ANSWERING THE CALL

3 year multigas

MGC Simple Plus

2 year multigas

MGC Simple

Detects combustible gases (LEL), hydrogen sulfide (H2S), carbon monoxide (CO) and oxygen (O2)

uTwo or three year run time with no charging or calibration

uDetect in oxygen deficient or oxygen enriched environments

uLEL sensor is immune to sensor poisoning

uFails to safe

uSimple, one button operation

uLogs data at one second intervals whenever gas is detected, records bump tests & events

u100% Quality control tested

uFull two or three year warranty

or

Multi Gas Clip

The portable multi gas detector that can run continuously for two months on one charge due to advanced infrared sensor technology. Detects combustible gases (LEL), H2S, CO and O2.

Multi Gas Clip Pump

Compact, light-weight, handheld/wearable multi gas detector with internal pump draws from 75 ft. & runs for an average of 52 hours on a single charge. Detects combustible gases (LEL), H2S, CO and O2.

Single Gas Clip

Eliminate downtime with our ultra-reliable portable gas detector. Detects H2S, CO or O2

Single Gas Clip Plus

Hibernate mode offers extended life option when detector is not in use. Detects H2S or CO.

All-in-one, portable, durable four-bay dock stations quickly bump test, calibrate & log data for up to four detectors at once with the push of a button and one stream of gas saving time and gas. Charge once every six months. Perform 2000+ bump tests with one 116L gas cylinder.

Single Gas Clip Dock, Multi Gas Clip Dock, MGC Pump Clip Dock & MGC Simple Clip Dock

In the face of an unprecedented pandemic, Canadian employers stepped up to help, with some converting operations to assist in manufacturing and others making major donations of essential PPE.

BY MARCEL VANDER WIER

Life behind the wheel came with significant health and safety challenges through COVID-19, but truckers kept on rolling. Deemed an essential service, they remained on the job, moving medical supplies and bringing products to market.

BY GRANT CAMERON

Use tried, tested approach

Considering the hazards of a new workplace reality and taking reasonable precautions to protect staff are the first steps towards returning to work following closures as a result of COVID-19.

BY DAVID REITER

COVID-19 has changed workplace safety forever

Without question, the coronavirus pandemic has brought about the largest shift in modern culture ever. Human behaviour has been completely upended. Safety is priority No. 1.

BY CHRISTOPHER HURLEY

leadership is nagging gap in prevention CEOs and their executive team are responsible for setting the tone, creating the values and maintaining a healthy workplace culture. During the COVID-19 pandemic, this is more important than ever.

BY MAUREEN SHAW

requires measurement – lots of it

Measuring fatalities from COVID-19 is necessary, but not sufficient to tell us what is working. Measuring the success of isolation, social distancing, handwashing and masking will help us know what actually works.

BY ALAN QUILLEY

What a time to be alive. At time of writing, Torontorians have been living the quarantine life for 11 weeks. And while we and other Ontario citizens remain under fairly strict social-lockdown procedure, it is with great hope that we watch other provinces and territories begin the cautious process of reopening.

I can speak for all Canadians in saying we will never forget these past few months. From a full-blown panic in March to a national lockdown through April, the COVID-19 pandemic has turned all of our lives upside-down.

Professionally, it has been a blur.

On March 12, shortly after the NBA lockdown was announced, OHS Canada’s website traffic exploded as employers and safety pros around the nation began looking for the answers to a pandemic very few saw coming. Over the next weeks and months, the news came fast and furious and we worked hard to keep our readership up to date.

This all happened as our parent company, Annex Business Media, quickly deployed a work-from-home solution that gave the majority of our staff the opportunity to continue business from our home offices. It’s been interesting and memorable times watching my wife teach her Grade 6 class via Zoom, and splitting the duty of helping my son finish out his year in senior kindergarten.

Like all of you, my family has endured a roller-coaster of emotions through this incredible time. So far, we’ve managed to hang on through the difficulties of self-isolation, and have found increased joy in the simple pleasures such as eating breakfast, lunch and dinner together as a family. We have maintained our health through the pandemic, and are grateful and thankful for that.

Not everyone has been so fortunate.

By late May, COVID-related deaths in Canada had surpassed 6,000, and the situation in certain long-term care homes appeared to be downright frightening. But Canadians are a resilient bunch, and have — mostly — remained cooperative in enduring this challenge together.

The stories that follow in this issue detail the work of organizations and OH&S professionals who helped Canada battle back against a global pandemic. To those who shifted operations to assist in building much-needed personal protective equipment, and those who worked day and night to ensure your workers were safe — you are the ones we salute.

To all health and safety workers, government leaders and essential employees who continue to serve on the front lines — thank you, from the bottom of our hearts for your service and bravery.

This pandemic landed unexpectedly on the world’s doorstep. Thank you for helping to push it back.

For the occupational health and safety profession, the COVID-19 pandemic could prove to be a watershed moment. Workplace safety is firmly entrenched as the No. 1 conversation all across Canada.

For those who know the annual statistics of injury and death for Canadian workers, let’s hope safety remains on the forefront of our discussions in the years to come.

Marcel Vander Wier

CANADA’S

HEALTH & SAFETY MAGAZINE

Vol. 36, No. 3 MAY/JUNE 2020

EDITOR MARCEL VANDER WIER 416-510-5115 mvanderwier@ohscanada.com

MEDIA DESIGNER MARK RYAN

ACCOUNT CO-ORDINATOR CHERYL FISHER 416-510-5194 cfisher@annexbusinessmedia.com

CIRCULATION MANAGER JAY DOSHI 416-442-5600 EXT 5124 jdoshi@annexbusinessmedia.com

NATIONAL SALES MANAGER ROSS ANDERSON 289-925-7565 randerson@annexbusinessmedia.com

GROUP PUBLISHER PAUL GROSSINGER pgrossinger@annexbusinessmedia.com

COO SCOTT JAMIESON sjamieson@annexbusinessmedia.com

Printed in Canada ISSN 0827-4576 (Print) ISSN 1923-4279 (Digital)

PUBLICATION MAIL AGREEMENT #40065710

CIRCULATION

Tel: 416-422-5600

Fax: 416-510-5140

Mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

SUBSCRIPTION RATES

Published six times per year – Jan/Feb, Mar/Apr, May/Jun, Jul/Aug, Sep/Oct, Nov/Dec Canada $100/yr plus tax USA $130/yr (100 USD) Foreign $214/yr ($164.50 USD)

Occasionally, OHS Canada will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbusinessmedia.com

Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2020 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Paula Campkin: chief safety officer at Energy Safety Canada in Calgary, Alta.

Marty Dol: president and founder of HASCO Health & Safety Canada in Toronto

Cindy Moser: director of communications for the Institute of Work & Health in Toronto

Natalie Oree: prevention consultant with SAFE Work Manitoba in Winnipeg

David Powers: director of HSE with Oxford Frozen Foods in Oxford, N.S.

Richard Quenneville: senior director of corporate services with T. Harris Environmental Management in Toronto

Maureen Shaw: lecturer and presenter in Victoria

Dylan Short: managing director of The Redlands Group in Oakville, Ont.

To all the men and women who, day after day, as essential workers, put themselves and their families at risk, while we stayed at home... THANK YOU . Keeping you safe with our innovative fall protection products and training has been our privilege and honor... THANK YOU .

1. Vancouver Island: In March, a fishing worker was alone on the back deck of a longline vessel, putting a 1.2-metre-by-1.2-metre lid onto a tote. When another crew member went to check on the worker, neither the tote lid nor the worker could be found. After an extensive search of the area by the fishing vessel, Coast Guard and search and rescue aircraft, the worker was found deceased.

Source: WorkSafeBC

2. High River, Alta.: An Occupational Health and Safety report says Cargill didn’t include workers in an internal review in April of circumstances that led to about 950 confirmed cases of COVID-19 in employees at its meat-packing plant. In May, the Alberta government announced that a second employee had died of COVID-19.

Source: The Canadian Press

3. London, Ont.: On April 6, two London pawn shops were issued provincial offence notices by the city after failing to comply with orders in place to help slow the spread of COVID-19. A provincial emergency order had gone into effect on March 25 ordering all non-essential businesses to close.

