look at trends and technologies

14 Product spotlight: Jaw crushers

The latest features and product offerings.

16 Choking off the Dust

A Manitoba company, successful internationally, is making domestic inroads with its dust-suppression and road stabilization products. 20 Border crossing moving along

An update on the Gordie Howe International Bridge.

24 Conveyor maintenance and design best practices: Part 2

Rock to Road speaks with Superior Industries' chief engineer for portable conveyors about conveyor design and maintenance best practices. 28 How to assess the effectiveness of workplace safety labels

AEM’s Jaime Vos discusses why labelling matters.

Time for a new, fair deal on infrastructure

Manitoba Heavy Construction Association president Chris Lorenc discusses the need for increased funding.

Put your people and projects in the spotlight!

It’s no secret that finding young people to fill positions for almost all of the skilled trades is a daunting task. Most trades have not done a great job of promoting their amazing and challenging industries to the next generation of workers, and the roadbuilding and aggregate producing sectors are no exception.

Every year, Rock to Road looks to do its part to help change that by showcasing some of the amazing young people rising through the ranks, and by highlighting some of the amazing projects the industry is a part of.

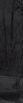

The team at Rock to Road is excited to announce we will be kicking off our brand-new Cover Photo Contest for the industry! The winner’s photo will grace the cover of the September issue. Many additional photos will be showcased inside the magazine.

What kind of photos are we looking for?

Here are a few ideas to get you started:

• Asphalt or concrete paving

• Traffic management

• Blasting

• Crushing, screening or washing

• Hauling or loading

To enter the contest, send a hi-resolution image to editor Andrew Snook by Aug. 15, 2022 at: asnook@annexbusinessmedia. com, along with a brief summary of the project, the date, and the location where the photo was taken.

Have a young up-and-comer on your team that you believe should be recognized for their hard work, dedication and innovation? Then nominate them for Rock to Road’s Top 10 Under 40 awards program! The deadline for submitting nominations of your best and brightest is Sept. 15, 2022.

This program will recognize 10 outstanding individuals from across Canada

who had made significant contributions to the industry before their 40th birthdays. This can include anyone who was under the age of 40 as of Dec. 31, 2022.

Nominees can come from anyone who is involved in Canada’s roadbuilding and aggregate industries, including business owners and management, heavy equipment operators, engineers, software programmers, technicians, industry educators, and research and development staff.

What are the qualifications to nominate an individual?

• Nominees must be younger than 40 before Dec. 31, 2022.

• Nominees must either be working in Canada or of Canadian nationality.

• Nominations are due by Sept. 15, 2022.

What type of information should be included?

Potential information to submit about the nominee can include projects or initiatives the individual has been involved in; results from past projects; job responsibilities; workplace initiatives outside of regular duties; and community involvement.

All nominees that are selected will receive a framed certificate recognizing their achievement, and will be featured in the November/December 2022 issue.

Still have more questions?

For more information on the Top 10 Under 40 program, contact editor Andrew Snook at asnook@annexbusinessmedia. com, or visit: rocktoroad.com/top-10-under-40.

Good luck to all the nominees for this year’s program. We look forward to featuring the industry’s best and brightest up-and-comers and projects in our upcoming issues of Rock to Road!

With decades of proven experience as a premier asphalt plant manufacturer with a reputation for building high-quality equipment, supported by world-class service, Astec is the ideal partner to our asphalt plant customers. We provide single source accountability by delivering a full range of services, including planning, manufacturing, setup, startup, and service. Astec maintains large parts inventories and has capabilities to manufacture custom parts when needed.

Scan QR code to see Astec’s full line of Asphalt Plant Products.

It was a successful turnout for the first edition of the Atlantic Heavy Equipment Show since the COVID-19 outbreak, as 9,985 industry professionals filled the halls of the Moncton Coliseum last week, including key decision makers and purchasers looking to upgrade their fleet and view the many pieces of equipment on the show floor.

“The Atlantic Heavy Equipment Show remains one of the biggest heavy equipment events in Atlantic Canada,” said Mark Cusack, national show manager. “It was a pleasure to welcome everyone back to the show after a twoyear hiatus. We heard many positive accolades from both exhibitors and attendees, which goes to show, everyone

was happy to be able to reconnect again in person.”

Show attendees included a mix of industry professionals including the leaders of the construction, road building, forestry, land improvement, and infrastructure industries.

The dates for the next edition of Atlantic Heavy Equipment Show will be released in the coming months.

Machinery Supply was recently announced as Lippmann Milwaukee, Inc.’s new dealer for Western Canada, with their territory including Alberta, Saskatchewan, Manitoba, and British Columbia. Based in Airdrie, Alta., Machinery Supply will represent all Lippmann crushing and screening equipment in the territory.

In 2020, Machinery Supply combined forces with longtime partner Power Equipment Company, headquartered in Denver, Colo., and is now a subsidiary of the company. With the added support from Power Equipment Company, Machinery Supply has been able to enhance its product and service offerings in Western Canada.

“Lippmann has been a part of my business from the start, purchasing my first crusher from them,” says Brian McAdam, president of Machinery Supply. “We chose to become a dealer because their premium products have proven themselves time and again.”

Metso Outotec has completed the acquisition of Tesab, a Northern Ireland-based company specializing mostly on mobile crushing equipment for aggregates applications, including quarrying, recycling, asphalt and concrete. Tesab’s offering will complement Metso Outotec’s offering in the mobile crushing and screening markets. Tesab continues as an independent product brand within Metso Outotec, with its more than 60 employees integrating to the Metso Outotec group.

Dynapac Seismic technology automatically detects the soil characteristics, works together with it, and applies the correct amount of vibration energy exactly when required.

n Reduces power and energy consumption up to 30%.

n Eliminates the guess work for the operator by automating the process and achieving optimal compaction results.

n Upgraded advanced technology package on CA1500-6500 soil rollers to include Dynapac Active Bouncing Control (ABC), and Compaction Meter.

n Active Bouncing Control – A unique technology developed by Dynapac that prevents over compaction of the Soil, avoiding damage to both the material and the machine.

