From the Editor

By Marcel Vander Wier

By Marcel Vander Wier

Not long after the initial coronavirus lockdown began in March, one of my columnists reached out and said COVID-19 may just be the topic of the year.

At the time, I was prepared to return to the Annex Business Media offices in Toronto following an impromptu two-week stint of working from home. Boy, was I was wrong. We are now closing in on December and the pandemic is still raging across Canada.

While the vast majority of schools were able to reopen in September, it’s been a tentative few months for all of us, watching governments do their best to balance economic interests with health and safety.

In October, I visited our Toronto office for the first time in seven months. It was eerie walking past the rows of empty cubicles, only to reach mine and find my calendar still reading March 2020.

It’s been a wild year.

More than 10,000 deaths due to COVID-19 have been recorded across Canada, and the worldwide fatality total

has just ticked past 1.3 million at time of writing.

L ockdown measures continue, including border closures, travel restrictions and mandatory mask wearing in many parts of the country.

Prime Minister Justin Trudeau summed it up recently, saying the situation we’re dealing with “really sucks.”

Justin Trudeau summed up our current situation recently, noting it ‘really sucks.’

As we continue to get through this collectively, let’s do our best to focus on the positives — increased resiliency, embracing new ways of working, more time with household members, and more.

I’ve said it before, but health and safety is firmly No. 1 through these days. For many who are reading this, that in itself is a positive.

Speaking of positives, a thank you is due to you, our readers Your support of this magazine and our website through this topsy-turvy year has been nothing short of incredible.

Despite the lockdown and restriction measures, OHS Canada had a banner year, more than doubling our annual website traffic — closing in on 800,000 pageviews — and tripling the amount of newcomers accessing our content.

A nd beginning with this very issue, we are pleased to unveil a redesigned print magazine that builds on the past successes of our 36-yearold publication, but with eyes firmly focused on the future.

We hope you enjoy the increased visuals throughout the magazine, as well as the new “Hot Items” section, showcasing PPE and safety products available in North America.

We have some exciting partnerships and initiatives planned for 2021, and we look forward to continuing to provide you with the most up-do-date health and safety information in the nation.

That said, I’m more than ready to leave 2020 behind.

From all of us at OHS Canada, we wish you peace and joy through the upcoming holiday season, and best wishes on a Happy New Year!

Paula Campkin: chief safety officer, Energy Safety Canada

Marty Dol: president and founder, HASCO Health & Safety Canada

Cindy Moser: director of communications, Institute of Work & Health

Natalie Oree: prevention consultant, SAFE Work Manitoba

David Powers: EHS director (Atlantic), Sysco Canada

Richard Quenneville: senior director of corporate services, T. Harris Environmental Management

Maureen Shaw: lecturer and presenter

Dylan Short: managing director, The Redlands Group

November/December 2020 Vol. 36, No. 6 ohscanada.com

EDITOR Marcel Vander Wier 416-510-5115 mvanderwier@ohscanada.com

MEDIA DESIGNER Graham Jeffrey

ACCOUNT CO-ORDINATOR

Cheryl Fisher 416-510-5194 cfisher@annexbusinessmedia.com

CIRCULATION MANAGER

Jay Doshi 416-442-5600 ext 5124 jdoshi@annexbusinessmedia.com

NATIONAL SALES MANAGER

Ross Anderson 289-925-7565 randerson@annexbusinessmedia.com

GROUP PUBLISHER

Paul Grossinger pgrossinger@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

Printed in Canada

ISSN 0827-4576 (Print) ISSN 1923-4279 (Digital) PUBLICATION MAIL AGREEMENT #40065710

CIRCULATION

Tel: 416-422-5600 Fax: 416-510-5140

Mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

SUBSCRIPTION RATES

Published six times per year – Jan/Feb, Mar/Apr, May/Jun, Jul/Aug, Sep/Oct, Nov/Dec Canada $100/yr plus tax USA $130/yr (100 USD) Foreign $214/yr ($164.50 USD)

Occasionally, OHS Canada will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office

privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2020 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

(CP) — Pharmaceutical giant Pfizer says early results from its coronavirus vaccine trial suggest a 90 per cent efficacy rate at preventing COVID-19, a number that has Canadian infectious disease experts cautiously optimistic that a viable shot can be rolled out by spring of 2021.

Jean-Paul Soucy, an epidemiologist at the University of Toronto, called Pfizer’s announcement “fantastic news (and) very encouraging,” but there are still questions to be answered.

And there are many steps between a vaccine’s approval and its actual rollout.

“It’s important to temper our expectations,” Soucy said. “Even if it does turn out to be 90 per cent effective, keep in mind that what we’re seeing is very preliminary data.”

(CP) — Ontario revealed a new tiered system for COVID-19 restrictions on Nov. 3, saying it will help fight the pandemic at a regional level, but critics said the framework prioritized the economy over public health.

The system — which places health units in colour-coded categories depending on their caseload and transmission levels — was announced as Ontario reported a record 1,050 cases of COVID-19.

Some worried the framework wouldn’t place tougher measures on regions with rising infections fast enough, but Premier Doug Ford said it will allow the province to tackle the virus in a targeted way.

“We’re going to continue to be very vigilant,” he said, adding that the province needs to balance restrictions with economic factors.

With winter approaching, flu season will soon be one more thing businesses have to deal with.

In early November, Dr. Theresa Tam, said that masks with three layers — two cloth plus a filter — are now recommended over the two-layer face coverings previously suggested.

While Canada remains in the throes of the pandemic, discerning whether symptoms of sickness are due to a common cold, flu or COVID-19 is impossible without a test, according to Hope McManus, head of health and safety at OH&S consultancy firm Peninsula Canada.

As a result, businesses will be more likely to experience work refusals, absenteeism, as well as staff shortages while workers self-isolate to wait for test results.

There are several things employers can be doing this flu season to help prevent employee illness and consequences to their business, she said.

Workplaces should have proper screening procedures in place to ensure that no symptomatic staff are coming in to work.

“Since there is no simple way to tell the difference between flu, cold and COVID-19 symptoms, all staff who are experiencing related symptoms should be sent home immediately to prevent the spread of illness in the workplace,” said McManus.

“As cases of COVID-19 are still high, every business needs to play their part in preserving public health.”

This goes hand in hand with providing education and training to staff on how to self-monitor and identify symptoms.

Staff should be informed of expectations, should they begin experiencing signs of illness, said McManus.

“Workers should know what to do if they start experiencing COVID-19 symptoms at work, including who to notify and that they should immediately self-isolate,” she said.

Southlake Regional Health Centre in Newmarket, Ont., was fined $80,000 on Oct. 16, as a result of a 2019 incident that saw two workers injured by a patient.

According to a court bulletin, the incident took place on Jan. 17, 2019, in an enclosed unit known as the Mental Health and Wellness Area Unit (MHWA) of Southlake’s emergency department.

The patient’s blows were sufficient to result in serious injuries to both workers.

A patient brought to Southlake that morning by a York Regional police officer was admitted to the MHWA and flagged as being a moderate violence risk.

The violence escalated.

A worker was attempting to deliver food to a different patient and entered the unit accompanied by another worker. The food was delivered and the two workers approached the door to the nursing station to exit the common area.

The patient admitted that morning struck one of the workers and then struck the other. The blows were sufficient to result in serious injuries to both workers.

The investigation by Ministry of Labour, Training and Skills Development inspectors found that while Southlake did implement some policies dealing with workplace violence in the MHWA, several hazards

remained for which the employer had failed to conduct a proper risk assessment to determine what reasonable precautions were needed to the protect the safety of the workers.

Among the deficiencies:

• There was no effective means of communication between workers in the nursing station and persons in the common area.

• There was no procedure in place requiring the admitting staff to ask more extensive questions regarding a patient’s history of violence.

• There were no procedures in place to address generally the hazard of an escalating patient being present in the common area, and nothing specifically addressing how to safely enter or exit the common area in these circumstances.

Pursuant to section 25(2)(h) of the Occupational Health and Safety Act, Southlake had a legal duty as an employer to take every reasonable precaution in the circumstances for the protection of its workers. This includes protection against workplace violence.

That day, the hospital failed to take the reasonable precaution of establishing effective means of communication between workers in the nursing station and persons in the common area of the MHWA, contrary to section 25(2)(h) of the act.

