•A RASTECH SPONSOR SHOWCASE•

Pumps supply and move water integral to operations across industries, but for the aquaculture industry, they are the backbone of nearly every operation critical to success. Water intake, water circulation, water treatment, process temperature control, pH control, waste handling and treatment, effluent discharge, and human comfort operations within facilities depend on the effective use of pumps. These operations can directly impact the quality of the product delivered to the customer. Unfortunately, there is a growing number of facilities with operations burdened by

poor reliability and limitations imposed by fundamental errors in pump selection, piping configuration, and application of oversimplified rules of thumb – usually found on the internet. By optimizing your pumping operations you will see immediate improvements in system reliability and operating costs.

Grundfos, a global manufacturer in water technology, offers a family of pumps and solutions designed to maximize efficiency and reliability in water transfer operations. Partnering with Grundfos when developing or refining your plant pump

operations can benefit from efficient pump design and pump control technology. Supplying pumps to the aquaculture industry for decades, Grundfos offers its users a global footprint – which means that the same technology used at facilities in Europe and Asia can be purchased in Latin and North America equipped with ANSI flanges and NEMA motors as required. Parts for Grundfos equipment purchased from overseas systems developers can be sourced and serviced by local Grundfos partners.

High flow and low head operations are the hallmarks of recirculating aquaculture systems. Grundfos pumps offer best-inclass efficiencies and variable speed control, used when recommended, to achieve reliable, cost-effective water circulation.

Heat exchange operations rely on effective flow control, whether for heating or cooling your water. The flow control method used to maintain your temperature set point may result in highly inefficient pump operation, increased maintenance expenditures, or temperature variations that your system could do without. As you scale smaller systems, these issues will scale as well. Utilization of multi-speed pumps may both reduce the size of the motor required for your operation and increase the system’s reliability.

The Grundfos SMART digital range of diaphragm dosing pumps offers a high level of additive metering accuracy, a user-friendly interface, reliability, and energy efficiency. Grundfos dosing products come with a wide selection of accessories. In addition to metering functionality, product upgrades can be purchased if

advanced monitoring and self-diagnostics are required.

Grundfos Machine Health equipped end suction pumps will alert you when pumps need maintenance allowing you to plan outages and maintain water flow to your stock.

If you have ever thought of any of the following:

• Should I use a VFD for this application?

• Why does my pump keep failing?

• Is [this problem] common? Do I have to live with it?

• I wish I could….

• This would be so much better if…

Grundfos is here to answer these questions and more. Tell us what your system and your fish need, and we can help your facility establish the hydraulics and the system control to get you there efficiently. Grundfos is here to find the best solution for your Aquaculture business.

• Pumps designed to maximize efficiency and reliability in your water transfer operations

• Full range of solutions available for optimizing all applications within aquaculture

•Wide selection of pumps at the right price to meet your needs

Learn more and contact us here: grundfos.us/aquaculture

“As energycosts and therefore operating expenses continue to rise, optimizing hydraulic design, pump selection and pump controlwillbecome increasinglyimportant. It is no longer just about movingwaterbut ratherusing the least amount ofenergyto move it.The industry cannot afford to utilize outdated pump selection rules and system design and controlfeatures that result in long-term use ofoversized pumps and motors.The day-to-dayoperating costs aswellas maintenance costs overthe life ofthe installation are just too high. Consideration and comparison oftechnologymust go beyond comparison ofthe stated efficiencyofa pump undera single design point. Intelligent pump and system controlwillmake a noticeable impact on long term operating costs and overallsystem reliability. ”

Kristen Kowal, Grundfos Lead Sales Engineer

Aquaculture production is a major consumer of water. Serving as the inhabitance for fish to mature, the water in these ponds and enclosures is also a vector of waste, bacteria and viruses within the production process.

BIO-UV Group is a global player in water treatment, designing environmentally friendly, chemical-free disinfection solutions for a variety of water and wastewater applications, including aquaculture. Using ultraviolet light and/or ozone, to treat water in hatcheries, RAS, and wellboats, the company’s natural technologies improve hygiene, fish health, and contribute to the sustainable use of water and energy.

BIO-UV’s portfolio of natural water treatment systems, offered by the group for over 35 years, provide a number of benefits for aquaculture operations. UV and ozone systems destroy the bacteria or viruses that cause illness in species, thereby improving fish welfare, reducing mortality rates, and improving final product quality. At the same time, UV and ozone improve operational efficiency and protect the environment by reducing water demand, optimising performance of the wider water treatment system, and improving the quality of wastewater discharged.

Ozone has the unique property of breaking down spontaneously into its original form, Oxygen, so it supports increased dissolved Oxygen levels, simulating natural waters in healthy ecosystems, for optimum fish health and yield. It also acts as a flocculant and general water conditioner, to produce crystal clear water with no smell or taste (a benefit that is transferred to the quality of the final product on the customer’s plate!)

As nature’s most powerful oxidant, Ozone is

a simple and effective way to break down contaminants in several aquaculture applications, including Hatcheries, niche and small-scale fish farming applications, larger, Recirculating Aquaculture Systems (RAS), wellboats, and in the treatment of influent and effluent water, as well as in food processing applications and CIP, critical to the journey from ‘egg to plate’.

With the launch of the new triogen® PPO3 positive pressure ozone generators, BIO-UV Group is expanding its range of solutions for the aquaculture industry. The latest Ozone generation systems incorporate advanced safety and operational features, plus state-ofthe-art communications and connectivity, all designed and manufactured in-house – making good use of over 35 years’ experience in designing and developing Ozone systems. The ozone generators are available in two different control configurations, with a range of specifically sized ancillaries and also, the option of a skid-mounted complete turnkey system including feed gas and ozone injection.

Triogen managing director, Simon Marshall added, “we are delighted with the simplicity and ease of operation of our new ozone product range. Under the banner of “ozone made simple”, we are now able to offer customers a plug and play option that reduces installation time and with the option of a whole-life service and spares packages for both ozone and UV products, operators can rely on a stress-free water treatment solution that is simple, safe and compliant with all operational standards.”

UV-C offers a reliable, cost effective, eco-friendly alternative to chemicals without creating by-products. This natural phenomenon is reproduced inside the BIO-UV Group reactors

using powerful UV lamps. At 254 nanometres, the optimum wavelength to inactivate microorganisms (viruses, bacteria, algae, yeasts, moulds, etc.), UV-C penetrates the core of the DNA and disrupts cellular metabolism until the cells are completely inactivated. All microorganisms are eradicated (including Legionella, Cryptosporidium, etc.) and can no longer reproduce. The physio-chemical characteristics of the water are unaltered (taste, smell, pH, etc.). No disinfection by-products are generated by UV treatment. It is safe to human or animal health. UV can be used to disinfect water or to destroy ozone residuals in aquaculture, be it in fresh water, brackish water and sea water. From 2023, BIO-UV Group will provide professionals with a complete catalog of water treatment and disinfection systems using ozone and UV for aquaculture activities.

• Ozone and UV: natural technologies to ensure water quality

• New ozone generator to meet every aquaculture requirement

• Technicians and partners all over the world

Group +33 (0) 4 99 133 911 www.bio-uv.com

www.rastechmagazine.com

Reader Service

Print and digital subscription inquiries or changes, please contact

Angelita Potal, Audience Development Manager

Tel: 416-510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Account Coordinator/Sales

Morgen Balch 519-429-5183

mbalch@annexbusinessmedia.com

Freelance Journalist

Todd Humber thumber@annexbusinessmedia.com

Associate Publisher Jeremy Thain 250-474-3982

jthain@annexbusinessmedia.com

Group Publisher Anne Beswick 416-410-5248

abeswick@annexbusinessmedia.com

Audience Manager

Urszula Grzyb 416- 510-5180 ugrzyb@annexbusinessmedia.com

President & COO

Scott Jamieson sjamieson@annexbusinessmedia.com

Printed in Canada

SUBSCRIPTION

RAStech is published as a supplement to Hatchery International and Aquaculture North America.

Occasionally, RAStech will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbusinessmedia.com Tel: 800.668.2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2023 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Welcome to our second edition of Solutions In RAS, RASTECH’s annual resource guide written in collaboration with our trusted brand partners in the Recirculating Aquaculture Systems (RAS) sector.

In this year’s edition you’ll learn about the latest RAS technologies and innovations available to the land-based aquaculture industry. We’ve talked with solution providers from all corners of the world providing you with commentary about their latest products, systems and installations. The information in these pages will help you and your RAS team raise healthy fish in the most efficient and cost-effective way.

Solutions covered this year include optimizing your fish genetics to effective sludge management and everything in between. Our sponsors talk about RAS design, tanks, UV, oxygen, pumps and more. Their solutions and contact details are all here at your fingertips to have at hand throughout the year. You’ll also hear from some of our industry’s top executives with their insights as to how they see the RAS sector advancing over the next 12 months.

I’m proud to be part of a sector which continues to push the boundaries of fish farming with such innovative technologies, products and most of all, great people. The aquaculture industry continues to grow and developments in RAS technology are playing a leading role in its expansion.

Enjoy this edition and send me your feedback. It’s always welcome.

