SOLVING THE SAFETY RISKS OF GAS AND CORDS ON THE JOBSITE

HOW MILWAUKEE TOOL HELPED BASECRETE GO CORDLESS

When Basecrete first launched in 1998, the Toronto-based company focused on serving the concrete drain market. As the business grew, so did the company’s ambitions. In 2012, Basecrete expanded into low-rise concrete forming. With both divisions experiencing steady growth over the following years, the company expanded again in 2023 adding excavation services to its portfolio.

“The reason we did that is because the three are combined on site and builders like having one company overseeing all three aspects of this part of residential construction,” explains Tony Smeriglio, president of Basecrete Inc.

Facing Health and Safety Challenges Head-On

The company performs a great deal of concrete forming work for basements and other underground walls and floors, primarily for residential, commercial, and industrial construction contractors. While the growth of the business has been substantial, it hasn’t come without its challenges. One of those challenges is ensuring all occupational health and safety measures are meeting Ministry of Labour requirements.

In basements and other confined spaces, air flow can be restricted, making gas-powered trowels less than ideal.

“Fumes in confined places like basements have become a big issue with the Ministry. It's been one of the topics that they've been looking at, and it's really grown over the last four or five years,” Smeriglio explains.

While operating gas-powered equipment in these spaces, employees needed to carry around carbon monoxide detectors and often reported headaches during long shifts. Since carbon monoxide is invisible and odourless, it strikes without warning, mimicking other illnesses as it silently replaces oxygen in the blood. Basecrete sought a solution and considered electric-powered equipment, but corded tools presented their own challenges.

With corded equipment, workers need to have power on site to operate the trowels. However, laying out extension cords across jobsites often leads to accidental damage, creating unnecessary headaches. “Running extension cords back and forth is very hectic. Cords get broken, they get cut, and then the guys patch them up with tape. We're always replacing those cords because they get damaged. The lifetime of a cord is maybe a month and a half,” says Smeriglio, adding that his company used to get written up regularly by occupational health and safety officers for damaged extension cords.

I don’t think we will be using anything that’s electric or gas anymore on sites “ ”

The High Price of Trips and Falls

According to Ontario’s Workplace Safety & Prevention Services’ “Slips, Trips and Falls” article published in 2023, there are approximately 17,000 lost-time injuries due to falls in the workplace. About twothirds of those injuries are same-level falls, typically caused by tripping hazards, slippery or uneven surfaces, debris, dark or obstructed pathways, and unsuitable footwear.

In Ontario, about 80 workers are injured by falls every day. The cost of these claims is incredibly high.

In 2023, an average Workplace Safety and Insurance Board (WSIB) claim was $11,771, and this doesn’t include the added costs of lost productivity and staff replacement. According to WSIB data referenced within the article, that can cause the costs to rise to approximately $59,000 per injury.1

Many contractors are trying to reduce the number of extension cords being used on active jobsites, as they create additional tripping hazards for workers.

Fortunately for Basecrete, these types of trips and fall injuries have not been common to date, but the company remains committed to removing as many extension cords from its jobsites as possible.

Finding a Cordless, Emission-Free Solution

While attending World of Concrete in Las Vegas, Smeriglio found a promising solution to this issue – Milwaukee® Tool’s MX FUEL™ 36" Walk-Behind Trowel Kit. “Contractors who have adopted the MX FUEL™ 36" Trowel consistently point to lower operating costs, reduced downtime, and improved crew comfort. Beyond those benefits, eliminating carbon monoxide exposure addresses one of the greatest ongoing health hazards in concrete finishing, proving that innovation in equipment can drive both business impact and worker safety,” says James Mitchell, director of product marketing, Milwaukee® Tool Canada.

The potential for having cordless, emission-less trowels on jobsites was enough for Basecrete to invest in one machine to see how it would perform on their projects in comparison to the company’s gas-powered models. Smeriglio was impressed with the results.

“Surprisingly, you could not tell the difference. It's been excellent in that sense,” he says. “It works the same. It's just as good as a gas-powered machine.”

In addition to matching the performance of gas-powered machines, the cordless Milwaukee® unit has offered additional benefits such as cost savings from no longer needing carbon monoxide detectors, fewer extension cords on site, and some efficiency gains.

“You're saving time by not pulling out the extension cords and you don’t need to have power. That solves a lot of problems on sites that don’t have power when we start, so they have multiple generators. That always becomes an issue,” Smeriglio says. “Now the guys go to work, and the tools are charged. So, everything's fine.”

