At SMS Equipment, we’re more than machines from trusted brands like Komatsu. No matter your project, we’re the people beside you— today and every day—bringing industry-leading technology and expertise to your job site.

Because the right partnership makes everything possible.

This small, Ontario town is balancing the relationship between aggregate operators and the community.

14 Sustainable concrete production

Lafarge Canada’s EcoPact is a low-carbon concrete product. 16 Recycling wash water

Water-saving basics and best practices to follow in wet processing.

Product Showcase: Milling and Paving 22 Nearly complete

A closer look at the conversion of Edmonton’s Yellowhead Trail to a freeway.

of

country faces?

The recent federal election did not bring the result some were expecting or hoping for.

The finally tally left many people wanting. Conservatives did not get the reins of government as seemed likely, at least up until January of 2025 when U.S. President Donald Trump and new Canadian Prime Minister Mark Carney arrived on the scene.

The Liberals, just a half a year ago facing political annihilation, made slight gains in seats but still fell short of winning the majority government some polls were predicting in the weeks leading up to the vote.

And the NDP is on life-support.

Yet there are some positive signs that have come from this election. For one, Canadians were engaged. Turnout was pegged at 68.65 per cent, which is the largest for a federal vote since 1993.

Another positive is, as the campaign drew on, it became clear there is broad agreement on the big issues Canada must focus on.

From my perspective, those include:

1. Diversify our trade relationships so we are not so reliant on the United States.

2. Negotiate an end to the American president’s broad tariffs on Canadian goods and work a new free trade agreement (one that hopefully has some teeth if the U.S. once again is in breach).

3. Bring down the cost to buy or rent a home.

4. Remove interprovincial trade barriers.

5. Tackle our mental health and addiction crisis.

6. Develop Canada’s vast resources, including oil, gas and critical minerals.

7. Deal with the growing resentment in western Canada.

8. Increase our military spending along with our presence in the artic.

9. Crackdown on crime.

That is a long list of difficult items. The new prime minister has a full agenda.

Of course, while there is broad agreement on the issues to tackle, the sticking point is around the details on how to solve these complicated problems.

That’s what makes this interesting. Mark Carney is a political neophyte. Is that lack of experience a plus or minus?

Conventional wisdom is his lack of experience is a detriment to governing, especially with a minority government. Managing parliament with a minority of seats is a challenge for veteran leaders. A key question is: without any legislative experience, how is PM Carney able to maneuver that?

However, with such immense issues to tackle and to do so quickly, perhaps someone without the baggage of a political past or a traditional view of governing can find success by doing things very, very differently.

I hope he is successful. Every Canadian should. If he succeeds, Canada succeeds.

Yet I can understand the trepidation many have. While the Liberal leader is new, those around him have been in charge for the last decade. Many of the issues we need to address are a direct result of those people not doing so.

The big question right now is: will a new leader change the direction and attitude of the Liberal Party?

We should have some signs of where that is heading over the next few months. That will be key to the longevity of this new government.

mlacey@annexbusinessmedia.com

Astec paves the way for sustainable, innovative asphalt plants. The new IntelliPac Moisture System is a revolutionary solution that integrates seamlessly with Astec control systems. This provides unparalleled, real-time visibility into virgin aggregate moisture content. IntelliPac empowers operators to optimize mix design, minimize energy consumption, and reduce environmental impact. With Astec, you get superior asphalt production – better for the environment, better for your business.

The Good Roads Conference 2025 was hosted at the Fairmont Royal York hotel in Toronto, Ont., from March 30 to April 2.

The Volunteer of the Year Award and Honorary Life Member Award, presented by Antoine Boucher, director of Public Works and Engineering, Municipality of the East Ferries, celebrated the accomplishments of Good Roads members.

The Volunteer of the Year Award

This award recognizes the invaluable and outstanding contribution to the municipal sector made by our dedicated instructors and committee members who have made a significant contribution to Good Roads.

The Volunteer of the Year Award was presented to Chris Traini, who has been the county engineer with the County of Middlesex for more than 20 years. Traini is a past Good Roads president and is involved with numerous organizations, including the National Association of County Engineers. Traini is currently serving as a member of the Board of Directors of the Municipal Engineers Association.

The Honorary Life Member Award

The Honorary Life Member Award was presented to Nazzareno Capano, director manager of transportation policy and innovation at the City of Toronto.

“Nazzareno joined the Good Roads board of directors in the early pandemic and has offered a source of insight and perspective,” says Boucher.

The Alberta government has created a Sand and Gravel Task Force to build a more efficient path forward for the construction industry.

“Sand, gravel and crushed stone are the backbone of Alberta’s construction economy, essential for building the roads we drive on, the homes we live in and the infrastructure that supports our communities," the government stated in a May 20 press release. Within the next six months, the task force is expected to deliver actionable recommendations on reducing bureaucratic delays, supporting landowners and strengthening Alberta’s aggregate supply chain.

Task Force members are:

• Brandon Lunty, Co-Chair and MLA for Leduc-Beaumont

• Glenn van Dijken, Co-Chair and MLA for Athabasca-Barrhead-Westlock

• Brock Helm, Board Member of Alberta Sand and Gravel Association’s Land and Environment Committee, and land manager at Lafarge

• Ken Kozakewich, Consulting Engineers of Alberta

• Amber Link, Rural Municipalities Association

• Tara Elwood, Alberta Municipalities Association

Rock to Road magazine is circulated free of charge to qualified individuals holding management and supervisory positions with companies engaged in the aggregate, roadbuilding, ready-mix concrete and asphalt production industry in Canada. The Publisher reserves the right to determine qualification.

McCloskey International, a manufacturer of mobile crushers, screeners, stackers and trommels, has appointed Connie Burns-Wolfe as their new marketing manager. Wolfe will oversee the company’s marketing strategies, driving brand growth and enhancing customer engagement across all platforms. Wolfe brings a wealth of experience to the role, having previously worked as a marketing manager in both the agricultural manufacturing industry and the fuel distribution industry.