Southlake also failed to take the reasonable precaution of developing and/or establishing a procedure for the safe entry to and/or egress from the common area of the MHWA when a person is presenting with escalating behaviour — also contrary to the act.

In October, the Canadian Centre for Occupational Health and Safety (CCOHS) launched a new customizable toolkit resource to help workplaces across Canada operate safely and prevent the spread of infection during the COVID-19 pandemic.

Anchored by the COVID-19: Workplace Health and Safety Guide, the online hub provides one-stop access to more than 40 free resources to reduce the spread and protect everyone in the workplace.

10,000

In October, Canada reached another grim milestone in the COVID-19 pandemic, surpassing 10,000 deaths connected to the novel coronavirus.

“Every workplace has unique challenges and risks associated with operating during the pandemic,” said CCOHS president and CEO Anne Tennier. “It’s important that workplaces have the comprehensive guidance they need to operate safely and prevent the spread of infection, regardless of what stage of reopening or working they are in.”

The guide includes information on the responsibilities of employers and workers, and what workplaces should do to control risks.

Great Lakes Greenhouses in Leamington, Ont., was fined $120,000 on Oct. 16 for a Nov. 2018 incident that resulted in a worker fatality.

The employee received a fatal electrical shock on equipment that had not been properly locked out.

On Nov. 19, 2018, workers were adding to an existing greenhouse. One was re-arranging wiring and doing breaker work, as well as connecting wires to an electrical panel.

While completing the job, the worker was working with a wire containing 600 volts of power, and received a fatal electrical shock.

The Residential Construction Council of Ontario (RESCON) and 21 industry partners have joined forces and formed a roundtable that will work to address racism in the construction industry.

The roundtable includes employers, unions, employment agencies, educators, organizations representing contractors, the provincial and municipal governments, and the health and safety sector.

“Our construction industry consists of an incredibly diverse, multi-racial and multi-cultural workforce, and we will not tolerate any acts of racism,” said RESCON president Richard Lyall.

“We were appalled at racist acts that occurred recently on construction sites and decided to spearhead this effort to bring about meaningful changes to deal with the problem. We have some incredible organizations and industry leaders in this roundtable who will work together to stamp out racism in the industry.”

The first roundtable meeting was held Oct. 15 to establish the ground rules for the organization.

Quarterly meetings have been established to develop ideas and policy responses on how to deal with racism and change the culture of the construction industry.

Will a second wave of the COVID-19 pandemic affect your company’s return-towork plans?

Alberta swine flu likely a one-off

(CP) — An infectious disease expert at the University of Alberta says it’s shocking to hear about Canada’s first human case of a rare swine flu variant, but she expects it’s likely a one-off.

“It’s usually a one-off situation where a person has gotten it from a bird or a pig source and that’s usually the end of it,” said Dr. Lynora Saxinger, associate professor in the department of medicine.

(CP) — British Columbia health officials are asking businesses to review their COVID-19 safety plans as the province reports another daily record for new infections.

B.C. confirmed 589 new cases of COVID-19 on Nov. 6, pushing the number of active infections to 3,741. Two more people have died after contracting the illness, bringing the death toll to 275.

Provincial health officer Dr. Bonnie Henry and Health Minister Adrian Dix say keeping businesses open is important and the majority of people are abiding by health plans.

But in a joint statement, they’re asking businesses — particularly those in the Lower Mainland — to review those plans to ensure customers are being kept safe.

(Mathews Dinsdale) — Ontario continues to see increasing numbers of COVID-19 cases in what may be a second wave of the virus.

As a result, on Sept. 26, preentry COVID screening of all workers and “essential visitors” became mandatory for all businesses in Ontario — effective immediately — regardless of sector.

The new requirement comes through an amendment to

Ontario Regulation 364/20, the “Rules for Areas in Stage 3,” which is a regulation under the Reopening Ontario (A Flexible Response to COVID-19) Act, 2020.

To be clear, the new screening requirement does not include temperature testing and does not apply to customers or patrons of businesses that serve the public directly — for example: retailers and hospitality.

(CP) — Health-care workers, businesses and non-profits could receive liability protection against COVID-19-related lawsuits under legislation proposed by the Ontario government in October, but critics said the bill would result in extra protection for long-term care providers who failed residents during the pandemic.

Attorney General Doug Downey said that if passed, the proposed law would ensure that anyone making an “honest effort” to follow public health guidelines while working or

volunteering would not be exposed to liability.

He noted, however, that the bill would not prevent

lawsuits against those who willfully or through “gross negligence” endangered others during the pandemic.

“This is not going to help anybody who’s a bad actor, people who ignore the public health guidance,” he said. “This is really to help those who are doing things in good faith.”

The government said health-care workers and institutions, front-line retail workers, charities, and non-profits would be covered by the bill.

The legislation would also cover coaches, volunteers and minor sports associations, and would be retroactive to March.

The Board of Canadian Registered Safety Professionals (BCRSP) is pleased to announce Jennifer MacFarlane with Workplace Safety & Prevention Services as the BCRSP Volunteer of the Year for 2020.

Jennifer MacFarlane has been a Canadian Registered Safety Professional since 1999 and is passionately committed to continual learning and collaboration. Her talents in these areas generate enthusiasm and engagement in everyone she works with, wherever she goes. Beginning her studies in Engineering Technology, Jennifer received a Bursary Award for Women in Technology in 1994. This award is bestowed in memory of the women who were murdered and injured at École Polytechnique in 1989.

Jennifer worked in the education and manufacturing sectors for several years and taught in post-secondary institutions for over a decade. She was recognized for her contributions to the latter with a Distinguished Associate Faculty Award at Conestoga College in

Since 2006, Jennifer has worked at Workplace Safety & Prevention Services, serving the health and safety needs of thousands of businesses in a variety of sectors. She started volunteering as an item writer with BCRSP in 2004. In 2005, she began a six-year assignment with the BCRSP Item Writing Committee. She began as Chair of the BCRSP Regional Screening Centre in 2008, serving until 2019. She currently serves on the Examination Committee.

The Board of Canadian Registered Safety Professionals (BCRSP) Volunteer of the Year program was initiated in 2001 in conjunction with its 25th anniversary and the United Nation’s “Year of the Volunteer”. The Board of Canadian Registered Safety standards for the OHS profession. BCRSP strives to advance the body of knowledge, the competency of the profession, and the in order that the public interest may be served and protected.

info@bcrsp.ca, www.bcrsp.ca

By David Johnston

COVID-19 has illustrated the need for qualified and competent occupational health and safety (OH&S) professionals to manage OH&S hazards and risks.

The electrical utility sector has clearly demonstrated that qualified and competent OH&S pros significantly reduce or eliminate risks and hazards through their application of principles, theories, knowledge and experience in the workplace.

Every day across Canada, hundreds of components in the electrical grid can and do fail. Transformers burn out, cables fault, wires come down.

To the average person, this usually goes unnoticed due to the redundancy built into the grid.

Unknown to most Canadians, thousands of power-line technicians across Canada are doing high-risk work 24/7 making sure this essential service is provided to all customers without interruption.

During the pandemic, as always, hospitals, airports, banks and industry are continuing operations without interruption, while hundreds of thousands of Canadians rely on electricity to stay safe by working at home.

When the COVID-19 pandemic was declared and lockdowns started in March, many organizations shut down and sent their employees to work from home to minimize the risk.

This was not an option in the electrical utility sector.

Adding the risk of COVID-19 to an already high-risk industry presented a new challenge to safety professionals.

No electrical utility has had to curtail or stop work due to occupational COVID-19 infections, attesting to the effectiveness of the risk mitigation measures put in place by OH&S pros.

In some ways, it is fortunate that the sector is a high-risk occupation because the industry has long recognized the

value of employing competent, qualified OH&S pros, many of whom hold the CRSP certification.

Prior to the pandemic, many electrical utilities had well-established safety management systems. This provided the framework to facilitate an effective response to COVID-19.

In fact, members of the Canadian Electricity Association — which includes most Canadian electrical utilities — are required to establish a safety management system aligned with ISO 45001.

Many of the industry’s professionals had earlier planned for the possibility of a pandemic and had integrated these plans into existing OH&S programs.