Building a Sustainable Future

Over the past several years, Basecrete has invested significantly in Milwaukee®’s various lines of cordless tools. The biggest drivers for brand loyalty have been excellent service, responsiveness to feedback offered, and reliable, interchangeable batteries.

“Having the same batteries has been the best thing ever,” Smeriglio says. “Our trucks carry six or seven pieces of equipment, a lot of different items. If you must have six or seven chargers, it's terrible.”

He adds that investing in battery-powered solutions aligns with the company's sustainability and OH&S goals.

“I'm switching all my equipment slowly. There's a handful of things that we have that are gas or electric. We're just waiting for Milwaukee® to come up with cordless versions, and we'll be switching over.”

In the future, Smeriglio believes all the tools his crews operate will be battery powered.

“I don't think we will be using anything that's electric or gas anymore on sites,” he says. “The equipment is getting better. It's either better than gas or equivalent to it.” 1 (Source:

SUSTAINABILITY AND RESILIENCE

Balancing carbon reduction with long-term durability, construction is turning to advanced concrete admixtures to build safer, stronger and more sustainable infrastructure.

BY JAFAR RASHIDI, CHRYSO CANADA

SENIOR TECHNICAL SERVICES SPECIALIST & LISA BARNARD, LEED AP, WELL AP, CHRYSO NORTH AMERICA

Sustainability has become the construction industry’s defining challenge. From embodied carbon accounting to net-zero targets, contractors, designers and material suppliers are all grappling with ways to lower emissions while keeping projects on budget and on schedule. Concrete, as the world’s most widely used building material, sits at the centre of this conversation.

Cement, concrete’s binding ingredient, is responsible for roughly seven per cent of global CO2 emissions. For many stakeholders, it’s “the elephant in the room.” But the path forward is not about eliminating concrete, it’s about producing, specifying and using it smarter. That’s where admixtures deliver new solutions, helping to reduce cement content, improve performance and integrate new supplementary cementitious materials (SCM).

Yet, there’s a missing dimension in today’s sustainability dialogue: resilience. It’s not enough to focus only on reducing environmental harm. We must also ensure our structures can withstand hazards of fire, flood, wind and seismic events. In short, true sustainability requires resilience.

RESILIENCE: THE MISSING HALF OF SUSTAINABILITY

In 2015, three landmark frameworks emerged from the United Nations: The Sustainable Development Goals, the Paris Agreement

and the Sendai Framework for Disaster Risk Reduction. While the first two frameworks have managed to capture widespread attention, the Sendai Framework, despite its direct relevance to our built environment, remains underutilized in mainstream construction dialogue.

Why does resilience matter? Because a “green” building that fails during the impacts of a wildfire or hurricane is not sustainable at all.

Rebuilding doubles the carbon footprint, displaces communities and disrupts economies. Data from Saint-Gobain’s Sustainable Construction Barometer underscores the shift: resilience is gaining traction globally, particularly in regions exposed to natural hazards. The percentage of respondents prioritizing resilience to

climatic events jumped to 21 per cent, the largest increase recorded to date.

Concrete plays a central role here. Its inherent fire resistance, structural integrity under seismic stress and durability in waterand wind-prone regions make it indispensable for resilient construction. From seismic-resistant foundations in Mexico City to hurricane-rated walls in Florida, concrete continues to prove itself as one of the most hazard-resilient materials available.

The Canadian Climate Institute reports that every dollar spent today on climate adaptation can return $13 to $15 in direct and indirect benefits over time. For the construction industry, investing in resilient infrastructure isn’t just smart planning - it’s a long-term gain for both communities and the economy.

Advances in admixtures are enhancing sustainability efforts.

A LEVER FOR CARBON REDUCTION

In practice, a sustainable concrete mix should look and perform just like a conventional one. The difference lies in how it is optimized behind the scenes. The goal is to minimize the carbon footprint by reducing cement, maximizing SCMs and using local resources. Admixtures are the enablers of this shift, unlocking multiple pathways to cut carbon without compromising performance. Four strategies illustrate how:

1

CEMENT REDUCTION THROUGH STRENGTH ENHANCERS

Admixtures like strength enhancers enable producers to achieve equal or greater performance with less cement. High-range water reducers and like EnviroMix SE deliver early and late strength gains of 2.4–4.0 MPa, allowing up to 10 per cent cement reduction without compromising quality.

2 MAXIMIZING SCM USE

Supplementary cementitious materials, including metakaolin and waste-stream products, are increasingly used. Admixtures offset challenges like slower strength gain or higher water demand, enabling greater cement replacement while maintaining performance.