Source: London.ca

4. Oakville, Ont.: Amidst disturbing reports of individuals discarding personal protective equipment on both private and public property, Mayor Rob Burton enacted a bylaw on April 9 to regulate discarding of PPE and ensure the safety and well-being of the community. Additional bylaws were passed to create penalties of $300 for littering in parks and other public places.

Source: Oakville.ca

5. Quebec City: The Commission des normes, de l’équité, de la santé et de la sécurité du travail (CNESST) launced a promotional campaign in April developed especially for COVID-19 with the theme “Getting Quebecers back to work safely.” The goal is to remind everyone how important it is to do everything possible to protect worker health and safety, following the safety directives issued by public-health authorities.

Source: CNESST

6,030

Total number of Canadian deaths due to COVID-19 as of May 20. The country had 80,091 confirmed cases, with more than half of those in Quebec.

Source: Government of Canada

132 million

Number of global citizens expected to be affected by river flooding in 2030 — more than double the amount in 2010.

Source: World Resources Institute

94%

Amount of Canadian office workers who are satisfied with their employers’ response to the COVID-19 pandemic.

Source: Robert Half Canada

29%

360°

Sightings of the Asian giant hornet have prompted fears that the vicious insect could establish itself in the United States and devastate bee populations. In Japan, the hornets kill as many as 50 people each year.

Source: New York Times

Number of Canadians who believe restrictions on workplace and leisure activities should only be lifted once the country is free of any new cases for at least two weeks.

Source: Leger and the Association for Canadian Studies

Freelance writer Andrew Snook earned an honourable mention at the 2020 National Magazine Awards: B2B on May 20 for his story featured on the cover of the July/August 2019 issue of OHS Canada

The story, entitled “Black Hat Hacker: The dark side of connectivity,” delved into cybersecurity on construction jobsites, outlining how technologies not previously vulnerable to hacking — such as cranes and industrial equipment — are now fair game.

Snook was one of six up for the Best Feature Article: Trade award offered by the National Media Awards Foundation in Toronto.

TORONTO (CP) — No one knows when a fresh surge of COVID-19 cases will emerge in Canada, but experts agree numbers are poised to rise and could very well explode in surveillance blindspots.

A “tried and true” principle with any respiratory virus is that infection risk is lower outside and in larger spaces where germs can dissipate, says Dr. Camille Lemieux, medical lead for the COVID-19 assessment centre at Toronto’s Western Hospital.

That’s opposed to small, confined areas with poor ventilation, but the speed of this novel coronavirus to find human hosts is what’s most concerning, she says.

“The one thing about COVID that I think has a lot of people stymied is the rapidity with which it spreads when it gets a foothold,” says Lemieux, also chief of family medicine at the University Health Network in Toronto.

Even with containment, the virus is circulating in the community thanks to a small percentage of people with mild and no symptoms who don’t even know they are sick, adds Dr. Gerald Evans, medical director of infection control at the Kingston Health Sciences Centre.

Evans says “second waves are inevitable” as regions open up, using the term loosely to mean any uptick big or small. He cautions against suggesting one sector of public life — such as the tennis court — is safer from the virus than others.

“If people start congregating around campfires and other things in parks, and then large groups of golfers are getting together and hanging out, that could facilitate transmission,” says Evans, also chair of the division of infectious diseases at Queen’s University.

If Evans were to guess, he says a Canadian resurgence is

“It’s an honour to be named a finalist at the National Magazine Awards: B2B in the Best Feature Article: Trade category,” said Snook. “I want to thank the judges for seeing value in my article, as well as (former OHS Canada editor) Jean Lian and the entire OHS Canada team for doing a great job editing the article and designing the cover of the issue.”

“Hopefully, the article opened some eyes to the important role that cybersecurity now plays in ensuring safe operations across many industries.”

A former Annex Business Media employee, Snook now owns his own publishing company — SnookBooks Publishing in Toronto.

very likely to start among younger adults who resume social activities, suggesting they’re more likely to risk exposure and will have been largely shielded from infection.

B.C. (CP) — One member of the Canadian Armed Forces has died and another was injured after a Snowbird plane crashed in a residential area of Kamloops, B.C., on May 17 while on a cross-country tour meant to impart hope during the COVID-19 pandemic.

Capt. Jenn Casey, a public affairs officer with the Canadian Forces, died in the incident, the Department of National Defence said.

Capt. Richard MacDougall, the pilot of the aircraft, was being treated for his injuries that the Snowbirds said are not life-threatening.

“Canadians look at the Snowbirds as a source of joy and an exhibition of the incredible feats that our people in uniform are capable of,” Minister of National Defence Harjit Sajjan said in a statement. “Operation Inspiration was intended to lift the spirit of Canadians at this difficult time and the Snowbirds accomplished their mission. I know that all Canadians grieve this tragic loss.”

Casey joined the Canadian Forces in 2014 and was based out of Trenton, Ont., after working in radio as a reporter, anchor and producer in her hometown of Halifax and Belleville, Ont., according to her Royal Canadian Air Force bio.

Casey spent most of 2018 with the CF-18 Demo Team, travelling around North America and the United Kingdom with the NORAD 60 jet. She joined the Snowbirds in November 2018.

OTTAWA (CP) — Canada’s public-health experts are now fully recommending Canadians wear non-medical face masks in public when they aren’t sure they will be able to keep their distance from others.

Dr. Theresa Tam said the new recommendation comes as stay-at-home orders are lifting in different provinces and more people are going outside, riding public transit or visiting stores.

“This will help us reopen and add another layer to how you go out safely,” Tam said May 20 in her daily briefing to Canadians on the COVID-19 pandemic.

The advice is slightly stronger than previous suggestions that people should consider wearing a face mask in public. It is a complete turnaround from her advice seven weeks previous that people who are not sick should not be wearing a face mask at all.

Tam said initially it was believed the novel coronavirus was only spreading from people showing symptoms. That understanding has changed, as it is now known people can transmit the virus days before symptoms show up. Some patients may never show symptoms at all and can still spread the virus to others.

Tam said in future respiratory outbreaks, wearing face masks might become a normal part of the public-health response. She said the tried-and-true public health measures of testing, contact tracing, handwashing and physical distancing have worked to slow the spread of COVID-19 in Canada.

ST-JEAN-SUR-RICHELIEU, Que. (CP) — Quebec schoolchildren were greeted by their teachers with smiles and squirts of hand sanitizer on May 11 as the province became the first to reopen some schools following the outbreak of the COVID-19 pandemic.

Daycares and elementary schools outside the Montreal area were allowed to open, with a maximum of 15 students per classroom and a new set of rules in place.

At Ecole St-Gerard in St-Jean-sur-Richelieu, southeast of Montreal, Marie Fortin watched as her twin seven-year-old daughters each received a spray of disinfectant from a staff member wearing a mask. She said sending her kids to school was “important for their routines.”

Fortin said she felt reassured after seeing all the preparations done by staff, including sectioning off classrooms with tape, devising a game around handwashing, and cleaning and disinfecting.

Across the province, students are being met by staff wearing masks and in some cases face shields, and they are being told to follow physical-distancing rules and wash their hands frequently.

Libraries, gyms and cafeterias were closed, and children were expected to spend the majority of the day at their desks.

NEW YORK (AP) — Questions remain about how prepared many countries are to end lockdowns.

The World Health Organization’s emergencies chief, Dr. Michael Ryan, said robust contact-tracing measures adopted by Germany and South Korea provide hope that those countries can detect and stop virus clusters before they get out of control.

But he said other nations have not effectively employed contact-tracing investigators to contact people who test positive, track down their contacts and get them into quarantine before they can spread the virus. He declined to name specific countries.

“Shutting your eyes and trying to drive through this blind is about as silly an equation as I’ve seen,” Ryan said. “And I’m really concerned that certain countries are setting themselves up for some seriously blind driving over the next few months.”

U.S. contact tracing remains a patchwork of approaches and readiness levels. States are hiring and sourcing contact tracers, and experts say tens of thousands will be needed across the country.

Apple, Google, some U.S. states and European countries are developing contact-tracing apps that show whether someone crossed paths with an infected person. But the technology supplements and does not replace labour-intensive human work, experts say.

Worldwide, the virus has infected more than 4.1 million people by mid-May and killed over 285,000, including more than 150,000 in Europe and 80,000 in the U.S., according to a tally by Johns Hopkins University. Experts believe those numbers understate the outbreak’s true toll.