Jeremy Thain

Associate Publisher - Aquaculture Division

Annex Business Media

jthain@annexbusinessmedia.com

Made possible with the support of

Move that water, save your fish: Pumps and solutions for aquaculture

BIO-UV Group offers innovative technologies and water treatment expertise for the aquaculture industry

Perfect water, energy efficiency and fish exercise: The recipe for profitable RAS operations

How to meet your RAS water discharge limits Group

Merck Animal Health’s Vaki SmartFlow system puts pumping, grading and counting at your fingertips

Pure Aquatics ‘no problems, only solutions’ approach helps RAS operations run effectively

FAIVRE / 18-19

Faivre Group - Innovation is key to success and longevity

22-23

Simple and effective: Aqua Ultraviolet’s filters and sterilizers ensure healthy water

BALMORAL TANKS / 26

blutanQ provides innovative solution backed by outstanding service and advice

BENCHMARK GENETICS / 20-21

Using technology to build the ultimate fish for land-based salmon farming

ANCI / 30-31

Panaferd®-AX - All the benefits of natural pigment

INTERNATIONAL / 24-25

OxyGuard takes fish farming to the cloud with powerful software

/ 28-29

Aquacare controlled environment aquaculture systems

RK2 / 32-33

Energy efficiency and science: RK2 System’s approach to protein skimmers and UV sterilizers

ADSOPTECH / 34

How your oxygen source can improve RAS reliability, efficiency and social sustainability

