding direction to avoid cold joints or other structural flaws that can occur when concrete cures unevenly. Other screed types may require a complete disassembly, drive head rotation and reassembly of the screed to reverse direction.

Despite all the conveniences batterypowered roller screeds offer, if power accessibility isn’t a concern or portable jobsite generators are abundant, some contractors may opt for a corded screed.

Corded electric roller screeds enjoy many of the same benefits and capabili-

ties as battery powered roller screeds. They are fume-free for indoor jobs and some provide a single push-button directional change for screeding unique pours. With a nearby outlet or reliable generator, contractors can have the reassurance and convenience of seemingly endless power.

While enjoying the convenience of power, contractors must consider proper care to ensure the cords don't become tangled, unplugged or damaged while on the jobsite. And relying on a separate power source, like a generator, can come with its own worries. That can include staying on top of fuel availability, general maintenance or fume concerns.

Battery and corded power can offer an immensely convenient and versatile screeding solution to any contractor’s fleet. But some heavy-duty applications, like road drainage and ditch liner pours, require large custom drums and a screed powerful enough to drive them. This is where hydraulic roller screeds shine.

Hydraulic-powered roller screeds have the power to move up to six inches of concrete along a pour while the operator remains in a standing position. Additionally, most hydraulic roller screeds accept 6-inch tube length up to 30 feet while some

√ No climbing over belts or up hundreds of feet to grease hard-to-reach bearings

√ Greases while plant operates = bearings greased even during busy season

√ Connects to plant PLC to remotely monitor Lube System for alarms

√ Reduces maintenance costs

√ Increases safety for your operator & maintenance personnel

√ Uses your standard in-shop grease

Hydraulic-powered roller screeds have the power to move up to six inches of concrete along a pour while the operator remains in a standing position. Additionally, they accept any 6-inch tube length up to 30 feet while some manufacturers also offer custom drums made to various job specifications such as sidewalks, parking lots, residential streets, large highway ditch liners and more. Photos: Curb Roller Manufacturing.

manufacturers also offer custom drums made to various job specifications such as sidewalks, parking lots, residential streets, large highway ditch liners and more.

Like corded screeds, hydraulic screeds require a separate power source. Look for a manufacturer that provides a portable hydraulic power pack to match their hydraulic screed’s exact specifications. With this option, contractors don’t have to tie up a host machine to power their hydraulic screed. To take on heavy-duty jobs, these screeds are also generally heavier than battery and corded roller screeds at two to three times the weight. Contractors should consider how to accommodate the additional weight before committing to these powerful screeds.

Gas-powered roller screeds have a similar setup as the other roller screeds but with a motor attached to the drive head. These screeds offer another option for contractors who typically screed large pours that require a longer pipe, often up to 30feet wide. The motor produces screeding power that rivals that of hydraulic screeds and offers a viable, familiar alternative for those preferring a gas engine.

Unlike the other screeds, more care is required as a gas-powered screed motor needs to be in an upright position to avoid gas and oil from leaking out. This can prove even more challenging due to the heavy weight of the engine on the drive head. These screeds have location limitations as well, as they cannot be used indoors due to the exhaust and fumes from the engine. Engine vibrations present another area of concern. The high vibration from the engine can cause the throttle cable

to slip and need continuous readjusting.

A major design shift from rollers, truss screeds level off concrete with vibration instead of a spinning pipe. These screeds are expandable and come in multiple sections that resemble a truss design to help maintain rigidity for longer lengths, even beyond 60 feet. Truss screeds can be an excellent option for the largest jobs, like screeding an entire roadway.

Vibrations from a motor attached to the truss carry throughout the screed as contractors guide it along concrete forms, flattening and settling the concrete to remove trapped air, increase concrete strength and provide a smooth finish. However, due to the vibration, these screeds are generally not used on a slope. The aggregate in concrete tends to settle with vibration and unevenly dispersed aggregate can create spots of varying strengths that can result in structural flaws and damage over time.

As a recent entry to the screed market, laser screeds are growing in popularity for larger concrete pours and those that require a high degree of precision. Laser screeds can be found in a variety of styles ranging from telescopic attachments to ride-along machines. The screed’s laser arm ensures a precise, accurate and evenly leveled surface while reducing the need for excessive labour. The average laser screed can screed approximately 240 square feet of concrete in one minute — making this equipment a game-changer

for the concrete industry. While laser screeds bring benefits including ease of use and reduced labour expenses, the biggest downside of purchasing a new laser-guided screed is the cost of up to $350,000. Additionally, some of the widest laser-guided screeds available on the market can have a maximum width of 20 feet, making their functions more specialized and significantly affecting their overall versatility. This may also pose problems for operations arranging to transport their equipment to and from job sites.

In what could be considered an assisted hand screeding method, power screeds, also known as wet screeds, consist of an engine and extended handle placed in the center of a traditional board/blade that is in contact with the concrete. Power screeds use vibration to help the blade level the concrete. These require a lot of skill and experience by the operator.

Although more ergonomic and efficient than traditional hand screeding, power screeds require the operator to stand in the poured concrete while screeding. The vibration has similar benefits and drawbacks to that of the truss screed. Due to their one-man operation and center support, manufacturers typically limit the board/blade sizes to around 15 feet.

Classic hand screeding, which traditionally uses a wooden board, might cut it for the one-off small concrete job, but any serious contractor knows the life-long pains that come from years of stooping over a heavy board and sawing it back and forth along forms to screed concrete. Although the materials have evolved over time from hefty two-by-four lumber to lighter weight aluminum alloy bars, the design and method has largely remained unchanged.