“I am incredibly excited to join the team

at McCloskey International and take on the role of marketing manager,” said Wolfe. “I look forward to using my previous industry experiences in my new role to drive innovative marketing strategies to strengthen the brand, customer engagement, and contribute to the growth of the company.”

As marketing manager, Wolfe will be responsible for developing and executing comprehensive marketing campaigns, managing social media efforts, collaborating with the sales team, and ensuring consistent brand messaging across

After eight years as CEO and nearly 45 years of service, Caterpillar Inc. chairman and CEO D. James Umpleby III became executive chairman of the Board effective May 1. Chief operating officer (COO) Joseph E. Creed, a 28-year Caterpillar veteran, succeeds him as CEO and joined the Board of Directors May 1.

After assuming the role of CEO in 2017, Umpleby led the development and execution of a new strategy for long-term profitable growth, creating significant shareholder value.

“I’m grateful to have had the opportunity to work with Caterpillar’s dedicated global team of employees and dealers for my entire career. As we celebrate our 100th anniversary, we honour those who came before us,” said Umpleby. “I have great confidence in my successor, Joe Creed.”

Creed joined Caterpillar in 1997 and has held numerous positions of increasing responsibility across multiple divisions of Caterpillar. He was promoted to chief financial officer for Caterpillar’s Energy and Transportation business segment in 2013, then to vice president of Caterpillar’s Finance Services Division in 2017. Creed also served as interim chief financial officer for Caterpillar in 2018. He then became vice president of the Oil and Gas and Marine Division and the Electric Power Division. In 2021, he was promoted to group president of Energy and Transportation.

“I’m proud to work alongside our talented Caterpillar employees and dealers as we continue to support customers across

all channels.

our businesses. I look forward to leading this amazing team as we build upon Caterpillar’s legacy of excellence,” said Creed.

Debra L. Reed-Klages, who has served as a director since June 2015, will remain on the Board as independent presiding director, a position she has held since June 2022.

“We are deeply grateful for Jim’s leadership and appreciate the outstanding results he achieved during his tenure. His impact on our customers, dealers, shareholders and employees will continue for years to come,” Reed-Klages said. “Joe’s selection as CEO is the result of a multi-year succession planning process by the Board of Directors. He is a proven leader with significant experience in Caterpillar’s global businesses. We are confident Joe will position Caterpillar for continued future success.”

BY MATT jones

> Uxbridge, Ontario has an extensive history in the aggregate industry.

There are a variety of gravel pits, quarries and other related businesses that have operated in and around the municipality for decades. And while the relationship between the businesses and the community has certainly had bumps in the proverbial road, it is by most accounts a positive and productive partnership. To find out more about how that relationship works, Rock to Road spoke with community members, business owners and Uxbridge’s own Mayor Dave Barton.

“Aggregates are an important industry in Uxbridge, but in many ways, we’re taking one for the team,” acknowledges Barton. “Our municipality is where the gravel is, so it’s not like we chose that industry. We are in the Oak Ridges Moraine, which is the area where the glaciers left all the ag-

"As soon as they can wrap their head around it, they seem to come around. So, we do get opposition, don’t get me wrong. But sometimes all they need is to see the face behind the application. And sometimes, we bring people in and show them the operation and then they can wrap their head around it and it seems to go better that way.”

– Victor Giordano, with VicDom Sand and Gravel >

gregate. So, part of living here is that it’s here and because we’re at the north end of the Greater Toronto Area (GTA), this is the only way to grow and build buildings and hospitals and roads and you need aggregate to do it.”

Barton points to an interesting aspect of the relationship between the industry and the community. There are times when local industries can find themselves in conflict with the community over issues such as land use, noise pollution or dust – and this has been the case in Uxbridge. However, often those conflicts have mitigating factors, such as that the industry is developing a product that the area benefits from or that it is the major employer in the area. Neither of those is especially true in the case of Uxbridge. Most of the gravel goes to other areas of the GTA, and, while important, the aggregate companies are not the dominant employer in the area.

However, Mayor Barton says that the stand-out aggregate companies in Uxbridge have stepped up and made themselves part of the community.

“When we were building a skate park, they stepped up and provided donations of aggregate and all the materials to make that skate park even better,” says Mayor Barton. “We’re building a new hospital in our community right now, and they’re the ones that have stepped up and offered to help and made significant donations. That’s how you become a good partner.”

Barton adds really good partners also understand having gravel trucks in the middle of the downtown core doesn’t make it an inviting place to shop. Those businesses, he says, have decided to avoid driving their trucks through the downtown area to minimize negative impacts.

“I think the businesses here do their best to accommodate genuinely to the community,” says Katerina Theodorelos, chief

administrative officer for Central Sand and Gravel. “Anybody that calls us about loud trucks or anything, we really do our very best to accommodate. But I think sometimes it’s hard because people own their houses, it’s their spot and it can get loud. So, they may not totally understand all the time. I think the noise is the main thing – the traffic. We do our best, but sometimes it can get hard.”

Theodorelos’ co-worker, operations manager Lorie Andrews, says that the direct neighbours who live near their operations are ‘awesome,’ and very easy to deal with and understand the realities of their business well – after all, Central Sand and Gravel has operated in the area for almost 40 years. Andrews states that in her experience, most of the issues that have arisen have involved people who moved to Uxbridge, as opposed to those who grew up in the area.

“You take the good with the bad and we know in the long run we’ve done everything in our power to make things right,” says Andrews.

VicDom Sand and Gravel also have an extensive history in the area. Assistant land manager Victor Giordano says that there will still be opposition to things that the company pursues. They have received opposition to their applications for new pits and expansions in the past but the issues have generally been well-resolved.

“Typically, it’s a matter of educating them on what’s going on,” says Victor. “And as soon as they can wrap their head around it, they seem to come around. So, we do get opposition, don’t get me wrong. But sometimes all they need is to see the face behind the application. And sometimes, we bring people in and show them the operation and then they can wrap their head around it and it seems to go better that way.”

