•A RASTECH SPONSOR SHOWCASE•

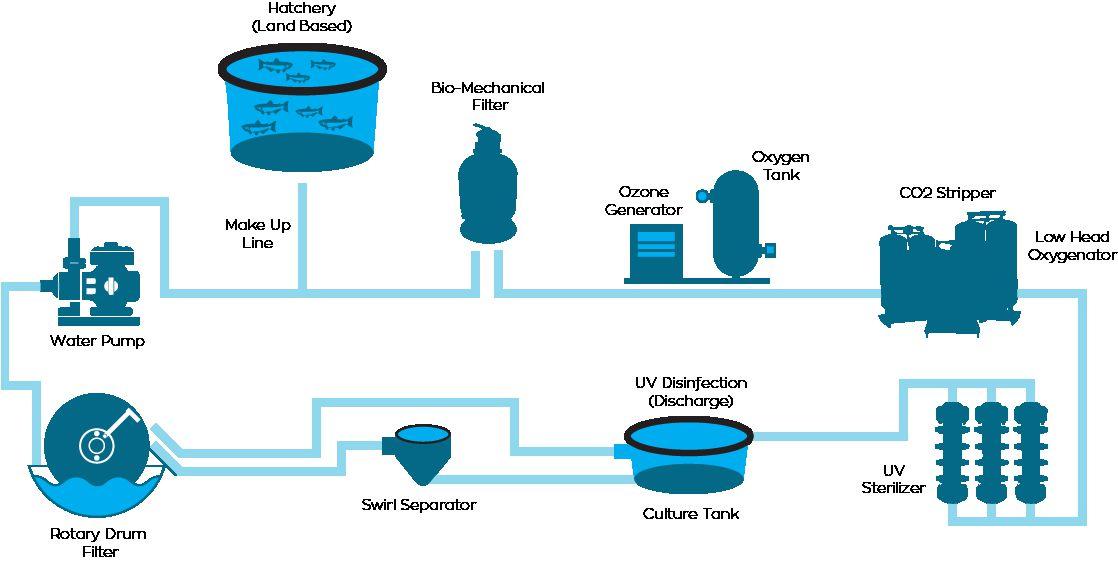

AQUACARE CONTROLLED ENVIRONMENT AQUACULTURE SYSTEMS

Aquacare Environment, Inc. was established in 1987 to supply cost effective industrial scale equipment to the growing aquaculture industry worldwide. Many of the farms supplied by Aquacare were designed by JLH Consulting; examples include Mainstream’s barramundi farm in Australia, Hudson Valley Fisheries in New York, Local Coho in New York, NIWA’s pilot yellowtail farm in New Zealand. In this relationship, Aquacare has generally been the equipment integrator and supplier to these customers which has meant that the company has been involved in much of the detailed design, value engineering, implementation and ongoing support. Aquacare has also typically designed the controls, monitoring and SCADA packages.

Since 2020 Aquacare has been building up its in-house design capacity. For example, new CTO Dr. Nick Brown brings a wealth of freshwater and marine RAS design and operating experience to the team. Recently designed projects include a new largemouth bass farm in Arkansas which is currently under construction and Aquaco’s pilot pompano farm in Florida which is about to undergo expansion after a successful 2 years in operation.

Distribution and OEM relationships with specialized manufacturers allow Aquacare to specify and ship the best value in components available. Adapting equipment manufactured for the larger water

treatment market to the specific needs of aquaculture provides considerable cost savings.

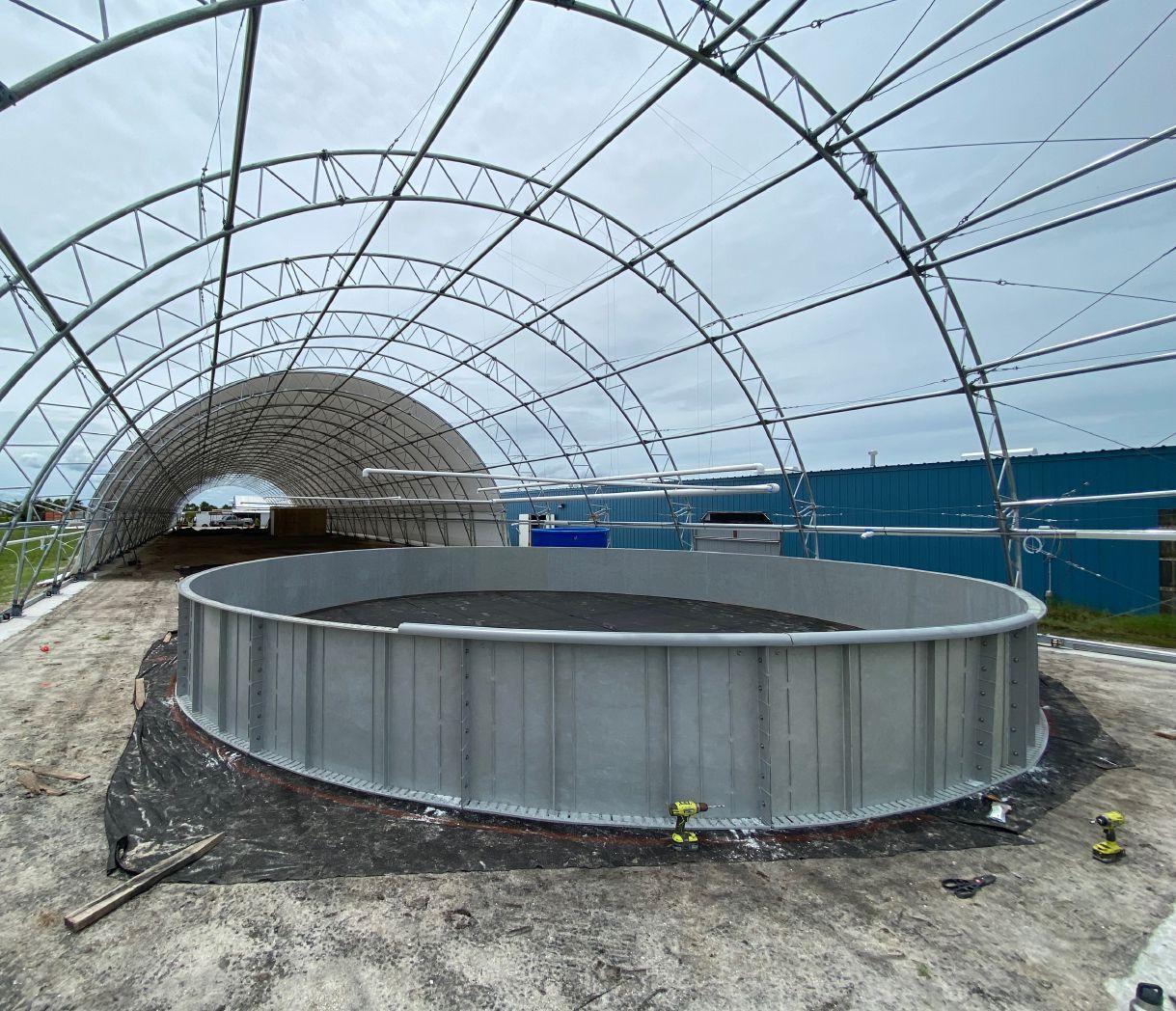

TANKS

Prior to establishing Aquacare, founding CEO Henning Gatz supplied factory coated bolted steel tanks to the agriculture market for animal feed and manure storage. Large circular tanks are now widely accepted in the RAS industry as the most effective option due to their low cost per volume and their ability to concentrate and rapidly transfer solids to the particulate filters. These advantages become even clearer as scale increases. Glass fused to steel tanks are suitable for freshwater, whilst for more corrosive marine environments Aquacare recommends epoxy coated steel.

SOLIDS REMOVAL

Drum microscreen filters are the first line solids removal mechanism used in modern fish farms. Aquacare typically supplies stainless or duplex models depending on the salinity. The company has supplied a large number of these robust and reliable machines over the years. For fine solids removal Aquacare uses either stand alone foam fractionators or custom low head in-sump models.