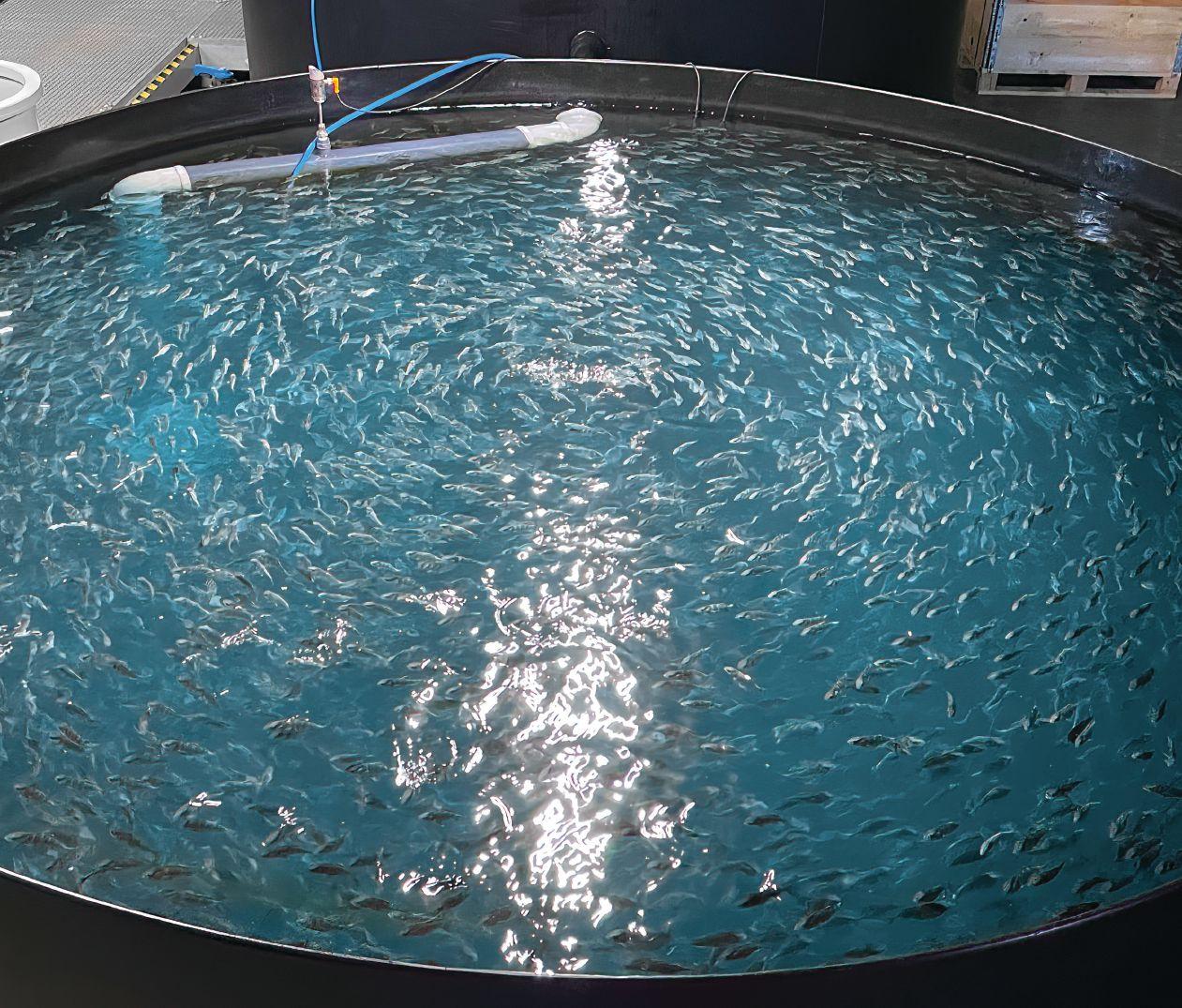

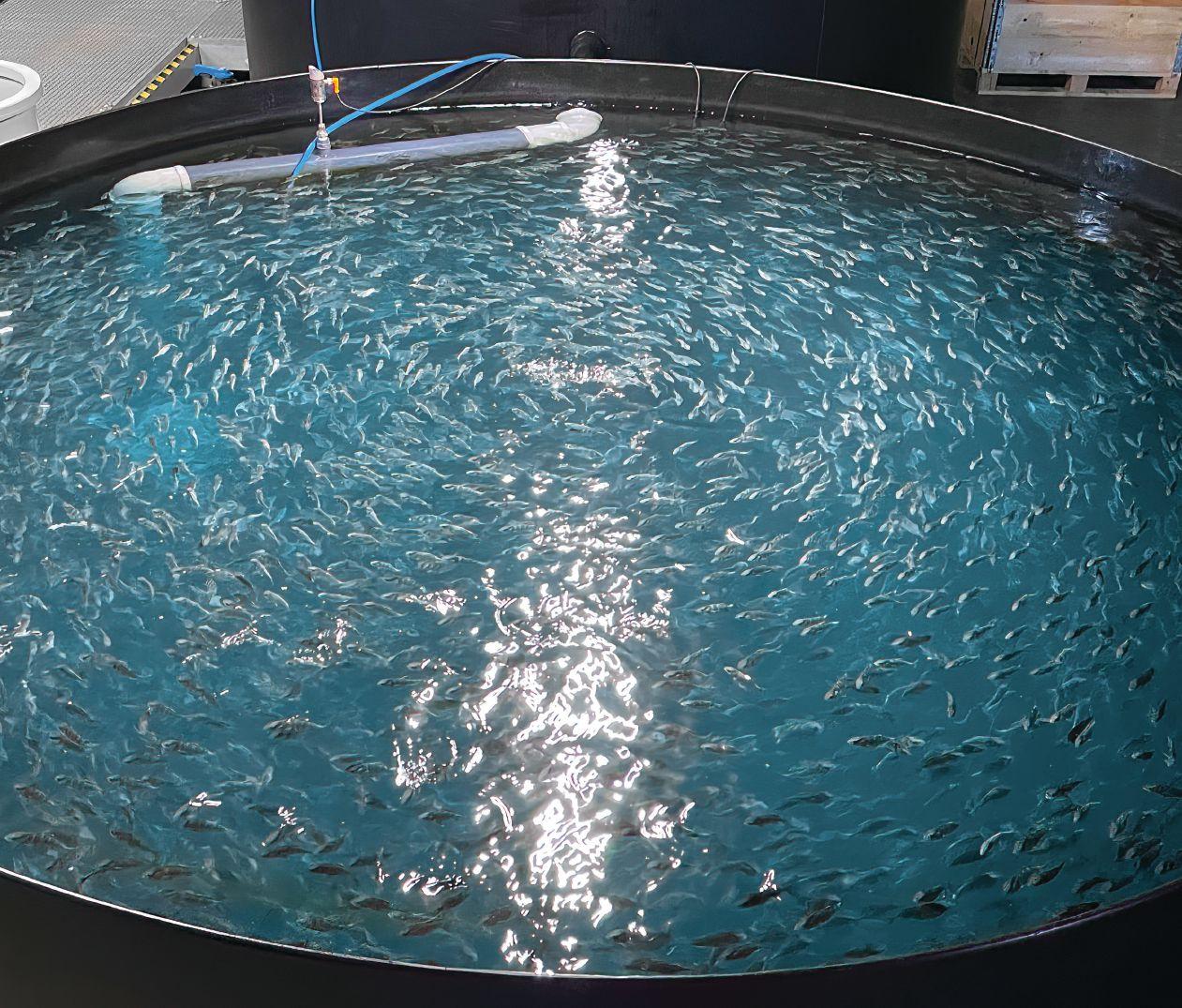

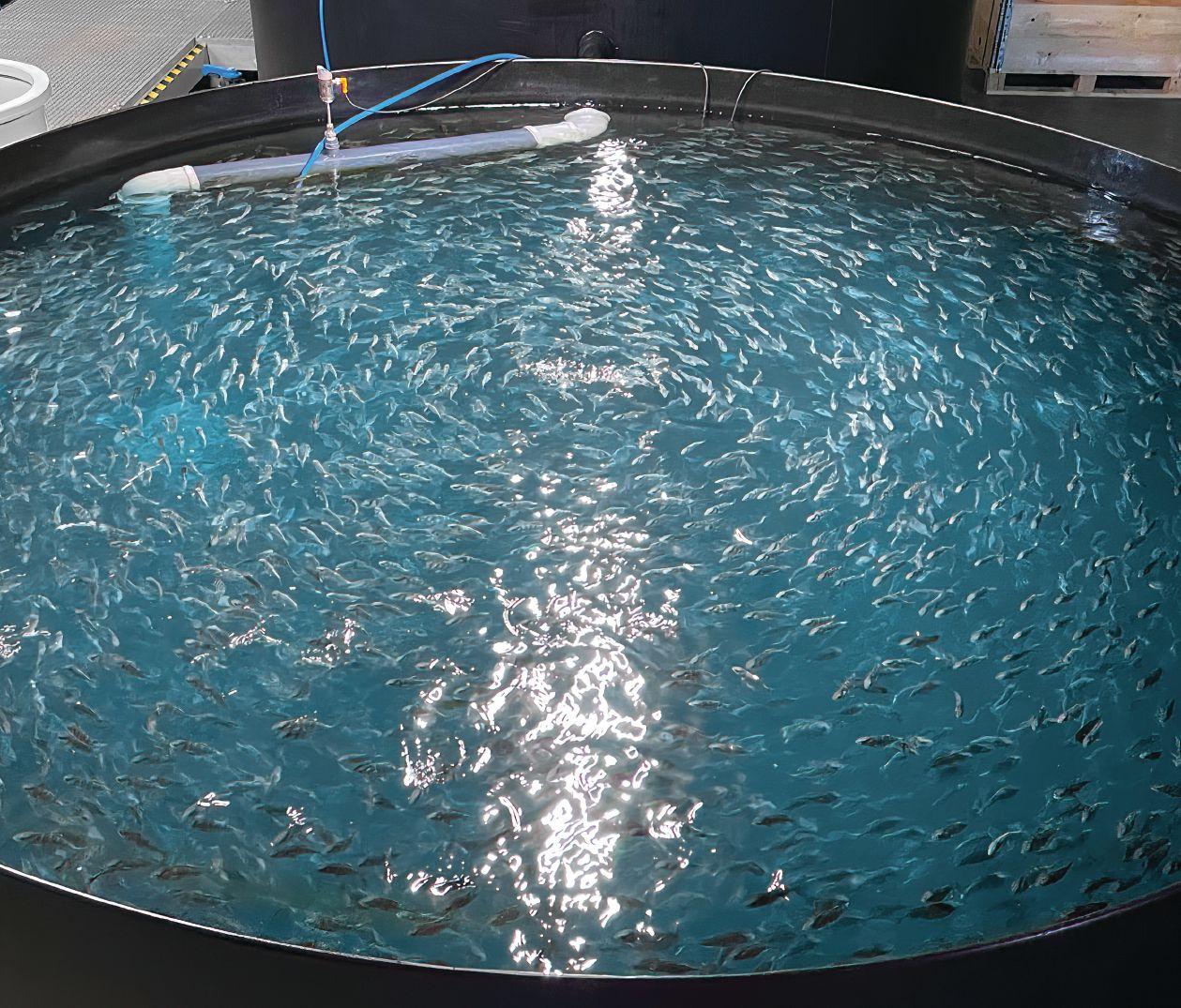

As the size and scale of RAS operations grow, Linde is keeping pace as it works with customers around the world to ensure operations remain sustainable and profitable.

Its SOLVOX® Oxystream low-pressure oxygenation system for seawater, brackish water and freshwater tanks has been designed to operate in an extremely efficient manner — because energy consumption is a key part of any RAS conversation, said Kenneth Glomset, senior aquaculture expert at Linde.

“It’s a complete package that the industry can use to optimize their production and make it sustainable to go on land,”

he said. “Energy is the key today. Everything is about energy, and this system is extremely efficient.”

Linde is working with some of the largest RAS operators and projects in the world because it has the system and the knowledge to optimize operations.

“If we run the numbers on some of these farms, we easily see that we can save them 10 per cent of the total energy consumed to produce one kilogram of fish,” said Glomset. “That really makes a difference.”

While oxygen is a critical part of successfully raising fish, its just one piece of the

puzzle, he said.

“The farm needs the system, or the fish tank, to perform well to get the most out of production — and that’s where we are different than any other supplier,” said Glomset. “The Oxystream system is the unit that creates the perfect environment for the fish to thrive in.”

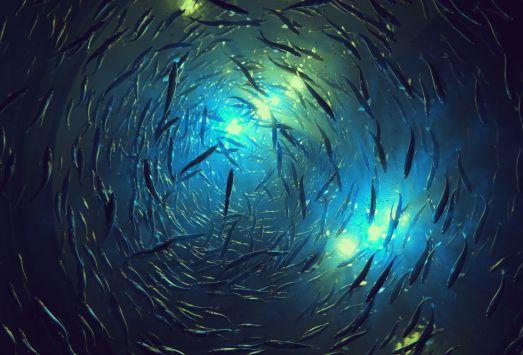

That includes creating the optimal swimming speed for the fish to keep them healthy.

“We move the water around with the system, in combination with oxygenating it to an optimum level, so that the fish gets exercise,” he said. “Just like humans — the more you exercise, the more fit and robust

you are. It helps your immune system and keeps muscles growing. It’s the same for fish.”

Feed remains the single biggest cost for operators, he said. Linde’s science has proven it is possible to boost fish growth by 19 per cent, and decrease feed conversion factor by 21 per cent at the same time, simply by optimizing how the fish behaves in the tank.

“The fish grow faster, and uses the feed more efficiently. So you get that much more yield, but you also have a lower production cost,” said Glomset. “That’s why you should exercise fish because it has such a strong correlation.”

SOLVOX® Oxystream leads to better water and a healthier environment for finfish in RAS operations and land based systems.

“You have clean water, you get the particles out, you distribute the oxygen better and you get the CO2 out of the tank easier — all of these things,” he said. “It’s complex, but that’s where we’re at today. We are not just a gas company providing a system that puts oxygen into the water. We’re going

deep into the process of our customers and optimizing fish production.”

The microbubbles created by the low-pressure system dissolve oxygen efficiently, reduce the concentration of dissolved nitrogen and the total gas pressure. The current created by the flow also collects waste matter and moves this efficiently to the outlet in the centre of the tank.

With three decades of experience, and more than 1000 successful installations of the SOLVOX® Oxystream system worldwide, Linde has perfected the science behind what farms need. That means, when a customer is looking to install a tank, the experts at Linde can predict exactly what will happen with the water inside regardless of the size.

“We actually have the knowledge of what’s going to happen in real life, not just a simulation,” he said. “We’re using this long experience; we have the tools and that’s extremely important to the industry. We don’t have to start from scratch on any project.”

The system is designed to work in any size project — from small family-run farms to

large-scale commercial enterprises. SOLVOX® Oxystream units can handle flows ranging from nine cubic meters of water per hour all the way up to 2,300 cubic meters of water per hour, he said. Multiple systems in each tank is very common as the tanks get bigger.

“It’s your key to profitable fish farming.”

SOLVOX® Oxystream comes with built-in water flow measurement capabilities. The angle of the waterflow can also be adjusted, even during operation.

The system can be fitted to existing farms, or can be incorporated from the ground up as new operations are designed and built, he said.

Kenneth Glomset a lead Senior Aquaculture Expert at Linde, working in the Global Applications Team. He is based in Ålesund, Norway at Linde’s Innovation Centre for Aquaculture. Kenneth holds a Mechanical Engineer degree and has developed many of the applications Linde is using in Aquaculture today. He also holds several patents mainly linked to oxygenation and fish tank hydraulics which is his main field of expertise.

THE SOLUTION

• SOLVOX Oxystream is extremely energy efficient, lowering consumption by 10 per cent

• System moves water around in an optimal way, creating the perfect swimming speed to grow healthy fish

• Three decades of experience and more than 1,000 successful installations around the world.

COMPANY

Linde 10 Riverside Drive Danbury, CT 06810 toll free: (844) 445-4633 (1-844-44LINDE) contactus@linde.com lindeus.com/aquaculture

The water that flows through recirculating aquaculture systems (RAS) can create headaches for fish farmers when it comes out the other end. But treated right, Alumichem can ensure operations are meeting and exceeding local government regulations and create a valuable commodity for use as agricultural fertilizer or input for biogas plants (digesters). That’s where an innovative and customized sludge treatment solution comes in to play.

“It’s all about sustainability,” said Trevor Gent, sales manager at Alumichem. “We return clean water to the global environment and return nutrient-rich sludge to agricultural partners as fertilizer or for use as a fuel.”

It starts with the water intake, and making sure that the system has clean water that is free of bacteria, viruses and other contaminants. Once the water winds its way through the RAS operation, it comes out the other

end in the form of an effluent water containing solids and nutrients – often referred to as sludge. That sludge can then be thickened and dried to various levels — from 10 percent solids to 90 percent solids — depending on the intended use and logistics.

Dry sludge is suitable for use at fertilizer plants, and a wetter product could be used at a biogas plant. The sludge is thickened, dewatered and dried by Alumichem’s system. The reject water is then further treated and polished before being discharged to ensure compliance with any environmental regulations, including removal of remaining solids, nitrogen, phosphorus, TOC and heavy metals.

“Alumichem approaches all its projects as a partnership”, said Christian Bang-Møller, chief commercial officer.

“Getting the right chemistry, the right technologyand the perfect interaction”

-

Christian Bang-Møller

“We are there, at every step, to ensure you’re meeting your discharge limits and finding the optimal way of handling the solids part of your effluent in an effective and sustainable way,” he said.

“That means the company is there not only during the installation, but also available for any troubleshooting and optimization to ensure the system is performing perfectly”, said Bang-Møller.

Typically, Alumichem is involved from day one at the design stage of RAS projects. But it can also help facilities that are starting to fail, or operations that suddenly must comply with new stricter government regulations. “Their system might not be designed to be able to deal with increased production or stricter discharge limits,” said Gent.