3 OPTIMIZING LOCAL MATERIALS

Declining access to high-quality sand drives the use of manufactured and marginal local sands. Admixtures, such as the ChrysoQuad line, improve workability, reduce variability and lower transport emissions.

4 ENABLING CIRCULAR ECONOMY PRACTICES

Products like ChrysoConvert C recycle returned concrete into usable aggregates. Together, these strategies lower carbon while maintaining performance.

PERFORMANCE UNDER EXTREME CONDITIONS

In Canada, sustainability solutions cannot be divorced from performance. Alberta illustrates this reality vividly. With temperatures swinging from -30°C in the winter to +30°C in the summer, producers face

unique challenges: hot, dry and windy conditions in summer lead to plastic shrinkage cracking and rapid slump loss, while extreme cold creates curing difficulties. Effective curing has long been a challenge in this region, and concrete mixes must be designed to maintain durability across these extremes.

Canadian standards provide clear guidance on these challenges. The National Building Code of Canada (NBCC) requires that concrete structures are designed for expected temperature ranges, wind loads and snow/water loads over their intended service life. Additionally, CSA A23.1 cold weather and hot weather concreting guidelines set limits on concrete placement, curing methods and admixture use to maintain performance in extreme climates.

Admixtures are essential to meeting these demands. They extend slump life, improve finishability and support mixes that achieve reliable strength gain even under punishing conditions. In addition to workability control, durability remains a central requirement in the Canadian climate.

Air-entraining agents play a critical role by creating an engineered air-void system with proper spacing factor and distribution. This controlled microstructure allows internal pressure relief during freeze–thaw cycles and improves resistance to salt scaling - a major durability concern in regions where de-icing salts are widely used. Crucially, sustainable concrete must look and act like conventional concrete. Contractors should not have to compromise workability or strength in exchange for carbon savings. By tailoring mixes with advanced admixtures, we can ensure that sustainability and

performance are aligned, even in one of the world’s most demanding climates.

RESILIENCE TOOLS:

BUILDING RESILIENCE INDEX

Material science, however, is only half the picture. Measuring resilience in a systematic way is equally important if we are to balance carbon reduction with long-term durability. This is where tools like the Building Resilience Index (BRI), developed by the International Finance Corporation, come in.

Unlike green certifications that focus mainly on mitigation, BRI evaluates a building’s ability to withstand four major hazards: wind, water, fire and geoseismic activity. A sustainable concrete mix must never mean weaker concrete. With advanced admixtures - strength enhancers, water reducers and SCM-enabling technologies - we can lower carbon while ensuring structures perform under extreme conditions.

While BRI provides a useful global framework, the concept of resilience takes on a unique urgency in Canada. The country already faces some of the most aggressive climate stressors in the developed world: record wildfire seasons in British Columbia and Alberta, catastrophic flooding in Quebec and New Brunswick, coastal erosion in Atlantic Canada and accelerated freeze-thaw deterioration in the Prairie provinces due to increasing temperature variability. These events have triggered a national shift from reactive repair to proactive resilience engineering, not only for buildings, but also for highways, water systems, transit networks and energy infrastructure.

Unlike many countries that rely solely on voluntary sustainability programs, Canada is

Sustainability and resilience are transforming concrete construction.

IMAGES COURTESY OF CHRYSO NORTH AMERICA.

formalizing resilience in codes, policy and public procurement. The Climate Resilient Buildings and Core Public Infrastructure (CRBCPI) initiative, led by the National Research Council of Canada (NRC), has introduced engineering guidance that goes beyond historical weather data by using future climate models that project performance over a 50 to 75-year service life. The goal is to design for evolving climate loads, more severe freeze–thaw cycles, higher rainfall intensity, wildfire heat exposure and longer durability expectations, all of which have direct implications for concrete specification and mix design.

As a practical outcome, resilience is now embedded in Canadian construction standards. The CSA S6:25 Canadian Highway Bridge Design Code requires climate resilience assessments and hydrological risk modeling. CSA A23.1/A23.2 concrete standards emphasize exposure class–based durability, stable air-void structure and resistance to chloride penetration and sulphate attack, critical for marine,

transportation and northern construction environments. Provinces like Ontario and British Columbia now include resilience criteria in public infrastructure tenders, meaning ready-mix producers and specifiers must demonstrate durability performance, not just compressive strength.