BIOFILTRATION

Aquacare’s approach to biofiltration is typically using MBBR technology. With the right combination of polyethylene media with a high surface area, correctly sized aeration grids and retention screens, these filters will carry out the essential task of nitrification 24 hours a day without any attention required. They are self-scouring and so prevent the buildup of sludge that can be a real problem in static filters.

CO2 REMOVAL

Fish farmers are much more aware of the deleterious effects of high dissolved CO2 than in the past. Reduced appetite, stress and poor feed conversion are all the result of elevated CO2. Removing it can be costly in terms of pumping and heat loss/ gain so efficiency is a challenge. Aquacare’s preferred solution is forced air stripping columns using structural plastic media to achieve high air-to-water surface area paired with efficient low-head turbine pumps. The company’s designs are scalable and cost effective to build and operate. One important aspect in the design is to provide good access for inspection of the media and when necessary, to allow for removal and cleaning of biofilms.

OXYGENATION

In any RAS facility, continuous supply of dissolved oxygen to the fish is a critical part of the operation. There are many designs; cones, LHOs, PPCs, U-tubes, in-line diffusers, etc. One design that has been gaining a serious following recently is the Oxyflow®. Designed by Bohumil Sevic, a French engineer with decades of experience, it represents probably the most efficient way to dissolve oxygen into the water. Depending on its size, OXYFLOW® dissolves 1.0 to 60.0 kg oxygen/hour at >95% efficiency. In Aquacare’s experience, adopters of this technology become permanent converts once they see the impact to their bottom line.

PUMPING

Moving water is the heart of an intensive aquaculture system. In Aquacare designs the focus is on low head systems where the water is pumped only once, after solids removal and biofiltration just before oxygen enrichment through the Oxyflow® and back to the fish tanks with sufficient head to create a healthy current in the rearing tank. Aquacare supplies many types of pumps and are very careful to select durable and efficient models.

FEEDING

Precision, computer-controlled feeding is essential for profitable aquaculture. One of the best ways to distribute the correct feed to the correct tank at the correct time is to use pneumatic feeders which deliver precise doses of feed frequently to each tank population. Frequent smaller feedings also help to maintain a balanced load on the biofilters and help to assure optimum feed conversion ratios. Fish Farm Feeder based in Galicia, Spain manufacture what Aquacare believe to be the highest quality feeding system for large land-based farms and the company have supplied a number of these to Canadian and US customers.

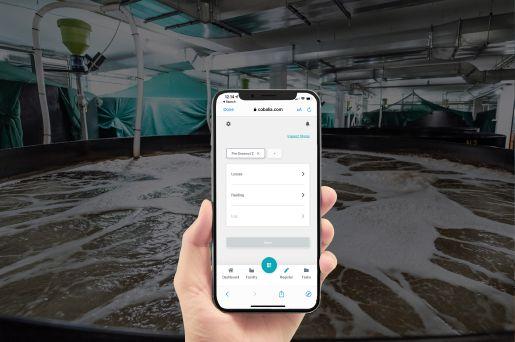

CONTROLS

Human operators cannot be replaced by machines, however knowing what the critical water parameters and the status of all critical equipment is in real time is an essential management tool. This is where customized monitoring, alarm and control systems as supplied by Aquacare provide a significant return on investment to the farm owners.

As the demand for controlled environment aquaculture systems continues to grow Aquacare is ready to engage with clients to design and build efficient, scalable and manageable fish farming systems world-wide.

THE SOLUTION

• Factory coated bolted steel tanks

• High efficiency oxygen transfer

• Precision computer controlled feeding

Aquacare Environment Inc. 708 Coho Way Bellingham WA 98225 USA www.aquacare.com info@aquacare.com

+1.360.734.7964

Industrial tanks specialist brings its A-game into aquaculture

There is an incredible transformation taking place in the aquaculture industry and Balmoral Tanks is not about to miss the opportunity to lend its expertise.

For the past 40 years, high-performance liquid storage solutions from the UK-based company have been the go-to solution in sectors spanning water, wastewater, anaerobic digestion, agriculture and mining. The recent emergence of land-based fish farming has opened up the opportunity to add aquaculture to its portfolio.

The company’s reputation clearly precedes it. In 2020, the Kingfish Company came knocking to source best-in-class tanks for its yellowtail kingfish RAS farm in the Netherlands.

That meeting proved momentous for Balmoral Tanks. Eighteen months since the first contact, the company is ready to install at Kingfish’s facility 24 tanks customized to meet its unique needs.

“Kingfish represents the real connection to the movement in the ‘true market,’ where RAS is now on a pedestal in terms of food production while at the same time reducing fish farming’s impact on the environment,” says Jonathan Smith, sales director at Balmoral Tanks.

Whether for small-scale proof-of-concept pilots or full-scale commercial implementation, Balmoral Tanks can provide the right choice. The steel tanks come with two coating options: epoxy and glass – both offering impact durability, lower cost manufacturing,

lower carbon footprint and design efficiency.

“We take a lean view on coating options,” says Smith. “Other manufacturers offer five or six different grades of coating. That’s almost like passing the responsibility of coating specification back to the customer. We don’t do that. Tell us what your requirements are, we’ll help tailor the perfect system for you. From a warranty and performance point of view, we’ll stand behind what we say.”

Smith underscores the company’s 25-year maintenance-free warranty. “It could cost an operator as much as half-a-million dollars just to drain a 5,000- to 6,000-m3 tank. So our role in the development of a plant is to ensure the design solution and the material selection marries up with what the customer is thinking.”

Kingfish Company is happy. “Having worked closely with Balmoral during the development phases, we’ve found them very supportive and experienced in their approach to our requirements,” it said.

With RAS aquaculture still a long way from maturity, Balmoral Tanks aims to stick around. “We’re not just here for the order,” says Smith. “We’re here for today and tomorrow. We’re here to do business.

“We won’t always win the order, but we’re here to develop relationships in the market. In five years’ time, we’ll be looking after our clients with as much intent and interest as we do today. From this, we believe the orders will take care of themselves.”

THE SOLUTION

• 40+ years’ design and build experience in industrial tank technology

• Independent innovative company with vast international experience

• 25-year maintenance-free warranty

Balmoral Tanks Thurnscoe Rotherham

United Kingdom

S63 0EW Tel: +44 1226 340370

Email:tanks-website@balmoral.co.uk

into existing and newly developed mar-

areas. Aquaculture represents a great challenge for myself and Balmoral and I hope my expertise delivers value to our RAS client base. My focus is always on the clients’ requirements and aligning those with the best engineering solutions.”

www.rastechmagazine.com

Reader Service

Print and digital subscription inquiries or changes, please contact Urszula Grzyb, Audience Development Manager

Tel: (416) 510-5180

Fax: (416) 510-6875

Email: ugrzyb@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Catarina Muia

519-410-0600 cmuia@annexbusinessmedia.com

Associate Editor Jean Ko Din 437-990-1107 jkodin@annexbusinessmedia.com

Associate Publisher Jeremy Thain 250-474-3982 jthain@annexbusinessmedia.com

Account Coordinator Morgen Balch 519-429-5183 mbalch@annexbusinessmedia.com

Group Publisher Todd Humber thumber@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

Printed in Canada

SUBSCRIPTION

RAStech is published as a supplement to Hatchery International and Aquaculture North America.

Occasionally, RAStech will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbusinessmedia.com Tel: 800.668.2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2022 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

WELCOME I Solutions in RAS

Welcome to the first edition of Solutions in RAS, RASTECH’s annual resource guide from our trusted brand partners in the Recirculating Aquaculture Systems (RAS) sector.

This publication is designed to inform professionals about the latest innovations and solutions in this fast-growing sector. In these pages, you’ll find information — produced in collaboration with leading suppliers — on products, technologies and systems that are advancing the industry and making your job easier.

This special brand showcase will be published each year, and is also available online so you can share it with colleagues or refer to it anytime you’re looking for more information.

We hope you find it useful, and I encourage you to share your thoughts with us on this new publication. At RASTECH, we’re always open to suggestions and are continuing our push to provide news, information and content to RAS professionals in every media format.

We’re already working on next year’s edition and we look forward to continuing to bring you content that improves your existing RAS operation and helps you implement new projects.