For example, respiratory protection programs ensured employees were regularly fit tested in sufficient numbers and resources to conduct testing were maintained in-house.

When the lockdowns started in March, the term “pivot” has been used to describe how we reacted.

Policy, procedures, programs, training materials and communications to address the risk the pandemic posed to the industry were developed overnight by OH&S pros and regularly updated as we learned more about the virus.

OH&S professionals took the lead in explaining the difference between a mask and a respirator, the importance of adhering to the hierarchy of controls and not relying on the last and least effective barrier — PPE, and building the “precautionary principle” into all decision making that affected employee health and safety.

The public began using terms like “PPE” and “N95” while health and safety became the No. 1 concern of many Canadians, illustrating the deep ongoing concern many Canadians have for this subject.

Despite the concern of the average Canadian, many electrical utility employees are satisfied with the steps taken by their respective companies to manage the COVID-19 risk.

OH&S professionals’ leadership in the electrical sector has ensured that employee health and safety has been effectively protected from COVID-19 infections and this has prevented the potential crisis of nation-wide power outages.

We know through this example that competent qualified OH&S professionals are key to minimizing occupational health and safety risks, including COVID-19.

All that said, the time has come for governments and regulators to formally recognize the safety profession and the value it adds to society.

In some jurisdictions, hairdressers, home inspectors and human resources professionals have title protection to protect the public from scammers and incompetent persons, yet there is no such protection of the public from unqualified and incompetent persons claiming to be an OH&S professional.

We can’t wait for another pandemic to learn this lesson again.

By Lisa McGuire

The continued rise of COVID-19 cases across Canada requires leaders to adapt and maintain safe operations through rapid change.

Leaders must be able to pivot rapidly to meet the emerging risks of the pandemic. The speed of change poses unprecedented challenges to protecting both business and the safety and well-being of our most important asset — people.

L eadership has always been a critical factor in the success of workplace health and safety.

C OVID-19 has become a catalyst for leaders to rethink how they lead — and more importantly, how to protect their people and their business in the “new normal.”

Health and safety programs often rest on the shoulders of the safety professional — but that role should never exist in isolation. The connection between the CEO and the OH&S professional is a critical partnership, in the pandemic and beyond.

L eaders need to connect with their teams often, communicate regularly, adapt to meet diverse requests and demonstrate compassion through actions.

L eaders need more than just business skills to be successful ; they need emotional intelligence to engage their teams. To build trust, they must demonstrate that they care about people as much as profits. The choices a leader makes to grow the business and support employees through challenges defines their leadership.

Start by asking the right questions. What issues do your workers, supervisors, and managers see on the job that need attention? What anxieties and concerns do employees have about COVID-19?

E ffective employee engagement can

help leaders and safety professionals develop solutions that go beyond compliance and adapt to their companies’ unique needs.

Work together with your employees to produce meaningful outcomes and build trust together.

The connection between the CEO and the OH&S professional is a critical partnership, in the pandemic and beyond.

Communicate clearly and often about changes and their impact on the workplace, safety procedures and policies. Let employees know why decisions have been made and outline the steps taken. Provide opportunities for two-way dialogue whenever possible.

W hen safety protocols mean leaders have less face-to-face time with workers, the need for frequent and transparent communication is critical.

Leaders face ongoing challenges to stay on top of rapidly changing information, determine credible information sources and adapt quickly.

A crisis does not always allow adequate time to make decisions and adopt needed actions. A delayed reaction can have serious consequences with costly impacts for your employees and your business. Be prepared to pivot rapidly to protect your people when new, reliable information becomes available.

To lead with empathy, a leader must consider what it means to walk in an employee’s shoes.

The impact of the pandemic goes be -

yond physical health. The effects on mental and emotional well-being are just beginning to be understood.

Many workers are facing challenges they have never encountered before, such as:

• working remotely for the first time

• using unfamiliar technologies

• w orking with children at home or sending children to school with anxiety about the risks

• working with reduced staffing when co-workers are sick, quarantined, or unable to come to work

• s ocial isolation and separation from extended family

• financial and job uncertainty.

I ncluding mental health in OH&S programs has never been so important. S till, a lack of understanding and comfort with this topic remains a challenge.

M ental health is not as straightforward as other health and safety risks. Leaders need to learn more about psychological safety and adapt to create an environment that integrates good practices and behaviours that support mental resilience.

COVID-19 has changed our behaviours and perspective on health and safety.

G lobally, companies have changed how they view risk, working smarter and taking new steps to protect employees, customers and their business.

In turn, this has reshaped corporate values and a culture that will serve us beyond the current crisis. S afety habits — such as good hand hygiene — are already manifesting a positive impact by reducing seasonal flu transmission.

Prevention and protection strategies that we build today will have long-term benefits for our employees’ health and well-being in the future.

L eaders have the opportunity now to consider what new behaviours they want to keep beyond the pandemic to build a healthier workplace tomorrow.

By Christopher Hurley

At a recent job, I was fortunate enough to be partnered up with a seasoned safety veteran, a real “OG” with a lot of experience and a lot of colorful stories. It got me thinking about the differences and similarities between health and safety professionals across different generations.

Technically, the approaches vary — younger generations will be quicker to implement systems with tablets, and will inherently understand the benefits of a central electronic document storage. Technical advances are the types of things that make new graduates giddy with the potential in front of them.

O n the other hand, physical, paper forms should be a thing of the past, but some of our more-seasoned professionals still hold onto them tightly — under the auspices of “if it’s not written down, it doesn’t exist” — still an incredibly powerful and accurate statement.

Although occasionally reluctant to adopt more technologically advanced platforms, the on-the-floor confidence demonstrated by our seasoned pros always impresses me.

This job was no different, as my partner was laser sharp in pulling regulation sections from memory, assessing what appear to be unique situations, and having a story about a similar situation to utilize as a reference point. The always patient, coach-like manner he presented in any given situation is something we can all learn from.

For some, this demeanour comes naturally. In a fast-moving demand-and-receive society, will our millennials and beyond pick this life skill up as easily as some of those that have come before?

This job was not an easy one, and although I’ve certainly been around for a while, I found myself enthralled by what my older partner was saying, his conversations with others, and his ability to really understand the dynamics of a complicated job.

There’s been long periods in my career where I haven’t had a mentor, and even though I’m in my mid-40s, I always appreciate and respect the opportunity to learn from others.

Bridging gaps

In a world neck-deep in division, it’s important to look more for our shared purpose with each other.

We can’t know it all, even though many of us attempt this impossible accomplishment.

In my own time mentoring others, I’ve seen incredible resourcefulness from young and eager safety pros. It’s refreshing to see their energy and their ability to hunker down, research a problem and come up with high-quality, effective solutions.

Despite this, it’s not uncommon for the older generation to talk about how doomed the business is as a result of the incoming troops.

In my experience though, it’s just not a concern. Our millennial counterparts will jump in with both feet and get the job to the finish line as safely as they possibly can.

At this point, I’m lucky enough to be looking ahead as well as behind, from a generational perspective. One thing that I find most fascinating between generations of safety professionals is the ability to care about people. Everyone is mindful of schedule, costs, time — but at the end of the day, safety professionals — regardless of age — are in it for the people. The conversations, the demonstration of care, the ability to navigate conflict and challenges — it’s all in our wheelhouse.

In a world neck-deep in division, it’s important to look more for our shared purpose with each other — always endeavouring to drive relationships to a higher level.

L everaging and learning the knowledge of older generations is a given ; we must also remain open-minded and curious about younger safety pros’ perspectives. Not only will that help us deliver on our commitment to all generations of workers, it will also drive cohesive teams and better overall safety performance outcomes.

That is something we can all enjoy, regardless if you were born in ’69 or ’99.

By Alan D. Quilley

When you look at things through a different lens, you tend to perceive what you are looking at differently.

My own thinking and professional self-development follows a staged process.

Predictably, my perceptions of what is true and important has followed the evolution of OH&S knowledge, through the research and experience of my professional peers and mentors.

Exposure to H.W. Heinrich’s accident pyramid and dominos first shaped my thinking about the involvement of humans in the causes of accidents.

If we could simply stop those “unsafe acts” by workers, all accidents would be prevented.