In addition to the back-breaking labor, hand screeding methods using boards require the skill of an experienced professional to remain true to grade and achieve consistent results since there’s no assistance from vibration or a spinning pipe. This can prove challenging on large pours, even with decades of experience.

No matter the method, choosing a manufacturer that offers not just options, but high-quality construction, parts and service will help limit problems to small, logistical inconveniences.

BY ANDREW SNOOK

> Every year Rock to Road celebrates 10 of the aggregates and roadbuilding industry’s young professionals rising up the ranks in their respective positions.

We had the opportunity to sit down and chat with all of the winners about what attracted them to the industry, their favourite projects, career advice for young people entering the industry, and more. Here are those interviews.

Congratulations to this year’s winners!

TROY MACBETH ABROMAITIS Director of Development

Bucci Construction

Vancouver, B.C.

Troy MacBeth Abromaitis was officially introduced to the construction sector when he took a job within the homebuilding and construction sector 16 years ago with Wallmark Homes in Burnaby, B.C. That said, Troy’s enjoyment within the sector began at a very early age, building with Lego and playing with Tonka trucks as a child.

“I'd always been passionate about construction. I felt that it was fascinating when it comes to being involved in building, whether it's a home, roads, or whatever the case is,” he says.

After working at Wallmark for seven years, Troy joined Bucci Developments in 2013. During his time with the company, he has been involved in a multitude of projects.

“I'm very involved in working with architects, engineers, civil consultants on the civil design, project infrastructure and many other project elements,” he says. “I’m actively involved in the development, schematic design, pre-construction and construction tendering of these projects. We do millions of dollars of work with roads and civil infrastructure as part of the community projects.”

One of Troy’s favourite aspects of his work is meeting a wide variety of people from different professions, backgrounds and cultures.

“When you're working with the construction teams, you come across different individuals with diverese backgrounds. For example, my background is First Nations. I'm a member of Lytton First Nation and I'm very involved and active within my community helping with the rebuild after the 2021 wildfires,” he says. “With Bucci, you're dealing with people from all different walks of life.”

Troy enjoys working with people at all levels of the construction process, whether that’s the person in the rain and snow coordinating the traffic when the roads are being worked on, someone tearing up the roads, performing soil compaction, or working on civil services upgrades under the roads.

“I find this work incredibly interesting, when you design a civil project, everything is typically perfect on paper. However, when you actually get into the thick of things, it's a hundred different people working on a thousand different details to bring it all together,” he says. “I really love that part of the construction lifecycle because you meet all types of people from different walks of life, and you get to know them. You might know them through friends of friends, or maybe they'll become a new life-long friend of yours. It's the human aspect, the personalities of civil construction and road projects that I personally enjoy.”

Over the course of his career, Troy has worked on many interesting projects. One that stands out is the Fleetwood Orion redevelopment project in the Fleetwood neighbourhood of Surrey, B.C., which will include the construction of three residential high-rise towers including more than 1,100 homes

“There’s was a ton of envisioned road work and civil work that has to be completed. When we were working with the City of Surrey on the design we were pushing road frontage on all sides of the site, and developers typically don't do that – they would rather develop more square footage and have less road frontage. Roads are critical infrastructure to be able to get cars and people from point A to point B. Accordingly, we're widening the roads and installing a traffic intersection. We're adding new street frontages all across the site we're working on. I'm particularly happy with that, because we're going above and beyond what you typically do on a site like this.

It's probably the largest civil project that I've ever worked on, so I'm really excited about that,” he says.

Troy says one of the biggest challenges facing the construction sector today is navigating all of the red tape.

“Unless the government has an incentive, or a push, to see a project through, it can take an unreasonable amount of time to get a regular road upgraded,” he says. “I think the biggest issue is making sure that the government works on an outcomebased approach, whether it's the municipal or provincial government, and they also focus on stakeholder engagement and people who are impacted by the road construction… I think there are better ways to get roads and infrastructure and other critical elements approved.”

When asked what advice he would give younger people looking to get into the construction sector, Troy recommends picking your passion and sticking with it.

“The industry is so broad, there's engineers, designers, planners, and there's government officials involved for approvals. And then there's the people who actually work on the sites, getting their hands dirty. The industry is really multifaceted,” he says. “I've never met someone who started in one position and didn't end up in another much more advanced position, whether it's through promotion, experience from years of the job, etc. Being able to work in this industry is really rewarding. But at the same time, you pick your passion, focus on that, and try to excel at it. I think if you do, you’ll have a really amazing career.”

Former colleague Jay Chadha says Troy is a natural leader, bringing poise, determination and passion to his endeavours.

“He was the first Indigenous president of the Real Estate Institute of British Columbia and a founding member of the National Indigenous Affordable Housing Corp. His leadership has been recognized by the National Center for American Indian Enterprise Development with the Native American Top 40 Under 40 Award,” he says. “He is also a champion for road works, civil services and new communities with an active portfolio in the development process in excess of $800 million. In his career, Troy has overseen

34 multi-family development projects totalling over $2 billion. At Bucci Construction, he oversees road works, civil and residential and commercial projects. He is one of the most accomplished Indigenous real estate professionals in Canada, having been recognized internationally for business professionalism, philanthropic efforts, volunteerism, and dedication to giving back to the community.”

Jay adds that Troy is working towards the reclamation of his culture and identity as a proud member of the Nlaka’pamux Nation.