Thank you for reading!

Jeremy Thain Associate Publisher - Aquaculture Division

Annex Business Media jthain@annexbusinessmedia.com

Made possible with the support of

COMPANY DIRECTORY

AQUACARE ENVIRONMENT / 2-3

Aquacare Controlled Environment

Aquaculture Systems

BALMORAL TANKS / 4

Industrial tanks specialist brings its A-game into aquaculture

BENCHMARK GENETICS / 8-9

Getting the best start for your RAS operation

AQUAMAOF / 10-11

Atlantic Salmon Production Performance in RAS

AQUA ULTRAVIOLET 12-13

Clarity and performance in your water system is only one phone call away!

FAIVRE / 18-19

Faivre Group - Innovation is key to Success and Longevity

STRUCTURAL ARMOR / 22-23

Top-grade modular solutions for in-shore aquaculture

BIO-UV GROUP / 27

Improve aquaculture water with UV and Ozone

FRESH BY DESIGN / 16-17

Keeping a fresh take on your RAS design needs

LINDE GASE / 20-21

Bringing RAS Aquaculture to a Greener Future

OXYGUARD INTERNATIONAL / 24-25

Building solid solutions since 1987

ADSOPRTECH / 28

How your oxygen source can improve RAS reliability, efficiency and social

GETTING THE BEST START FOR YOUR RAS OPERATION

It starts with optimal genetics! Benchmark Genetics is a long-established and trusted provider of genetic material to the salmon farming industry worldwide. More recently, Benchmark Genetics has been leading the way in land-based fish farming, providing to the majority of this new segment globally.

GEARING UP IN ICELAND

The company’s Icelandic operations supply the genetics for land-based farming, having farmed broodstock on land since 1991. Located on the West coast of Iceland, on remote lava ground far from any other aquaculture operations, the facilities hold the highest levels of biosecurity in the industry, enabling us to export to all parts of the world.

“We are in a unique situation, as eggs from Iceland can be exported to almost any country on the planet, including locations where new land-based Atlantic salmon facilities are operating, under planning or construction”, says Andrew Preston, the company’s Global Technical Manager for RAS.

To meet the projected increase in demand, Benchmark is expanding

its capacity. The company has a state-of-the-art incubation centre in the final stage of construction, holding as many as 10,000 single incubators that will significantly increase the capacity to more than 300M eggs annually.

“The new facility is designed to secure the clients a supply of eggs of high and stable egg quality, produced in biosecure compartments, for delivery all year round,” says Preston.

“This is particularly important to the land-based RAS producers as they have a much more regular delivery plan than the conventional netpen producers. It is not uncommon to have an egg reception every 4th to 8th week,” the recognised RAS expert explains.

SALMORAS 4+ - TAILORED EGGS FOR OPTIMISING PRODUCTION IN RAS SYSTEMS

Biosecurity is a critical factor in choosing a supplier for land-based producers. Having fewer diseases to worry about, they are more concerned about the health status of the eggs, growth, early maturation and fillet quality. The farming systems using freshwater only and running at high

temperatures are particularly vulnerable to high maturation levels.

“This is why we have developed a product range to meet these challenges, named SalmoRAS4+,” explains Andrew Preston.

To avoid the typical problem with the early sexual maturation of males, the SalmoRAS4+ eggs gives only females (“All-female”). To completely eradicate the issue with maturation also in the female population, Benchmark offers the additional choice of Triploidisation, allowing the producers to optimise the temperature in their systems without risking early sexual maturation. In addition to high selection pressure on growth, the product also includes quality traits for flesh colour, fat, harvest yield and body shape. RAS clients can also select the trait QTL-IPN giving high protection against the disease Infectious Pancreas Necrosis.

SUPPORTING CUSTOMER SUCCESS THROUGH PARTNERSHIP AND EXPERTISE

The sector’s expansion is high, and for many projects, securing a supply of good quality ova with their required traits is a key priority. The company’s Sales and Technical Support Manager, Ben Perry, who is in charge of RAS customers in North America, says, “Benchmark is frequently contacted by new companies that want a long-term partnership from a very early stage.”

“These collaborations often also include technical support and expert consultancy from the early stages of project planning,” he continues.

Harry Tziouvas, RAS Sales Manager in charge of RAS customers in Europe, Asia, Africa and South America, says: “We don’t just supply

eggs, but we also provide unique post-sale support for our customers. If they don’t succeed, then we don’t succeed. This is something that we live by.”

Benchmark acknowledges that the clients’ success highly depends on their ability to realise the genetic potential of the eggs delivered. As a result, the company have since 2018 been building a solid and competent sales- and technical team with a particular focus on RAS clients.

“Getting experienced staff has shown to be a bottleneck for many of the new RAS projects, making it even more critical for Benchmark to provide and share expert knowledge with them,” explains Harry Tziouvas.

BUILDING A TEAM OF RAS EXPERTS

The Benchmark team of experts includes Ben Perry, Sales and Technical UK and North America, who has extensive knowledge and passion for salmon aquaculture. Ben has a solid clinical background within freshwater and seawater developed since 2014. Harry Tziouvas, RAS Sales Manager, has extensive knowledge and field experience in Atlantic Salmon fish health management and seawater production from working in the Scottish salmon industry. Harry has a solid background in different commercial roles within the Salmon and Mediterranean aquaculture industries. Robert Runarsson, Global Sales Manager, has built his career in various positions in Benchmark Genetics Iceland and has supported the landbased RAS segment from its very beginning. Finally, Andrew Preston, Global Technical Manager RAS with a strong research and production background in salmon aquaculture and recirculated aquaculture systems (RAS).

“I truly believe that the Benchmark Genet-

ics RAS team complement each other with experience in many aquaculture applicable fields, and we leverage these experiences to deliver holistic customer support,” concludes Harry Tziouvas.

THE SOLUTION

• Advanced genetics adapted for RAS systems

• Highest levels of biosecurity and all year supply

• Preventing early sexual maturation

Meet us at RASTECH 2022

Ben Perry and Andrew Preston will be present at the RASTech 2022 conference and tradeshow at stand #49. Welcome to meet them for a RAS talk!

Contact information:

Website: www.bmkgenetics.com

Ben Perry

Sales and Technical Support Manager

Email: ben.perry@bmkgenetics. com

Tel.: + 44 (0) 788 009 2017

Andrew Cree Preston

Global Technical Manager for RAS

Email: andrew.preston@bmkgenetics.com

Tel.: +44 (0) 770 7270 444

ATLANTIC SALMON PRODUCTION PERFORMANCE IN RAS:

Key results and lessons learned from five years of operation and 30 cohorts of Atlantic salmon production

RAS (Recirculating Aquaculture System) technology is a proven solution for providing sustainable, high-quality protein to meet the increasing demand of the continuously growing population. Recognizing the potential of RAS technology, AquaMaof – a company with over 30 years’ experience in fish farming – is among the pioneers in RAS, providing high-end solution to customers around the world. Operating and managing its own full-scale RAS R&D facility in Poland, the company has gained extensive knowledge and operational experience, while achieving high-quality results.

AquaMaof’s RAS R&D facility for Atlantic salmon has been in operation since 2016, with a new cohort of salmon eggs stocked bi-monthly. The facility covers the full growing cycle of the salmon, from incubation, through first feeding, smolt nursery, and grow-out up to 4-5 kg, after which the product is supplied to the local market.

The innovative design of each AquaMaof RAS facility includes a tailor-made solids settler, a unique biofilter, oxygen-dissolving systems with low head requirements, a depuration capability, and a built-in denitrification system that enables the recycling of water and significantly reduces water consumption.

Great emphasis is placed on fish welfare throughout the entire lifecycle, by maintaining a balanced density and creating a unique, tailor-made ecosystem, which closely resembles their natural habitat.

With strictly-controlled biosecurity protocols in place, fish are raised without the use of antibiotics or chemicals. AquaMaof’s unique facility design prevents fish disease and reduces the potential for human error, mitigating the operator’s risk. Since operations began at the company’s R&D facility, fish mortality has been maintained at less than 10% in the post-smolt phase, with no incidents of major fish loss or disease in more than 30 cohorts over the past five years.