BY ANDREW snook

A look at the latest trends and technologies

> When it comes to jaw crushers, one thing that OEMs, equipment dealers and aggregate producers can agree on is that low cost per ton is a top priority. With surging fuel prices and severe labour shortages in most of the country, producers are looking for ways to keep costs down. This can be through moving to more fuel-efficient crushers or hybrid equipment, enhancing preventative maintenance programs, and investing in automation and enhanced telematics software.

Astec product marketing manager Chris Worley says the key features customers are currently looking for in a new jaw crusher are ease of closed side adjustment, ease of maintenance, high production, lower cost per ton through lower energy consumption, heavy-duty use, and a tramp iron release system.

Daryl Todd, president for Frontline Machinery, dealer for Keestrack Equipment in Canada, says producers need to look beyond the price tag on equipment to find true cost per ton.

“It is important that consumers look at the overall cost per produced tonne and not just the equipment price,” he says. “For instance, what output does the equipment provide? How much

Your ability to turn virgin material and waste product into high quality aggregates requires equipment with unmatched power and precision. From reducing shot rock to sizing and shaping fine sand, we design and manufacture the most versatile and efficient crushers. Not sure what you need? Let our experts partner with you to apply the ideal solution.

fuel does it consume? Is the machine easy to maintain and access or replace parts? Does it provide an energy-efficient electric option? Just as importantly, who is the dealer supporting the unit? By taking all these into consideration, you get a true perspective on your total costs per ton and the value of the equipment versus just price.”

At Superior Industries, ease of maintenance is top of mind for their customers. Grant Holmes, product manager and engineer for jaw crushers at Superior Industries says when it comes to jaw crushers, producers just want to turn them on and have them work.

“What people want is to not have to think about it. People don’t think of a jaw crusher as something they’ll need to do fine adjustments to, whereas, there are other parts of the equipment on their circuit, where they understand there’s a little more micromanaging going on. Typically, people don’t look for that in a jaw crusher. They want to set it up, turn it on, and will spend their time dealing with other stuff,” he says. “When we are developing our jaw crushers that’s definitely something we kept in mind.”

Paul McLaren, technical sales manager for Wirtgen Group, says some of the key features customers are looking for in a jaw crusher are productivity, reliability, transportability, longevity and ease of operation.

“These features can be achieved through integrating items such as independent double-deck pre-screens to remove fines and increase overall machine throughput,” he says.

McLaren says that electric drive concepts using electric drive motors to increase efficiency, decrease fuel consumption and allow for continuous drive utilization monitoring are also of interest to customers.

He adds that another feature his clients are interested in are feed control systems that not only work based on the material fill level of the crusher and load on the crusher drive to maximize production, but also load monitoring of the crusher box itself to adjust the feed rate to ensure the stresses of crushing are not negatively affecting your machine.

”This allows, for example, the crusher gap to open automatically should a piece of uncrushable material enter the jaw to protect the toggle plate and crusher

box from extreme stresses that could cause damage and downtime. Not only do these systems offer instant protection due to uncrushables, but systems such as these increase the overall longevity of the machine by reducing stresses on the crusher box, the most important component on the machine,” he says.

By reducing the amount of time people are spending around the machine, companies are reducing the opportunities for accidents on sites.

“The days of manual adjustments, people are moving further and further away from that,” Holmes says. “Things like hydraulic adjustment and hydraulic tension, where there’s a decent of time where people are having to crawl around under crushers and on top of crushers, that’s something everyone is thinking more about these days. We’re trying to make the crushers easier to work on, with less downtime and safer in general, so there’s less opportunity to be actually working on them.”

Worley says there are several new maintenance features being built into jaw crushers that are helping reduce the

amount of scheduled and unscheduled downtime.

“Auto lube systems; being able to reverse the jaw, as well as hydraulically open the jaw to dislodge oversize rock; the ability to hydraulically raise and lower the under crusher belt,” he says.

Another feature on some jaw crushers is a removable engine.

“The Keestrack B4e Jaw Crusher is available with a removable engine/ genset option. This option improves engine access and allows the engine to be placed away from the dusty abrasive environment during operation, which lowers the service cost and extends the longevity of the unit,” Todd says. “The jaw crushers include an innovative patented Non-Stop System, which has automatic gap adjustments and safety releases when the equipment encounters non-crushable material. The machine will automatically expand the jaw in 5-mm increments until the obstruction passes. This protects the bearings and the shaft allowing the obstruction to pass without causing damage to the crusher.”

Worley says that customers are looking for new automation technologies to optimize the production of their jaw crushers.

“I believe that automating the feeder with the jaw to optimize production and efficiency is very important to the customer,” he says, adding that having the ability to adjust the closed side setting and tramp iron release system remotely is also important.

Another requirement for optimizing production is the automation and interlinking of several machines, McLaren notes. “For example, a jaw crusher feeding a cone crusher and several downstream plants. If one of the screening plants stops or slows down, it is critical that the cone crusher and, in turn, the jaw crusher do the same to avoid a situation of overfilling and stalling belts, leading to costly downtime and hard labor to dig out the machines. This can be achieved using material stockpile sensors at the conveyors of each machine to measure the height of the stockpile or be calibrated to measure the fill level of

a downstream feed hopper. Even when just stockpiling material, it is essential that a distracted operator does not allow material to get into the head pulley, and with an automated system like this, the machine would simply turn off the feed to avoid damage, and then automatically resume feeding when the stockpile was managed,” he says.

Todd says that new advances in automation help prevent downtime, including jams, and allow for plant recovery time.

“On Keestrack equipment, the computer monitors many aspects of the machine, including crushing chamber load, the speed sensors, pressure and amperage on all conveyors. Systemtriggered codes alert operators to a potential issue before it becomes a major concern resulting in a full shut down,” he says.

In North America, Holmes says another big factor customers consider in their jaw crushers is portability.

“We do a mid-mount on a lot of our jaws. Basically, the mounting piece is somewhere in the middle of the jaw body. That lets the crusher sit down low in the chassis rails of a portable plant and reduces the overall height,” he says.