In hindsight, I equate this early learning to the children’s book The Little Train That Could — far too simplistic to be useful, but inspiring. It started me thinking that accidents just don’t happen… they are caused.

In 1972, the federal government enacted the Canada Labour Code, Part II.

In a flash, the railway I was working for was thrust into “compliance mode.” We needed to put fall protection and hard hats on our workers. Asbestos and lead exposures needed to be controlled and we needed a “safety committee.” Safety clearly became rules and regulations based.

Six years later, I found myself working as an enforcer of OH&S law of the newly formed inspections branch of Alberta Labour.

Our job was to enforce compliance through inspections and, where necessary, issue legal orders and prosecutions for violations.

The enormously influential Practical Loss Control Leadershi p by Frank Bird Jr. and George L. Germain (now in its third edition) first appeared in 1985 and quickly became a standard text in the field.

Fundamentally, Canada’s Internal Responsibility System model is in no small way a reaction to Bird’s work.

Perhaps the most unique and valuable of the book’s contributions to the safety world was the M of ISMEC — identify, set standards, measure, evaluate, correct/commend.

Measurement is at the heart of the ISMEC system. Most started to focus on management system failures as the cause of loss.

The mid-’80s revealed the connection with employee perception and positive safety outcomes.

This moved thinking from systems to starting to understand that — as Dan Petersen puts it: “paper doesn’t save people; people save people” — towards the movement of knowing that passing a safety audit measuring process can lead to a false sense of success.

What became more important is not the intention of the safety management system, but the actual implementation and how the people within and working with the organization correlated to the success of the overall system.

The term “safety culture” emerged as a description (either good or bad) about the realities and results of the safety efforts and behaviours.

The evolution of OH&S knowledge has included many stages over the years.

In the ’90s, the behaviourists came into their own and started to apply the considerable knowledge we have about human behaviour to the sub-culture of “safety.”

By the end of the decade, popular versions by several “celebrity” companies and “rock-star” psychologists emerged.

The term behaviour-based safety (BBS) — with all its success and giant failures — was on everyone’s lips.

Poor examples of doing BBS “to employees and not with employees” were all too common.

The new millennium brought us a wave of “standards” for us all to use. Some came with certifications and others with promises of business prosperity and rebates. They say that “all models are broken.”

The assumption that if you pass the audit, excellence is guaranteed just hasn’t materialized. Most popular audits have absolutely no science behind the veiled promise that “if you do this… you’ll get that.”

The OH&S binder filled with policies and intentions became king!

We now understand that humans aren’t lab rats — but complex, flawed and capable beings. We have discovered that managing safety efforts with people openly and honestly gets the best results.

Relationships and trust matter Without them, safety efforts predictably fail.

What’s next? If only we knew. Whatever it is, we will hopefully build on the successes and avoid the failures of our past.

We will continue to try new things and let go of those that simply don’t work.

featuring Carolyn Homes

Si nce March, companies across Canada have been grappling with new health and safety restrictions and lockdown measures as a result of the COVID-19 pandemic.

Carolyn Homes is a health and safety manager, and a member of the environmental, health and safety team, at Walmart Canada’s Store Support Centre (SSC) in Mississauga, Ont.

OHS Canada: How difficult has it been to adjust Walmart operations as a result of the pandemic?

Carolyn Homes: As set out by legislation, Walmart Canada was deemed an essential service during this pandemic; therefore, we needed to adjust many of our operations.

In the stores, here are some examples of protocols that were put in place:

• fencing at the entrance to assist control capacity

• fl oor markings to ensure proper social distancing

• P lexiglas for our cashiers, customer service and pharmacy

• enhanced COVID-19 cleaning protocols

• Wellness Screening, including a temperature check for our associates

• COVID-19 signage.

The industry saw an immediate shortage on key products such as cleaning supplies and toilet paper, which really challenged our merchandise teams to deliver for our customers.

We saw customers change

Carolyn Homes has helped ensure Walmart Canada employees and customers have remained safe through the pandemic.

their shopping habits with less visits but higher volume, and we needed to increase our online presence.

With the growth in pickup and delivery, we needed to ensure safety protocols were in place to protect our customers and associates. The goal is to ensure that all associates are working safely under these challenging conditions and going home safely at the end of their shifts!

Walmart also needed to provide instruction to our vendors regarding the new protocols that have been put in place. The positive is that many of the protocols are consistent across the retail

industry and are becoming the “new normal.”

OHS: How has Walmart adjusted employee operations to reflect health and safety measures?

CH: In March, one of the biggest adjustments was the closing down of SSC that supports all businesses. Months later, remote working continues unless necessary, and several protocols have been put in place to attend the SSC.

Over time, this new way of working is being received very positively and associates are very productive. Efforts have been put in to ensure associ-

ates feel part of their team and the overall Walmart team through updates from senior leaders, utilizing creativity and fun that has been built into the Zoom meeting environment.

One step that Walmart took very early on with our SSC associates was instituting “meeting-free” times throughout the day. This has had a very positive impact on the health and well-being of the associates.

In the stores and distribution centres, employee operations have changed in countless ways, but I believe that retail associates choose a dynamic career for a reason and are very much accustomed to rapid change.

They have done amazing throughout this pandemic.

OHS: What difficulties have there been in operating in multiple jurisdictions with various regulations in place?

CH: Managing health and safety for a national retailer is always a challenge in normal times, as you need to be aware of federal, provincial and municipal legislation that can impact your business.

Since the pandemic began, there have been many times that key members of the response team have needed to react very quickly to ensure the businesses were equipped with communication and tools they needed to support changing protocols.

Customers are not always aware of the current standards that have been put in place, even with the investment

retailers have made in sharing these publicly.

I n these stressful times, this can cause friction; however, with the support in place, store managers have really been able to de-escalate situations.

An example of a step that was taken — because it was the right thing to do — was an early move to “mandatory masks” for associates, customers and vendors. Early on, this was met with some customer resistance , but consistent messaging was in place and helped to successfully reinforce this initiative.

In addition, if situations escalate, management knows

they have the support from many individuals — including the existing Violence in the Workplace team.

OHS: What health and safety lessons have you learned as a result of the current situation?

CH: Canadian retailers have dealt with many different health and safety risks over the years, but this pandemic is unprecedented and the learnings have been large.

With Walmart being a global company, there is a benefit to gaining intelligence and best advice from other countries who have already experienced similar issues.

change

Jim, Our welding crew could sure use the feature of this respirator. Would you please contact Dentec? THX Jane

Many processes have been altered, but one of the biggest lessons learned is that the efficiencies that have been implemented will have positive impacts going forward.

For example, although our in-house computer-based health and safety training was not affected, the in-person H&S training conducted by third-party providers was.

S ome provinces did grant certification extensions for certain training. However, with the record number of new hires this year and the turnover that is traditional in retail, new certification training was needed.

By working with our vend-

ors, we were able to move all theory training to online/virtual and are able to conduct socially distanced practical training as required.

The great news is that associates love it! A lesson that is key is the need to build relationships and work together during these difficult times.

I am very proud to be working for a company whose message from Day 1 of this pandemic has been “safety is our priority.” You will see this message throughout the organization and across public platforms.

In my experience, companies can say this — but Walmart is living proof of it!