Canada also recognizes that resilience is not only a materials issue - it’s a societal and economic priority. Through the federal Disaster Mitigation and Adaptation Fund (DMAF), resilience metrics are now tied to eligibility for major infrastructure funding. In Northern Canada and Indigenous communities, climate resilience strategies prioritize reliable performance in extreme environments where permafrost movement, remoteness and short construction windows present unique engineering challenges. In these regions, the durability of concrete relies heavily on technology-enabled mix designs, including low-temperature accelerators, shrinkage-reducing admixtures and engineered air-entrainment systems that improve resistance to freeze-thaw damage and surface scaling.

A HOLISTIC VIEW: SUSTAINABILITY + RESILIENCE

The conversation should not pit carbon reduction against resilience. In fact, they reinforce each other. Durable structures mean fewer rebuilds, avoiding the “hidden carbon” of reconstruction. Concrete, properly designed with admixtures, can meet both mandates: lowering embodied carbon while delivering superior resilience.

The construction sector is entering a new era. Net-zero goals remain urgent, but they must be paired with resilience benchmarks to ensure buildings can withstand tomorrow’s hazards. Tools like BRI, combined with admixture-driven low-carbon solutions, offer a way forward.

For the Canadian construction industry, success will depend on collaboration between engineers, producers and policymakers. And with the right technologies and mindset, we can build a future that is not only lower carbon but also stronger, safer and more resilient.