Ever wonder what other OH&S types are thinking? Find out by making our website poll a regular stop.

“We don’t feel unsafe at all,” she said.

The province has said attendance is not mandatory, and one school bus pulled in with a lone student aboard.

Marie-Claude Audet, a special education teacher, said about half the school’s parents had elected to send their children. The school is bringing them back gradually, beginning with kindergarten and first grade.

Does your organization have adequate planning in place for natural disasters and pandemics?

By David Reiter

It has been more than two months since COVID-19 shut a large part of the world economy down. Hopefully, the worst of it is behind us and businesses will gradually be allowed to start opening up again.

Assuming that is what happens, what should employers be doing from an occupational health and safety perspective to ensure that their workers are protected from COVID-19?

Perhaps unsurprisingly, the answer is straightforward.

Two things need be remembered. First, employers — as always — need to take all reasonable precautions to protect the health and safety of their staff. Second, employers can do that by following the tried and tested method of identifying those hazards that their workers may face, and by implementing policies and procedures that address them.

We know that COVID-19 is a highly communicable virus that spreads easily and quickly through people’s interactions both with one another and with objects.

As such, the first question that employers should be asking is: What facets of my operation create opportunities for the virus to spread?

In answering that question, employers should start by identifying all of the instances in which their workers could come into contact with others without the protection of physical distancing.

In an office environment, that would involve looking at how workspaces are laid out. In industrial facilities, it may also include assessing the layout of workstations and storage arrangements. Finally, in all work environments, employers should be considering how their workers interact in common areas such as breakrooms, boardrooms and washrooms, as well as how staff arrive at and leave the workplace.

Employers should also be considering what opportunities workers may have to come into contact with non-workers — such as deliverypeople, customers and suppliers. Businesses should also be concerned with their workers’ interactions with objects.

The primary concern will likely always be the workplace itself, as workers in an office or facility will inevitably end up touching the walls, fixtures and furniture.

Given that there is evidence that the virus can survive on surfaces such as cardboard and packaging, things that are being brought into the office and handled — such as

supplies, deliveries and even money — should also be considered as a potential hazard.

At the end of the day, it is in, and on these touchpoints that the COVID-19 hazard resides.

The next step involves creating and implementing policies and procedures that address those hazards effectively.

This will involve ensuring that physical distancing is maintained so that interpersonal transmission of the virus is prevented. At the same time, it will also involve instituting hygienic controls so that the virus is removed from commonly accessible surfaces.

Inevitably, as a first step, businesses will have to ensure that workspaces are appropriately physically distanced, that washing facilities are available and properly stocked with soap and sanitizer, that hygienic cleaning and sanitizing protocols have been put in place for the workplace itself, and that workers are given access to — and have been required to use — personal protective equipment such as gloves and masks, as may be appropriate.

However, these are only the first steps. Others will also have to be considered. For example, employers may need to consider staggering workers’ shifts, start and finish times — even breaks — limiting opportunities to congregate.

Similar controls may have to be considered for businesses’ shipping and receiving departments, so that workers do not have to contend with multiple non-workers congregating at any one time in the workplace. As well, actual facility changes may have to be considered to ensure physical distancing is maintained.

It is important to remember that all of the points that are set out above are simply examples. The policies and procedures that businesses consider will inevitably vary, depending on the nature of the operations being undertaken.

Given that, what businesses should be keeping in mind is that the essence of their obligation is to take all reasonable precautions to protect their workers, and that the most effective way to do that when dealing with COVID-19 is to identify from where the risks to workers are coming, and how those risks can be addressed most effectively.

If businesses do that, and take guidance from publichealth authorities as well as the general industry standards that have been and are being implemented, they will likely have gone a long way — if not all the way — toward protecting their workers from the risks posed by COVID-19.

David Reiter is a partner with Aird and Berlis in Toronto.

New tools for health & safety professionals to track and manage pandemic exposures in the workplace.

Coping through COVID-19

In March, companies across Canada were confronted with an unprecedented pandemic. Here’s how three safety professionals led their teams through it. Responses have been edited for length and clarity.

What measures did you put in place at your organization to protect staff?

Across the organization, we’ve increased the frequency and requirements of our cleaning services in our warehouses, offices and stores and made sure all are supplied with hand sanitizer.

We also developed custom health and safety signage across each area of the business, which includes floor markings to help maintain physical distancing and posters to remind employees of best practices, such as frequent hand washing and sanitizing. To provide additional support, we have created a compassionate leave to provide financial support of up to four days of paid leave to all active LCBO employees, waived medicalnote requirements, developed and made available a variety of health and wellbeing resources and created a dedicated COVID-19 employee safety website with the latest information available.

As our stores are our highest traffic areas, we’ve taken many steps to protect our frontline retail employees and customers. This includes the installation of Plexiglas barriers at open cash registers

in more than 660 stores, providing retail staff with protective face shields and gloves and limiting the number of customers in-store at a time.

We also reduced store hours and operational days and allow employees to wear their own non-medical masks, if they wish to do so. Across our LCBO retail service centres and depots, we introduced a body temperature screening process with plans to implement this in other areas of the business as well.

To promote physical distancing and manage traffic flow, we created new signage and floor decals, and are limiting the number of customers in our stores at one time. We have also increased our cleaning practices and availability of hand sanitizer, including dedicating an employee to cleaning at stores where possible and sanitizing shopping carts before and after each use.

We have continued to leverage our social-media channels and consumer website during this time to share information with customers and remind them of the safety measures in place. We have been focused on providing customers with more shopping options including the expansion of our same-day pickup program where customers can purchase online and pick up in store, which limits the amount of time spent in-store.

Additionally, any customers who are sick, in isolation or returning from travel have been asked to refrain from visiting LCBO stores. If a customer self-identifies as in this category or makes remarks of having COVID-19 symptoms, staff have the right to refuse service and ask customers to leave the store.

The LCBO has been following recommendations of public-health agencies at the various levels of government — municipal, provincial and federal — to inform our decisions and establish new practices and policies. For additional best practices and guidance, we also look at other provinces, the Retail Council of Canada and similar retailers.

Clarke Director of business continuity and workplace safety at IMAX

What measures did you put in place at your organization to protect staff?

The IMAX Pandemic/Infection Control Plan specifies a phased approach in co-ordination with local regulatory requirements.

Our approach leading up to quarantine measures in each of our locations was phased, as will be our return to on-site activities. Implementation of each of the phases is driven by regulatory guidelines and the risk associated with our operations at each work location around the globe.

We started out with restrictions of visitors and moved to limiting to only essential contract employees and vendors. We reduced travel to essential business travel and progressed to no business travel. Travel will resume based on phases implemented by each country, state and province, and will also be dependent on risk of infection within each business activity.

We revised seating and path of travel arrangements in the office, testing, manufacturing, warehouse, depots and theatre settings.

We increased cleaning and sanitization protocols, working with janitorial staff and vendors to develop consistent cleaning protocols at all facilities between staggered shifts and showings.

Our workplace cafeterias, kitchens, concessions and refreshment stations switched to disposable versus reusable dinnerware and cutlery, and moved from self-serve to served food only, alongside increased cleaning in these areas.

We increased the availability of hand sanitizer throughout our facilities, along with cleaning products for shared workstations.

Masks and gloves were provided to staff in office, and fit testing occurred for anyone who was utilizing N95 masks at the time.

We implemented daily employee and essential contractor and vendor health screening via an emergency notification system — text and email.

What changes did you make to protect the health and safety of your customers?

We will be implementing social distancing within all of our facilities, seating arrangements to respect social distancing, increased cleaning protocols between screenings and in public spaces, health screening and PPE requirements, increased signage and rigorous awareness as well as communication programming.

What type of effect did the increased pressure have on you personally?

I have been extremely busy in my role with response efforts under safety and business continuity. There have been many long nights and weekends worked. So much so, that at one point I found myself ill-prepared for the pandemic in my personal life. By that, I mean at one point while we were mobilizing everyone to work from home, I realized I needed to go out to stock up on groceries just like everyone else!

I am feeling fatigued at the moment, as this impacted our operations in January due to our presence in China. Just as China was returning to work in our offices, the rest of the world was entering quarantine measures. For someone in my role, that has meant zero downtime. Having been involved in pandemic planning in the health-care industry, I was not caught off guard. I always knew that it was just a matter of time before this occurred.