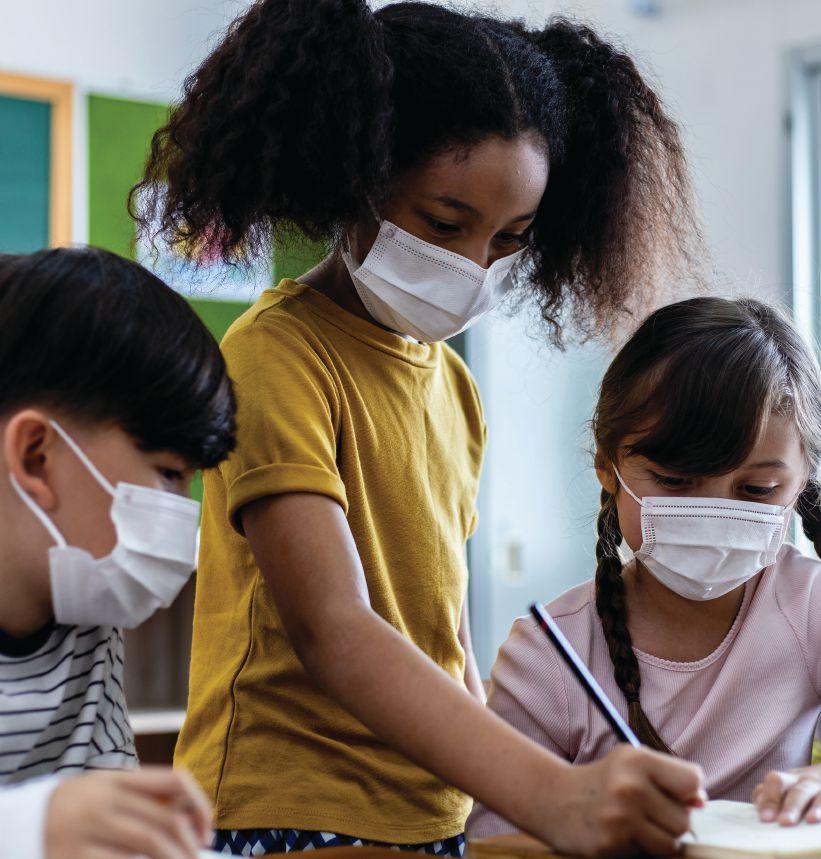

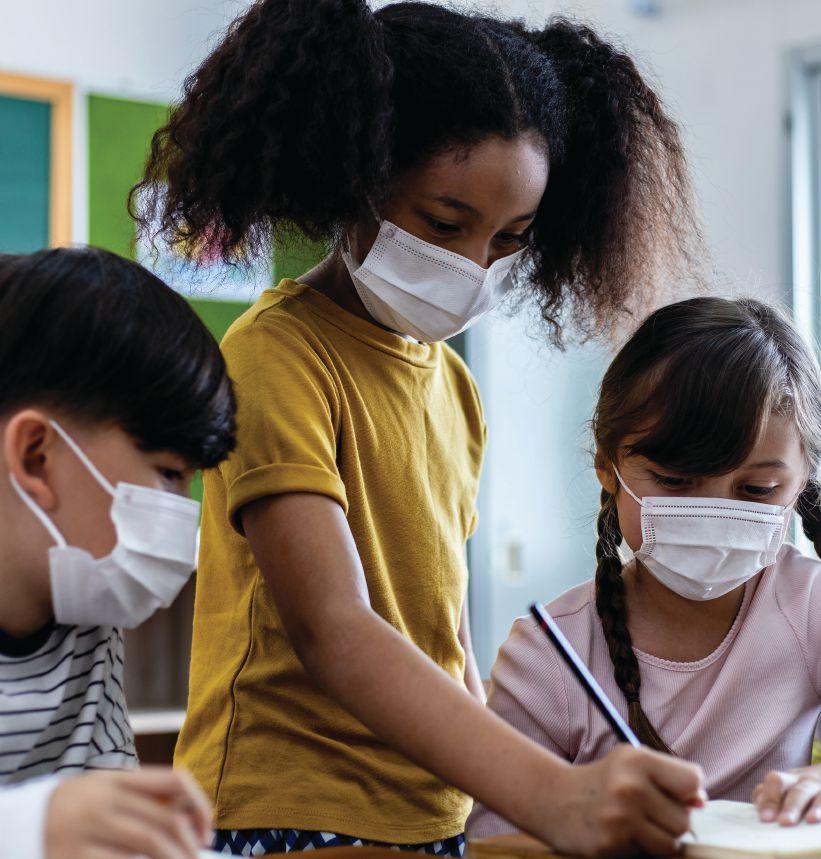

Across Canada, classrooms have been transformed due to the COVID-19 pandemic, in an academic year unlike any others

By Pierre Chauvin

At the end of August, teachers across Canada were preparing for a year like no other.

“Our hearts were breaking,” said Robyn Gasparini, a kindergarten teacher in Mississauga, Ont.

With 29 years of experience behind her, fall’s return to school started with a difficult task for Gasparini — undoing years of work put in to make her classroom welcoming to her students.

Carpets, little couches, cozy furniture: everything had to go.

“Everything that we’ve done to make our spaces welcoming and comfortable — a place where you feel like you belong — all of a sudden were very sterile,” she said.

New health guidelines to reduce the risks of COVID-19 transmission meant that many activities requiring sharing games and space were no longer possible.

By her own account, half of Gasparini’s teaching time is now spent completing cleaning tasks.

While her junior kindergarten students got used to the new routine, it wasn’t the same for senior kindergarten children who had experienced a “normal year” in 2019.

“’Miss Gasparini, do you remember when we used to be able to sit on the carpet and hold hands?’” Gasparini recounts children asking her.

Her voice breaks.

“It’s really hard right now,” she said. “The hardest part is not letting the kids see how hard it is on us.”

Across the country, provinces and territories have rolled out various back-to-school models playing on similar variations — a combination of in-class and remote learning.

But it’s not just the cleaning and technical requirements that are putting pressure on teaching staff. For many, it’s having to adapt an entire curriculum to new teaching realities that don’t allow for much of the student-led model.

“ There’s a lot of co-operative work between students, as teachers guide processes and make tools available and provide instruction where it’s needed,” said Elizabeth Mitchell, who works for the Halton Elementary Teachers Local in Ontario, referring to the pre-pandemic model.

Her local is part of the Elementary Teachers’ Federation of Ontario, which represents 83,000 teachers across the province.

“ That kind of teaching is absolutely impossible in this virtual classroom environment,” according to Mitchell.

In Ontario, teachers had two to three professional development days to get acquainted with the new model. But as Mitchell puts it, a few days aren’t enough to learn “a brand-new job.”

The logistics involved require the teachers’ constant attention.

Maria Marcello, a Grade 2/3 teacher in Woodbridge, Ont., juggles between two to three computers — one projecting on an interactive board for her in-class Grade 3, one for the Google Meet for her Grade 2 students, and a third one to share the screen of what Grade 2 is working on.

But even when everything runs smoothly on the technical side, it’s still a struggle to recreate the in-class experience with many students turning their cameras off, she said.

“How effective can we be before burning out? On top of teaching, we’re doing so much more.”

– Maria Marcello, Grade 2/3 teacher

“I can’t gauge their understanding of anything that I’m teaching, and then I also lose that connection with my remote learners because I miss the cues of their body language,” said Marcello.

For other students, the process of unmuting themselves and speaking in front of the entire virtual class, with everybody explicitly listening to them, seems to bring as much apprehension as a class presentation.

“ If we ask questions and they don’t respond, we don’t have any follow-up; we can’t get a hold of them because they’re not there, they’re not in front of us,” said Michael Kearns, a Grade 11/12 teacher in Cambridge, Ont.

Remote learning brings in other sets of unexpected challenges — more sources of distractions for students sitting in front of a computer, and for younger students, the occasional parent intervention to troubleshoot technical issues.

With the added responsibility of keeping their students safe, the classroom clean, and running a new model of teaching, many teachers in Ontario point out it will be impossible to complete the curriculum.

“ How effective can we be before burning out?” Marcello asked. “On top of teaching, we’re doing so much more.”

A variety of interviews reveal the same trend — teachers are exhausted, mentally and physically, and don’t feel protected.

In late October, the Canadian Teacher Federation (CTF) launched a survey asking teachers about their mental health and well-being.

Of the 13,777 who responded, 46 per cent reported concerns about their own mental health and well-being. Compared to the same set of questions asked in June, the situation appears to be deteriorating quickly.

“ These comparative results show a significant and negative change in teachers’ feelings of well-being,” the survey reads.

Physical health and safety ranked fourth in teachers’ overall concerns for their well-being, behind mental and emotional exhaustion; workload and work-life

balance; and stress, anxiety and depression.

Marcello told OHS Canada of “teachers in tears,” while Gasparini says she forces herself to put on “a happy face” for her kindergarten students.

In British Columbia, a recent survey found that the majority of teachers regarded health and safety protocols to be inadequate or completely inadequate.

B.C. Teacher Federation (BCTF) president Teri Mooring said a mask mandate and a reduction in class sizes are two measures many are asking for.