In situations like that, Alumichem can come in and look at existing systems to see how they can be optimized and determine what adjustments need to be made to meet the discharge limits and deal with the sludge and effluent treatment. “We are partners for the fish farmers, plain and simple,” said Bang-Møller.

Since many fish farms are in remote areas, the costs of transporting and disposing of sludge can be prohibitive.

“It makes a lot of sense to dewater the sludge and dry it up because it reduces the volume you need to truck away very significantly and turns the sludge into a valuable resource that is stable and can be stored,” said Bang-Møller.

A Norwegian salmon producer was expanding their RAS facility but was concerned about their new stricter effluent discharge limits and what to do with their increasing sludge amounts. Alumichem worked closely with the fish farmer and their RAS supplier to customize a solution that would effectively dewater and dry their sludge to 90 percent solids and clean the water effluent.

With the treatment system in place, the effluent discharge limits were safely ensured, and a stable, hygienized and valuable dry sludge produced. Through partners, Alumichem organized for the logistics and reuse of the dry sludge with a Norwegian organic fertilizer producer who was more than happy to take the phosphorous-rich sludge.

This solution brought the highest level of clean water back to the ecosystem and ensured the sludge was being reused in a circular economy.

Water intake Water reuse or discharge

Sludge reuse or disposal

Recovered phosphorous (P)

Alumichem’s solutions are scalable to any size project and can be designed to meet the needs of specific operations anywhere in the world. “We have tried this technology in real-world scenarios and built successful facilities,” said Bang-Møller.

The company’s goal is to help fish farmers operate sustainable, environmentally friendly farms in a cost-effective manner.

“We are not only a technology provider, this is what sets us apart from other RAS solution providers” said Gent. “We blend environmental chemistry, technology and knowledge and we are there for the long haul with our clients,”

At Alumichem we bring over 40 years of experience in water treatment, we make sure that the chemical process works optimally with the systems that are treating the water, and this is really what is important. “Making sure that the client is getting the the right chemistry, the right technology, and the perfect interaction,” said Christian Bang-Møller.

> Turnkey sludge treatment and water management systems.

> Turning sludge into a valuable resource and reducing disposal costs.

> Meeting and exceeding local government regulations.

> Support before & after start-up.

Meet us at RASTECH 2023

Stop by for a RAS talk!

Pumping, counting and grading fish is one of the most important steps in any recirculating aquaculture system (RAS) operation.

And it’s just gotten a whole lot easier, and powerful, thanks to VAKI’s SmartFlow system. It marries the company’s industry-leading fish pumps, graders and counters into one easy-to-use system that can be monitored and controlled via computer or a portable device such as a smartphone or tablet.

It’s the perfect fish handling setup that is more than the sum of its parts, according to Ryan Vasak, who handles sales for VAKI North America, an aquaculture division of Merck Animal Health.

“It’s not so much the individual components that I think is really exciting for RAS,” he said. “It’s actually the concept of being able to connect every single piece of equipment and have all of that information at your fingertips either through the VAKI cloud or the SmartFlow hub.” HOW IT WORKS

For a RAS operator, it’s a turnkey and elegant solution.

“During fish handling events, the pump is operating at a certain RPM and, from that computer, you can speed it up, slow it down, prime it — whatever you need to do,” said Vasak.

As the fish travel through the grader and the counter, that data is also fed into the SmartFlow system, which enables operators to react in real time.

“If I notice something’s wrong with the pump, I can be on my phone and change it. If something’s going on with the grader, I have the opportunity to fix that,” he said.

One of the most appealing features of the system is that one person can run the entire show, said Vasak.

In the past, it would have taken about four people to effectively run

the system — but not anymore.

“One of the challenges facing our industry is that it’s getting harder and harder to find qualified labour,” he said. “So, to have the ability for just one person to run this whole thing is pretty incredible.”

It also means roles like quality assurance and quality control can be done remotely as well, he said.

“If I’m the manager and I’m in a different location, I can see what’s going on throughout the day — which is pretty useful,” he said.

VAKI makes all its equipment in Iceland, Denmark, and Portugal.

“It’s really high quality, high precision — everything is stainless steel and there’s a very intense quality assurance and quality control process all our equipment goes through,” said Vasak. “VAKI keeps innovating and coming up with either new technology or machinery or equipment that the industry needs. Being tied into the industry, with our partners and customers, helps ensure our equipment is relevant and extremely useful.”

VAKI has long recognized the importance of minimizing the handling of fish to reduce stress.

Stress can have a significant impact on fish health and growth, which ultimately affects the bottom line for any RAS operation. With that in mind, VAKI is dedicated to developing technological solutions that prioritize

fish welfare and reducing stress from overhandling.

The Smartflow system minimizes that stress by allowing fish to be moved and monitored, directly from one tank to another without ever leaving the water.

“All VAKI equipment is manufactured with fish welfare in mind, along with ease of use and user safety,” said Vasak. “We consistently strive to ensure that fish culturists have the information and technology needed to produce fish in an efficient and sustainable manner, all while focusing on improving handling methods and stress reduction.”

This commitment is part of a larger mission at VAKI and Merck Animal Health, to support the RAS industry in achieving its full potential. By providing information and technology that supports sustainable, welfare-focused practices, VAKI is helping to ensure a bright future for aquaculture and the communities they serve.

• SmartFlow connects all Vaki Smart Pumps, Graders and Counters for full overview and control of the fish handling system.

• With Smart Flow all Vaki Smart devices can be controlled and fine-tuned to achieve high levels of efficiency and accuracy to maximise fish welfare while minimizing labour.

• SmartFlow collects the key data from all the equipment to facilitate continued optimization and allow full reporting of the complete process.

CONTACT INFO

Tyler Lettunich

705 S. 8th Street Boise, Idaho 83702, USA

+1 (208) 275 0011

biomarkservice@merck.com

“What advancements in 2023-2024 will help shape the RAS segment of the aquaculture industry?”

Managing Director, Balmoral Tanks

“As the RAS sector develops, and the scale of projects increases, we feel that security of our clients’ supply chains, with an unswerving attention to product quality, is key. We must ensure that the RAS projects being built today set the standards for tomorrow as there is so much attention on those and how successful, or otherwise, they are. As industry enablers, we must play our part in supporting that success. The foundation for that success and support is great customer service – our mantra at Balmoral Tanks.”

General Manager, Aqua Ultraviolet

“Our products are proven effective. We have seen technological advancements in our specific industry that are flashier and possibly prettier, but do they perform? At Aqua Ultraviolet, we believe in keeping true to our core brand and knowledge and, although we are always working on advancements, we have found that elevating knowledge around our product is an advancement in itself”

VP of Sales and Business Management, Linde

“Linde’s focus is on providing advanced oxygenation technologies that optimize tank conditions in Recirculating Aquaculture Systems. These will be critical to development of the sector because of the pressing need to get maximum efficiency from all inputs to the process – energy, feed, capital – both to demonstrate the environmental sustainability of RAS systems and to support the financial viability of the RAS model itself.”

President, RK2 Systems

“Two words: Energy efficiency. A big move is already underway between DC motors for pumps and LED lighting lowering equipment heat. Plus better flow design with smart engineering are the keys I see for the future of RAS Aquaculture systems, which in my opinion will be dependent on bringing down every aspect of energy cost, to be able to compete with net pen farming.”

EVERSON

President & CEO, ANCI, Inc.

“Communication of the quality and value of RAS produced salmon will shape the immediate future of the RAS industry. The Panaferd® team, in collaboration with the farmers, will promote the benefits of RAS fish raised on a healthy diet, including Panaferd®AX, the natural source of color from nature’s own carotenoids.”

Director of Sales & Marketing, Engineering Solutions, Alumichem ”I believe that the biggest advancements in our segment of RAS will be in the areas of denitrification systems for effluent treatment along with improved reuse options for sludge use in the circular economy.”

JEAN-LOUIS FAIVRE

Co-Manager, Faivre Group

“Data analytics and AI will certainly shape and consolidate the RAS industry in the coming years. Why? Because, data analytics and AI will help fish farmers optimize their production processes, improve fish health, reduce conversion ratio, and reduce waste. By integrating predictive maintenance, it will also optimize the equipment durability, reducing risk and cost. But we need to overall remember who’s the boss of the whole system in the aquaculture industry: The fish.”

JAMES FLAHERTY

President and CEO, Adsorptech

“To materially lower the operating costs of RAS technology fish farms, it is essential that the entire system power efficiency be optimized. If low-head, high-efficiency, and RAS-scale oxygen dissolution equipment can be proven, the water pumping costs and the power efficiency of RAS scale oxygen VPSA generators will be dramatically improved, thereby having a lasting and impactful lower permanent operating cost. A system capable of running at or below an operating pressure of 15 psig, 1 barg, will achieve optimal sustainable operations.”

KRISTEN KOWAL

Lead Sales Engineer, Grundfos

“As energy costs and therefore operating expenses continue to rise, optimizing hydraulic design, pump selection and pump control will become increasingly important. It is no longer just about moving water but rather using the least amount of energy to move it. The industry cannot afford to utilize outdated pump selection rules and system design and control features that result in long-term use of oversized pumps and motors. The dayto-day operating costs as well as maintenance costs over the life of the installation are just too high. Consideration and comparison of technology must go beyond comparison of the stated efficiency of a pump under a single design point. Intelligent pump and system control will make a noticeable impact on long term operating costs and overall system reliability.”