What did you learn about navigating your company’s health and safety policy through a pandemic?

We have a really good program in place that formed a very good foundation for us to build upon in an everchanging and unprecedented situation. I learned the importance of conducting exercises for various threats before they occur. When you are having difficulty obtaining buy-in to plan for an event, exercise that scenario.

Simon Kaplansky Senior manager of health, safety and well-being at Longo’s in Vaughan, Ont.

What specific measures did you put in place at your organization to protect staff?

We regularly monitored and made continuous changes as the pandemic evolved taking what we felt were appropriate steps at the time to protect the safety of our workers and the general public who shop in our stores. What was sometimes considered to be a crazy “out there idea” one day, turned into a reality the next day or next week. We needed to remain as agile as possible as the events of the pandemic advanced to keep ahead of the risk and protect our workers.

Some of the measures we implemented include the following:

We provided hand sanitizer to our cashiers in our front end to use immediately after serving our guests, alongside the flexibility to leave their workstation to wash their hands on a regular basis.

We provided disposable nitrile gloves to our team members, as well as guidelines and instruction on safe use and removal of gloves.

We monitored Public Health Agency of Canada and Public Health Ontario updates and continue to follow their advice and recommendations.

We have been providing daily updates to all of our team members through all of our communication channels.

We installed Plexiglas barriers at all of our cash lanes and service departments to protect our team members.

We implemented an isolation payment for team members who were required to isolate and paid for 14 days.

We sent messaging to all of our vendors, suppliers and contractor partners on our policies and expectations during the COVID-19 crisis

to ensure everyone’s safety and wellbeing. We are holding all of these vendors accountable for non-compliance.

What changes did you make to protect the health and safety of your customers?

We implemented physical distancing guidelines at the checkout lanes and regular disinfection of hightouchpoint surfaces including PIN pads at the checkout lanes.

In some areas we have modified how we do business. We have limited the number of guests in our stores at any given time to facilitate physical distancing, made our shopping aisles one-way to avoid guests crossing paths in our aisles.

We have started doing “wellness checks” at our store entrances that include a pre-screen questionnaire for our guests. We have also required that all of our team members and guests wear face coverings to protect each other and everyone who enters our facility.

Where did you look for guidance on establishing policy during this period?

The Public Health Agency of Canada (PHAC) and Public Health Ontario (PHO) have been our primary sources of information throughout the COVID-19 pandemic. We have also referred to the World Health Organization and occasionally the Centers for Disease Control and Prevention (CDC) in the U.S.

What type of effect did the increased pressure surrounding health and safety have on you personally?

I am very fortunate to have a strong network, both within our company and across my professional network, to support me in navigating through this crisis. It has been a big adjustment to this new (and temporary) way of life. I have missed my colleagues in the office in spite of the technology we have used to stay connected, but have also enjoyed being able to have lunch (almost!) every day with my family.

By Christopher Hurley

Well, I’ll admit it. My crystal ball may have been a little foggy. In January, I wrote that technology trends would dominate the safety profession through 2020. That was pre-pandemic.

Although I can still state with certainty that tech trends will remain incredibly important to safety moving forward, COVID-19 now dominates every headline and conversation. For at least the short term, everything about the way we do business has changed. Long-term impacts are pending, but in the meantime, let’s look ahead to what this all translates to for safety professionals moving forward.

Without question, COVID-19 has brought about the largest shift in modern culture ever. Period. Full stop. And not just with safety, but with all facets of our life. Human behaviour has been completely upended.

As a safety professional, it’s fascinating to see such an embrace of — and commitment to — standard safety protocols on everything from HVAC maintenance to PPE adoption to distancing markers in grocery store lineups. All in the name of protecting ourselves and others.

It’s important to remember that just like in our challenges with buy-in on any safety topic, there will be dissenters. And there certainly are in the case of COVID-19. But this is different. Loss is far more tangible. Fear runs rampant and people, for the most part, have responded.

Let’s take that response and open our minds to this presented, once-in-a-lifetime opportunity.

Momentum on a new (or old) safety program component is difficult. You need a recognized gap, adequate resources, buy-in from senior management, a consulted supervisory and worker population, and then incentive — usually more than just legislation — to drive it all home.

That’s a lot, and as we all know, even if the moons properly align, it never goes smoothly.

But momentum is huge. The laser focus and current inertia COVID-19 has presented to the safety world will likely never be seen again.

Can safety professionals leverage the spotlight on the profession to push correction and compliance on culture

challenges faced for years? At their essence, the issues are the same — a hazard exists, controls must be put in place, and it’s up to everyone to look after each other. Right?

It’s hard to know for sure, but a huge opportunity could be lost if this momentum diminishes or wavers because of time, absent consequences or financial challenges.

COVID-19 will forever be a reference point to our collective (macro or micro) ability to accomplish anything regardless of cost, level of difficulty or perception of impossibility. Never again should a safety challenge run into a barrier of cost, interest or risk-reward measurements.

OK, perhaps that’s a bit of a safety pro’s utopia, but at the end of the day, how many things have we watched change around us that many would have labelled as “impossible” or “would never happen” since mid-February?

It felt like in a heartbeat we went from having the NBA season postponed to undergoing a full-scale countrywide shutdown because of risk. Simply incredible.

It begs the question: How often in the future will safety pros harken back to the days of COVID-19 where magic happened and miracles occurred all because of engagement at all levels across all people? Nothing was impossible. The world’s response to COVID-19 demonstrates how pure willingness and engagement will drive results.

We can see it so clearly. Lockdowns, physical distancing, testing and tracing have had a specific tangible result in the number of infected and the number of deaths.

Money, time, difficulty and maintenance of these items will all be overcome to ensure businesses can remain successful through the pandemic, as well as post-pandemic. It is now the responsibility of everyone — and our collective commitment to safety.

At the end of the day, everyone is all in when it comes to keeping our businesses thriving and alive when safety concerns presents a business risk.

But when the dust settles, will the protection of people be paramount because culture around safety has changed? I guess we will have to wait and see.

This safety pro’s crystal ball is currently on hiatus.

Christopher Hurley is the founder of Safety Services Canada, a multi-functional health and safety consulting firm located in Caledonia, Ont.

By Maureen Shaw

We are currently living in a different reality. Over the past three months, global citizens have endured a period of massive upheaval and change unlike anything seen since the Second World War.

The COVID-19 pandemic has resulted in a seismic shift in how we live, work and play. Even after the pandemic is ultimately addressed, it is unlikely we will return to what we previously thought of as normal — certainly not soon. But a new, even better, future could emerge — if leaders step up.

The Association of Workers’ Compensation Boards of Canada (AWCBC) tells us that 1,027 workplace fatalities were recorded in Canada in 2018, an increase of 76 lives lost over the previous year. Among these deaths were 27 young workers aged 15 to 24.

AWCBC also recorded 264,438 accepted claims (an increase from 251,508 the previous year) for lost time due to a work-related injury or disease, including 33,058 from workers aged 15 to 24.

While OH&S professionals have expressed concerns over these persistently rising statistics, the bottom-line question is: What is truly preventing the meaningful reduction or potential elimination of these needless deaths and injuries?

Some might suggest a reported reduction in the number of accepted claims is evidence of declining injury rates. In fact, there are many reasons accepted claims are down, but that trend is not solely a result of injuries and illness elimination. That’s another story!

We are working to manage the impacts of COVID-19 by having the right policies, procedures and support in place for all our workers and our communities.

At the same time, we need to ensure we keep the focus on core health and safety by having an effective health and safety management system in place.

While some organizations and their leaders are doing an excellent job, historically a lack of senior-level leadership and support for health and safety in organizations has created a critical gap that sadly persists today.

Given some of the questions, concerns and outcomes, leadership from the top — the C-suite — is imperative. Simply delegating responsibilities to OHS professionals, managers, supervisors and workers is not leadership.

While having an effective joint health and safety committee is critical — and all levels of a workforce must be part of the process — trusted, active, resilient, caring, agile leadership is vital, especially in light of current and future events.

In some parts of our country there are evident gaps in co-ordination amongst public organizations responsible for health and safety. In addition to providing much-needed guidance on COVID-19 health and safety practices, these organizations should also support businesses by working with them to develop clear guidelines, products and services — and share them broadly.