It helps to have a supportive local government, adds Victor’s father, operations manager Bruno Giordano.

“They’re of an open mind,” says Bruno. “So anytime we have a stage in our process that needs a little bit of help with licensing and permitting they always have an open mind. We always have good dealings with them.”

The relationship between an industry and a local community can be based on the idea of ‘buying in.’ If a business wants the community to ‘buy in’ on their company, they need to buy into the community.

In addition to the donations to skate parks and hospitals that Mayor Barton alluded to, Andrews notes that Central Sand and Gravel have donated materials and financially to a variety of local projects such as creating new roads to keep heavy trucks away from more populated areas. VicDom have made similar donations to projects such as the Uxbridge Pump Park and have also sponsored the local Uxbridge Bruins hockey team and made donations to the Bonner Boys charitable group.

Elizabeth Calvin, president of the Green Durham Association (GDA), cites several examples of the gravel companies contributing to support her organization’s efforts – donating gravel to help replace boardwalks that were no longer fit for purpose in a local trail system, for one.

“They bring the gravel in and a bill just never arrives,” says Calvin. “In their scheme of things, I guess it’s small, but for us, it’s huge. To get a truckload of gravel is a big thing.”

Calvin notes that it’s not always sunny in the relationship between the aggregate companies and the community or groups like the GDA. They have fought back on issues that they believe conflict with their vision for trails in the area. But even if they wanted to, they can’t fight against all the projects.

“We’re in gravel pit country, and it’s a fact of life,” says Calvin. “But if there’s a relationship, you can really help their projects and reduce community pushback. Sometimes the community is right to push back but if there’s a relationship, I think things can be resolved.”

An interesting ongoing project in the area that could also help bolster community relations is reclaiming pits that have reached

the end of their life and rehabilitating them into parkland or other uses.

Ralph Toninger, associate director restoration and resource management with the Toronto and Region Conservation Authority, says that one such reclamation projects has been achieved in Uxbridge so far with others planned for the future. Toninger notes that these are extensive projects with difficult logistics – it can take up to 400,000 truckloads of material to fill the pits before you even get into the complexities surrounding hydrology and tree planting on the sites. There are also opportunities to profit from filling a pit with material such as topsoil, though redeveloping on top of that is less than ideal.

“Uxbridge are redeveloping and developing new subdivisions, and there’s an excess of top soil or fill material in the municipality,” says Toninger. “Getting rid of topsoil has become quite costly, and filling pits is a very simple way of getting rid of excess topsoil and fill material. And you can charge a tipping fee per load and the individual pit owner can generate significant revenue. It’s a perfect scenario. You run a pit, you get paid to take all the gravel out, and then you get paid to fill it back in again.”

BY MACENZIE REBELO

> Concrete is the most commonly used building material not only in Canada, but across the world.

Although concrete is reliable, strong and durable, it is also one of the biggest emitters of carbon dioxide (CO2) and greenhouse gases (GHG) globally. According to the World Economic Forum, global cement and concrete manufacturing is responsible for about eight per cent of the world’s total CO2 emissions. In Canada alone, concrete production makes up 1.4 per cent of Canada’s CO2 emissions, according to Canada’s National Inventory

Report.

To address the environmental impacts of cement and concrete production, Lafarge Canada, a provider of sustainable building solutions, created a green concrete product designed to reduce carbon emissions.

“We as a company have strong ambitions to reduce our carbon emissions. The climate concerns are very real,” says Robert Cumming, head of sustainability and public affairs, Eastern Canada at Lafarge.

EcoPact is a low-carbon concrete product range that can reduce the embodied

carbon of buildings, infrastructure, and homes up to 90 per cent, explains Abdullahi Gaal, the technical services supervisor at Lafarge Canada (East).

EcoPact was introduced to Canada in 2021, before the government of Canada’s 2022 Emissions Reduction Plan (ERP). The government’s ambitious climate target is to cut emissions by 40 per cent (below 2005 levels) by 2030 to achieve net-zero emissions in Canada by 2050.

“We have our internal drive to decarbonize and so do our customers,” says Cumming.

EcoPact is incorporated with Supplementary Cementitious Materials (SCMs) and advanced additive technology, explains Gaal. There are multiple strategies in developing sustainable concrete solutions, including cement optimization, which uses high-efficiency cement blends with lower clinker content.

“These cements have a lower carbon content through the utilization of alternative raw materials in place of limestone,” says Gaal.

Lafarge uses low-carbon alternative fuels in the process of making cement, such as industrial byproducts like construction and demolition wood and plastic/ wood composite materials. The company also uses circular economy practices, including recycled aggregate materials and alternative raw materials from recycled crushed aggregates.

“It is important that we are delivering low-carbon mixes that maintain the same level of constructability and workability expected on every jobsite,” he says. “CO2 reduction supports lower embodied carbon, which means hitting regulatory sustainable targets.”

According to Cumming, Holcim Group, the parent company of Lafarge Canada, is aiming to reduce CO2 and GHG emissions by 25.1 per cent in 2030 and 95 per cent in 2050 globally,

“We are on track for hitting our 2030 targets,” he says.

Although there can be misconceptions that sustainable materials are not as strong or durable as standard concrete, Gaal explains otherwise. According to him, SCMs can enhance resistance to factors like chemical attacks, sulphate exposure and long-term wear, which is beneficial to customers and their projects.

“People have a perception that low-carbon concrete is weaker. That perception is inaccurate and outdated. Modern mix design approaches ensure the same strength development and durability over time.”

However, the biggest disadvantage to sustainable concrete is cost. As the demand for more sustainable concrete increases in the industry, so will the price, says Gaal.

“Low-carbon mixes may have higher

up-front cost, but the full life cycle assessment savings potentially offset these.”

To encourage the use of sustainable concrete in construction, Lafarge works with its customers to create a custom mix and design plan to meet all their specific project needs.

Cumming is optimistic that Canada can hit its net zero goals by 2050, especially considering the developing technologies

in the construction materials industry.

“With cooperation with our clients, we can make progress towards net-zero.”

