Strong like a specia li st.

PERFECT FOR HIGH THROUGHPUT PERFORMANCE – IN NATURAL STONE AND FOR RECYCLING APPLICATIONS. The MOBIREX MR 110/130 EVO2 mobile impact crushers feature a state-of-the-art material flow concept and a powerful diesel-directdrive – for high throughput combined with optimised wear and consumption. With their compact design, the machines are easy to transport and as quick to set up as they are to dismantle. The MR 110/130 EVO2 – versatile and ready for high performance. www.kleemann.info

MR EVO2

Staying Safe

Roadbuilders are most vulnerable while working in noisy, dark and busy jobsite conditions especially if there are distracted drivers disregarding hazard signs and blockades.

14

Building a blueprint

Ontario mine operator pushing to reach net-zero status.

18

Stronger foundations

Dr. Amma Agbedor explains how aggregate selection shapes asphalt performance.

20 Rethinking safety design

When the 2009 recession caused the Vandergeests to change business direction, they decided to take a leap of faith and start a rather niche company in an untouched market in Canada – safety guarding for material handling equipment.

22 Ontario paving forecast

Amin Mneina provides a deep dive into the 2025 Ontario municipal paving forecast survey.

24

On the move

More and more operations are being drawn to mobile plants for their ability to offer quick mobilization and cost savings.

Halfway there

Am I alone in finding it hard to believe that we are now at the halfway mark of 2025?

It's been half a year, but feels like a decade has passed by.

Just think about everything that has transpired so far in 2025.

Mark Carney became the new leader of the Liberal Party of Canada, then took over as prime minister. An election was called and he received a mandate from Canadians.

NDP leader Jagmeet Singh lost his seat and stepped aside as leader. Conservative Party leader Pierre Pollievere also lost his seat but hasn’t stepped aside as leader. A byelection was just announced in the Alberta riding that he is now running in.

In Ontario, Premier Doug Ford easily won another term in office after calling a snap election in February.

Of course, all this upheaval was driven in large part by what occurred south of us.

In January, Donald Trump was sworn in as president. He immediately placed obscene tariffs on Canada. Then removed some of those. Then placed 25 per cent tariffs on steel and aluminum, later increasing the steel tariffs to 50 per cent. Then imposed massive tariffs on countries around the world. Then pulled back those tariffs, somewhat. He attached significant high tariffs on China, increased them two more times, then pulled back.

There have been so many tariffs put on and taken off that I can’t make sense of it anymore. In fact, having written this in early-July, there is a very good chance by the time you read this, the entire U.S. tariff scheme has been upended again. (And, as I am writing this, it was just announced Japan and South Korea will have 25 per cent tariffs imposed on them as of Aug. 1. Wait, check that, another announcement just dropped. Copper imports will face a 50 per cent tariff. Oh wait, another day and another letter from the American president: he's increasing tariffs on Canadian goods to 35 per cent as of Aug. 1. Will any of this hold? Who knows.)

Of course, all of these decisions by the United States president has created an economic climate that can best be described as “on pause.” Just think, three and a half more years of this.

Can’t wait.

On a positive front, it looks like the federal and provincial governments are finally ready to tackle two main issues that have plagued this country. The first is removing interprovincial barriers to trade and labour mobility. Significant movement has already taken place this year and momentum should continue into the second half of 2025. There have been a series of memorandum of understandings signed between provinces pledging to eliminate all sorts of trade barriers. The most recent was signed between Alberta and Ontario that pledged to improve co-operation on critical minerals and energy projects.

The Canadian Federation of Independent Business has noticed. In July, it released its annual scorecard on these barriers. Nova Scotia scored top marks for its work on removing these barriers, followed closely by Ontario. In fact, most of Canada’s largest provinces have shown a real desire to change.

Also moving in a positive direction is our ability to get large, important infrastructure projects completed. New federal legislation is expected to speed the approval process for such projects down to two years. Provinces are also jumping on the building boom and promising to pour significant amounts of money into infrastructure work.

The politicians have talked a good game but is it just talk? We will find out in the second half of the year if these promises are realized.

So far, it’s been a wild year.

Mike Lacey is editor of Rock To Road Magazine. He can be reached at mlacey@annexbusinessmedia.com

RocktoRoad

MIKE lacey

NEW IntelliPac ™ Moisture System

Astec paves the way for sustainable, innovative asphalt plants. The new IntelliPac Moisture System is a revolutionary solution that integrates seamlessly with Astec control systems. This provides unparalleled, real-time visibility into virgin aggregate moisture content. IntelliPac empowers operators to optimize mix design, minimize energy consumption, and reduce environmental impact. With Astec, you get superior asphalt production – better for the environment, better for your business.

BUILT TO CONNECT

See you later Lafarge Canada, welcome Amrize

After more than 60 years helping build Canada, the name Lafarge Canada is transitioning into something new.

However, while the name is gone, the company and those who work there will continue, albeit under the new name Amrize.

“This isn’t goodbye, but a renewed promise to lead the future of building,” Lafarge Canada stated on its LinkedIn Page.

Earlier this year, parent company Holcim Group announced it would spin-off its North American holdings into a new, independent public company. On June 23, Amrize was officially born.

The new company has more than 1,000 sites and a distribution network across every Canadian province and American state. As well, its 19,000 employees serve every construction market from foundation to rooftop, from infrastructure, commercial and residential to new build, repair and refurbishment.

For the now former Lafarge Canada, the only change is in the name. All other aspects of Canadian operations will continue without disruption.

“It’s been a fantastic journey as Lafarge Canada,” the company stated on LinkedIn. “For over 60 years, we’ve helped shape skylines, roads, and communities across the country, and none of it would have been possible without the people who built this story with us.”

According to Amrize, the new name is a combination of two concepts: ambition and rising. The “Am” represents the company’s commitment to high-performance and innovation to meet its customers’ greatest ambitions. Meanwhile, “Rize” symbolizes the company’s drive to lead construction forward across North America to shape the essential buildings and infrastructure that advance how people live.

“This is an exciting day for all our teammates across North America as we begin our journey together as Amrize,” said Jan Jenisch, Amrize chairman and CEO. “As an independent, publicly traded company, Amrize will capitalize on North America’s attractive construction market driven by long term mega-trends from infrastructure modernization and onshoring of manufacturing to data center expansion and the opportunity to bridge the housing gap. With our track record of profitable growth, market-leading operations and broad range of advanced building solutions, we are ideally positioned to be the partner of choice for the professional builders of North America and to unlock value for all stakeholders.”

Heidelberg Materials acquires Calgary concrete recycling business Concrete Crushers Inc.

Heidelberg Materials has acquired the assets of Concrete Crushers Inc., the largest concrete recycling company in Calgary, Alberta.

The transaction includes a recycled aggregates yard in southeast Calgary and a contract crushing business with four mobile plants.

According to Heidelberg Materials, this acquisition strengthens the company's existing footprint, and advances its focus on sustainable and circular products in the growing Calgary market.

The parties have agreed not to disclose the financial terms of the transaction.

Chris Ward, member of the Managing Board of Heidelberg Materials and CEO of Heidelberg Materials North America, said the acquisition is an example of how the company is combining

growth and sustainability.

“Besides expanding our existing footprint in an attractive market as part of our ongoing portfolio optimisation, we are further advancing our focus on sustainable and circular products,” he says.

Heidelberg Materials also recently completed its acquisition of Giant Cement Holding Inc.

The company is an established cement producer on the east coast of the United States with a strong focus on using wastederived fuels.

Heidelberg Materials states it is committed to advancing sustainable products and increasing the circular economy in North America.

Bailey Electronics is moving into a new facility

British Columbia-based Bailey Electronics is expanding.

The company recently broke ground on a new facility in Victoria, B.C.

Formerly known as Sure Grip Controls, the company specializes in designing and manufacturing custom controls for heavy equipment manufacturers in industries such as agriculture, construction, forestry and transportation. It is a division of Bailey International, which is headquartered in Knoxville, Tennessee.