Superior Industries also uses a composite style of guarding, which is lightweight and helps reduce overall weight of the crusher.

“We also do a motor mounted right

into the jaw frame. That clears up the need to have a remote motor base somewhere else on the portable plant. It can all be mounted directly to the jaw and that just clears up space,” Holmes adds. “Real estate is very limited so we’re always looking for ways to help alleviate some of that.”

Telematics is another area that has came a long way in tracked mobile crushers, McLaren notes.

“Due to the advancement of technology on the crusher itself, the amount of information that can be gathered from a crusher using telematics is abundant. Not only can this telematics data be used for the monitoring of production numbers and machine status, but can also be used for maintenance reminders and to assist in troubleshooting should anything happen with the machine. In addition to telematics, there are also WiFi-based systems that can communicate with an app on your phone that allow for data collection and reporting right from your smart phone in real time,” he says.

Todd says that as labour costs and the pressure for operators’ efficiency continues to rise, equipment owners and operators are looking for intelligent insight into their machine and day-to-day operations.

“In response, manufacturers are having to find ways to incorporate reporting and telematics into the equipment to support these field requirements. The Keestrack-er

telematics software system provides real-time data and analytics,” he says. “Telematics enables equipment owners and dealers to stay connected even in remote sites. By utilizing the machine’s data, we can help mitigate downtime, improve productivity, and support best practices for operation. The data can be used to develop preventative maintenance schedules and if necessary, the remote updates to the software can be performed by the dealer. Thus, reducing the cycle time traditionally required for services and repairs. The telematics system data provided is highly valuable to both the owner/operator and dealer. With telematics, if a customer is down, we can access fault codes without being on site.”

Worley says recycled concrete and demolition, as well as industrial minerals, are potential future growth markets for jaw crushers for Astec.

Superior Industries is also actively designing jaw crushers for concrete recycling applications.

“We are developing a recycle-specific jaw crusher that’s extra-wide for handling sidewalk slabs. We are seeing recycling become a bigger target, particularly in different parts of the world where the untouched stone or green sites have been mined out or crushed out,” Holmes says. “Recycle is something were starting to hear more about and have a jaw specific for that application that’s 63 inches wide. It’s very lightweight for the size of jaw it is. People are going to like that a lot. It’ll be portable and extra wide.”

Todd says increasing fuel prices and the tightening of environmental standards is resulting in development and growth in alternative power sources.

“A key technology being brought to the market is hybrid drives,” he says. “Keestrack, for example, offers its jaw crushers in a fully hybrid eco drive option. During ‘plug-in' operation to an external genset or the main electric grid, the diesel engine doesn't have to be started, and complete energy management is controlled automatically, including the electric supply of a secondary unit such as a screener or stacker. Electric hybrid drives greatly reduce fuel consumption in the machine, and there are almost zero maintenance costs when running from the grid.”

BY ANDREW SNOOK

A look at the latest features and product offerings

Astec Iron Giant series jaw crushers are designed for optimal performance in the toughest crushing environments. Alloy steel plates are made of AR400 alloy steel for long service life and the hydraulic wedge lock provides a fast, safe and reliable adjusting system without the use of special tools. The replaceable liner behind the jaw die protects the mainframe and pitman for extended jaw life and the tension spring bracket moves during adjustment to maintain constant tension. Finally, a replaceable impact plate protects the barrel. www.astecindustries.com

For primary crushing, landfill recycling, and concrete recycling, the Keestrack B4 jaw crusher includes a patented

non-stop system ensuring continuous processing while protecting the machines when working through uncrushable materials. This powerhouse is suitable for a wide array of applications including most medium and hard stones, quarrying and mining, construction and demolition waste, and many more including coal, gravel, and slag. The B4 is designed with an

independent double-deck vibrating prescreen and automatic feeding system. This system ensures an optimal supply within the crushing chamber by detecting an overload and slowing down the feed for the best results and prevention of jamming. Load sensing hydraulics reduce fuel usage by 25% and if environmental responsibility is important for your business, the B4 is also available in a full-hybrid e-version. www.frontline-machinery.com

The crushing plants of the MOBICAT series are used for the precrushing of almost all natural rock and in recycling. However, the output of the MOBICAT crushing plants is determined not only by the jaw crusher alone. In fact, the optimal interaction of all components plays a decisive role. The focus is increasingly on cost and environmental awareness, availability of the plants, versatility, and quality of the final product. www.wirtgen-group.com

Designed to withstand the toughest conditions worldwide, the McCloskey J6 meets the evolving requirements of today’s projects and operations. Delivering high production with its innovative jaw chamber design and enhanced material flow, the J6 is particularly effective in hard rock applications, and offers an optional factory-fit rock hammer to maximize resources on site. The large 48” x 34” (1204mm x 864mm) jaw opening accommodates large feed sizes, also contributing to higher production in material processing. The J6 is enabled for 365SiteConnex telematics, a complete connectivity solution for highly accurate monitoring of McCloskey products. www.mccloskeyinternational.com

Superior’s Liberty Jaw Portable Crushing Plant – typically used in primary crushing applications – is capable of accepting feed sizes up to 47 inches while producing a maximum of 1,600 tons of rock per hour. The jaw crusher

is designed with a mid-mount base frame, which allows for compact installations on height-conscious portable chassis. Popular features of Liberty Jaw Crushers include composite guards to simplify removal before maintenance, aggressive nip angles to ensure consistent processing, and hydraulic wedge adjustment to easily modify closed side settings. www.superior-ind.com

The Finlay LJ-130 hybrid jaw crusher is the largest mobile jaw crusher in the Terex Finlay range and has been developed for large-scale quarry and mining operations. The machine can operate as a standalone primary crusher or integrated into a mobile or static crushing and screening plant.