“He is working actively with his Nation and other local Nations to develop and innovate new opportunities. His goal is to help prepare First Nations to utilize their territories to benefit their communities and members,” Jay says. “Troy is also a member of Lytton First Nation and his community was decimated by the wildfires in B.C. As an Indigenous business leader, he recognized this was a serious issue and he personally fundraised more than $60,000 to help rebuild his community. His efforts did not stop there, he also serves on the board for the economic development committee to further benefit his nation’s community rebuilding efforts. Troy is passionate about helping his community recover.”

In the future, Troy would like to become involved in politics to help fix problems within the approvals process within the construction sector.

“Based on my experience in construction, I want to get involved in helping eliminate some of that red tape. So, one of my future goals at some point – probably when I’m retired from development and construction– is I may get into politics. I just don't know when or in what capacity, but that's always something that I think about,” he says, adding that he also wants to dedicate his time to helping Lytton First Nation. “I want to continue to help my First Nation. I'm one of the only members in my community that has these skills in real estate, development and construction. Being able to reintegrate with my community and help them with the rebuild, whether it's housing, infrastructure, roads, or whatever the case is, I’d like to immerse myself in it and try to help.”

For Sarah Bond, being introduced to the industry was sort of an accident. After graduating from McMaster University in Hamilton with her Bachelor of Engineering degree in 2008, she immediately started looking for work, but prospects weren’t great in Ontario.

“I started out by working for Lafarge [Canada] in Edmonton. I had applied to Lafarge because I graduated with a double cohort and there were not a lot of job opportunities in Ontario,” she says. “I wasn’t really focused on the mining world, but the job for Lafarge came up and I just loved it and stayed in the industry.”

Sarah started off in the company’s sand and gravel pits in Edmonton and worked at various plants in quality control, land management and permitting. She learned a lot through her time in Edmonton, but once an opportunity came up to work at bigger quarries she jumped at the chance.

“The bigger quarries on Texada Island came up and I haven’t looked back,” she says.

Sarah’s favourite aspects of her role as mine manager are being able to work outdoors managing the complexities of the operation, while also knowing that the products her mine produces are needed in a wide variety of applications.

“I like that this is a very complex job, where you might not think that it would be. We deal with chemical composition of the limestone as well as gradation

requirements. There are waste seams to move around and out of spec materials to remove. It becomes more dynamic than a typical sand and gravel operation,” she says. “You’re the first step in countless manufacturing processes and consumer products. It’s interesting and exciting and changes everyday as the mine progresses. I really like mine planning and development, it’s a massive chess game where you’re moving the pieces around to make a seamless operation. It’s satisfying when you look back at the work over a few months and see how many things have changed in the quarry and the long-term progress that has been made.”

Sarah has had several key projects that she’s been proud of over her years in the industry. One of them is her current role developing a mine plan for the site she’s managing.

“I’m changing the direction of how the mine has been operating, opening it up for long-term success. I did the same thing at Lafarge. Being involved in the mine planning at Lafarge was another big one I’m proud of,” she says.

As far as challenges the industry faces goes, Sarah believes industry perception and permitting are two big hurdles to overcome.

“There is a tendency within communities to project a negative light on the mining industries. I would like to shift that mindset where there is an understanding that mines and sand and gravel pits are vital operations to our way of life, helping to support infrastructure in our communities. We are a strong partner within our community and continue to work on building our relationship. Mines are held to a high standard for safety, environmental compliance, First Nations relationships and I don’t think the general public realizes that there are conditions required by regulating bodies to operate,” she says. “Also, it’s a heavy burden to get anything permitted and there are a lot of conditions that need to be adhered to, and things to be monitored. We need to build better relationships with the communities we operate in because it goes hand in hand with meeting our high standard.”

Sarah’s future goals for her career are to keep accepting new challenges, developing her experience, and to continuously improve.

“I never want to stop learning. If I stop learning, it’s a problem,” she says. “Every time you turn a stone over there’s a different puzzle, whether its learning about the different haul trucks, mechanical assemblies, crushing equipment and chemistries. I think that’s one of the reasons I like it so much. You’re always on your toes, and the learning that comes with that is pretty fantastic.”

She adds that one of biggest drivers in her career is focusing on trying to change the negative perception of the industry and to partner with the community and “change the face of mining, so it’s something that people want to have in their community.”

Being a woman in the aggregate industry can also come with additional hurdles to overcome.

“As a woman, you have to know 10 times more to be taken seriously,” she says. “If it’s a man [in the same role], his knowledge is assumed. My knowledge has to be proven.”

To attract more women into the industry, Sarah says equal opportunity is obviously a good start, but she adds that it’s not an industry all women are going to want to get into, so a big part of companies’ focus should also be on retention of the

women already there. She says having good maternity leave programs and training programs would help.

Former work colleague and friend, Jennifer Chilton, says Sarah is well deserving of the important roles she plays at Imperial Limestone.

“Sarah is an amazing, accomplished person. She has worked her way up in the industry from mascot to mine manager. She is dedicated to her work and her employees. She is an icon for women in the industry and STEM in general, as a professional engineer. She is positive, intelligent and humble,” she says. “I think she is deserving of this spotlight. She is a rising star in her company, with a stellar reputation in the industry. Besides work, she is also an amazing mother to two boys, volunteers on the local fire department, and can finish a Rubik's Cube in record time. It doesn't take much digging to find all the reasons Sarah is a perfect candidate for this feature.”

When asked what advice she would give young people looking to get into the industry, she says to not shy away from being boots on the ground.