The discretion towards sustainable building materials are changing the more the industry and customer base is educating themselves, highlights Cumming.

“I know there is pessimism, but there are so many solutions on the table we can utilize together.”

Maintaining clean wash water is essential – and whether you’re adding a first wash plant or tweaking an existing one – certain basics and best practices may help you avoid the common pitfalls in wet processing.

It’s a whole new world out there in wet processing. Most ‘easily mined’ reserves are long gone –and we’re short on aggregate folks who’ve washed rocks all their lives. Washing is a unique process for each and every operation.

If you’re reusing dirty water in your wash system, you’re putting all the dirt, debris, clay and fines right back on the product you’re trying to clean – while at the same time causing wear, tear, clogging and buildup on the equipment, water pipes and spray bars.

Here are the basics about three common methods of recycling and reusing wash water, as well as several “best practices” in wet processing.

A simple concept – dirty water is pumped to a settling pond – and over time and with gravity, the particles settle out naturally, and the fresh water floats off naturally to the next level of the pond and is reused. The disadvantages are space requirements and permitting restrictions that make it harder to establish settling ponds.

There are also evaporation issues and maintenance costs – which can be hefty when having to dig out sediments to ensure the depth needed for required settling.

On the plus side, settling ponds may work well for operations whose pond management may include a larger footprint and the successful use of flocculants for greater settling efficiencies.

An ultra-fines recovery (UFR) system offers the ad -

vantage of removing a good portion of material down to a #400-mesh, keeping more fines out of the pond, and resulting in less digging during pond maintenance.

A UFR also provides a stackable material that can become a saleable product, resulting in minimized waste. Also, the water remains much cleaner and requires less processing before reusing it.

One of the downfalls of UFRs is an occasional situation where the wastewater travels too far downstream in the pond –requiring the need for additional flocculants to separate out particles – as there are not enough larger particles present to stimulate the settling process. The latter results in a double dipping during the process. However, as long as a UFR can minimize the need to dig out the pond, there is a savings in operating costs.

Growing in usage, clarification systems start with something as simple as a thickener, or the use of a clarification tank. No matter the option, there are space requirements and flocculant requirements. Yet clarification systems are becoming more popular as they’re less likely to incur permitting issues, and they allow operations to eliminate the use of a settling pond.

Clarification systems discharge a sludge waste product that’s typically pumped off to a designated area where it must sit and dry. Sometimes, this waste product requires the use of filter or belt presses that pull out extra moisture, creating a solid, stackable cake that’s potentially used as a fill product.

Certainly, the biggest drawback is the large capital investment required – often more than $1 million for a simple setup. But depending upon the cycle time of the complete clarification system (which can create a bottleneck), it delivers extremely clean water back into the wash circuit.

Efficiency improves when optimizing all the equipment in the wash plant. For

Each wet processing operation is different, and the right solutions depend upon specific parameters. Avoid “cookie-cutter” or “one-size-fits-all” equipment approaches. Photo: Superior Industries

example, if sand screws are not running properly, an operation may be washing out valuable product and sending it to the pond. Conduct a thorough plant audit to evaluate the performance of each piece of equipment in the plant.

Again, each wet processing operation is different, and the right solutions depend upon specific parameters such as material type, moisture content, specification requirements, size of footprint,

permitting restrictions, financial limitations, water rates, water availability and more. Proper analysis by an experienced applications engineer is advised. Avoid “cookie-cutter” or “one-size-fits-all” equipment approaches.

The best practice is relying upon highly targeted, customized solutions.

Lauren DeBow is a washing applications engineer for Superior Industries.

The 18-foot long, eight-foot six-inch transport width 8680 is powered by a 210 hp Kubota engine. The machine has a variable paving width of up to 15 feet six inches. The 8690 weighs 33,600 pounds with the LB5 screed or 36,000 pounds with the LB7 screed.

Leeboy states the paver features high speed smooth rubber tracks with oscillating bogeys, a 4-speed drive system, power tunnel shields, and height adjustable augers.

For the operator, the machine features coloured LED sunlight viewable control screens with digital readouts. It also has full width screed walkboard and slide out extensions, as well as pivoting, swingout seats and control panels.

Leeboy says the 8616D sleek footprint suits the commercial contractor looking for a heavier unit even though it has many features of a larger highway-class paver.

The 16-foot four-inch long machine has a transport width of eight feet six inches and a width of 10 feet when the hopper wings are down.

It can switch from high deck (7 feet 10 inches tall) to low deck (6 feet 8 inches) within minutes.

It is powered by a 127 hp Kubota engine. Leeboy states the machine's easy to locate components means improved serviceability, while the Legend HD PRO Screed brings higher production yields.

The SUPER 800-5 P is Vögele’s new generation in the mini-class paver market. The machine was shown off for the first time at Bauma 2025. The SUPER 800-5 P is suited for narrow construction project as, in combination of extending screeds AB 200 and AB220, it has operating widths between 0.5 m and 3.5 m.

The material hopper’s new folding mechanism is an advantage of the machine.

Vögele’s Super 2000 3i is its new Highway Class paver for the North American market. The 10foot machine is suited for highway construction and large-scale commercial applications. It has a paving width of 8.6 m and is powered by a six-cylinder engine.

Both hopper walls are now adjusted hydraulically, which allows the best possible position to be set depending on the material feed. As example, Vögele notes, when working along a wall, the asymmetrical setting can now be implemented on both sides at the touch of a button. The machine’s hoper walls can also be folded in two, which gives the operator an unrestricted view of the front.

The machine can be combined with the VF 600 extending screeds (with extending units mounted in front of the basic screed), or with the VR 600 or AB 600 screeds (with extending units mounted behind the basic screed).

The Super 2000 3i’s large material hopper has a capacity of up to 16.5 US tons, with large hopper sides and rubber baffles. According to Vögele, the hydraulically operated hopper front prevents mix from spilling when feed trucks change and ensures complete emptying, without requiring any manual work. The wide conveyor tunnel and powerful separate hydraulic drives for the conveyors and augers support a high laydown rate of up to 1,540 US tons/h.