The machine can be powered either by the onboard genset powerpack configuration or connected to an external power source. Both power options provide operators with significant power, servicing and maintenance cost savings in direct comparison to a diesel/hydraulic powered plant. For easy transport movement between locations, the plant can be split down and reassembled without the need for heavy crane assistance on site. The plant’s electrically driven power systems provide significant cost advantages and environmental efficiencies. The large feed width and gape enables the crusher to accept larger and coarser material reducing the need for hammering of oversized product. Automatic variable speed VGF ensures continuous choke feeding of the crushing chamber for optimal productivity. The high-powered electric drive ensures precise chamber controls and reverse functionality for clearing blockages and assisting in construction demolition, asphalt and recycling applications. T-Link telematics hardware and software along with free seven-year data subscription are fitted and installed as standard. www.terex.com

BY CARROLL mccormick

A Manitoba company, successful internationally, is making domestic inroads with its dust-suppression and road stabilization products

> In cinematic fantasies, romance is a car kicking up a milelong plume of dust as the protagonist escapes to somewhere. In the real world, however, road dust is a curse. When fought at all, it is with endless applications of water or products typically containing corrosive, toxic salts. Winnipeg-based Cypher Environmental is working hard to change that.

Cypher has been making and selling two products for just over a decade now that speak to these problems: DUST/BLOKR, a dust suppressant concentrate that is mixed with water and sprayed on roads with a standard water truck, and ROAD/ STABILIZR, which is worked into poor-quality roads to stabilize and strengthen them, as well as to suppress dust.

Unlike commonly used products that contain, for example, magnesium chloride and calcium chloride, Cypher promotes its formulations as non-corrosive and non-toxic.

A few years ago, DUST/BLOKR caught the attention of

LOOKING FOR A LITTLE INSPIRATION?

Here are some possible photo ideas to get you started:

Asphalt or concrete paving | Milling

Traffic management | Blasting operations

Crushing | Screening | Washing

Hauling | Equipment maintenance

ALONG WITH A HI-RESOLUTION IMAGE, PLEASE ADD THE FOLLOWING:

• A BRIEF SUMMARY (50 TO 100 WORDS) ON THE PROJECT

• DATE OF PHOTO

• LOCATION WHERE PHOTO WAS TAKEN

• MODEL OF EQUIPMENT (IF APPLICABLE)

PHOTO SUBMISSION DEADLINE – AUGUST 15, 2022

Please submit your photos to, and for any further questions, contact: Editor Andrew Snook at asnook@annexbusinessmedia.com

a Winnipeg resident, Darren Van Wynsberge, who was fed up when his new truck began showing signs of corrosion, and he lost trees on his property due to magnesium chloride road dust treatments.

“I went to the City [of Winnipeg] and demanded that our street should no longer be treated with these road chemicals,” said Van Wynsberge in a Cypher press release issued last October.

The city tried it.

“It led to awareness that there were alternatives to road salts that the City should consider. Even after [one] year and a winter of snow, the results are still very good,” Van Wynsberge added.

While the City of Winnipeg declined to comment for this piece, citing its policy of not wanting to be seen as endorsing specific products, Cypher CEO Todd Burns stated that, after three years of testing, “... [the City] contacted us and said they wanted to expand the program, and they wanted to include our ecofriendly product in their annual road dust control tender.”

Applying DUST/BLOKR is straightforward: First, grade out any potholes and washboarding. Next, check the weather forecast, as the product should not be applied in the rain. Once absorbed, DUST/BLOKR provides cohesiveness of the fines on the road, so they no longer become airborne.

“It's designed to bind to almost any type of material on the road – gravel, sand, silt, and clay. Once the product is applied and dried, it becomes very hard, so the road becomes more stable,” Burns notes.

The contained fines help bind together the gravel component to hold the road together. Once DUST/BLOKR is applied, bring on the traffic – no significant downtime is needed before vehicles can use the freshly treated road. The hardened surface sheds more water and the road will require less grading, according to Andrew Lindsay, senior vice-president of business development for Cypher.

“For longer lasting results, our customers will scarify the surface to a depth of anywhere from two to five centimetres. This will loosen the surface to allow the DUST/BLOKR to penetrate further into the road, then be recompacted by the traffic as soon as the application is done,” Lindsay says.

Cypher has customers in 40 countries,

split roughly half and half between public roads and mining operations. Canadian mining companies using DUST/BLOKR include Teck Resources, Syncrude, Suncor, Arctic Canadian Diamond Mine, and Agnico Eagle. Baffinland Iron Mines, for which Inuit concerns about dust contamination has been an impediment to its expansion plans, has already received over two million litres of DUST/BLOKR for application on its 100-kilometre tote road between its Mary River mine and Milne Port on Baffin Island.

In a collaborative effort between Baffinland, Nunavut Sealink & Supply Inc., and Cypher, which donated 38,000 litres of DUST/BLOKR to Pond Inlet, just outside Milne Port, the hamlet, plagued by dust, treated, under Cypher supervision, about 10 kilometres of its dirt roads in 2021. Baffinland reported that the treatment could result in a more than 90-per-cent reduction in airborne dust off the roads.

In Northern Canada, where dirt roads are the norm, eight communities in Nunavut and the Northwest Territories have already, or intend to place orders for Cypher’s product for their 2022 sealifts, according to Greg Peters, director of business development, BBE Expediting Ltd.

In British Columbia, Mountain Side Earthworks Ltd. has so far used DUST/ BLOKR on about 12 projects: pipelines, parking lots and local private roads, including three kilometres of donated product for the Whispering Pines/Clinton Indian Band roads, located 35 kilometres north of Kamloops in 2021.

As for treating public roads, B.C.’s Ministry of Transport is proving to be a tough nut to crack. The province, says Burns, told him that, “The only things we will consider has to contain chloride,” despite one of their six approved dust palliative suppliers stating specifically that its product contains no chloride salt products. This stance perplexes and vexes Burns. “What really bothers me is the lack of willingness to sway from known toxic products. They are, in effect, saying that if your product is non-toxic and noncorrosive, we won’t use it.”

There may be light at the end of that tunnel though: Mountain Side Earthworks president and project manager Terry Sulphur says that the BC MoT paid for a test project in 2021 on two kilometres of First Nations roads in

Salmon Arm.