Creating a pathogen-free environment, AquaMaof’s unique biofilter design consistently demonstrates stable, highly-efficient carbon dioxide stripping and lower water recirculation rates. Additionally, throughout five years of operation, hydrogen sulfide problems have not been observed.

Significant R&D efforts have been focused on a depuration technique, resulting in major advances for consistently low concentrations of off-flavors, yielding high-quality salmon. Indeed, AquaMaof has received excellent feedback regarding fish taste,

texture, and colour, both from customers and in blind tests.

Featuring several water-treatment patents and filtering techniques that significantly reduce water consumption and efficiently utilizing energy, R&D efforts focused on the development of water treatment have enabled most of the water from both the depuration facility and denitrification system to be recycled and used in the main production RAS.

In addition to these R&D efforts, production planning to achieve timely production goals and high utilization, is an important factor always considered by AquaMaof. The operational experience gained from the past five years at the facility has aided in the development of a

system design that supports an innovative and effective production plan which facilitates maximal production from capital investment, while ensuring a sustainable solution.

In today’s reality, with high global demand for quality protein and a clear understanding that countries cannot rely only on import/ export of food supplies, to ensure food security local production is necessary. Operating its own R&D facility full time has enabled AquaMaof to carry out on-going optimization and development of its RAS technology alongside continuous production. The company has successfully reached its production goals, supplying high-quality market-size salmon.

THE SOLUTION

• Operating and managing a full-scale RAS R&D facility in Poland, the AquaMaof has gained extensive knowledge and operational experience, while achieving high-quality results.

• The facility covers a full growing cycle of the salmon, from incubation, through first feeding, smolt nursery, and grow-out up to 4-5 kg.

• Operating R&D facility full time has enabled AquaMaof to carry out on-going optimization and development of RAS technology alongside continuous production with no incidents of major fish loss or disease in more than 30 cohorts over the past five years.

AUTHOR:

Gary Meyers Senior Technology Officer.

CONTACT INFORMATION: Kira Zibnitzky Marketing Communications

Email: kira.zibnitzky@aquamaof.com

CLARITY AND PERFORMANCE IN YOUR WATER SYSTEM IS ONLY ONE PHONE CALL AWAY!

Aqua Ultraviolet has been providing ultraviolet (UV) sterilizer and bio-mechanical filtration solutions to the residential and commercial markets for decades as the world’s population begins to realize life depends on water.

“Thirty years ago, Ron James founded Aqua Ultraviolet for one simple reason: He was in a position at the time where he saw there was a need for something that could provide clear water solutions other than chemicals,” said sales manager Tony Riggio. “Ninety percent of our products are used in man-made facilities and 10 per cent in natural.”

Disease found in habitat water sources is an increasing concern, especially in hatchery and seafood rearing facilities. UV sterilizers have proven to be the most cost-effective disinfection technology for the inactivation of many types of bacteria, viruses and parasites harmful to fish.

Especially in land-based hatchery systems, UV can also play a role in ozone destruction. Ozone is often used to enhance the quality of problematic water sources when incubating and rearing fish. However, residual ozone in the water can be toxic, or even fatal, to the aquatic life being reared. UV light sterilizers

are applied in the bulk water prior to contacting the fish.

“Business dynamics in California is a challenge in every sector, but California (as with most states and the world) is facing a water crisis, increasing prices and accessibility,” said Riggio. “So it would suggest any type of improvement to the Water Process Procedure would be beneficial to the aquaculture process and the challenge of limiting costs of additional chemical additives and safe water processing.”

Aqua Ultraviolet UV sterilizers have the same germicidal rays as the sun, only hundreds of times stronger and much more cost-effective. The UV light sanitation system will clear your water in three to five days sometimes overnight and keep it that way. Because it is a purely physical process, it does not alter the water’s chemistry, taste, smell or pH.

Performance is guaranteed when sized, installed and operated according to our instructions.

The Classic Series is a general purpose line of products that are ideal for ponds, aquariums, and water features based on the volume of water. The Classic’s modern design has features that allow for quick installation and easy maintenance.

THE SOLUTION

Riggio says the 57W 2-inch Classic Series UV Sterilizers are the biggest sellers both in the USA and worldwide. Its compact and lightweight design was developed to disrupt the DNA-RNA of any single-cell protozoa that might be free floating in the water when passing through UV.

The Viper Series are idea for large commercial or residential ponds, aquariums, and water features. This product line is specially designed to disinfect faster and have greater cell penetration capability. The compact body design of the UV water filters have a small footprint, which makes it easy to handle, install and maintain. Vipers are engineered to accommodate extreme flow rates. A provided flow switch shuts the unit off if flows fall below 95 GPM.

The SL Series is the best of both the Classic Series and Viper Series worlds. It is a hybrid, designed to be bigger than a Classic and smaller than a Viper. Its compact and lightweight design is for large ponds, aquariums and water features.

With this diverse range of products, Aqua Ultraviolet’s team of experts will find the best fit for your recirculating aquaculture system.

• Get water treatment advice

• Exceptional same day service

• Great prices

Tony Riggio, Sales Manager Aqua Ultraviolet Street: 42371 Ave Alvarado Temecula, CA 92590

Mailing: PO Box 2189 Temecula, CA 92593 (951)296-3480

EPA Est 68177-CA-001

NEW OPERATING HOURS Monday - Friday 8:30am to 3:30pm

EXECUTIVE INSIGHT

“What advancements in 2022-2023 will help shape the RAS segment of the aquaculture industry?”

DAN EPPLE

Vice-President of Trivector Manufacturing, Structural Armor

“We solely concentrate on the tanks for the industry, and of course, we believe our beaded liner system coupled with our modular tanks will help mid-sized farms set-up faster and producing quicker at a lesser price than contemporary tanks.”

AUBERT FAIVRE

Sales Manager of FAIVRE Group

“The aquaculture sector has seen accelerated expansion for many years now.

Like most players in the industry, we are keeping up with the trends, constantly innovating to respond to market demands. By introducing higher capacity graders and more expansive range of fish pumps soon, we hope to help the aquaculture industry move forward.”

JAMES FLAHERTY

President and CEO of Adsorptech LLC

“To get all the players in the RAS ecosystem to understand how each RAS farm component properly fit into the entire farm puzzle to achieve maximum sustainability.”

HENNING GATZ

CEO of Aquacare Environment Inc.

“Standardization will continue to improve land based fish farms. Factory coated bolted steel tanks are now well accepted. Oxygen transfer efficiency will grow in value. Precision computer controlled feeding systems are proving their value to the bottom line. More agressive solids filtration and CO2 removal will enhance water and fish quality. These are components being designed into new farms now under construction. Established farms also have the opportunity to upgrade and improve sustainability and profitability.”

RON JAMES

Founder and CEO of Aqua Ultraviolet

“We are currently not looking to change our product line, because as a business we are just barely knocking at the door of the aquaculture industry as a whole. Our units are only just starting to be utilized and recognized in this very important industry and we feel that as we continue to work with companies in this field, we will begin to find additional solutions to products that already are proving to be 100% successful. The most important factor with our compliment of sterilization units, is to ensure they are sized correctly to application.”

JAN-EMIL JOHANNESSEN

Head of Benchmark Genetics

“We need to see some commercial success stories in the industry. Projects are delayed by covid and by investors’ reluctance to put new money into the sector. Increased building costs and energy prices have not helped. So, there is a bit of a ‘wait and see’ attitude in the investor market. The good thing is that demand for salmon is growing, and prices record high, so this should be a perfect starting point to reach commercial success in the RAS segment.”

ALLAN JOYCE

Managing Director of Balmoral Tanks

“The levels of activity in the sector will lead to greater demands on the supply chain while the volume of equipment required will test the capacity of suppliers. As key equipment providers are central to the successful delivery of projects, we believe trusted service-based relationships with developers will shape the future of the sector.”