The levels of exhaustion witnessed across the country among teachers is unusual for this early in the school year, CTF president Shelley Morse noted.

“ The people who have the power to change these situations need to step up and support our teachers, or we’re going to have a shortage of teachers because of ailments,” she said.

While the CTF calls on governments to take measures regarding staffing and teachers’ well-being, it’s interesting to note it’s also asking for unified safety guidelines within provinces and territories.

In Ontario, Mitchell points to a Toronto District School Board proposal to shorten teaching days in order to cap classes at 15 students in an effort to respect health guidelines.

“ The (Ontario) Ministry of Education just threw the proposal out,” Mitchell said.

OHS Canada requested an interview with Ontario’s Ministry of Education.

Instead, it received a statement listing the additional money provided to school boards and detailing the measures developed with the chief medical officer of health.

“School boards are permitted to adopt adaptations that support smaller class sizes, more physical distancing and other health and safety measures, provided they meet certain parameters,” the statement reads.

The Halton District School Board did not reply to multiple requests for comment.

In some schools in Ontario, “teacher zones” have been implemented to allow for physical distancing. But as Mitchell learned when a concerned teacher reached out to her, those zones can’t always be used.

“ The best they could do for that teacher’s ‘teacher zone’ would be for her to stand in the very corner of the classroom and teach from there,” she said.

“She couldn’t access the board, she couldn’t access the projector, she couldn’t even pull a cart with a small whiteboard and chart paper... but that was the place that she was supposed to teach in order to stay safe.”

In B.C., Mooring points to the lack of enforcement

“The people who have the power to change these situations need to step up and support our teachers.”

– Shelley Morse, president Canadian Teacher Federation

mechanisms to make sure school boards follow safety guidelines.

“ We haven’t really seen WorkSafeBC playing an active role in enforcing those guidelines under a COVID scenario,” she said.

“Some districts are questioning whether the Ministry of Education guidelines are actually enforceable and, of course, that hasn’t been tested.”

And while the BCTF could file a grievance, that process would take up to six months, a timeline not feasible when a lapse in safety measures during a few hours could cause a COVID-19 outbreak.

Still, the BCTF says they’ve been working with the government to find a solution.

In a statement provided to OHS Canada , B.C.’s education ministry noted that “all boards of education and independent school authorities are required to implement strict health and safety guidelines” to deal with the pandemic.

The pressure the pandemic brought on the education system is also felt at the school board level.

Since March, school boards have had to deal with unprecedented logistical challenges.

In B.C., the Francophone school board’s students and staff use over 8,000 laptops and tablets. Another 1,400 had to be ordered, all of which have to be properly set up by the IT staff, on top of bandwidth issues.

“ That... has been let’s say, a kind of success because the IT people did work like crazy,” according to Michel St-Amant, head of the B.C. Francophone School Board.

But that’s not the only department that had to field a never-ending workload.

Communications, he said, “has been working at 200 miles per hour.”

With anxiety running high and parents hearing from different sources, St-Amant said his team has had to debunk a number of false stories.

In one case, the school board was falsely accused of a lack of transparency.

Because of confidentiality rules, a school board will know about a case from public health, but won’t be able to disclose it unless it’s already been disclosed by public health.

B ut nothing prevents individuals from disclosing they’ve tested positive — creating a false impression of secrecy, St-Amant said.

“ We don’t know what we don’t know — no one went through that kind of thing before,” he said.

Even with his experience working in Ontario during the H1N1 pandemic of 2009, the current COVID-19 is completely new territory.

And, of course, there are the COVID -19 cases. When interviewed in early November, the Francophone school board executive director told OHS Canada seven of the 45 schools were dealing with cases.

In Ontario, there have been more than 2,600 COVID-19 cases in schools through the first two months of the school year.

With the second wave in full force across the country, the situation seems more and more untenable.

20_2235_CN_OHnS_NOV_DEC_CN Mod: October 21, 2020 11:29 AM Print: 10/29/20 4:42:12 PM page 1 v7

By Meagan Gillmore

The increase of workfrom-home arrangements due to the COVID-19 pandemic hasn’t reduced the need for proper workplace safety.

Home offices, if not properly constructed, can cause muscle strain and fatigue and lead to musculoskeletal injuries if not prevented and treated. This means employers and employees need to focus on ergonomic safety.

Office ergonomics is about more than properly arranging furniture. It requires understanding how a worker interacts with their work.

It’s “fitting a job to the worker, understanding the characteristics of workers — their size, shape, strengths and limitations,” said Judy Village, president of the Association of Canadian Ergonomists.

Designing work to fit the worker helps prevent injuries, she said, and allows workers to perform their jobs better.

“It’s not just about injury,” said Village. “It’s also about errors and inefficiencies and working productively.”

Office environments carry the risk of upper-body injuries to the neck, back, shoulders, hands and wrists.

These risks are exacerbated when office equipment — such as desks, chairs, computers and lighting — aren’t set up properly. Some workers may not have dedicated office space at home, or even a workstation where they live.

If employees are going to be able to work safely at home for an extended time, businesses need to invest in properly equipping home offices.

“Employers and their employees (need) to go into this realizing that they’re going to be working from home for a long period of time,” said Cheryl Schwientek, a California-based certified ergonomist and remote-working specialist with Briotix Health.

“It shouldn’t be considered as temporary anymore.”

And according to Jennifer McGillis, certified ergonomist and owner of ProErgonomics, a consulting firm with offices throughout Ontario, “we’re not investing the amount of resources into making sure the setup is ideal.”

Adjustable chairs that fit individuals properly are key to preventing injuries, she said. But those aren’t always available at home.

“We’re allowing someone to sit at home on a kitchen chair. That would never happen in a more traditional workplace environment.”

McGillis encouraged workers to make their chairs as comfortable and adjustable as possible.

Employers are always obligated to ensure workplace safety.

“Ultimately, the employer has the legal responsibility to take every reasonable precaution to ensure the safety of the worker — even in remote-work situations,” said Lin Xi Yu, an occupational health and safety specialist at the Canadian Centre for Occupational Health and Safety.

Businesses do this differently. Some provide employees with equipment, others leave it to employees to gather the equipment but require them to show their workstation is properly set up before they can work from home, while some give staff money to purchase the equipment they need.

As working from home becomes more common, McGillis said she expects to see companies develop “a more formalized system” to ensure ergonomically correct remote workstations.

Setting up a proper home office doesn’t need to be expensive.

“There’s all kinds of ways you can configure something as long as you get the heights appropriate to yourself,” said Village.

Working at proper height and maintaining correct posture are the most important considerations when making a workstation.

Keyboards should be at elbow height, so elbows are at a 90-degree angle when working. The top edge of a computer screen should be level with the employees’ eyes.

This can’t be achieved automatically when using a laptop, according to Village.

“Laptops compromise either your neck, or your shoulders and wrists, because if you’ve got the keyboard at the right height for your shoulders and wrists, the monitor’s too low for your neck and vise versa,” she explained. “If you’ve got the monitor at the right height for your neck, then it’s too high for your shoulder and wrists. Having a separate keyboard and mouse or separate monitor is key if you’re working on your laptop.”

The goal is achieving ideal posture, said McGillis.

“If you can do that, your risk of injury is significantly decreased because your body is in the optimal posture.”

Chairs need to be raised if hands are below the desk or lowered if hands are above the desk, said McGillis. Workstations can also be raised. Placing books and boxes underneath a computer keyboard can be a quick and inexpensive way to make a workstation more ergonomically correct.

Feet also need to be firmly on a solid surface, said Village.

“You don’t want your feet dangling, because that puts pressure on the underside of your thighs. It also lowers your knees below your hips,

which creates a strain on the low back,” she explained. “You want your feet to be solid and supported, which is why you want something solid. It doesn’t have to be the floor; it can be a footrest.”

Employees also need to protect themselves from eye strain and eye fatigue.

Computer screens need to be kept at least an arms’ length away; using larger text sizes make reading easier. Proper lighting is also key.

“At home, what is more relevant now is illumination — trying to figure out where to place your workstation, or whether to have a desk lamp on the table as well, or

how to set up (a) workstation that puts less strain on your eyes,” according to Yu.

Eye strain and fatigue can lead to headaches.

Screens should be perpendicular to windows. Blinds and curtains are important to control light.