Addressing the COVID-19 pandemic’s impacts on workplaces demands this kind of guidance and support. It also provides a rich opportunity for leadership engagement.

Transformative senior-executive leadership is needed now, more than ever. A lack of leadership will continue to see businesses lost, alongside a continuing increase in the number of ill and injured workers.

CEOs and executives are responsible for setting the tone, creating the values and maintaining a healthy workplace culture. They have the sphere of influence to ensure health and safety is integral and embedded into operations. Ensuring health and safety messages are consistently communicated firmly, with empathy and understanding, is urgent.

Health and safety professionals understand the hierarchy of controls. The upside-down pyramid that moves from top to bottom: elimination – substitution – engineering controls – administrative controls – PPE.

At the very top should be leadership from the CEO and executive team. The effectiveness of the hierarchy is dependent on leadership being strong, committed and consistent.

Health and safety concerns have never been higher in the minds of people as they are now. Carefully and properly implemented, measures to protect health and safety provide the opportunity to emphasize injury and illness prevention in our workplaces and our communities.

Those at the top of organizations must lead, inspire, and empower.

Now is the time to bridge the nagging leadership gap and truly foster a healthier and safer future for all workplaces and communities in Canada.

Maureen Shaw is the former president and CEO of the Industrial Accident Prevention Association. Living in Victoria, she is a member of the OHS Canada editorial advisory board.

In the face of an unprecedented pandemic, Canadian employers stepped up to help

By Marcel Vander Wier

As the COVID-19 pandemic rained down hard on Canadian workplaces and workforces, employers across the country stepped up.

While governments of all levels worked to protect their most vulnerable citizens and health-care facilities through a nationwide economic shutdown, manufacturers pivoted quickly to begin providing appropriate personal protective equipment (PPE) to the front lines of the pandemic.

Other organizations donated excess supplies to workers in need as part of a heroic effort to flatten the curve and protect health-care workers and other essential employees.

In March, the federal government called on businesses and manufacturers to help deliver critical health supplies. Thousands responded by offering expertise and expanding capacity to meet the country’s need for PPE.

“Canadian companies are answering the call to provide critical support to our health-care workers who are on the front lines of our country’s fight against COVID-19,” Prime Minister Justin Trudeau said in April.

“We’re going to get through this together by leaning on each other and protecting our frontline workers.”

In May, with the country beginning to emerge from the pandemic, here’s a look back at the ways in which four companies across Canada took it upon themselves to help.

Bauer factory pivots to face shields

It was a plea from the prime minister that caused Bauer Hockey to sit up and take notice.

Trudeau’s March 19 briefing caused the company’s skateproducing factory in Blainville, Que., to pivot to face shields, said Dan Bourgeois, vice-president of product innovation.

“We had a ton of different ideas at the beginning,” he said. “In ice hockey, we’re committed to protect our players. We said, ‘How can we protect our first responders?’”

“Of course, at the beginning when we started this project, we had no clue of the magnitude of the need.”

Bauer’s face shields followed in the footsteps of its hockey visors, said Bourgeois.

Following a review of protective products already on the market, Bauer added its knowledge on head metrology and moved to build a face shield offering equal parts comfort and protection.

With the need for PPE at an all-time high, Bauer went on to share its prototype online, he said.

The zigzag-shaped foam included in the Bauer solution is meant to allow face shields to form perfectly to the user’s forehead, said Bourgeois.

By late April, the factory was producing 200,000 shields per week, many of which were shipped for use by the federal government, Quebec hospitals and frontline health needs in other provinces, he said.

Pivoting away from skates to masks — skate production was later temporarily paused under a provincial government order — required some swift changes in production and safety measures, said Bourgeois.

Appropriate physical-distancing measures were implemented, alongside morning temperature scans. Employees were outfitted with gloves, gowns, ASTM Level 1 masks — and, of course, shields.

Typically operating with 60 to 80 employees building skates, staff levels dropped to 40 during the COVID-19 pandemic, he said.

“We don’t want people to be at risk or get a transmission of the virus.”

All Bauer-manufactured shields were cured in an oven prior to being shipped, noted Bourgeois. “We’re not taking any risks.”

A commitment to agility was critical, as was locating enough raw materials to produce the masks, he said.

“From Day 1 to today, the line is totally different,” said Bourgeois.

“Now it’s better because it’s more in control, but the first week of the pandemic, the need and people calling us and almost crying… We feel proud of what we’re doing, but at the same time we have mixed emotions — feeling sad with the situation.”

Superior Glove shifts to sanitizer, PPE

In early March, Superior Glove in Acton, Ont., also shifted its manufacturing lines — from gloves to face shields.

“Every day, our mission is to try and protect workers,” said company vice-president Joe Geng. “That was basically the idea. ‘What can we do? Because we have a lot of capabilities and how do we shift to try to help?’”

Hand-sanitizer production was the next addition to the Superior Glove fold, followed by mass production of cloth masks at its Newfoundland facility, he said.

“It kind of felt like every couple days I was getting an email that we’re getting into a new product line.”

Employees stepped up to reconfigure product lines — the initial sanitizer bottling line was “Macgyvered” together, Geng admitted.

With a food-safe environment needed, staff with engineering and other related experience stepped up, he said. While staff faced continual bottlenecks due to the rapid pace of change, they stuck with it and continually came up with solutions.

It took 20 days from the decision to shift focus to actually shipping product, said Geng. By late April, Superior Glove’s Acton plant was producing 10,000 face shields and 2,000 1.5-litre bottles of hand sanitizer per day.

Support from their existing clientele gave the company confidence to go ahead on the quick remodel. Appropriate site and product licences to operate were also applied for and responded to quite rapidly, he said.

One room required an upgrade to epoxy flooring to ensure it could be sanitized more regularly.

It was locating raw materials for hand sanitizer that became nearly a “full-time job,” said Geng, noting the project may become a long-term one for the hand protection company.

“They really had to call dozens and dozens of companies to find any supply whatsoever,” he said of his staff. “That was a challenge.”

Implementing COVID-19 safety measures was another challenge. Staff were outfitted with cotton masks and were required to work at an appropriate physical distance, said Geng.

Superior Glove actually added staff during the pandemic to keep up to demand, swelling from 19 to 54. Plexiglas was installed between workstations and staff was divided into teams of eight with no intermingling.

“Those eight would be working at the same time, but they

wouldn’t intermingle with another team of eight, just in case somebody got infected,” he said. “They’d have a designated washroom that they would use and they’d have a designated lunch space that they would use.”

The urgency of the situation pushed the rapid changeover. Typically, the changes would have taken six months to implement, said Geng.

“There’s that sense of urgency of like, ‘OK, we’ve got to ship. Because if we do, we’re protecting workers. And if we don’t, you’re not. You could potentially save a life if you ship this week versus next week.’ That sense of urgency and purpose behind things — that really helps you move and make things happen.”

Williams & White protects B.C. workers

For Williams and White in Burnaby, B.C., the decision to assist others in the pandemic fit right in its operational wheelhouse.

It’s common for the precision machinery manufacturer to take on custom projects, said partner Justin Williams.

In early March, the company decided to begin building protective barriers, before adding face shields and hand sanitizer to the mix, he said.

“Because we have a custom-manufacturing portion of our business, we just saw what was happening out there and we heard about stories in retail,” said Williams. “I thought, ‘Hey, wait a minute, we can help out with this, too.’”

“People were really scrambling at the very beginning of everything. Because we do custom production, we were able to just switch over to producing barriers for point-of-sale application. And then it just sort of grew from there.”

Williams and White’s decision came before the provincial government lockdown, he said. The company moved swiftly to build protective barriers for companies in B.C. and the United States.

The changeover was fairly standard for the custom company which already adheres to strict safety standards, said Williams.

“Guys are pretty used to switching over… We don’t have very many workers that are unskilled labour,” he said.

“The biggest thing that we had to do was adjust our policies for the COVID element,” said Williams of his staff of 40. “Distancing of people. We all wear face masks… all of our office staff work remotely. We have a skeleton crew in the office.”

Bruce Power makes record PPE donation

Not all Canadian organizations were able to retool in the fight against COVID-19. However, many still found ways to chip in.

In April, Bruce Power, a nuclear facility in Bruce County, Ont., made two separate donations totalling 1.2 million pieces of PPE — the largest announced private-sector donation during the pandemic.