“[Bailey Hydraulics is] a manufacturing distributor of hydraulic components and subsystems. On the electronic side, we complement them with electronic controls that are used on those subsystems or in complement with their products,” explains Darren Lockyer, vice president of Bailey’s Electronics. “We have a distribution and manufacturing network right across North America as well.”

They worked with officials to find suitable space in the new Vancouver Island Technology Park. While the park is geared more toward office space, due to the nature of what Bailey Electronics is manufacturing, the site fits.

“The type of work we do, we need to have transfer trucks come and go, but not heavy welding or machinery or anything like that. And the products that we make, very few of them weigh more than 10 pounds each. They’re the size of a case of beer, essentially, they’re not huge pieces of equipment,” he says.

The company’s workstations have a modular design so the transition to the new location should not take too long, Lockyer explains.

The groundbreaking of a new Bailey Electronics facility comes following a decade of growth for the company. They outgrew their current 14,000-square-foot facility and rented a second location that provided a further 8,000-square-feet of room.

“We realized that running kind of two facilities [and] not having room for growth, we needed to find a new home,” Lockyer says.

“We can take each one of those stations and within about 20 minutes, we can have that whole thing broken down and ready to go into a back of a truck,” he says. “They’re modular, and so we can fairly easily move those stations to a new facility and then get them set up.”

Lockyer explains that is a result of the lean manufacturing principles the company has put in place. While those principles create a more productive and efficient operation, there is the added benefit of enabling a quicker move to a new facility.

Northstar Clean Technologies Inc. has announced its inaugural asphalt shingle reprocessing facility in Calgary, Alberta, has produced its first liquid asphalt.

Northstar has now fully commissioned the hydrocarbon processing back-end of the facility and major processing units. Further ramp-up of commissioning volumes will ensue in the short term, with the target to achieve the Emission Reduction Alberta Commissioning Milestone three volume of 80 tonnes/day.

Northstar marks the culmination of commissioning efforts for the facility to process material from the beginning to the end of the plant and successfully produce liquid asphalt. As previously communicated in prior releases, the front-end of the plant was fully commissioned early in the second quarter of 2025. Samples taken from the last stage of the process were delivered to an independent laboratory testing facility to measure qualities within the liquid asphalt. Results from

those preliminary tests indicate asphalt quality that is significantly better than the delta pilot plant product and will satisfy requirements contained in a number of the company’s commercial agreements.

“The asphalt produced in Calgary is the highest quality we have ever produced demonstrating that our technology works which is an important step in de-risking the business,” said Aidan Mills, president and CEO.

According to Mills, Northstar will increase production levels to meet the ERA Milestone 3 threshold and name plate capacity for the facility.

Advisory group helps with the rehabilitation of the Quebec Bridge

An advisory group has been established to support efforts to rehabilitate the Quebec Bridge.

Last year, the government of Canada stated that the conditions necessary for the retrocession of the Quebec Bridge to the federal government had been met. Canada has regained ownership of this historic infrastructure, which is essential to the economy of both Canada and Quebec. Management of the Quebec Bridge was entrusted to the federal Crown corporation Jacques Cartier and Champlain Bridges Incorporated (JCCBI), which is responsible for elaborating and implementing the

Haver & Boecker Niagara opens its doors

Haver & Boecker Niagara hosted customers, partners and industry professionals at its St. Catharines, Ont., facility Open Day event.

The event featured guided tours of the St. Catharines facility, offering a behind-the-scenes look at the manufacturing process and the team behind the technology. Throughout the day, Haver & Boecker Niagara experts were available to answer questions, share technical knowledge, and discuss tailored solutions for a wide range of mineral processing challenges.

Attendees had the opportunity to see the Niagara F-Class Portable Plant and explore its design and engineering. Known for its construction and double eccentric technology, the F-Class portable plant delivers high-capacity screening performance with the flexibility of mobility.

Live demonstration of the company’s Pulse Diagnostics system showcased how real-time monitoring and predictive analytics can transform equipment maintenance. Attendees saw how the system reduces downtime and improves operational efficiency through intuitive reporting and actionable insights.

bridge’s rehabilitation program.

To support JCCBI in its mandate, the federal government is creating an advisory group to rehabilitate the Quebec Bridge. The purpose of this group is for JCCBI to benefit from a diversity of expertise, to learn about the Quebec City environment and raise awareness of the Crown corporation and its mandate.

The advisory group’s mandate is for two years, the estimated time required to develop the rehabilitation plan. Once this phase has been completed, whether the group continues, in its current or revised form, will be reassessed in light of future needs.

Lippmann welcomes PacWest Machinery as new Pacific northwest dealer

Lippmann shares that PacWest Machinery is its newest authorized dealer, expanding Lippmann’s service in the Pacific northwest. PacWest will provide sales, rentals, and aftermarket support for Lippmann’s full line of crushing and screening equipment, bringing a wealth of experience and resources to aggregate producers in the region.

With six fullservice branches located in Seattle, Spokane, Mount Vernon, and Pasco, Washington, and Portland and Eugene, Oregon, PacWest Machinery offers coverage throughout the Pacific Northwest. Their extensive mobile service fleet and remote service technicians ensure customers receive responsive, on-site support to keep their operations running smoothly.

PacWest Machinery has been a provider of equipment and aftermarket support, representing leading manufacturers such as Volvo Construction Equipment, Metso Minerals, and Gomaco. Their focus on customer success and operational efficiency makes them a valuable addition to Lippmann’s growing dealer network.

With this partnership, customers in the Pacific Northwest will benefit from easy access to Lippmann’s premium equipment, along with PacWest’s comprehensive support network and industry expertise. Whether through their full-service facilities or mobile service units, PacWest is committed to delivering service and support to help customers maximize their productivity.

BY MACENZIE rebelo

STAYING SAFE

Noisy and busy jobsite conditions are even more dangerous if distracted drivers are disregarding hazard signs and blockades

> In Canada, 22.5 per cent of fatal and serious injury collisions are caused by distracted driving, according to 2021 Transport Canada’s National Collision database.

For roadbuilders, protecting themselves from distracted drivers is a top concern when on the jobsite.

From January 2017 to December 2023, there were 232 critical injuries and 25 fatalities resulting from vehicle and equipment strike-by incidents in Ontario construction workplaces, according to the Ontario Ministry of Labour, Immigration, Training and Skills Development.

The government of Alberta states in a 2023 press release that the province had 2,229 struck-by incidents from 2014 to 2018. According to WorkSafe B.C., the province saw 35 struck-by and 10 struck-against injuries in the road construction and maintenance sector in 2023.

Peter Wehmeyer, founder and president of Cobblestone Safety Consultants Inc. explains a traffic management plan is the best way to keep workers safe on the job site. PHOTO: Daniel Avram/ iStock / Getty Images Plus

To maintain worker safety while on the jobsite, the road building industry is developing practices to keep drivers alert and workers safe, especially in low visibility or noisy environments.

In May the province of New Brunswick in partnership with WorkSafeNB, the New Brunswick Road Builders and Heavy Construction Association, and the New Brunswick Construction Safety Association launched their annual traffic safety awareness campaign.

New Brunswick’s campaign reminds drivers to slow down, follow speed limits and exercise caution in construction zones via social media posts, signage and local radio stations.

A TRAFFIC MANAGEMENT PLAN IS KEY TO KEEPING WORKERS SAFE

Peter Wehmeyer, founder and president of Cobblestone Safety Consultants Inc., has worked in the industry for more than 30 years. In 2010, Wehmeyer started his company managing temporary traffic control, and it is safe to say traffic management is his bread and butter.

When it comes to keeping roadbuilders safe on the jobsite, Wehmeyer explains a traffic management plan is the best way to go. This means inspecting the site beforehand and delegating where to place signs and preventive barriers.

“In our industry, the biggest thing to do is attract the driver’s attention. Positive guidance is key, so the driver has the information they need to understand and react appropriately.”