SIMON MARSHALL

Delegate General Director & Managing Director triogen, BIO-UV Group

“PPO3 is our new generation of ozone systems with enhanced monitoring, control, and optimized footprint. An Opex Calculator provides operators with a real-time cost of ownership and trending view of the plant. Additionally, PPO3 has been specifically designed with ‘eco-friendly’ reusable ozone modules that can be refurbished and refitted, thereby saving precious metals, and lowering the whole life cost of ownership. We also have a new range of UV units based on our extensive experience of the ballast water treatment market, targeted at the aquaculture market and applications requiring the disinfection of low-quality, high-volume intake water or wastewater discharge for recycling. The systems provide a high quality and efficiency that optimizes Capex versus more conventional designs.”

PAW PETERSEN

CEO, OxyGuard International

“Much of global aquaculture growth is based on the farming of marine species. Most marine fish species produce many small eggs, and the newly hatched, almost microscopic fish larvae cannot eat dry food. They need natural live feed. Rotifers and artemia are the types of live feed available today. Unfortunately, this ‘artificial’ prey lacks several essential omega fatty acids and amino acids that the fish larvae need to develop into healthy marketable fish. On the other hand, Copepods, which are found in all oceans, are nature’s mother’s milk containing all necessary substances and thus better prey/feed for marine fish larvae. The benefits of using copepods have already been demonstrated on an industrial scale at Viet Uc, the biggest Vietnamese shrimp producer. Based on Danish R&D, they set up algae production to feed the copepods and have had good results feeding live copepods to the shrimp larvae. We expect an increased diversification of fish species in aquaculturenot least, new marine species will benefit from using copepods as feed in the early life stages.”

HENNING GATZ

CEO of Aquacare Environment Inc.

“Standardization will continue to improve land based fish farms. Factory coated bolted steel tanks are now well accepted. Oxygen transfer efficiency will grow in value. Precision computer controlled feeding systems are proving their value. More aggressive solids filtration and CO2 removal will enhance water and fish quality. These are components being designed into new farms now under construction. Established farms also have the opportunity to upgrade and improve sustainability and profitability.”

GEIR OLAV MELINGEN

Commercial Director, Benchmark Genetics

“The Norwegian government’s possible implementation of a resource tax may motivate Norwegian companies to invest in RAS projects closer to the market, potentially leading to successful ventures like Nordic Aqua Partner in China, Proximar Seafood in Japan, and Salmon Evolution in Norway. Genetic improvements in adapting salmon genetics to closed landbased systems will continue to be a focus for biotech companies like Benchmark, aiming for some major breakthroughs in the near future in areas such as sterility.”

JEFF HEINDEL

Merck Animal Health Aquaculture Specialist

“Merck Animal Health is proud to continue innovating technologies to both support and advance the RAS Industry. Merck’s HyperInfusion and Vaki brands of RAS solutions focus on both the human and animal welfare aspects of aquaculture and our products value will be showcased in 2023, truly revolutionizing multiple components of the RAS industry! RAS will feed the world in the coming decades; Merck Animal Health is committed to advancing this growing industry by developing solutions that will guide the aquaculture industry for the next 100 years.”

LINDSAY HOPPER

Managing Director, Pure Aquatics

“Airlift technology and “low head” RAS are still relatively unexplored in the industry. There are a few companies making great strides, but optimising airlift and low head models, and especially pushing the boundaries with aeration/oxygenation and higher stocking densities I believe will make RAS even more competitive economically than it already is. New species or even older species (like the jade perch) that perform well in RAS will help to create local markets serving customers and open up the options for RAS technology as a primary farming system. We are already seeing this with Aquaponics systems servicing local markets, demanding higher prices for premium product that is as fresh as it can possibly be, a focus on quality and sustainability in today’s market allows RAS a unique opportunity, where can farm any species almost anywhere.

Pure Aquatics derived the catch phrase “no problems, only solutions” from the culture that has evolved throughout its years in business. Its culture defines they way it approaches business, innovation and how it works with its customers to give the best RAS products and services in the market.

“We’ve got a high level of technical knowledge, and we make sure that we can transfer that information clearly to our clients — taking into account all their requirements and in finding that best solution,” said Lindsay Hopper, director of Pure Aquatics, who has more than 30 years’ experience in aquaculture.

The Australian-based company approaches everything as a partnership, which paves the way to success for all involved.

“We are very proud to have long standing partnerships with some of Australia’s leading aquaculture producers, research and universities alike,” he said. One example of that is a major project it has been working on with Ornatas, which is focused on tropical rock lobsters.

Ornatas, which has operations in Tasmania and northern

Queensland in Australia, works with the University of Tasmania and they’ve developed a lot of intellectual property around lobster hatchery production.

“Our roll is to collaborate and facilitate the commercialization of technology,” said Hopper. “We have been kicking goals in that area and will continue to do so with the current builds of RAS systems in commercial sizes.”

Pure Aquatics has partnered with Duraplas, supported by Southern Cross University (SCU), to develop poly oxygen cones that are rotomolded from high-density polyethylene (HDPE).

“Typically, oxygen cones have been fabricated out of fibreglass. The hangup with fibreglass models is their lack of compatibility with ozone and despite the use of internal vinyl ester resin coating, degrade shortening their life span. No such problems with HPDE fabricated rotomolded cones.”

The new cones from Pure Aquatics are available in five model sizes, ranging from 450mmD to 1250mmD (200 up to 2,900LPM).

SCU were involved in design of the oxygen cones and the finite element analysis (FEA) engineering.

Pure Aquatics also works extensively with international partners, including Canada’s Industrial Plankton. “We’re representing those guys over here now,” he said. The photo bio reactors from Industrial Plankton create “stable, biosecure, consistent and continuous algal production,” said Hopper, adding that it’s also suitable for seaweed production.

“It’s been around a little while, but the technology is only now starting to really take off,” he said.

It produces algae as a food source for hatcheries and are proving to be a significant technological step forward.

“Seaweed is being used for waste remediation and that’s where it could play a part in many RAS’s facilities,” he said.

The company’s Trome drum screen filters are the industry standard for pre-filtration, solids and TSS removal in aquaculture applications.

The HDPE constructed drum filters are ideal for fresh and marine applications, with models running from 1.7 m3/hr to 140 m3/hr.

“They’re constructed on the smaller side, but are a nice little product suitable for a wide range of applications,” said Hopper. Trome Drum Filters are a beautifully built, compact product. Whilst they tend to lean

to the smaller side they are suited to a wide range of applications.

For Hopper & Barber (Gareth Barber head of sales and technical support), it all comes back to working closely with customers and being that true partner.

“It is all about working closely with our people maybe they be customers, suppliers, employees, even the live animals themselves,” he said. “We are committed to an outstanding level of service every step of the way, including ongoing service and support.

Its commitment to seeking out the most practical, cost effective and innovative solution for customers is what makes it stand out against the rest. The company has a track record of helping operations with efficiency and productivity.

BY THE TEAM.

“We look at how the current and proposed systems impact energy efficiency, physical impact on the team, labour hours, cleaning requirements, service and maintenance costs,” he said.

Plus, their customers benefit from the relationships Pure Aquatics has built with is international suppliers.

“We seek out the best are constantly seeking out the best possible international supply partnerships,” he said. “Through our selection process we ensure we eliminate the fear customers have of imported items by ensuring we hold stock levels and spare parts in house.”

• Pure Aquatics’ approach is based on a “no problems, only solutions” culture that focuses on partnerships with customers, universities, and research institutions to provide the best RAS products and services.

• It has developed and sells new products and technologies, including poly oxygen cones made from high-density polyethylene, photo bio reactors for algal and seaweed production, and Trome drum filters.

• Pure Aquatics focuses on finding innovative, practical and cost-effective solutions to help farmers improve their efficiency and productivity. It also maintains strong relationships with international suppliers to ensure the availability of stock and spare parts to keep operations running.

Contact information: Lindsay Hopper, Managing Director Phone: 049 116 945 | 02 6585 2421

Email: lindsay@pureaquatics.com.au

Pure Aquatics PO Box 104 Wauchope, NSW, Australia 2446

https://pureaquatics.com.au/

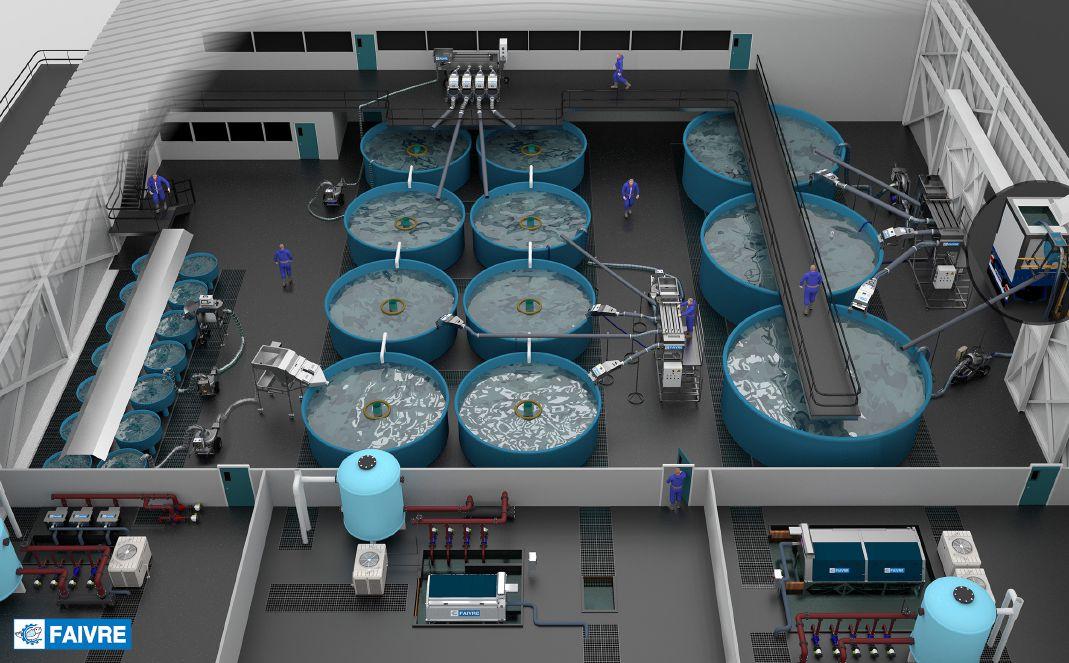

Innovation often comes from unexpected places. Nearly seven decades ago, Claude Faivre was searching for ways to work more efficiently on his trout farm in France.