The donation included surgical masks, N95 masks, O2 masks, gloves and face shields, said John Peevers, the company’s director of corporate communications.

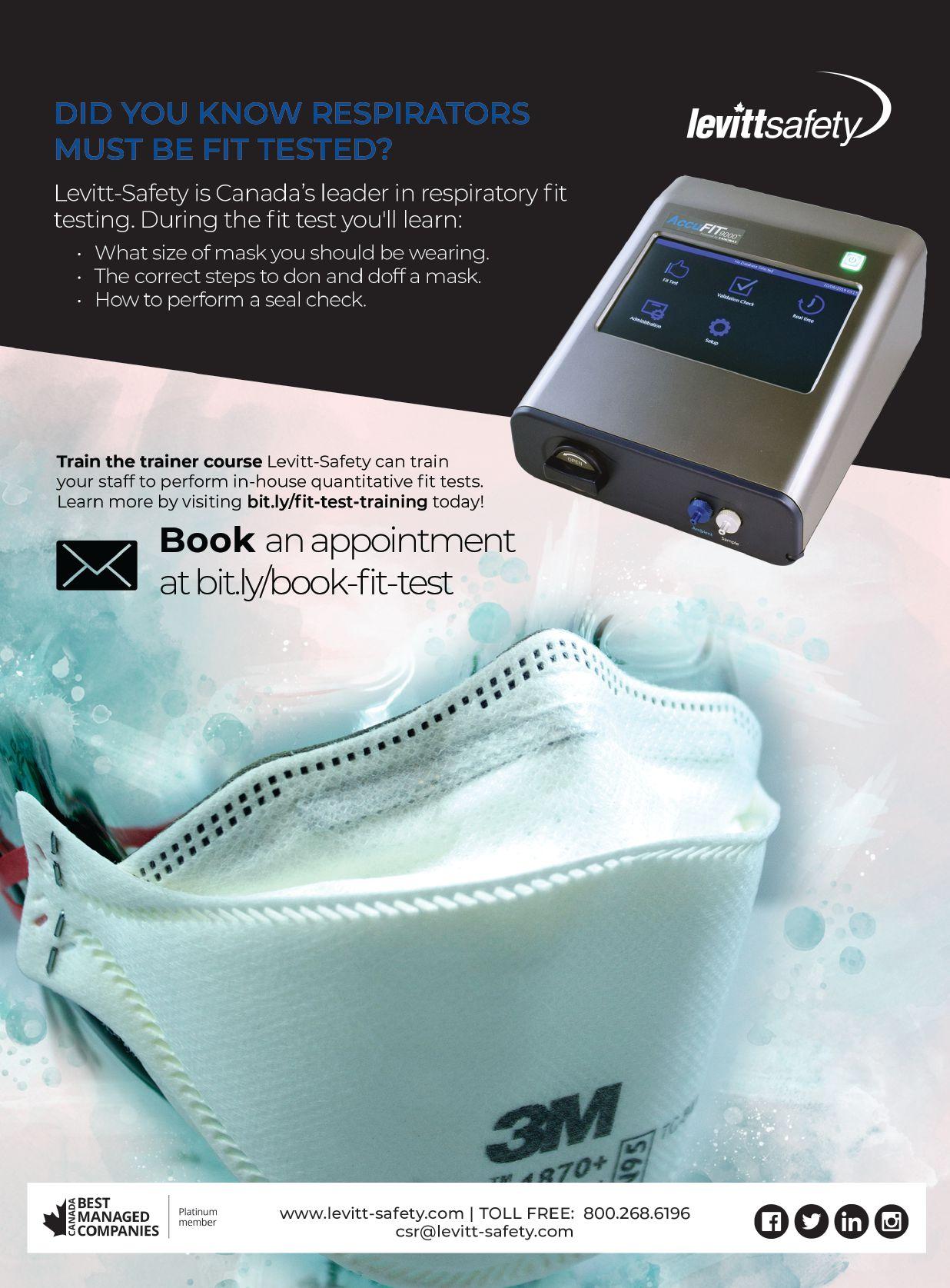

The initial donation was from Bruce Power’s reserve, while the second was sourced material — with an assist from LevittSafety in Oakville, Ont.

“Some of that was inventory we had in stock and in reserve, and we have gone out and sourced a whole bunch of stuff,” he said. “We’re fortunate in that we have those supply chain connections with suppliers that allow us to get our hands on things that other companies and even health-care professionals might be having a hard time getting.”

The major donation is in line with Bruce Power’s core business values, said Peevers.

“Companies go back to those during times of trouble like we’re in right now,” he said. “We felt like we have a responsibility as a large Ontario company to help out where we can, and we saw a real opportunity to contribute.”

“It’s hard for us to retool ourselves — we’re an electricity generator, first and foremost,” said Peevers. “(A donation) is

where we thought we could make the biggest difference.”

The decision to donate was easy to make, he said.

“Obviously, we want to make sure we’ve got enough personal protective equipment for our own staff so that they can do their jobs. And then it was a matter of what do we have on hand? What do we need? What can we give right now to help? Because I think as you recall, the situation was pretty dire for some frontline health-care workers.”

The PPE was distributed to government and health facilities in Ontario, alongside many organizations in Bruce County. The effort was a source of much pride for all involved, said Peevers.

“It’s important that everybody do their part,” he said. “We’re all seeing that times like this bring out the best in people. And we’re seeing that all over in our communities and all across Ontario.”

“It really is a responsibility in our view — it’s not a luxury. It’s something we feel like we have a responsibility to do.”

Marcel Vander Wier is the editor of OHS Canada.

The BCRSP is a self-regulating, self-governing organization certified by BSI Management Systems to ISO 9001. The CRSP certification is accredited by the Standards Council of Canada to ISO/IEC 17024.

Congratulations to the newest CRSP/PSAC and CRST/TSAC certificants!

The following individuals have been granted certification as a Canadian Registered Safety Technician (CRST)/Technicien en sécurité agréé du Canada (TSAC)

Miguel Alejandro Antipan CRST

Mamoke MacGodson Arubasa CRST

Bartlet Ray Beckman CRST

Rob Henry Bergeron CRST

Brady Robert Boghean CRST

Kyle Francis Brockerville CRST

Alexandra Bush CRST

Carol Casey CRST

Hilary Chalmers CRST

Gordon Christensen CRST

David Todd Cooke CRST

Lisa Diane Fernandes CRST

Melanie Flynn CRST

Jillian Michelle Foley CRST

Christopher Gilbert CRST

Jennifer Goldade CRST

Neil Norman Graham CRST

Michelle Haase CRST

Brittany Anne Marie Hemstreet-Ryan CRST

Lucie Janosek CRST

Angela Knight CRST

Jean-Marc Joseph Labonte CRST

Shadab Mahpour CRST

Erin McCabe CRST

Jacob Thomas Mole CRST

Alexander Morihovitis CRST

Jaclyn Nay CRST

Tyler David Neill CRST

Eric Leslie Nixon CRST

Miranda Patmore CRST

David Purdy CRST

Bhooma Raghavan CRST

Sunil Ramlal CRST

Anastasia Riabkova CRST

Michelle Ricco CRST

Laura Riffel CRST

Luc Robichaud CRST

Crystal Ann Saffel CRST

Jacob Bradley Saunders CRST

Steven Scuor CRST

Kaitlyn Kelly Sergerie CRST

Cindy Shaw CRST

Dylan James Short CRST

Jamie Smith CRST

Priyanjali Sookdeo CRST

Darryl Evan Sparling CRST

Melissa Standing CRST

Christopher Ronald Scott Stevens CRST

McKenna Stitzenberger CRST

Bradley Ernst Tye CRST

Tyler Kenneth W Whalen CRST

Kyle Richard Woodhouse CRST

Karen Young CRST

Yi Yu CRST

The following individuals have been granted certification as a Canadian Registered Safety Professional (CRSP)®/Professionnel en sécurité agréé du Canada (PSAC)®