Vögele is calling the SUPER 1803-5 X the first wheeled paver of the new generation. With its Dash 5 extending screeds AB 500 and AB 600, the versatile machine has operating widths between 2.55 metres and 8.25 metres.

As a wheeled machine it has high maneuverability and great mobility during relocation but also comes with the Dash 5 advantages of automated processes, shorter set-up times, low noise and low exhaust emissions.

Astec’s RP-195 is a 10-foot rubber-track paver that the company says provides a smooth ride due to its fully oscillating track frame.

The machine also has Astec’s exclusive anti-segregation design of the feed tunnel, discharge and rear augers. The company states it engineered the heavy-duty frame, front axle and sturdy conveyors for durability. Seats on the RP-195's dual operator stations can move hydraulically out beyond the sides of the machine. This provides the operator a view down the sides of the paver.

The RP-195 has a standard paving width of 3.04 metres to 5.94m and a maximum paving width of 9.14m.

Vögele premiered its VR 500 screed for the eightfoot class pavers at this year’s World of Asphalt event in St. Louis, Missouri. The new VR 500 is equipped with extending units that can be sloped by up to 10 per cent and is tailored to the paving requirements of the North American market.

In combination with the SUPER 1700-3i and SUPER 1703-3i pavers, it achieves pave widths of between 2.55 metres and 6.40 metres, making it suitable for road construction and medium to large paving jobs.

Vögele states it developed the screed from a

clean-sheet perspective -- it has a low design, is extremely compact and offers an optimum view of the entire auger tunnel. The two-stage telescopic guidance system enables smooth and precise width adjustment. The robust center joint for hydraulic adjustment of the crown also ensures a high level of stability, even with larger pave widths. The height of the VR 500’s end gates can be adjusted hydraulically at the touch

of a button. Another feature of the new VR 500 is the adjustable edge which allows the operator to continuously adjust the angle of the edge from 0° to 90°.

The electric screed heating also ensures high paving quality, bringing the VR 500 up to temperature evenly and quickly. All components that come in contact with the material are constantly heated, which ensures a uniform surface structure.

For those seeking a smaller cold planer, the RX-405 provides the flexibility to operate in a variety of applications. The machine made its debut at Conexpo in Las Vegas, Nevada in 2023. It features control stations focused on user comfort and intuitive use. The control station design allows operators to protect the controls from tree limbs and other obstacles by adjusting the tilt on the fly. That title mechanism also allows the controls to be turned over for safe storage when the machine is not in use.

The RX-405 has a maximum milling depth of 330 mm and milling widths between 0.6 metres and 1.5 m.

The compact mill’s design is intended to make changing drums quick and easy. There is a hinged door on the side of the cutter housing providing quick access to necessary parts. The side door is part of a single cutter housing that can transition from two feet to five feet wide. As a result, Astec states no matter the jobsite, the base machine will be ready to go.

The RX-405 is equipped with Astec’s SiteLine operator environmental awareness camera system. The technology offers operators with a panoramic view of their surroundings, enhancing safety and efficiency on the job site by allowing them to see previously unseen obstructions.

This year’s World of Asphalt marked the world premiere of Wirtgen’s W210 XF large milling machine.

Wirtgen states the new model combines high-performance and efficiency with compact dimensions. The machine offers milling widths between two metres and 2.5 metres and a maximum milling depth of 330 mm, it is suitable for tasks ranging from surface layer rehabilitation and complete pavement removal to fine milling work with maximum efficiency in a wide range of project scenarios.

According to Wirtgen, the main areas in which the W 210 XF is deployed are where high milling performance and relatively compact dimensions are required, such as highways and airports.

Key features include:

• The SiteLine system provides panoramic view around mobile equipment, eliminating blind spots and potential hazards.

• Image processing seamlessly stitches multiple camera feeds together, creating an uninterrupted view for the operator.

• Ability to tap any one of the camera screens to zoom in and get a closer look at a specific area of the machine, then be able to return to the bird’s eye view.

BOMAG’s 47,179-pound BM 1200/35-2 cold planer is designed for the selective milling of road and ground surfaces. Due to the machine’s maneuverability and compact design, it’s a fit for country roads, inner-city work and roundabouts.

It has a maximum milling depth of 330 mm and a max milling width of 1,200 mm.

It’s lateral arrangement of the milling roller allow for milling right up to curbs or walls. The rear right-hand track drive can be automatically swivelled to a position in front of the milling drum for this purpose.

BY GRANT cameron

The conversion of Edmonton’s Yellowhead Trail to a freeway should wrap up in 2027

> The finish line is finally in sight for the expansive $1.1-billion Yellowhead Trail Freeway Conversion Project in Edmonton.

The venture, presently the largest roadworks program in northern Alberta, is expected to wrap up sometime in 2027, with some carry-over work to be completed in 2028.

A strategic plan for the undertaking, which consists of both large and small projects along a 15-kilometre stretch of the roadway, was first approved in 2011 and

construction work began eight years later.

Crews are presently building new service roads along the stretch to better manage traffic flow and installing underground utilities and piles for new interchanges at 127 and 121 streets. A new pedestrian bridge is being built, and signalized intersections are being removed.

A slew of major road-widening, network improvement and pedestrian crossing projects have already been completed along the east-west roadway in the northern part of

nections will provide those who walk, cycle and roll with efficient options along and across the corridor.”

The trail is being upgraded to a freeway because of traffic congestion and safety issues on the key corridor. At-grade intersections are being eliminated and new interchanges are being constructed.

Yellowhead Trail first opened to the public in 1970. The route sees up to 81,000 vehicles daily, 20 per cent of which are transport trucks. Traffic volume is expected to grow to 87,000 and 155,000 vehicles daily by 2047.

Planning for the freeway conversion began with a strategic plan approved 14 years ago. A budget was approved in 2016 and construction started in 2019, primarily on roadways and areas surrounding Yellowhead Trail.