SIMON MARSHALL

Triogen Director at Bio-UV Group

“UV and Ozone are both exceptional standalone water disinfection technologies for use in recirculating aquaculture systems (RAS). Both technologies disinfect and remove unwanted contaminants – reducing water consumption, improving fish health and yield, and ensuring biosecurity for the facility. When combined into a single system, the two technologies become an Advanced Oxidation Process (AOP), providing a multi-barrier approach to disinfection, leaving no chemical trace, and removing an even wider range of organic and inorganic contaminants.”

PAW PETERSEN CEO of OxyGuard International

“We are currently working on two major areas that we believe will change many things. One of them is applying ozone water treatment to help remove the offflavor in the farmed fish. The other big area is digitalization. We have been working together with the Danish fish farmers and feed-producing companies like BioMar and Aller Aqua to develop cloud-based aquaculture management tools that fish farmers can quickly integrate into their routine.”

BEN POPE

Managing Director of Fresh By Design

“RAS operators love new tech to become more efficient, though with increasing consumption of farmed product around the world, farmers and their distributors will continue to focus on fish welfare. I see further development in harvest technology as a priority for all producers, ensuring the industry is employing the best technology and practises relating to fish welfare.”

ANDREW SARANTAPOULAS

VP Sales and Marketing at Linde Gas

“Ensuring the viability of RAS at scale will require innovative oxygenation technologies and highly reliable oxygen supply networks.”

SHAI SILBERMANN

VP Marketing & Sales at AquaMaof Aquaculture Technologies

“With new collaborations and advancements in 2021, the operational Grieg Newfoundland facility (Canada), the Proximar Seafood salmon facility (Japan), and the Akvaprodukt salmon facility (Vologda, Russia) are expected to enter first stages of production by the end of 2022/2023. We are also looking forward to making progress at facilities in Norway, the Russian Federation, and a new Smøgenlax RAS facility set to be part of a circular economy industrial park in Sweden.”

You can also check out the Digital Edition of this exclusive Sponsor Supplement online at www.rastechmagazine. com/digital-edition

KEEPING A FRESH TAKE ON YOUR CUSTOM RAS DESIGN NEEDS

Serving more than 2,000 active clients, Fresh By Design is a leading aquaculture industry supplier in Australia and New Zealand of everything from complete RAS systems, Drum Filters, UV’s, Protein Skimmers, Water Pumps, Fish Feeders, Fish Pumps, Counters and Graders, right down to plumbing fittings, hoses, and even Drones and Ultrasound devices.

With an expansive network of offices and partners, the company has been delivering top quality equipment, systems design, and consultancy services to a wide variety of seafood production and aquatic research facilities across the region for nearly two decades.

Fresh by Design (FBD) specializes in all areas of RAS design, supply, and construction. The company also offers consultancy services in systems design, site selection and business plans For existing facilities, FBD offers system optimization, evaluations, equipment replacement and maintenance services.

FBD was founded back in 2004. The company grew alongside some of Australia’s pioneering land-based aquaculture farms during the early years of recirculating aquaculture systems (RAS), according to Ben Pope, managing director of the company. FBD actually evolved out of a barramundi pilot farm started by Pope in 2002.

“The fish we produced was marketed under the brand Fresh by Design,” recalls Pope. “But at that time, we also got a lot of new land-based fish farmers inquiring about where we got our equipment and asking us for advice on how to set-up their facilities. We sensed that there was a potential market for what we offered. A couple of years later, we left farming, kept the name and went into the design and consultancy business.”

Why would an aquatic research facility or a RAS farmer chose to have their system supplied and designed by FBD?

“Because we know what matters to them,” says Pope. “Every single member of our staff has either worked on a farm or an aquaculture research facility at some point of their career. We understand our customers’ problems and concerns and can work with them to find solutions. Clients also come to Fresh by Design for the company’s custom design expertise, adds Lachlan Bassett, general manager of FBD.

“We don’t just come and install equipment that customers specify. One of our strengths is our ability to sit down with our clients and design a solution package that’s tailor-made according to their particular needs,” says Bassett.

The company also continually conducts product assessments and field trials to ensure that equipment they recommend to clients are top quality.

FBD’s design and planning prowess shines through in projects such as the New Sydney Fish Market redevelopment. The $750-million undertaking is envisioned as a worldclass waterfront building that will showcase Australia’s aquaculture industry and the country’s seafood. Slated to open in 2023, the state-of-the-art complex is touted as a rival architectural design to the iconic Sydney Opera House.

Fresh by Design was awarded the contract to design and build the live seafood support system for the redevelopment project. The holding system will provide wet storage for a variety of species including rock lobster, abalone, coral trout, spanner crabs, and others.

The plan calls for the construction of seven holding systems equipped with media and bio filters, protein skimmers, ozone generators, UV sterilizers, heat exchangers, recirculating pumps, and other equipment.

Another noteworthy project landed by FBD was the design and construction of the world’s largest Chinook salmon research facilities for the Finfish Research Centre for the Cawthron Institute in New Zealand.

The project includes four large feed trial systems and two smaller systems that can use either freshwater or seawater. The system allows research on Chinook salmon from fry through harvest size. The flexible design also allows the system to be used for multiple fish species.

Clients of FBD also like the company’s ability to rapidly adjust its operations to ensure that customers operations are not disrupted.

For example, when the COVID pandemic broke out, FBD made the decision to double their inventory of critical equipment to ensure the company was able to continue supplying customers so that their day-today operations were not disrupted. Another strategy employed during the border closures was remote project management and installation support through digital tools such as video calls and instant messaging with clients and local contractors. This proved vital for a number of projects to be completed on time. FBD was also able to get around travel restrictions because it had a large network or offices and partners across different states in the region.

“We invested a lot in developing relationships and finding the right people to build our network,” says Pope. “It’s very important to us that we get to our customers when they need us.”

THE SOLUTION

• Nearly 20 years of excellence in RAS design and build

• Highly trained staff with first hand experience in the aquaculture industry.

• Extensive network in Australia and New Zealand

Fresh By Design

Tel. 02-486-2500

freshbydesign.com.au

sales@freshbydesign.com

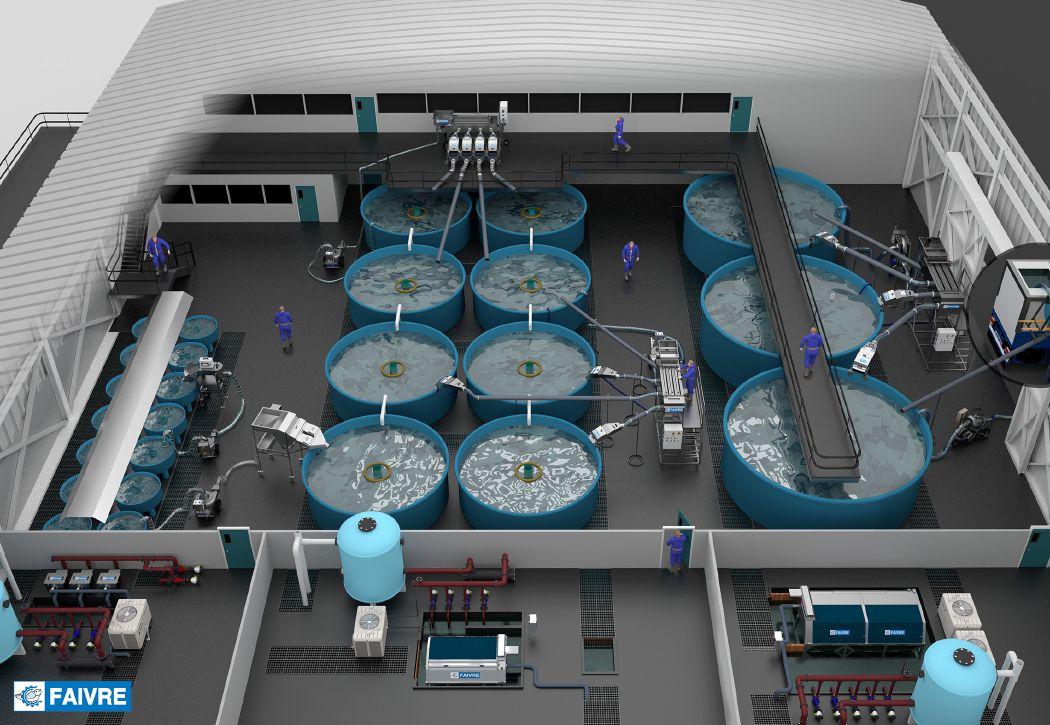

FAIVRE GROUP - INNOVATION IS KEY TO SUCCESS AND LONGEVITY

From its 6,000-sqm building complex in Baume-les-Dames in Eastern France, FAIVRE Group runs a tightly knit crew of skilled technicians, assemblers and packers to produce the high-grade specialised machines used by fish farmers worldwide.