“Don’t be afraid to get your boots dirty. Ask questions and get out there, learn everything, become a big sponge,” she says. “You can’t be afraid to get out and ask questions. Learn from everybody. It’s an older industry, listen to those people, absorb that information.”

Cambridge, Ont.

Operations Manager

Nelson Aggregate

For Valerie Snowdon, getting into the aggregate industry was very much a family affair.

After working a variety of a positions including working at a machine shop creating orthodontics and aerospace products, she decided to join her father, John Krueger, at Nelson Aggregate (Waynco Myers), where he worked for 30 years.

“Ten years ago, my Dad was the lead hand and they were looking for a QC technician,” Valerie recalls. “I started in QC, but then they were short employees in the pit, so the operations manager asked if I minded helping out boots on the ground a little bit.”

Valerie took advantage of every opportunity she had to learn more about the business and found herself working within a wide range of positions at the company.

“I transitioned into learning the loaders, skid steers, haul trucks, screening plant and wash plants. I eventually transitioned to dispatch at that site, and have continued to work my way up,” Valerie says, adding that she learned a lot about the business from her father and her uncle, Joe Horn, who worked as an equipment operator and as a member of the maintenance crew with the company for 28 years. “It was an amazing time because I got to work with family. We had a crew of six who were very knowledgeable and I learned a lot from them.”

Five years ago, a tragic workplace accident took the life of her uncle, Joe. Valerie

chose to push through that tragic loss and work towards making a positive impact in her role in memory of her uncle.

Valerie’s favourite aspect of working within the aggregates industry is the relationships formed over the past decade.

“It’s not an easy industry at times and can be very challenging however it can also be rewarding when you find similar, like-minded people with similar goals, for succeeding and putting safety first”

One of the people she has a great working relationship with is Alex Caruana, national manager for Canadian aggregates at Polydeck, who nominated Valerie for the Top 10 Under 40 Award.

“Valerie is a textbook example of working hard to continuously learn and apply oneself. In doing so, she has progressed through various roles at Nelson Aggregate to where she is now as operations manager at the Waynco Pit. I have no doubt that Valerie will be a crucial part of Ontario's aggregate industry,” Alex says. “Valerie is not just a dedicated problem solver, but she is also very willing to help others. Recently, when another aggregate operations manager had a problem that Valerie had gained quite a bit of knowledge about, Valerie did not hesitate to share solutions with them so that their operation could bounce back into production quickly. Valerie belongs in the Top 10 Under 40!”

When asked about one of the projects that Valerie is most proud to have been a part of, she thinks of the ongoing highway improvement project still ongoing in the Kitchener-Waterloo-Cambridge (KWC) area.

“I was the quality manager a couple of years ago and we were one of the main suppliers. This was rewarding because it’s in my home city, Cambridge, five minutes from where I live. I was out there sampling ensuring quality products were going into the work. Knowing it came from your pit is something to be proud of,” she says.

When asked about the challenges facing the industry, Valerie says recruiting employees is probably the most challenging.

“It’s a difficult industry, we work very hard for nine months of the year for 10- to 12-hour days on a regular basis. It’s like that old saying, ‘Make hay when the sun shines.'

When you bring in the elements of upwards of 40C in the summer months, and then in the fall you’re working out there when it’s -15C, finding individuals that don’t mind getting their hands dirty and working in those tougher days is probably the hardest part of the industry,” she says.

Valerie says more education efforts could be made by the aggregate industry to help educate young people about the various career opportunities in the sector.

“Prior to coming on board, I knew my Dad came to a pit but didn’t fully understand what he did,” she recalls. “There definitely could be more awareness brought to job fairs and high schools to educate younger people on what we do. Everyone understands the construction aspect of roadwork, you see that as a kid driving past it all the time. But you never see quarries with blasting, extraction, or the crushing aspects to get it down to the final products.”

Being a woman in the aggregates sector has also created some hurdles for Valerie to overcome.

“You need to have tough skin as there are times where you may need to work a little harder or may not be taken seriously. This can be disheartening; however, there are equally a number of fantastic men that I have encountered through my ten years that are beyond supportive that I have wonderful friendships with.”

When asked what advice she would give to young people considering a career in the aggregates industry, Valerie says to take a good look at all the different career options available in the sector.

“It can be a tough industry, but it’s a very rewarding industry. There’s lots of room for growth, whether you work in the sand and gravel pit or the construction on the side of the highway. Every day brings new challenges, no two days are ever the same, it can be fun in that respect,” she says. “It’s an industry that’s always going to be around. There’s always going to be infrastructure needs, and there’s long-term employment in it. There’s lots of departments, whether it’s the sales side, quality, safety, equipment, there’s somewhere you’d fit. My dad always says it’s like a kid playing in the sand box, if you’re into machinery, it’s an industry you’re made for.”

JARED KUEPFER

ARRO Crushing Ltd. Owner Millbank, Ont.

Jared Kuepfer got introduced to the construction sector through his father’s dimensional stone business.

“We would go with him to different quarries in Ontario and watch the equipment, and thought it was pretty cool. We saw people pulling rocks out of the ground and crushing rocks and thought that was pretty awesome. Early on, I knew I wanted to be involved in heavy equipment,” he says.

Witnessing his father start up his own business fuelled Jared’s desire to do the same. While thinking up ideas for a new business he had considered an excavation business, but found the market was already saturated and too competitive. That’s when he thought about a crushing operation.

“I heard it was hard to find crushing guys, so that’s how I got the idea to start up a crushing company,” he says.