“If you’ve got glare directly at you, it makes it harder to see on the screen,” explained Village. “If you’ve got glare behind you, then it’s lighting up the screen and making it brighter than you want.”

Preventing musculoskeletal injuries in the office includes periodically leaving the office.

“Your body ultimately is built to move,” said McGillis. “The No. 1 thing that people can do is to get up and move as much as possible.”

Ergonomists recommend people move for five to 10 minutes per hour, and change positions as often as possible. Both sitting and standing for extended periods of time can be harmful.

“The real goal is to build movement into your work and not be sitting for eight hours, but also to not be standing for eight hours,” said Village.

Schwientek encouraged people to move during even the smallest

“Your body ultimately is built to move. The No. 1 thing that people can do is to get up and move as much as possible.”

breaks in their day, available when waiting for participants to join a meeting or call.

She suggested people set timers, reminding them of when they need to move, and when the timer goes off, to ask if there’s something they can do to increase their movements.

“Hopefully the answer is ‘yes,’” said Schwientek.

People can march in place while reading reports, or do subtle stretches during video meetings, she said.

“Be strategic about when there are opportunities for movement during the day,” said McGillis, encouraging people to take walking meetings as much as possible.

Using speakerphones and headsets can also help, and reduce the amount of time people cradle their phones — which can be an awkward position.

Clear communication key Having open and clear communication with employees is key to ergonomic success, said Yu.

Working from home can increase the hours people spend at work, which can lead to muscle fatigue and heighten the risk of injury.

“If workers feel like they’re working more, that should be communicated to their employer so they can work something out — not necessarily so they can do less work, but so they can do the work in a safer way,” she said.

“The power of the employee is that they’re always on the ground floor, whether that’s in an office or on a shop floor,” said Yu. “They are with the work day-in and day-out. They’re most likely to notice (if something is wrong).”

“Everyone has a role to play in health and safety, so participation of all parties is greatly encouraged.” Meagan

By Marcel Vander Wier

The current global pandemic has provided many lessons for occupational health and safety professionals, according to experts.

Work refusals, remote worker safety, management of anxiety, and health privacy issues have all come to the forefront as a result of COVID-19.

“A number of employers really are in hard times,” said Dylan Short, managing director of The Redlands Group, a boutique management consulting firm in Oakville, Ont., during a webinar hosted by OHS Canada.

“Economically, this has been a devastating year for a lot of Canadian businesses — large and small.”

Many saw their workforces begin working from home en masse in March — a situation that presented many unique situations for health and safety professionals, said Dan Black, an employment and labour lawyer with Caravel Law in Toronto.

“One of the questions that I get most often from my clients is: ‘Am I responsible for the health and safety of my employees when they’re working at home? That’s their home. Isn’t that their problem?’”

Rudimentary workspaces can lead to requests for ergonomic upgrades, and there aren’t always clear legal obligations in terms of what an employer must pay for, he said.

“ There’s no clear obligation to provide your employees with that equipment,” said Black. “But it’s also clear that you are responsible for their safety when they’re working in their homes… If you’ve assigned or permitted your employees to work from their home, you as their employer do have

an obligation to make sure that they’re safe there.”

In this area, providing clear guidance may suffice for employers, he said.

Work refusals are another issue arising as a result of the pandemic.

“You’re going to have employees who don’t really have a valid excuse not to report to work, but they’re afraid to come to work,” said Black. “Theoretically, you could discipline them for it. You could terminate their employment.”

But employers should take a “long-term view” of their relationship when these situations occur, he advised.

“This isn’t forever, we hope. And so, try and work with the employees… Let them know that you’re aware of what the risks are; let them know that you’re keeping up to date on what the public-health and other recommendations are; be clear in your communications about what is being done to protect them, so that you can try and gently encourage them to come into the workplace.”

“If you’re thinking about taking a hardline approach with your employees, move carefully and then think about whether that’s really in your best interest as an employer in the long-term, as well.”

Empathetic conversations and providing flexibility in work relationships are important for workers to maintain mental health through COVID-19, said Elizabeth Horvath, manager of workplace mental health and Opening Minds at the Mental Health Commission of Canada in Ottawa.

“ The pandemic is adding additional pressure onto people, whether they’re having to go out and do shopping and stand

in lines, or you’re having to try and figure out how do I work at home with my children and my spouse,” she said.

“We’re seeing increases in anxiety; we’re seeing potential increases in depression — definitely people are having more concern over their mental health.”

Open, transparent conversations between employer and employees are beneficial through these times, said Horvath.

“ When leadership is very transparent and open about their own feelings around the pandemic, and around even being in the workplace, that helps other people understand that they’re not alone in those feelings.”

Health and safety leadership has been critical through the pandemic, said Manisha Mistry, senior director of occupational health, safety, environment and change management at the CSA Group in Toronto.

“Most successful organizations that are going to get through this on the other side with a different lens of their organization (are) the ones where the leadership has really shown that the value of health and safety is the most important priority for the organization.”

Consistent communication from senior leaders at the CSA Group has been of great benefit, she said.

By Marcel Vander Wier

The swing towards single-use gloves has led to a global shortage and price increases, according to Brad Machado, regional sales manager for PIP Canada in Burlington, Ont.

The changes came quickly after the COVID-19 lockdowns went into effect in March, he said.

“ Essentially, like what we saw with toilet paper and bottled water on the shelves… the same thing was happening out in the industrial world.”

And the high demand continues today, said Machado.

Hand protection was not immune to the COVID-19 pandemic of 2020, with shifts in buyer habits and spikes in demand for single-use options.

“ If you’re looking to buy disposable gloves and position yourself for 2021, good luck,” he said.

“You want to start positioning yourself for 2022, just because I think for 2021, we’re still going to be going through supply issues.”

Sales in single-use and reusable nitrile gloves have positioned Quebec’s SHOWA Group for a “great year,” said national sales manager Terry Smith, even as general-purpose and cut-resistant brands have taken a hit, due to multiple manufacturing shutdowns across Canada.

Single-use products are hard to come by during the COVID-19 pandemic, he said. “Nobody has them on the shelves.”

Price and comfort remain major determinants for those purchasing gloves for their workforce, according to manufacturers.

“ Will people wear the glove? The most expensive, advanced gloves are useless unless people wear them,” said Joe Geng, vice-president of Superior Glove in Acton,

Ont. For that reason, worker input on comfort is important when deciding to purchase PPE.

“It’s a very personal decision,” he said. “Find gloves workers actually want to wear — they’re out there.”

Going forward, Geng expects protective gloves to offer increased comfort levels alongside higher levels of protection, be specifically designed for individ-

ualized tasks, and trend towards increased ergonomics — taking cues from sports gloves.

S uperior Glove’s TenActiv 21-gauge cut-resistant gloves with foam nitrile palms are an example of highly protective PPE that is touch-screen compatible and conducive to maximum dexterity — as close as one can get to a barehanded feel, he said.

Meanwhile, w ith more than 2,000 glove styles serving many industries, comfort is No. 1 for SHOWA clients, said Smith.

“If your glove doesn’t fit right or feel right, the person wearing it would be more likely to remove the glove and hence risk hand injury,” he said.

Even for cut-resistant gloves, “everyone’s looking for the best cut protection, but with the most dexterity they can still have.”

Price point continues to be the other main factor in purchasing, according to Machado.

But the cheapest option isn’t necessarily best. Savings can occur over time with a better quality product — even a low-cost reusable glove, he said, noting reusable options give users better cost-per-wear, and also saves single-use PPE for essential workers that truly need it through the duration of the pandemic.

“ When crises like this happen, I think people get a little more educated and have a better respect for PPE and safety,” said Machado, noting he expects the market to shift towards a product in-between a reusable and disposable glove.

“ The whole fear is — what happens if five years from now another crisis hits,

and the same thing with disposables happens? What’s the next option out there?”

At PIP Canada, the trend is towards synthetic knit gloves, as clients want to ensure their hand protection works with them — not against, said Machado.

C omfort and breathability — even through coatings — is the claim to fame for his company’s ATG product line, he said.

“Our ATG line of hand protection is like our Ferrari, Rolls Royce when it comes to gloves,” said Machado. “It is a premium, but it will outlast a lot of products out on the market.”