Traffic management plans include spotters, flaggers, Road Work Ahead signs, traffic cones, barriers and barricades, as well as personal protective equipment (PPE), such as high-visibility vests and hard hats. However, Wehmeyer argues PPE is a last resort for worker safety.

Even with all the necessary precautions, distracted drivers still cause jobsite intrusions and accidents.

“Distracted driving comes in various forms, whether it’s someone on their phone or using a GPS,” says Rob Covassin, director of EHS, Civil East Aecon.

“As an employer, we don’t have control over people in vehicles, so we must come up with strategies to keep workers safe.”

In 2024, there were 102 critical struckby injuries in Ontario, according to the Infrastructure Health and Safety Association (IHSA). Jennifer McKenzie, director, stakeholder and client engagement of the IHSA, explains that keeping the driver’s attention is crucial.

Example of WorkSafe B.C. safety ads alongside work zones. PHOTO: WorkSafe B.C.

Cone Zone awareness images by Road Safety At Work campaign by the province of B.C. PHOTO: Road Safety at Work

“Look at the 400 series highways (in Ontario), it takes only a moment of distracted driving for a tragedy to occur,” says McKenzie. “So ensuring that there’s high visible signage and a clear traffic control plan is essential.”

As an employer, a concise and effective traffic control plan is the first step to keep employees safe, explains Covassin.

“Communication is the most important thing,” says Covassin.

One-on-one discourse about the jobsite, exposure, activities, potential hazards and how to protect yourself is paramount.

“Call it a pre-task brief, a more morning huddle, or a daily risk assessment,” ex-

plains Covassin. “Don’t fall into a routine where you become complacent in one location. The work environment changes every day.”

Like Wehmeyer and McKenzie, Covassin echoes the importance of visible and clear signage and cone barriers. Throughout his career, Covassin noticed that having a police presence in the work zone has improved driver awareness.

“They [drivers] tend to slow down, be more alert, and pay attention. Speed radar signs and devices within the work zone have also changed drivers’ behaviours because they don’t want to get a ticket.”

> “Look at the 400 series highways (in Ontario), it takes only a moment of distracted driving for a tragedy to occur. So ensuring that there's high visible signage and a clear traffic control plan is essential.”

- Jennifer McKenzie, director, stakeholder and client engagement of the IHSA

ONE MUNICIPALITY MADE SIGNAGE PERSONAL

Another method to keep drivers alert are public awareness signs. These serve as a reminder to those behind the wheel that every worker deserves to get home safe at the end of the day.

“Municipalities should have these signs,” says McKenzie, who initially saw them used by the City of Kawartha Lakes in Ontario. “They picture a worker and read ‘Keep me safe’ It reminds drivers that the safety of road workers is important, and that they have families to get home to as well.”

The City of Kawartha Lakes included

The first step to keep workers safe is a concise and effective traffic control plan.

PHOTO: FatCamera/ iStock / Getty Images Plus

‘Mom’ Cone Zone images by Road Safety At Work campaign by the province of B.C. PHOTO: Road Safety at Work

messaging in its campaign signs such as ‘Together, we can all get home safe!’ with the primary objective to put the onus on the driver to protect both themselves and the road crew. Campaign signs also included images of the workers, their names and where they are from.

According to the Occupational Health and Safety Specialist, Canadian Centre for Occupational Health and Safety (CCOHS), states that Canada has 14 jurisdictions, each with their own unique health and safety acts and regulations.

WorkSafe B.C., in conjunction with the government of B.C., has developed safety ads to remind and educate the public of the importance of respecting work zones. Similarly, the Ontario government has introduced Bill 229, Working for Workers Six Act, 2024, which proposes to enhance roadside worker safety by expanding existing requirements for drivers to slow down and move over when passing emergency vehicles and tow trucks under the Highway Traffic Act.

The Manitoba Government and General Employees’ Union and SAFE Roads Committee launched the 2025 SAFE Roads campaign. The campaign emphasizes that ‘They’re Not In Your Way, They’re At Work.’

Despite causing traffic or road closures, it is important to remind the public that road builders are just doing their job, says McKenzie.

If a driver feels frustrated by the traffic caused by construction, they can sometimes ignore the signs that are strategically placed for everyone’s safety.

In 2024, a construction worker was struck by a driver in a fit of ‘road rage’ in Brockville, Ont., states the Brockville Police Service in a press release.

“The driver was disobeying signs and traffic. One of the workers attempted to stop the vehicle, which led to a verbal dispute between the driver and a construction worker,” states the Brockville police.

McKenzie argues that humanizing construction workers is an important part of keeping them safe.

“The majority of the time, it’s people taking their daily commute to and from work. And our job is to ensure the roads are safe for them to drive on. People should keep that in mind.”

Crushing Confidence

Looking for crusher wear parts that deliver performance and peace of mind?

ME Elecmetal offers premium wear solutions for aggregate, construction, recycling, and mining operations —engineered for maximum efficiency in primary, secondary, and tertiary crushing.

With proprietary alloys, custom designs, and proven durability, we tackle your toughest challenges while boosting safety and uptime. Our specialized crusher safety tooling takes protection and productivity to the next level.

On the right, an example of the City of Kawartha Lakes’ campaign. Scot R. from Sturgeon Point, Ont. PHOTO: Kawartha Lakes

BUILDING A BLUEPRINT

BY MATT jones

Due to a fortunate coincidence, Ontario mine operator looking to reach net-zero status

> Canadian Wollastonite is on track to become the first netzero mine in North America.

Through a partnership with carbon removal business UNDO, the Seeley’s Bay, Ontario firm is using technology and techniques such as enhanced rock weathering to decarbonize the air to achieve net-zero status. For the uninitiated, to achieve net-zero is to completely mitigate all greenhouse gasses that are emitted by an operation.

Canadian Wollastonite president and founder Bob Vasily says the project didn’t start with a desire to become the first net-zero mine in North America. He describes that as “a fortunate coincidence.” Vasily says that his intention has always simply been to build and operate the company in the most environmentally

The UNDO Team holding crushed wollastonite at Canadian Wollastonite. PHOTO: UNDO

responsible way possible.

“Canadian Wollastonite mines and sells wollastonite as a non-CO2 emitting source of calcium and magnesium to industries aiming to lower their emissions by substituting wollastonite for high CO2 emitting carbonate mineral sources,” says Vasily. “Wollastonite is also used in several environmental remediation soil amendment applications. It is essential for us to produce these products with the lowest emissions possible.”

Canadian Wollastonite own a 30 million tonne deposit which stretches across the boundaries of the City of Kingston, the Township of Leeds and the Thousand Islands. Vasily says that the permitting process comprised of two steps, starting with a pilot operation on the Thousand Islands and then seven years of land acquisitions, rezoning and mine plan amendments expanded the scope of the operation before they were granted municipal and provincial approvals in 2020.

PARTNERSHIP WITH UNDO A GOOD FIT

Vasily says that the partnership with UNDO came about after he learned about their work with enhanced rock weathering using basalt in the U.K. Since Canadian Wollastonite had been actively involved in atmospheric carbon removal using wollastonite since 2015, it seemed like a good fit, so he reached out to them in early 2023.

“I sent UNDO our research and findings,” says Vasily. “They quickly recognized the value of wollastonite as an ideal demonstration mineral and arranged a visit to see our operation. By September 2023, we launched our first joint demonstration project, using farm fields local to our deposit. This collaboration was highly successful, leading UNDO to wholly focus on our wollastonite, aiming to accelerate the proof of their geochemical models and demonstrate their scientific approach to Enhanced Rock Weathering.”

But what is the Enhanced Rock Weathering technique? UNDO Global Operations Manager Anthony Parkinson says that it is a carbon removal technique that involves reactions with rain water.

washes out into the rivers, into the water courses, and eventually will reach the ocean, which then allows the CO2 to be locked away for 10s of thousands of years.”

Parkinson says that particle size distribution and how fine the aggregate is are key considerations. Fine aggregate creates a quicker reaction, and thus a larger reactive surface area, so more CO2 can be drawn down.