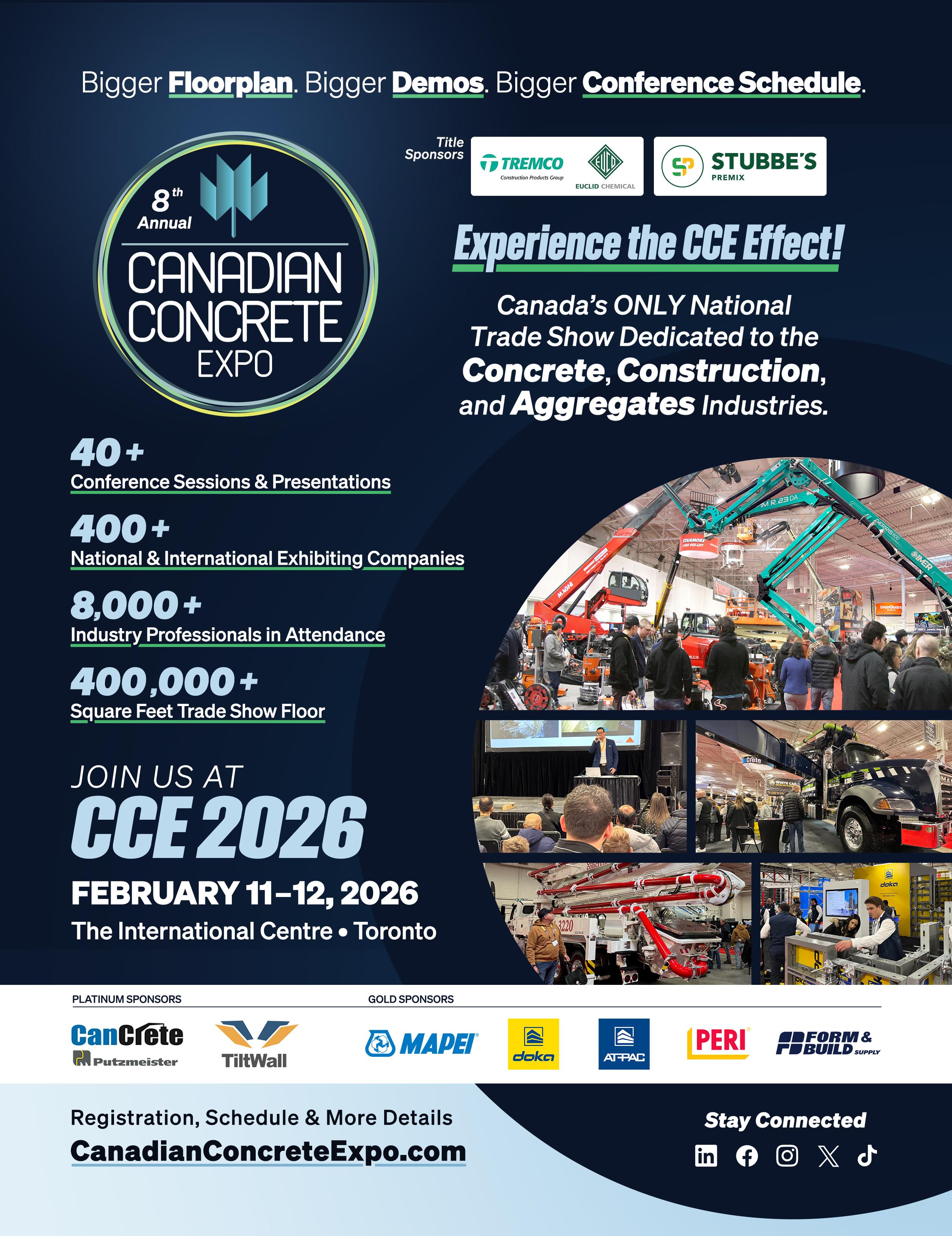

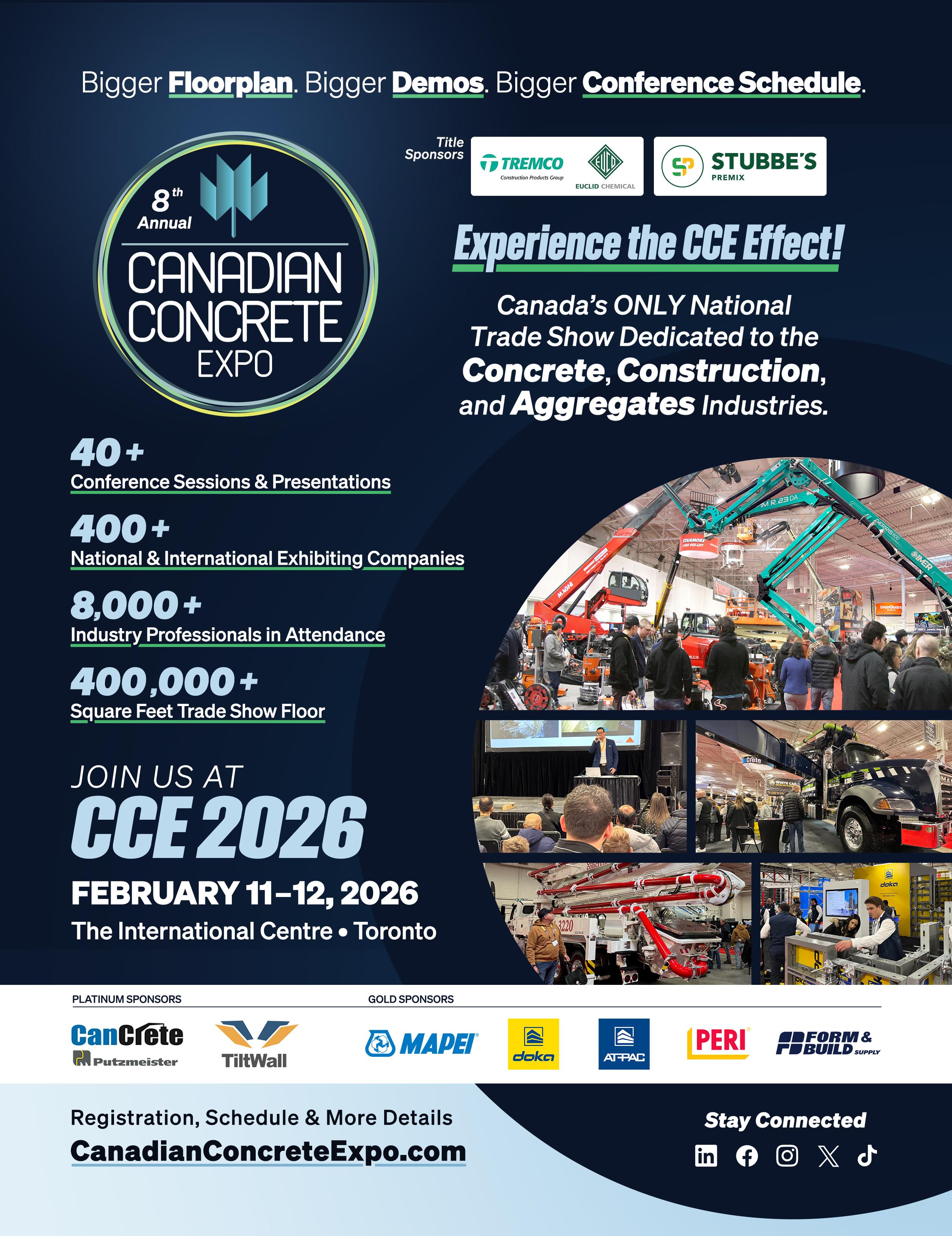

Building Momentum

LEARNING AND LEADERSHIP

CCE 2026 will host 40 sessions covering technical and business topics, including formwork design, admixture innovation, curing technologies, recruitment, succession planning and attracting Generation Z to skilled trades. “Labour shortages are a major challenge, so we’ve added practical sessions on hiring, retention and workforce planning,” Galloway notes. “The combination of education and hands-on demos keeps attendees returning.”