“One Salmon Arm road had to apply calcium magnesium four times in one year,” Sulphur says. An application of DUST/BLOKR can be good for more than a year. “The requirement [for chloride] is still something we don’t understand. They are limiting us from applying the product in environmentally sensitive areas,” he adds.

East of Brandon, Man., unpaved haul roads from a dozen quarries link up with the unpaved Currie’s Landing Road, a main road with people living along it. Truck traffic caused washboarding and horrendous dust, in the words of Dr. Hamid Mumin, a geological engineer and professor in the Geology Department at Brandon University.

Since coming across Cypher and its other product, ROAD/STABILIZR, Dr. Mumin has developed a professional interest in researching and testing rural and haul road stabilization technologies specific to Cypher.

“Road test work and lab work, the two inform each other,” he says.

Cypher designed ROAD/STABILIZR for roads with far worse issues than dust. That haul road, for example, was making no friends.

“The dust on gravel roads is tremendous. Gravel roads under heavy loads are very hard to maintain,” says Dr. Mumin.

ROAD/STABILIZR is normally applied in-situ and requires clay to function; the clay binds all the other materials in the road together permanently, providing lasting stabilization, according to Burns.

Exceptionally, the Cornwallis projects

were done by mixing clay with aggregate at a quarry and transported to site, Dr. Mumin says.

“[It was] hauled to the road and laid down in a compacted layer six to eight inches thick (eight to ten inches uncompacted). Roll it with the wheel packer, then let the traffic, the heavier the better, do the rest,” he says. “In our area, about 15 kilometres of road have been done. It is not brittle; it is not loose. It is a semi-solid, I’d say, with ductility. The surface is so hard that it has to be soaked even to be able to scratch up the top one or two inches, then smooth it and pack it back down.”

As for upkeep, Dr. Mumin says, “We told the municipality [of Cornwallis] and contractor that there would be a one-year maintenance protocol. But they didn’t bother [because the road didn’t need it.]

Going into our eighth season there are no signs that the road is any worse than when it was built,” including no signs of potholes or frost damage – just a small amount of roughness. “ROAD/STABILIZR is a permanent binding of your aggregate and road material. Cornwallis will tell you, on one three-mile gravel haul road from quarry to highway, they are saving over $100,000 a year, Dr. Mumin adds.

While Burns laments that the domestic take-up of DUST/BLOKR and ROAD/ STABILIZR could be quicker, word is spreading. Resistance by provincial MoTs’ may ultimately be futile. Using known toxins and dispatching repair crews and diesel-guzzling heavy equipment is neither environmentally nor fiscally sound. There are better alternatives.

BY GRANT cameron

> Slowly but surely, the hulking metal framework of the $5.7-billion Gordie Howe International Bridge, a six-lane cable-stayed structure over the Detroit River at Windsor, Ont. is starting to take shape.

Tower legs, which aptly resemble the curved blade of a hockey stick, have reached their full height of 140 metres, enabling crews to now work on the final portion of the supports – known as the pylon head.

It’s a major step in the construction of the bridge. The massive towers are located on each side of the Detroit River. The final 80-metres of the two towers will be completed over the remainder of 2022.

“It is an exciting time as the towers – arguably the most visible aspect of construction to date – move into the next and final build phase,” explains Bryce Phillips, CEO of the WindsorDetroit Bridge Authority. “With the towers currently standing at over two-thirds of their final 220 metres/722 feet height, they represent the significant progress the project team has been able to achieve.”

JOIN US

HALIFAX, NS – OCTOBER 13TH, 2022

CALGARY, AB – OCTOBER 18TH, 2022

Rock to Road is excited to announce that Quarry Tech is back live and in person in 2022! These popular one-day forums focused on the optimization of quarry and pit operations will be coming back to Calgary and Halifax this fall.

Quarry Tech is an exclusive event for quarry and pit owners and operators that will offer attendees case studies and panel sessions presented by industry experts covering a wide variety of key industry-specific topics.

The call for proposals to present at both Quarry Tech forums will be opening soon!

In preparation for the transition work, the towers were built up steadily. The lower pylon makes up the longest portion of the towers and is composed of 29 different segments. Each segment has a height of 4.67 metres and required 98 cubic metres of concrete and 55 tonnes of rebar.

Each tower is supported by 12 shafts drilled into the bedrock to a depth of 36 metres – the equivalent of a 12-storey building. Each of the shafts was filled with approximately 262,000 litres of concrete.

“Before you can build up, you have to build down,” notes Phillips. “Substantial work was done underground to help support these massive towers that have become a very visible sign of the project’s progress.”

The transition from the tower legs to the pylon head is expected to be completed this spring. It involves modifications to the jump form systems and concrete pours to construct an upper cross beam that will merge the tower legs

into a single structure. The jump forms have encased the tower legs to provide workers with an enclosed environment.

The exterior of the jump forms provided the perfect canvases for murals that were painted by artists from Walpole Island First Nation, Caldwell First Nation and Southwest Detroit. The murals, which can be seen by travellers on local streets and the Detroit River, feature the Canadian maple leaf and the American stars and stripes and visual stories about the culture and diversity of the region.

Instead of a jump form on each tower leg, they will become one and will continue to provide access for workers as they continue to build up the two massive towers on each side of the border.

Two concrete pours will be completed in the transition area to construct the upper cross beam. Approximately 182 cubic metres of concrete will be used in two separate pours for the upper cross beam.

Bridging North America (BNA) is the private-sector partner that was hired to design, build, finance, operate and maintain the bridge project. The consortium is comprised of ACS Infrastructure, Fluor and Aecon.

“Bridging North America is completing a major engineering feat,” says company CEO Michael Hatchell. “The joining of the two tower legs will mean we’ve achieved an important milestone for the project. BNA has been able to reach this point in the project safely and efficiently and is extremely pleased with the work of our team.”

Once the transition work is complete, construction will start on the pylon head. Critical to the cable-stayed design, anchor boxes within the pylon head will house cables that will connect the towers to the bridge and decks.

The project team has also begun installing corbels, which act like brackets to support construction of the bridge deck. Construction of the bridge deck is

expected to begin in 2023.