The freeway conversion is a priority in the city’s Major Goods Movement Strategy and supports the goals of the City of Edmonton’s Transportation Master Plan, which aims to develop a more efficient transportation system and road network that improves movement of goods.

“Yellowhead Trail is a major goods movement route and converting it to a freeway is critical for improving safety and traffic flow, reducing delays for all users,” says Lima.

The city decided to turn the trail into a freeway because the roadway is classified as a major goods movement route. The thoroughfare experiences delays during peak periods and mid-day on weekends. With traffic growth, delays will be even longer if improvements aren’t made.

Lima says that safety is of the utmost importance. Nearly 1,000 collisions have occurred annually on the trail over the past decade, and free-flowing traffic, without stopping at signals, will help prevent collisions.

The result will be improved travel speeds of greater than 80 kilometres per hour, reduced delays, and safer, uninterrupted travel for both commuters and commercial vehicles, he notes.

the city that is part of the TransCanada Highway and a core transportation route.

The project will widen the existing roadway from St. Albert Trail to 97th Street and introduce 10 interchanges and eight signalized intersections.

New sidewalks and a sound wall, streetlighting and underground drainage are also being installed.

“The upgraded corridor will improve the active transportation network with pedestrian crossings at all major crossing points and new service roads,” explains Kris Lima, director of the Yellowhead Trail Freeway Conversion Program at the City of Edmonton. “Upgrades such as new shared pathways and improved sidewalk con-

The entire project entails conversion of the existing roadway to three lanes of free-flow traffic in each direction, along with construction of two new interchanges, new channelized access points and service roads, and removal of signalized intersections and direct accesses.

At 123 Avenue, a new sidewalk was installed to support pedestrian traffic, intersection modifications were made to truck turning lanes, driving lanes were reconfigured and roadway changes were made.

At 124 Avenue, a new sidewalk was installed on the south side, intersection modifications were made, a railway crossing was removed and driving lanes were revamped.

Meanwhile, at 128 Avenue, a new sidewalk was built on the north side, modifications were made to the intersection and driving lanes were reconfigured.

Between the 156 Street to St. Albert Trail segment of the Yellowhead Trail, the roadway was widened to three lanes in each direction, new service roads were added, signalized intersections were removed, a new concrete sound wall was added, sidewalks were upgraded, and underground drainage was improved to make road conditions safer during heavy rainfall.

Construction is also complete on 125A Avenue between 97 and 82 streets. Traffic signals were removed and improvements were made to the intersection.

Widening of the trail to six lanes from 61 Street to the North Saskatchewan River was also completed and overhead signs were installed.

Fort Road and a CN rail underpass were also widened between 66 Street and Yellowhead Trail and network improvements were made at 123, 124 and 128 avenues.

Construction has started on a section from St. Albert Trail to 97 Street. The roadway is being reconstructed, two new interchanges are being built, and underground utilities are being installed. Traffic signals are also being removed. Two lanes in each direction will remain open while the construction work is going on.

Meanwhile, designs are under way for removal of an at-grade

“The city has relied on extensive planning, phased construction and close co-ordination with interested groups to keep disruptions to a minimum while ensuring safety.”

– Kris Lima, director of the Yellowhead Trail Freeway Conversion Program

signalized intersection at 66 Street and Yellowhead Trail. Construction is expected to begin in 2026.

Lima says a major challenge of the project has been maintaining traffic flow along the Yellowhead Trail corridor while the construction work progresses.

“The city has relied on extensive planning, phased construction and close co-ordination with interested groups to keep disruptions to a minimum while ensuring safety,” he says.

The original budget for the project has also been exceeded.

Work on the thoroughfare was originally approved in 2017 with an estimated cost of $1 billion. The federal and provincial governments each committed $241.6 million to the overall program, for $483.2 million in total, and the city was on the hook for the remainder.

However, since that time, several factors have contributed to a project program funding shortfall of approximately $105 million, or 10 per cent of the original 2017 approved budget.

According to Lima, the primary cost drivers for the program from 2017 to 2025 were higher market inflation, volatility and uncertainty, as well as a significant increase in the scope of drainage infrastructure improvements.

There have also been increased costs associated with rail coordination and higher costs due to land acquisitions.

Lima says that project teams continue to identify opportunities for cost savings or reductions through design changes, scope reduction or deferrals, cost concessions and risk mitigation while balancing the level of service and the needs of area businesses and residents.

The cost overrun is within the tax-supported debt limit of the city, according to Lima. The annual cost of servicing the additional debt translates to an estimated tax levy of 0.33 per cent over four years. The amounts will be included in the 2027-2030 operating budget.

BY MIKE LACEY

Construction equipment dealer Nors has stopped in Canada as part of a global rebranding process.

The Portuguese company purchased Canadian companies Strongco in early 2020 and Great West Equipment in 2024. It now operates 36 branches in eight provinces across Canada, as well as other jurisdictions around the world, including Portugal, Brazil, Canada, Angola, Botswana, Namibia and Mozambique.

“Why decided to go to Canada [because] according to our strategy for 2030, one of our main purposes was to reinforce our presence in heavy equipment industry, reinforce our presence in more developed countries with stable currency,” says Nors COO Francisco Ramos. “It’s an honour for us to be in Canada.”

Companies under the Nors umbrella had continued to operate under separate names.

However, at the end of 2024, Nors announced it was rebranding and all companies would take on the Nors name. The company’s leadership spent the first few months of 2025 on a roadshow tour at all its locations, including Canada, to help reinforce the new brand name and the Nors culture. Ramos explains this is not simply about a name change, but about ensuring the values of the company are uniform.

“In these meetings, we spent quite time expanding and underlining some features of the brand in order to have all in the organization properly informed and have all our employees to be ambassadors of this new brand,” he says.

While Nors is a multinational company, Ramos notes it is also a family-based company. Group CEO Tomas Jervell is the third generation to head the company, which was founded

in the 1930s by Jervell’s grandfather.