BUILT FOR NETWORKING

CCE’s Canadian focus creates a tightknit, productive networking environment. “Canadian contractors often feel out of place at Vegas shows,” says Galloway. “Here, they know the suppliers and competitors. Connections happen organically on the floor, in sessions and in demo areas.”

A ONE-STOP SHOP

The Canadian Concrete Expo continues its remarkable growth.

BY SEAN TARRY

Since its launch in 2018, the Canadian Concrete Expo (CCE) has grown from a niche gathering into Canada’s largest dedicated event for the concrete, aggregates and construction sectors. Preparing for its 2026 edition, the show remains a key meeting place for contractors, suppliers and design professionals nationwide.

For Stuart Galloway, CCE’s President, the rapid growth demonstrates Canada’s need for a home-grown alternative to U.S. trade shows. “The show grows about 20 per cent each year. Canadian companies want an event that speaks to their needs without heading to Las Vegas,” he says.

EXPANDING IN EVERY DIRECTION

The 2026 Expo will expand by 100,000 square feet, bringing total exhibit space to nearly 400 exhibitors. Attendees will see heavy equipment, formwork systems, software, materials and emerging technologies. International companies, including French firm Selfbeton with its automated concrete dispensing system, are debuting at the show.

THE ONLY INDOOR EQUIPMENT DEMO AREA IN CANADA

A hallmark of CCE is its indoor demo space. For 2026, it quadruples from 25,000 to 100,000 square feet, letting visitors operate telehandlers, concrete pump trucks, material handling gear and power tools. Major brands such as Milwaukee and DeWalt will showcase cordless tools and new safety features. “People can put equipment in their hands, touch and feel the tools, and that makes all the difference,” says Galloway.

The Expo caters to both newcomers and veterans, offering opportunities to learn, network, and grow. “If you’re serious about Canada’s concrete and construction industry, you’ll find value here - whether it’s new equipment, services, partnerships or knowledge,” Galloway emphasizes.

LOOKING AHEAD

As the Canadian construction industry navigates shifting tariffs, the federal government’s “Buy Canadian” policies, and global economic uncertainty, Galloway remains optimistic that the Expo’s continued growth mirrors the strength and resilience of the industry it serves.

“Despite the challenges, we’re seeing companies refocus on Canada and invest here,” he says. “That’s exactly what the Canadian Concrete Expo is about - supporting Canadian business, innovation and community.”

The 2026 Canadian Concrete Expo promises to be the show’s biggest and most dynamic edition yet - a true showcase of where Canada’s concrete and construction sectors are heading.

Building through THE FREEZE

THE SCIENCE BEHIND WINTER CONCRETING IN CANADA

Cold-weather concreting demands science-driven techniques, advanced admixtures and strict temperature control to maintain strength, durability and productivity throughout Canada’s increasingly harsh winter conditions.

BY MICHAEL MAHONEY, CENTRAL REGION MANAGER OF THE

As Canada’s construction season stretches deeper into the winter months, concrete contractors face one of the industry’s oldest challenges: balancing productivity with performance when temperatures fall below freezing. From Ontario’s lake-effect snow to the subarctic conditions of Alberta and the Maritimes, working through the cold requires an understanding of material science.

Cold-weather concreting is often viewed as risky, expensive or simply impractical. But the reality is that low-temperature work, when approached scientifically, can actually yield concrete with equal, or even superior, durability to summer placements. The real obstacles are not the conditions themselves, but misconceptions about how concrete behaves when the mercury drops.

UNDERSTANDING THE CHEMISTRY OF COLD

The performance of concrete during the winter months is governed by hydration - the exothermic reaction between cement and water that produces calcium-silicate-hydrate (C-S-H), which is the microscopic glue that gives concrete its strength. As ambient temperatures fall, the rate of this reaction slows dramatically. Below about 10°C, hydration proceeds sluggishly. And below 5°C, it can nearly stop. If the pore water inside the concrete freezes before sufficient C-S-H forms, ice crystals expand and rupture the paste matrix, permanently compromising the material’s integrity.

This is why cold-weather concreting is less about avoiding freezing and more about controlling temperature and time. Maintaining the internal temperature above critical thresholds - typically 10°C for the first 48 hours - allows early-age strength to develop before freezing becomes a threat.