Harith Aboud CRSP

Muhammad Akber CRSP

Farhan Ali CRSP

Jeff Anderson CRSP

Muhammad Usman Anjum CRSP

Nwamba Arinze Benedict CRSP

R Mitchell Brewer CRSP

Brian Leroy Brown CRSP

Jason Buckle CRSP

Olena Kubrak Chapovalov CRSP

Kavita Chauhan CRSP

Nadia Cicco CRSP

Galo Xavier Cifuentes Sigcha CRSP

Sanjeet Dangi CRSP

Leonard Richard de Castro CRSP

Avraan Dhawan CRSP

Justin Dixon CRSP

Kurt Fehr CRSP

Amanda Freije CRSP

Keenan Geiger CRSP

Ashley Dawn Gould CRSP

David Martin Gregor CRSP

Boyd Hanel CRSP

Richard A Hankinson CRSP

Jackson Heng CRSP

Steven Michael Hnatishin CRSP

Kelsey Jennifer Hynes CRSP

Sergey Isaev CRSP

Dallas Michael Jones CRSP

Watshidimba Kabongo CRSP

Heather Kelly CRSP

Danny Khoury CRSP

Kateryna Kurylo CRSP

Bernadette Lalonde CRSP

Richard Wade Lampert CRSP

Colleen Michelle Leitch CRSP

Ryan Levesque CRSP

Amanda Ley CRSP

Kevin Lyons CRSP

Alex Katherine McCrindle CRSP

Melissa McElwee CRSP

David Merabishvili CRSP

Melissa Mercer CRSP

Amritpaul Minhas CRSP

Andrew Monkman CRSP

Olivia Monk-Saigal CRSP

Colin Montgomery CRSP

Jillian Nielsen CRSP

Jayson Daniel Nelson CRSP

Steven Nieboer CRSP

Seun Holiness Oloruntoba CRSP

Olubunmi Olasunkanmi Olumoyin CRSP

Safa Qoussini CRSP

Santhosh Kumar Ramakrishnan Chettiar CRSP

John Ratcliff CRSP

Nikhil Rattan CRSP

Nelson Alexander Rebello CRSP

Mackenzie Restrick CRSP

Christina Reynolds CRSP

Neil Reynolds CRSP

Pierre Romao CRSP

Eryn Jean Sample CRSP

Steven Sanders CRSP

Laura Anne Saydak CRSP

Olga Vladimirovna Semenchik CRSP

Nimesh Priyavadan Shah CRSP

Anoop Simon CRSP

Melissa Simpson CRSP

Jennie Small CRSP

Timothy Smith CRSP

Matthew Soules CRSP

Jason Lester Spurrell CRSP

Myriam Tellier-Doiron CRSP

Thomas Daniel Tenkate CRSP

Jolene Turcotte CRSP

Samantha Twynam CRSP

Drew Unsworth CRSP

Chelsey Van Ee CRSP

Teser Wong CRSP

Cody Woolf CRSP

BY GRANT CAMERON

Canada’s truck drivers always answer the call and they proved it once again during the COVID-19 crisis. While many businesses shut down, truckers continued to roll.

Deemed an essential service, they remained on the job, bringing food to grocery stores and moving medical supplies and products to market.

However, life behind the wheel came with a significant set of health and safety challenges, especially in the early days of the crisis.

Many gas stations, highway rest areas and restaurants limited access to facilities or closed altogether, making it difficult for truckers to find a bathroom, hot shower or warm meal.

“It’s been tough,” said Jean-Marc Picard, executive director of the Atlantic Provinces Trucking Association, which represents more than 320 companies. “However, I can say that there’s been some good initiatives across the country now for food and rest areas and we’ve had some local hotels offer free showers.”

“Some places are now offering their washrooms to truckers and are cleaning them every time somebody uses them,” he said. “Everybody is just taking double the precautions these days, which is nice.”

In the early days of the pandemic, while many businesses shuttered, truckers risked jeopardizing their own health. To their credit, they kept the big rigs rolling.

Some restaurants eventually rose to the challenge and opened their doors to truckers.

McDonald’s was first out of the gate, offering a curbside service to help feed truckers. Companies like Tim Hortons, Swiss Chalet and Harvey’s soon followed suit.

Ontario’s provincial government also stepped up by providing a 511 app, which gave information from cameras on highway conditions and identifying rest areas that offer food and fuel.

While the crisis over food and washrooms has apparently been settled, the situation has prompted carriers in the trucking industry and the associations which represent them to take a closer look at their health and safety guidelines.

It also resulted in drivers following good hygiene and social distancing practices.

To stay safe, drivers, carriers, shipping companies and border officials are finding new ways to limit contact with one another. More companies are also making use of virtual documentation and cargo tracking.

Carriers are ensuring that drivers have access to credit cards for food, fuel, tolls and any potential emergencies, and are providing hand sanitizer and disinfectant in trucks to clean high-touch surfaces. Vendors are making use of tappayment options.

Many in the supply chain now wear medical gloves as a precaution.

Dave Earl, president and CEO of the BC Trucking Association, said the organization sourced 60,000 bottles of hand sanitizer and developed new best-practice guidelines for drivers to follow when on the job.

The association has also been trying to source masks, as Health Canada and the Centers for Disease Control and Prevention have come out and supported the practice of wearing them, he said.

“We’re starting to see more shippers and receivers requiring them,” said Earl.

“Drivers have used them but we’re starting to see a proliferation of different agencies saying, ‘Hey you might want to think about it.’”

Shippers and receivers are also now taking a closer look at their procedures to explore whether they can provide virtual documentation so drivers will not be required to leave their cabs to do paperwork, he said.

An issue of concern for drivers is what to do if they’re asked to pick up a load in a highly contagious area, said Earl.

“They might be asked, ‘I want you to pick up a load of lettuce in San Jose,’ or, ‘I want you to pick up these goods in New Jersey.’ We are sending them in to areas of concern and that’s the No. 1 concern.”

Of equal concern is what a driver should do upon returning from a trip outside the country, he said.

Although the federal government has declared that commercial truck drivers are exempt from the requirement to self-isolate for 14 days upon entering Canada from abroad, many are still isolating themselves for the safety of their families. Others just stay on the road or refuse to go back out, according to Earl.

“When they come home, what do they do? They’re in the same boat that health-care workers are from that personal risk standpoint,” he said. “Some self-isolate when they come home and say, ‘I’m not going back.’ So it really varies from individual to individual and carrier to carrier what they’re doing and what they’re seeing.”

Jonathan Blackham, director of policy and public affairs for the Canadian Trucking Alliance (CTA) which represents more than 5,000 companies, said the group has been working with the federal and provincial governments to keep as many facilities as possible open and clean, with accessible washrooms and food.

The CTA launched a successful #ThankATrucker campaign that has drawn attention to the cause and resulted in governments at all levels recognizing that truck drivers are indispensable, frontline workers who are critical in the fight against the spread of COVID-19, and to keeping the wheels of commerce moving.

While individual companies may have policies tailored to their own specific workplace needs, the CTA has produced a tip sheet for carriers which includes guidance on best practices when they are reviewing and updating their policies. Transport Canada has also recommended practices for road carriers along with resources available through other departments and provincial trucking associations.

“These are trying times for companies, and we know it can often be difficult to find the information you’re looking for,” said Blackham. “We’ve tried to consolidate much of the information carriers are asking for into an updated, single document to make it easier on our members to get the information they need.”

The CTA recommends that truckers adhere to socialdistancing rules and that carriers try to limit contact with drivers by reducing paperwork that’s exchanged, or simple things like ensuring they don’t use the same pen when signing paperwork.

According to Christopher Monette, director of public affairs at Teamsters Canada, cleanliness of trucks is a big issue that employers must address, as they may be used by many different drivers over a period of time.

“You have several people using the truck and you’re getting into a truck and you don’t know how many people have touched the high-touch surfaces. There are some employers who have stepped up to make sure these trucks are clean but it’s still an ongoing issue whether it’s local delivery or long haul,” he said.

“Having access to hand sanitizer, for example, in their truck and cleaning material like disinfectant to really clean those high-touch surfaces is important and we feel is a responsibility that falls upon the employer.”

The union flagged the issue to Transport Canada and the government put out the recent guidelines for truck drivers which recommend everything from using hand sanitizer to wearing gloves at pumping stations.

Monette said governments, industry and society are all in battle together, so everybody must do everything possible to keep truck drivers safe, as Western civilization and the supply chain depends on them.

“Everything we buy from store shelves, everything we order online, everything that factories need to produce the goods that society needs — all that has been transported at one point or another on a truck,” he said.