Two tower cranes – one in Canada and the other in the U.S. – are being used to build the towers. The cranes have a horizontal jib which can reach 60 metres and have a maximum load capacity of 50,000 kilograms. As the towers rise in height, so do the cranes. At their maximum height of 244 metres, the cranes will be taller than the actual bridge towers.

Once completed, the two towers will rival the height of Detroit’s tallest building, the 73-storey centre tower of the GM Renaissance Center. The tower legs are already the tallest structures in the City of Windsor and taller than the Statue of Liberty in the U.S.

Each tower required 10,000 cubic metres of concrete and 4,500 metric tons of steel rebar. The full weight of just one tower will be approximately 30,000 metric tonnes – the weight of 165 jumbo jets.

Together, the bridge towers and cable system are being constructed to support nearly 34 million pounds of weight.

The bridge project is a once-in-ageneration undertaking and is being constructed over a six-year period. Not only will the project deliver muchneeded transportation improvements for international travellers, it will also provide jobs and opportunities for growth in the Windsor-Detroit region.

The bridge itself will be 2.5 kilometres long and 37.5 metres wide and feature three Canadian-bound and three U.S.bound lanes and a dedicated multi-use path that will accommodate pedestrians and cyclists.

The crossing will have a clear span of 853 metres – the longest main span of any cable-stayed bridge in North America. There will be no piers in the water and the towers are on either side of the Detroit River. Once completed, the structure will be among the top five longest bridges in North America.

In addition to the crossing, the project includes a number of road improvements and construction of new roads, bridges and infrastructure on both sides of the river. There will be one approach to the bridge on each side of the crossing to connect ports of entry in Canada and the U.S.

The Canadian side will have 16 toll booths and 22 inspection lanes while the U.S. side will have 36 inspection lanes.

The bridge will be 220 metres tall and the deck will be 42 metres above the water.

On the Canadian side, four new road bridges and five pedestrian bridges are being built, and roads are being widened at key intersections to allow transport trucks to make full uninterrupted turns.

Construction of buildings on the Canadian side is well underway. For some buildings, excavation and foundation work continues, while others are further along with structural steel frames and decking installation work happening. In addition, interior building partitions and

fit-out work has started.

Underground utility installations are ongoing throughout 2022. Grading and paving will begin later this year.

On the U.S. side, the project includes construction of primary connecting ramps to and from the U.S. port of entry, four bridges crossing a railway line and connecting I-75 to the U.S. port of entry, reconfiguration of I-75 interchange ramps and service drives. Foundation work continues for some buildings and steel work and deck roofing has started on others.

BY ANDREW snook

Part two of a two-part series on best practices

> Ensuring conveyors are optimally designed is key for keeping future maintenance costs as low as possible. To learn more about conveyor design and maintenance best practices, Rock to Road reached out to Travis Thooft, chief engineer for portable conveyors at Superior Industries. This is Part 2 of 2 on conveyor maintenance and design best practices. Part 1 can be found on Rock to Road’s website in the March/April digital edition.

There’s a lot of options for the material inlet and outlet areas. What do the different components do and why should I use them?

Yeah, this could be an endless topic. And when we're talking about inlet-outlet areas, we're basically looking at how to pick the material on the belt, and how to get the material off the belt effectively. And the inlet area, again, referring to what type of material you're running, you want to make sure you match that up with the components. As we mentioned earlier, the biggest thing that we see done incorrectly is impact management, and that can be managed a number of different ways, whether it's using the solution like impact gathering-type cradles, or impact idlers, to reduce the damage to the components from the impact of what’s on the belt.

But, again, it's best to put on some sort of rock shelf system, or if contamination is an issue, at least a taper designed to help material shed into the centre area.

When we look at the inlet, the biggest thing to take into consideration is the skirting area, which is going to centre the material flow up and prevent mistracking. It’s also going to hopefully settle the material on the belt. So, having a long enough skirting distance, which you can reference to make sure you get the appropriate length for the material to settle down and get going in the right direction. That's both an operator maintenance item and a safety item to make sure that there's no material going off the belt. And then it looks pretty similar on the discharge end. So, hopefully you don't have to manage the impact with anything and you can go on to the next piece of equipment direct from the conveyor belt. That's the lowest maintenance way to approach it. But that's not always reasonable. So, where possible, using rock shelf really helps with maintenance, so there’s a built-in system to manage both the impact and the wear.

I know belt tracking is important. Why is it a big deal and how can I make sure I’m doing it correctly?

It seems like a basic conveyor question, but it still tends to be one of the easiest ways to make sure that you're doing a good job with your conveyor. What belt tracking is referring to is keeping the belt centred on the idlers on the conveyor. Where it comes into play is anytime there's mistracking, what tends to happen is you'll introduce a reduced lifespan of the components and the structure, especially if a belt mistracks far enough to start cutting into the structure itself. And even if it isn't to that point, a mistracked belt will tend to spill material off one edge and add extra weight to the components on the other edge, which reduces the overall lifespan of everything that's involved. The easiest way to start is with your structure. Make sure your structure is in good condition and the overall structure is square and straight. And then from there, we recommend looking at all the pulleys. The best thing to do is make sure that the pulleys are square to the structure including the take-up. There’s an old way to track the belt using the take-ups. This will work temporarily, but eventually it will cause the belt to warp and that correspondingly will make it more and more difficult to track the belt. So, start off by setting up the pulleys to the structure

and then take a look at the belt running empty, and then look for areas where the belt is mistracking on the idlers. Typically, you want to go 10 to 20 feet ahead of that area and start by turning the idlers. You want to turn the idlers, like you’re turning the handlebars on a bike, but steer the belt the opposite direction of the mistracking. Then, keep working your way down the conveyor to get the tracking straight. For radial stackers, or even on a variable structure, make sure the belt is level side to side before you start.

Carryback (material sticking to the return strand of the belt after the discharge pulley) is making a mess under my conveyors at my site. What options do I have? I’ve still got issues with sticky material and build-up. What else can I do?