MYTH #1: “JUST ADD MORE CEMENT”

It’s tempting to think that increasing cement content will compensate for slower hydration. While cement does release heat during hydration, it is short-lived and insufficient to offset environmental losses. Moreover, adding excess cement without adjusting water content or admixture

dosage can disrupt the water-to-cementitious ratio, leading to excessive shrinkage, cracking and permeability.

Canadian producers are increasingly turning to non-chloride accelerating admixtures, such as those based on calcium nitrate or triethanolamine chemistry, to promote early hydration without compromising durability or corroding embedded reinforcement. These accelerators stimulate the tricalcium silicate and dicalcium silicate phases that drive early strength development, helping contractors meet schedule demands even when temperatures hover near freezing.

MYTH #2: “CONCRETE ONLY FREEZES BELOW 0°C”

In practice, freezing damage begins long before the point when temperatures reach zero. In fact, when temperatures dip below 5°C, hydration has already started to slow so much that set times can double or triple. If concrete cools below freezing before reaching 3.5 MPa (500 psi), internal water can freeze, expand and generate microcracking that may remain invisible until weeks later, when the surface scales or delaminates under traffic or deicing salts.

In provinces like Quebec and Manitoba, where freeze-thaw cycles are extremely common, early-age protection must be treated as a non-negotiable. Using insulated curing blankets or heated enclosures ensures consistent curing and prevents the stop-start reaction cycles that can weaken

long-term performance.

MYTH #3: “DAYLIGHT IS ENOUGH TO KEEP CONCRETE WARM”

Even under direct sunlight, concrete placed on a frozen subgrade can lose heat faster than it can even generate it. The subgrade acts as a heat sink, drawing thermal energy away from the mix and slowing strength gain. Once temperatures fall overnight, the concrete slab can then develop thermal gradients that cause curling, surface cracking or differential strength.

As such, subgrades should be fully thawed and dry prior to placement. Heating the mix water to around 60°C (140°F) and aggregates to 38°C (100°F) produces a discharge temperature between 13°C and 18°C - ideal for maintaining hydration momentum. Hydronic heating systems, insulated formwork and maturity sensors can further ensure uniform temperature profiles through the curing period.

MYTH #4: “CALCIUM CHLORIDE IS THE BEST ACCELERATOR”

Calcium chloride is still widely used for unreinforced concrete, but its use introduces serious risks in structural or exposed applications.

Chloride ions can corrode reinforcing steel, compromise bond strength and cause surface discoloration - problems that are only magnified by Canada’s frequent freezethaw and deicing salt exposure.

Non-chloride accelerators now offer

Canada’s harsh climate range presents cold-weather concreting challenges.

COLD WEATHER CONCRETING

comparable set acceleration and early strength gains without the corrosion hazard. Many Canadian ready-mix producers have adopted calcium nitrate or formate-based admixtures, which are compatible with air-entraining agents and water reducers that are essential for freeze-thaw durability. These chemistries not only accelerate early hydration but also improve long-term microstructure density, resulting in significantly reduced permeability and enhanced resistance to scaling.

MYTH #5: “COLD-WEATHER MEASURES ARE TOO EXPENSIVE”

While heating, insulation and protection systems add cost and logistical complexity, their value is undeniable.

In fact, rework that’s required as a result of early-age freezing or surface scaling can be exponentially more expensive than proper temperature control. In fact, maintaining adequate curing conditions during the first 72 hours of a job can

increase ultimate compressive strength by up to 30 per cent.

Many Canadian contractors have found that by extending their working season through proper winter procedures, they’ve been able to offset seasonal shutdown costs. Steady productivity, better resource utilization and fewer springtime backlogs all contribute to a stronger bottom line and a reputation for reliability.

ADMIXTURE TECHNOLOGY

Current advances in admixture chemistry have redefined what’s possible in coldweather concreting.

Non-chloride accelerators allow faster setting without corrosion risk. Shrinkage-reducing admixtures minimize thermal stress during temperature swings. And air-entraining agents, which are crucial for freeze-thaw resistance, create microscopic air voids that relieve internal pressure as ice forms.

In addition, supplementary cementitious materials (SCMs) such as slag

cement, fly ash and silica fume play an important role in cold-weather concreting. While SCMs can slow early hydration, adjusting their dosage in winter helps balance strength gain and durability. Optimizing the ratio of SCMs to cement allows mixes to achieve both sustainability goals and performance targets in harsh climates.

THE IMPORTANCE OF QUALITY CONTROL AND FIELD MONITORING

Modern cold-weather concreting in Canada increasingly relies on digital tools. Maturity meters, infrared thermography and embedded sensors enable real-time tracking of in-place temperature and strength development. This data-driven approach allows crews to make more informed decisions about when to remove blankets, apply loads or proceed with form stripping.