“If truck drivers get sick, our supply chain collapses and everyone suffers. And that’s something we all have a vested interest in avoiding.”

Grant Cameron is a freelance writer in Burlington, Ont. OVER 2,700 SAFETY PRODUCTS IN STOCK

BY SAM SPEZIALE

The COVID-19 pandemic has struck uncertainty into the minds of many Canadians. With public gatherings periodically banned across the country, many may feel nervous when they leave their homes to use an essential service.

Enter industrial cleaners.

An increased state of paranoia has driven the demand for services from companies such as QM Environmental in Mississauga, Ont., which offers specialized bio-hazardous cleanup for businesses.

Securing a reputable bio-hazard decontamination provider early in the recovery will be critical in ensuring businesses and services are able to return

to normal as quickly as possible, said a company statement issued in March.

Government guidelines indicate that those cleaning public areas should know that frequently touched surfaces such as counters, elevator buttons and door handles should be cleaned at least twice per day to limit the potential spread of viruses.

Spikes in demand

GTA Restoration is a cleaning and restoration business servicing residential and commercial buildings in Toronto.

“Right now, we’re just doing things as we go,” said company founder Tony Lleshi. “We get a call, we go out, we help and that’s it. There is no schedul-

ing ahead unless it is a hotel or supermarket that we do on a weekly or daily basis.”

“It’s been 80 per cent changed in our daily regulations, I would say. We got texts coming in and out; we’re tired and just going to work, but we’re trying hard in regards to helping out. We have no contact in the office, no contact with the regular clients. Only unless we get emergency calls,” he said.

ServPro Burlington in Burlington, Ont., is another cleaning and restoration business facing increased demand.

The company’s cleanup services range from mould remediation to commercial office cleanups, said general manager Paul Hammond.

To defend technicians from COVID-19, teams meet before entering a building to ensure their protective gear is properly fitting, said Lleshi.

In confirmed case areas, T100 masks are used, along with Tychem gloves and full Tyvek suits. In nonconfirmed case areas, N95 masks are acceptable, he said.

“Even when we don’t know it’s a confirmed-case area, it’s still very serious so we are very careful.”

Technicians are not able to work for extended periods of time while using mask models like the T100, said Lleshi.

As a result, they work in groups, have regular breaks and take turns doing jobs.

Hammond said that depending on the client’s discretion, technicians could enter the home or office while they the client is present, or create a scenario where the site is empty.

Clients are screened before facilities are serviced to protect technicians from interacting with infected persons, he said.

“I’ve been doing a lot of reading on it; there’s lots of associations that provide information. So, I just follow what I read. But there is no directive to me from anybody that would say to ask these questions.”

Sam Speziale is a Centennial College journalism student interning with OHS Canada.

BY SAM SPEZIALE

Navigating through a pandemic in a safe manner requires more than guarding one’s physical well-being. Workers are also highly susceptible to mental health risks, according to experts.

Spending extended periods of time at home due to isolation has links to mental stresses.

“During any type of uncertainty, it’s natural for people to experience stress and potential mental-health issues,” said Emma Ashurst, manager of inquiries and technical services for the Canadian Centre for Occupational Health and Safety in Hamilton, Ont. “We’re all facing different challenges. And it’s not just (on the) work front, (but) a personal front, too.”

Battling loneliness

Isolation and loneliness correlate, according to Bill Howatt, workplace pro

ductivity research chief with the Conference Board of Canada in Ottawa.

“The amount of objective isolation — where people are asked to stay away from each other and create new social norms — has an impact on people’s psyche, which we will not know until we go back to work,” he said.

It’s important to note that even before the mass isolation incurred as a result of COVID-19, loneliness was already a major issue — just discussed less openly, said Howatt.

“COVID-19 has shined a light on a social epidemic that has not been addressed,” he said.

The general uncertainty behind COVID-19 adds to stress levels, said Ashurst, noting physical well-being also has an impact on how the mind handles stress.

“If you’re fatigued, not getting outside or eating right, that can also play

into the effects of the overall negative well-being of the individual.”

Ensuring a supportive work environment as an organization is the best strategy for employers to help mitigate mental-stress issues, said Ashurst.

Proper workplace values like respect should be promoted, enabling workers to feel comfortable talking about concerns with isolation or ask for help in balancing responsibilities, she said.

What is missing from the solution is the inability for employers to educate workers on developing authentic relationships, said Howatt.

A critical way for employees to combat loneliness stemming from isolation is for employers to educate them on ways to move through certain cognitive-behavioural barriers with tools available digitally, he said.

Sam Speziale is a Centennial College journalism student interning with OHS Canada.

Because the safest fall protection harness is the one you’ll actually want to wear, each V-SERIES harness includes unique features to deliver exceptional comfort – so you can focus on your work, not your harness. Try it for yourself... visit MSAsafety.com/vseriesfallprotection

By Marcel Vander Wier

As the COVID-19 pandemic swept across the globe in early 2020, the demand and desperation for respiratory protection did as well.

N95 respirators became the hottest personal protective equipment (PPE) item in the world, with many organizations donating available reserves to frontline workers.

Minnesota-based manufactuer 3M expects demand for PPE to continue outpacing supply for the next while, according to board chairman and CEO Michael Roman.

“Our products — including respirators, surgical and procedural masks and hand sanitizers — are being used globally in the response to the outbreak. We expect demand for these products to outpace supply for the foreseeable future,” he said in a March press release.

“We have notified our authorized distributors that we are prioritizing orders to help serve our base business — including hospitals — due to high global demand.”

In response to global demands, 3M has doubled its global annual output to 1.1 billion National Institute for Occupational Safety and Health (NIOSH)-approved N95 respirators, and will increase that to 2 billion per year within the next year, according to a statement by 3M Canada.

Disposable N95 respirators are easily the most in-demand category of respirators through the pandemic. A properly selected and fitted respirator provides its user protection from airborne particulates — including bioaerosols, said 3M Canada.

Honeywell also added to its production capabilities — adding manufacturing lines to its Rhode Island facility, according to Kristin Ware, respiratory product marketing manager at the company’s offices in Charlotte, N.C.

“We definitely, like everyone, have seen an increase in demand throughout our respiratory products — specifically for our N95 masks,” she said. “There’s just a lot of demand right now from a global standpoint — specifically from the U.S. and Canada. We can’t keep up from a production standpoint with the demand that we’re receiving.”

Those in need of immediate respiratory protection were being referred to half masks known as reusable air-purifying

respirators, said Ware, noting elastomeric half masks were another alternative from the disposable N95s.

“We’re just doing what we can at Honeywell to help everybody that we can on the front lines of this,” she said.

Dentec’s U.S. manufacturing facilities also ramped up production, moving to 24-hour moulding, said Claudio Dente, president of Dentec Safety Specialists in Newmarket, Ont.

“This is an extraordinary time,” he said. “The demand for respiratory protection is unprecedented... We have some supply issues with raw materials, because the volumes that are being directed to us are unprecedented.”

“And so, we are working with our supply chain and logistics to secure raw materials. We have also ramped up our production; we’ve gone to 24-hour moulding,” said Dente. “We’re taking measures, we’re doing everything that we possibly can to accelerate the delivery and the manufacturing of our product.”

N95s weren’t the only facial protection in demand through the early days of the pandemic.

As all disposable offerings began being diverted to health-care workers, Dentec looked to provide alternative solutions for industrial workers, said Dente.

The company’s Comfort Air series of respirators provides

comfort alongside the ability to manipulate the filter cartridges in four different positions for versatility when wearing additional PPE such as grinding shields or welding helmets, he said.

While these types of masks are not disposable, they do require disinfection.

The demand has been “enormous” and includes the health-care market, said Dente.

The 400 series has proved most popular and economical. The 100 series is silicone and more comfortable, but is also more expensive, he said.

The masks feature filter material that is mounted in protective housing, allowing for in-field fit checks, said Dente. The rubber mask also contains an exhalation valve which allows for quick test procedures that ensure the seal is fit for duty.

“Each and every time you take the mask off, you can conduct a quick fit check. You can’t do that with a disposable,” he said.

In April, Health Canada warned that fraudulent or unauthorized N95 respirators were being sold with more frequency.

Counterfeit producers shift quickly to begin producing goods that suddenly come into high demand, said Lorne Lipkus, founding partner with Kestenberg Siegal Lipkus in Toronto.