“The main thing is the feedstock – the quality of the material,” says Parkinson. “[Wollastonite is] very unique in its minerology. It’s typically a very pure product. And second to that is location – it’s an absolute hub for enhancing our technology.”

“As it rains, it combines with the CO2 in the atmosphere and ultimately there’s a reaction which takes place with the mineralogy of the wollastonite product,” says Parkinson. “It creates a weak carbonic acid, it combines with the mineralogy and ultimately creates bicarbonate ions, which dissolve down into the groundwater, which

Vasily notes that while the partnership with UNDO will serve to push Canadian Wollastonite towards net-zero, the goal of the partnership is not to reduce the company’s specific carbon footprint. They already have a carbon efficiency of 99.98 per cent (i.e. less than 2kg of carbon emissions per 1,000 kg of products) due to efforts such as electrifying mining operations, incorporating solar and phasing out diesel power. The company is also working with Komatsu to integrate advanced equipment to minimize the emissions

Canadian Wollastonite President Bob Vasily says that his intention has always been to build and operate the company in the most environmentally responsible way possible.

PHOTO: Canadian Wollastonite

UNDO found that wollastonite was a very effective mineral for their Enhanced Rock Weathering technique. PHOTO: Canadian Wollastonite

from the explosives that they use.

The net-zero designation will refer to the company’s overall impact, as they produce and spread wollastonite on agricultural lands, generating carbon credits in that process which will be sold to corporations and individuals looking to offset their carbon emissions.

Parkinson says that one reason why this carbon removal technology is so appealing is that it uses existing and wellestablished technologies.

“We’re using a typical production technique as you would for producing road surface material,” says Parkinson. “We’re using lime spreaders to spread the material, we’re utilizing typical haulage vehicle, pumping trucks. So, you can scale extremely quickly because we’re not changing anything about the process.”

UNDO covers the cost of spreading the material on agricultural lands and only asks that the farmers cover the cost of hauling. This can be a challenge for UNDO, as there can be a significant level of skepticism – after all, no one gives anything away for free. But the benefit that UNDO gets out of the process is in selling those carbon credits to other businesses. Another potential challenge for UNDO themselves will be scaling up

their operations and increasing their own footprint as they likely will end up dealing with more large-scale agricultural landowners in time.

HOPEFUL PROJECT INSPIRES OTHER COMPANIES

Vasily says that the biggest challenge for Canadian Wollastonite in this effort was getting the support of Hydro One, Ontario’s largest electric transmission and distribution service provider. The permitting process has been arduous and has stretched for over two years.

“However, there’s some good news on the horizon,” says Vasily. “It seems that Hydro One has recently realized the potential benefits of our project. As a substantial industrial power user, we will predominantly draw power during the spring and autumn campaigns when Hydro One has an abundance of supply. Additionally, we’ll be feeding power back into the grid during the summer and winter when demand is at its peak. As we demonstrate this, I think the pathway for other industries may be a lot easier.”

On that note, Vasily says that he hopes the project will serve as an inspiration for others to follow suit – the strategies and approaches that the company has taken are applicable to other quarries or mines looking to achieve zero emissions. However, as with all things, it will be important for those with access to wollastonite to consider whether or not it is a perfect fit as dictated by the logistics of the business, the wollastonite deposits, or other factors.

“The motivation behind these efforts might not be as strong in other companies as it is for Canadian Wollastonite,” says Vasily. “There are certainly increased costs involved with the capital and environmental projects required to reach a zero-emissions goal.”

Vasily notes quarry operations may be working within an industry where cost is the most significant factor in securing projects. This economic pressure could make it challenging for the operators to voluntarily undertake the necessary measures to lower their emissions.

“This is where federal incentives could play a crucial role in encouraging wider adoption of these environmentally-friendly practices across the sector,” says Vasily.

Parkinson says that while UNDO’s work with mines could be more short term –simply purchasing wollastonite or other materials piecemeal – they have entered a

Crushed wollastonite is spread over agricultural land to lower the farm’s carbon footprint. PHOTO: Canadian Wollastonite

partnership with Canadian Wollastonite to work collaboratively on enhanced rock weathering technology for the foreseeable future. But his hope is that this will be a long-term effort in Canada.

“This is certainly not something which is only going to be readily available in the near term,” says Parkinson. “The position of what we’re building in Canada is ultimately going to be the blueprint for how we move our projects globally further and further around the world. This is a hotbed for demonstrating and improving our technology which we can then just transfer over to other regions globally. This is very much a long-term initiative and will continue for years to come.”

CANADIAN WOLLASTONITE EXPECTS TO BE CARBON-NEUTRAL MINE WITHIN 18 MONTHS

Beyond mines they are currently working closely with partners such as the Kingston Economic Development Group, Ontario’s Ministry of Agricultural and Rural Affairs, the Ontario Center for Innovations and a number of smaller affiliates along eastern Ontario.

Vasily says that Canadian Wollastonite’s mine electrification effort is on track and

> "It seems that Hydro One has recently realized the potential benefits of our project. As a substantial industrial power user, we will predominantly draw power during the spring and autumn campaigns when Hydro One has an abundance of supply."

- Bob Vasily, Canadian Wollastonite president and founder

should be in place by the end of August, with a solar farm planned for a year and a half from now. Their collaboration with Komatsu is underway, and they are working with other OEMs to minimize emissions.

“In short, I believe within 18 months, we aim to be very close, if not already, across the line as a carbon-neutral mine operator,” says Vasily. “In the event of any shortfall, we plan to offset it with wollastonite ERW removals sponsored by ourselves within our own agricultural and forest lands and those of the local municipalities surrounding us.”

Canadian Wollastonite has also engaged in ecological efforts such as creating managed wetlands within the property and planting more than 15,000 trees to compensate for those removed during operations.

Matt Jones is a freelance writer with a specialization in trade publications. He is based in Fredericton, New Brunswick.

Introducing ScaleLink

Elevate your production efficiency with ScaleLink’s advanced conveyor belt management solutions. Designed and manufactured in Canada, our enterprise-grade software seamlessly integrates with a wide range of belt scales, providing real-time data to streamline your operations.

Key Features:

• Production Efficiency: Evaluate, monitor, and manage production efficiency with unlimited access to graphs and reports.

• Live Monitoring: Access data from anywhere using your phone, tablet, or computer.

• Inventory Control: Keep track of production with detailed reports.

• Downtime Reports: Minimize disruptions and maximize productivity.

• Visual Alerts: Quick overview of the state of the plant.

• Easy Installation: Seamless integration with almost all types of belt scales.

• Custom Software Solutions: Tailored to your specific needs, collecting data such as weight, tons per hour, speed, and load percent.

quality control

STRONGER FOUNDATIONS

DR. AMMA agbedor, Ph.D., P.Eng

How aggregate selection shapes asphalt performance

As agencies shift toward performance-based specifications, understanding how aggregate properties affect asphalt mix behavior is more important than ever. From resisting rutting and cracking to surviving decades of environmental stress, the long-term success of asphalt pavements hinges on more than just the binder; it depends on the stone skeleton itself.

This article explores how aggregate selection and testing fit within Balanced Mix Design (BMD) frameworks to ensure asphalt performs as intended, not just in the lab, but in the field.

WHY PERFORMANCE EXPECTATIONS ARE CHANGING

Modern pavements are under pressure, literally and figuratively. They’re expected to last longer, carry heavier traffic, and do so in more variable environmental conditions than ever before. The top causes of failure: cracking, fatigue, rutting, and moisture damage, aren’t new, but our approach to preventing them is evolving. Agencies are moving away from purely volumetric designs and toward performance-based specifications that better reflect how pavements behave over time.

THE CRITICAL ROLE OF AGGREGATE PROPERTIES

Aggregates aren’t all created equal, and picking the right ones means looking past cost and convenience. Particle size distribution, shape, angularity, texture, absorption,

and moisture susceptibility all influence how a mix performs. In particular, angular and well-textured aggregates interlock more effectively, increasing a mix’s ability to resist rutting and fatigue cracking.