Jared says he really enjoys creating products that go into important infrastructure.

“The public has no idea what goes on behind those [quarry] fences, realizing the amount of work it takes to build aggregate

so you can have roads and hospitals. I like being part of where society starts, building a base so you can commute to work or wherever you need to go,” he says. “Sometimes you don’t really know where your aggregate goes, but once in a while, you hear they hauled 10,000 tonnes to a hospital site… crushing can be hard, dirty work, and it can be very rewarding for the society that we live in, and the local economy. We’re kind of an unseen industry.”

When it comes to employing people, Jared isn’t afraid to train someone that has no industry experience.

“I’ve brought in a handful of employees that came to me with zero experience in the aggregate industry and trained them from scratch,” he says. “They’ll come to me six months after working here and they’ll say they had no idea there was so much opportunity. They had no idea there were these huge quarries within kilometres of where they live, or how much

concrete gets recycled in this industry.”

Mark Nesbitt, founder of Nesbitt Training, has been working with Jared for well over a year, and has witnessed tremendous growth in his leadership skills.

“Jared is by far one of the most serious company owners I have ever worked with,” he says. “He understands the future of his company is completely dependent on developing, training and retaining people. His goal is to show the industry he can make crushing fun again, while remaining professional. He is doing this by creating and living his own company values that are easy to apply and live out. The results of his efforts have made ARRO a company that is always attracting new people to an industry that needs people badly.”

One of Jared’s favourite projects that his company has worked on to date is an ongoing 400-series highway project with a major contractor.

“We’ve been doing a lot of work with a major contractor, recycling concrete and asphalt off the QEW (Queen Elizabeth Way). We’ve crushed well over 100,000 tonnes of concrete and asphalt that has gotten directly laid down on that road expansion,” he says. “Recently, I drove out to that highway and showed my guys that the contractor is paving that highway with material they’re crushing right now. I tell them, ‘You’re running a crusher to feed that asphalt paver.’”

Jared says finding enough skilled labour to fill demand is the biggest challenge facing the industry.

“Hands down it’s the labour shortage. Talented labour can be tough to find. When it comes to labour, we need to do a better job showcasing what this industry does,” he says, adding that pits, quarries and recycling operations receive a lot of negative reactions from local residents that might not want the trucks on their roads or are worried about environmental impacts of operations. “We’ll always need aggregates, and we’ll always need to recycle. We need to get better at showing what we’re doing. [The public should] go ask an aggregate producer to see if they’ll give you a tour of their operations. A lot of people will be amazed at the things the aggregate industry is doing for people on a daily basis.”

When asked what advice he would give to young people looking to enter the industry, Jared says they should start by looking online at companies that are showing off their work.

“Look at their work, so you can get passionate about what they’re doing, then start applying for jobs. Be passionate about it. Try and care as much as you can. Have a good attitude and show up on time and you’re going to go places,” he says. “You hear a lot about young people not knowing how to work, I don’t buy into that. They want to work for more than their paycheque… young guys come on looking for a job in heavy machinery and say, ‘Look at the impact I’m making, and they take a lot of pride in that.”

Jared’s future goal is to keep growing his company within the recycling industry.

“Whether that’s adding more crushing spreads or other aspects of the crushing industry – like the bio waste, for example,” he says. “The future is in recycling. We can do a lot better job in recycling

our materials. We need to reuse more through better recycling processes. As the world gets more populated, there’s going to be more and more trash. Thirty years ago, we were burying concrete all time. Now we’re essentially mining it out and turning it into aggregate because we’ve realized the value in that. I’m hopeful about the recycling industry’s future.”

Land & Environment Manager

Vicdom Sand & Gravel

Uxbridge, Ont.

Working at Vicdom Sand & Gravel is a family affair for Victor Giordano. Originally started up by his grandfather in the 1950s under the name, Giordano Sand and Gravel, before becoming VicDom Sand and Gravel in 1976, the company has been part of Victor’s life as long as he can remember.

“I grew up around the business. As soon as I could legally work, I was there,” he says.

Victor worked his way up from cutting the grass into a variety of other roles so he could get as knowledgeable of the family business as possible.

“I started with cutting grass and worked my way up from there to maintenance, compliance, all types of things. Then, all of a sudden, I’m helping out with licensing, new equipment purchases and where we’re setting up new equipment,” he says. “Being in the industry was almost a no-brainer for me, I’ve enjoyed it from a young age.”

One of Victor’s favourite aspects of working in the aggregate sector is witnessing the direct results from his work.

“If I make a change on a property, I can see the results – as opposed to if I was working away on a project and didn’t see the fruits of my labour. If I make a change to a wash plant, the tonnage either goes up or down, or the quality of the product improves, that’s a direct result,” he says.

Starting up Sebright Quarry is Victor’s favourite project he’s worked on to date.

“Turning that over from planning the initial stripping to cutting of the trees, building the entrance, getting our first initial blasts taking place and the crushing of the first blasts, starting that quarry from nothing,” he says. “Now we have our license and our first phase of the project underway. It was one of the first ones I was able to do on my own.”

Alex Caruana, national manager for Canadian aggregates at Polydeck, says that Victor clearly loves what he does and is involved in every aspect of Vicdom’s operations.