First of all, you want to make sure that you've got people cleaning around the conveyor, make sure it's appropriately tensioned, and that the blade is decent working conditions. Start by making sure the components you have are adequately set. Make sure that the scraper is located appropriately. The manufacturer will give a recommendation on how to locate the scraper in relation to the pulley. We typically recommend using a cleaner that is eight inches narrower than what is required for the amount of material sticking on the bill. From there, look at adding additional cleaners as needed. You can add a secondary cleaner, if space allows, and then tertiary cleaners back near the return idlers if there's space to do so. There's lots of solutions out there that allow you to keep constant tension or add additional components or provide tertiary cleaners. If you're running an cleated belt, it

cannot use a traditional cleaner, and then if it becomes relevant, start looking at brush cleaners or even some air cleaners for dusty material. In very limited applications, there's pressurized water cleaners being introduced, although they come with their own limitations in terms of how much water and sticky material it’s creating versus removing. Something else you can look at if you have the space to do so, and you want to remove the material from the belt to a certain location, is adding a beater-bar type return, which basically helps shake the belt and drop material at a certain area. The other area to consider is looking at a plow on the clean side to help with any material that may be sticking to the inside of the belt. Where that can be particularly useful is if there's any issues with slippage on the wrap drive pulleys. And it will help get back to a scenario where you're running the clean side of the belt against the pulley itself, whether it's a lagged or not lagged pulley.

I want my guys to go home every day the same way they came in. What should I consider in terms of safety? For somebody that’s going to own and operate a conveyor, it’s important to think about the different areas the operator can get into with different components and make sure they’re adequately guarded. At a minimum, I’d be looking at all of the pulleys and making sure that there’s no access to the pulley area. It’s important to make sure an operator doesn’t have access to fall into the trough side idlers. OSHA or MSHA would recommend that there’s either a handrail or safety shaft run along the topside of the top belt area to make sure if an operator were to fall it would protect

them from falling either into the belt or into the conveyor. It’s better to have those elevated out of the way or have a full guard to prevent access to the belt or pulley itself. When it comes to working around the conveyor, it’s good to think about where the material is going and block off any of those areas.

Also, although this is basic, it’s important to have good procedures for lockouttagout. Make sure everyone is aware of the procedure for the different sites. Particularly people that don’t work there every day –vendors or maintenance personnel – and make sure they’re paying attention and following the regulations for the site.

I would recommend you reach out to the manufacturer of the equipment and see what they have in terms of a daily maintenance inspection or a periodic maintenance inspection and use that as a starting point.

Most of what we recommend is periodic inspection of the overall conveyor structure and the components themselves. Reviewing the conveyor, reviewing the frame, make sure it’s safe to continue running, that there’s no damage. Review the site conditions to make sure there’s no outside influence that are going to affect it. Have setups around all the visual components – the pulleys, the bearings, the drive components, the motor, the cleaning items like the belt scraper, and make sure they’re in working order. Make sure there’s appropriate tension on the system. If you haven’t done so, do an overall review on the safety side and any additional guarding. Review the conveyor belting for worn edges or others surface cuts to the surface of the belts. Check the inlet-outlet of the conveyor. Those are pretty basic in terms of the checklist for the conveyor.

I think the Internet of Things (IoT) and other technologies can be leveraged as well to make it easier for operators to know where their issues could be on the conveyors and proactively monitor those items. I think it’s important for an owner or operator to pay attention for what’s going to be easiest for people to use. You can come up with a really great system in terms of technology, but if the access and the user-friendliness of it is very poor, you can bet that the operator that’s going out there is going to ignore it.

Workplace signage is important. But what about the labeling on the equipment itself? How does that factor into worker safety, and how does it differ from the safety message in the workplace?

I had never considered the specifics behind equipment labelling and its importance in the safe operation of machinery. So, feeling like I was a little over my head, I decided to consult an expert.

Angela Lambert is the head of standards compliance at AEM component member company Clarion Safety Systems. She has more than 15 years of experience in the field of warnings and liability and is actively involved at the leadership level in the (U.S.) ANSI and (international) ISO standards for product safety and visual safety communication.

Angela outlined the important processes used in creating effective equipment safety labelling: ON PRODUCT LIABILITY/SAFETY/RISK AND EQUIPMENT SAFETY LABELS

• Effective warning labels are critical in the construction industry, where the interaction between people and machinery is frequent, making the potential for injuries possible. Labels can play a vital role in ensuring safer equipment and workplaces.

• Warnings and instructions can also decrease liability exposure. That is because manufacturers have a legal duty to warn: they must give people the information needed to avoid potential hazards throughout their product’s expected life (e.g., through transportation, installation, testing, operation, shut down, inspection, maintenance, final decommissioning and disposal).

• By following industry consensus standards that define today’s best practices in visual safety communication – the ANSI Z535.4 and ISO 3864-2 – manufacturers can improve product safety and reduce their liability exposure.

• Generally speaking, a warning label should identify the hazard; indicate the severity level of the hazard; indicate the likelihood of the hazard resulting in harm; give instructions on how to avoid the hazard; and describe what will happen if the warning is not heeded.

• When it comes to the documentation needed in preventing liability, three key aspects are: a

documented risk assessment; product safety labels; and product manuals and instructions.

These areas are interconnected, and each support each other.

Risk assessment is fundamental when it comes to machine and product design – as well as safety. Engineers cannot design out a risk, safeguard a hazard or warn about a risk unless they first assess it. A thorough risk assessment will identify potential risks and control actions related to them to protect those who interact with the product during its lifecycle. Warning systems – including labels and instructions – are an outcome of the risk assessment process. Intelligent decisions need to be made concerning how to warn effectively, so people can take the steps necessary to avoid harm.

THREE EFFECTIVE STRATEGIES FOR WARNINGS AND INSTRUCTIONS

• Use a quality risk assessment process (the foundation of a strong safety program and of a company’s labels/warnings) – performed routinely.

• Follow the latest versions of the ANSI/ISO standards for labels/warnings.

• Continuously reevaluate equipment safety programs (including labels/warnings) in line with equipment and standards updates.