At the heart of this complex is the mechanical design office that undertakes research and development where the company’s team of engineers and technicians develops next-generation machines that would take fish farming operations to a new level of efficiency and productivity.

To date, the most innovative machines in its portfolio are the Pescasight fish counters, which have a high accuracy rate from 98% to 100%. They are equipped with a touch-screen panel and a USB port that allows fish farm operators to store and save the counting report – whether text or video – onto a USB device.

“Our range of PESCASIGHT counters is a real innovation. They are camera-based fish counting system designed for quick and easy on-site installation at the fish pump outlet for loading trucks or for fish transfer. It can count fish as small as 0.2 grams up to 1 kilogram soon. We are developing a range of counters based on this innovation,” said Aubert Faivre, commercial director of FAIVRE Group.

A HISTORY OF FIRSTS

For nearly 65 years, FAIVRE Group has been blazing the trail in mechanized fish farming as the first manufacturer of aquaculture equipment in France. Company founder Claude Faivre, a miller and trout farmer, was seeking for an easy and quick way to sort trout. Inspired by the river-fed mill near the trout farm, he got the idea of transporting fishes in pipes and invented the first automatic fish grader in the process.

“He sold his first Calibromatics, which was patented, in 1958 and that was the start of the FAIVRE Group as we know today,” said Faivre. “We started with trout, but today, our machines are working with all types of fishes: trout, salmon, tilapia, carp, barramundi, sea bream, sea bass and eels, to name a few. We work with a view of always satisfying our customers, which means also helping them.”

Over the years, the company has diversified its product offerings to include fish pumps, fist counters, drum filters and aerators. These new types of machines have been introduced to address gaps in the aquaculture equipment market.

For example, FAIVRE Group came out with its own complete line

of drum filters (with sizes ranging from 40 cm to 200 cm) in the mid-1990s amid the growing market demand for filtration materials. The company developed its own patented technology – a new revolutionary filter plates called “spiderplates”, which delivers better performance compared with what is currently available in the market.

Another FAIVRE innovation, its Heliovision machine, combines a fish grader and a fish counter delivering two machines in a compact, movable unit.

According to Faivre, the company’s unique selling proposition is its ability to deliver a complete package of machines needed to run various stages of aquaculture operations – from nursery/hatchery, grow out to harvesting. Currently, the company has 15 packaged solutions on offer.

“This ensures that all equipment is compatible with each other. All the connecting elements (pipes, hooks etc...) are included in the package. The pump is adapted to the size and speed of the grader and the counter. All machines can be connected to the same power supply box. And the package can be modified to meet a customer’s specific requirements, Faivre explained.

GLOBAL EXPANSION

FAIVRE Group now ships its machines to over 70 countries across five continents through a network of resellers and importers and di-

rect to customers. We have very diverse customer demographics that goes from very large groups to very small fish farmers,” said Faivre. No matter the size of the project, the company remains committed to its vision: making reliable, productive and ergonomic machines that are very easy to use and fast to take in hand.

“In partnership with clients, we participate in the development of machines on the ground then we realize the machines best suited to aquaculture. Through regular contacts on the ground, user experience is taken into account that allows us to tailor make operational machines for each installation,” said Faivre.

He added that the robustness, reliability and ease of use of the machines allows the company to maintain a lean 45-man headcount because it doesn’t have to invest heavily on maintenance support.

In its six and half decades in the business, the company has sailed through the many storms that rocked the aquaculture market virtually unscathed.

“We have never really been severely impacted by any crisis; we registered a little decrease in demand during the subprime crisis. The electrical components shortage we experience since 2021 and the raw materials inflation are the challenges we currently face,” said Faivre.

Nevertheless, the company is determined

to design and build better, higher-capacity machines.

“With the help of our research and development team, we hope to bring innovation to new products. This will allow us to stand out from competitors and attract new customers,” said Faivre.

THE SOLUTION

• The new patented filter plates called “spiderplates”, which delivers better filtration performance

• Innovative camera-based Pescasight fish counter is fitted with touch-screen panel and USB port

• Packaged solutions – Various FAIVRE machines bundled in a complete package

CONTACT INFO

Aubert Faivre

FAIVRE Group

Address: 7 rue de l’industrie, 25110 Baume-les-Dames, France www.faivre.fr info@faivre-aqua.com

BRINGING RAS AQUACULTURE TO A GREENER FUTURE

Concerns about energy use and fish wellbeing in recirculating aquaculture systems (RAS) will be top of mind with consumers as they further sharpen their focus on sustainability. It is a trend that will put oxygenation at the forefront as the industry strives to meet expectations.

For Linde, reducing aquaculture’s footprint through efficient oxygenation of fish tanks while helping fish farming operations become economically viable is at the core of its technology offerings.

Although sustainability advocates tout RAS-based land-based farms as a greener alternative to other production methods, its high energy requirement is an unsettling reality.

“RAS technology is not exactly a cheap technology. One of the biggest challenges of making a RAS plant economically interesting is energy consumption,” says

Stefan Dullstein, Head of Aquaculture and Water Treatment, Linde Gases Division.

“Most of the energy is required to pump the water in a loop, getting it through the biofilters, creating the hydraulics in the fish tank,” he continues. “And, in order to dissolve the oxygen, you need a certain pressure or waterhead to get the oxygen into the water – that’s something we have a very strong focus on. So, it is rather how the technologies come together and the way we deliver them that RAS plants become economically interesting.”

Dullstein acknowledges the central role oxygenation technologies play in RAS operations. After all, “if you don’t get the oxygen right, you’ll never get the rest of it right,” he says.

And while indeed there are other companies that provide oxygenation technolo -

gies, only Linde has an innovation center dedicated to the aquaculture industry, noted Dullstein.

Located in Ålesund, Norway, the Linde Innovation Center is where it all happens. From concept to prototyping to rigorous testing under various simulated conditions, the company’s product offerings are optimized at the center. A highlight is a 55m 3 tank that allows both aquaculture technologists and customers to observe how the latest oxygenation technologies impact fish development within an optimal on-land farming enclosure.

“It’s where we could run performance tests on gas dissolving equipment and see its limits under any kind of conditions one might find in fish farming – cold water, warm water, freshwater, sea water to even up to what we call the ‘Red Sea,’ where it’s really hot and very salty. This allows us to

develop a very in-depth expertise on all the equipment that may be used by customers,” says Dullstein.

Beyond dissolving the gas, questions regarding how its oxygenation technology interfaces with fish density are also explored by the R&D team. “You have to understand how the entire production process of the customer is done when the fish is at a certain size. How fast do they swim? What is the stocking density of the fish in the fish tanks? That will require a certain water exchange rate in the fish tanks. It also requires a certain swimming velocity for the fish in the tanks, and that is something which we can deal with, with our equipment,” he says.

The state-of-the art R&D center is also where an essential tool in the RAS industry was developed: the SOLVOX® Oxystream, a highly energy-efficient oxygenation system for sea water, brackish water and freshwater tanks. It oxygenates the water and evenly distributes it around the fish tank using an adjustable flow regime.

“Both the research and development and the subsequent

testing of the latest oxygenation technologies is unquestionably needed to ensure the future success of land-based aquaculture. Our entire infrastructure enables us to supply not just the technologies but also the know-how,” Dullstein highlights.

He is excited about the future of RAS aquaculture and the role Linde plays in its evolution. But with the growth of the sector come new challenges.