Nors is a Volvo CE dealer and part of the company’s global strategy is to become the largest Volvo construction equipment player in North America.

Along with moving forward with their rebranding, 2025 will likely be a challenging year for Nors and all other heavy equipment dealers. Ramos says the industry should expect uncertainty and reductions in the market until some stability returns.

However, he says every challenge also brings with it opportunities.

“When sometimes you are forced, you manage to create new opportunities to develop things in the past you were not so open to develop,” he says.

As such, he says they will be looking for new opportunities in the Canadian market.

Elevate your production efficiency with ScaleLink’s advanced conveyor belt management solutions. Designed and manufactured in Canada, our enterprise-grade software seamlessly integrates with a wide range of belt scales, providing real-time data to streamline your operations.

Key Features:

• Production Efficiency: Evaluate, monitor, and manage production efficiency with unlimited access to graphs and reports.

• Live Monitoring: Access data from anywhere using your phone, tablet, or computer.

• Inventory Control: Keep track of production with detailed reports.

• Downtime Reports: Minimize disruptions and maximize productivity.

• Visual Alerts: Quick overview of the state of the plant.

• Easy Installation: Seamless integration with almost all types of belt scales.

• Custom Software Solutions: Tailored to your specific needs, collecting data such as weight, tons per hour, speed, and load percent.

BY MACENZIE

> In Ontario, a coalition of engineers, stakeholders and road builders are advocating for municipalities to implement recycled crushed aggregate (RCA) in public infrastructure projects.

In the province, less than seven per cent RCA is used in road building, tunnel and groundwork construction, according to the Toronto and Area Road Builders Association (TARBA).

TARBA, alongside the eight other associations, including Concrete Ontario, Good Roads and the Ontario Road Builders’ Association (ORBA), are pushing for 20 per cent of RCA to be used in public infrastructure projects. This adoption of RCA, according to TARBA, could save local governments more than $260 million and reduce greenhouse gas emissions, “equivalent to removing 15 million cars from the

road annually.”

Raly Chakarova, executive director at TARBA, explains the coalition’s movement and how a 20 per cent mandate could positively impact and create Ontario roads.

Chakarova: TARBA is the collective bargaining agent on behalf of unionized contractors working in the Greater Toronto and Simcoe Country areas. We negotiate collective agreements on behalf of our unionized contractors. They build a lot of the transportation infrastructure in this geographic area, which includes roads, highways, bike lanes, transit projects, you name it. These unionized contractors work for public owners, such as municipalities, the province, agencies like Metrolinx, and private developers, such as residential building subdivisions.

Chakarova: When you think about all of the maintenance projects throughout the province, we demolish thousands of tons of concrete and asphalt every day as part of rebuilding and maintaining our roads and highways. When the asphalt gets demolished, there are two choices. The first one is a landfill, which exacerbates our landfill capacity issues, or it can be recycled. Asphalt and concrete are 100 per cent recyclable, which means that we can take that demolished product, bring it into a recy -

cling plant, have it be crushed, screened and processed for its desired application, and then used again in new construction process. RCA is cost-effective, sustainable, and high-performing.

Chakarova: It comes down to sustainability and cost. From an industry perspective, it makes sense.

RCA is a valuable resource that can be reused. It makes no sense why we would crowd our landfills with a product we very much need. Especially because we have an ambitious infrastructure agenda in Ontario. The Ontario Ministry of Transportation has been a big and early adopter of RCA. It has been used in the 400 series highways and Pearson International Airport, among other projects. If RCA is good enough for our highway system, considering the high amounts of stress it takes, why wouldn’t it be good enough for a municipal road? And that is what we’re trying to tell municipalities that are uninterested.

Chakarova: Municipal specifications that prevent the use of recycled materials in road construction. The allowable limits currently are 100 per cent recycled concrete and 30 per cent reclaimed asphalt pavement (RAP). Those are the provincial standards, and they are set by the Ministry

of Transportation in collaboration with the Municipal Engineering Association. Unfortunately, despite that, municipalities have discretion on whether or not they want to adopt those provincial standards or create their own. Many of the larger municipalities follow their own specifications and others forbid RCA from being used. Another barrier is when a municipality allows RCA, but puts out tenders that allow only primary aggregate. So, just because the specifications are updated doesn’t mean the material is used.

Chakarova: From an industry perspective, this is the future. To be fair, there were some performance issues 30 years ago. Someone decided to use recycled aggregate and didn’t get the outcome they were hoping for, and unfortunately, that has created some negative stereotypes about RCA. But as we know, technology and quality control have significantly improved. There’s been much research and testing that shows that recycled material performs equivalent to, or, in some cases, better than primary aggregate. When you think about it, it does make sense because the material has already been approved once. It met specifications and performed well, so now all you’re doing is taking that and putting it through another rigorous process that screens and tests to ensure performance expectations. So, it’s about educating and bringing that awareness.

Chakarova: The first is simply to allow recycled use in tenders. If a municipality or any other project owner is putting out a request for proposal, they can include recycled and crushed aggregates on that project. We recommend 20 per cent RCA because that’s where the Ministry of Transportation is at. Ideally, we would also harmonize specifications across all Ontario municipalities. One provincial standard should be enforced because it’s well-informed, assures performance and is already in use by some municipalities.

BY MACENZIE REBELO

> Canadian roadbuilding leaders discussed the future of recycled aggregate and circular materials in infrastructure based on a research project made public for the first time.

The research project demonstrated recycled concrete aggregate has significant potential, providing benefits such as cost savings and reductions in carbon emissions, explains Ahmed Soliman, panelist, researcher and associate professor of building, civil and environmental engineering at Concordia University.

Soliman, who led the project, presented his findings at the Good Roads Conference 2025 in Toronto, Ont. He was joined by fellow panelists Tyler Renaud, QA project manager for the City of Hamilton; Raly Chakarova, executive director with Toronto and Area Road Builders Association (TARBA); Mike McSweeney, executive director of the Ontario Stone, Sand and Gravel Association (OSSGA); and moderator Robert Cumming, VP of sustainability at Lafarge.