Even though equipment safety labelling may seem straightforward to most people, the processes behind the wording, design and risk communication are often multilayered and complex. Safety professionals such as Angela have dedicated themselves to establishing standards to ensure that safety labelling goes through a documented process that is clear and consistent. Employers and workers should always make sure they are aware of these standards, that they are trained properly to understand the safety messages behind them, and that risk assessment programs are continually updated.

Businesses can ensure a safe workplace when leaders and employees make a personal commitment in championing a culture of safety. When goals are established, trained to, measured, and truly owned by everyone working together, the company will be well positioned to improve safety across the organization.

Jaime Vos is the director of safety materials at the Association of Equipment Manufacturers.

> MAY 25-26

BCSSGA AGM

Vernon, B.C. www.gravelbc.ca

> JUNE 21-22 Hillhead 2022 Buxton, England www.hillhead.com

> SEPTEMBER 18-20

BCRB Fall Conference

Kelowna, B.C. roadbuilders.bc.ca

> SEPTEMBER 23-25

CANS AGM

Cardigan, P.E.I. cans.ns.ca

> OCTOBER 3-5

SC&RA Crane & Rigging Workshop

Dallas, Texas www.scranet.org

> OCTOBER 13

Quarry Tech

Halifax, N.S. www.quarrytech.ca

> OCTOBER 18

Quarry Tech

Calgary, Alta. www.quarrytech.ca

> OCTOBER 24-30 Bauma Germany www.bauma.de

> DECEMBER 1-3

BCRB AGM

Victoria, B.C roadbuilders.bc.ca

We’ve all seen the meme – in Britain they drive on the left side of the road; in Winnipeg we drive on what’s left of the road. So funny. I almost laughed. This has been an extremely painful spring for everyone travelling on our cratered streets. Motorists have blown tires and bent rims; vehicles have been abandoned at the sides of our higher-speed regional roads.

For cyclists, however, the curbside potholes and crevices — sometimes lurking beneath pools of water — are downright dangerous. At this point, our pocked streets have become a tourist spectacle. Enough is enough.

The damage done to streets from the winter that never ended and the spring that wouldn’t let up is extreme. But it is also the very predictable outcome of a decades-long problem. This hot mess can’t be solved by a quick, cold-mix fix. The solution lies in proper asset management and a sustainable, multiyear financing plan.

City council often cites its road-repair budget as hitting “historic” levels. But that obscures the truth of the matter.

In the early 2000s, city hall adopted a road-renewal program designed to get roads in good shape and keep them there (asset management) with a sustainable revenue source (multi-year financing plan).

In 2013 and 2014, Winnipeggers accepted an annual two per cent tax hike because, they were told, those revenues, combined with other identified funding pots, would be dedicated to fixing streets and building the new roads required.

By 2022-23, the new local and regional street renewal reserve was to reach a sufficient level to keep city streets well maintained. That was the plan. But the other funding sources have shifted, and the revenues from the annual tax hike are no longer funding just streets.

Further, city councillors are increasingly calling for the reserve to fund a variety of other priorities. Undermined in this way, the policy/ financing plan cannot hit its goal, and our streets continue to deteriorate. Each spring, the plentiful potholes expose a growing problem.

Road maintenance has been so neglected that stretches of our regional routes, many of which were built post-1960s, require expensive reconstruction (It is generally accepted that one dollar in maintenance delays spending $6 to $10 on rehabilitation or reconstruction).

But potholes don’t stop at the Perimeter Highway. Municipalities across Manitoba (and Canada, actually) simply do not have the money or the taxing flexibility to adequately fund road renewal, because they’re

forced to work with revenue streams drawn from an antiquated system of taxation and revenue sharing.

Provincial and federal governments collect 90 per cent of tax revenues; they transfer revenues, based on their own priorities, to municipalities for a variety of purposes. And those transfers are volatile, rising and falling unpredictably.

In contrast, south of the 49th parallel, states and local governments benefit from meaningful revenue sharing and dedication. You notice the difference in the roads as soon as you enter North Dakota, which has similar weather and soil conditions.

The U.S. federal government raises a lot of revenue for transportation infrastructure primarily via excise and fuel taxes. Its transfers are predictable, dedicated and augmented by state and local government taxes for roads. The U.S. system of revenue sharing and taxing authority strikes a fairer deal, recognizing the outsized pressures on municipalities for services.

In Canada, municipalities are trying to deliver modern services while financially strapped. When the original fiscal structures were set down postConfederation, cities and towns owned far less infrastructure. Today, they own more than 50 per cent of total public infrastructure. Yet they collect just 10 per cent of every tax dollar.

Infrastructure agreements typically are equally split among the levels of government, and the costsharing does not contemplate life-cycle costs — the tens of millions of dollars required to maintain and renew our roads.

Winnipeg’s “investment deficit” for its roads and streets is $1.9 billion (what it would cost over 10 years to repair streets and build new roads). Puts the “historic” $165-million roads budget for 2022 in perspective, doesn’t it?

Municipalities need a fairer deal, and the ability to source new revenues, along with multi-year infrastructure agreements with provinces and Ottawa that acknowledge life-cycle costs.

Winnipeggers should call on city council to lead the campaign for a new fiscal deal. But we should also all call our provincial and federal elected representatives — and tell them to fix our roads, with a new deal worthy of the 21st century.

Chris Lorenc is president of the Manitoba Heavy Construction Association and Western Canada Roadbuilders & Heavy Construction Association. This column originally ran in The Winnipeg Free Press.

> The innovative MILL ASSIST machine control system guarantees low operating costs.

> Unique two-speed DUAL SHIFT powershift transmission enables extremely high milling output and reduces pick wear.

> Achieve new standards of quality with the new LEVEL PRO ACTIVE leveling system.

> MCS expands the machine’s broad range of applications by making it possible to quickly switch milling drums or the milling drum unit.

www.wirtgen.com/milling

No matter how challenging your needs, BKT is with you offering a wide range of OTR tires specifically designed for the toughest operating conditions: from mining to construction sites.

Sturdy and resistant, reliable and safe, able to combine comfort and high performance. BKT is with you, even when work gets tough.