“Whether it is looking at the longevity of an operation, moving a dredge, or ensuring lubrication points are tended to on equipment, Victor is there working at every little detail with his crews,” he says. “Clearly enjoying his work, and always sporting a big smile, Victor's attitude, constant learning and positive, solution-oriented ways are exactly what you'd expect to see in a strong developing leader. Capable of going from permitting to processing, safety to logistics, Victor is a self-starter with a great future in our industry. When I get the call to visit Vicdom’s operations, it is always something I look forward to – working with Victor and his crews, since not only is work done safely and well, but fun is had getting the work done, too. In a nutshell, Victor is accomplished and positive, always looking for and applying a better way.”

The current labour shortage and sterilization of resources in the aggregate sector are the biggest challenges facing the industry, Victor notes. He says close-to-market aggregate deposits being sterilized and having homes built over them is a big challenge.

“They’re either building houses on it, or protecting species on it, and then those resources are gone forever,” he says.

When offering advice to the younger generation thinking about a career in the aggregate sector, Victor says to not stay complacent in your position.

“Try your hand at everything. This industry has so many departments and silos. You can learn huge skill sets from health and safety to land management, purchasing, accounting, maintenance of machinery, dispatch, trucking and sales,” he says. “It’s valuable for your growth and to the company, which ultimately improves your value.”

In the future, one of Victor’s goals is find better solutions for hauling aggregates.

“I’d like to tackle the hurdle of transporting aggregate around the province. Trucking is a huge issue. If I do anything in the aggregate industry, trying to figure out the issues around trucking aggregate and finding out a better way to do it more efficiently for everyone would be it. Then we could go up north and, if its economical, have a high-quality resource brought down to the GTA that would be more sustainable.”

PAVAN SIDHU General Manager Lafarge Canada, Saskatoon, Sask.

For Pavan Sidhu, the construction industry wasn’t part of her career plans growing up.

“I definitely got into the industry by accident, it wasn’t something I intentionally sought out, however it has turned out to be a very rewarding and challenging accident," she says.

After her first year as an undergrad in Vancouver, Pavan took a summer job working for Lafarge Canada as an accounting administrator to earn some extra money. She had no idea she had just started on a path towards an extremely successful career.

“Lafarge leadership asked me to stay on after that and said they would put me through school,” she says. “I spent the first eight years of my career in finance.”

During that time, the construction market in Saskatchewan was starting to boom and Lafarge Canada was expanding its presence throughout the province. This presented an opportunity for Pavan to gain some valuable experience.

“They needed a finance department with processes setup. I signed up to do an 18- to 24-month term to set up a finance team in Saskatchewan,” she says. “I was in that role for 18 months and said to them, ‘I feel like I’ve completed this role and I would like to head back to B.C. and as much as I am enjoying finance, I am not sure this is the part of the business that I am the most excited about.’”

Lafarge Canada management helped create a career roadmap for Pavan so she would have the opportunity to grow beyond her role in finance. In 2011, she moved into an operations role on the

concrete side of the business. She then held a variety of roles from 2011 to 2017. At that point, the general manager position came up for all of the product divisions for Saskatchewan.

“It was definitely a stretch role, but I was excited for the opportunity to learn and develop,” Pavan says.

As general manager of Lafarge Canada’s Saskatchewan operations since 2017, Pavan’s role encompasses several product lines, including aggregates, ready mix, asphalt and paving. She applies her financial acumen, passion for business strategy, networking abilities and construction knowledge in leading her teams across the business. Pavan now has over 18 years industry experience and has worked on several notable projects including: BHP Jansen Potash Mine, Cyclotron at the University of Saskatchewan, Chief Mistawasis Bridge, University Drive rehabilitation project, and the home of the Saskatchewan Roughriders.

“Pavan’s notable projects are complemented by record-breaking years for the business. When faced with challenges during COVID-19, she worked alongside her team to implement additional safety processes while managing costs due to a sharp drop in revenue; ultimately creating more trust and a deepened culture of ownership,” says Emilia Salamon, human resources coordinator for Lafarge Canada.

Emilia says Pavan has worked hard to create teams that are more agile in how they problem solve and execute on internal issues and processes, as well as project delivery.

“Pavan’s team recently overhauled their local safety practices and culture by adapting a methodology from the tech space called ‘sprints.’ The sprint process allowed the teams to focus on a single key area of safety every couple of weeks and completely overhaul practices without distraction for a focused time. Over the period of four months, safety practices in every aspect of their operations were improved,” Emilia says.

Pavan’s favourite aspect of working in the construction sector is that it’s very dynamic and challenging.

“You’re trying to get a project completed, but you’re dealing with many variables including weather, people, machinery and you’re not always able to control how many people you’re going to get in this labour market,” she says. “There’s no two days that are the same in the construction market and find that’s interesting.”

Pavan prioritizes diversity and creating inclusive space in the industry. In 2014, her operations recruited their first woman concrete truck driver to Lafarge Saskatoon, which at the time was quite challenging and even involved retrofitting the restrooms at the shop.

In 2022, Pavan was nominated and voted in by peers to join the Saskatoon Construction Association board of directors. As part of her work with the board, they launched the first Diversity, Equity and Inclusivity Committee for the association.

“We’ve been doing a lot of work to find ways to attract and retain diverse talent in our industry, including new Canadians, women, and members of different minority groups to the construction industry,” Pavan says.

She worked with the board of directors for Concrete Saskatchewan from 2015 to 2017 and has participated as a mentor in the Anne Heggie Women’s Mentorship program focused on support-

ing women that are new to their career. Pavan has also taught business strategy at the University of Saskatchewan to share her passion for the subject, and to additionally increase the visibility of women in the construction industry.

She says the biggest challenge facing the industry is the shortage of skilled labour.