AASHTO T 304/ASTM C 1252 test for uncompacted void content of fine aggregate. The test provides a void content under standardized conditions, an indirect measure of the fine aggregate particle shape, angularity, and surface texture. An increase in void content indicates greater angularity and texture, while a decrease indicates more roundness and smoothness.

Testing standards like AASHTO T 335 (for coarse aggregate angularity) and T 304 (for fine aggregate angularity, pictured below) provide critical data on how aggregates will contribute to load-bearing capacity and deformation resistance. These characteristics become especially important in high-stress environments like intersections, ramps, or heavily loaded freight corridors.

Water also plays a major role. When moisture infiltrates the pavement, it can strip the binder from the aggregate surface, weakening the bond and accelerating failure. That’s why aggregate absorption and moisture susceptibility are essential considerations in both mix design and quality control.

CLOSING THE GAP BETWEEN VOLUMETRICS AND PERFORMANCE

Traditional mix designs have relied heavily on volumetric properties to predict performance. But volumetrics alone can’t always capture how a mix will behave under realworld stress. That’s where performance tests come in.

Tests like the Hamburg Wheel Tracking Test (pictured below) evaluate a mix’s resistance to rutting and moisture damage. Others, such as the Texas Overlay Test and IDEAL-CT, help quantify cracking resistance under repeated loads. Indirect tensile strength (ITS) tests are used to assess moisture susceptibility by comparing conditioned and unconditioned specimens.

These tests give engineers a more complete picture of how a mix will perform over time, but interpreting results isn’t always straightforward. Variability in sample

The top causes of pavement failure continue to be cracking, fatigue, rutting and moisture damage.

PHOTO: Asphalt Institute

The

PHOTO: Asphalt Institute

preparation, aging protocols, and differences between lab and field specimens continue to challenge consistency. Even so, performance testing is becoming an essential tool in the evolution of mix design.

BALANCED MIX DESIGN (BMD): A FRAMEWORK FOR SMARTER PAVEMENTS

BMD offers a more intentional way to create asphalt mixes, one that considers not just whether a mix meets specs, but whether it will stand up to the demands of real-world performance. By combining engineering judgment with targeted performance testing, BMD helps ensure that materials deliver both durability and constructability across the pavement’s life cycle.

Implementing BMD typically involves a series of structured steps: identifying suitable performance tests, training personnel, establishing performance thresholds, and building consensus among stakeholders. States like Texas, California, and Virginia have already embedded BMD into their specifications and are reporting encouraging results in terms of longer-lasting, better-performing pavements.

Yet as BMD adoption grows, so does the need to re-evaluate the foundational elements of mix design, especially aggregate selection. Are our current specifications truly aligned with long-term performance goals? Are we emphasizing the right aggregate properties, such as angularity, texture, and moisture resistance? And how do we ensure that what performs in the lab holds up in the field?

LOOKING AHEAD: ELEVATING AGGREGATE SELECTION

The future of asphalt mix design lies in

bridging the gap between lab results and field performance. As we refine testing protocols and align specifications with realworld outcomes, aggregate properties, particularly angularity, durability, and moisture resistance, will become even more central to quality control and acceptance.

Ultimately, we must remember that while binder is often the visible focus of innovation, it’s the stone skeleton underneath that bears the load. In the words of many seasoned engineers: binder holds it together, but aggregate holds it up.

Dr. Amma Agbedor has been with the Asphalt Institute since 2018, and she is the Institute’s Research Engineer and Senior Regional Engineer for Canada. After earning her degree from McMaster University in 2007, Amma integrated her academic pursuits with full-time work in the asphalt paving industry, completing her master’s and Ph.D. in Civil Engineering at the University of Waterloo. She specializes in asphalt binder and mixture characterization and has played a key role in advancing pavement technology and sustainability through various research projects.

A LONG WAY TOGETHER

wherever you are, bkt is with you

No matter how complex your tasks, BKT offers an extensive range of tires designed for every use in the industrial sector from warehouse and port to excavation operations. Strong, safe, reliable, and resistant to cuts, tears and punctures - these tires stand out for durability, superior performance, and comfort, even under extreme conditions.

BKT: always by your side, in any operation.

Joe Dias

Eastern Zone Manager

Directeur Régional, Est du Canada

BKT Tires (Canada) Inc.

Cell: 514-792-9220

Web: www.bkt-tires.com

The Hamburg Wheel Tracking test evaluate a mix’s resistance to rutting and moisture damage. PHOTO: Asphalt Institute

BY MACENZIE

RETHINKING SAFETY DESIGN

A closer look at Belt Conveyor Guarding and its 10,000-square-foot fabrication shop

> When the 2009 recession caused the Vandergeests to change business direction, they decided to take a leap of faith and start a rather niche company in an untouched market in Canada –safety guarding for material handling equipment.

The shift for the pair was less than ideal, but it led to longterm and unexpected success for their manufacturing company.

Founded in 1990 by Paul and Karen Vandergeest, the welding business started as Vandergeest Welding Inc. Paul worked in a field service welding truck providing maintenance services for local quarries, asphalt and ready mix plants. The two-person business gradually became more popular as it offered installation and servicing of quarry machinery in Central Ontario.

“He hired another employee, bought another welding truck, and the business gradually grew,” explains Scott Monkman, general manager of Belt Conveyor Guarding (BCG).

rebelo

Belt Conveyor Guarding’s technician Sevag Baoukian. PHOTO: Macenzie Rebelo

Monkman has worked for BCG for the last 21 years and recently took over for Paul after he retired.

Around 2007, the company grew to 60 employees and moved to a 25,000-squarefoot fabrication shop.

“We had six field service trucks, and we were fabricating conveyors, portable cement plants, aggregate bins, fresh water supply fittings and safety guards,” says Chris Allen, business development specialist with BCG.

Allen, with the company for 14 years, explains that the company faced an economic downturn in 2009.

“Local quarries started making their own fittings,” she says. “So, Paul and Karen decided the company would focus solely on manufacturing safety guarding, specifically on rotation equipment.”

That’s when the Vandergeests decided to rebrand the company, calling it Belt Conveyor Guarding, a division under Vandergeest Inc. Today, the business is in a 10,000-square-foot fabrication shop in Barrie, Ont, and employs around 30 people.

”We don’t have a lot of competition

in Canada, so we can perfect what we do well,” says Monkman. “Our products are important.”

BCG offers a variety of safety guarding services, such as grinding mill barrier guards, flat guards for quarries and V-Belt guards.

“Quite often, safety guarding in the industry is seen as a nuisance,” he says. “If it is hard to install or take off, usually they don’t go back on, especially when somebody’s not looking.”

BCG has six designers who work on products, and the company makes sure to patent their work. Two technicians travel all over North America to visit customer sites, assess their equipment for guarding and providing quotes.

“Our designers work off the technician’s notes, so we design a product that is specific to the customers’ needs,” says Monkman.

According to Allen, BCG’s products are sold in Europe but are primarily popular in North America.

“We’re needed in several different industries,” says Allen.

Cement, mining, power and steel are all examples of industries that involve rotating equipment conveyors.

“Even something as simple as a fixed ladder could use safeguarding to prevent unwanted access.”

Monkmans explains the company is always innovating and looking for new solutions for issues impacting the industry. The same is true for shop supervisor Jodi Dalley, who oversees the shop floor and production.

“Every day is different, and I love it,” says Dalley. “There is always a new problem to solve or a challenge.”

Dalley joined the company as a welder in the late 90s, but when the company restructured in 2009, she moved into her current role.

“All of our products are manufactured and welded here, by hand. Then shipped to customers.” For the BCG team, smart product design and quality are the number one priority.

“We send out products all over Canada,” says Allen. “We do our best to cater to all the companies that need guarding, no matter how small the task.”