“With increasing size comes the challenge of scale-up,” Dullstein concurs. “This is among the latest challenges or, as we call it, ‘research paths.’ RAS farms are growing in size almost year by year or quarter by quarter. Three to four years ago, a farm producing 3,000 tons a year was considered large. Today, a lot of projects are in the range of 5,000 to 10,000 tonnes a year. Some are even 20,000 tonnes a year. So now we’re working on a project to scale up our flagship oxygenation product, the SOLVOX® Oxystream, to the size that customers will require in the future.”

Dullstein expects the company’s market to expand as

the sector grows. Linde’s name recognition and global presence puts Linde in good stead.

“This is what makes the RAS industry very appealing for us: our global reach,” he points out. “We are present in more than 100 countries. We can serve customers regardless where they want to have their next project.

“The aquaculture industry is becoming more and more global. We see that when we go to fairs, it’s mostly the same people, whether we meet them in Norway, in Chile, in Central Europe or in the US. It’s a small community that acts globally and, excitingly, we are part of it,” he concludes.

Dr. Stefan Dullstein is Senior Technology Expert in Aquaculture at Linde. He started at Linde in 2001 as an Application Engineer following studies in Process Engineering at the University of Stuttgart, and received his PhD from the University of Bremen in 2005. Stefan speaks three languages (German, English and French) and enjoy movies, literature, and hiking in his free time.

• Gas dissolution technologies •Network of air separation plants

• Oxygen supply to meet needs

Linde 10 Riverside Drive Danbury, CT 06810 toll free: (844) 445-4633 (1-844-44LINDE) contactus@linde.com lindeus.com/aquaculture

TOP-GRADE MODULAR SOLUTIONS FOR IN-SHORE AQUACULTURE

Operating from a 140,000, square-foot facility and employing 150 technicians and personnel, Structural Armor WRS serves a growing clientele of land-based aquaculture operators across the United States.

Structural Armor entered the aquaculture space in 2017, but don’t let its young age fool you. The company draws from a well-established pool of water retainment systems (WRS) expertise develop by Indiana’s Trivector Manufacturing, a leading innovator in fibre-reinforced composite walls and WRS technology since the late 1970s. Structural Armor is also using Trivector’s network to spread its reach to the overseas aquaculture space.

Structural Armor specializes in building compress molded, fibre-reinforced composite tanks using a patented modular design. The company also offers a variety of finishing options such as thermo polymer coating which is of NSF/ANSI61-complient and pH-neutral, fish-grade Epoxy paints and aquatic liners with developed in-house.

The company designs WRS for both recirculating aquaculture systems (RAS) and non-RAS grow-out tanks and hatchery runway systems.

Among the company’s notable projects was its installation last

year of 10 tanks for Benchmark Genetics’ shrimp RAS project in Florida. There are plans for Structural Armor to install 10 more tanks in the near future.

What advantages does Structure Armor offers its clients?

Four main things, according to Daniel Epple, vice president of Trivector: strength and durability, customizable design, rapid installation, and low price.

The company’s compress molded tanks were developed in-house from technology and experience obtained from nearly 40 years of WRS engineering and enhanced for aquaculture implementation.

The fibre-reinforced composite panels are bolted and bonded together with 3M marine adhesive sealant and anchored and secured with a footer. The panels are corrosion resistant and strong enough to endure any weather conditions. This makes them ideal for indoor or outdoor use. The material is designed to give the option of inground or on-ground applications.

The company also uses a patent protected formulation that strengthens its water retainment system panels. The same composite used by the likes of Toyota, NASA, and Boeing is built into Structural Armor‘s fibre reinforced composite panels.

The company also developed a snap-in, non-pleated liner which helps farmers get production up and running sooner, with less long-term issues. The product eliminates hard-to-clean folds where debris and waste can accumulate. These liners are easily interchangeable. Two workers can easily remove and replace a liner after roughly just an hour of training with Structural Armor staff, according to Epple.

He likens the installation of Structural Armor tanks to building Lego blocks.

“Our systems are modular. We can build them to client specification in any size and shape,” says Epple. “This also cuts down on installation and take down time, making it easy for our customers to add to or remove components and move around the pieces whenever and wherever their business needs require.”

At a recent project, a shrimp farm owner in Florida told Epple that it took up to four of his employee two weeks to assemble and install a single round tank. “It took me and just one of our staff, one afternoon to install one of our 12-foot round tanks for him,” Epple recalls.

Structural Armor tanks and components are also cheaper and easier to transport. The company’s systems are typically ready to ship in as little as five business days.

For example, the company’s 24-foot road tank and liner can fit in two pallets. There’s

no need to arrange custom shipping “it can share a ride with other cargo, you cut down on gas and carbon footprint,” the Structural Armor executive says.

Since Structural Armor develops and manufactures their products in-house the company is able to pass on saving to customers in the form of prices, according to Epple. “We can provide out customers comparable or better products at a lower cost to what competitors offer.”

Epple is proud of the Structural Armor team’s ability to think outside the box. He says company designers and planners will discuss with clients their specific needs and do their best to find the applicable solutions. “We customize installations for them. Our team can also recommend alternative solutions to their problems.”

Structural Armor’s job does not end with the installation. The company also provides the staff training and maintenance service needed to keep systems running smoothly, according to Epple.

“Before we leave the site, we make sure that our customer’s staff are trained on how to use and maintain our products,” he says. “And if any issues arise, we have a customer service department dedicated to responding to their call. I head that department, so customer satisfaction is my personal responsibility.”

THE SOLUTION

• Water retainment system expertise stretching back 40 years

• Innovative and reliable products developed in-house

• Rapid installation and customizable systems

Structural Armor WRS Tel. 260-637-0141 www.structuralarmor.com

BUILDING SOLID SOLUTIONS SINCE 1987

OxyGuard’s mission statement is simple: it is dedicated to aquaculture and not only as a business, but to make a difference.

“Ebbe Höffner started the Danish company in 1987,” says CEO Paw Petersen. “At the same time, my parents were building a fully recirculated eel facility. As a kid, I was helping my parents on the farm, it was my first encounter with fish farming.”

Later on, while studying to become an engineer specializing in embedded software, he worked at OxyGuard during the summer and cleaned the office on the weekends. His graduation project was OxyGuard’s first digital hand-held oxygen meter –Delta (in 1996). Shortly after graduation, Petersen was hired at OxyGuard and became the company’s first engineer. In 2000, he purchased the company.

Today OxyGuard offers a wide range of products, ranging from single parameter sensors to hand-held instruments to complete process control systems that can manage the whole fish farming facility. Around 30-40 products are the ones we sell most. The standard price list includes approximately 200 titles, excluding the special products. Special products are usually developed in co-operation with the specific customer, according to their needs.

OxyGuard is world-renowned, with customers in more than 120 countries every year. Sixty-five international distributors

help with local sales. Petersen says he takes customer support very seriously; that is why he chose to have international distributors who can offer customer care in the local language and time zone.

Most customers are fish farms, but we have several customers in other industries. For example, GE-power is one of our largest customers, ordering several thousands of probes per year.

The question: Does your instrument measure correctly?” is asked most often when measuring dissolved oxygen. Petersen admits it is challenging to prove that it is measured correctly. It is also the essential parameter for the fish farmers, as it is directly related to FCR (Feed Conversion Ratio). OxyGuard’s instruments are used both in nuclear power and even NASA has purchased. The company has instruments that can measure 1,000-10,000 times lower than what are measured in fish farms.

“Today we also get a lot of questions regarding CO2 and ozone,” Petersen said.

OxyGuard has been through three phases in 35 years. The first phase holds the idea the company can survive - the second phase is more about production, sales, and shipping. The third phase is about development and “leading the way.” OxyGuard is a production company, but over 30% of the employees only

work in R&D, which is a very high number for a production company.

Polaris (hand-held instrument) and Commander Pacific systems are among the most popular products, which have helped many fish farmers over the years.

“Our equipment is known for keeping the investment value.” Petersen says. “There is a lot of equipment delivered over 35 years that we can still repair. We also update all the time. For instance, the latest hand-held instrument Polaris C has many new features.”

Danish Salmon is a revolutionary project, where the entire growth of the salmon takes place on land using OxyGuard measuring, monitoring, and control equipment for recirculating aquaculture systems. The aim is to achieve sustainable production of salmon without damaging the environment.