As his business grew, he found the job was becoming increasingly difficult. He began to dream of a machine that would make his life, and that of all fish farmers, easier. That’s when a stroke of genius hit: He envisioned a machine that would automatically grade the fish.

The main stumbling block was how to transfer the fish from one place to another, without human intervention. That’s when a second epiphany hit. Faivre also worked as a miller, and pipes at mills were commonly used to transfer flour. The same principle could be used to move fish, he realized.

Faivre put his idea into action, and the result was the Calibromatic, the first automatic trout grading machine. With this invention, the foundation of mechanization for fish farming was laid. It’s a tradition the Faivre Group carries on to this day at operations around the globe, explained Jean-Louis Faivre, the co-manager at the company and son of that innovative farmer.

“My father made the first grading machine 65 years ago,” he said. “Who better to invent the product than a farmer?”

In 1973, Faivre opened its first factory — an 800-square-metre building in Baume-les-Dames in the east of France.

The innovative fish grading technology enjoyed great success not only in France, but around the world. The first fish graders were sold in France, Germany and Italy, and exports have always been a main driver for the company.

In 1985, Claude Faivre was awarded the National Order of Merit by French President François Mitterrand in recognition of his export prowess. Today, more than 80 per cent of the company’s revenue is generated by exports, making it a global leader in the industry.

The original factory has expanded to a 7,000-square-metre complex. The high-quality machines, including pumps, graders, counters, drum filters and aerators, are built by skilled technicians and sent to operations around the world.

Faivre is the only company that offers a complete range of grading packs for farms, catering to all fish sizes — from 100 grams up to 3.5 kilograms.

From hatchery-nursery, to grow out and harvesting equipment, it’s a one-stop shop for everything farmers need to run efficient and effective operations.

The innovation at Faivre continues to this day. In 2020, Jean-Louis came up with a new way of helping customers choose the right set of machines. He classified them into several series and renamed them to simplify the process of selecting the right equipment.

There are five distinct series, including the 10, 30, 40, 50 and 60 series. The 10 series is for small fish, and 60 series is for the largest. Using this logic, it’s easy to create a set of mutually compatible machines.

For example, using a Pescamotion 10 pump allows farmers to work with a Helios 10 or 100 grader and Pescavision 10 counter. All the machines are connected to the same power box, which makes installation and operation simple and efficient.

With a TDH (total dynamic head) of 12m, the new Pescamotion 50 — a 10-inch propeller pump — is ideal for supplying the Helios 50 grader and the Pescavision 50

counter. It can also be used to transfer fish to a tank or truck and is powerful enough to move them over long distances.

Pescamotion 50 is designed to be used in the most difficult conditions. It’s housing is made from 316L stainless steel, which means it can be used in a wide range of sea water operations including sea cages, boats and RAS.

This 10-inch fish pump also offers highcapacity pumping and works on fish with an average weight of three kilograms (salmonids). It features a belt-drive system, which keeps maintenance costs low, automatic priming systems, and an optional remote control.

Faivre continues to build on Claude’s legacy of innovation and making the lives of fish farmers easier through automation and technology.

Today, the team is working on ways to connect everything together into a smart, comprehensive system — including pumps, graders and counters — reducing the need for manual intervention. For example, if a pump’s flow rate is too high for the grader, it can automatically “ask” the pump to slow the rate down, and vice versa.

It’s the latest example of the company’s commitment to creating efficient and user-friendly solutions for aquaculture professionals.

• The Calibromatic, the first automatic trout grading machine, was invented by Claude Faivre, a fish farmer in France, who had the idea to use pipes to transfer fish based on his experience as a miller.

• Faivre Group is a global leader in fish farming equipment. The company offers a complete range of grading packs and is the only onestop shop for everything farmers need to run efficient and effective operations.

• Faivre continues to innovate and build on its legacy of automation and technology by working on connecting everything together into a smart, comprehensive system, including pumps, graders, and counters, reducing the need for manual intervention.

Aubert Faivre FAIVRE Group

Address: 7 rue de l’industrie, 25110 Baume-les-Dames, France

www.faivregroup.com

info@faivregroup.com

When it comes to building the optimal Atlantic salmon for aquaculture, breeding and selection have been heavily focused on production efficiency and disease-resistance traits. However, more than 5 years ago, Benchmark Genetics foresaw the huge potential in land-based production. As a forerunner in the land-based sector, Benchmark identified synergies with its own broodstock production methods and the potential of significant performance gains from individuals selected for specific environments.

Back in 2018, the first of the land-based benchmarking trials began with families produced on land within Iceland. These animals were tested in net pens in Iceland and land-based grow-out facilities. To complement this initial study, Benchmark has undertaken an additional global benchmarking test.

Andrew Preston, global RAS technical manager at Benchmark Genetics, said the company, which has four decades of experience managing Atlantic salmon broodstock, is again putting salmon through its paces in different commercial grow-out operations around the world.

“From our Icelandic operations, where we have ISA-free compartment status and high biosecurity, we have selected over 100 families and strategically placed the same families in 5 different countries. We have animals in Chile and continental Europe — in Norway, Iceland and Scotland. And what we’re trying to ascertain from this is whether there’s a genetic and environmental effect on the animals,” Preston said. This will enable Benchmark to assess how the animals perform in diverse real-world operations.

Benchmark Genetics has more than 25 core geneticists and technical experts working on in-house and external breeding programmes and actively participating in global R&D projects. The geneticists use a range of the latest genomic technologies to manage our three balanced

breeding programmes for salmon in Iceland, Chile and Norway.

“The primary rationale for this global test is to assess the genetic x environment (GxE) interaction within convention net pens and land-based farms. Currently, the fish have performed very well in each country, and the first of the batches is scheduled for harvest during Q3/2023. During harvesting, commercially relevant production or phenotypic data will be collected, including harvest weight, maturation status and others.

Salmon ova from Benchmark Genetics Iceland will supply more than 90 per cent of our land-based projects going forward, and by placing families in different environments around the globe, we can assess the impact of the environment on grow-out performance,” he said. Suppose there are individuals that perform better in land-based operations versus net pens. In that case, the company can use this information to hone and improve the strain and create a more tailored product for land-based operations.” In addition to salmon, Benchmark Genetics also provides tilapia and shrimp to customers.

“We don’t just have 40 years of expertise in-house for salmon,” he said. “We have in-house breeding programmes for tilapia and shrimp, as well as managing many external breeding programs for many other relevant species to land-based operations.”

Currently, Benchmark Genetics supplies salmon eggs worldwide — shipping the highest quality eggs to operations in 37 different countries. It has three salmon breeding programs in Norway, Iceland and Chile. Its long history of research enables farms to select a proven fish for their specific operations.

“We have many different salmon genetics traits, whether associated with disease-resistance, flesh quality or productivity such as growth, and a customer can select different traits on a product depending on

the environment they produced and what market they are targeting,” said Preston. “For instance, you might have a risk of infectious pancreatic necrosis — so they will look for a trait which covers that specific disease.”

The company constantly monitors how its stock is performing and regularly checks to ensure the traits in its animals are performing as expected.

Benchmark Genetics currently sells an all-female sterile product which is performing well with customers that, when paired with an optimised diet, is well suited to a land-based environment.

The goal of these products is to control and reduce the maturation and energy allocated to the process to achieve greater productivity, he said. Just like in terrestrial farming where males can mature quicker than females, it is therefore advisable to not have males in a population in land-based salmon farming to avoid precocious male maturation.”

“Generally, the females are late to maturing,” he said. “We’ve got a methodology where we produce eggs that give only female offspring and all-female sterile offspring, which eliminates the problem of early maturing males that would normally come into production.”

Benchmark is working closely with the University of Iceland on R&D projects, including a sterility project that holds potential for the industry, said Preston. “It could be a silver bullet for salmon farming in terms of controlling maturation— and we’re pretty close to commercial testing,” he said.

Benchmark Genetics works with land-based projects from the ground up. They work with

operators to help determine expected growth rates based on the commercial setup.

“We’d sit down with the client, and we can model that and determine what we’d expect from their production,” he said. “We’d refer them to all the products that we have — so really, this is what you need. You’re going to be contained, and your biosecurity will be good. You don’t need all the disease traits because you’re not exposed to the pathogens that we see in the net pens and oceans. The salmon product is far simpler on land than in net pens and heavily weighted for fast growth.”

“There’s a lot to the services we provide. It’s not just a great product in terms of the quality of the egg and salmon you’re getting from decades of breeding. We also provide our clients with technical service before, during and after delivery courtesy of the Benchmark Genetics commercial team.”

Many operations are being started and run by professionals who don’t necessarily have aquaculture backgrounds. The team at Benchmark Genetics can help any operation get off the ground because of its expertise in hatchery management, health management and salmon production-this is a huge resource for the customer.

“We’ve got umpteen different sites around the world where we grow the salmon commercially ourselves,” he said. “We can facilitate with things like growth models and smoltification and how to control maturation and these types of technical know-how because we’ve all worked in the industry, we’ve worked as research scientists, and we’re closely linked with the industry globally.” By facilitating this knowledge transfer to the customer, Benchmark Genetics is actively supporting the development of the land-based salmon sector by providing optimal genetics and bespoke sales and technical services.