CRUSHING

ONTARIO PAVING FORECAST

A deeper look at findings from the 2025 Ontario municipal paving forecast survey

This article will delve into key findings from the 2025 Ontario Municipal Paving Forecast study and learn about: Total Paving Tonnage across Ontario, Paving Sustainability Practices and Trends in Ontario, Variations on Standards Specifications, and Geographical Analysis of Total RAP Available and Total RAP Consumed in 2025.

This year marks the ninth year of data collection under the Municipal Paving Forecast survey. For the 2025 study, 77 out of 444 municipalities participated, representing 83 per cent of Ontario’s total population. Collectively, these municipalities are projected to use 2.05 million tonnes of hot mix asphalt for capital road projects in 2025—enough to pave Highway 401 approximately 6.7 times. A breakdown of the paving tonnage based on geographical zones is presented in Figure 1. Overall, the participating municipalities anticipate a 1.8 per cent decrease in paving volume compared to the 2024 season. Notably, municipalities in the Southwest zone are expecting a five per cent increase in paving activity. Figure 2 shows the per cent change in paving tonnage in each of the geographic zones. Twenty-one per cent of municipalities reported piloting new products and technologies, with fibrereinforced asphalt emerging as the most commonly

piloted innovation.

The municipal paving practice in Ontario continues to make progress towards sustainability. Ontario municipalities are projected to utilize 194K tonnes of RAP in their 2025 paving projects which is estimated to result in the following savings:

• Fresh water for 1,684 households for the entire year. AMIN mneina, P.Eng., MSc.

Figure 1 - Percent Change in the Paving Tonnage in the year 2025 compared to 2024

Per cent Change in the Paving Tonnage in the year 2025 compared to 2024

• 60,000 barrels of asphalt cement.

• Eliminating GHG of 796 cars for the entire year.

While municipal adoption of RAP is showing encouraging progress, Ontario’s total RAP inventory of 3.7 million tonnes would take approximately 19 years to deplete at the current usage rate. Figure 3 shows the location and quantities of RAP stockpile inventory and RAP usage in municipal projects. In addition to RAP usage, municipalities are projected to use a total of 388,000 tonnes of Warm Mix Asphalt (WMA), and 830 km of in-place recycling.

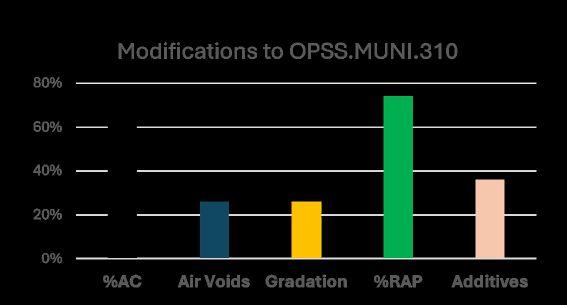

In Ontario, municipalities rely on the Ontario Provincial Standards (OPS) for infrastructure works and the OPSS.310 for HMA paving work. 49 per cent of municipalities reported that they use OPSS.310 as written, while the remaining 51 per cent modify the standard specification through special provisions. The modifications to OPSS.310 are broken down in Figure 4. In addition, 61 per cent of municipalities responded that they would benefit from having a third party HMA plant certification process with focus on:

• Mix quality

• Testing procedures.

• Environmental compliance.

• Gradation and quality of stockpiles.

• Confirming RAP per centage during production.

On the maintenance and operations side, Ontario municipalities reported repairing a total of 586,496 potholes in 2024. One municipality alone accounted for 285,000 of these repairs. Excluding this outlier, the average number of potholes repaired per municipality was 5,383. When normalized by lane kilometer, the average equates to approximately six potholes per kilometer. Figure 5 illustrates the geographic distribution of potholes across the province, along with the categorical breakdown of pothole amounts as reported by municipalities during the 2024 maintenance season.

The Ontario Municipal Paving Forecast study continuous to gain interest amongst municipalities and provide vital data and metrics for the municipal paving industry. The study showed a growing appetite for RAP usage in municipal paving with 79 per cent of municipalities allowing the use of RAP and a total RAP utilization of 194K tonnes. Potholes continue to be a concern for Ontario municipalities with one to 10 potholes per lane kilometers being the most common number of potholes seen, and potholes concentrated in the Central zone with almost 60 per cent of the total potholes fixed.

Good Roads utilizes data from Municipal Paving Forecast and the Ontario RAP Survey to publish the ON Paving Report. More information can be found on www.GoodRoads.ca

Amin Mneina is Senior Specialist | Technical Programs & Research with Good Roads. He also serves as a member of the Board of Advisors for the Ontario Provincial Standards, where he helps shape policies and guidelines for infrastructure projects across the province.

Ontario's 2024 RAP Stockpile vs. 2025 Municipal Consumed RAP Projection

Pothole Fixing Trends in Ontario Municipalities in 2024

BY MIKE lacey

ON THE MOVE

More and more operations are being drawn to mobile plants for their ability to offer quick mobilization and cost savings

> As companies look to control costs or meet sustainability goals, more operations are turning to mobile plants as an option.

The increasing demand for mobile plants is being driven by a few factors, explains Russ Burns, sales director with Canica Cedarapids Simplicity. That includes pressure to finish projects more quickly, limited space due to remote or urban jobsites, and rising fuel and transportation costs.

“The growing focus on sustainability and resource optimization is making mobile equipment more attractive than ever,” he says.

Mobile plants provide operations the opportunity to ramp up work quickly, explains Burns.

“One of the biggest advantages is the ability to quickly mobilize and demobilize the plant, which reduces downtime between jobs. This is especially valuable for contractors or operations that need to move between multiple sites,” he explains. “Additionally, mobile plants typically require less site preparation, which saves time and lowers initial setup costs.”

Mobile plants, such as Haver & Boecker Niagara’s F-Class, provide operations the ability to quickly move between projects, limiting downtime between jobs. PHOTO: Haver & Boecker Niagara’s F-Class

Burns points to Cedarapids CRC1150S mobile plant, which was designed for a quick setup and is suitable for a variety of project sizes. The plant combines the TC1150 Cone Crusher with the TSV Horizontal Screen, and has a feed capacity of 165-320 tons per hour.

Mobile plants are an ideal option for producers looking to move quickly between sites or work in a remote location, says Karen Thompson, president of Haver & Boecker Niagara’s North American and Australian operations.

“Mobile plants are all about reducing material transportation costs while offering flexibility and speed of set-up,” she explains.

The company wowed attendees at this year’s World of Asphalt/AGG1 Academy and Expo with its full-size Niagara F-Class portable plant on display.

“With our Niagara F-Class portable plant, setup can take as little as 30 minutes. That’s a big time-saver when every production minute counts,” Thompson says.

The F-Class is suited for high-volume applications and, although portable, can also be set up permanently.

“It’s built to handle material surges and frequent relocations without missing a beat,” Thompson says.

However, while mobile plants offer flexibility, they also come with trade-offs, Burns explains. First, they may have lower throughput or capacity compared to stationary plants.

>

"Mobile plants typically require less site preparation, which saves time and lowers initial setup costs."

- Russ Burns, sales director with Canica Cedarapids

Simplicity

“[That’s] due to design limitations aimed at enhancing portability,” he says.

Historically, mobile plants require increased maintenance needs over time as frequent relocation creates more wear-and-tear.

“Advancements in rugged design and component durability, like what you’ll find in the CRC1150S, have helped bridge this gap,” Burns says. “Additionally, any increase in maintenance is often offset by the operational sustainability benefits, such as reduced power consumptions and the ability to process materials right at the source.”

When designing the F-Class, Haver & Boecker Niagara wanted to address that durability concern.

“Mobile setups can sometimes raise concerns about durability or capacity compared to stationary systems,” Thompson explains. “That’s why it’s so important to build them tough, with smart features that keep performance high and maintenance low, even in demanding conditions.”

She says they focused on creating a reliable, efficient machine that keeps the operator in mind.

“The industry is evolving fast, and producers need equipment that can keep up. That’s why we’ve focused on making our mobile plants not just tough, but smart and easy to use,” she says.