“There are not enough folks out in the market that want to be in trades and driving trucks. There’s a shortage of candidates for every position that we post,” Pavan says. “We also have people on our teams where expectations on work-life balance is changing… it’s about attracting people to our industry and rationing the people that we have.”

Pavan’s advice for young people considering a career in the construction industry: think beyond the heavy equipment.

“We often think that a career in construction means being on a job site, working in a trade or operating equipment. However, there are many roles and positions that look very different than this. So, please do not rule out this industry without learning about some of the other careers that touch on areas like sustainability, resource/operations manager and design,” she says. “If you want an exciting, dynamic and interesting career where a job well done means something tangible to look back at, a new hospital, a new bridge, then this is definitely an industry to consider.”

PAUL LEVEILLE Chief Technology Officer

TerraShift/AMI RockChain Edmonton, Alta.

While studying to obtain an engineering degree at the University of Alberta, Paul Leveille quickly became intrigued by the world of mining.

“I learned about it when I was in my first year there, and it seemed like a pretty exciting industry,” he recalls.

After working for a variety of mining-related companies holding positions including surveyor, coal quality engineer, shortrange planning engineer, and permitting and reclamation planner between 2010 to 2017, Paul and a few of his colleagues decided they wanted to branch off on their own and start up their own consulting firm.

“We went off and created TerraShift Engineering. We wanted to start our own firm because we had this idea of using technology for aggregate companies to manage their sites and explore for new resources. At TerraShift, I led the development of the application, TerraMaps,” he says. “The purpose of the application was to enable companies to conduct exploration for new aggregate resources, to monitor the regulatory compliance of their gravel pits and quarries, as well as see who else is operating in the space through an intelligent data reporting platform,” he says.

As a co-founder of TerraShift Engineering, Paul helped turn the company into a very reputable and well-known consulting firm specializing in providing engineering services to the mining industry, says Derek Apel, one of Paul’s former professors at the University of Alberta.

“As chief technology officer, Paul has developed an advanced GIS system which is currently used by many sand and gravel, and peat moss harvesting companies,” Derek says.

One of the highlights from the TerraMaps platform took place in 2019, when the Alberta Sand and Gravel Association used data analyzed by the platform to successfully lobby the government to acknowledge and invest resources to address the backlog of regulatory applications that the aggregate industry was facing, which has led to the development of the Digital Regulatory Assurance

System (DRAS).

That GIS system, known as TerraMaps, has grown from being a platform for sand and gravel producers in Alberta to natural resource operators across Canada, says co-worker Janeen Ogloza.

In 2020, a presentation summarizing the results from TerraMaps captured the attention of Athabasca Minerals Inc. (AMI), and approximately six months later, TerraShift was brought into the AMI family and Paul was introduced to the RockChain platform, Janeen explains, adding that in 2020, Paul helped AMI RockChain Inc. launch its client-facing, online aggregate purchasing and selling platform. This allowed them to reach similar audience levels by securing a national group procurement contract with the Canoe Procurement Group of Canada for the purchase of aggregate.

“Although Paul had not imagined that his career would evolve in the direction it has, his success in developing and expanding two online platforms has led to his current role as chief technology officer, where he will continue to enhance these platforms and change how data is used. Paul has a positive impact on both projects and people, I look forward to seeing what else he does.”

Paul says one of the biggest challenges facing the industry today is the same as society as a whole: climate change.

“I truly believe in cost and environmental footprint reduction, and I think this will require a concerted effort by everybody,” he says. “Another challenge we face is Canada’s slow adoption rate of technology, which could work to help our sector's lower environmental impacts. For example, if we look at the geospatial aspect of RockChain, it can allow a company to assess the carbon risks of a project. Whether it is choosing one location for supply of aggregates to another, or using a specific route for hauling, you can use our platform to calculate the difference in carbon footprints that a portion of a project would have. We can help companies quantify their environmental impacts.”

Paul says that the development of RockChain 2.0 is one of the projects he’s most proud to have worked on throughout his career.

“When TerraShift was merged, I became closely involved in RockChain and I became the chief technology officer. At the time, RockChain was more of a fuzzy idea that wasn't totally formulated on how to execute. I was able to take this fuzzy idea and clarify the aggregate procurement process to an automated online workflow. And we did it in a way that’s scalable and accessible. It's rather unique, you don't have anything else quite like RockChain in the market and we’re filling a need for suppliers and buyers,” he says.

Paul’s long-term goal is to expand the reach of the RockChain platform.

“We’re very well established in Alberta, Saskatchewan and British Columbia, and we deliver aggregates on projects from Vancouver Island all the way to Ontario. But I really want to increase our adoption across Canada and get a better presence in each of the provinces. Our reason behind that is because we feel we can deliver a valuable product not just for the buyers and consumers of the aggregate, but also for the suppliers. We think

we can improve the business practices of aggregate companies and simplify how they bid on jobs, and how they access the opportunities that are out there.”

What advice would Paul give younger people looking to get into the aggregate sector? Get your hands dirty.

“Don't be afraid to work in remote places or to do jobs that might not be your ideal position, because you never know where you'll end up or where it could take you,” he says. “Learn to say ‘Yes’ to opportunities as they present themselves. I also think everyone should get their hands dirty at some point in their career, and take the opportunity to learn as much as possible. Also, learning to code never hurts.”

CHRIS FOREMAN Territory Manager, B.C. Foreman Equipment

Chilliwack, B.C.

For Chris Foreman, it was an easy decision to get involved in the family business his grandfather, John Foreman, started up in 1984.