According to Soliman, the report assessed recycled aggregate sources to determine their

ability to meet standards, including technical methods to assure quality, and concluded recycled aggregate is effective. The panel discussion highlighted why recycled aggregate is essential to meeting sustainable infrastructure needs.

“The research concluded that cycle directors can be used successfully in conjunction with some quality enhancement,” said Soliman.

However, regardless of the data, there is still a lack of adoption of recycled aggregate across municipalities in Ontario.

“Most municipalities across Ontario have declared climate emergencies,” says McSweeney. “I always tell people that asphalt and concrete can be 100 per cent recyclable. They can reduce the environmental impact by reusing the materials.”

To McSweeney, it is paramount that municipalities build “better roads with better aggregate.” He urges politicians and municipal leaders to educate themselves on the positives of recycled aggregate.

Chakarova echoes McSweeney’s senti-

ment, “We are seeing in other international jurisdictions that governments are driving that recycling aggregate conversation forward. International governments are mandating the use of recycled materials. But, in Ontario, industry is saying, ‘Please, let us use this for the love of the environment, for your capital budget, let us use recycled aggregate so that it doesn’t end up in bank bills,’ and the municipalities aren’t interested.”

Renaud believes that there is a negative perception of recycled aggregate.

“People see it as waste.”

However, he argues, there is still plenty of value and pre-used aggregate materials.

“A shift in the mindset is key,” he says.

The scientific data proves that recycled aggregate works, explains Renaud, now the real challenge is enforcing what should be the new standard in Ontario.

“Recycled materials are viable and completely effective, and as long as you do your assurance testing, you have nothing to fear. The performance should be comparable to other viable material.”

BILL Gowdy

Gravel pits and quarries play a vital role in infrastructure development, providing the raw materials necessary for roads, buildings and other projects.

However, as with any development, there is a nuisance factor associated with operations that is unavoidable. Operations can sometimes create friction with local communities due to concerns about noise, dust, traffic and environmental impact, whether real or perceived. Concerns of local stakeholders can be elevated to the point of regulatory compliance or even the potential suspension of operations. By proactively addressing these issues and maintaining open lines of communication, gravel operations can foster positive relationships with their neighbours.

Here are some key strategies to encourage harmony and co-operation.

One of the most common complaints from nearby residents is noise pollution caused by heavy machinery, blasting and truck traffic. To mitigate noise impact, gravel operations could schedule high-noise activities such as blasting and crushing to specific hours of the day, avoiding early mornings, late evenings and weekends, when possible. Operators can also install berms, tree buffers, or noise-reducing fencing to help absorb and deflect sound away from residential areas. Strategic placement of processing equipment in an operation can further mitigate offsite noise. Additionally, regular maintenance of machinery reduces unnecessary noise from worn-out parts and inefficient engines. Where possible, use modern, low-noise equipment and electric or hybrid machinery.

Dust from gravel operations can pose health and environmental concerns for neighbouring properties. To minimize dust, regularly spray water or use environmentally-friendly suppressants on roads and stockpiles. Other methods include paving access roads or using gravel treatments to minimize truck traffic dust, sweep roads as required and address tracking of material offsite immediately. Adjust operations on particularly dry and windy days to prevent excessive dust dispersal.

Gravel trucks can create concerns about road congestion, safety, and wear and tear on local infrastructure. Work with municipalities to establish routes that minimize disruption

to residential areas. Encourage drivers to adhere to speed limits and drive courteously in shared spaces. Collaborate on road maintenance agreements with local municipalities and ensure compliance with weight restrictions to prevent road damage. If possible, stagger truck schedules to reduce peak-hour trucking activity to alleviate traffic congestion as much as possible.

A lack of communication can quickly lead to frustration and misunderstandings between gravel operations and their neighbours. To maintain positive relationships, it is helpful to regularly engage with residents to discuss concerns, upcoming projects and mitigation strategies. Ensure the community has a point of contact for questions or concerns and respond promptly. Public frustration will only grow if concerns aren’t addressed promptly—especially when a company does not understand the issue in the first place. Have a clear, structured method for addressing concerns and demonstrating action taken in response to community feedback. Keep neighbours informed through newsletters, emails, or social media updates about operational changes, scheduled blasting, or environmental initiatives.

Beyond operational adjustments and good communication, gravel operations can foster goodwill by actively contributing to the community. This can include donations of product, time, or funding. Supporting local events, sponsoring environmental initiatives, or participating in community service projects can create a positive association with the industry. When companies take the time to listen, adapt and engage with their neighbours, they build longterm relationships that benefit both the industry and the communities in which they operate.

By taking proactive steps in noise and dust control, responsibly managing road use, and proactive communication and community relations, gravel operations can effectively mitigate concerns and maintain strong, positive relationships with their neighbours. A little effort in collaboration and compromise goes a long way in ensuring a sustainable and harmonious coexistence.

William (Bill) Gowdy is a geologist has 35 years of experience in the aggregate, geology, mining, reclamation, and exploration fields throughout Canada and overseas (USA, Indonesia, South Africa, Mexico, Panama).

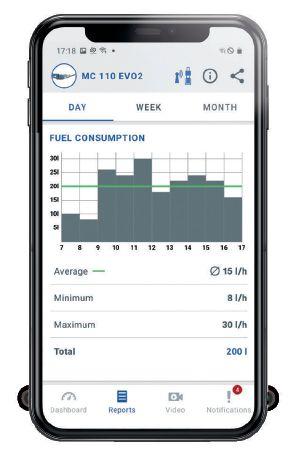

INTELLIGENT, EFFICIENT AND VERSATILE. With SPECTIVE for the most user-friendly operation, all the information you need on your smartphone with SPECTIVE CONNECT, and intelligent control and overload systems – for successful performance in natural stone or recycling. The MOBICAT mobile jaw crusher excels with exceptionally cost-effective solutions. The efficient MC 110i EVO2 powerhouse.

www.wirtgen-group.com/mc-110-evo2-kleemann