The synthetic knits are not cut or sewn, but rather formed seamlessly on a knitting machine. Options vary from no coating to various amounts of dips to provide splash protection and grip, he said.

All ATG products have a skin-friendly manufacturing process, and are washed three times before shipping.

A popular PIP Canada product is the MaxiFlex Ultimate AD-APT, a seamless knit nylon elastane glove, said Machado.

“ What’s very unique about that glove is ATG has figured out a way to infuse an essential oil right into the yarn,” he said.

Sweat activates the oil, allowing hot air to escape the glove, keeping the user’s hand 30 per cent cooler, explained Machado.

“ The goal is to keep the glove on the worker’s hand. As soon as they take off a glove, that’s when they are exposed to a mechanical hazard.”

At Superior Glove, a five-year project with hopes of protecting construction workers against nail-gun injuries culminated in the Shield — a nail-gun hand pad with plating in areas most susceptible to injury.

Released in 2019, the PPE is meant to be worn over existing work gloves, rather than as a standalone product, said Geng.

With armour plating built from Kevlar, the design is the result of working directly with workers through prototypes, he said.

Superior Glove also has products protecting fingertips from being crushed — meant for industries such as mining, construction and oil and gas. The PinchGuard protection system forms around the fingertips and is a first in the North American market, according to Geng.

The Endura line of products is made from goatskin, durable in very tough conditions.

Superior Glove recently received national attention for its innovative production strategies and product development.

For Smith, the future of gloves is biodegradable.

“ We’ve developed and invented the world’s first disposable nitrile glove, and we’ve expanded our offering on those products — now we have four single-use biodegradable nitrile disposable gloves,” he said.

“Everybody’s looking for green initiatives and to cut their carbon footprint. Any regular nitrile glove will be in a landfill site for 100 years. These biodegradable gloves will break down between two and five years.”

SHOWA’s 6110PF glove is a fully biodegradable nitrile disposable glove with Eco Best Technology, said Smith.

Through this product line, SHOWA is doing its part to protect the environment for future generations, he said.

“You look at grocery stores — they’re banning plastic bags,” said Smith. “It’s all less waste to landfill.”

“Every company has their green initiatives — it could be ISO 9001 or 14001. Everyone has been challenged to cut back on waste.”

By Paul Demers

The purpose of workers’ compensation systems is to provide fair compensation for workers who become ill or injured due to work.

W hile the system has worked relatively well for injuries and acute illnesses, underrecognition is a significant problem when it comes to diseases like cancer that take a long time to develop.

Based on data from the the Association of Workers’ Compensation Boards of Canada, Ontario has one of the better workers’ compensation systems in the nation.

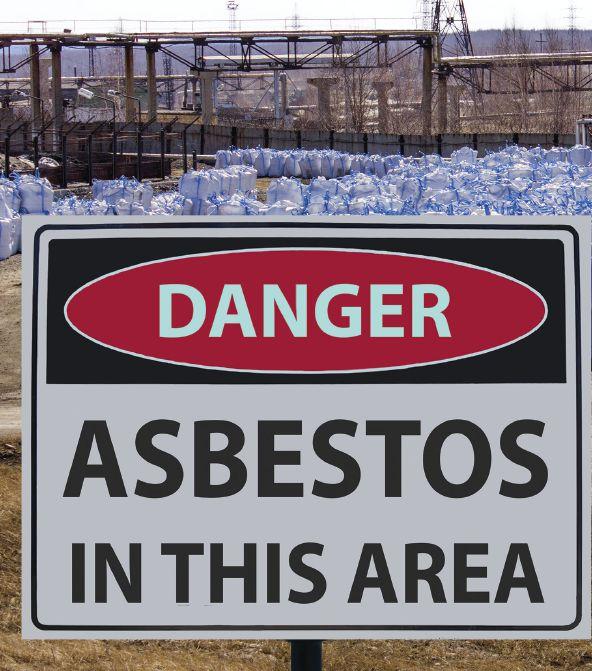

Over the past 10 years, an average of 400 claims were submitted annually for cancer, of which an average of 170 were compensated, primarily for asbestos-related cancer.

In contrast, the Burden of Occupational Cancer Project estimates that there are actually more than 3,000 occupational cancer cases diagnosed each year in Ontario, due to the most common, well-established carcinogens alone.

There is a gap between the number of claims submitted and those accepted, but there is an even larger gap between the number of claims submitted and the estimated true number of cases. Similar gaps exist in other Canadian jurisdictions.

Our understanding of the causes of cancer in the workplace has evolved over the past 50 years, and every year more carcinogens and suspected carcinogens are identified.

The Occupational Cancer Research Centre in Toronto recently examined the list of agents evaluated by the International Agency for Research on Cancer (IARC).

Over the past 10 years, an average of 400 workers’ compensation claims were submitted annually for cancer in Ontario.

Overall, 67 of the known human carcinogens (Group 1), 54 of the probable human carcinogens (Group 2A), 195 of the possible human carcinogens (Group 2B) and 325 of agents that had inadequate data to classify (Group 3) are found in workplaces.

There are many other new and emerging workplace exposures that have not yet been evaluated. As our scientific knowledge evolves, it is essential for us to keep up.

Public awareness of workplace cancer has also increased, largely due to media coverage of issues like the campaign to

ban asbestos, IARC evaluations and workers’ compensation controversies.

Efforts by workers diagnosed with cancer, their families and advocates have resulted in greater public attention and awareness of the impact of occupational cancer, as well as concerns over how claims are handled by the compensation system.

Some recent examples in Ontario include the large numbers of claims from General Electric Peterborough and the Kitchener rubber industry.

In response to these concerns, the Ontario Ministry of Labour, Training and Skills Development commissioned an independent review by the Occupational Cancer Research Centre to answer three questions:

• How can scientific evidence best be used in determining work-relatedness in an occupational cancer claim, particularly in cases with multiple exposures?

• Are there any best practices in other jurisdictions that Ontario should consider adopting?

• What scientific principles

should inform the development of occupational disease policy?

The ensuing report reviews scientific theories and principles regarding cancer causation and how exposure to different carcinogens at different times can impact this process.

I t also discusses some of the major challenges for workers’ compensation systems, including lack of exposure data, challenges in appropriately applying scientific evidence, and lack of scientific capacity.

The report makes a series of recommendations that include updating compensation policies, enhancing scientific capacity, improving access to exposure data and improving medical education.

The goal is to increase recognition, improve adjudication of claims and contribute to improved prevention of occupational cancers.

While the recommendations are tailored to the needs of Ontario, the broader implications are relevant to the situation across Canada.

Compensation policies should be reviewed and updated on an ongoing basis to reflect current and rapidly evolving, scientific knowledge.

This requires scientific capacity, which can partially be met by funding external researchers and partnering with academic and research institutions, as well as the development and use of surveillance systems to identify high-risk populations.

However, it also requires internal scientific capacity, including scientists with graduate-level training in exposure science, epidemiology and toxicology in order to appropriately apply and understand scientific evidence and principles, and to review new evidence as it becomes available to develop appropriate policies.

For Ontario, it’s also recommended that an independent, standing Scientific Review Panel be created to review and recommend changes to compensation policies.

Decision-making about the work-relatedness of cancer claims requires good, quantitative exposure data and this data is scarce.

M any Canadian jurisdictions do not collect their own exposure measurements, or collect very few. In principle, this responsibility now falls to employers, but these privately collected measurements are very rarely publicly available.

This data gap needs to be filled.

The biggest gap in occupational cancer compensation is between the estimated true burden and the number of claims submitted.

Many people and their health-care providers may not realize that a diagnosed disease could be connected to their work, especially for diseases like cancer that can occur many years after the exposure occurred.

However, appropriate scientific expertise is a scarce resource and many jurisdictions are too small to afford the capacity necessary.

Sharing scientific resources across jurisdictions would be a cost-effective solution.

M any compensation systems in Canada have presumptive lists of diseases that are presumed to be work-related, provided the worker meets the specified exposure criteria.

T hese lists can increase transparency and improve and streamline the adjudication process, but they must be continually reviewed and updated to remain relevant and keep pace with evolving knowledge.

Another priority area is the need for policies that account for the effect of multiple carcinogen exposures on cancer risk.