The F-Class also offers easy maintenance as the vibrating screen can be lowered in less than five minutes for simple changeouts. As well, its Pulse Condition Monitoring system provides real-time monitoring to detect anomalies or potential failures.

The plant can be customized depending on operational needs as its custom-built chassis holds the vibrating screen and periphery equipment, such as crushers or conveyors.

“The F-Class is designed to be a versatile partner in any setup,” Thompson states. “Its consistent g-force and positive circular stroke help it handle a wide range of materials and feed sizes, keeping screening performance strong no matter what’s feeding it.”

Along with the flexibility and cost savings of a mobile plant, another advantage is its ability help meet a company’s sustainability goals.

“Sustainability is more than a buzzword. It’s a real priority for many producers,” Thompson says. “Mobile plants can help by using energy more efficiently and reducing transportation time and costs.”

For example, Haver & Boecker Niagara's F-Class’s inclined, circular motion technology uses gravity to help move material down the screen deck. This not only reduces pegging but also energy and horsepower requirements.

Meanwhile, The CRC1150S helps reduce the environmental impact by minimizing material handling and allowing producers to reclaim and reuse aggregates more efficiently.

“Mobile plants are not just operationally flexible, they’re also key tools for achieving greener, more sustainable outcomes,” Burns says.

He adds the plants’ ability to process material onsite also reduces transportation needs, leading to less fuel consumption and emissions.

When purchasing a mobile plant, capacity and power should be considerations, but there are a host of things to look out for.

“Companies should consider factors such as ease of transport (including region requirements/limitations), setup time, and the support network behind the equipment. Integration with existing fleet, availability of spare parts, and after-sales service are critical but sometimes overlooked,” Burns says. “It’s also important to evaluate the plant’s automation and control systems — features like centralized controls and diagnostics can boost efficiency and reduce operator error.”

Karen Thompson, Haver & Boecker Niagara

equipment showcase Mobile crushing and screening

Cedarapids: CRC1150S Portable Cone and Screen Plant

Cedarapid’s CRC1150S Portable Cone and Screen Plant can be deployed for a variety of project sizes. The plant combines the TC1150 Cone Crusher with the TSV Horizontal Screen.

It has a feed capacity of 165-320 tons per hour.

“The CRC1150S is designed for fast setup and features a high-performance cone crusher and screen on a single chassis, making it a powerful and compact solution,” says Russ Burns, Sales Director, Canica Cedarapids Simplicity.

TC1150 has a 300 HP motor and highefficiency roller bearings. Some of the key features include automated cone controls, larger close-side settings and rubber isolation mounting on a heavyduty chassis frame.

The TSV is 6X20 three-deck horizontal screen has a high g-force oval stroke motion and can easily handle heavy deck loads. The machine’s design provides more steel in the ‘rock-zone,’ which improves durability, while capacity is increased by 10 per cent thanks to a patented deck deflector plate.

The plant can also help companies reach their sustainability goals.

“The CRC1150S enables high-efficiency material processing directly at the source, which not only saves time and money but also reduces carbon footprint,” Burns says.

The plant has a travel height of 14 feet and a travel width of 12 feet.

Haver & Boecker Niagara F-Class portable plant

The portable plant can be customized depending on operational needs as its custom-built chassis holds the vibrating screen and periphery equipment, such as crushers and conveyors.

The plant is manufactured with six hydraulic run-on jacks to raise and lower the vibrating screen quickly. According to the company, producers gain the production benefits of an inclined screen with the maintenance benefits of a horizontal screen.

“The F-Class is a true workhorse, and a reliable screening solution our customers can trust,” says Karen Thompson, president of Haver & Boecker Niagara’s North American and Australian operations.

The F-Class offers easy maintenance as the vibrating screen can be lowered in less than five minutes for simple screen media changeouts. As well, its Pulse Condition Monitoring system provides real-time monitoring to detect anomalies or potential failures.

“You’re not just reacting to problems, you’re staying ahead of them. That means predictable downtime, efficient maintenance and an overall extended lifetime for your equipment,” Thompson says.

The F-Class shines in high-volume, heavy-duty applications.

“It’s built to handle material surges and frequent relocations without missing a beat. Whether it’s part of a portable plant or a permanent setup, it’s designed to keep things running smoothly and efficiently,” she says.

Thompson says what makes the plant unique from others is its combination of smart design and rugged performance. The circular-motion inclined vibrating screen features a double-eccentric shaft assembly that maintains constant g-force during startup, shutdown and extreme conditions, including overloading and surging.

“The F-Class maintains a steady g-force even during surges, which keeps screening consistent. Its non-welded, lockbolt design makes maintenance safer and faster. And with Pulse Condition Monitoring, operators get real-time insights that help them stay ahead of potential issues. No surprises, just smooth operation.”

Superior Industries Portable HSI Plant

Superior Industries’ portable HSI plants are engineered for high-production primary, secondary and tertiary crushing — whether you’re recycling concrete, reclaiming asphalt, or processing virgin pit material.

At the heart of each system is the Sentry Horizontal Shaft Impactor, which offers interchangeable configurations, thick blow bars in a variety of materials and a reliable, consistent output.

Portable HSI plants are available in a range of layouts including side-feed, rear-feed, and closed-circuit options, with electric or diesel power. With hydraulic features and user-friendly maintenance access, Superior’s HSI plants are built for quick setup and long-lasting performance in the field.

Kleemann highlighted its new mobile impact crusher, the MOBIREX MR 100 NEO, at this year’s World of Asphalt in St. Louis, Missouri.

The machine can handle the processing of concrete, rubble and asphalt, as well as the processing of soft to medium-hard natural stone. It has a feed capacity of 250 t/h.

Kleeman has included in the MR100 NEO many of the benefits and features one will find in their other machines, such as a continuous feed system and the Spective system. There is also an option for it come with a wind sifter, which will remove any debris that’s in recirculation of the machine.

MB Crushing Crusher Buckets

MB Crusher’s jaw crusher excavator attachment makes road construction and repair work more efficient by allowing you to use what is already on site. Regardless of the location operating in, the jaw crusher enables you to build a reliable road subbase without relying on outside materials or expensive transport operations. MB Crusher buckets can turn soil, gravel and stone into resources used onsite. According to MB Crusher, this both cut costs but also reduces your environmental footprint.

However, the jaw crusher can also help in aggregate operations. The attachment allows you to reduce oversized material before it even leaves the quarry. MB Crusher notes that means fewer trips to the processing plant, less fuel, less wear on machines and lower operating costs.

Anaconda C12R tracked cone crusher

Anaconda’s latest addition to its mobile crushing lineup -- the C12R tracked cone crusher -- can handle a diverse range of applications. According to Anaconda, the combination of the machine’s FKSmidth Raptor cone chamber with a tracked design makes it suited for a variety of uses. The C12R has options for short and standard heads, as well as liners that can be shaped for specific crushing needs, which allows operators to handle various materials while achieving desired product specifications.

The C12R’s after-screen system includes a high-energy 12-foot by five-foot double-deck screen box so any oversized material is recirculated back into the crusher or stockpiled for future use.

The machine was designed to improve operational efficiency and reduce downtime. As a result, the machine has ground access for easy serviceability, as well as quick setup times. A standard feature is a timed pre-heat.

Sandvik QH443E cone crusher

Sandvik calls the electric-driven cone crusher plant its next step in its sustainability journey. It’s been designed for secondary or tertiary crushing in aggregate production, quarries and mines.

The QH443E has an updated track platform, and is powered by external electrical power sources or by an onboard diesel genset. According to Sandvik, using an external supply or grid connections provides

several advantages, including lower running costs, extended drivetrain service intervals, minimal onsite emissions and lower noise levels. The alternator is sized so that a downstream screening plant can be operated

Finlay J-1280 Jaw Crusher

In late June, Finlay released the J-1280 jaw crusher into the market.

The newest addition to the company’s tracked mobile crusher lineup, the machine was designed to bridge the gap between the J-1175 and the larger J-1480.