Petersen said OxyGuard

controls all the equipment on the facility - starting with oxygen regulation and continuing with pumps, feeders, lights, and everything the customer needs.

“We work with the local electrician, who builds our control into the motor control cabinets (MCC), and then we start and stop everything that is in ‘Auto.,’ he said. “All this occurs in close collaboration with the customer or the plant builder.

According to the number of the sensors, the Eel Ras is the biggest in the world. However, eel is farmed in much smaller tanks than salmon, and there are many more tanks needed for 15,000 tons of eel than for 15,000 tons of salmon.

The number of input/output/sensors (I/O) are counted in the thousands in such a project. Salmon projects need up to 100,000 tons to reach the same number of I/Os, depending on how they are built.

THE SOLUTION

• Meets new and changing needs in aquaculture sector

• Monitors the water quality conditions in recirculating systems.

• Contributes to successful fish production in ponds

CONTACT INFORMATION Office address: Farum Gydevej 64 3520 Farum, Denmark

www.oxyguard.com

Phone: +45 4582 2094

Email: oxyguard@oxyguard.dk

Improve aquaculture water with UV and Ozone

After more than twenty years pioneering the use of environmentally safe water treatment technologies across a diverse range of industries, from shipping to municipal water works, pools, aquariums, and water parks, Francebased BIO-UV Group is now carving a niche in the global aquaculture and fisheries segments.

BIO-UV Group designs and manufactures water treatment and disinfection solutions using ultraviolet, ozone and Advance Oxidization Processes (AOP), employing more than 150 water industry professionals at facilities in France and Scotland.

A major milestone for the company came in 2011, when BIO-UV Group launched its BIO-SEA ballast water treatment system, rapidly gaining a strong foothold in the market for vessels.

Following significant success in this market, the company adapted its ground-breaking UV technology to meet the rigorous and more regulatory demanding requirements of the aquaculture and wellboat sectors. R&D led to the introduction of BIO-UV Group’s Integra UV range – a completely new UV water treatment system specifically designed for wellboats and fish farms.

With a control cabinet certified for use in marine environments, the robust Integra UV system is designed to ensure saltwater and freshwater farms benefit from effective, chemical-free water treatment/disinfection without the high energy consumption associated with other UV systems.

“Water quality is critical to any aquaculture operation, be it on land, in rivers and lakes or in coastal waters,” says Patrick-Jean Pichavant, Sales Director for the BIO-UV Group’s opera-

tions in Europe and Africa.

“Our customers want to avoid the use of any harmful chemicals and ensure a safe environment in the fish habitat. This is where UV and Ozone-based water treatment is effective. UV-C radiation penetrates into the cells of bacteria and other micro-organisms, disrupting the DNA to prevent reproduction.

BIO-UV Group’s entry into the global aquaculture market took a further step forward with the acquisition in 2019 of triogen®, the Scotland-based manufacturer of ozone and AOP systems.

“The acquisition enabled us to reinforce our worldwide positions, enhance our product ranges and technologies, and expand our distribution network,” says Pichavant. “We now have ozone and AOP water treatment systems for flow rates ranging from 0.5 to 7,000m³/h. The system is very easy to install and maintain.”

Ozone breaks down particles in the water recirculation systems commonly used in aquaculture facilities and fish farms. The ozone is generated by corona discharge and then dissolved into the water. This causes an oxidation of organics and inorganic materials in the water. The process also increases the concentration of dissolved oxygen in the water.

“UV-C and Ozone are both exceptional standalone water disinfection technologies for use in Recirculating Aquaculture Systems (RAS). Both technologies disinfect and remove unwanted contaminants – reducing water consumption, improving fish health and yield, and ensuring biosecurity for the facility. When combined into a single system, the two technologies become an Advanced Oxidation Process (AOP), providing a multi-barrier ap-

proach to disinfection, leaving no chemical trace, and removing an even wider range of organic and inorganic contaminants,” explains Simon Marshall, Managing Director, triogen.

Asked about what clients like about working with BIO-UV Group, Pichavant said it’s the company’s ability to meet every demanding projects.

“We have technicians and partners all over the world, committed to servicing and offering local support to BIO-UV Group’s customers. We can provide a packaged solution. Not only can we design and manufacture the system but also rely on our partners to deliver, install and provide after sales service globally. Answering tenders is one thing. Being there for the customers two, three or more years later is different.”

WATER TREATMENT SOLUTIONS

• More than 30 years of expertise in UV and Ozone water treatment system

• Technicians and partners all over the world

• Responsive and flexible teams able to meet every demanding projects

How your oxygen source can improve RAS reliability, efficiency and

social

One of the costliest mistakes that can be made by large-scale aquaculture farmers new to Recirculating Aquaculture Systems (RAS) is to underestimate the importance of appropriate and reliable oxygen source. Oxygen is the first limiting factor in RAS farming wherein insufficient oxygen levels can quickly kill most fish and other useful aquatic organisms raised in high volumes in indoor tanks under a controlled environment.

Jim Flaherty, president and CEO of Adsorptech LLC, has traced the culprit to a lack of knowledge by RAS designers, Engineer, Procurement and Construction (EPC) service providers, as well as equipment suppliers, owners, and operators.

Flaherty said, “RAS technology for large farms is relatively new, and the school-ofhard-knocks is taking its toll on them. The conventional belief was that the near-exclusive viable liquid oxygen (LOX) supply was 100% reliable. However, this was proven false when the pandemic triggered supply chain issues and the resulting global LOX shortage caused panic across the aquaculture industry.”

RAS farmers are beginning to realize that as their operations continue to grow, so does the need for alternative oxygen sources. This is where Adsorptech’s expertise comes into play.

As a US-based and global supplier of EcoGenTM oxygen-generating Vacuum Pressure Swing Absorption (VPSA) equipment and consulting firm, Adsorptech offers solutions that can generate highly efficient and highly

reliable operations while achieving economic, environmental and social sustainability.

Flaherty said that, unlike LOX which has no implications related to the oxygen specifications such as quantity, purity, pressure, and redundancy, the Adsorptech’s EcoGenTM oxygen VPSA offers RAS farmers many benefits including:

• The lowest lifecycle cost of oxygen which includes the cost of installation, utility, maintenance materials, and other labor costs for RAS facilities requiring 150kg/hr. or more of oxygen.

• Most power efficient source of oxygen in the world

• Built-in cost-effective redundancy with no water utility requirements for improved oxygen supply reliability.

Adsorptech’s EcoGenTM oxygen VPSA has been deployed in many RAS aquaculture farms, gold and silver mines, oil refineries, wastewater treatment, non-ferrous metals smelting, glass, and contributing to the development of carbon capture and waste-to-energy technologies.

EcoGenTM can be operated remotely and Adsorptech offers customers global remote support. The company is also actively expanding international distributorship to provide in-country services.

Flaherty hopes that in the near future all the players in the RAS ecosystem will understand how each RAS farm component properly fits into the entire farm puzzle to achieve maximum sustainability.

THE SOLUTION

• Large-scale fish farmers new to RAS will likely make costly mistakes if they do not understand the importance of appropriate and reliable oxygen source.

• As the global supplier of EcoGenTM oxygen-generating Vacuum Pressure Swing Absorption (VPSA) equipment, Adsorptech enables RAS farmers to operate highly efficient and reliable farms while achieving economic, environmental and social sustainability

• One distinct advantage offered by Adsorptech Inc. is its capacity to operate globally and remotely, thus breaking logistic barriers to business.

James Flaherty

Adsorptech LLC

Address: 22 Stonebridge Rd, Hampton, New Jersey, USA (Sales Office)

Telephone: +1 908 735 9528

Email: james.flaherty@adsorptech.com www.adsorptech.com

The 2022 RAS Virtual Summit will deliver executive insights, highlight best practices and provide opportunities for attendees to engage with RAS experts through an innovative online platform. Featuring live presentations, Q&A sessions and panel discussions, plus a host of on-demand presentations from some of the industry’s leading RAS practitioners and experts, this annual virtual event will give RAS farm managers, owners and investors some valuable take aways to consider.

RASTECH SPONSOR SHOWCASE•