“I was doing different odd jobs here and there around the business, but in 2017, I jumped in full force. I first worked in the shop, gaining an understanding working around and maintaining the equipment. When I was given the opportunity to grab a pack of brochures to take on a trip to to northern B.C., I never looked back,” he says.

Chris has worked extensively performing service and maintenance, has attended countless overseas OEM training seminars, and is now the technical sales lead. He applies his unique skill set and experience working on projects of all sizes and scope throughout B.C. and Alberta.

“In recent years, the British Columbia construction industry has been active and allowed Chris to share his expertise, working with contractors providing crushing and screening solutions on projects like the Site C dam, Prince Rupert Port Expansion, Transmountain Pipeline, LNG Canada, and several projects within Indigenous communities,” says Wade Bühler, marketing specialist for Foreman Equipment.

The Transmountain Pipeline continues to be one of the larger

projects for Chris and Foreman Equipment.

Some of the biggest challenges in B.C. have come from the massive devastation from the wildfires and floods that have plagued the province in the past year, and new environmental regulations.

“Wildfires and massive flooding have wiped out infrastructure like highways, bridges, and entire towns. The Province of B.C. has also implemented new excess soil relocation regulations to prevent usable soil from going to landfills and ensure that contaminated soil is disposed of safely and in an environmentally friendly manner. This is a huge concern for local Indigenous communities because they accept a significant amount of fill for their projects,” Wade explains. “All of the land used in new construction or where demolition has taken place now has to have all of the overburden and soil screened to be cleared by archaeologists. Under government legislation, operators must test soil for contaminants to determine if it can be reused or disposed of. Chris has worked extensively with contractors and Indigenous stakeholders, and is providing solutions to get all this work done. Our equipment is self-contained and track-mounted, so it’s easier to move and doesn’t require outside power to run, which makes it ideal for all of this work. Chris has been running full throttle on this for the past year.”

Chris says building relationships with the customers, problem solving and working with family are his favourite aspects of the business.

“That’s what I always enjoyed growing up. Somebody phones you up and says they’ve got to make certain products right now. You’ve got to put things together for them and have creative solutions,” he says. “I work with my uncle very closely, which has brought us closer over the past five years, and I work with my Dad, and that’s brought us closer. It brings challenges, too, but the family aspect is definitely the most rewarding. It makes you more engaged.”

Chris says managing costs and equipment availability has been a constant challenge in recent years.

“Supply chains have been the biggest struggle in the last oneand-a-half years. Demand is high, so it’s a tough thing to tackle and move through,” he says.

Chris’ advice to young people looking to get into the industry is to be willing to learn.

“Every day, try and take one thing away that you didn’t know at the start of the day. People do things their own way, so you need to take watch and listen, absorb advice, and apply it so you’re a bit smarter for the next job. My job is to go out and talk to all the aggregate producers, and everyone has a different style of doing things. The biggest thing with this industry is having an open mind and a willingness to learn,” he says.

Chris’ long-term goal is to continue growing the family business.

“I'd like to create some future locations and grow into a larger role,” he says. “There’s always room for improvement when it comes to customer relationships and building better connections with clients.”

JOSEPH GVILDYS

Cement Industrial Director

Lafarge Canada

Exshaw, Alta.

While studying chemical engineering at Queen’s University in Kingston, Ont., Joseph Gvildys noticed a position for engineerin-training at a nearby cement plant in Picton, Ont. He applied for the role and was selected, opening his eyes to the world of building materials.

“I started my career at a cement manufacturing plant, and I got exposure to the entire building materials industry for about four years there. I enjoyed it and I ended up staying in this industry,” Joseph says.

When Joseph joined Lafarge in 2011 as a process and quality engineer, he applied his process engineering knowledge to resolve a major bottleneck in production. Later, while managing the lab in Exshaw, Alta., Joseph focused on accuracy and performance and ensured top quality cement was supplied for Canada’s longest new runway at the Calgary airport.

Currently, Joseph oversees all cement and slag manufacturing for Lafarge in Western Canada and the Pacific Northwest U.S. With a team of 350 people reporting to Joseph, he drives capital allocation, performance, project management, and strategy across two cement manufacturing plants and two slag grinding facilities.

“Joseph has made notable achievements across diverse technical and leadership roles in cement manufacturing,” says Emilia Salamon, human resources coordinator for Lafarge Canada.

He is currently driving construction of a low carbon fuel system at the Lafarge Exshaw Cement Plant in Exshaw, Alta., to replace 35 per cent of the plant's energy needs with low carbon fuels, while at the same time diverting construction waste away from landfills and lowering the carbon footprint of cement.

“Joseph is quick to embrace new technologies to advance the digitalization of operations to improve efficiencies and customer service,” Emilia says. “His current focus is on digitalizing the safety and preventive maintenance program of the cement manufacturing facilities.”

His favourite aspect of his work is the variety of projects he’s involved in.

“My focus has been manufacturing and distribution up until this point. But the company that I've worked for specifically, Lafarge Canada, for the last 11 years, we basically do it all,” he says. “I've been able to be exposed to many different parts of our industry. By being part of this large organization, it’s pretty exciting for an engineer, especially a new engineer, because you have a lot of freedom to make improvements.”

Joseph says trying to make improvements is encouraged throughout the company.

“We want people coming in, being creative and trying things, and you know, sometimes failing, but hopefully not all the time,” he says. “In our industry, we're pretty flexible. We're pretty adaptable, which I think is pretty cool.”

Joseph’s passions intersect at manufacturing and sustainability.