According to Finlay, the J-1280 is geared toward medium-sized quarries and larger contractors who are looking for high capacity without the logistical problems that come with heavier equipment.

The machine was built for easy transport and weighs less than the J-1480. Finlay notes the J-1280’s 1200 mm by 820 mm jaw chamber offers a wide gape and robust throughput capabilities for hard rock applications.

A feature of the J-1280 is its hydrostatic drive system, which allows the crusher to continuously operate in reverse. This allows blockages to be cleared quickly and safely, without the need to manually lift material from the chamber. This improves safety by reducing the need for working at height. It also minimises downtime by eliminating the need for lock-out/tag-out procedures during unblocking.

The J-1280 is available in three feed-in configurations: a standard vibrating grizzly feeder, a pre-screen option, and an extended pan feeder with pre-screen. As a result, operators can set up the machine to their specific needs.

from the plant’s onboard genset.

The machine has a feed capacity of 388 t/h. Its heavy-duty rigid feed hopper and conveyor are electrically driven while the CHH440 hydrocone allows fine tuning that Sandvik states will lead to more optimal material shape and capacity.

It has a transport length of 17.2 metres, a transport width of three metres and a transport height of 3.8 m.

Kleeman MOBIREX MR 100

Komatsu fitting its quarry-class haulers with autonomous tech AUTONOMOUS HAULING

BY MIKE LACEY

> Komatsu is rolling out autonomous capabilities for some of its HD haulers.

“We’re co-operating with Pronto, out of San Francisco, who’s a leading providing of Autonomous Haulage Systems (AHS),” says Komatsu’s Mark Anderson.

The technology uses sensors, cameras and artificial intelligence to create a fully autonomous vehicle that can operate in complex environments. The area the truck operates in is called the Autonomous Operating Zone (AOZ). To program a new route within the AOZ, a human operator just needs to drive the route once, called “dropping

a trail.” From there, Pronto’s AHS will take over.

“The truck will be able to run that route or any of the others set for that location,” Anderson explains, adding the system allows the truck to learn and dynamically change course as required. “If the AHS can only go to the same spots every time, it doesn’t provide much value to your quarry or mine. It needs to be able to adapt as you work through a bench throughout the day.”

To do so, the loader operator dynamically “spots” the AHS by hitting a button on their control pad that tells the autonomous truck where to position itself to get loaded.

“On the loading side, the AHS will dynamically route the trucks to wherever the loading is progressing, modifying its route to accommodate the operation,” he says. “The system has a similar capability on the dumping side. If you’re paddock dumping, the AHS will automatically develop an optimized dumping pattern.”

Pronto is currently automating Komatsu’s HD605-7, HD605-8, and HD605-10 haul trucks.

Historically, autonomous vehicles have been the purview of Komatsu’s large haulers that carry the heaviest loads. Komatsu’s FrontRunner Autonomous Haulage System has been in operation for nearly two decades, but the cost to scale the technology down to its smaller line of trucks was prohibitive, explains Anderson.

“Pronto utilizes a much lighter hardware stack and its AHS is designed to avoid necessitating a control room that requires dedicated staff, which isn’t economically viable for smaller operations,” he explains.

Komatsu is adding autonomous capabilities to its HD605-7, HD605-8, and HD605-10 haul trucks. PHOTO: Komatsu

> SEPT. 14-16 2025 Fall Conference of BC Roadbuilders and Heavy Construction Association

WHISTLER, BC www.roadbuilders.bc.ca

> OCT. 5-8 TACConf

QUEBEC CITY, QC www.tacconf.ca

> DEC. 3-4 Saskatchewan Heavy Construction Association’s Infrastructure Summit and Trade Show

REGINA, SK www.saskheavy.ca

> DEC. 4-6

59th annual AGM & Holiday Celebrations of BC Road Builders & Heavy Construction Association

VICTORIA, BC www.roadbuilders.bc.ca

> FEB. 11-12, 2026 Canadian Concrete Expo MISSISSAUGA, ONT. www.canadianconcreteexpo.com

> MARCH 3-7, 2026 CONEXPOCON/AGG LAS VEGAS, NEVADA www.conexpoconagg.com

one more load

A natural solution

BILL gowdy

Plants and trees can bring balance to your gravel pit

Gravel pits, while essential for sourcing materials for construction and infrastructure, can have an impact (whether real or perceived) on the surrounding landscape and stakeholders.

To some, operations may appear visually unappealing, generate more noise and dust, and potentially reduce biodiversity activity. To mitigate these effects, incorporating trees or a variety of plant species in and around gravel pit areas offers a simple solution with a range of ecological, aesthetic and practical benefits. From improving the visual appeal of the site to positively contributing to climate change mitigation, trees and plant species serve as a powerful tool for balancing industrial needs, with environmental stewardship and stakeholder perceptions of operations.

Gravel pits, as stand-alone features, can appear barren and disrupt the natural continuity of the surrounding landscape. Strategically placed tree lines can soften the hard edges of the site, blending the area more harmoniously into the local environment. Trees also bring seasonal colour and variety, enhancing the visual experience for nearby residents, workers, and passersby. In addition to these aesthetic benefits, trees can serve as effective visual barriers, screening industrial operations from neighboring properties, roadways, or recreational areas. This natural screen helps reduce the visual footprint of the pit, contributing to a more pleasant viewscape.

Industrial activity in gravel pits may generate significant noise—from truck traffic and excavation equipment to sorting and crushing machinery. Trees can serve as a natural sound buffer. When planted in dense clusters, especially using species with broad leaves and thick branches, trees can absorb and deflect sound waves. This leads to a noticeable reduction in noise levels for nearby communities, improving quality of life.

Trees also provide essential habitat for birds and other wildlife. In areas where open gravel pits have displaced vegetation, the reintroduction of trees can help restore ecological balance. Bird species benefit from the nesting and feeding opportunities trees offer, while mammals and insects can find shelter and sustenance. A thriving tree line near a gravel pit can become a small yet meaningful biodiversity hotspot, particularly in regions where habitat fragmentation is

a concern.

From a broader environmental perspective, trees play a critical role in mitigating climate change. Through the process of photosynthesis, trees absorb carbon dioxide (CO2) — a major greenhouse gas — and store it as biomass. Without vegetation, pits can become hotspots for heat and dust, which is often an unavoidable aspect of operations. By planting trees, operators can actively offset some of their carbon footprint, contributing to local and global sustainability goals. Additionally, tree cover helps cool the surrounding area, reducing the “heat island” effect that often accompanies large, exposed sites. Progressive planting in reclamation areas can also help stabilize soil, reduce the overall area of disturbance, and potentially lower reclamation security requirements.

Selection of various tree species should be considered for each site. Deciduous trees will lose their leaves in the fall and have less noise and visual impact in the winter, whereas conifers will have year-round foliage. Maintenance may be a consideration for some species. Young trees may require care and time to establish with fertilizing and watering, especially in poor soil conditions. Some hybrid species are genetically engineered to grow quickly.

Challenges can be addressed with thoughtful planning. Buffer zones can be established between tree plantings and active excavation sites. Native species that are well-adapted to the local soil and climate can minimize maintenance requirements.

Trees near gravel pits offer far more than decoration—they serve as vital tools in managing the social, environmental, and visual impacts of resource extraction. From reducing noise and CO2 levels to supporting wildlife and enhancing the landscape, trees help transform gravel pits from potentially undesirable to environmentally conscious operations. While a few practical concerns must be addressed, the overwhelming benefits make a strong case for integrating trees into gravel pit planning and rehabilitation efforts.

William (Bill) Gowdy is a geologist has 35 years of experience in the aggregate, geology, mining, reclamation, and exploration fields throughout Canada and overseas (USA, Indonesia, South Africa, Mexico, Panama).

DOWNTIME? NOT ON OUR WATCH.

Keep everything running exactly as it should with the right parts, consumables and preventative maintenance programs backed by our team of skilled technicians and equipment experts.