• Benchmark Genetics is using technology to build the ultimate fish for land-based salmon farming.

• The company has conducted global benchmarking tests to assess how salmon perform in diverse real-world operations and is using the results to improve the strain and create a more tailored product for land-based operations.

• Benchmark Genetics supplies salmon eggs worldwide, and its long history of research enables farms to select a proven fish for their specific operations.

Contact information:

Website: www.bmkgenetics.com

Ben Perry

Sales and Technical Support Manager

Email: ben.perry@bmkgenetics. com

Tel.: + 44 (0) 788 009 2017

Andrew Cree Preston

Global Technical Manager for RAS

Email: andrew.preston@bmkgenetics.com

Tel.: +44 (0) 770 7270 444

The fish swimming around in any recirculating aquaculture system (RAS) operation don’t really care about clear water, said Tony Riggio, sales manager for Aqua Ultraviolet.

It’s the health of the water itself that matters, and that’s where its ultraviolet sterilizers, sanitizers and filters come into play.

The Ultima II biomechanical aqua filter is designed to strip ammonia from the wa-

ter, with nine different models designed for tanks anywhere from 500 gallons up to 60,000 gallons.

“Inside of the filter is our bio-media that is our patent,” said Riggio. “It grows nitrifying bacteria that are needed to process waste, which is the ammonia that the fish create. High ammonia will burn their lungs, and they’ll be at the surface gasping for air.”

The Ultima II filters are also simple to clean. Simply set the valve to backwash and

rinse, and the internal jets do all the work so operators don’t need to get their hands dirty.

Another piece of the puzzle in providing healthy water is ultraviolet sterilization. And with nearly four decades of expertise, Aqua Ultraviolet has perfected the science. It has a wide range of sterilizers available, from small residential-grade units to large

commercial ones.

“We spec by volume and flow rate, and if you get that right they work perfectly,” he said.

For example, the Classic 25 Watt — designed for smaller operations — can handle a flowrate up to 1,200 gallons per hour. The Classic 40 Watt works up to 2,900 gallons per hour. There are 11 models available in total that can handle anywhere from 650 to 7,200 gallons per hour.

The Viper Series of sterilizers are designed for large commercial operations, and are built to disinfect faster with greater cell penetration capabilities. There are six models to choose from, ranging from the Viper 400 Watt Plastic up to the Viper 1,200 Watt Stainless Steel.

The flow rates range from 17,500 to 52,500 gallons per hour and can sterilize tanks ranging from 14,400 gallons to 90,000 gallons. They also feature a compact body design, giving them a small footprint — which makes handling, installation and maintenance simple.

“Aqua Ultraviolet’s system eradicate the organisms without anyharmfulresiduals,which controls the spread of fish disease,viruses and other invasive pathogens.”

The ultraviolet light sanitizer emits a germicidal ray that alters, or disrupts, the DNA or RNA of single celled microorganisms. It’s a proven way to purify water and control algae, bacteria and protozoa.

Aqua Ultraviolet’s system eradicate the organisms without any harm residuals, which controls the spread of fish disease, viruses and other harmful pathogens. And they work fast, cleaning the water in three to five days — sometimes overnight — and keeping it that way.

The powerful units have the same germicidal rays as the sun, only hundreds of times

stronger and much more cost effective.

Performance is guaranteed when size, installed and operated according to the instructions. And, because it’s a purely physical process, it does not alter the water chemistry, taste, smell or pH.

Combining the Ultimate II with the UV sterilizers creates an ideal pair to ensure water quality remains high for optimal fish growth and health.

“It’s a very simple closed-loop system,” said Riggio. “The pump is moving water to the filter, then into the UV and back to the RAS tank.”

• Get water treatment advice

• Exceptional same day service

• Great prices

Tony Riggio, Sales Manager

Aqua Ultraviolet Street: 42371 Ave Alvarado

Temecula, CA 92590

Mailing: PO Box 2189

Temecula, CA 92593

(951)296-3480

EPA Est 68177-CA-001

NEW OPERATING HOURS Monday - Friday 7:00am to 3:30pm

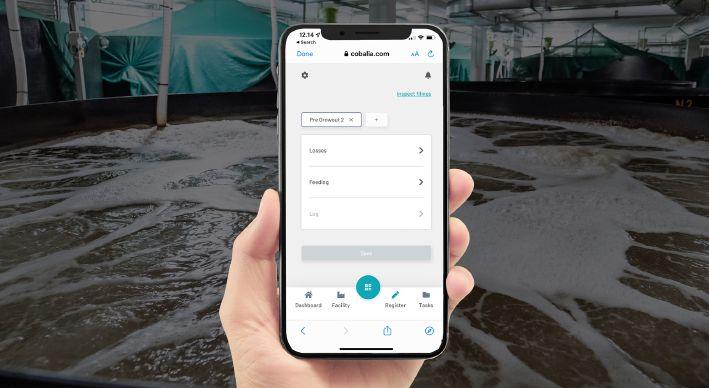

Fish farming is going from the tanks to the clouds thanks to Cobália, powerful new software from OxyGuard that provides data automation for RAS operators and fish-farmers operating other facility types.

The cloud-based system collects and analyzes data, using artificial intelligence, to help producers monitor their systems and identify and pinpoint trouble spots.

It sounds complicated, but using it is quite simple, said Paw Petersen, CEO of OxyGuard. He gave the example of a worker going out with hand-held equipment to monitor the oxygen and temperature.

“They go back into the office and write down what they have,” he said. “If you are quite a skilled fish farmer, you will start to put those numbers into a spreadsheet and start to see some graphs of how your farm is performing, how the oxygen level compares to the previous day or over a week or month.”

But with Cobália, all you need to do is download an app to your smartphone and hold it up to a QR-code installed on the tank — everything else happens seamlessly. The data is automatically uploaded to the cloud and the software crunches the information. The same QR code has another advantage in that it can provide the employee with information about his tasks at the current tank, e.g., maintenance of equipment, cleaning, feeding etc. “You don’t have to do anything. You just connect

your mobile device and start to collect the values; it is even possible to add information based on manual observations,” said Petersen.

The farm management system will keep track of daily, monthly and yearly tasks, auto-generate reports for the management, and giving a complete visual overview of the conditions on your farm.

The coming integrated AI-unit can analyze and optimise production possibilities (for example, inter-correlation between water chemistry and the physical environment for improved growth). The farmers own their own data but Cobália offers users to draw best practise conclusions though

benchmarking based on anonymous data from thousands of connected farms showing trends with median, top and bottom, thus enabling individual farms to measure themselves against such an overview. Cobália will also offer the possibility for the farmer to share data with e.g., veterinarian, authorities, feed-companies etc.

The software can already track additional measurements from chemical kits, like nitrate and ammonia, that used to be just scribbled down on paper. Adding that data to Cobália allows the system to track and analyze that information as well.

Another benefit of Cobália is that it registers each time a reading is done.

“Often, you have to prove that you in fact have done the measurement if you want to be certified for e.g., GLOBAL G.A.P.,” said Petersen.

Cobália is designed to be used on any farm, of any size and type, nearly anywhere in the world. You just need an Internet connection and a mobile device with the app installed. Versions are available for both Android and Apple smartphones.

“We can go from traditional pond-based farms, to the most advanced tank-based recirculation facilities,” he said. “From a farm with three ponds and a restricted annual production to a farm with 400 tanks and annual production of several thousand tons, Cobália will serve them all well.”

There are two different levels of software available. The light version collects the data and presents it in an easy-to-read format. The full version has more powerful features, including growth prediction, feeding curves, advice on how to feed your fish and a task manager.

Cobália has been co-developed through feedback from farmers and feed companies around the world. OxyGuard, which has been operating for more than 35 years, is putting a lot of resources into research and development. Thus, OxyGuard will continue the development of more facilities in Cobália - in interaction with the users to satisfy their wishes. About 30 per cent of OxyGuards employees are focused on R&D, and there are additional innovations in the pipeline, said Petersen.

For example, we just came out with a brand-new ozone sensor that can measure ozone directly in the water,” he said. “We have a big development department that we think is quite important for the industry. We’re not just a production company, we’re also contributing to the development of the industry.”

• The possibilities of Cobália are endless, including:

• Smart farming with a modern digital and visual production management system

• Automation of tasks and auto generation of reports

• Tailored advice from feed companies based on your specific farm data

• Optimization of your production based on sector-wide benchmarking and AI analysis

• Full control over which data you share

• And much more

Currently, OxyGuard is involved in EU-supported work, where traceability and transparency are the focus. The aim is that consumers can find information about the path of the purchased seafood product through the entire value chain from egg to refrigerator. This means that data from the primary producers, including data from producers of eggs, fish feed etc., are collected trough Cobália and transferred to the process industry, which can supply data from the manufacturing process, the total data-set brought forward to retailers, and thus reach consumers. Data as CO2 footprint, environmental impact, fish welfare can in this way be presented to the consumer and hopefully lead to a greater trust in - and consumption of farmed seafood.

For more information, visit our website www.cobalia.com

THE SOLUTION

• Cobália is powerful cloudbased software, leveraging artificial intelligence to monitor systems and identify trouble spots.

• Designed for any size operation with easy-to-use mobile apps for Android and Apple devices.

• Backed by OxyGuard, which has more than 35 years’ experience in research and development for aquaculture professionals.