These technologies are particularly valuable when used on public infrastructure projects where compliance with CSA A23.1 and A23.2 standards requires documentation of curing conditions and early strength attainment. By integrating field monitoring with proper mix design and protection planning, contractors can ensure that winter placements meet both structural and durability specifications.

ADAPTING COLD-WEATHER CONCRETING TO CANADA’S REGIONS

Canada’s geography presents a broad spectrum of winter concreting challenges. In coastal British Columbia, mild but wet conditions demand strict control of moisture and surface protection. Across the Prairies, low humidity and high winds increase the risk of plastic shrinkage cracking. In the North, permafrost and temperature swings impose unique logistical demands for heating, staging and curing.

Despite these variables, the principles remain consistent: maintain temperature, manage moisture and monitor performance. And collaboration among ready-mix producers, admixture suppliers and contractors is vital. The most successful projects are those where material design, delivery and placement are synchronized under a shared understanding of the science driving hydration and durability.

The Worldwide Leader in Concrete Paving Technology

GOMACO offers the full range of concrete slipform pavers, curb and gutter machines, trimmers, placer/spreaders, texture/ cure machines and bridge/canal finishing equipment. GOMACO equipment features our exclusive and proprietary G+® control system, created in-house by our software engineers from the wants and needs of contractors paving in the field. At the heart of GOMACO equipment is our passion for concrete and our commitment to our customers. We look forward to visiting with you about your upcoming paving projects and your concrete paving equipment needs. Our worldwide distributor network and our corporate team always stand ready to serve and assist you.

WORLD OF CONCRETE BUILDING THE FUTURE

International event in Las Vegas set to explore the future of concrete and masonry construction.

BY ADAM FREILL

Live demonstrations and networking opportunities help professionals stay ahead of the curve.

Featuring thousands of exhibitors across the Las Vegas Convention Center’s indoor and outdoor spaces, World of Concrete 2026 (WOC) is set to deliver another major check on the pulse of the concrete and masonry industries. Now entering its 52nd year, the show returns January 20–22, with education programming beginning January 19.

MUST-SEE EVENT

Organizers expect WOC 2026 to build on the momentum of last year’s strong turnout. “WOC 2025 drew nearly 58,000 registered professionals and more than 1,500 exhibitors across over three-quarters of a million square feet,” says show manager Steven Pomerantz. “For 2026, we’re promising an even bigger stage for innovation, training and connection - reinforcing WOC as the must-attend global gathering for

the trades that build the world around us.”

LIVE DEMONSTRATIONS

Attendees will find the latest products, equipment and services spanning material han-dling, trucks, software, robotics, grinding and cutting tools, surface protection, and more. Outdoor exhibits will highlight live equipment demos, heavy machinery displays and hands-on experiences with decorative concrete products. The outdoor lots will also host international competitions, including the quest for the title of World’s Best Bricklayer, alongside apprentice and tender events. Drivers with commercial licenses can test their skills for prizes in Western Star’s Get Tough Challenge.

EDUCATION AND LEARNING

WOC’s education program remains one of its biggest draws. Participants can begin their day at Breakfast with the Experts, where industry leaders address technical challenges in an interactive setting. Specialized luncheons and forums will cover concrete polishing, slab treatment best practices and emerging technologies such as 3D construction printing.

The 2026 edition features more than 160 education sessions, offering in-depth training for every experience level. Topics include concrete applications, business management, project delivery and safety - designed for both newcomers and seasoned professionals seeking to sharpen their skills.

World of Concrete 2026 will occupy the North, Central and South Halls of the Las Vegas Convention Center for indoor exhibits, with outdoor events in the Silver and Bronze Lots. The show runs from January 20 to 22, 2026, with education sessions available from the 19th to the 22nd. For more information, and to register, visit www. worldofconcrete.com.

EXHIBITS: JANUARY 20-22, 2026

EDUCATION: JANUARY 19-22, 2026

LAS VEGAS CONVENTION CENTER

Push limits. Smash barriers. Break boundaries. And when you’ve conquered all those obstacles? You discover your full capacity for greatness. World of Concrete delivers all the real-world solutions that will crush your challenges and take your expertise to new heights. Growth opportunities are everywhere, whether you’re getting hands-on with game-changing tools and tech or shaking hands with your future partners. Ready for maximum success? Nothing’s standing in your way.

ACHIEVE PEAK PERFORMANCE VIEW GLOBAL EVENTS