CONTACT INFORMATION

www.oxyguard.dk/cobalia cobalia@oxyguard.dk

Tel: +45 4582 2094

www.oxyguard.dk/cobalia cobalia@oxyguard.dk

Balmoral Tanks has a forty-year track record of engineering excellence in the design, manufacture and installation of tanks in a wide range of sectors, including wastewater treatment facilities, offshore oil installations and wind farms.

“The offshore energy sector is a super high-tech, high scrutiny arena where product performance cannot be questioned,” said Jon Smith, U.K. sales director.

The company has brought all that expertise to the world of recirculating aquaculture systems (RAS) with the development of its blutanQ product line. Earlier this year, it put the finishing touches on the installation of 24 tanks at The Kingfish Company’s farmed Dutch Yellowtail operations in Holland. It is scheduled to go into operation in early summer 2023.

The blutanQ coated, bolted steel tanks are different from other tanks on the market because of their coating, said Smith. They use Balmoral Tanks’ proprietary ‘efusion’ epoxy coating, which provides a highly resistant surface for the tank panels.

The right product is only part of the equation, said Smith, as the company has been welcomed warmly in the world of RAS because of the level of service it offers — from the design phase to installation, to the maintenance and general advice on running a strong operation.

“The engineering expertise, the coating application expertise and then the installation expertise that we bring to the table really resonates,” he said.

“It’s quite a broad spectrum of discussion,” and the team at Balmoral Tanks is happy to consult on a wide variety of issues to ensure RAS operators get the right system, he said.

blutanQ can be used in both freshwater and saltwater environments, with different coatings available for optimal operation, said Smith.

The tanks are manufactured in the U.K. at the company’s new state-of-the-art production facility in South Yorkshire that gives the company essentially unlimited capacity to meet demand. It also uses 3D modelling for its tanks to help the customer throughout the design process.

“The customer can use those models and situate them in the overall plan design to make sure all the pipe work, the overhead structures, the access points are married exactly to our 3D model,” he said.

Shipping is also easy, as the panels are packed flat — similar to the way IKEA ships its furniture, he said.

“From a shipment point of view, you can get about 19 tons of tank into a 40-foot container,” he said, which helps keep costs down.

• 40+ years’ design and build experience in industrial tank technology

• Independent, innovative company with vast international experience

• 35+ year product design life

Contact: Jonathan Smith Balmoral Tanks Thurnscoe

South Yorkshire

United Kingdom

S63 0EW tanks-website@balmoral.co.uk

Tel +44 (0)1226 340370 www.balmoraltanks.com

Aquacare Environment, Inc. was established in 1987 to supply cost effective industrial scale equipment to the growing aquaculture industry worldwide. Aquacare is both a designer and equipment supplier for land based aquaculture facilities and we also work with other designers. For example, many of the farms supplied by Aquacare were designed by JLH Consulting; examples include Mainstream’s barramundi farm in Australia, Hudson Valley Fisheries in New York, Local Coho in New York, NIWA’s pilot yellowtail farm in New Zealand. In this relationship, Aquacare has generally been the equipment integrator and supplier to these customers which has meant that we have been involved in much of the detailed design, value engineering, implementation and ongoing support. Aquacare also designs the controls, monitoring and SCADA packages.

Distribution and OEM relationships with specialized manufacturers allow Aquacare to specify and ship the best value components available. Adapting equipment manufactured for the larger water treatment market to the specific needs of aquaculture provides considerable cost savings.

Prior to establishing Aquacare, founding CEO Henning Gatz supplied

bolt together steel tanks to the agriculture market for animal feed and manure storage. Large circular tanks are now widely accepted in the RAS industry as the most effective option due to their low cost per volume and their ability to concentrate and rapidly transfer solids to the particulate filters. These advantages become even clearer as scale increases. Glass fused to steel tanks are suitable for freshwater whilst for more corrosive marine environments we recommend epoxy coated steel.

Drum microscreen filters are the first line solids removal mechanism used in modern fish farms. We typically supply stainless or duplex models depending on the salinity. We have suppled a large number of these robust and reliable machines over the years. For fine solids removal we use either stand alone foam fractionators or custom low head in-sump models.

Our approach to biofiltration is typically using MBBR technology. With the right combination of polyethylene media with a high surface area, correctly sized aeration grids and retention screens, these filters will

carry out the essential task of nitrification 24 hours a day without any attention required. They are self-scouring and so prevent the buildup of sludge that can be a real problem in static filters.

Fish farmers are much more aware of the deleterious effects of high dissolved CO2 than in the past. Reduced appetite, stress and poor feed conversion are all the result of elevated CO2. Removing it can be costly in terms of pumping and heat loss/ gain so efficient is a challenge. Our preferred solution is forced air stripping columns using structural plastic media to achieve high air-to-water surface area paired with efficient low-head turbine pumps. Our designs are scalable and cost effective to build and operate. One important aspect in the design is to provide good access for inspection of the media and when necessary to allow for removal and cleaning of biofilms.

In any RAS facility, continuous supply of dissolved oxygen to the fish is a critical part of the operation. There are many designs; cones, LHO’s, PPC’s, U-tubes, in-line diffusers, etc. One design that has been gaining a serious following recently is the Oxyflow®. Designed by Bohumil Sevic, a French engineer with decades of experience, it represents probably the most efficient way to dissolve oxygen into the water. Depending on its size, OXYFLOW® dissolves 1.0 to 60.0 kg oxygen/hour at >95% efficiency. In our experience, adopters of this technology become permanent converts once they see the impact to their bottom line.

Moving water is the heart of an intensive aquaculture system. In our designs we focus on low head systems where the water is pumped only once, after solids removal and biofiltration just before oxygen enrichment through the Oxyflow® and back to the fish tanks with sufficient head to create a healthy current in the rearing tank. We supply all types of pumps and are very careful to select durable and efficient models.

Precision, computer-controlled feeding is essential for profitable aquaculture. One of the best ways to distribute the correct feed to the correct tank at the correct time is to use pneumatic feeders which deliver precise doses of feed frequently to each tank population. Frequent smaller feedings also help to maintain a balanced load on the biofilters and help to assure optimum feed conversion ratios. Fish

Feeder based in Galicia, Spain manufacture what we believe to be the highest quality feeding system for large land-based farms and we have supplied a number of these to our US customers.

Varicon Aqua Solutions Ltd. is the manufacturer of the Phyco™ range of photobioreactors and the Cell-Hi line of algal nutrients, with more than 30 years’ experience in the algae and aquaculture sectors. Varicon Aqua is represented in the United States by Aquacare. In partnership, Aquacare will broaden the number of Varicon products and services on offer to fish farms and hatcheries within the American market.

Human operators cannot be replaced by machines, however knowing what the critical water parameters and the status of all critical equipment is in real time is an essential management tool. This is where customized monitoring, alarm and control systems as supplied by Aquacare provide a significant return on investment to the farm owners.

As the demand for controlled environment aquaculture systems continues to grow Aquacare is ready to engage with clients to design and build efficient, manageable and scalable fish farming systems world-wide.

• Factory coated bolted steel tanks

• High efficiency oxygen transfer

• Precision computer controlled feeding

Aquacare Environment Inc. 708 Coho Way Bellingham WA 98225 USA

www.aquacare.com info@aquacare.com

+1.360.734.7964

When shopping for salmon or trout, color is a critically important factor in determining the quality of the product before you. Panaferd®-AX has developed a natural pigment source that has become the standard in the salmon industry for Scottish salmon, as well as premium salmon from Norway, Iceland, and beyond. The use of this natural pigment is also beneficial in RAS farming.

BENEFITS ON IMAGE:

As more customers are turning to natural foods that are free of synthetic additives, they expect to pay more for premium salmon than they would for conventional salmon - so long as the color of the filet is similar (Olesen et al, 2020). Most premium farms understand the benefits of this strategy. As a way to strengthen their image as connected to nature, RAS farming messaging uses statements such as “free of synthetic additives”. Contrary to synthetic pigment,

Panaferd®-AX is approved in all standards, including organic, and is requested by such retailers as Whole Foods. Serving as an example of this success, prestigious Singapore Airlines recently selected Hudson Valley Fisheries RAS trout to be served on their flights. Superior Fresh is an aquaponics farm in Wisconsin that is focused on providing an organic, natural diet for their salmon. Superior Fresh is also certified Non-GMO by A Greener World (AGW).

BENEFITS ON COLOR:

Compared to the synthetic pigment which only contains astaxanthin, Panaferd®-AX has the clear advantage of naturally containing a wide range of carotenoids such as Adonirbin and Adonixanthin etc. It is well known for its bioavailability and efficiency in ensuring that salmon, trout, and shrimp have a vibrant pink color. Studies have also confirmed the stability of the pink pigmentation.

In high density RAS farms, the environment may be challenging for fish through high density optimal growth conditions year round. For salmonids, carotenoids have proven antioxidant benefits, immune health, and vitamin A boosters. A recent study (Ytrestoyl, et al, 2021) investigated the effect of astaxanthin on the gene expression and performance on Atlantic salmon that were fed diets with a low marine ingredient content, similar to their actual feed formulation.

Salmon (initial weight @ 200g) were fed two similar diets with different levels of astaxanthin - below 1 and 48 mg/kg respectively. At the end of this trial period, there was no significant effect of astaxanthin on survival, growth rate, or final body weight. However, in the intestine of the salmon fed without astaxanthin, there was an effect of decreased expression observed

on several immune genes including those of innate antiviral immunity. In the liver, the effects of astaxanthin deficiency on lipid metabolism were also similar to fish fed diets deficient in omega-3 fatty acids. Carotenoids from Panaferd®-AX, such as adonirubin and adonixanthan, have proven clear nutritional benefits in other animals such as broilers where reducing the oxidation process can improve meat quality.